Page 1

INSTALLATION &

OPERATION MANUAL

SCALEBLOCKER

TM

WATER FILTRATION SYSTEM

MODEL PART NO.

SPS600V 854893-1

SPS620V 854893-2

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART P.O. BOX 696, LOUISVILLE, KY 40201-0696

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC TEL. (502) 778-2791

WWW.VULCANHART.COM FORM 31228 Rev.A (Sept. 2004)

Page 2

Installation, Operation and Care of

SCALEBLOCKER

TM

WATER FILTRATION SYSTEM

MODELS SPS600V & SPS620V

SAVE THESE INSTRUCTIONS

GENERAL

Vulcan water filters are produced with quality workmanship and material. Proper installation,

usage and maintenance of your water filter will result in many years of satisfactory performance.

It is suggested that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

The water filtration system conforms to ANSI/NSF Standard 53 and ANSI/NSF Standard 42 for

the specific performance claims as verified and substantiated by test data.

Filter capacity will vary according to flow rate, influent water pressure and local water conditions.

Service life for the filter cartridge for model SPS600V is 7,500 gallons (

SPS620V, the service life for the filter cartridge is 15,000 gallons (

replacement is recommended at least every 6 months to maintain equipment warranty. Filter

cartridge replacement is also recommended if water pressure goes below 20 psig (

28,390 liters); for model

56,780 liters). Filter cartridge

138 kPa).

INSTALLATION

UNPACKING

The water filter was inspected before leaving the factory. The transportation company assumes

full responsibility for safe delivery upon acceptance of the shipment.

IMPORTANT: Immediately after unpacking, check for possible shipping damage. If the water

filter is found to be damaged, save the packaging material and contact the carrier within 15 days

of delivery.

TEST THE WATER AND RETURN THE RESPONSE CARD

Test the incoming unfiltered water supply with the enclosed 4-IN-1 City Water Check test strip by

carefully following the instructions on the package. Record the results on the enclosed Filter

Registration Card. Be sure and use the Vulcan-Hart Equipment model and serial number. Do

not use the filter system model and serial number. Fill the registration card out completely and

return the information to Vulcan in one of the following three ways: Mail the postage-paid selfaddressed card to Vulcan, FAX the completed card per instructions on the cord or contact Vulcan

on-line at

www.vulcanhart.com

, select service tab and answer all the necessary questions.

NOTE: Filter registration is required at time of installation to begin warranty coverage on the

equipment being installed with the filter.

LOCATION

The water filter should be mounted on a sturdy support structure or wall and must be level. Do

not mount the filter system directly on the steamer.

LEVELING

Use a carpenter's level to level the top of the water filter's mounting head.

© VULCAN-HART 2002, 2004

– 2 –

Page 3

INSTALLATION REQUIREMENTS

The model SPS600V and SPS620V water filters are designed to be

installed in the cold water line only. Installation of the water filter in

a hot water line can seriously damage the filter housing. The filter

must be in contact with water at all times after installation. Installation

must comply with any existing state or local plumbing codes.

WATER PARAMETERS

pH 6 to 9

Alkalinity 0 to 250 ppm

Chlorine 0 to 4 ppm

Hardness 0 to 300 ppm

Refer to the Water Parameters table, right, for recommended water quality limitations. If your

local water supply does not meet the recommendations in the Water Parameters table, Vulcan

may request that a water sample be returned for laboratory testing. After evaluation of the water

test, other specific recommendations may be made for additional filtration or water treatment to

make the local water supply meet the acceptable limits for use in steam generator equipment.

The recommended incoming flow rate for SPS600V is 2 gallons per minute

The recommended incoming flow rate for SPS620V is 4 gallons per minute (

(7.6 liters per minute).

15.1 liters per minute).

The SPS600V and SPS620V water filters must be protected against freezing. Failure to do so

could result in breakage of the filter housing and water leakage.

Minimum operating temperature: 45°F (

Minimum operating pressure: 20 psig (

Minimum line pressure: 40 psig (

276 kPa). Maximum line pressure: 125 psig (862 kPa).

If the filter pressure gauge is over 60 psig (

to a maximum of 60 psig (

414 kPa). Install a water pressure reducing regulator (part number

7°C). Maximum operating temperature: 100°F (38°C).

138 kPa). Maximum operating pressure: 125 psig (862 kPa).

414 kPa), you must reduce the pressure to the boiler

854322 or equivalent) after the filter, move the pressure gauge downstream of the regulator and

set the pressure at 60 psig (

414 kPa).

Do not use with water that is microbiologically unsafe or of unknown quality without adequate

disinfection before or after the filter.

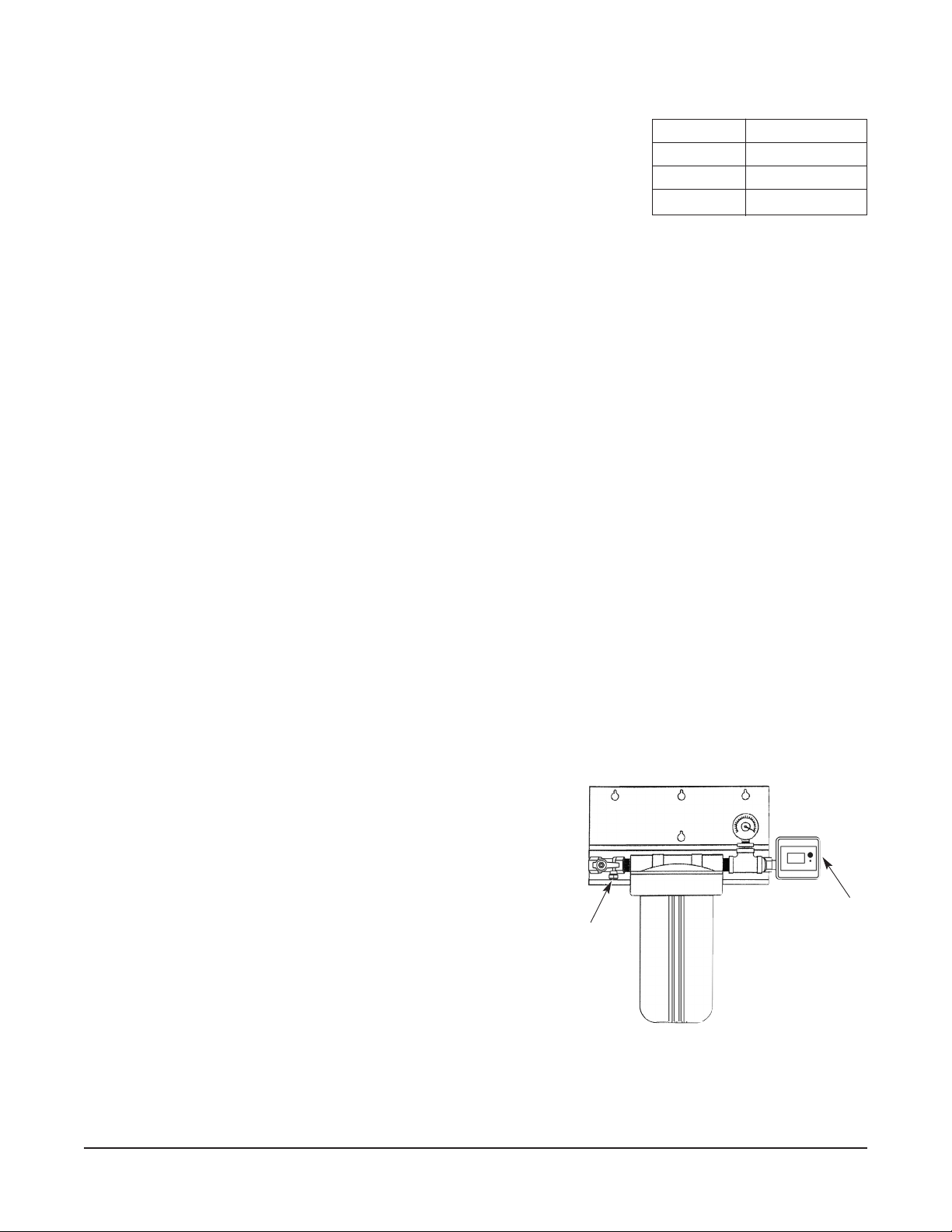

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY,

SAFETY AND PLUMBING CODES.

The filter housing on models SPS600V and SPS620V

3

comes with

/4" NPT internal pipe threads on the inlet

side. The inlet is on the left; outlet is on the right, after

the pressure gauge and the water meter. The outlet

3

side of the water meter comes with a

pipe thread connection.

/8" NPT internal

OUTLET

INLET

Connect the incoming cold water line to the water

filter's inlet connection (left side).

Connect the incoming water line to the boiler (or steam

generator, steamer or combi oven) from the outlet side

of the water filter (right side of water meter).

COLD WATER

DRAIN LINE

CONDENSER

CONNECTION TEE

(SUPPLIED)

BOILER/GENERATOR

FEED CONNECTION

Steamers and combi ovens with two water connections

have a boiler or steam generator feed line and a cold

water drain line condenser feed line. Connect the drain

3

line condenser feed line to the tee using the

3

compression fitting for

/8" copper tubing, provided

/8 "

Fig. 1

(Fig.1).

– 3 –

Page 4

OPERATION

WATER FILTER

The proper water filter cartridge should already

be installed in the filter housing. Make sure the

filter housing is firmly screwed into the filter

mounting head. Use the supplied wrench if

necessary.

Turn on the filter water supply valve.

BATTERIES

+

+

COVER

Press the red pressure relief button on top of the

filter mounting head until all air is purged from

the filter.

DIGITAL FLOW METER

Installing Batteries (Fig. 2)

Slide off the cover to the battery housing on top of the flow meter. Install two AAA batteries. Slide

the cover back.

Capacity and Time

Capacity and Time settings are preset at the factory as

indicated in the Capacity & Time table, at right:

Connection to Water System

3

The Flow Meter has

water system using

Operating the Digital Flow Meter

The meter is automatically on when there is water flowing through the sensor. The meter is

automatically off when no water is flowing for 10 seconds.

Display Button

Pressing the Display button shows the three

values that the flow meter tracks: The flow

rate in gallons per minute, the remaining

number of days and the remaining gallons.

/8" NPT female threaded fittings allowing the meter to be connected to the

3

/8" NPT male threaded fittings.

Digital Flow Meter

1.05 g/m

DISPLAY

RESET

Fig. 2

CAPACITY & TIME

Model Capacity Time

gal days

SPS600V 7,500 180

SPS620V 15,000 180

162 days

890 gal

Alarm

The buzzer beeps once and the display flashes to notify you that the filter cartridge will need to

be changed soon. This alarm occurs when the capacity goes below 30 gallons or when the

remaining time is less than 7 days. The alarm displays when water is flowing through the flow

meter or when you press the Display button.

Warning Alarm

When Capacity reaches 0 gallons or Time reaches 0 days, the buzzer beeps twice and the display

flashes to notify you to change the water filter cartridge right now. This alarm displays when there

is water flowing through the flow meter or when you press the Display button.

Low Battery Alarm

When the battery power is low, the buzzer will beep twice and an icon will

display to notify you to change the batteries. Capacity and timing data will be

kept in memory when the battery power is low or when the battery is removed

and changed.

– 4 –

570 gal

Page 5

MAINTENANCE

ORDERING PREVENTIVE MAINTENANCE KITS

FILTER CARTRIDGE REPLACEMENT (PM) KITS

To order the Preventive Maintenance Kit for your

filtration system, contact your Vulcan

representative, the Vulcan-Hart Service

Department (at the address or phone number on

the cover of this document) or visit Vulcan online

www.vulcanhart.com

at

and click on Service.

Refer to the part numbers in the table above when ordering. Only genuine Vulcan water filters

can be used to maintain the warranty.

FILTER SYSTEM MAINTENANCE

Maintenance on the filter, including the use of ScaleBlocker Release and replacement of the filter

cartridge, is necessary when the capacity register on the water meter declines to 0.0 gallons or

when the time register declines to 0 days (equivalent to six months of usage). Another indicator

that maintenance is necessary is if the filter pressure gauge declines to 20 psig (138 kPa).

NOTE: Failure to follow use, care and maintenance instructions may void your Vulcan equipment

warranty.

If the filter is to be installed on a steamer or combi oven that has been in use for a period of time,

before installing the filter, delime per the equipment's

FilterFilter ScaleBlocker PM

ModelHeightPreventive Maintenance Kit

Part Number

SPS600V 10" 854306-4

SPS620V 20" 854306-13

Installation & Operation

manual.

After installation of the filter on a used or new steamer it is necessary that you follow the

instructions in the filter cartridge replacement and preventive maintenance kit and do not delime

per the instructions in the equipment's

Installation & Operation

manual.

If the filter is being installed on a new combi oven, maintenance on the filter is necessary when

the capacity register on the water meter declines to 0.0 gal (

0.0 liter) or when the time register on

the water meter declines to 0 days (equivalent to six months of usage). Another indicator that

maintenance is necessary is if the filter pressure gauge declines to 20 psig (

combi oven, follow the Clean Cycle Deliming Procedure in the equipment

Installation & Operation

138 kPa). For the

manual along with the instructions in the ScaleBlocker PM Filter Cartridge Replacement Kit.

REMOVING THE FILTER CARTRIDGE

Turn off the steamer or combi oven. Shut off the incoming water supply valve to the water filter.

Press the red pressure relief button on the filter mounting head to release the water pressure in

the filter housing. Unscrew the lower filter housing using both hands or use the wrench supplied.

Use care. The lower housing will be loaded with water and can be heavy.

Inspect the O-Rings: One O-Ring is a large black rubber gasket that fits in the groove on top of

the filter cartridge housing. Two small white O-Rings are located on the top and bottom of the

filter cartridge. New O-Rings are supplied with the replacement water filter cartridge (ScaleBlocker

PM Preventive Maintenance Kit — be sure to mention the model number when ordering).

The large black O-Ring seal may lift out of the groove and stick to the filter mounting head. One

of the small white O-Rings may stay in the bottom of the filter housing. Discard the used filter

cartridge.

– 5 –

Page 6

USING SCALEBLOCKER RELEASE

TM

Do not use alcohol-based cleaners. Clean the inside of the filter housing with a mild soap.

Inspect the O-Rings for damage and replace if necessary.

Wipe the large black O-Ring clean with a rag, press it down into the groove and then apply a very

light coating of white petroleum jelly (Vaseline). Make sure the O-Ring fits in the groove and is

properly seated each time the filter is reassembled, otherwise a water leak could occur.

With the filter removed, insert the dip tube into the housing cap. Pour the contents of both

ScaleBlocker Release packages 2 lbs. total (

0.746 kg) into the bowl of the lower filter housing.

Add warm water, stir to dissolve.

Using the supplied wrench, screw the lower filter housing into the filter mounting head until a

definite stop is felt.

On combi ovens, follow the Clean Cycle Deliming Procedure in the

Installation & Operation

manual (on older model combi ovens, follow the deliming procedure in the manual shipped with

the oven).

On steamers, turn on the filter water supply valve and turn the steamer on. Allow the steamer

to operate so steam is flowing through the compartments for approximately 35 minutes. Turn the

steamer off.

On steamers and combi ovens, turn off the incoming water supply valve to the filter. Press the

red pressure relief button on top of the filter mounting head to release pressure in the system.

Unscrew the lower filter housing and dump out the water. Replace the filter cartridge.

RETEST THE WATER AND RETURN THE RESPONSE CARD

Test the incoming unfiltered water supply with the enclosed 4-IN-1 City Water Check test strip by

carefully following the instructions on the package. Record the results on the enclosed Filter

Registration Card. Use the Vulcan-Hart equipment model and serial number, not the filter system

model/ serial number. Fill the registration card out completely and return the information to Vulcan

in one of the following three ways: Mail the postage-paid self-addressed card to Vulcan, FAX the

completed card per instructions on the card or contact Vulcan online at

www.vulcanhart.com

, select

the Service tab and answer all the necessary questions.

NOTE: Returning the Filter Registration Card is required at the time the PM is performed to continue

warranty coverage on the equipment installed with the filter.

REPLACING THE FILTER CARTRIDGE

Make sure the large black O-Ring and the two flat white rubber washers are in their proper place

when the new filter cartridge is installed and the lower housing is reassembled to the filter

mounting head. Make sure the filter cartridge is oriented so the hole in the middle of the top is

up. Make sure the lower flat washer is properly positioned as the cartridge is lowered. Make sure

the upper white flat washer is over the top hole of the filter cartridge. Make sure the large black

O-Ring is properly seated in the groove. Using the supplied wrench, screw the lower filter

housing into the filter mounting head until a definite stop is felt and the filter cartridge is sealed.

Make sure the boiler tank has completely drained.

Turn on the incoming water supply valve to the filter. Press the red pressure relief button on top

of the filter mounting head until all the air is purged from the filter. Depress the water meter reset

button using a blunt object such as a paper clip.

– 6 –

Page 7

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE SUGGESTED CORRECTIVE ACTION

Short filter life. Filter clogs due to excessive particles in water. An additional filter may be needed.

Low incoming water pressure. Check water source.

Excessively hard water or water quality beyond Additional water treatment may be needed

specification. before filter.

Filtered water not going to boiler feed line. Check plumbing lines.

A leaking Fill Valve on the steamer equipment Contact Service (to replace valve) if water

will deplete the filter quickly. is flowing through the filter when the

steamer is off.

Steamer not Incoming water supply valve off. Turn supply valve on.

operating. Filter cartridge installed upside-down. Reinstall filter right side up.

Steamer not turned on. Turn steamer on.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this water filtration system, contact the Vulcan-Hart

Service Department at the address or phone number shown on the front cover of this manual or visit

Vulcan online at

www.vulcanhart.com

Model SPS600V, Part No. 854893-1

and click on Service.

Part No. Name Qty.

854306-1 Backplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-5 Clear Housing, 10" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854306-3 U-Bracket, Large . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-8 O-Ring, Large, Black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-24 Brass Ball Valve, 3/4" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-12

3

/8" Tubing Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FP-069-02 Tee Pipe Fitting, Stainless Steel, Internal Threads, 3/4" . . . . . . . . . . . . . . . . . . . . . . 1

FP-081-25 Pipe Bushing, Stainless Steel, 3/4" x 1/4" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854306-9 Brass Pressure Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FP-041-54 Nipple, Brass, 3/4" x 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FP-054-29 Nipple, Stainless Steel, 3/4" x 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-25 Reducer, Plastic, 3/4" to 3/8" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-26 Nipple, Plastic, 3/8" x 11/2" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-22 Wrench (10") for Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854306-19 4-IN-1 City Water Check + Test Strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-3 Filter Mounting Head, Red. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-28 Dip Tube, 10" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-20 Label, Backplate, SPS600V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Filter, 10" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-14 Flat Washer, Small White (Bottom) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-15 Flat Washer, Small White (Top) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-11 Water Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

F-32553 Filter Registration Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

F-31228 I & O Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Service Kit

854306-4 ScaleBlocker PM Kit, 10" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

– 7 –

Page 8

Model SPS620V, Part No. 854893-2

Part No. Name Qty.

854306-1 Backplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-7 Clear Housing, 20" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854306-3 U-Bracket, Large . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-8 O-Ring, Large, Black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-24 Brass Ball Valve, 3/4" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-12

FP-069-02 Tee Pipe Fitting, Stainless Steel, Internal Threads, 3/4" . . . . . . . . . . . . . . . . . . . . . . 1

FP-081-25 Pipe Bushing, Stainless Steel, 3/4" x 1/4" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854306-9 Brass Pressure Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FP-041-54 Nipple, Brass, 3/4" x 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FP-054-29 Nipple, Stainless Steel, 3/4" x 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-25 Reducer, Plastic, 3/4" to 3/8" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-26 Nipple, Plastic, 3/8" x 11/2" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-23 Wrench (20") for Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854306-19 4-IN-1 City Water Check + Test Strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-3 Filter Mounting Head, Red. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-29 Dip Tube, 20" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-21 Label, Backplate, SPS620V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-14 Flat Washer, Small White (Bottom) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-15 Flat Washer, Small White (Top) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

854893-11 Water Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

F-32553 Filter Registration Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

F-31228 I & O Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3

/8" Tubing Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Filter, 20" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Service Kit

854306-13 ScaleBlocker PM Kit, 20" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FORM 31228 Rev.A (Sept. 2004) PRINTED IN U.S.A.

– 8 –

Loading...

Loading...