Page 1

INSTALLATION &

GAS RESTAURANT RANGES

MOD

ELS

V24

V36

V36F

V60

V60F

V260

OPERATION MANUAL

www

.vulcanhart.com

ITW Food Equipment Group, LLC

An Illinois Tool Works Company

3600 North Point Blvd.

Baltimore, MD 21222

F-35692 (10-09)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

— 2 —

Page 3

GAS RESTAURANT RANGE MODELS

V60

V260

V36

—3—

PL-53007

Page 4

Installation, Operation and Care of

GAS RESTAURANT RANGES

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

GENERAL

Vulcan ranges and ovens are produced with quality workmanship and material. Proper installation,

usage and maintenance of your range will result in many years of satisfactory performance.

Vulcan-Hart suggests that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

INSTALLATION

UNCRATING

This range was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the range is found to be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

Uncrate unit carefully and place in a work-accessible area as near to its nal installed position as

possible. Remove all shipping wire and wood blocking.

Before installing, check the electrical service (convection oven series ranges only) and type of gas

supply (natural or propane) to make suretheyagreewiththespecicationsontheratingplatelocated

on the inside of the lower kick panel. If the supply and equipment requirements do not agree, do not

proceed with the installation. Contact your dealer or Vulcan-Hart Company immediately.

LOCATION

The equipment area must be kept free and clear of combustible substances.

The range,when installed,must havea minimumclearance fromcombustible constructionof 12"(304 mm)

atthe sides and 10" (253 mm) attherear.Clearancefromnon-combustibleconstructionis0" at the sides

and 6" (152 mm) at the rear.

The installation location must allow adequate clearances for servicing and proper operation. A

minimum front clearance of 40" (1016 mm) is required.

The range must be installed so that the ow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber must beprovided. Make sure there

is an adequate supply of air in the room to allow for combustion of the gas at the burners.

—4—

Page 5

INSTALLATION CODES AND STANDARDS

Ranges must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code,ANSI/Z223.1(latestedition).Copies may be obtainedfromTheAmerican

Gas Association, Inc., 1515 Wilson Blvd., Arlington, VA 22209.

NOTE: In the Commonwealth of Massachusettes,

All gas appliances vented through a ventilation hood or exhaust system equipped with a damper

or with a power means shall comply with 248 CMR.

3. National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from The

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

4. VaporRemoval From CookingEquipment

, NFPA-96 (latestedition). Copies maybe obtained from

The National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CSA B149.1 Natural Gas and Propane Installation Code.

3. CSA C22.1 Canadian Electric Code.

4. CSA C22.2 Canadian Electric Code.

The above are available from the Canadian Standard Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

ASSEMBLY

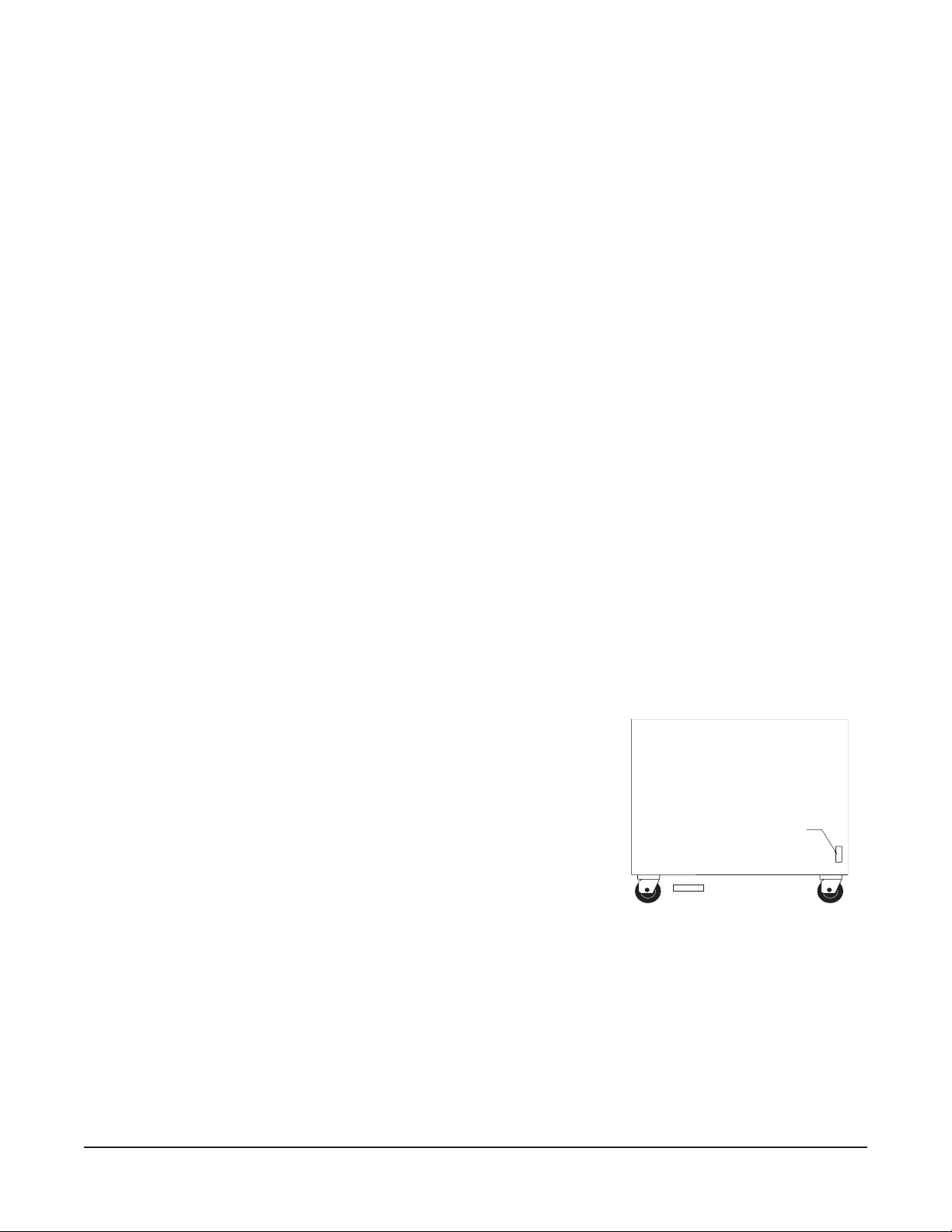

Ranges Mounted on Casters

Ranges mounted oncastersmustuse a exible connector(not

supplied by Vulcan) that complies with the Standard for

ConnectorsforMovableGasAppliances,ANSI-Z21.69•CSA 6.16

and a quick-disconnect device that complies with the

Standard for Quick-Disconnect Devices for Use With Gas

Fuel, ANSI-Z21.41 • CSA 6.9. In addition, adequate means

must be provided to limit movement of the appliance without

depending on the connector and the quick-disconnect device

CONNECT GAS LINE

STRAIN

RELIEF HERE

oritsassociatedpipingtolimitappliancemovement.Attach the

restraining device at the rear of the range as shown in Fig. 1.

PL-51219

Remove two screws from the rear of the range and install the

Fig. 1

tie-down strap shipped with the casters using these screws

(Fig. 1). Attach the gas line strain relief to the tie-down strap at the rear of the range (Fig. 1).

If disconnection of the restraintis necessary, turno the gassupply before disconnection. Reconnect

this restraint prior to turning the gas supply on and returning the range to its installation position.

Separate instructions for installing casters to the range are included with the casters.

Note: If the range is installed on casters and is moved for any reason, it is recommended that the range

be releveled front to back and side to side.

—5—

Page 6

Installation of Broiler/Griddle Bricks

TheRestaurant Range broiler/griddle utilizes ceramic re bricksfor heatradiation of the burners. Install

the broiler bricks before connecting the gas supply line.

1

1. Remove the six 5

/4"x21/4" (133 x 57 mm) and (6) 51/4"x51/16" (133 x 128 mm) bricks from the

shipping box.

2. Install the six 5

1

/4"x21/4" (133 x 57 mm) bricks to the left- and right-hand sides of the burner. To

install the bricks, insert them one at a time through the opening in the frontof the broiler. Angle the

brick sideways so that it will slip between the burner edges. Set the bricks at in place resting on

these edges. Push each brick installed as far to the rear of the burner as possible so that the last

brick will install easily (Fig. 3).

3. Install the six 5

1

/4"x51/16" (133 x 128 mm) bricks to the center burners as described in Step 2.

Fig. 3

—6—

Page 7

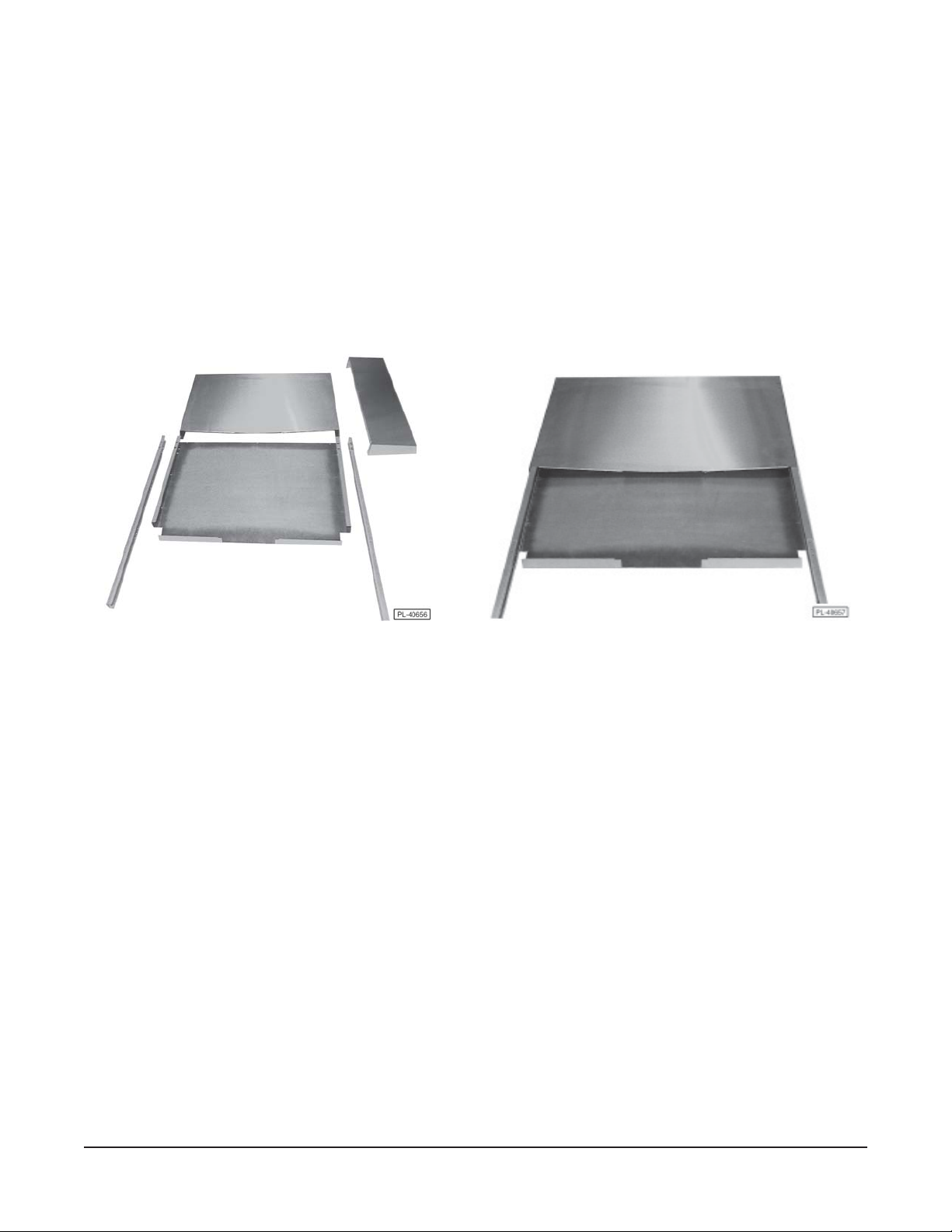

Backsplash

The standard Restaurant Range is equipped with a 23" (584 mm) high backsplash and shelf.

1. Remove the backsplash components from the crating materials.

2. Check the backsplash component parts against the list on page 10 to ensure that all the required

partsfor the backsplash installation havebeenobtained.(SeeFig’s.8& 9.) If any parts aremissing,

contact your dealer or closest parts depot immediately.

3. Assemble the required components as shown in Fig’s. 8 and 9.

4. Lift the assembly up, sliding the channelsinto the space provided atthe rearof the range (this may

require two people).

9.giF8.giF

—7—

Page 8

Backsplash Component Parts

W36 W60 W260

Std. 23" (584 mm) High Std. 23" (584 mm) High Std. 23" (584 mm) High

Backsplash (1) Backsplash (1) Backsplash (1)

Backsplash Channel Backsplash Channel Backsplash Channel

Heat Shield (1) Heat Shield (1) Heat Shield (1)

#10 Sht.Metal Screw #10 Sht. Metal Screw #10 Sht. Metal Screw

1

/4-20 x 25/16" (59 mm) Lg.1/4-20 x 25/16" (59 mm) Lg.1/4-20 x 25/16" (59 mm) Lg.

Machine Screw (4) Machine Screw (4) Machine Screw (4)

Shelf Assembly (1) Shelf Assembly (1) Shelf Assembly (1)

MODELS

)2()1()2(

8)(4)( (8)

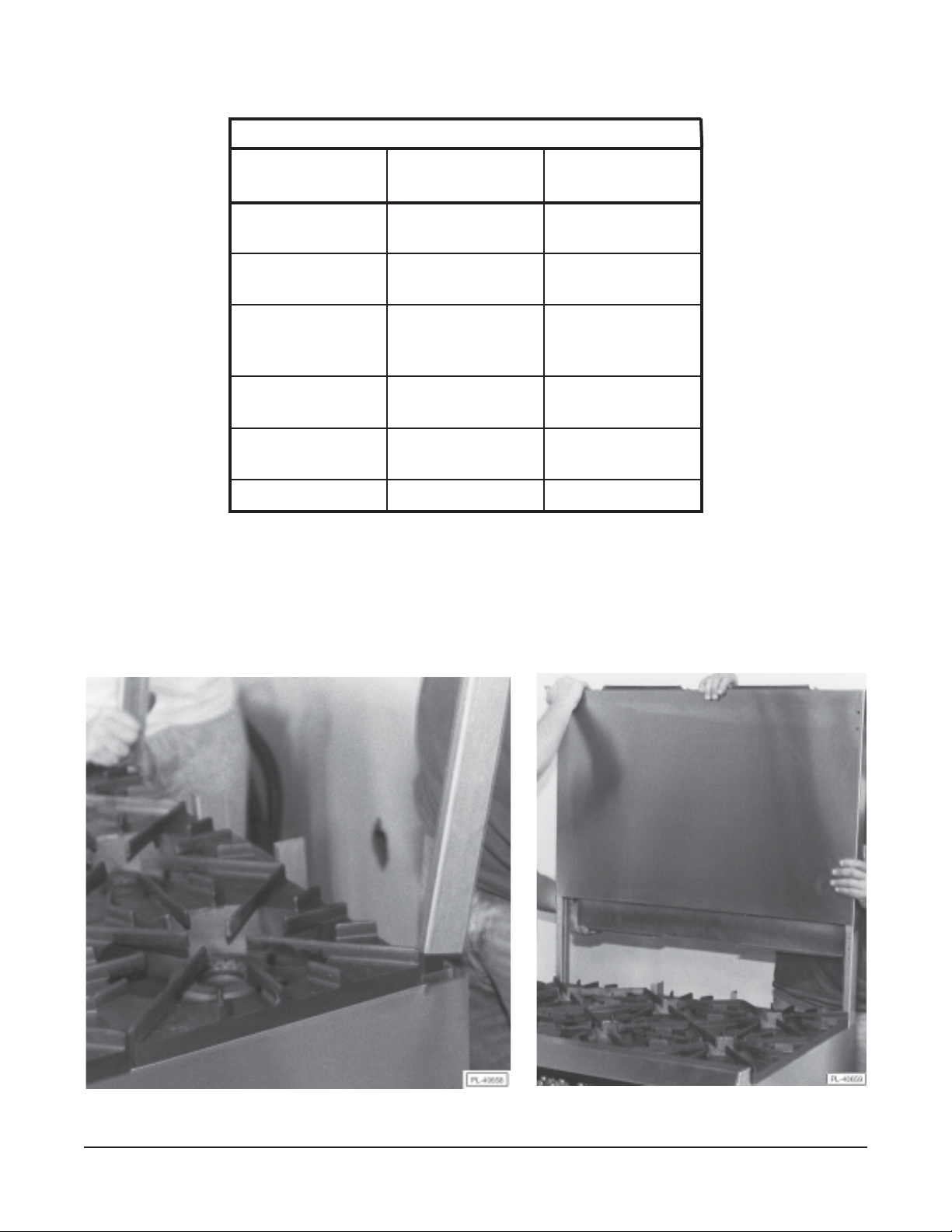

5. Itmaybenecessarytopulltheheatshieldbottomoutslightlyin ordertoclear theoven ueboxarea.

Be sure the backsplash isrestingevenlyand the channel holes areliningupwiththe holes provided

in the right- and left-hand body side (Fig’s. 10 & 11).

—8—

11.giF01.giF

Page 9

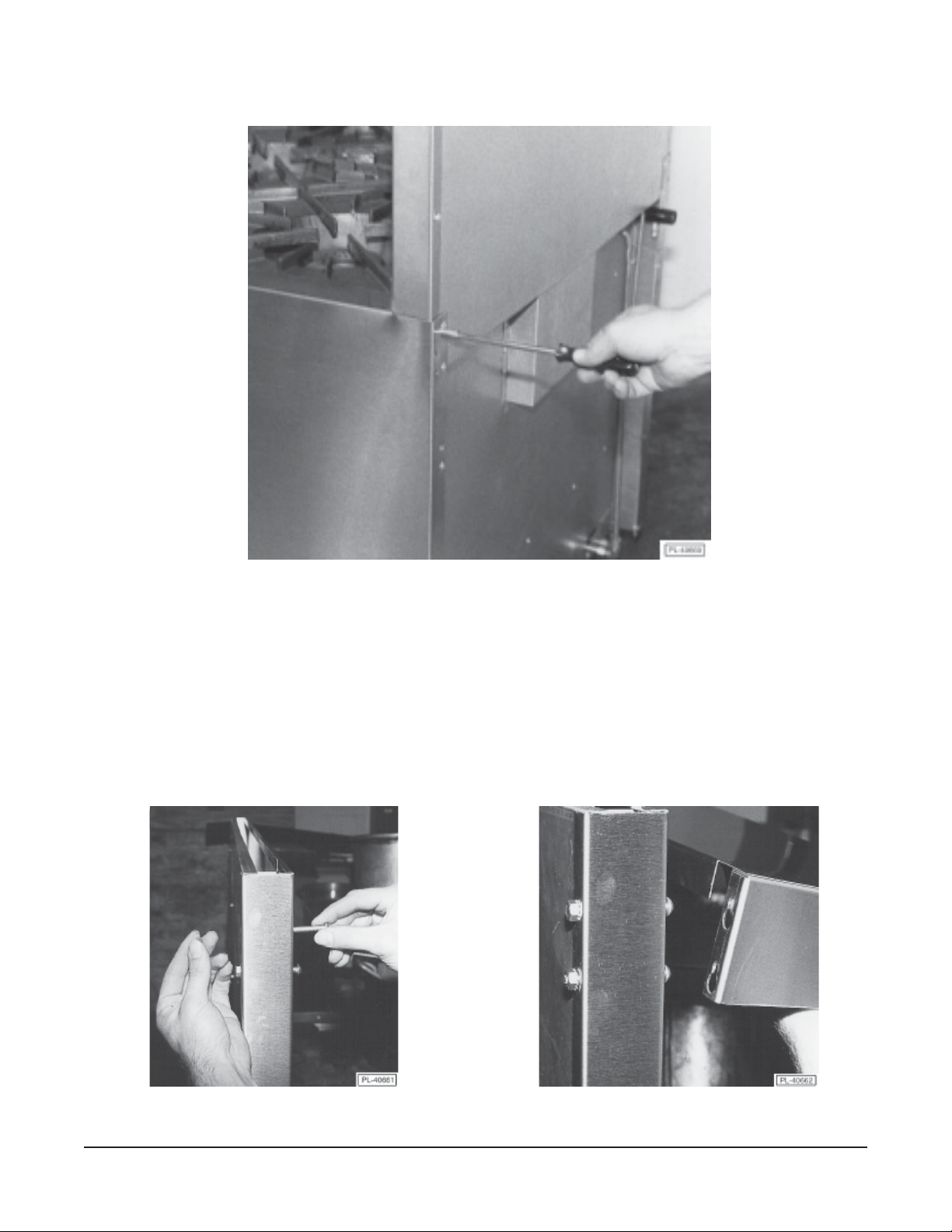

6. Install four #10 sheet metal screws (2 to each channel leg) (Fig. 12).

Fig. 12

7. From the front, install four1/4-20 x 25/16" (59 mm) long machine screws and secure bolts with

locknuts. Do not tighten thescrews all theway down. Leave about

1

/4" (6 mm)of playin each screw

(Fig. 13).

8. Lift the shelf up and slide the shelf into position over the screw heads (Fig. 14).

9. Tighten the four screws to secure the shelf.

—9—

41.giF31.giF

Page 10

LEVELING

Checkthelevelingoftherange.Placeacarpenter’slevel insidethe ovencavity acrossthe ovenrack(s).

Level front-to-back and side-to-side.

To adjust the leveling, tilt the range to one side and, using channel locks, unscrew the adjustable leg

insert as required. Repeat this procedure as necessary for each leg.

Casters for thisrange are of the non-adjustabletype. Therefore, theoor must belevel. If oor surface

is not level, the range will experience cooking problems.

GAS CONNECTIONS

CAUTION: All gas supply connections and any pipe joint compound used must be resistant

to the action of propane gases.

Each range is factory-equipped for the type gas specied on the rating plate. The installation gas

connection is a

3

/4" (19 mm) 14 FPT ANSI schedule #40 standard pipe.

Connect gas supply. Make sure the pipes are clean and free of obstructions.

Codes require that a gas shuto valve be installed in the gas line ahead of the range.

Standard ranges are equipped with xed burner orices which coincide with installation elevation.

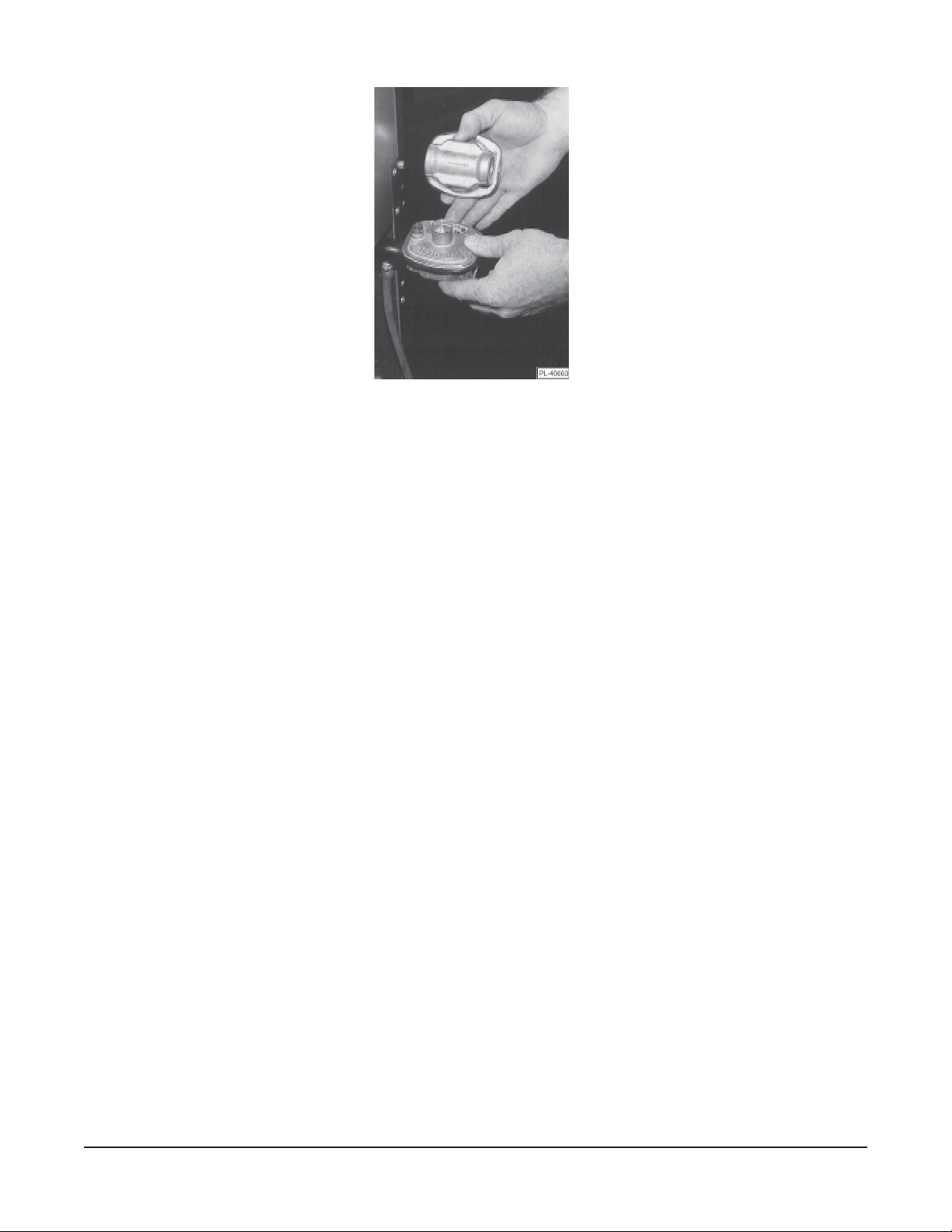

Install the gas pressure regulator.

Before installing, ensure that regulator supplied agrees with rating plate gas supply.

As of 7/11/90, the gas pressure regulator is NOT factory installed. The regulator for this gas type is

sealed within a plasticbagattached to the ovenrackinside the oven cavity.Thisregulatormust be eld

installed by a qualied installer.

Natural gas regulators are preset for 4" W.C. (Water Column) (.99 kPa); propane gas regulators for

10.0" W.C. (2.5 kPa)

1. Locate

3

/4" (19 mm) gas connection pipe extending from rear of range.

2. Cover pipe threads with leak sealant.

3. Screw regulator hand-tight onto pipe with regulator arrow pointing towards range body back (Fig. 15).

4. Using pipe wrench, tighten regulator securely in an upright position (Fig. 15).

The arrow on the regulator shows the direction of the gas ow (Fig. 15). The pressure regulator must

bemounted horizontally to ensure proper preset outletpressure.Iftheregulatorisinstalledin any other

position, the outlet pressure must be reset for proper operation.

A leak limiter is supplied with every regulatorto allow excess gas pressure to escape. Do not obstruct

leak limiter on gas pressure regulator, as obstruction may cause regulator to malfunction.

—10—

Page 11

Fig. 15

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

Before operation, verify thermocouple is securely seated in the safety valve. The thermocouple should

be tightened a1/4 turn past nger tight. DO NOT OVERTIGHTEN. Overtightening may damage the

thermocouple or safety magnet.

TESTING THE GAS SUPPLY SYSTEM

When gas supply pressure exceeds1/2 psig (3.45 kPa), the range and its individual shuto valve must

be disconnected from the gas supply piping system.

Whengassupplypressureis1/2 psig(3.45kPa) or less, the rangeshouldbeisolatedfromthegassupply

system by closing its individual manual shuto valve until the range is ready for start-up.

FLUE CONNECTIONS

DO NOT obstructtheowofuegasesfromtheuelocatedontherearoftherange.Itisrecommended

that the ue gases be ventilated tothe outside of the building through a ventilationsystem installed by

qualied personnel.

From the termination of the ue to the lters of the hood venting system, a minimum clearance of 18"

(457 mm) must be maintained.

Information on the construction andinstallationofventilating hoods may be obtainedfromthestandard

for the "Removal of Vapors from Commercial Cooking Equipment”, NFPA No. 96 (latest edition),

available from The National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

—11—

Page 12

OPERATION

WARNING: THE RANGE AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE RANGE.

CONTROLS

THERMOSTAT DIAL - STANDARD OVEN — Allows operator to regulate oven temperature from low to

500°F (260°C).

GRIDDLE BURNER KNOB STANDARD AND CONVECTION OVENS — Regulates gas ow to the griddle or hot top burner. To

increase heat, turn knob counterclockwise; to decrease,

turn knob clockwise.

BEFORE FIRST USE

Griddle Seasoning

CAUTION: This griddle plate is steel, but the surface is relatively soft and can be scored

or dented by the careless use of a spatula or scraper. Be careful not to dent, scratch, or

gouge the plate surface. Do not try to knock off loose food that may be on the spatula by

tapping the corner edge of the spatula on the griddle surface.

A new griddle surface must be seasoned to do a good cooking job. The metal surface of the griddle is

porous. Foodtends to get trapped in these pores and stick; therefore, it is important to “season”or “ll

up” these pores with cooking oil before cooking. Seasoning gives the surface a slick, hard nish from

which the food will release easily.

To season, heat griddle top section at a low burner setting. Pour one ounce of cooking oil per square

foot of surface overthegriddle top section. With an insulated cloth, spreadtheoil over the entire griddle

surface to create a thin lm. Wipe o any excess oil with an insulated cloth.

Repeat this procedure 2 to 3 times until the griddle has a slick surface.

—12—

Page 13

LIGHTING AND SHUTTING DOWN PILOTS

All adjustment proceduresassociatedwith pilot lightingmustbe performed by an authorizedVulcan-Hart

installation or service person.

HOT TOP AND GRIDDLE TOP BURNERS

1. Turn main gas supply ON.

2. Wait 30 seconds and, using a taper, light the hot top or griddle top pilot (Fig. 16).

89/1evitceffesbonkrenrubelytsweNsbonkrenrubelytsdlohtiwnwohS

Fig. 16

3. If pilot fails to light, turn main gas supply OFF. Wait 5 minutes and repeat the above procedures.

4. Turn one hot top or griddle top burner valve ON to remove air from the gas line. Turn burner valve

OFF when gas begins to ow.

Nightly Shutdown

Turn burner valve OFF; pilot will remain lit.

Complete Shutdown

1. Turn burner valve OFF; pilot will remain lit.

2. Turn main gas supply OFF.

—13—

Page 14

OPEN TOP BURNERS

1. Turn main gas supply ON.

2. Wait 30 seconds and, using a taper, light the open top pilot (Fig. 17).

Fig. 17

3. If pilot fails to light, turn main gas supply OFF. Wait 5 minutes and repeat the above procedures.

4. Turn one open top burner valve ON to remove air from the gas line. Turn burner OFF when gas

begins to ow.

Nightly Shutdown

Turn burner valve OFF; pilot will remain lit.

Complete Shutdown

1. Turn burner valve OFF; pilot will remain lit.

2. Turn main gas supply OFF.

BROILER/GRIDDLE

1. Turn main gas supply ON.

2 Wait 30 seconds and, using a taper, light broiler/griddle pilot (see Fig. 16).

3. If pilot fails to light, turn main gas supply OFF. Wait 5 minutes and repeat Steps 1 and 2.

4. Turn burner valve ON to purge air from the lines. Turn burner valve OFF when gas begins to ow.

Nightly Shutdown

Turn burner valve OFF; pilot will remain lit.

Complete Shutdown

1. Turn burner valve OFF; pilot will remain lit.

2. Turn main gas supply OFF.

—14—

Page 15

STANDARD OVEN LIGHTING AND SHUTDOWN INSTRUCTIONS

NOTE: Light open top/griddle pilots before lighting oven pilot.

1. Turn thermostat to the “OFF” POSITION.

2. Wait 5 Minutes.

3. After pilot is lit, turn the thermostat to the desired setting.

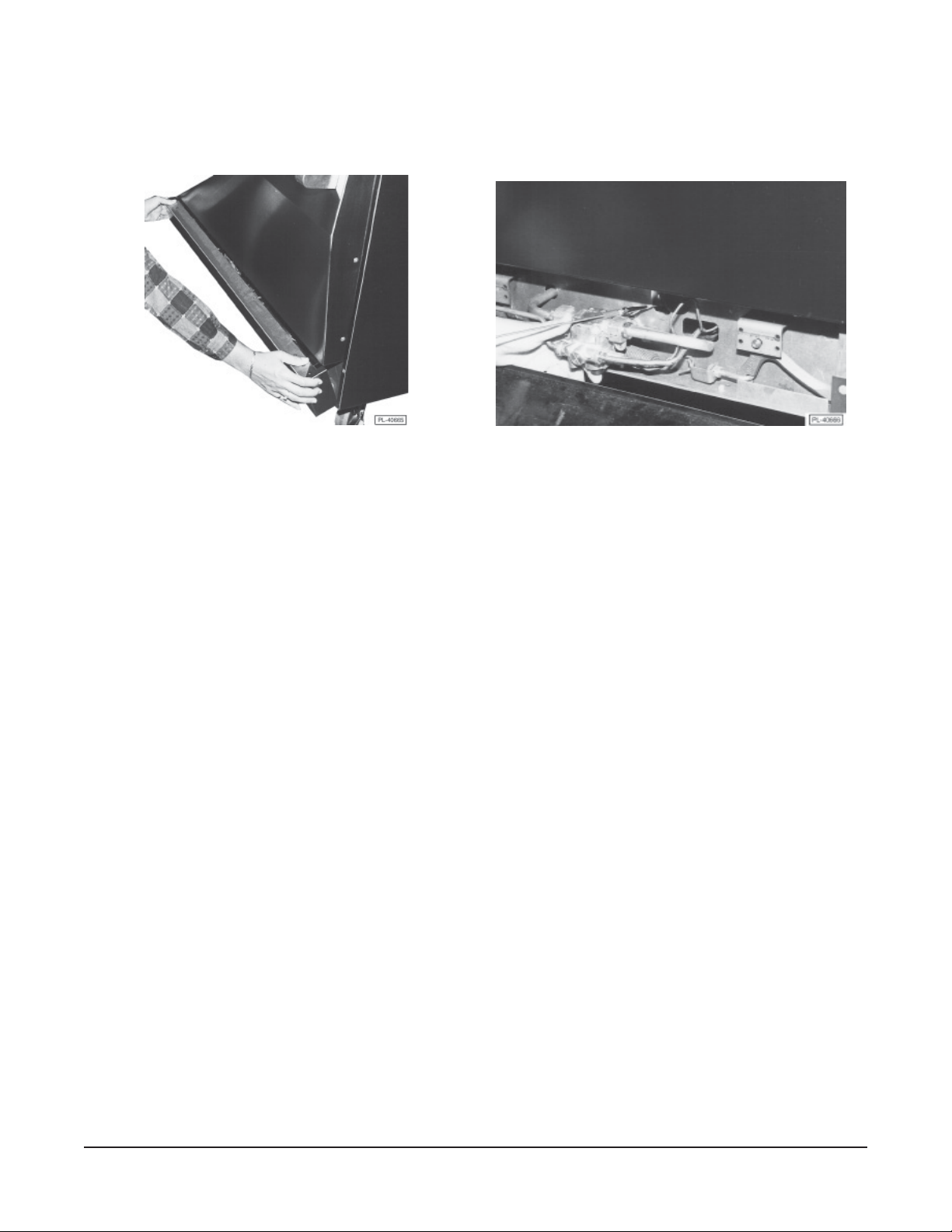

4. Remove the lover panel. (Fig. 18)

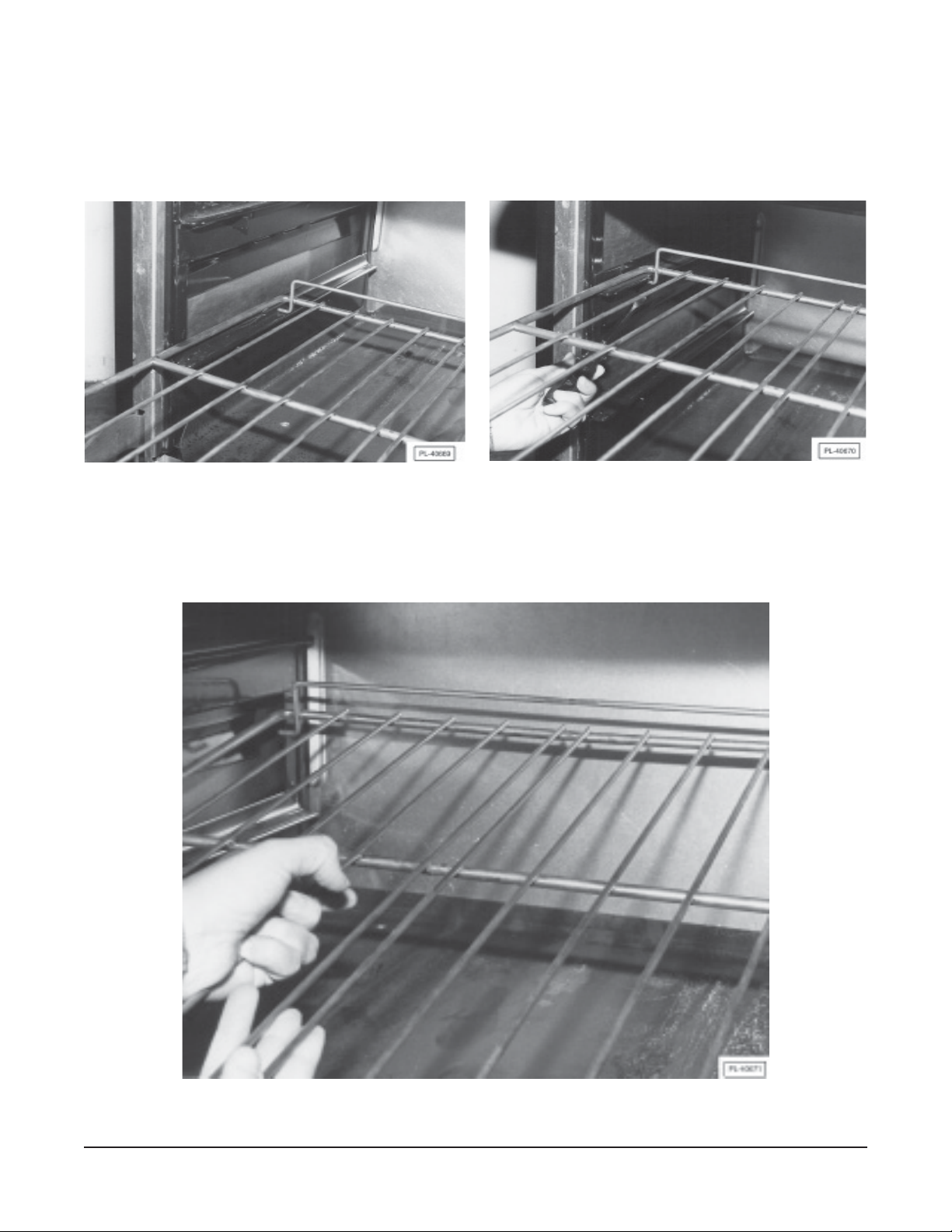

5. Depress the red button on the safety valve and light the pilot

through the observation area. (Fig. 19)

6. Hold down the red button for atleast 30 seconds.

7. When button is released, pilot should remain lit.

8. Replace lower panel.

9. Turn thermostat to desired temperature.

10. If the pilot becomes extinguished repeat the above procedure.

91.giF81.giF

Nightly Shutdown

Turn oven thermostat OFF.

Complete Shutdown

1. Turn oven thermostat OFF.

2. Turn main gas supply OFF.

RACK ARRANGEMENT - STANDARD OVEN

The standardoven has two rack positions and is supplied withone ovenrack. Additional racks may be

obtained through a Vulcan-Hart parts depot.

For best results when baking cakes andpastries, it is recommended that only asingle rack position be

utilized. However, proper rack usage and positioning is really determined by the individual cooking

needs ofthe operator. If you are cooking a large roast, the entire oven cavitymay beutilized. Remove

the oven rack completely from the range and place the roasting pan directly on the oven bottom.

—15—

Page 16

STANDARD OVEN

Light open top/griddle pilots before lighting oven pilot.

1. Open kick panel and lift up the pilot lighting hole cover (Fig. 18).

91.giF81.giF

2. Light pilot by depressing the reset button located behind the kick panel (Fig. 19). Continue to hold

reset button in for1minute.If pilot fails tolight,turn main gas supplyOFFandwait 5 minutes before

repeating Step 2.

3. After pilot is lit, turn the thermostat to the desired setting.

Nightly Shutdown

Turn oven thermostat OFF.

Complete Shutdown

1. Turn oven thermostat OFF.

2. Turn main gas supply OFF.

RACK ARRANGEMENT - STANDARD OVEN

The standardoven has four rack positions and is supplied with oneoven rack.Additional racks may be

obtained through a Vulcan-Hart parts depot.

For best results when baking cakes andpastries, it is recommended that only asingle rack position be

utilized. However, proper rack usage and positioning is really determined by the individual cooking

needs ofthe operator. If you are cooking a large roast, the entire oven cavitymay beutilized. Remove

the oven rack completely from the range and place the roasting pan directly on the oven bottom.

—16—

Page 17

INSERTING AND REMOVING STANDARD

The oven rack has a stop to keep the rack from being pulled all the way out when unloading product.

To install rack, place rack along side of top of side liner runners and slide rack completely to the rear

of the oven compartment until rack drops into place (Fig’s. 24 & 25).

52.giF42.giF

Toremoverack,reversetheprocedureabovebyraisingrearof ovenrack stopaboverunner andpulling

rack forward (Fig. 26).

Fig. 26

— 17 —

Page 18

PREHEATING

Standard Oven

Turn thermostat control to the desired cooking temperature and preheat oven for25 minutes. To save

on gas consumption, do not operate oven at maximum heatwhen it is not necessary.Turn thermostat

down to 250°F (121°C) or OFF when oven is not in use or during idle cooking periods.

Hot Top Burners

Turn burner ONto highest heatto heat hottop section quickly.Hot top willbe ready to cookon in about

10 minutes.After topsection has reached operation temperature, turn some of the burners down. You

will save as much as80% of gas consumption and notice very little dierence in cooking performance

as long as you have allowed the entire hot top section to preheat properly.

Open Top Burners

Open top burners ignite quickly and do not require any preheating time. When food comes to a rolling

boil,cut back to slower boil to conserve energy, yetcontinueboiling.TurnburnersONonlywheninuse.

Broiler/Griddle

Turn the three manualgasvalve knobs to fullON.After preheating for 5minutes,turn valves down until

desired ame or heating level is achieved. Position the removable broiler gridinto one of the two slide

positions, depending on which will achieve the proper product results.

LOADING AND UNLOADING STANDARD

Openthedoorand load as quickly as practical to conserve heat. Take care to avoid spilling liquids while

loading. Close the door and refer to recipe for cooking time.

Provide adequate space for product unloading. Rapid unloading will conserve heat and reduce

preheating for the next load.

— 18 —

Page 19

COOKING CHART

Recommended temperatures and times are intended as a guide only. Adjustments must be made to

compensate for elevation, variations in recipes, ingredients, preparation and personal preference on

product appearance.

Meatroasting is most satisfactory at temperaturesof225°Fto325°F(107°Cto162.7°C) for beef, lamb,

poultry and ham, and 325°F (162.7°C) for fresh pork as recommended by USDA and American Meat

Institute.

A pan, approximately12"x 20" x 1"(305x 508 x25mm), full of watermaybe placed in theovenbottom

to supply humidity; this will reduce shrinkage. Water should be added if necessary during roasting.

Roasting pans should be nodeeper thannecessary to holddrippings, usually2" to 2

1

/2" (51 to 64 mm).

Cooking time and shrinkage may vary with roasting temperature, cut, grade of meat and degree of

doneness.Smallercutswill generally showgreatertimesavingsthan larger cutsatagiventemperature.

ROASTING TEMPERATURES AND TIMES

ERUTAREPMETTCUDORP APPROXIMATE TIME

Standing Rib Roast 250°F/121°C 3-4 Hrs. - Rare

Rolled Rib Roast - 20-22 lbs. (9.1-10 kg) 275°F/135°C 4 Hrs. - Med.

Veal Roast - 15 lbs. (6.8 kg) 300°F/148.9°C 3 Hrs. - Med. Well

Turkey - 15-20 lbs. (6.8-9.1 C°9.841/F°003)gk 3 Hrs.

Meat Loaf - 8-10 lbs. (3.6-4.5 kg) 350°F/176.7°C 45 to 60 Min.

1

4-4)gk8.6(.sbl51-ydaeRnevO

/2 Hrs. - Med.

RECOMMENDED TEMPERATURES, TIMES AND LOADS FOR BAKING

APPROXIMATE

Cakes (Standard Oven)

1

3

/2 lbs. (1.6 kg) Sheet Cakes - 18 x 26 x 1" (457 x 660 x 25 mm) 350°F/176.7°C 45 Min.

31/2 lbs.(1.6 kg) Sheet Cakes - 12 x 18 x 2" (305 x 457 x 51 mm) 350°F/176.7°C 1 Hr. and 15 Min.

—19—

TIME

).NIM(ERUTAREPMETTCUDORP

Page 20

APPROXIMATE TIME

Angel or Sponge Cakes

Sheet pans 18 x 26 x 1" (457 x 660 x 25 mm)

Scaled 5-6 lbs. (2.3-2.7 kg) per pan 300 to 325°F/148.9 to 162.8°C 15 to 20

Loaf or Tube Pans 315 to 340°F/157.2 to 171°C 20 to 30

Cup Cakes 350 to 400°F/176.7 to 204.4°C 6 to 12

Frozen Fruit Pies 350 to 375°F/176.7 to 190.5°C 30 to 45

Pumpkin or Custard Pies 300 to 350°F/148.9 to 176.7°C 30 to 45

Cobblers

12x18x2"or12x20x21/2 " pans

(305 x 457 x 51 mm or 305 x 508 x 64 mm) 350 to 400°F/176.7 to 204.4°C 30 to 45

Meringue Pies 350 to 425°F/176.7 to 218.3°C 6 to 10

Fruit Turnovers

NOTE: Cobblers, fruit, custard and pumpkin pies should be placed on sheet pans for baking.

).NIM(ERUTAREPMETTCUDORP

52ot51C°5.091ot7.671/F°573ot053snapteehS

Cookies

Brownies 350°F/176.7°C 12 to 20

Yeast Breads

NOTE: Yeast breads should be fully proofed for best results.

Rolls 01ot5C°4.402ot7.671/F°004ot053)smarg82.(.zo1-

11/2 to 21/2 oz. (42.5 to 70.8 grams) 350 to 400°F/176.7 to 204.4° 8 to 15

Loaf Bread 04ot02C°5.091ot8.261/F°573ot523)gk5.0(.bl1-

Sweet Rolls and Pastries 325 to 375°F/162.8 to 190.5°C 5 to 15

Biscuits - Rolled1/2 " (13 mm) thick 350 to 400°F/176.7 to 204.4°C 5 to 15

Muffins 325 to 375°F/162.8 to 190.5°C 6 to 18

Corn Bread

18 x 26 x 1" (457 x 660 x 25 mm) pan,

18 x 26 x 2" (457 x 660 x 51 mm) pan,

8-20 lbs. (3.6-9.1 kg) per pan 335 to 400°F/168.3 to 204.4°C 15 to 25

21ot6C°4.402ot7.671/F°004ot053desserProdelloR

51ot6C°4.402ot7.671/F°004ot053porD

02ot01C°4.402ot3.861/F°004ot533naprep)gk3-3.2(.sbl7-5

Corn Muffins 335 to 385°F/168.3 to 196°C 10 to 20

—20—

Page 21

OVEN BROILING OR FRYING

Hamburger Patties

8 per lb. (0.5 kg) - Med. well done 400 to 450°F/204.4 to 232.2°C 5 to 6

Fish Sticks & Portions

Frozen bread. - 1 oz. (28.3 grams) 350 to 400°F/176.7 to 204.4°C 6 to 10

21/2 51ot8C°5.091ot7.671/F°573ot053)smarg58ot8.07(.zo3ot

Chicken Pieces

Broiled or Oven Fried

2to21/2 51ot8C°3.812ot5.091/F°524ot573)gk1.1ot9.0(.sbl

21/2 52ot51C°4.402ot7.671/F°004ot053)gk4.1ot1.1(.sbl3ot

Lobsters

1to11/2 61ot21C°2.232ot4.402/F°054ot004)gk6.0ot5.0(.sbl

Lobster Tails

Frozen,1/2 to 1 lb. (0.2 to 0.5 kg) 350 to 400°F/176.7 to 204.4°C 16 to 20

APPROXIMATE TIME

).NIM(ERUTAREPMETTCUDORP

01ot7C°2.232ot4.402/F°054ot004)gk5.0(.blrep6

21ot8C°691ot5.091/F°583ot573)gk5.0(.blrep4

REHEATING PREPARED FOODS

Frozen French Fries 400 to 450°F/204.4 to 232.2°C 6 to 8

Frozen TV Dinners 350 to 400°F/176.7 to 204.4°C 10 to 12

Frozen Entrees - 1" (25 mm) thick 300 to 350°F/148.9 to 176.7°C 10 to 20

Frozen Meals

CASSEROLES

Food Service Pans

Ramekins or Foil Pans

Up to 11/2 6ot5C°4.402ot7.671/F°004ot053peeD)mm83("

03ot02C°4.402ot7.671/F°004ot053egakcapliof)gk2.0(.zo8

52ot51C°5.091ot8.261/F°573ot523peed)mm67ot15("3ot"2

53ot02C°5.091ot8.261/F°573ot523peed)mm201ot67("4ot"3

51ot01C°4.402ot7.671/F°004ot053nezorF

—21—

Page 22

MISCELLANEOUS PRODUCTS

APPROXIMATE TIME

Baked Potatoes

120 count per 50 lbs (22.7 kg) 400 to 450°F/204.4 to 232.2°C 25 to 35

100 count per 50 lbs. (22.7 kg) 400 to 450°F/204.4 to 232.2°C 35 to 45

80 count per 50 lbs. (22.7 kg) 400 to 450°F/204.4 to 232.2°C 40 to 60

Pizzas

Frozen or with prebaked

ot524tsurc 475°F/218.3 to 246°C 5 to 10

Grilled Cheese Sandwiches 400 to 425°F/204.4 to 218.3°C 8 to 10

SPECIAL BAKING PROCEDURES

YEAST BREADS

).NIM(ERUTAREPMETTCUDORP

Cooking starts immediately in the convection oven. Yeast breads do not usually rise as much in

the convection oven as in a conventional oven. Therefore, it is necessary to allow 2

1

/2 to 3 times

longer for the dough to reach its proong capacities.

PIES

When baking pies in your convection oven, 3 or 4 pies should be put on an 18 x 26"(457 x 660 mm)

sheet or bun pan. This procedure helps the bottom crust to bake, makes handling easier and

reduces the possibility of boil-over, spoiling the appearance of the pies on the lower racks.

—22—

Page 23

CLEANING

Do not use Dawn dish detergent to clean the exterior or interior components of the range.

Donotusescouringpowder.Itisextremelydiculttoremovecompletely.Itcanbuildupaccumulations

that will damage the oven.

Vulcan painted surfaces may be cleaned using a soft cloth and mild detergent solution.

RANGES

Daily

Remove nickel-plated racks and clean in a sink.

While still warm, wipe top with a soft cloth or other grease absorbing material to remove spillovers,

grease, etc., before they burn in. A crust on top of the hot top range looks unsightly and slows down

cooking speed because it reduces the ow of heat to the utensil.

Clean oven and oven door daily, especially if fruit pies or tomato sauces were baked, meats roasted,

and if there have been spillovers.

After processing some foods at low temperatures, odors may linger in the oven. These odors may be

cleared by setting the thermostat at 500°F (260°C) and allowing the oven to operate unloaded for 30

to 45 minutes.

Empty the broiler grease pan/trough daily or as often as necessary. CAUTION: Remove the grease

pan/trough slowly and be careful of liquid wave action. It is recommended that the grease pan/

trough be emptied whenever it is

3

/4 lled. The drip shield, grids and grease pan/trough should be

washed with a mildgrease-dissolvingsolution.Some chefs scrape thegridwitha three-cornered metal

scraper. Scrub the broiler chamber and body front frequently and you will have less smoking.

Clean cast iron open top grates with a mild soap and water solution. Rinse thoroughly and dry with a

clean, water-absorbent towel. Immediately after drying (with grates still removed from the range top),

season grates lightly with liquid vegetable or Pam spray-type cooking oil.

After seasoning, replace grates onto the range. Turn all open topsections ON LOW and allow them to

burn for at least 15 minutes before using pots or pans on the range top.

Season the open top grates after each cleaning. Failure to season grates will cause grates to rust.

Weekly

Boil burners in a solution of washing soda. Rinse and dry parts thoroughly. Flash rusting may occur.

This is a normal condition and will not aect the performance or the product prepared.

When reinstalling the burner back onto the range, be sure the burner heads are properly connected.

Do not light the pilot or turn burner valve ON with the burner head removed.

—23—

Page 24

GRIDDLE PLATE

Cleaning the griddle section will produce evenly cooked, perfectly browned griddle products and will

keep the cooking surface free from carbonized grease. Carbonized grease on the surface hinders the

transfer of heat to the food. This results in loss of cooking eciency and spotty browning which gives

foods an unappetizing appearance. To keep the griddle clean and operating at peak eciency, follow

these simple instructions:

After Each Use

Carefully clean griddle with wire brush or exible spatula.

Daily

Thoroughly clean backsplash, sides and front. Remove grease pan, empty and wash out in the same

manner as any ordinary cooking utensil.

Clean griddle surface thoroughly. If necessary, use a griddle stone, wire brush or steel wool over the

surface. Rubwith the grain of the metal while still warm. A detergent may be used onthe platesurface

to help clean it, but the cleaner must be thoroughly removed. After removal of detergent, the surface

of the plate must be reseasoned with a thin lm of oil to prevent rusting and food sticking.

Ifthegriddleistobeshutdownforanextendedperiod,putaheavycoat ofgreaseoverthe griddleplate.

MAINTENANCE

WARNING: THE RANGE AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE RANGE.

VENT

When cool, the vent should be checked every six months for obstructions.

SERVICE AND PARTS INFORMATION

Toobtainserviceand parts information concerning this model, contact the Vulcan-Hart Service Agency

in your area (refertoour website, www.vulcanhart.com foracomplete listing of AuthorizedServiceand

Parts depots).

When calling for service, the following information must be available: model number, serial number,

manufacture date (MD) and voltage.

—24—

Page 25

TROUBLESHOOTING GUIDE

STANDARD AND CONVECTION OVEN RESTAURANT RANGE

OVEN

SESUACMELBORP

b) Improper uing

b) Oven burner, bottom or baes improperly installed

c) Warped pans

b) Not level front to back; check casters and legs

c) Door not closing properly

noitalitnevtneiciffusnI)ataehmottobhcumooT.1

gnittesssapybtatsomrehtreporpmI)cerutarepmetwolooT.a1

noitarbilacfotuotatsomrehT)dgninrubediS.b1

erusserpsaggnitautculF)etaehpothcumooT.c1

edisotedisleveltoN)aedisotedisekabnevenU.2

eulfevitcarevO)araerottnorfekabnevenU.3

TOP BURNER OPERATION

1. Improper burner combustion a) Improper ventilation

Excessive valve handle temperatures b) Poor door t

nikcitS

)gnikoocrevo(erutarepmetwolooT)astcudorptuodeirD.4

b) Too long baking time

c) Thermostat calibration

wolootemalftoliP)aegatuotoliP.5

b) Restriction in pilot orice

c) Problem with shuto valve

d) Possible uing problems

e) Low pressure

f) Improper gas line sizing

g) Burner box cover not properly installed

h) Oven cavity requires resealing

nepotfelroodnevO)csevlavrenrubpotg

d) Improper use of excessively large pans or pots

tupnitneiciffusnI)anoitingirooP.2

b) Poor air-gas adjustment

c) Restriction in pilot orice

d) Restriction in main burner ignition port

—25—

Page 26

F-35692 (10-09) PRINTED IN U.S.A.

— 26 —

Page 27

MODE D’INSTALLATION ET

CUISINIÈRE AU GAZ POUR RESTAURANTS

MOD

ELS

V24

V36

V36F

V60

V60F

V260

www

.vulcanhart.com

MODE D’EMPLOI

Pour de plus amples détails concernant Vulcan-Hart ou pour repérer le détaillant de

pièces et de service autorisé le plus près, visiter notre site Web à : www.vulcanhart.com

TRAH-NACLUV P.O. BOX 696, LOUISVILLE, KY 40201-0696

WWW.VULCANHART.COM

CLL,ERIATNEMILATNEMEPIUQÉWTIEPUORGEDNOISIVIDENU TÉL. (502) 778-2791

F-35692 (10-09)

Page 28

MESURES DE SÉCURITÉ IMPORTANTES

CE MANUEL A ÉTÉ PRÉPARÉ À L’INTENTION D’UN PERSONNEL QUALIFIÉ ET AUTORISÉ À

INSTALLER DES APPAREILS FONCTIONNANT AU GAZ ET À EFFECTUER LE DÉMARRAGE

INITIAL CHEZ LE CLIENT DE MÊME QUE LE RÉGLAGE DES APPAREILS CONCERNÉS DANS

CE MANUEL.

AFFICHER À UN ENDROIT VISIBLE LES PREMIERS SOINS À ADMINISTRER À TOUTE

PERSONNE AYANT RESPIRÉ LES GAZ QUE CET APPAREIL DÉGAGE. ON PEUT SE

PROCURER CES INFORMATIONS CHEZ LE FOURNISSEUR DE GAZ LE PLUS PRÈS.

IMPORTANT

EN CAS D’ODEURS DE GAZ, ÉTEINDRE L’APPAREIL PAR

LE ROBINET D’ARRÊT PRINCIPAL ET COMMUNIQUER

AVEC LA COMPAGNIE DE GAZ LA PLUS PRÈS OU

AVEC LE FOURNISSEUR DE GAZ ATTITRÉ POUR

L’ENTRETIEN.

MESURE DE SÉCURITÉ

NE PAS RANGER NI UTILISER DE L’ESSENCE NI TOUT

AUTRE LIQUIDE OU VAPEUR INFLAMMABLE À

PROXIMITÉ DE CET APPAREIL OU DE TOUT AUTRE

APPAREIL.

AVERTISSEMENT

L’INSTALLATION, LE RÉGLAGE, LA MODIFICATION

ET L’ENTRETIEN INCORRECTS DE CET APPAREIL

PEUVENT CAUSER DES DOMMAGES MATÉRIELS,

DES BLESSURES ET MÊME LA MORT. LIRE LES

INSTRUCTIONS D’INSTALLATION, DE FONCTIONNEMENT

ET D’ENTRETIEN AVANT DE PROCÉDER À TOUTE

INSTALLATION OU TOUT ENTRETIEN.

EN CAS DE PANNE DE COURANT, NE PAS FAIRE

FONCTIONNER CET APPAREIL.

— 2 —

Page 29

MODÈLES DE CUISINIÈRES AU GAZ

POUR RESTAURANTS

V60

V260

V36

* Modèle discontinué.

—3—

Page 30

Installation, fonctionnement et entretien

CUISINIÈRE AU GAZ POUR RESTAURANTS DES

SÉRIES 90 ET VG

DOCUMENT À CONSERVER EN CAS DE BESOIN.

GÉNÉRALITÉS

Les cuisinières et fours Vulcan sont fabriqués avec le plus grand soin et à partir des meilleurs

matériaux. Leur installation, utilisation et entretien appropriés permettront d’en obtenir un

rendement optimal pendant de nombreuses années.

Il est recommandé de lire ce manuel au complet et de suivre attentivement toutes les instructions.

INSTALLATION

DÉBALLAGE

Cette cuisinière a été inspectée avant de quitter l’usine. En acceptant de livrer cette marchandise, le

transporteur en assume l’entière responsabilité jusqu’à la livraison. Immédiatement après avoir déballé

l’appareil, vérier s’il n’a pas été endommagé lors du transport. En cas de dommages, conserver le

matériel d’emballage et aviser le transporteur dans les 15 jours suivant la date de réception.

Sortir l’appareil de sa caisse avec soin et le placer le plus près possible de l’emplacement prévu.

Enlever tous les câbles et blocs de bois servant à l’expédition.

Avant de l’installer, s’assurer que l’alimentation électrique (modèles pourvus d’un four à air pulsé

seulement) et le type de gaz (naturel ou propane) de l’immeuble correspondent aux spécications de

la plaque signalétique se trouvant sur l’intérieur du panneau inférieur. S’ils ne correspondent pas, ne

pas installer l’appareil et communiquer sans tarder avec le détaillant ou la Compagnie Vulcan-Hart.

EMPLACEMENT

Aucune substance combustible ne doit se trouver à proximité de cet appareil.

Lors de l’installation de la cuisinière, observer un dégagement d’au moins 304 mm (12 po) derrière et de

chaque côté de toute construction combustible. Observer un dégagement de 253 mm (10 po) derrière

l’appareil de toute construction incombustible; aucun dégagement n’est requis de chaque côté de l’appareil.

La cuisinière doit se trouver dans un endroit susamment espacé pour permettre son entretien et son

fonctionnement appropriés. Un dégagement minimal de 1 016 mm (40 po) est requis devant l’appareil.

Installer la cuisinière de manière à assurer la circulation de l’air nécessaire à la combustion des

gaz et à la ventilation appropriées de l’appareil. Observer un dégagement susant autour des

ouvertures d’approvisionnement d’air de la chambre de combustion. S’assurer d’une bonne

ventilation dans le local pour permettre la combustion des gaz.

—4—

Page 31

CODES D’INSTALLATION ET NORMES

L’installation des cuisinières Vulcan doit se faire selon les codes suivants :

Aux États-Unis :

1. Codes locaux.

2. Norme ANSI/Z223.1 (dernière édition) du National Fuel Gas Code dont on peut se procurer un

exemplaire auprès de l’American Gas Association Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. Norme ANSI/NFPA-70 (dernière édition) du National Electrical Code dont on peut se procurer un

exemplaire auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

4. Norme NFPA-96 (dernière édition) sur la dispersion des vapeurs chargées de graisse et de la

fumée provenant des appareils de cuisson dont on peut se procurer un exemplaire auprès de

la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

Au Canada :

1. Codes locaux.

2. Norme CSA B149.1 du Code d’installation des appareils fonctionnant au gaz naturel et propane.

3. Norme CSA C22.1 du Code canadien de l’électricité.

4. Norme CSA C22.2 du Code canadien de l’électricité.

On peut se procurer un exemplaire des normes ci-dessus auprès de l’Association canadienne de

normalisation, 5060 Spectrum Way, Bureau 100, Mississauga, Ontario, Canada L4W 5N6.

ASSEMBLAGE

Appareils sur roulettes

Les appareils sur roulettes doivent être pourvus d’un tuyau de

raccordement flexible (non fourni par Vulcan) conforme à la norme

ANSI-Z21.69 • CSA6.16 et d’un raccord à débranchement rapide

satisfaisant les exigences de la norme ANSI-Z21.41 • CSA6.9.

Ils doivent aussi être pourvus d’un dispositif de retenue

permettant de limiter le mouvement de l’appareil sans devoir compter

sur le connecteur ou le raccord de débranchement rapide, ni même

sur la tuyauterie pour la garder immobile. Fixer ce dispositif à

l’arrière de la cuisinière (Fig. 1).

FIXER LE DISPOSITIF DE

RETENUE DE LA CONDUITE

D’ALIMENTATION EN GAZ ICI

CONNECT GAS LINE

STRAIN

RELIEF HERE

PL-51219

Fig. 1

Enlever les deux vis à l’arrière de la cuisinière et installer l’attache boulonnée expédiée avec les

roulettes en utilisant ces vis (Fig.1). Fixer cette attache au dispositif de retenue de la conduite

d’alimentation en gaz à l’arrière de la cuisinière (Fig. 1).

S’il s’avère nécessaire de détacher le dispositif de retenue, couper l’alimentation en gaz de

l’appareil. Le rattacher avant de rétablir l’alimentation en gaz et de remettre l’appareil en position

d’exploitation.

Des instructions pour l’installation de roulettes sont incluses avec les roulettes séparément.

Nota : Si la cuisinière est installée sur des roulettes et doit être déplacée pour une raison ou une

autre, il est conseillé de la niveler à nouveau d’avant en arrière et d’un côté à l’autre.

— 5 —

Page 32

Barres de choc (Fours à air pulsé seulement)

ATTENTION : En l’absence des barres de choc, le moteur risque de s’endommager, ce qui aurait

pour effet d’annuler la garantie.

Enlever les vis #10 déjà en place. Poser les barres de choc (fournies) comme l’indique l’illustration

pour les fixer ensuite à l’aide des mêmes vis (Fig. 2).

VUE ARRIÈRE DE LA CUISINIÈRE

REAR VIEW OF RANGE

NOTES:

NOTA :

1. Bumper bars required for all

1. Barres de choc requises pour toutes les cuisinières pourvues

2. Dispositif de retenue requis pour toutes les cuisinières sur roulettes.

3. Dispositif de retenue non fourni par le fabricant.

BUMPER BAR

BARRE DE CHOC

Fig. 2

Convection Oven Ranges.

2. Restraining device required for

d’un four à air pulsé.

all ranges with casters.

3. Restraining device not supplied by

unit manufacturer.

RESTRAINING DEVICE

DISPOSITIF DE RETENUE

#10 SHEET METAL SCREW

VIS À TÔLE #10

PL-50109

Installation des briques d’une plaque à frire-grilloir

La plaque à frire-grilloir d’une cuisinière pour restaurants est munie de briques réfractaires en

céramique permettant le rayonnement thermique des brûleurs. Les insérer à leur emplacement

respectif avant de raccorder la conduite de gaz de l’appareil.

1. Sortir les six briques de 133 x 57 mm (5 1/4 x 2 1/4 po) et les six briques de 133 x 128 mm

(5 1/4 x 5 1/16 po) de leur boîte.

2. Mettre les six briques de 133 x 57 mm (5 1/4 x 2 1/4 po) de chaque côté des brûleurs. Pour ce

faire, les insérer une à la fois par l’ouverture avant du grilloir. Les insérer de biais de manière

qu’elles puissent glisser entre le rebord de chaque brûleur. Les déposer à plat pour qu’elles

reposent sur ces mêmes rebords. Pousser chaque brique le plus possible vers l’arrière afin de

pouvoir déposer facilement la dernière brique (Fig. 3).

3. Procéder de la même manière pour l’installation des six briques de 133 x 128 mm (5 1/4 x 5 1/16 po)

des brûleurs centraux tel que décrit à l’étape 2.

Fig. 3

— 6 —

Page 33

Installation des briques d’une plaque à bouillir

La plaque à bouillir des cuisinières pour restaurants comporte des briques réfractaires en mortier

compositepermettantladistributiondechaleur produiteparlesbrûleurs. Lesinséreràleuremplacement

respectif avant de raccorder la conduite de gaz de l’appareil ou de mettre en place le conduit

d’évacuation des gaz brûlés.

1. Les briques en mortier composite sont expédiées dans une boîte rectangulaire en carton. Sortir

avec soin deux briques de 254 x 102 mm (10 x 4 po) et deux briques de 178 x 102 mm (7 x 4 po).

Chaque plaque à bouillir comprend une boîte de briques.

NOTA : Une brique cassée en deux peut quand même être utilisée. Placer simplement les

morceaux tels qu’illustrés à la Fig. 4.) Cependant, si une brique est cassée en plusieurs morceaux,

elle devra être remplacée. Communiquer avec le service de pièces Vulcan le plus près.

2. Ranger la plaque à bouillir dans un endroit sécuritaire.

3. Mettre les deux briques en mortier composite de 254 x 102 mm (10 x 4 po) de chaque côté du

brûleur, la petite extrémité vers l’avant des déecteurs (Fig. 4).

4. Mettre les deuxbriques de 178 x 102 mm(7 x 4 po)de chaque côtédu brûleur, surla partie arrière

des déecteurs (Fig. 4).

5. Si les brûleurs ont été attachés, couper les courroies métalliques à l’aide d’un coupe-l.

6. S’assurer que toutes les briques et tous les brûleurs sont bien installés. Remettre la plaque à

bouillir en place avec soin.

Dosseret

Chaque cuisinière standard pour restaurants est munie d’un dosseret de 584 mm (23 po) de hauteur

et dotée d’une tablette.

1. Sortir les composants du dosseret de leur matériel d’emballage.

2. À l’aide de la liste en page 10, vérier si tous les composants requis sont présents (Fig. 8 et 9). Si certaines

pièces manquent, communiquer sans tarder avec le détaillant ou le service des pièces le plus près.

3. Assembler les composants requis comme l’illustrent les Fig. 8 et 9.

4. Lever le dosseret équipé et glisser les prolés à l’arrière de l’appareil, dans l’espace prévu à cette

n (cela peut nécessiter deux personnes.)

—7—

9.giF8.giF

Page 34

Composants du dosseret

MODÈLES

*48L, 481L ET *148L 60L ET *160L

24L/VG24 36L/VG36 *VG48 VG60/*160 260L/VG260

Dosseret std de 584 mm (23 po) Dosseret std de 584 mm (23 po) Dosseret std de 584 mm (23 po) Dosseret std de 584 mm (23 po) Dosseret std de 584 mm (23 po)

de hauteur (1) de hauteur (1) de hauteur (1) de hauteur (1) de hauteur (1)

Prolé du dosseret Prolé du dosseret Prolé du dosseret Prolé du conduit d’évacuation Prolé du dosseret

)2()1()2()2()2(

Écran thermique (1) Écran thermique (1) Écran thermique (48L) (1) Écran thermique (1) Écran thermique (1)

Écran thermique (481L) (1)

Vis à tôle #10 Vis à tôle #10 Vis à tôle #10 Vis à tôle #10 Vis à tôle #10

)4()02()61()61()61(

Vis à métaux (4) Vis à métaux (4) Vis à métaux (4) Vis à métaux (4) Vis à métaux (6)

1

/4-20 x 59 mm (2 5/16 po)1/4-20 x 59 mm (2 5/16 po)1/4-20 x 59 mm (2 5/16 po)1/4-20 x 59 mm (2 5/16 po)1/4-20 x 59 mm (2 5/16 po)

Tablette équipée (1) Tablette équipée (1) Tablette équipée (1) Tablette équipée (1) Tablette équipée (1)

* Modèle discontinué.

5. Il peut s’avérer nécessaire de tirer légèrement la base de l’écran thermique pour franchir la région

de l’enveloppe du carneau. S’assurer que le dosseret repose de niveau et que les trous des

prolés sont alignés avec ceux des parois gauche et droite du châssis (Fig. 10 et 11).

—8—

11.giF01.giF

Page 35

6. Poser huit vis à tôle #10 (4 par prolé) (Fig. 12).

Fig. 12

7. Par l’avant de l’appareil, poser quatre vis à métaux de 1/4-20 x 59 mm (2 5/16 po) de longueur et

xer solidement les boulons au moyen de contre-écrous. Ne pas serrer les vis au maximum.

Maintenir un jeu d’environ 6 mm (1/4 po) pour chaque vis (Fig. 13).

8. Lever la tablette pour l’accrocher aux têtes de vis (Fig. 14).

9. Serrer les quatre vis pour xer la tablette en place.

—9—

41.giF31.giF

Page 36

NIVELAGE

Vérier si l’appareil est de niveau en déposant un niveau de menuisier en travers des grilles du four.

S’il ne l’est pas, procéder à son nivelage d’avant vers l’arrière et d’un côté à l’autre.

Pour ce faire, incliner la cuisinière sur le côté et, à l’aide de pinces multiprises, dévisser la pièce

rapportée du pied réglable tant qu’il faudra. Au besoin, reprendre le processus à chaque pied.

Les roulettes de ces appareils ne se règlent pas. Ainsi, le plancher doit être de niveau sans quoi

des problèmes de cuisson pourraient survenir tant que la cuisinière ne sera pas nivelée.

BRANCHEMENT DU GAZ

ATTENTION : Tous les raccords d’alimentation de la conduite de gaz et la pâte à joints de

tuyaux doivent résister à l’action du gaz propane.

Chaque appareil est préparé en usine en fonction du type de gaz indiqué sur la plaque signalétique.

Le raccord de gaz est constitué d’un tuyau standard n° 40 de 19 mm (3/4 po) au letage 14 FPT

conforme aux normes ANSI.

Raccorder la conduite de gaz à l’appareil. S’assurer que les tuyaux sont propres et qu’ils ne sont

pas obstrués.

Conformément aux exigences des codes, installer un robinet d’arrêt dans la conduite de gaz en

amont de la cuisinière.

Les appareils standard sont munis de brûleurs à injecteurs xes conçus en fonction de l’élévation

requise de la amme.

Installer le régulateur de pression du gaz.

Avant d’installer le régulateur, s’assurer que l’alimentation en gaz de l’immeuble correspond à

l’alimentation de la plaque signalétique.

Depuis le 7/11/90, le régulateur de pression n’est PLUS installé en usine, mais expédié dans un sac

en plastique scellé dans l’enceinte du four pour l’installation par un technicien qualié.

Les régulateurs de pression sont préréglés à 0,92 kPa (3,7 po de colonne d’eau) pour le gaz naturel

et à 2,49 kPa (10 po de colonne d’eau) pour le gaz propane.

1. Repérer le tuyau de raccordement du gaz de 19 mm (3/4 po) à l’arrière de la cuisinière.

2. Enduire les lets du tuyau d’agent d’étanchéité.

3. Serrer solidement à la main le régulateur sur le tuyau, la èche pointant vers l’arrière de

la cuisinière (Fig. 15).

4. Au moyen d’une clé à tuyau, serrer solidement le régulateur à la verticale (Fig. 15).

La èche sur le régulateur indique la direction du débit de gaz (Fig. 15). Fixer le régulateur à

l’horizontale pour s’assurer de la pression d’échappement appropriée. S’il se trouve dans une

autre position, régler à nouveau la pression d’échappement pour assurer le fonctionnement

approprié de l’appareil.

Chaque régulateur est muni d’un limiteur de fuites permettant l’échappement de l’excès de pression

du gaz. Ne pas obstruer le limiteur de fuites du régulateur de pression du gaz pour ne pas nuire

à son fonctionnement.

—10—

Page 37

Fig. 15

AVERTISSEMENT : AVANT DE PROCÉDER À L’ALLUMAGE, FAIRE CIRCULER DE L’EAU SAVONNEUSE

DANS TOUS LES JOINTS DE LA CONDUITE DE GAZ POUR S’ASSURER QU’ILS NE PRÉSENTENT

AUCUNE FUITE. NE PAS SE SERVIR D’UNE FLAMME NUE.

Après avoir enrayé toute possibilité de fuite, purger toutes les conduites de gaz pour évacuer tout

l’air qui pourrait s’y trouver.

Avant d’eectuer cette opération, s’assurer que le thermocouple est bien appuyé sur la soupape de

sûreté. Après avoir serré le thermocouple à la main, faire encore 1/4 de tour avec une clé. NE PAS

TROP SERRER . Ceci pourrait endommager le thermocouple ou l’aimant de sécurité.

ESSAIS DE LA CANALISATION DE GAZ

Si la pression de la canalisation de gaz est supérieure à 3,45 kPa (1/2 psig) lors d’essais de pression,

débrancher la cuisinière et son robinet d’arrêt de la conduite de gaz.

Lorsque la pression d’essai est égale ou inférieure à 3,45 kPa (1/2 psig), isoler l’appareil de la

canalisation de gaz en fermant son robinet d’arrêt manuel jusqu’à ce que la cuisinière soit prête à

fonctionner.

CONDUIT D’ÉVACUATION

NE PAS obstruer le débit des gaz de combustion dans le conduit d’évacuation à l’arrière de l’appareil.

Il est recommandé que les gaz de combustion soient ventilés à l’extérieur de l’immeuble par un

système de ventilation installé par un personnel qualié.

Maintenir un dégagement minimum de 457 mm (18 po) entre l’extrémité du conduit d’évacuation

de l’appareil et les ltres de la hotte de ventilation.

Les informations sur la construction et l’installation des hottes de ventilation sont comprises dans

la norme NFPA n° 96 (dernière édition) relative à la dispersion des vapeurs chargées de graisse et

de la fumée provenant des appareils de cuisson dont on peut se procurer un exemplaire auprès de

la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

—11—

Page 38

RACCORDEMENT ÉLECTRIQUE (MODÈLES POURVUS D’UN FOUR À AIR PULSÉ, [SÉRIE

90] SEULEMENT)

AVERTISSEMENT : LE RACCORDEMENT ÉLECTRIQUE ET LA MISE À LA TERRE DOIVENT

ÊTRE CONFORMES AUX NORMES CONCERNÉES DU CODE CANADIEN DE L’ÉLECTRICITÉ

OU TOUT AUTRE CODE D’ÉLECTRICITÉ EN VIGUEUR.

AVERTISSEMENT : COUPER L’ALIMENTATION ÉLECTRIQUE DE L’APPAREIL ET SUIVRE LES

PROCÉDURES DE VERROUILLAGE ET D’ÉTIQUETAGE.

AVERTISSEMENT : LES APPAREILS MUNIS D’UN CORDON D’ALIMENTATION FLEXIBLE SONT

POURVUS D’UNE FICHE DE MISE À LA TERRE À TROIS BROCHES. LA PRISE DANS LA QUELLE

ELLE EST BRANCHÉE DOIT ÊTRE CORRECTEMENT MISE À LA TERRE. SI ELLE NE L’EST

PAS, COMMUNIQUER AVEC UN ÉLECTRICIEN. NE PAS ENLEVER LA BROCHE DE MISE À

LA TERRE DE LA FICHE.

Cet appareil est conçu pour fonctionner à un courant de 120 V ou monophasé (en option) de 240 V

et 15 A.

Tous les appareils de 120 V sont munis d’un cordon d’alimentation exible. Avant d’ouvrir le gaz,

brancher la che dans une prise de courant appropriée. Si l’appareil requiert une source de courant

électrique sans être muni d’une che de mise à la terre, mettre l’appareil à la terre à l’aide de la

cosse fournie à cette n. Tous les systèmes électriques de 240 V sont fabriqués en fonction d’un

raccordement par ls rigides (voir le schéma de câblage ci-joint). Un schéma de câblage a été

apposé sur l’arrière du châssis près du moteur.

Ne pas établir l’alimentation électrique tant que tous les raccordements du gaz n’auront pas été faits.

—12—

Page 39

FONCTIONNEMENT

AVERTISSEMENT : LA CUISINIÈRE ET SES COMPOSANTS SONT CHAUDS. EXERCER UNE

EXTRÊME PRUDENCE LORS DE SON UTILISATION, NETTOYAGE OU ENTRETIEN.

COMMANDES

CADRAN DU THERMOSTAT – — Dispositif servant à régler la température du four de la

étisnetnielbiafsulpLENNOITNEVNOCRUOF jusqu’à 260 °C (500 °F).

CADRAN DU THERMOSTAT – — Commande à rupture brusque servant à régler la

BOUTON DES BRÛLEURS DÉCOUVERTS - - - Bouton servant à régler le débit du gaz. Pour

FOURS CONVENTIONNEL ET À AIR PULSE augmenter la chaleur, tourner le bouton dans le sens

contraire des aiguilles d’une montre et dans le sens

inverse pour la réduire.

INTERRUPTEUR GÉNÉRAL - —Interrupteur ON-OFF (marche-arrêt) servant à

.ruelahcedeévirra’lednammocruofudÉSLUPRIAÀRUOF

.)F°005à051(C°062à5,56edruofuderutarépmetÉSLUPRIAÀRUOF

.ruofudsednammocsednoitatnemila’lrednammocÉSLUPRIAÀRUOF

tatsomrehteleuqeuqidni,émullasiofenu,iuqtnayoV—–EGAFFUAHCEDTNAYOV

ROBINET DE LA PLAQUE À FRIRE - — Robinet servant à régler le débit de gaz de la plaque

FOURS CONVENTIONNEL ET À AIR PULSE à frire ou à bouillir, selon le cas. Pour augmenter

l’intensité, tourner le bouton dans le sens contraire

des aiguilles d’une montre et dans le sens inverse

pour la réduire.

AVANT UNE PREMIÈRE UTILISATION

Apprêtage de la plaque à frire

ATTENTION : Cette plaque à frire est en acier, mais sa surface est relativement tendre et

peut rayer ou bosseler suite à l’utilisation d’une spatule ou d’un racloir d’une manière

négligente. Prendre soin de ne pas la bosseler, l’égratigner ou la rayer. Ne pas y cogner

les coins ou les rebords d’une spatule pour tenter de déloger les particules d’aliments qui

pourraient s’y trouver.

Il est nécessaire d’apprêter une plaque à frire neuve pour obtenir une bonne qualité de cuisson.

Sa surface de métal est poreuse et les aliments ont tendance à s’incruster dans les pores et à y

adhérer. Il est donc important d’apprêter la surface ou de “remplir” les pores d’huile de cuisson

pour qu’elle devienne lisse et dure, ce qui facilite l’enlèvement des aliments.

Ainsi, chauer la plaque à frire à basse température et y verser une once d’huile de cuisson par

pied carré. À l’aide d’un chion isolé, l’étendre sur toute la surface de la plaque de manière à

obtenir un mince lm, puis essuyer le surplus d’huile.

Reprendre la manoeuvre à deux ou trois reprises, soit jusqu’à ce que la surface soit lisse et

miroitante.

—13—

Page 40

ALLUMAGE ET EXTINCTION DES VEILLEUSES

Seul un technicien Vulcan-Hart autorisé doit procéder aux réglages ayant trait à l’allumage des

veilleuses.

PLAQUES À FRIRE ET À BOUILLIR

1. Ouvrir le robinet de gaz principal.

2. Attendre 30 secondes, puis allumer la veilleuse de la plaque à frire ou à bouillir à l’aide d’une

bougie (Fig. 16).

Ancien modèle de boutons de réglage

Fig. 16

Nouveau modèle de boutons de réglage depuis janv. 1998

3. Si la veilleuse refuse de s’allumer, fermer le robinet de gaz principal. Attendre cinq minutes avant

de reprendre le processus.

4. Ouvrir le robinet d’un des brûleurs pour évacuer l’air contenu dans la conduite de gaz. Fermer

le robinet dès que le gaz commence à circuler.

Arrêt nocturne

Fermer le robinet de chaque brûleur; la veilleuse demeure allumée.

Arrêt complet

1. Fermer le robinet de chaque brûleur; la veilleuse demeure allumée.

2. Fermer le robinet de gaz principal.

—14—

Page 41

BRÛLEURS DÉCOUVERTS

1. Ouvrir le robinet de gaz principal.

2. Attendre 30 secondes, puis allumer la veilleuse des brûleurs découverts à l’aide d’une bougie

(Fig. 17).

Fig. 17

3. Si une veilleuse refuse de s’allumer, fermer le robinet de gaz principal. Attendre cinq minutes

et reprendre le processus.

4. Ouvrir le robinet d’un des brûleurs pour évacuer l’air contenu dans la conduite de gaz. Fermer

le robinet dès que le gaz commence à circuler.

Arrêt nocturne

Fermer le robinet du brûleur; la veilleuse demeure allumée.

Arrêt complet

1. Fermer le robinet du brûleur; la veilleuse demeure allumée.

2. Fermer le robinet de gaz principal.

PLAQUE À FRIRE-GRILLOIR

1. Ouvrir le robinet de gaz principal.

2. Attendre 30 secondes, puis allumer la veilleuse de la plaque à frire-grilloir au moyen d’une

bougie (Fig. 16).

3. Si la veilleuse refuse de s’allumer, fermer le robinet de gaz principal. Attendre cinq minutes et

reprendre les étapes 1 et 2.

4. Ouvrir le robinet d’un des brûleurs pour évacuer l’air contenu dans la conduite de gaz. Fermer

le robinet dès que le gaz commence à circuler.

Arrêt nocturne

Fermer le robinet du brûleur; la veilleuse demeure allumée.

Arrêt complet

1. Fermer le robinet du brûleur; la veilleuse demeure allumée.

2. Fermer le robinet de gaz principal.

—15—

Page 42

FOUR CONVENTIONNEL

Allumer les veilleuses des brûleurs découverts et de la plaque à frire avant d’allumer celle du four.

1. Ouvrir le panneau inférieur et relever le couvercle du trou d’allumage de la veilleuse (Fig. 18).

91.giF81.giF

2. Allumer la veilleuse. Pour ce faire, appuyer sur le bouton de réenclenchement derrière le panneau

inférieur (Fig. 19) et le maintenir enfoncé pendant une minute. Si la veilleuse refuse de s’allumer,

fermer le robinet de gaz principal et attendre cinq minutes avant de reprendre l’étape 2.

3. Une fois que la veilleuse est allumée, régler le thermostat à la température désirée.

Arrêt nocturne

Régler le thermostat à la position OFF (arrêt).

Arrêt complet

1. Régler le thermostat à la position OFF (arrêt).

2. Fermer le robinet de gaz principal.

FOUR CONVENTIONNEL À ALLUMAGE PAR BOUGIES (FIG. 20)

1. Pousser l’interrupteur à bascule à la position ON

(marche). Le voyant ON (marche) du four va devenir

THERMOSTAT

THERMOSTAT

lumineux. La veilleuse va automatiquement s’allumer.

2. Une fois que la veilleuse est allumée, le voyant READY

(prêt) va devenir lumineux.

3. Régler le thermostat du four à la température désirée.

Arrêt nocturne

Pousser l’interrupteur à bascule à la position OFF (arrêt).

INTERRUPTEUR

TOGGLE

À BASCULE

SWITCH

Arrêt complet

1. Pousser l’interrupteur à bascule à la position OFF (arrêt).

2. Fermer le robinet de gaz principal.

—16—

OVEN "ON"

LIGHT

VOYANT DU FOUR

«ON» (MARCHE)

OVEN "READY"

VOYANT DU FOUR

LIGHT

«READY» (PRÊT)

Fig. 20

PL-53531

Page 43

FOUR À AIR PULSÉ (SNORKEL

MD

) (SÉRIE 90 SEULEMENT)

Allumer les veilleuses des brûleurs découverts et de la plaque à frire avant d’allumer celle du four.

1. Ouvrir le panneau inférieur et relever le couvercle du trou d’allumage de la veilleuse (Fig. 18).

2. Régler le robinet de gaz rouge (derrière le panneau inférieur) à ON (marche) pour évacuer tout l’air

contenu dans la conduite de gaz (Fig. 21). Fermer le robinet de gaz et éteindre l’interrupteur

général. Fermer la porte de four.

22.giF12.giF

3. Allumer la veilleuse. Pour ce faire, appuyer sur le bouton de réenclenchement (Fig. 22) et allumer la

veilleuse au moyen d’une bougie. Maintenir le bouton de réenclenchement enfoncé pendant

30 secondes ou jusqu’à ce que la veilleuse s’allume. Ouvrir le robinet de gaz.

4. Si la veilleuse refuse de s’allumer, fermer le robinet de gaz principal. Attendre cinq minutes et

reprendre les étapes 2 et 3.

5. Une fois que la veilleuse est allumée, allumer l’interrupteur général et régler le thermostat à la

température désirée.

Arrêt nocturne

Éteindre l’interrupteur général et régler le thermostat à 0 degré.

Arrêt complet

1. Mettre l’interrupteur général hors tension.

2. Fermer le robinet de gaz rouge (derrière le panneau inférieur).

3. Fermer le robinet de gaz principal.

4. Débrancher le cordon d’alimentation.

—17—

Page 44

FOUR À AIR PULSÉ (SNORKELMD) À ALLUMAGE PAR BOUGIES (FIG. 23)

BOUTON DU

THERMOSTAT

BOUTON DE BRÛLEUR

DÉCOUVERT

VOYANT DU FOUR

«ON» (MARCHE)

TOP SECTION

BURNER KNOB

OVEN "ON"

LIGHT

THERMOSTAT

VOYANT DU

KNOB

THERMOSTAT

THERMOSTAT

LIGHT

VOYANT DU FOUR

«READY» (PRÊT)

ROCKER

SWITCH

INTERRUPTEUR À

BASCULE

OVEN READY

LIGHT

PL-53530

Fig. 23

1. Pousser l’interrupteur à bascule à la position ON (marche). Le voyant ON (marche) du four va

devenir lumineux. La veilleuse va automatiquement s’allumer.

2. Une fois que la veilleuse est allumée, le voyant READY (prêt) va devenir lumineux.

3. Régler le thermostat du four à la température désirée. (Le voyant du thermostat va devenir

lumineux. Ceci indique que le thermostat commande l’arrivée de la chaleur.)

Pour que laveilleuse du four s’allume, lethermostat du fourà air pulsé doit êtreà ON (marche)et qu’il

commande l’arrivée de la chaleur.

Arrêt nocturne

Pousser l’interrupteur à bascule à la position OFF (arrêt).

Arrêt complet

1. Pousser l’interrupteur à bascule à la position OFF (arrêt).

2. Fermer le robinet de gaz principal.

—18—

Page 45

ARRANGEMENT DES GRILLES — FOUR CONVENTIONNEL

Un four conventionnel peut cuire un maximum de deux grilles d’aliments par enceinte de cuisson.

Chaque four comporte une grille. Il est possible de se procurer des grilles additionnelles auprès du

service des pièces Vulcan-Hart.

Pour obtenir de meilleurs résultats lors de la cuisson de gâteaux et de pâtisseries, il est recommandé

de n’utiliser qu’une seule grille par fournée. Toutefois, c’est à l’utilisateur de déterminer le nombre

et la position appropriés des grilles selon ses besoins. Pour la cuisson d’un gros rôti, il est possible

d’utiliser l’enceinte sur toute sa hauteur. Pour ce faire, sortir la grille du four et déposer la rôtissoire

directement sur la sole.

ARRANGEMENT DES GRILLES - FOUR À AIR PULSÉ (SÉRIE 90 SEULEMENT)

Un four à air pulsé (Snorkel

MD

) peut cuire un maximum de trois grilles d’aliments par enceinte de

cuisson. Sa crémaillère à cinq positions permet une plus grande variété d’utilisations de la cuisinière.

Les arrangements de grilles énumérés ci-dessous sont les plus recommandés. Les positions des

grilles dans le four sont numérotées en ordre, à partir du bas.

Arrangement n° 1

Un maximum de trois grilles aux positions 1, 3 et 5 pour les grillades, la cuisson de biscuits ou la

remise en température de repas surgelés. Cette disposition est également recommandée pour la

cuisson sur des tôles de produits ne dépassant pas 64 mm (2 1/2 po) de hauteur.

Arrangement n° 2

Deux grilles aux positions 2 et 4 pour la cuisson en général de plaques à pâtisseries, moules à muns,

moules à tarte ou à gâteau et bols à pudding de 89 mm (3 1/2 po) de profondeur et dont la hauteur

du produit ne dépasse pas 102 mm (4 po). Cette disposition est également possible lors de l’utilisation

de cocottes, de plats à rôti ou de plats de services alimentaires de 305 x 508 x 64 mm (12 x 20 x 2 1/2 po)

de la série 200.

Arrangement n° 3

Deux grilles aux positions 1 et 4 pour la cuisson de pains, de gâteaux dans des moules à pain ou à

cheminée et de tartes meringuées élevées. Cette disposition est également possible pour l’utilisation

de cocottes, de plats à rôti et de casseroles de 114 mm (4 1/2 po) de profondeur dont les produits

ne dépassent pas 127 mm (5 po) de hauteur.

Dans certaines cuisines où l’on procède régulièrement à la cuisson de diérents produits en même

temps, on a recours à divers types d’arrangements de grilles choisis en fonction des besoins.

—19—

Page 46

POSE ET ENLÈVEMENT DES GRILLES DE FOURS CONVENTIONNELS ET À AIR PULSÉ

Les grilles de four sont munies d’une butée (crochet) qui les empêche de sortir entièrement du four

lors de leur chargement. Pour les installer, placer la grille sur chaque glissière et la glisser au fond

de l’enceinte de cuisson jusqu’à ce qu’elle tombe en place (Fig. 24 et 25).

52.giF42.giF

Pour enlever la grille, procéder dans l’ordre inverse, soit en la soulevant par l’arrière pour que le

crochet se retrouve sur la glissière pour ensuite la tirer (Fig. 26).

Fig. 26

—20—

Page 47

PRÉCHAUFFAGE

Four conventionnel

Régler le cadran du thermostat à la température désirée et préchauer le four pendant 25 minutes.

Pour réduire les coûts de gaz, ne pas faire fonctionner le four à la chaleur maximale lorsque ce n’est

pas nécessaire. Baisser le thermostat à 121 °C (250 °F) ou le régler à la position OFF (arrêt) lorsque

le four ne sert pas ou pendant les périodes de temps mort.

Four à air pulsé (Série 90 seulement)

Mettre l’appareil sous tension par l’interrupteur général, régler le thermostat à la température de

cuisson appropriée et laisser le four préchauer pendant 15 minutes. Pour réduire la consommation

de gaz et d’électricité pendant les périodes de temps mort, régler le thermostat à la moitié de la

température de cuisson ou à la position OFF (arrêt).

Plaque à bouillir

Ouvrir le brûleur au maximum pour chauer rapidement la section du dessus. Elle sera prête à servir

au bout de 10 minutes. Dès que la section du dessus a atteint la température désirée, baisser l’intensité

de quelques brûleurs, ce qui permettra de réduire la consommation de gaz jusqu’à 80 % sans aecter

la qualité de cuisson, pour autant que la plaque à bouillir au complet ait bien été préchauée.

Brûleurs découverts

Les brûleurs découverts s’allument rapidement et ne nécessitent aucun temps de préchauage.

Lorsque le produit a atteint un point d’ébullition constant, baisser l’intensité des brûleurs de manière

à économiser l’énergie, puis laisser bouillir. Éteindre les brûleurs lorsqu’ils ne servent pas.

Plaque à frire-grilloir

Ouvrir les trois robinets manuels de gaz au maximum. Laisser préchauer pendant cinq minutes,

puis baisser l’intensité de la amme jusqu’à ce qu’elle atteigne le niveau de chauage approprié.

Mettre la grille amovible du grilloir à une des deux positions qui permettra d’obtenir les résultats de

cuisson recherchés.

CHARGEMENT ET DÉCHARGEMENT DES FOURS CONVENTIONNELS ET À AIR PULSÉ

AVERTISSEMENT : NE JAMAIS DEMEURER DEVANT UN FOUR À AIR PULSÉ AU MOMENT

D’OUVRIR LA PORTE. MÊME SI LE VENTILATEUR S’ÉTEINT AUTOMATIQUEMENT DÈS

L’OUVERTURE DE LA PORTE, UNE CERTAINE QUANTITÉ DE CHALEUR S’ÉCHAPPE

TOUJOURS DU FOUR. SE TENIR À L’ÉCART POUR NE PAS RECEVOIR D’AIR CHAUD.

Ouvrir la porte et charger le four le plus rapidement possible pour lui conserver sa chaleur. Prendre

bien soin de ne pas y déverser du liquide. Fermer la porte et consulter la recette pour le temps de

cuisson requis.

Prévoir susamment d’espace autour de la cuisinière pour décharger le four. Le déchargement

rapide du four permettra de lui conserver sa chaleur et de réduire le temps de préchauage du

prochain lot.

—21—

Page 48

GUIDE DE CUISSON

Les températures et temps de cuisson sont suggérés à titre d’exemple seulement. Les adapter aux

recettes, aux ingrédients, à l’installation et aux goûts personnels.

Selon le ministère de l’Agriculture des États-Unis et l’American Meat Institute, les températures de

rôtissage doivent varier idéalement entre 107 et 162,7 °C (225 et 325 °F) pour le boeuf, l’agneau,

la volaille et le jambon et entre 162,7 °C (325 °F) pour le porc.

Placer un plat rempli d’eau (environ 305 x 508 x 25 mm [12 x 20 x 1 po]) dans le four. L’eau dégage

de l’humidité et réduit le étrissement. En ajouter pendant le rôtissage, au besoin.

Les plats à rôtir ne doivent pas excéder la profondeur requise pour contenir la graisse, soit de 51 à

64 mm (2 à 2 1/2 po) en général.

Le temps de cuisson et le étrissement varient selon la température de rôtissage, la coupe et la

catégorie de viande ainsi que le degré de cuisson. À une même température, les petits morceaux

de viande cuisent en général plus rapidement que les gros morceaux.

TEMPÉRATURES DE RÔTISSAGE

TEMPS DE CUISSON

PRODUIT TEMPÉRATURE °C (°F) APPROXIMATIF

Côtes de boeuf – 121 (250) 3 à 4 h (saignant)

)tniopà(03h4à4)bl51(gk8,6ruofuarellaàsetêrP

Côtes de boeuf désossées – 135 (275) 4 h (à point)

9,1 à 10,0 kg (20 à 22 lb)

Rôti de veau – )tiucneibàtniopà(h3)003(9,841)bl51(gk8,6

Dindes – h3)003(9,841)bl02à51(gk1,9à8,6

Pain de viande – 3,6 à 4,5 kg (8 à 10 lb) 176,7 (350) 45 à 60 min

TEMPÉRATURES, TEMPS DE CUISSON ET QUANTITÉS RECOMMANDÉS POUR LES PÂTISSERIES

TEMPS APPROX.

DE CUISSON

PRODUIT TEMPÉRATURE °C (°F) EN MINUTES

Gâteaux (Four conventionnel)

54)053(7,671mm52x066x754edxuaetâgàeuqalP

(18x26x1 po)

Poids de 1,6 kg (3 1/2 lb) par plaque

54)053(7,671mm15x754x503edxuaetâgàeuqalP

(12x18x2po)

Poids de 1,6 kg (3 1/2 lb) par plaque

—22—

Page 49

TEMPS APPROX.

DE CUISSON

PRODUiCT TEMPÉRATURE °C (°F) EN MINUTES

Gâteaux des anges ou de Savoie

Plaques de 457 x 660 x 25 mm (18 x 26 x 1 po)

Poids : 2,3 à 2,7 kg (5 à 6 lb) par plaque 148,9 à 162,8 (300 à 325) 15 à 20

Moules tubulaires ou à pain 157,2 à 171 (315 à 340) 20 à 30

Petits gâteaux 176,7 à 204,4 (350 à 400) 6 à 12

Tartes aux fruits congelés 176,7 à 190,5 (350 à 375) 30 à 45

Tartes à la crème ou à la citrouille 148,9 à 176,7 (300 à 350) 30 à 45

Tourtes aux fruits

305 x 457 x 51 mm ou 305 x 508 x 64 mm

(12 x 18 x 2 po ou 12 x 20 x 2 1/2 po) 176,7 à 204,4 (350 à 400) 30 à 45

Tartes meringuées 176,7 à 218,3 (350 à 425) 6 à 10

Chaussons aux fruits

(Plaques) 176,7 à 190,5 (350 à 375) 15 à 25

NOTA : Tartes et tourtes aux fruits : cuire les garnitures en conserve pour tartes à la crème et à la citrouille dans des plaques.

Biscuits –

Carrés au chocolat 176,7 (350) 12 à 20

Pain au levain

NOTA : (Bien fermenter la pâte pour de meilleurs résultats.)

Petits pains – 01à5)004à053(4,402à7,671)zo1(g82

Miche de pain – 04à02)573à523(5,091à8,261)bl1(g5,0

Brioches et pâtisseries danoises 162,8 à 190,5 (325 à 375) 5 à 15

Biscuits — Roulés de 13 mm (1/2 po) d’épaisseur 176,7 à 204,4 (350 à 400) 5 à 15

Muns 162,8 à 190,5 (325 à 375) 6 à 18

Pain de maïs

Moule de 457 x 660 x 25 mm (18 x 26 x 1 po)

ou de 457 x 660 x 51 mm (18 x 26 x 2 po)

21à6)004à053(4,402à7,671sitalpauoséluoR

51à6)004à053(4,402à7,671erèlliucalÀ

51à8)004à053(4,402à7,671)zo2/12à2/11(g8,07à5,24

02à01)004à533(4,402à3,861)bl7à5(gk3à3,2:sdioP

52à51)004à533(4,402à3,861)bl02à8(gk1,9à6,3:sdioP

Muns à la farine de maïs 168,3 à 196 (335 à 385) 10 à 20

—23—

Page 50

CUISSON ET GRILLAGE AU FOUR

TEMPS APPROX.

PRODUIT TEMPÉRATURE °C (°F) EN MINUTES

Fricadelles de bœuf

— 8 par 0,5 kg (1 lb) À point - bien cuit 204,4 à 232,2 (400 à 450) 5 à 6

Bâtonnets et portions de poisson

Morceaux de poulet

Cuits sur le gril ou au four

- Poulet de 0,9 à 1,1 kg (2 à 2 1/2 lb) 190,5 à 218,3 (375 à 425) 8 à 15

- Poulet de 1,1 à 1,4 kg (2 1/2 à 3 lb) 176,7 à 204,4 (350 à 400) 15 à 25

Homards

DE CUISSON

01à7)054à004(2,232à4,402)bl1(gk5,0rap6—

21à8)583à573(691à5,091)bl1(gk5,0rap4—

01à6)004à053(4,402à7,671)zo1(g3,8251à8)573à053(5,091à7,671)zo3à2/12(g58à8,07-

61à21)054à004(2,232à4,402)bl2/11à1(gk6,0à5,0-

Queues de homards

- Surgelées – 0,2 à 0,5 kg (1/2 à 1 lb) 176,7 à 204,4 (350 à 400) 16 à 20

RÉCHAUFFAGE DE PLATS CUISINÉS

Frites surgelées 204,4 à 232,2 (400 à 450) 6 à 8

Repas rapides surgelés “TV Dinner” 176,7 à 204,4 (350 à 400) 10 à 12

Entrées surgelées 25 mm (1 po) d’épaisseur 148,9 à 176,7 (300 à 350) 10 à 20

Repas surgelés 0,2 kg (8 oz)

CASSEROLES

Plats de service

- 51 à 76 mm (2 à 3 po) de profondeur 162,8 à 190,5 (325 à 375) 15 à 25

- 76 à 102 mm (3 à 4 po) de profondeur 162,8 à 190,5 (325 à 375) 20 à 35

Ramequins ou plats en aluminium

Jusqu’à 38 mm (1 1/2 po) de profondeur 176,7 à 204,4 (350 à 400) 5 à 6

à7,671sélegruS 204,4 (350 à 400) 10 à 15

03à02)004à053(4,402à7,671muinimula’lsnadséppolevnE

—24—

Page 51

ALIMENTS DIVERS

PRODUIT TEMPÉRATURE °C (°F) EN MINUTES

Pommes de terre au four

Pizzas —

Sandwiches au fromage fondant 01à8)524à004(3,812à4,402

MODES DE CUISSON SPÉCIAUX

PAIN AU LEVAIN

TEMPS APPROX.

DE CUISSON

53à52)054à004(2,232à4,402)bl05(gk7,22rap02154à53)054à004(2,232à4,402)bl05(gk7,22rap00106à04)054à004(2,232à4,402)bl05(gk7,22rap08-

01à5)574à524(642à3,812etiucérpetâpuoseélegruS

La cuisson commence immédiatement dans le four à air pulsé. Habituellement, le pain au levain ne

lève pas autant dans un four à air pulsé que dans un four conventionnel. Il faut donc laisser la pâte

atteindre 2 1/2 à 3 fois son volume pour de meilleurs résultats.

TARTES

Pour la cuisson de tartes dans un four à air pulsé, les mettre par groupe de trois ou quatre dans une

tôle de 457 sur 660 mm (18 sur 26 po) ou dans un moule à brioches. Ainsi, les fonds de tarte cuisent

mieux, les tartes sont plus faciles à manipuler, les risques de débordement sur les tartes des grilles

inférieures s’en trouvent réduits et les produits conservent leur apparence savoureuse.

—25—

Page 52

NETTOYAGE

Ne pas utiliser du détergent à vaisselle Dawn

MD

pour nettoyer les composants extérieurs et intérieurs

de la cuisinière.

Ne pas utiliser de la poudre à récurer. Elle s’enlève très dicilement et peut s’accumuler, ce qui

risque d’endommager le four.

La surface peinte des appareils Vulcan se nettoie au moyen d’un chion et d’un détergent doux.

CUISINIÈRES

Nettoyage quotidien

Sortir les grilles nickelées et les laver dans un évier.

Enlever les déversements, la graisse, etc. avant qu’ils ne brûlent en essuyant le dessus pendant

qu’il est encore chaud à l’aide d’un chion doux ou de toute autre matière absorbant la graisse. Une

croûte sur la surface de la cuisinière ne donne pas une belle apparence à l’appareil et réduit la vitesse

de cuisson puisqu’elle nuit au transfert de la chaleur vers les chaudrons.

Nettoyer le four et la porte quotidiennement, particulièrement après la cuisson de tartes aux fruits,

de sauces aux tomates ou de viande ou après un débordement.

Après la cuisson de certains produits à basse température, il peut se dégager des odeurs dans le

four. Pour les enrayer, régler le thermostat à 260 °C (500 °F) et laisser chauer le four à vide

pendant 30 à 45 minutes.

Vider le plateau à graisse du grilloir quotidiennement ou aussi souvent que nécessaire. ATTENTION :

Sortir le plateau à graisse lentement pour ne pas renverser le liquide qu’il contient. Il est