Vulcan Hart SPE Service Manual

INSTALLATION, SERVICE

& PARTS MANUAL FOR

SPE SERIES FRYERS

VULCAN-HART CORPORATION, 3600 NORTH POINT BOULEVARD, BALTIMORE, MARYLAND 21222, TEL. (301) 284-0660

OPERATING, INSTALLATION AND SERVICE PERSONNEL

Operating information for this equipment has been prepared for use by qualified and/or authorized operating

personnel.

All installation and service on this equipment is to be performed by qualified, certified, licensed and/or

authorized installation or service personnel, with the exception of any marked with a o in front of the part

number.

Service may be obtained by contacting the Factory Service Department, Factory Representative or Local

Service Agency.

DEFINITIONS

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified or authorized operating personnel are those who have carefully read the information in this manual

and are familiar with the equipment's functions or have had previous experience with the operation of the

equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, a firm, corporation or company which either in person or

through a representative are engaged in, and are responsible for:

1. The installation of gas piping from the outlet side of the gas meter, or the service regulator when the meter

is not provided, and the connection and installation of the gas appliance. Qualified installation personnel

must be experienced in such work, be familiar with all precautions required, and have complied with all

requirements of state or local authorities having Jurisdiction Reference in the United States of America National Fuel Gas code ANSI Z223 1 (Latest Edition). In Canada-Canadian Standard CAN1-B149 1 NAT

GAS (Latest Edition) or CAN1-B149 2 PROPANE (Latest Edition).

2. The installation of electrical wiring from the electric meter, main control box or service outlet to the electric

appliance. Qualified installation personnel must be experienced in such work, be familiar with all

precautions required, and have complied with all requirements of state or local authorities having

jurisdiction. Reference: In the United States of America-National Electrical Code ANSI NFPA No 70

(Latest Edition). In Canada-Canadian Electrical Code Part 1 CSA -C22 1 (Latest Edition).

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Vulcan equipment who have been endorsed by

the Vulcan-Hart Corporation. All authorized service personnel are required to be equipped with a complete

set of service parts manuals and stock a minimum amount of parts for Vulcan equipment.

For your protection, please note that equipment in this shipment was carefully inspected and packed by

SHIPPING DAMAGE CLAIM PROCEDURE

skilled personnel before leaving the factory. The transportation company assumes full responsibility for safe

delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE — Be certain this is noted on freight bill or express receipt and signed by

person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY — Regardless of extent of damage.

3. CONCEALED LOSS OR DAMAGE — If damage is unnoticed until merchandise is unpacked, notify

transportation company or carrier immediately, and file "concealed damage" claim with them. This should

be done within (15) days of date of delivery is made to you. Be sure to retain container for inspection.

We cannot assume responsibility for damage or loss incurred in transit We will, however, be glad to furnish

you with necessary documents to support your claim.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

IMPORTANT NOTES FOR ALL VULCAN APPLIANCES

1 These units are produced with the best possible workmanship and material. Proper installation is vital if best performance and

appearance are to be achieved Installer must follow the installation instructions carefully.

2 Information on the construction and installation of ventilating hoods may be obtained from the 'Standard for the installation of

equipment for the removal of smoke and grease laden vapors from commercial cooking equipment, NFPA No 96 (latest edit ion)

available from the National Fire Protection Association, Battery March Park, Quincy MA 02269.

3 For an appliance equipped with a flexible electric supply cord, the cord is equipped with a three prong (grounding) plug. This

grounding plug is for your protection against shock hazard and should be plugged directly into a properly grounded three prong

recepticle. Do not cut or remove the grounding prong from this plug If the appliance is not equipped with a grounding plug, and

electric supply is needed, ground the appliance by using the ground lug provided (refer to the wiring diagram).

(FOR GAS APPLIANCES ONLY)

4 Do not obstruct the air flow into and around the appliance. This air flow is necessary for proper combustion of gases and for

ventilation of the appliance. Provisions for ventilation of incoming air supply for the equipment in the room must be in

accordance with National Fuel Gas Code ANSI Z223. 1 (latest edition).

5 Do not obstruct the flow of flue gases from the flue duct (when so equipped) located on the rear (or sides) of the appliance. It is

recommended that the flue gases be ventilated to the outside of the building through a ventilation system installed by qualified

personnel.

6 For an appliance equipped with casters, (1) the installation shall be made with a connector that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21. 69 (latest edition), and Addenda, Z21.69a (latest edition), and a quickdisconnect device that complies with the Standard for Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z21.41 (latest

edition), and Addenda, Z21.41 a (latest edition) and Z21.41 b (latest edition), and (2) adequate means must be provided to limit

the movement of the appliance without depending on the connector and the quick-disconnect device or its associated piping to

limit the appliance movement. If disconnection of the restraint is necessary, reconnect this restraint after the appliance has been

returned to its originally installed position.

7 The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig (3.45 k Pa).

8 The appliance must be isolated from the gas supply system by closing its individual manual shutoff valve during any pressure

testing of the gas supply system at test pressures equal to or less than 1/2 psig (3.45 k Pa).

CAUTIONS

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS EQUIPMENT OR ANY OTHER APPLIANCE.

1. KEEP THE APPLIANCE FREE AND CLEAR FROM ALL COMBUSTIBLE SUBSTANCES.

2. IN THE EVENT A GAS ODOR IS DETECTED, SHUT UNIT(S) DOWN AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

3. POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION MAY BE OBTAINED FROM A

LOCAL GAS SUPPLIER.

SPE FRYER INSTALLATION, SERVICE

AND PARTS MANUAL INDEX

Your Vulcan fryer is produced with the best possible

workmanship and material. Proper usage and

maintenance will result in many years of satisfac tory

performance.

DESCRIPTION PAGE

DEFINITIONS OF PERSONNEL (Operating, Installation & Parts) and

SHIPPING DAMAGE CLAIM PROCEDURES

CAUTIONS 1

INDEX 2

UNCRATING 3

SECTION I INSTALLATION 4

INSTALLATION NOTES 4

SECTION II SERVICE 5

MELT CYCLE SERVICING 5

CONTROLS 5

CLEANING HEATING ELEMENTS & THERMOSTAT BULB 6

CALIBRATION PROCEDURES 7

HIGH LIMIT BULB LOCATION 7

TROUBLE SHOOTING 8-9

SECTION III PARTS LIST 10

PARTS LIST & PHOTOS 11-20

REVISION PAGE (INSIDE BACK COVER)

A rating plate is located on the inside fryer door panel

stating the model number, serial number, voltage and

amperage.

The manufacturer suggests that you thoroughly read this

entire manual and carefully follow all of the instructions

provided.

(Inside Front Cover)

This appliance is to be installed with a six inch clearance

at the sides and rear adjacent to combustible

construction.

Fryer must be installed at least 16 inches away from open

top flame units.

2

UNCRATING

The following procedure should be followed when uncrating all SPE Fryers.

1.Using caution, cut two horizontal and one ver-

tical strap.

2. Lift outer carton from the unit.

3. Lift inner crate liner from the unit .

4. Remove cardboard box containing component

parts off the 2 x 4 wood packaging braces.

5. Using caution, cut two straps and remove two

2 x 4 wood braces.

6. Remove protective plastic liner from unit.

7. Remove packaging material from unit.

8. Open cardboard box containing component

parts and unwrap parts. Care should be taken

when checking unit quantities. See chart below

for correct contents of parts.

PART DESCRIPTION

BASKETS 2 4 6 2 4 6

CLEAN OUT ROD 1 1 1 1 1 1

BASKET HANGER 2 4 6 2 4 6

UNIT QUANTITIES

1 11 111 2 22 222

3

SECTION I INSTALLATION

4

Place fryer as near to its' final position as possible.

Connect 3 phase line to X, Y and Z of terminal block. To

reach terminal block, remove electric cover plate from

unit. (SEE DETAILS A & B)

For each I5 1/2" section a 3 phase supply line capable of

handling 16 KW at the unit's rated voltage (208, 240,

480) is required. If a fan interlock is needed, it should be

connected to 1 and 2 on the 4 pole barrier strip. 1 and 2

go to a set of dry contacts on the power switch.

DETAIL "B”

NOTE: Remove lower back panel from unit and

check to see that harness cable "A" is fastened

securely to the temperature controller box "B". Field

repair of the temperature controller board is not

practical, therefore, when the board malfunctions, it

must be completely replaced. Remove board from

unit by disconnecting cable harness from controller

box and open controller box by removing the (2)

screws that tie into the back of the electric

connection box "C". (See detail "C")

Detail “A” Detail “B”

SECTION II SERVICE MELT CYCLE SERVICING

(Reset required)

1. With solid frying compound set the fry -melt

switch in the melt position, set the temperature

control knob to the frying temperature and turn

on the master switch.

2 Elements will cycle for 2 seconds and off for 28

seconds until the fry -melt switch is turned to fry

or the fryer comes up to set temp.

DETAIL "F" INDICATES THE LOCATING DIMENSIONS OF THE

HIGH LIMIT BULB IN RELATIONSHIP TO THE FRYER ELEMENT.

CONTROLS

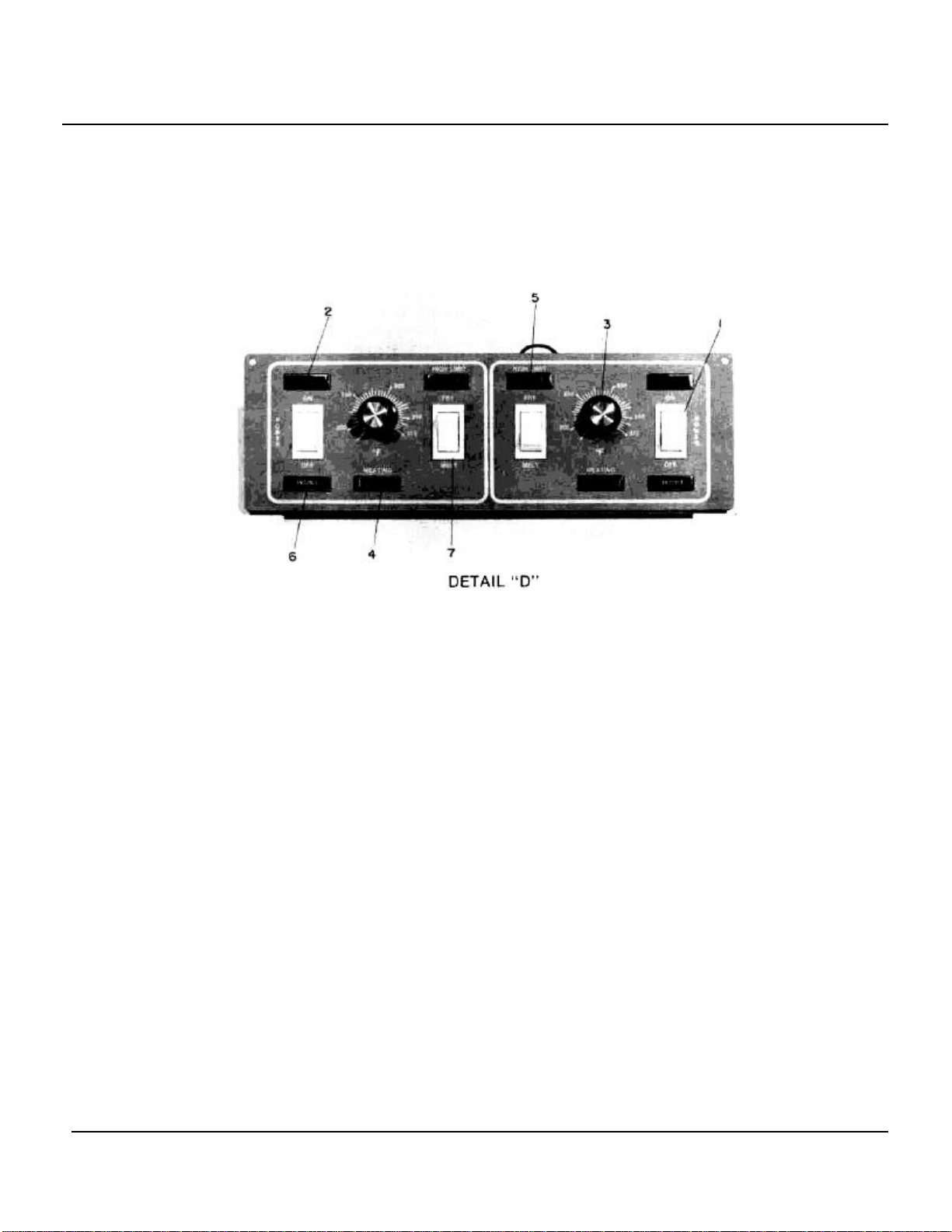

CONTROLS (Refer To Control Panel Detail "D")

1. Master Switch — Controls electric supply to unit. (Optional - Ventilator interlock)

2 Power "ON" Light — Light Indicates when electrical supply Is On.

3. Temperature Control — Maintains frying temperature by controlling power supply.

4. Heating Light — When "ON", indicates temperature control is calling for power to elements.

5. 1-2 Limit Light

6 Trouble Light — Indicates unit has been shut down by second high limit thermostat.

7. Fry-Melt

— When 1 is "ON" indicates first high limit thermostat has shut down unit.

(Reset required)

When 2 is "ON" indicates second high limit thermostat has shut down unit.

— Selects the fat melt cycle for melting solid frying compound. Not needed

with liquid frying compound When solid frying compound is melted move FryMelt switch to the fry cycle and dial desired frying temperature.

5

Loading...

Loading...