Page 1

Model SG4D

SERVICE MANUAL

SG4 & SG6 SERIES

FULL SIZE GAS

CONVECTION OVENS

MODELS

SG4D ML-114875

SG4C ML-114876

SG6D ML-114877

SG6C ML-114878

- NOTICE -

This manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified. If you have attended a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this manual.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you

should read, in it's entirety, the repair procedure you wish to

perform to determine if you have the necessary tools, instruments

and skills required to perform the procedure. Procedures for

which you do not have the necessary tools, instruments and

skills should be performed by a trained Vulcan Service

Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan-Hart, is prohibited.

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

– 1 –

P.O. BOX 696, LOUISVILLE, KY 40201-0696

TEL. (502) 778-2791

FORM 35626 Rev. A (02-08)

Page 2

© VULCAN-HART, 2008

– 2 –

Page 3

TABLE OF CONTENTS

GENERAL .............................................................................................................................................................. 5

Introduction ............................................................................................................................................... 5

Installation ................................................................................................................................................ 5

Operation ................................................................................................................................................... 5

Cleaning .................................................................................................................................................... 5

Lubrication................................................................................................................................................. 5

Specifications ........................................................................................................................................... 5

Electrical Data .................................................................................................................................... 5

Gas Data............................................................................................................................................. 5

Tools ......................................................................................................................................................... 5

Standard ............................................................................................................................................. 5

Special ................................................................................................................................................ 5

REMOVAL AND REPLACEMENT OF PARTS ..................................................................................................... 6

Component Location ................................................................................................................................. 6

Covers and Panels ................................................................................................................................... 7

Top Front Cover.................................................................................................................................. 7

Bottom Front Cover ............................................................................................................................ 7

Control Panel ...................................................................................................................................... 7

Right Side Panel ................................................................................................................................. 7

Control Panel Components ....................................................................................................................... 8

Procedure ........................................................................................................................................... 8

Component Panel Components ................................................................................................................ 9

Procedure ........................................................................................................................................... 9

Temperature Probe .................................................................................................................................. 10

Gas Burners .............................................................................................................................................11

Gas Orifice ...............................................................................................................................................12

Gas Solenoid Valve .................................................................................................................................12

Ignition Control Module ............................................................................................................................ 13

Spark Igniter and Flame Sense ...............................................................................................................13

Blower and Motor ..................................................................................................................................... 14

Oven Doors and Bearings .......................................................................................................................15

Roller Latch Assembly.............................................................................................................................16

Door Catch Assembly ..............................................................................................................................16

Door Window ............................................................................................................................................ 16

Door Switch ..............................................................................................................................................17

High Limit Thermostat .............................................................................................................................18

Interior Lights ...........................................................................................................................................18

Lamp Assembly.................................................................................................................................18

Cooling Fan ..............................................................................................................................................19

Fan Installation Tips ..........................................................................................................................19

SERVICE PROCEDURES AND ADJUSTMENTS ............................................................................................... 20

Solid State Temperature Controller Test (SG4D/SG6D) ........................................................................20

Test Steps .........................................................................................................................................20

Solid State Temperature Controller Calibration (SG4D/SG6D)..............................................................21

Calibration Steps ...............................................................................................................................21

Calibration Tips ................................................................................................................................. 21

Temperature Probe Test (SG4D/SG6D) .................................................................................................22

Test Steps .........................................................................................................................................22

– 3 –

Page 4

TABLE OF CONTENTS (Cont.)

Computer Controller (SG4C/SG6C) ......................................................................................................... 23

Operation ...........................................................................................................................................23

Setup Mode ....................................................................................................................................... 23

Probe Test .........................................................................................................................................23

Solid State Relay Test ......................................................................................................................24

Computer Controller Calibration (SG4C/SG6C) .......................................................................................24

Calibration Steps ............................................................................................................................... 24

Gas Pressure Adjustment ....................................................................................................................... 25

Verification of Spark at Igniter ................................................................................................................ 26

Door Switch Adjustment .......................................................................................................................... 26

Flame Current Measurements .................................................................................................................27

Blower Adjustment ...................................................................................................................................27

Door Adjustment ...................................................................................................................................... 28

Door Strike Adjustment............................................................................................................................ 28

Door Catch Roller Adjustment ................................................................................................................. 29

ELECTRICAL OPERATION .................................................................................................................................30

Component Description ...........................................................................................................................30

Plug, Socket and Components (SG4D/SG6D) ........................................................................................31

Plug, Socket and Components (SG4C/SG6C) ........................................................................................32

Sequence of Operations ..........................................................................................................................33

SG4D/SG6D with Solid State Temperature Controller ..................................................................... 33

Cook Cycle ........................................................................................................................................ 33

Timer Cycle .......................................................................................................................................34

Cool Down Cycle (Solid State Temperature Controller) ...................................................................34

SG4C/SG6C with Computer Controller ............................................................................................. 35

Normal Cook Cycle ..................................................................................................................... 35

Temperature and Time Cycle (Normal Cooking)............................................................................... 37

Function Switch (SG4C/SG6C) .........................................................................................................37

Roast and Hold Cycle........................................................................................................................ 37

Wiring Diagrams .......................................................................................................................................38

Schematics .............................................................................................................................................. 40

TROUBLESHOOTING ..........................................................................................................................................42

Error Codes ..............................................................................................................................................44

– 4 –

Page 5

GENERAL

ledoM tupnIUTBrh/ erusserPdlofinaM

,D4GS

,C4GS

,D6GS

C6GS

larutaNsaGPLlarutaNsaGPL

000,06000,06

.C.W"5.3

)aPk9.0(

.C.W"01

)aPk2.2(

INTRODUCTION

Procedures in this manual will apply to all models unless specified. Pictures and illustrations can be of any model

unless the picture or illustration needs to be model specific. All models are equipped with a two-speed 1/2 HP electric

motor, porcelain interior and two 30,000 BTU/hr burners as standard equipment. A power level control permits

variable burner input from 15,0000 BTU/hr to 60,000 BTU/hr.

Models SG4D and SG6D are equipped with solid state-controls and a 60-minute timer (a 5-hour timer is optional).

Models SG4C and SG6C have a computer control with built-in Roast & Hold.

Models SG6D and SG6C have a 4" deeper cavity than models SG4D and SG4C.

INSTALLATION

Generally, installations are made by the dealer or

contracted by the dealer or owner. Detailed installation

instructions are included in the Installation & Operation

Manual which is sent with each unit.

OPERATION

Detailed operation instructions are included with each

oven.

CLEANING

Detailed cleaning procedures are included in the

Installation & Operation Manual for the appropriate

model.

LUBRICATION

Motor bearings are sealed and prelubricated.

Gas Data

TOOLS

Standard

• Hand tools (standard set).

• VOM with AC current tester (any quality VOM

with a sensitivity of at least 20,000 ohms per

volt can be used).

• Gear puller to remove blower.

Special

• Temperature tester (thermocouple type).

• Manometer

SPECIFICATIONS

Electrical Data

ledoM stloV ztreH esahP spmA

D4GS

C4GS

D6GS

C6GS

0210615.7

8020616.3

04206157.3

– 5 –

Page 6

REMOVAL AND REPLACEMENT OF PARTS

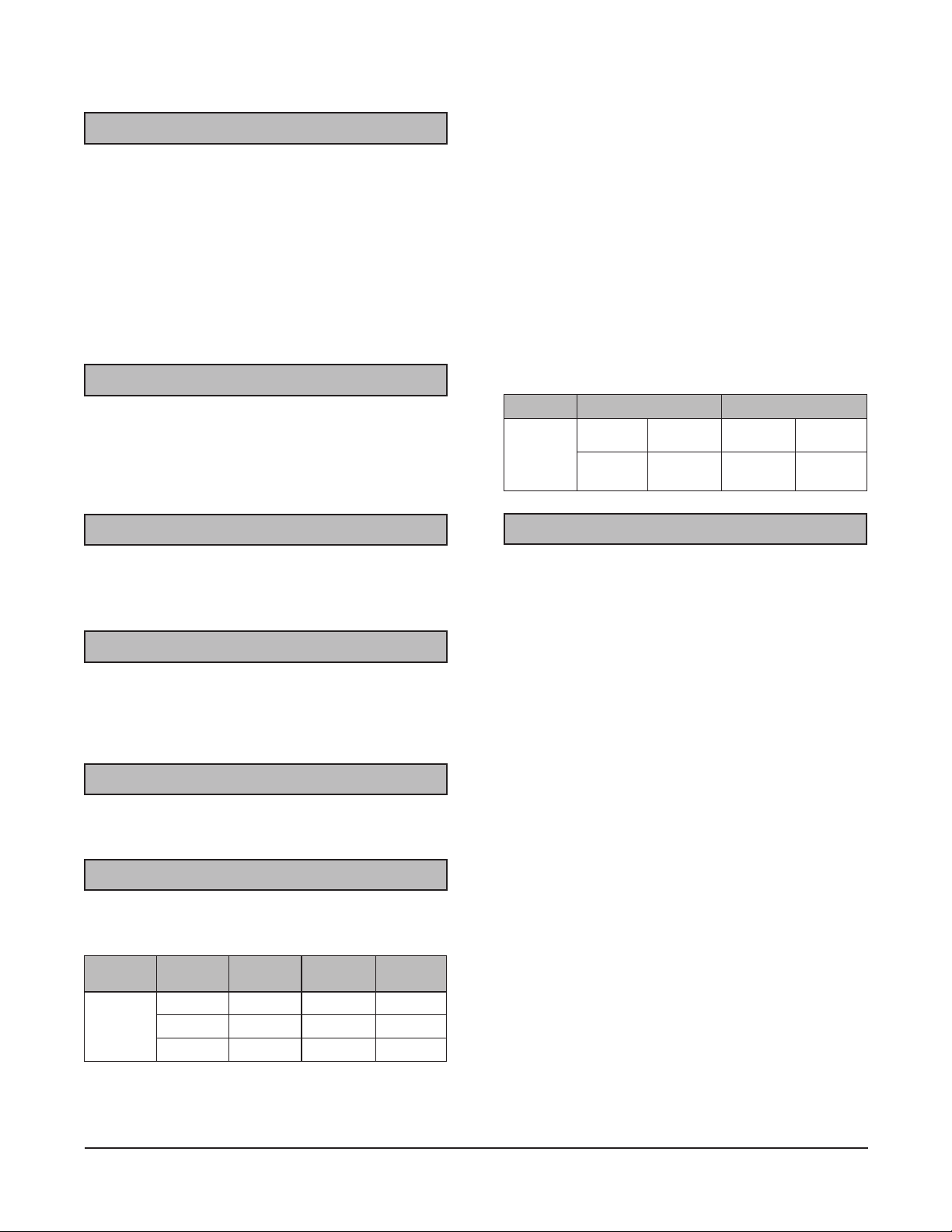

COMPONENT LOCATION

TOP VIEW

BLOWER MOTOR

OVEN LIGHTS

TEMPERATURE PROBE

GAS BURNERS

IGNITER &

FLAME SENSE

HIGH LIMIT

DOOR

SWITCH

COOLING

FAN

COMPONENT

PANEL

GAS VALVE

CONTROL

PANEL

PL-56044

– 6 –

Page 7

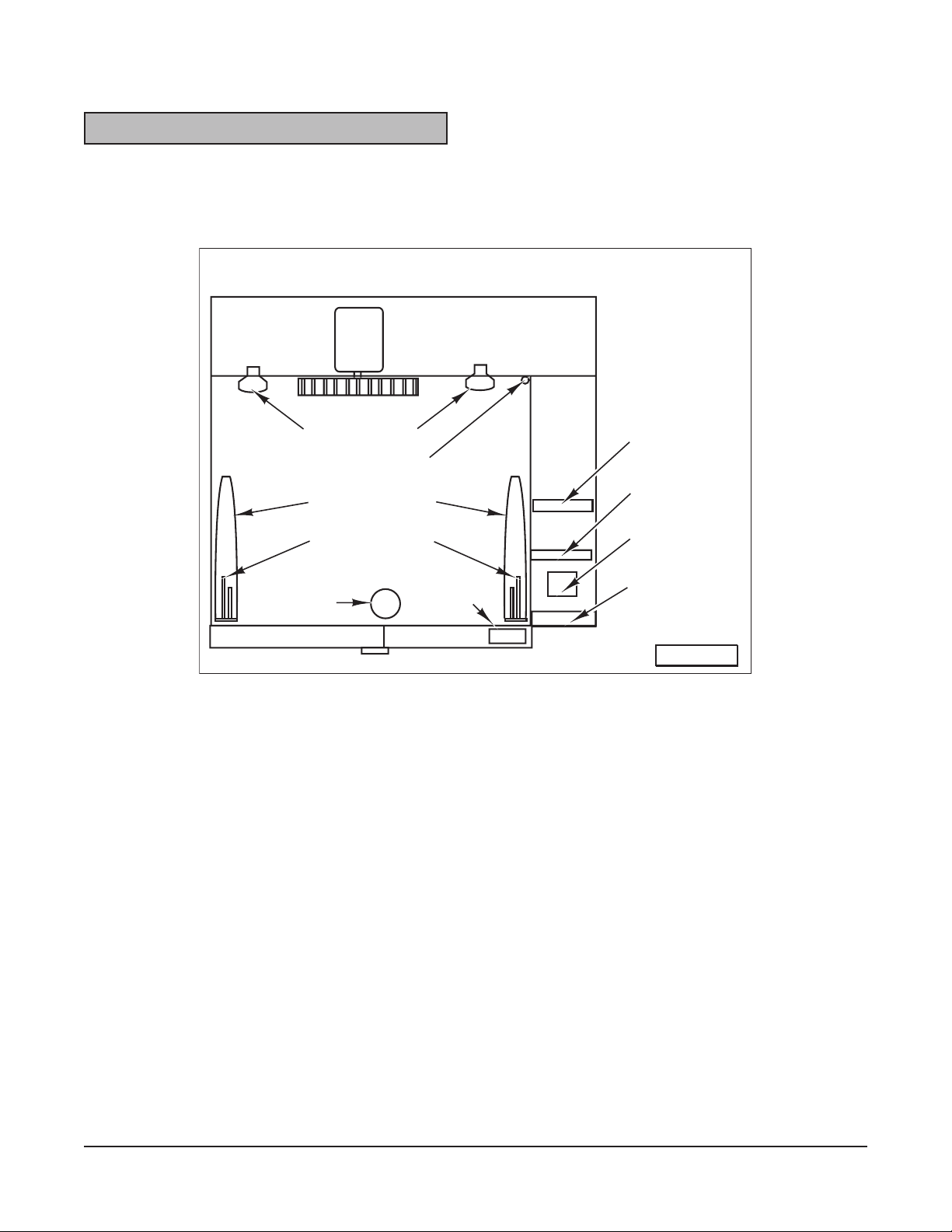

COVERS AND PANELS

RIGHT SIDE

REMOVE

SCREWS

REMOVE

SCREWS

CONTROL

PA NE L

ON

HI

OFF

LOW

LIGHTS

FAN SPEED

SG4D SHOWN

TH

ERMO

ST

AT

POWER

LEVE

L

OFF

OV

E

N

COOL

MA

STER

SWITC H

PL-56042-1

BOTTOM FRONT COVER

REMOVE SCREWS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Top Front Cover

1. The top front cover is secured with four

screws, two on each side of cover. Remove

these screws, then remove the cover from

the oven.

REMOVE SCREWS

TOP FRONT COVER

OVEN

COOL

AST

M

HEAT

IGNITION

Control Panel

1. Remove three screws on the right side which

secure the control panel. Pull the panel away

from the oven.

CH

IT

SW

ER

F

F

O

ON

2. Disconnect the temperature probe leads from

the solid state temperature controller.

3. Unplug the wire harness connector to the

control panel components.

PL-56040

2. Reverse the procedure to install.

Bottom Front Cover

1. The bottom front cover is secured with six

screws, two on each side of cover and two on

the top. Remove these screws then remove

the cover from the oven.

REMOVE SCREWS

BOTTOM FRONT COVER

2. Reverse the procedure to install.

4. Reverse the procedure to install.

Right Side Panel

1. Remove the screws that secure the right side

of the control panel.

2. Remove the remaining screws securing the

right side panel.

3. Pull the right-side panel out at the bottom

then down to remove.

RIGHT SIDE

REMOVE

SCREWS

PL-56041

PL-56043

4. Reverse the procedure to install.

– 7 –

Page 8

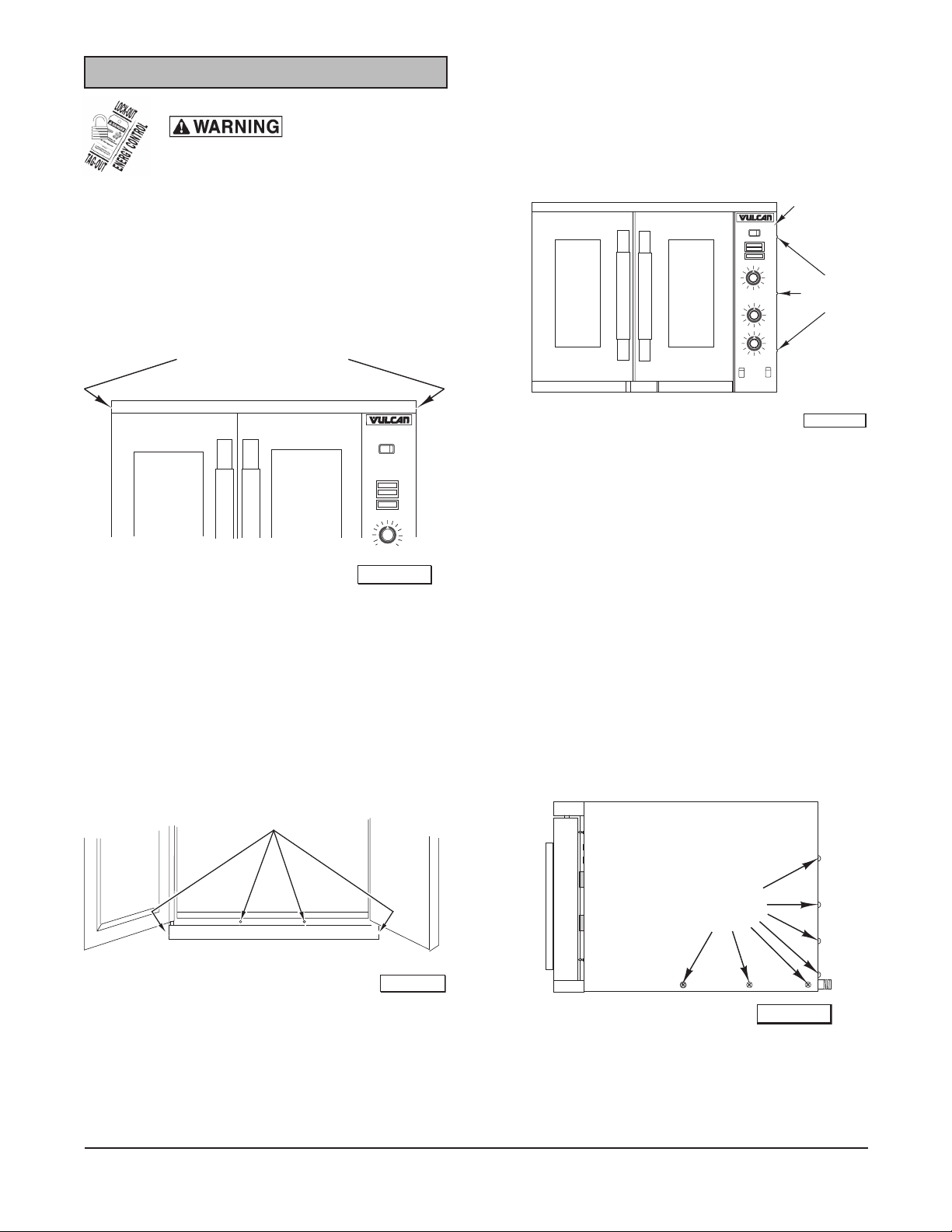

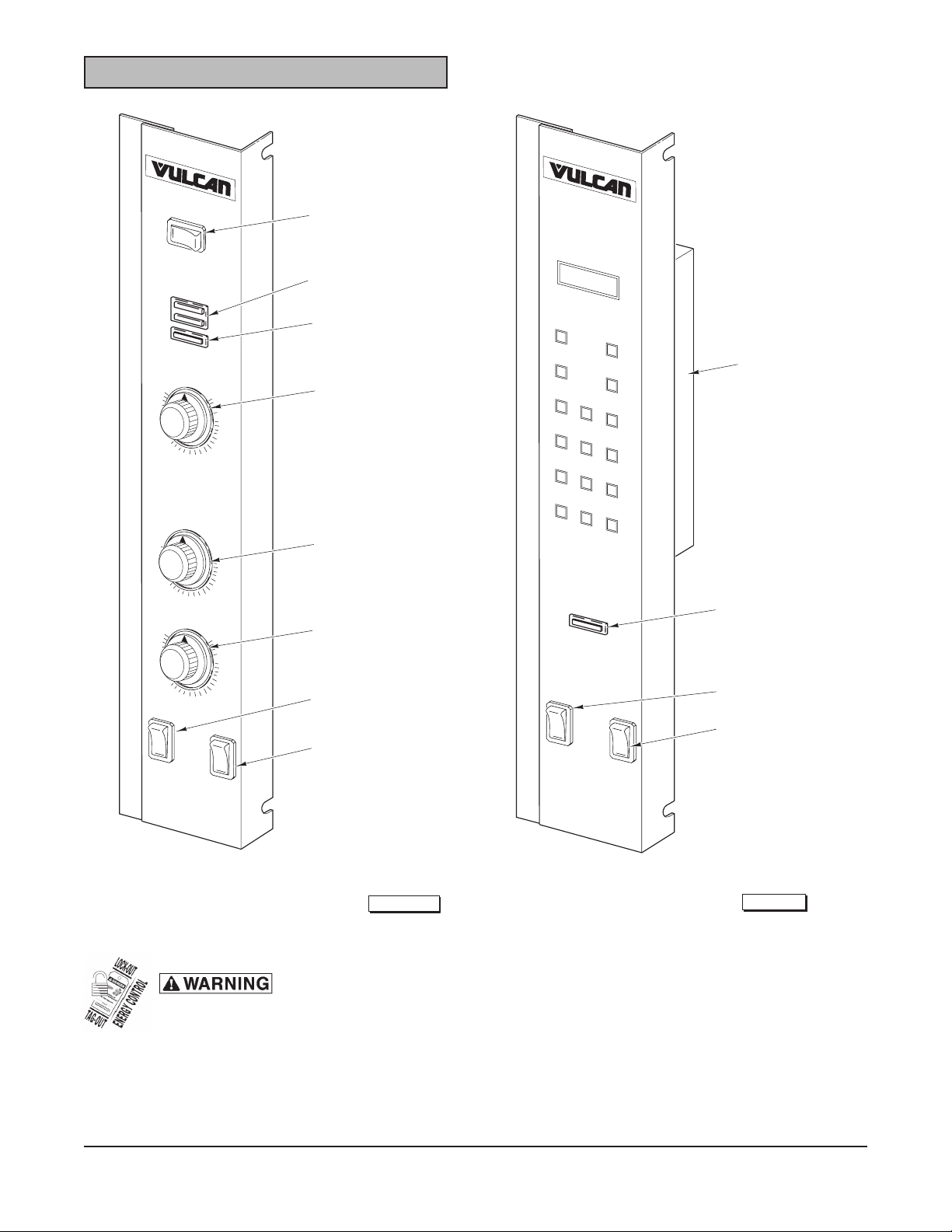

CONTROL PANEL COMPONENTS

O

COOL

FAN

VE

N

SPEED

MASTER SWITCH

OFF

THERMOSTAT

0

25

POWER LEVEL

TIMER

0

25

HI

LOW

MASTER

SWITCH

ON

ON/HEAT

INDICATOR

LIGHTS

NO IGNITION

LIGHT

COMPUTER

CONTROLLER

55

50

45

40

35

30

TEMPERATURE

CONTROLLER

(THERMOSTAT)

POWER CONTROL

NO IGNITION

55

50

45

40

35

30

LIGHTS

ON

OFF

TIMER

FAN SPEED

SWITCH

LIGHT

SWITCH

P

O

WER

ON

LIG

HT

S

ON

O

FF

O

V

EN

C

OOL

O

FF

LIGHT

POWER

SWITCH

LIGHT

SWITCH

SG4D/SG6D

Procedure

1. Remove the control panel as outlined under Covers and Panels.

2. Remove the component being replaced.

3. Reverse the procedure to install the new component, then check oven for proper operation.

procedures.

SG4C/SG6C

PL-56045-1

Disconnect the electrical power to the machine and follow lockout / tagout

– 8 –

PL-56046

Page 9

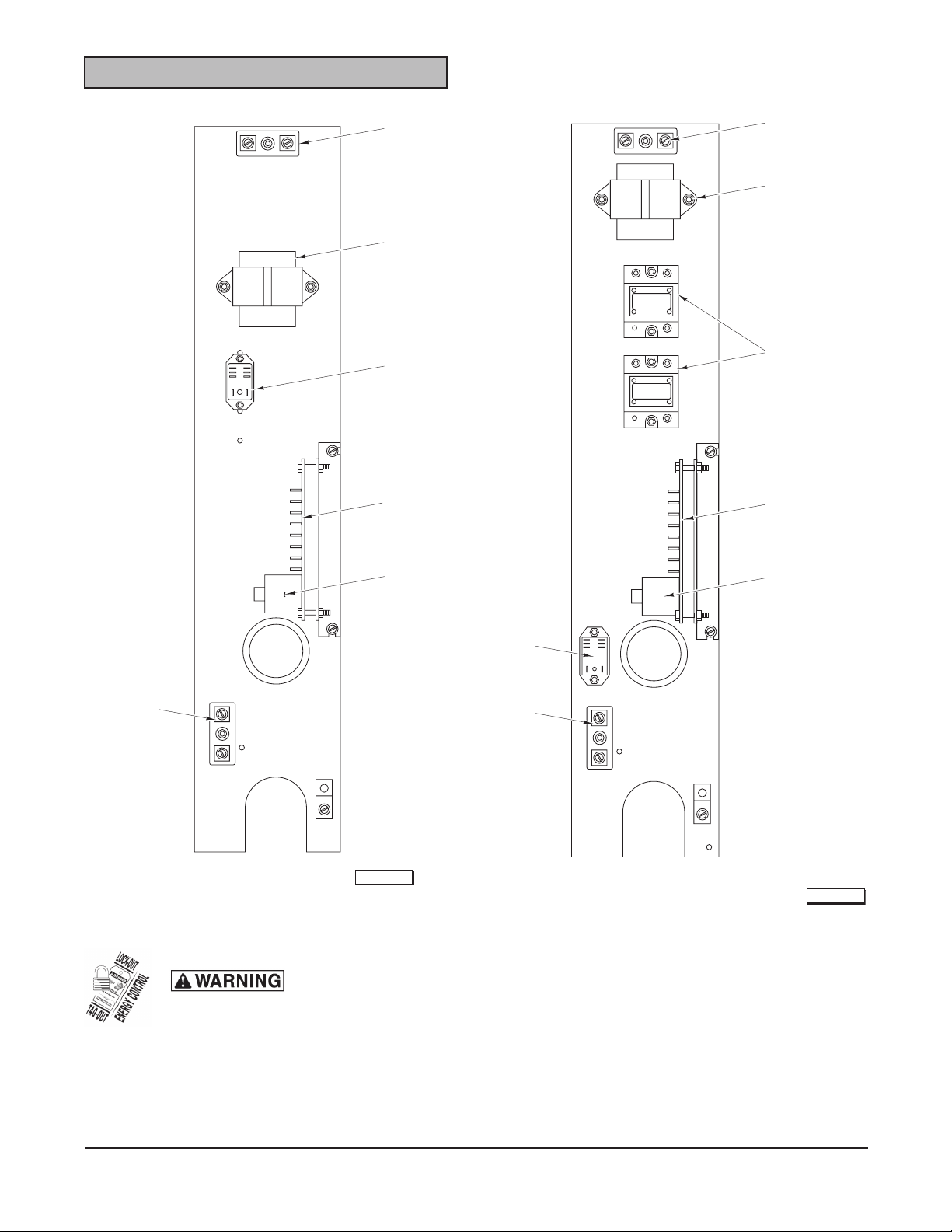

COMPONENT PANEL COMPONENTS

PORCELAIN

BLOCK

ASSEMBLY

TRANSFORMER

HEATING

RELAY

IGNITION

MODULE

BOARD

PORCELAIN

BLOCK

ASSEMBLY

TRANSFORMER

MOTOR

CONTROL

RELAYS

IGNITION

MODULE

BOARD

PORCELAIN

BLOCK

ASSEMBLY

Procedure

SG4D/SG6D

procedures.

IGNITION

MODULE

PL-56047

HEATING

RELAY

PORCELAIN

BLOCK

ASSEMBLY

SG4C/SG6C

IGNITION

MODULE

PL-56048

Disconnect the electrical power to the machine and follow lockout / tagout

1. Remove the right side panel as outlined under Covers and Panels.

2. Disconnect the wire leads to the component being replaced.

3. Remove the component.

4. Reverse the procedure to install the new component and check oven for proper operation.

– 9 –

Page 10

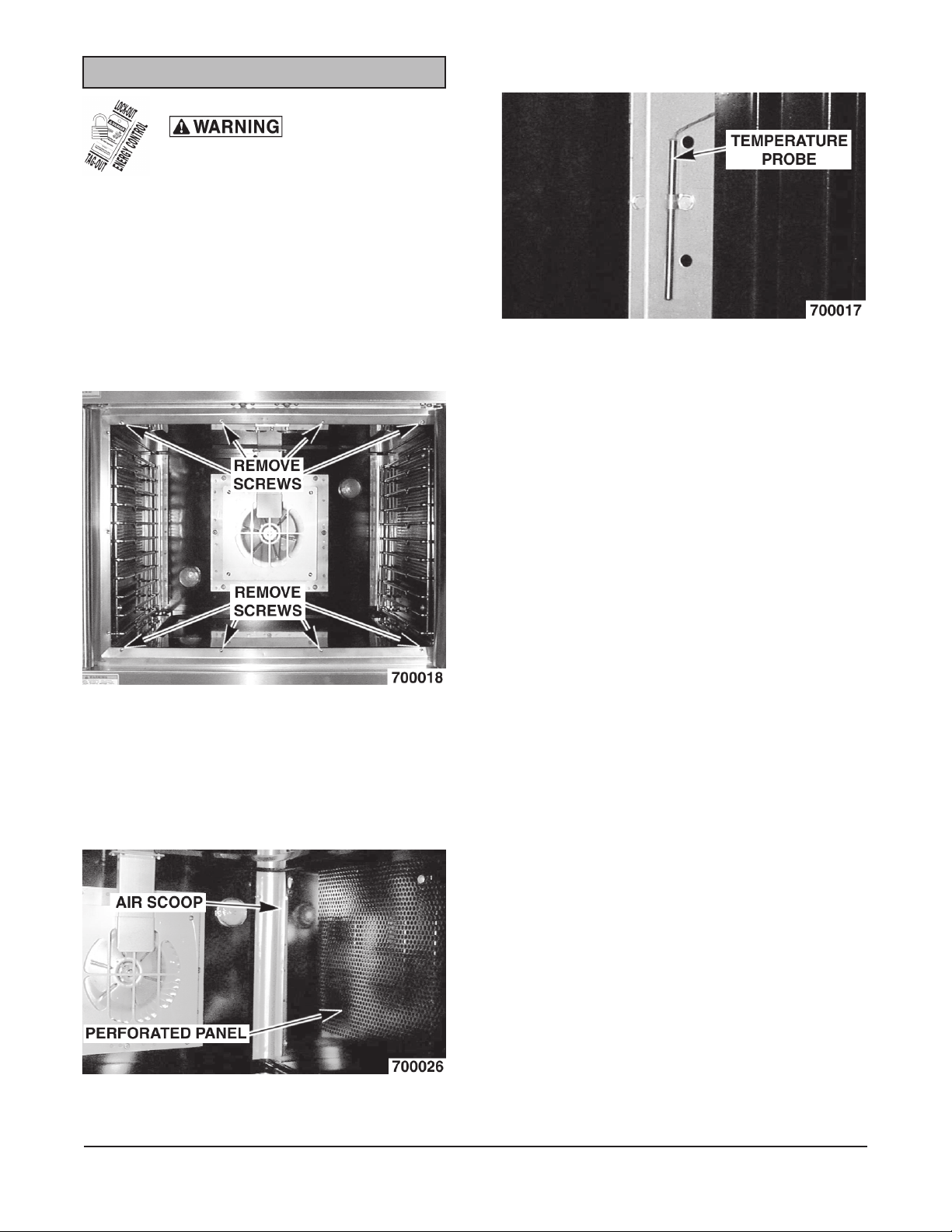

TEMPERATURE PROBE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the right-side panel as outlined under

Covers and Panels.

2. Disconnect probe leads from the solid state

temperature controller on the SG4D/SG6D or

the computer controller on the SG4C/SG6C.

3. Remove the racks and right rack support.

7. Remove the probe from the bracket(s).

4. Remove the upper and lower door seals.

5. Loosen the three screws securing the right

side air scoop to the rear heat exchanger.

Rotate the air scoop off of the heat exchanger

tube into the oven cavity.

6. Remove the screws that secure the perforated

side panel and lift out.

SG4C/SG6C Temperature Probe Shown

8. Push the probe through the oven wall and into

the control panel area.

9. Reverse the procedure to install the new

probe.

10. Calibration:

A. SG4D/SG6D: Adjust the temperature

controller as outlined under Solid State

Control Calibration.

B. SG4C/SG6C: Adjust the computer

controller as outlined under Computer

Controller and/or Computer Controller

Calibration in Service Procedures and

Adjustments.

– 10 –

Page 11

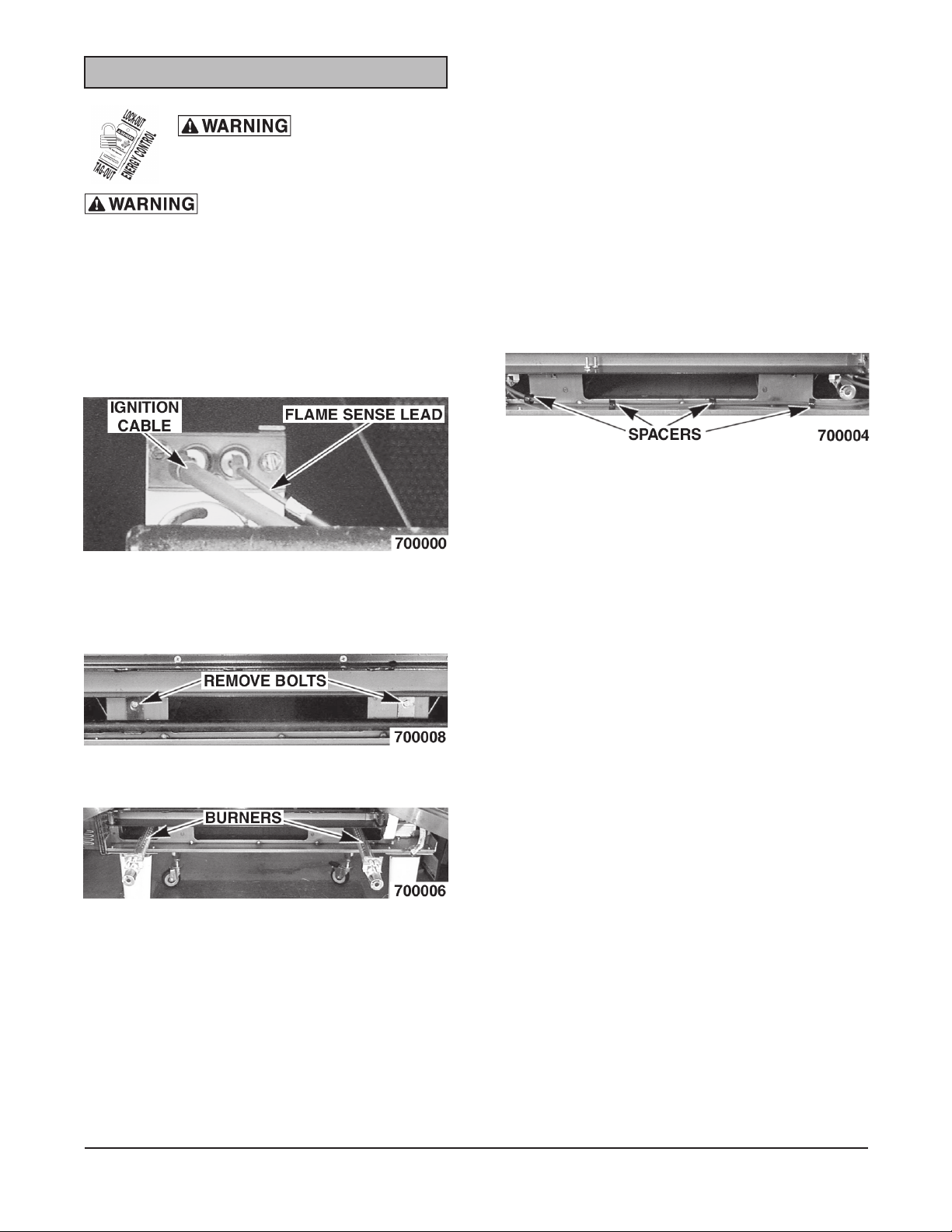

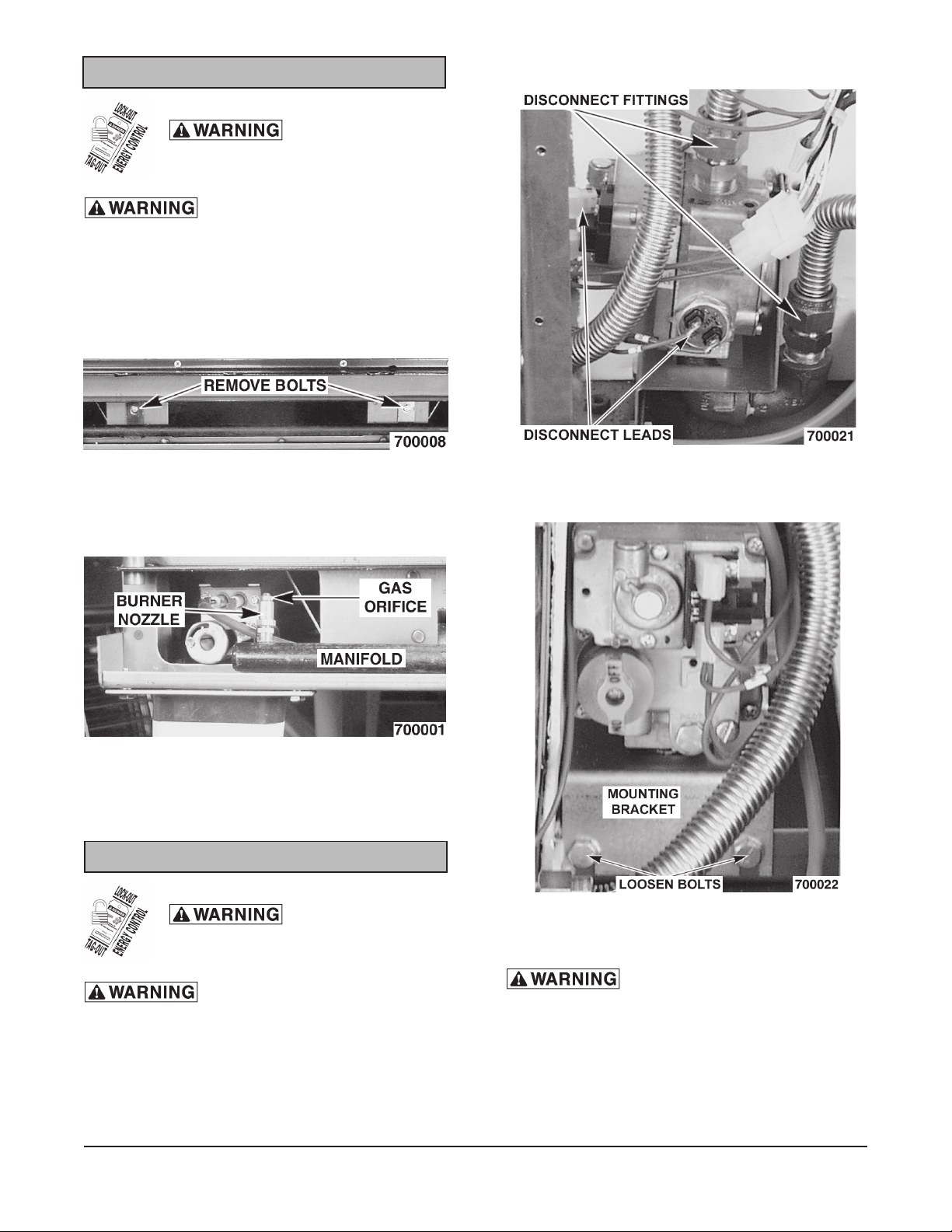

GAS BURNERS

5. Reverse the procedure to install and check

for proper operation.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing

the oven.

1. Remove the lower front cover as outlined

under Covers and Panels.

2. There are two burners located on the bottom

left and right side of the oven. Disconnect the

ignition cable and the flame sense lead from

each burner.

A. Ensure the spacers are in place on the

ignition wires. The spacers are intended

to keep the ignition wires from laying flat

on the oven chassis.

B. Ensure that the bracket on the back of

the burner is inserted into the slot at the

rear of the burner chamber.

Note: Check the flame current by following the Flame

Current Measurement procedures under the

Procedures and Adjustments Section of this manual.

3. Remove the bolts securing the gas manifold

and place manifold aside.

4. Grasp the burner and lift out.

– 11 –

Page 12

GAS ORIFICE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing

the oven.

1. Remove the lower front cover as outlined

under Covers and Panels.

2. Remove the bolts securing the gas manifold

and place manifold aside.

3. There are two gas orifices on the manifold.

Remove each orifice and replace with the

correct orifice for the given altitude as needed.

3. Disconnect compression fittings from the

valve.

4. Loosen the bolts securing the valve and

bracket assembly, then remove the screws

securing the valve to the bracket.

4. Reverse the procedure to install manifold and

check for proper operation.

GAS SOLENOID VALVE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing

the oven.

1. Remove the control panel and the right side

panel as outlined under Covers and Panels.

2. Disconnect the lead wires.

5. Reverse the procedure to install the

replacement gas valve.

All gas joints disturbed during

servicing must be checked for leaks. Check with

soap and water solution (bubbles). Do not use an

open flame.

6. Verify gas pressure as outlined under the

Gas Pressure Adjustment in Service

Procedures and Adjustments. Check for

proper operation.

– 12 –

Page 13

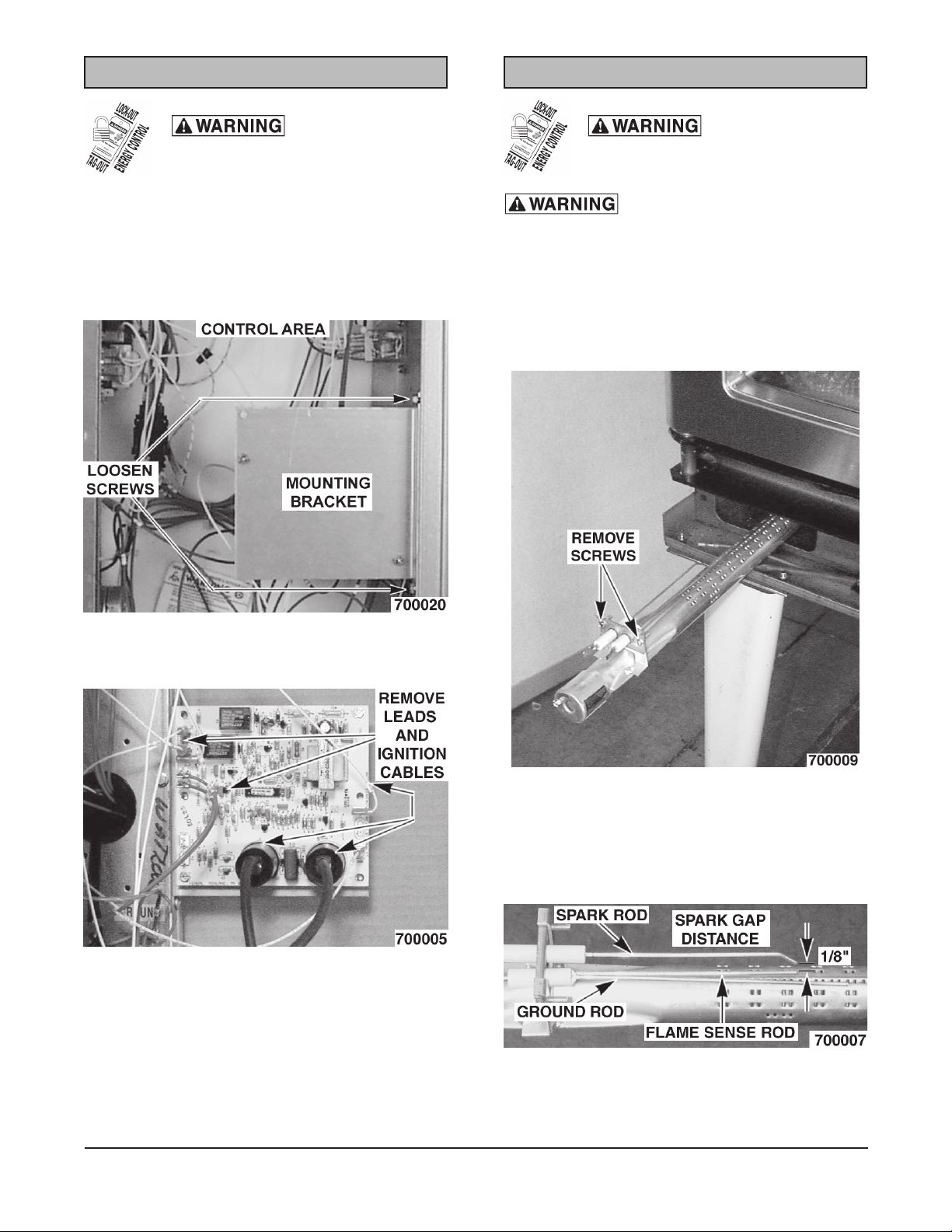

IGNITION CONTROL MODULE

SPARK IGNITER AND FLAME SENSE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the right side cover as outlined

under Covers and Panels.

2. Loosen the screws securing the mounting

bracket to the component panel and remove

the bracket.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing

the oven.

1. Remove the two gas burners as outlined

under Gas Burners.

2. Remove the screws securing the igniter and

flame sense to each burner. Remove the

assembly.

3. Disconnect the lead wires and igniter cables

from the ignition module board.

4. Remove the ignition module board from the

mounting bracket.

5. Reverse the procedure to install the

replacement ignition module board.

6. Check for proper operation.

3. The spark gap is 1/8" from the inside of the

spark rod to the inside to the ground rod. The

ground rod (the end of the spark) is 1/8" above

the burner. If the gap is not correct or poor

sparking is occurring, then adjust accordingly.

4. Reverse the procedure to install the assembly

and check for proper operation.

– 13 –

Page 14

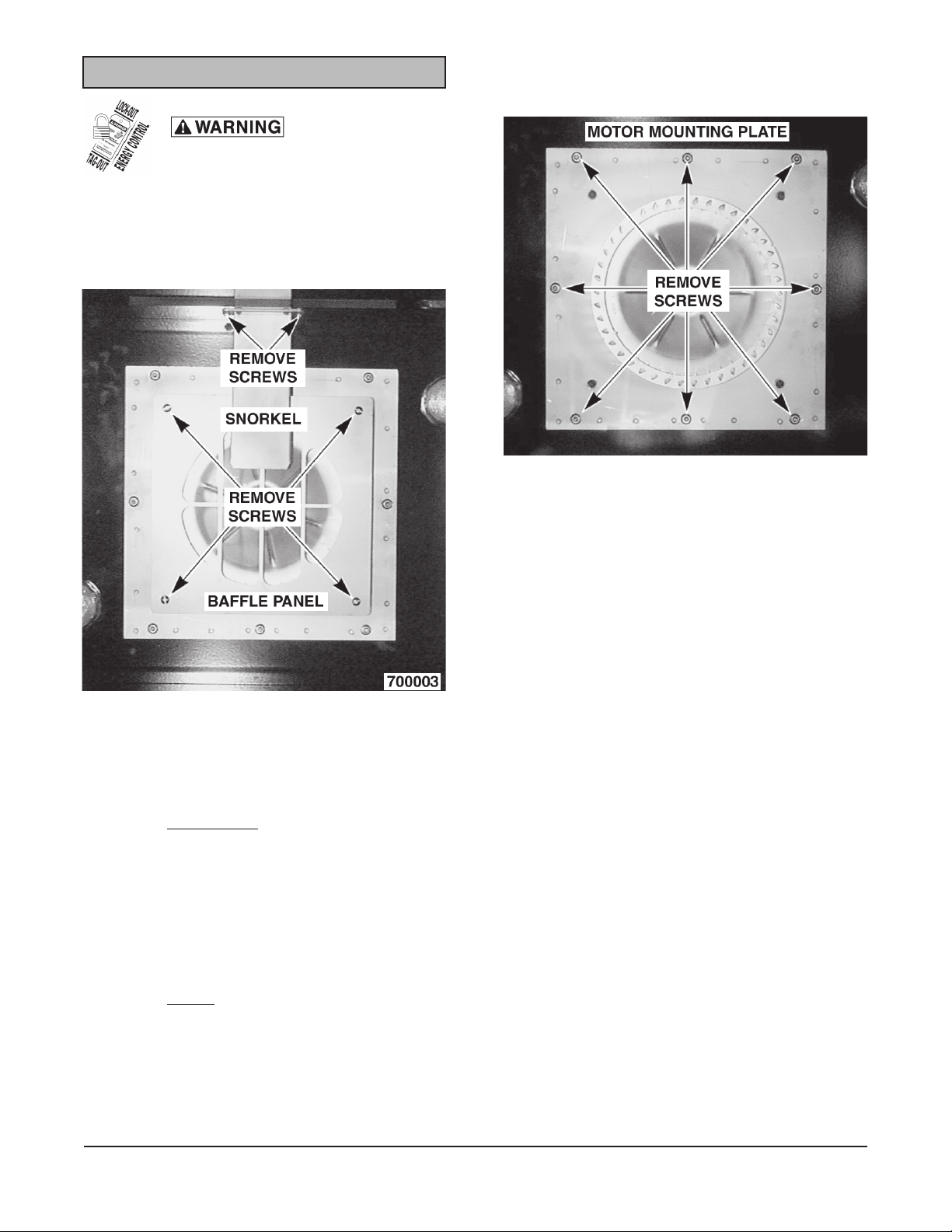

BLOWER AND MOTOR

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove racks.

2. Remove the screws securing the snorkel and

remove the snorkel.

5. Remove the screws that secure the motor

mounting plate to the rear wall.

6. Place a piece of cardboard on the bottom of

the oven cavity to protect its surface from

any damage during motor assembly removal.

3. Remove screws securing baffle panel and

remove the panel.

4. If replacing:

A. Blower Only - Loosen set screws on

blower hub and using a bearing puller,

remove blower from motor shaft.

1) Reverse procedure to install and

adjust blower position as outlined

under the Blower Adjustment in

Service Procedures and Adjustments

section.

B. Motor - Perform step 4A and continue

procedure.

7. Pull the motor assembly into the oven cavity

and place it on the cardboard.

8. Remove the junction box cover from the

motor, disconnect lead wires and remove the

conduit.

9. Remove motor mounting bolts and flat

washers, then lift the motor from the mounting

plate.

10. Position the replacement motor on the motor

mounting plate and install mounting bolts and

washers. Hand tighten mounting bolts only.

11. Reconnect to lead wires at the motor, and

replace conduit and junction box cover.

– 14 –

Page 15

FRONT VIEW OF MOTOR

FROM INSIDE OVEN CAVITY

OVEN DOORS AND BEARINGS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the top front cover and bottom front

cover as outlined under Covers and Panels.

2. Remove the door switch lever.

MOTOR ROTATES CLOCKWISE

PL-56051

12. Slide blower onto motor shaft until hub is

flush with end of shaft, then tighten setscrews.

13. Adjust motor position until blower is parallel

to motor mounting plate as outlined in Blower

Adjustment under Service Procedures and

Adjustments.

14. Position motor mounting plate on the rear

wall and secure with nuts and washers.

15. Replace the baffle panel and snorkel.

16. Replace the air baffle on the rear wall at the

lower right hand corner.

17. Remove cardboard from the bottom of the

oven cavity.

18. Install racks.

19. Check oven for proper operation.

3. Remove the lower door seal strip to expose

the mounting screws of the door assembly.

4. Remove the two lower sill bolts by the lower

door shaft and the four countersunk screws

from the lower sill.

A. The door assembly is heavy and will drop

down once the last screw is removed. If

removing the door assembly without

assistance, the ignition cable, flame

sense lead and gas manifold should also

be removed to avoid damage to these

components.

– 15 –

5. Tilt the top of the door slightly forward and lift

the door up until the bottom of the door shaft

clears the opening in the sill.

6. Lay the door flat to prevent damage.

Page 16

7. The top and bottom bearings are now

accessible for inspection and/or replacement

if needed.

DOOR CATCH ROLLER ASSEMBLY

(INDEPENDENT DOORS)

A. If bearings are OK, proceed to step 8.

B. If replacing the top bearing, remove the

top bearing retainer and top bearing.

C. If replacing the bottom bearing, remove it

from the door shaft or the lower sill

opening.

8. Reverse procedure to install door assembly

and check for proper operation as outlined

under the Door Adjustment and Door Switch

Adjustment section in Procedures and

Adjustments.

ROLLER LATCH ASSEMBLY

(INDEPENDENT DOORS)

NOTE: For units with serial number starting with 48

made after 8/12/07 and serial number starting with 54

made after 8/26/07.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

NOTE: For units with serial number starting with 48

made before 8/13/07 and serial number starting with

54 made before 8/27/07.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the top front cover as outlined under

COVERS AND PANELS.

2. Remove the nuts and bolts that secure the

door catch assembly.

3. Reverse the procedure to install.

4. Adjust the roller catch as outlined under the

Door Catch Adjustment in Service Procedures

and Adjustments.

DOOR WINDOW

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the screws at the top and bottom of

the door.

1. Remove the screws that attach roller latch

assembly to door.

2. Reverse procedure to install.

– 16 –

REMOVE

SCREWS

OVEN CAVITY

GLASS

PL-56052

Page 17

2. Remove the door handle, then remove the

outer door panel.

DOOR SWITCH

3. Lift out the inner door panel window assembly.

4. Remove the door seal from the inside of the

left door only.

5. Remove the screws securing the window

tabs to the door bracket and lift the window

assembly out from the door frame.

INNER DOOR PANEL ASSEMBLY

GLASS

REMOVE

SCREWS

GLASS

PL-56053

6. Reverse procedure to install the replacement

window.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the top front cover as outlined under

Covers and Panel.

2. Disconnect the lead wires to the door switch.

3. Remove the switch.

4. Reverse procedure to install the replacement

switch and check for proper adjustment as

outlined in Door Switch under Service

Procedures and Adjustments.

– 17 –

Page 18

HIGH LIMIT THERMOSTAT

INTERIOR LIGHTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the top four racks from the oven.

2. Remove the high limit thermostat cover/

mounting plate. It is located at the top of the

oven cavity.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the racks from the oven.

2. Unscrew the glass lens for the light being

replaced, then unscrew the bulb.

LENS

OVEN CAVITY

LENS

PL-56054

3. Replace bulb, then reverse the procedure to

install.

3. Disconnect the lead wires from the high limit

thermostat. Remove the high limit thermostat

from the cover mounting plate.

4. Remove the old RTV silicone from the cover

and mating surfaces inside the oven cavity,

and apply new RTV silicone before installing.

5. Reverse procedure to install.

Lamp Assembly

1. Remove the lens and bulb.

2. Remove the springs from the retaining tabs

(two places) on the socket.

RETAINING TABS

SPRING

CROSS SECTIONAL VIEW

3. Depress the retaining tabs and pull the socket

out from the oven, far enough to disconnect

the lead wires.

4. Remove the socket from the oven.

PL-56055

– 18 –

Page 19

5. Attach the lead wires to the replacement

socket.

NOTE: Ensure the case is connected to the

green ground wire.

6. Insert the socket into the hole in the oven and

push until the socket is held in place by the

retaining tabs.

7. Install the light bulb and lens.

8. Check for proper operation.

COOLING FAN

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the right side panel as outlined under

Covers and Panels.

2. Disconnect the lead wires to the fan motor by

removing the wire nuts.

Fan Installation Tips

• The fan must be installed so air is pulled from

the rear of the oven and blown into the control

area. The arrow on the fan body indicates

airflow direction and should be pointing toward

the controls.

• Ensure the fan is seated squarely against the

air tube and the oven bottom.

• The air deflector should be angled upward at

approximately 30 degrees to properly direct

the airflow.

3. Remove the screws securing the air deflector

to the fan, then loosen the tab screw holding

the fan to the component panel. Rotate the

tab so that the fan will clear. Remove the fan.

4. Reverse the procedure to install the

replacement fan and check for proper

operation.

– 19 –

Page 20

SERVICE PROCEDURES AND ADJUSTMENTS

Certain procedures in this section require electrical test or measurements while power is

applied to the machine. Exercise extreme caution at all times. If test points are not easily accessible, discern

power, attach test equipment and reapply power to test.

SOLID STATE TEMPERATURE

CONTROLLER TEST

(SG4D/SG6D)

Test Steps

1. Remove the right side panel as outlined

under Cover and Panels in Removal and

Replacement of Parts.

2. Place a thermocouple in the geometric center

of the oven cavity. Oven temperature must

be below 450°F.

3. Set the temperature control to the maximum

setting.

4. Set the power control to 100%.

5. Check machine data plate for correct voltage

to oven. Refer to diagram below for proper

terminal locations and voltages before

checking temperature controller. Use the

correct terminals for the corresponding

voltage.

6. Turn the ON-OFF-OVEN-COOL switch to

ON.

8. Check for voltage to the switching output.

a. For 120 VAC controls, check across

terminals J3 and J4 for input voltage and

between J4 and J5 for output voltage

from the internal switching device.

b. For 208/240 VAC controls, check across

terminals J3 and J9 for input voltage and

between J9 and J5 for output voltage

from the internal switching device.

1) If input voltage is correct, proceed to

step 9. If input voltage is not present,

the problem is not in the controller

(See Troubleshooting).

2) If output voltage is correct, proceed

to step 9. If output voltage is not

correct, check temperature probe,

as outlined under Temperature Probe

Test (SG4D/SG6D).

c. If the probe connected to J6 and J7 is

either shorted or opened, the red LED

located just above J6 (to the left of J6

when mounted) will flash. With the probe

connected and the LED not flashing,

slowly turn the Temperature set knob

until the pointer passes through the mid

point of rotation. At the mid point of

rotation, the red LED will come on. If the

control is set and left at the mid point, the

LED will stay on. With the LED on at mid

point, you have tested the entire front

end of the control circuit as well as the

probe and verified that the control is

functioning normally.

7. Check for voltage across terminals J2 and J4

(120 Volt) or J2 and J9 (208/240 Volt) for

power to the control.

a. If correct, proceed to step 8.

b. If incorrect, the problem is not in the

temperature control (see

Troubleshooting).

9. Set temperature control to minimum setting.

Oven temperature must be above 300°F.

10. Check for zero volts (0.00 Volts) across

terminals J4 and J5 (120 Volt) or J9 and J5

(208/240 Volt) for no output from the internal

switching device.

a. If correct, temperature control is

functioning properly.

– 20 –

Page 21

b. If incorrect, check temperature probe as

outlined under Temperature Probe Test

(SG4D/SG6D).

1) If temperature probe is functioning

properly and the temperature

controller failed the test in 8c above,

replace the temperature control and

check for calibration as outlined under

Solid State Temperature Controller

Calibration (SG4D/SG6D).

SOLID STATE TEMPERATURE

CONTROL CALIBRATION

(SG4D/SG6D)

Before attempting any calibration, see Section 8C of

SOLID STATE TEMPERATURE CONTROLLER

TEST (SG4D/SG6D) on previous page.

Calibration Steps

1. Place a thermocouple in the geometric center

of the oven cavity.

2. Set the ON/OFF/OVEN COOL switch to ON.

3. Set the temperature controller dial to 350°F.

Set the power control to 100% (10).

4. Allow the oven temperature to stabilize

(minimum three heating cycles).

5. Record the temperature at which the Heat

lamp comes ON (heating starts) and goes

OFF (heating stops). This is the control

differential. Heat lamp OFF temp - Heat lamp

ON temp = Control Differential.

6. The nominal control differential should be

less than 20°F.

7. Calculate the average oven temperature by

adding the actual minimum temperature to

the actual maximum temperature and dividing

by 2.

EXAMPLE:

Oven set to 350°F.

Actual minimum oven temperature = 335°F

Control cuts on at 334°F

Actual maximum oven temperature = 347°F

Control cuts off at 340°F

335 + 347 = 682

682/ 2 = 341 (the control is 9°F out of calibration)

340 - 334 = 6°F Control Differential

347 - 335 = 12°F Oven Temperature Differential

A. If the average oven temperature is within

+/- 5°F from the dial setting, no calibration

is necessary.

B. If the average oven temperature is not

within +/- 5°F, calibration is

recommended.

8. Loosen the set screw on the temperature

controller and carefully remove the knob from

the shaft, without rotating the shaft. This will

expose the calibration adjustment control

access hole in the front panel.

9. Monitor the internal oven temperature and

determine at what temperature the control

should cut on to give you the required minimum

temperature (Example: 350-341=9;

334+9=341. 341°F is the temperature at which

you would wish the controller to cut on).

10. After allowing the oven to operate through

several cycles (minimum 3 cycles), monitor

the temperature as it falls to the desired "cuts

on" point. Using a small screw driver, adjust

the calibration adjustment until the controller

cuts on at the desired "cuts on" temperature.

A. If the control differential is less than

20°F, the temperature control circuit is

functioning properly. Proceed to step 7.

B. If the control differential is more than

20°F, check the temperature probe as

outlined under Temperature Probe Test

(SG4D/SG6D).

C. If the control differential is more than

20°F and the probe passes its' test

parameters, then temperature controller

is malfunctioning. Install a new

temperature controller and run calibration

steps again.

– 21 –

11. The calibration control is adjusted clockwise

in order to increase the set temperature and

counter clockwise to decrease the set

temperature.

12. The controller has only +/- 25°F of adjustment.

1

/4 turn of the calibration adjustment represents

approximately 20°F shift in calibration.

Page 22

TEMPERATURE PROBE TEST (SG4D/SG6D)

Disconnect the electrical power to the machine and follow lockout / tagout

procedures.

The temperature probe used in conjunction with the Solid State Temperature controller is an RTD (resistance

temperature detector) of the Thermistor type. As temperature increases the resistance value decreases.

Test Steps

1. Remove the right side panel as outlined under Cover and Panels in Removal and Replacement of Parts.

2. Place a shielded thermocouple in the geometric center of the oven cavity and determine the temperature

in the oven cavity.

3. Remove the probe lead wires from the solid state temperature controller.

4. Test the probe with an ohmmeter.

A. If the measured resistance values are inside the given tolerance, then the probe is functioning properly.

B. If the measured resistance values are outside the given tolerance, then replace the probe and make

sure wires are secured to the terminals of the temperature controller. Recheck the temperature by

preforming step 2.

1) Check the oven for proper operation.

5. Reverse Procedure to install.

)F°(PMET *SMHO

77000,09

042770,4

062610,3

082662,2

003627,1

023233,1

043140,1

063228

083656

004925

524424

054433

574662

seR)*(

– 22 –

%01±smhoniecnatsi

Page 23

COMPUTER CONTROLLER

(SG4C/SG6C)

3. Listed are the parameters and data in the

setup mode.

Operation

Refer to the Installation & Operation Manual for

specific operating instructions.

Setup Mode

Use the setup mode to verify that the control is

configured to the factory settings which result in the

proper operation of the oven. If the CAL1 parameter

is other than zero, see Computer Control Calibration

(SG4C/SG6C).

CAUTION: Changing the C_F, InP1, rL1 and rH1

parameters will default all menus.

1. Use this key sequence to access the setup

mode: UP arrow, Rack 1, Temperature,

Temperature, DOWN arrow, Rack 1.

11

PL-56075

2. Once in the setup mode the display will

alternate between the parameter and

programmed data.

A. To change data to the factory setting,

use the arrow keys.

B. To select the next parameter, press the

Rack 1 key.

YALPSIDNOGNITANRETLA

UNEM

RETEMARAP ATAD

tiehnerhaF_suisleCF_CF

dnaBdrauGbg0004

erutarepmeT

noiatsnepmoC

1epyTtupnI1PnIJ

1woLegnaR1Lr57

1hgiHegnaR1

siseretsyH1SYH3

tesffOnoitarbilaC1LAC0

edomputestixE

otnruterdna

.edomnoitarepo

PnctFFO

Hr005

sierutarepmettniopteS

,taeh

rofgnillacfirodeyalpsid

.deyalpsidera)----(sehsad

Probe Test

If the oven is not heating or displaying the proper

temperature, the temperature probe may be

malfunctioning. Determine if the probe is good or

causing the operational problem.

C. After the last parameter and data are

viewed, press the Rack 1 key to exit the

setup mode and return to operations

mode. The current set point temperature

will be displayed.

D. If there are no key activations after 1

minute, the control will return to operation

mode.

1. Temporarily disconnect the existing lead wires

from the computer control and connect them

to a good J-type thermocouple.

2. Turn the power switch to ON and set the

temperature controller to 350°F.

A. If the oven reaches the set temperature

and cycles with the temporary

thermocouple, then the existing probe is

malfunctioning.

3. Replace the temperature probe with the correct

part and check for proper operation.

– 23 –

Page 24

Solid State Relay Test

1. Remove the right side panels as outlined

under Covers and Panels in Removal and

Replacement of Parts.

C. Press the set key again to save the change,

then exit the temperature set mode.

4. Allow the oven temperature to stabilize

(normally three cycles).

2. Turn the power switch to the ON position.

3. Check for +5 VDC on input side of SSR-1 in

the normal heating mode (terminals 3 & 4)

and SSR-2 in the roast and hold mode.

A. If +5 VDC is present, continue to step 4.

B. If no voltage is present, computer control

is not functioning properly.

4. Check for 120 VAC at load side of SSR

(terminals 1 & 2).

A. If no voltage is present, solid state relay

is not functioning properly.

1) Replace the SSR and check for proper

operation.

B. If 120 VAC is present, component is

functioning properly.

5. Reassemble oven and check for proper

operation.

5. Compare the controls set point temperature

to the thermocouple meter reading when the

heat light goes out.

A. A temperature variance more than 5°F

indicates an adjustment is needed.

1) To make the adjustment, proceed to

step 6.

2) If temperature variances is less than

5°F, then the computer control is

functioning properly.

6. Enter the setup mode as outline in Setup

Mode under Computer Control (SG4C/SG6C).

A. Advance through the menu until CAL1

(calibration offset) appears.

1) If the thermocouple reading is higher

than set point temperature, press the

down arrow key and enter a negative

offset value that is equal to the

number of degrees above the 5°F

tolerance.

COMPUTER CONTROL CALIBRATION

(SG4C/SG6C)

Calibration Steps

1. Place a thermocouple in the geometric center

of the oven cavity.

2. Set the ON-OFF-COOL DOWN switch to ON.

A. If the set point temperature is 350°F,

proceed to step 4.

B. If the set point temperature is other than

350°F, proceed to step 3 to change the

temperature.

3. Press the set key then temperature key to

enter the temperature set mode.

A. The display will alternate between the

term StPt (set point) and the current

oven temperature setting.

B. Press the UP or DOWN arrows to make

the proper selection.

2) If the thermocouple reading is lower

than set point temperature, press the

UP arrow and enter a positive offset

value that is equal to the number of

degrees below the 5°F tolerance.

3) Exit the setup mode.

7. Allow the oven to cycle at least two times

between adjustments.

A. If the temperature variance still differs

more than 5°F from the set point, verify

the correct calibration offset value was

entered and retained.

1) Adjust the calibration offset value as

outlined in step 6, until the cycling

temperature is within tolerance.

B. If the above adjustment cannot be

obtained, replace the computer control

and check for proper operation.

– 24 –

Page 25

GAS PRESSURE ADJUSTMENT

SAG

EPYT

).C.WNI(SGNIDAERERUSSERP

DLOFINAM

ENIL

DEDNEMMOCERNIMXAM

larutaN5.30.70.5

41

enaporP010.110.11

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Accurate gas pressure adjustments can only be

made with the gas on and the burner lit. If the

incoming line pressure to the valve is less than the

minimum stated, then the manifold pressure cannot

be set correctly.

1. Turn gas supply off at manual shutoff valve.

2. Remove the right side panel as outlined

under Covers and Panels in Removal and

Replacement of Parts.

3. Remove the plug from the manifold pressure

port.

4. Install hose barb adapter and attach

manometer tube.

5. Remove adjustment screw cap from the gas

valve and turn gas supply to the oven back

on.

The following steps require power

to be applied to the unit during test. Use extreme

caution at all times.

6. Plug the unit in and turn the power switch ON.

7. Set the temperature controller to its highest

setting and allow burner to ignite. The burner

must be lit during test and adjustment.

8. Turn the set screw to obtain the proper gas

pressure (clockwise = pressure increase;

counterclockwise = pressure decrease).

– 25 –

Page 26

VERIFICATION OF SPARK AT IGNITOR

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

The following steps require power

to be applied to the unit during the test. Use

extreme caution at all times.

4. Plug the oven in and set the temperature

controller to the maximum setting.

5. Turn the power switch ON.

Shut off the gas before servicing

the oven.

1. Remove the bottom front cover as outlined

under Covers and Panels in Removal and

Replacement of Parts.

2. Disconnect the high voltage ignition cable

from the spark igniter.

Do not hold the wire with your

hands for this test. The manual gas valve must be

closed.

3. Clamp the ignition cable in a manner that will

position the end of the cable 3/16" from the

oven frame (bare metal surface). It is critical

that the cable be held 3/16" away from the

surface of the oven frame or sparking may

not occur even though the sparking circuit is

functioning properly.

6. Sparking should occur after a 4 second delay

and continue for 7 seconds. The cycle will

repeat twice after a 15 second purge time.

Arcing from the ignition cable to the oven

frame should be observed.

DOOR SWITCH ADJUSTMENT

Disconnect the electrical power

to the machine and follow lockout / tagout

procedures.

1. Remove the top front cover as outlined under

Covers and panels in Removal and

Replacement of Parts.

2. Door operation:

A. The switch actuator is engaged by the

switch lever when the right door is between

1" and 1 1/2" from being closed.

3. If adjustment is necessary, bend the switch

actuator to obtain the proper setting.

– 26 –

4. Install the top front cover.

5. Apply power to the oven and check for proper

operation.

Page 27

FLAME CURRENT MEASUREMENT

BLOWER ADJUSTMENT

MICROAMP METER

4

FENWAL

LED

DIAGNOSTIC

INDICATOR

DUAL

56

56

55

8

59

345519-4

U

424471-G1

2

3

TH

46

AB

V

57

C-2

2

1

5

417856-1

S1

123

S2

2

1

6

57

48

GND.

AB

CONNECT 200-240 VOLT

SUPPLY TO L1 & L2

V1

V2

NC

W

S1

S2

FC2-

FC2+

FC1-

FC1+

D

L2L1

CHANNEL

IGNITION

MODULE

SPARK

OUT

L

WHITE

GREEN

BLACK

RED

52

24V

GND

SPARK

OUT

48

W

120 VOLT UNITS PROVIDED

WITH 3 PRONG GROUNDED

PLUG.

T

X

LEFT RIGHT

BURNER BURNER

S2

Y

1. Use a Microampere (µamp) meter to measure

the flame current on both wires S1 & S2.

2. Connect a Microampere meter as shown

above to S1 & S2, to read the actual flame

current of each igniter.

3. The ignition system is 1 µamp sensitive.

4. You should be able to attain a reading of 4

µamps when connected as shown.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

10

S1

1. Remove the blower motor and mounting

assembly as outlined under Blower and

Motor in Removal and Replacement of Parts.

2. Loosen the motor mounting bolts.

3. Adjust the motor position until the blower is

parallel to and 1/4" inch away from the motor

mounting plate. Check to see if the blower is

square to the motor mounting plate at the

top, bottom, left and right of the blower.

A. If the blower is square, then tighten

motor mounting bolts and proceed to

step 4.

B. If the blower is not square, continue

adjusting until proper spacing is achieved

then tighten motor mounting bolts. If

necessary, place shims between motor

and frame.

5. The meter is to be placed in series with the

flame sense wires S1 & S2.

6. Connect at the board or the igniter end,

whichever is more convenient.

PLACE SHIMS UNDER REAR OF

MOTOR TO WIDEN TOP SPACE.

PLACE SHIMS HERE

WHEN NEEDED.

FLAT

WASHER

MOTOR

FRAME

FLAT WASHER

NUT/STAR

WASHER

PLACE SHIMS UNDER FRONT OF

MOTOR TO WIDEN BOTTOM SPACE.

MOTOR MOUNTING PLATE

1/4 INCH AT

ALL PLACES

TOP

BLOWER

BOTTOM

PL-56058

4. Reverse the procedure to install. Use

locktight on mounting nuts and bolts.

– 27 –

Page 28

DOOR ADJUSTMENT

DOOR STRIKE ADJUSTMENT

(INDEPENDENT DOORS)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Check the doors to make sure they have an

equal gap between them and that the vertical

edge of the door is parallel to the vertical door

seal. If the doors are not positioned in this

manner, adjust the doors as described.

EQUAL GAP

EQUAL GAP

EQUAL GAP

PL-56059-1

NOTE: For units with serial number starting with 48

made after 8/12/07 and serial number starting with 54

made after 8/26/07.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the top front cover as outlined under

COVERS AND PANELS in REMOVAL AND

REPLACEMENT OF PARTS.

2. Open the doors and inspect the door strike for

proper shape.

A. Replace if bent. Do not bend strike plate.

B. If adjustment is necessary, loosen

fasteners, close doors and insure contact

between the door inner surface and upper

horizontal seal. Slide door strike plate

until contact with roll latch is made.

Tighten strike plate fasteners.

2. Remove the top front cover.

3. Loosen the screws that secure the upper door

bearings and related hardware, just enough to

allow door movement.

UPPER

BEARING

DOOR

SHAFT

LOOSEN

SCREWS

PL-56060

4. Move the door until proper alignment is

achieved, then tighten the screws on the

upper door bearing hardware.

5. Repeat steps 3 and 4 on the opposite door if

necessary.

3. Open and close the doors several times while

observing the roller latch and strike plate

operation.

A. Replace roller latch if malfunctioning as

outlined under ROLLER LATCH

ASSEMBLY (INDEPENDENT DOORS)

and adjust as outlined in this procedure.

4. Each oven door should be open with a force

of 8 to 25 pounds when pulled at the handle.

The adjustments must allow the doors to

remain closed during normal operation and

allow opening without exertion by the user.

6. If one door is higher than the other, add or

remove shims under hinge pin as needed.

– 28 –

Page 29

DOOR CATCH ROLLER ADJUSTMENT

NOTE: For units with serial number starting with 48

made before 8/13/07 and serial number starting with

54 made before 8/27/07.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the top front cover as outlined under

Cover and Panels in Removal and

Replacement of Parts.

2. Inspect the door strike to make sure it is

straight, and replace if bent.

3. Inspect the door catch assembly, and replace

if it is damaged.

4. Check for proper door alignment.

A. Doors should be centered in the cavity

opening and parallel to top and bottom of

oven as outlined under Door Adjustment.

6. Place a standard flat screwdriver through the

opening in the top channel into the slot in the

cylinder of the catch assembly.

5. With the door in closed position, check to see

that the ball of the catch is centered and

touching the door strike. If not, if may be

necessary to adjust and add a shim piece to

the door strike.

7. Turn the screwdriver clockwise to increase

the ball pressure or counterclockwise to

decrease the pressure onto the door strike.

The ball pressure should be tight enough to

hold the door in place when the blower is

engaged.

8. After the adjustment is complete, lubricate

the inside of the door catch cylinder.

– 29 –

Page 30

ELECTRICAL OPERATION

COMPONENT DESCRIPTION

Master Switch (S1) - Determines the mode of

operation; ON, OFF or OVEN COOL

Lights Switch (S2) - Controls the oven cavity lights.

Fan Speed Switch Hi/Low (S3) - Controls blower

motor speed between HI and LOW settings. Available

on models SG4D/SG6D.

Alarm/Buzzer - Signals the end of the normal cook

cycle when cooking time expires.

Timer - Times the cooking cycle and signals the

buzzer at the end of the cycle.

Door Switch - Allows the oven to operate when the

doors are closed but stops the oven from operating

when the doors are opened.

Blower Motor - Operates the oven cavity blower.

Also, an internal centrifugal switch on the motor is

utilized to allow the connection of power to the heat

relay when the motor is at operating speed.

Transformer (T1) - Provides 24 VAC power to the

ignition control module and heating circuit.

Motor Control Relay(s) (SG4C/SG6C) - Provides

power to HI and LOW speed motor windings based on

operator requirements.

Solid State Temperature Controller

(SG4D/SG6D) - Monitors temperature sensor and

regulates the oven cavity temperature by controlling

the heat relay through the blower motor centrifugal

switch contacts.

Ignition Control Module - Provide ignition spark and

monitors burner(s) flame current during ignition

sequence.

No Ignition Light (SG4C/SG6C) - Lit when power is

turned ON, during ignition trial and gas purge time and

when no flame is detected by flame sensor. If the

oven fails to ignite after three attempts, it will remain

lit until power is reset.

Temperature Probe (SG4D/SG6D) - This temperature

probe is a thermistor device. A thermistor is a calibrated

resistor which changes resistance with the

temperature. As the temperature increases, the

resistance of the thermistor decreases. The resistance

of the probe is compared to the resistance of the

temperature controller resistor in to control and

maintain temperature.

Temperature Probe (SG4C/SG6C) - This temperature

probe is a J-type thermocouple. As the temperature

increases, a DC voltage is generated within this

thermocouple and compared to a list of temperature

values stored within the cooking computer memory to

control and maintain temperature.

High Limit Thermostat - Protects the oven from

temperatures above 550°F by removing power from

the first valve (safety) on the dual solenoid gas valve

which stops the flow of gas to the burner. Auto resets

at 500°F.

Gas Valve (Dual Solenoid) - Contains two valves.

The first valve is opened when the unit is turned on

and the limit temperature is not exceeded. The second

valve is turned by the heating system. Both valves

must be open in order to get gas to the main burners.

SSR1 and SSR2 (SG4C/SG6C) - When SSR1 is

energized, it connects power to the blower motor for

HI fan speed operation. When SSR2 is energized, it

connects power to blower motor for LOW speed

operation.

Cooling Fan - Circulates cooler air from rear of oven

forward to cool components in the control area.

Ignition Electrode and Flame Sense Device - Ignites

the gas and senses the presence of a flame. The

flame presence generates a micro-amp flame sense

current that is monitored by the ignition control module.

A flame sense current of 1 micro amp (minimum and

stable) is required to maintain burner ignition.

Power On Light (SG4D/SG6D) - Lit whenever the

Master Switch (S1) is turned to ON or OVEN COOL

mode.

Heat Light - Lit whenever temperature controller is

calling for heat.

Computer Control (SG4C/SG6C) - Monitors

temperature sensor and regulates the oven cavity

temperature by controlling the heat relay (R1) through

the blower motor centrifugal switch contacts. Also,

counts the time of the product and signals the

electronic alarm at the end of the cook cycle.

Power Level Control - Selects the percent of heat

input between 22% and 100%. Power level must be

on for oven to work.

– 30 –

Page 31

Plug, Socket and Components (SG4D/SG6D)

SOLID STATE

THERMOSTAT

COOK TIMER

2S

LIGHT SWITCH

CONTROL PANEL

(REAR VIEW)

4

1

2

5

3 6

2

1LT

ON

HEAT

2LT

2

2

3 LT

5 COM 6

3 NO 7

2 (COM AC)

4 (120VAC)

9 (240VAC)

4

NO IGNITION

1

124

5

3 6

1

2

336

1

1

1

4

5

1S

ON/OFF/

COOLDOWN

SWITCH

INDICATOR

LIGHTS

POWER

CONTROL

3S

FAN SWITCH

PORCELAIN

BLOCK

ASSEMBLY

HEAT

RELAY

(R3)

PORCELAIN

BLOCK

ASSEMBLY

COMPONENT PANEL

(FRONT VIEW)

NH

IN

1T

TRANSFORMER

OUT

14

5 8

912

13 14

NH

GROUND

IGNITION

CONTROL

MODULE

BUZZER

1

23

4

56

7

89

10

1112

1P (FEMALE)

(PLUGS VIEWED FROM PIN SIDE)

– 31 –

3

21

6

54

9

87

12

1110

PL-56081-1

Page 32

Plug, Socket and Components (SG4C/SG6C)

COMPUTER

CONTROLLER

CONTROL PANEL

(REAR VIEW)

2J (FEMALE)

2J

789

PIN NUMBERS

456

123

1 EVENT 2 OUT

2 EVENT 1 OUT

3 EVENT COM (IN)

4 EVENT 1 (IN)

5 EVENT 4 OUT

6 EVENT 3 OUT

7 NOT USED

8 POWER 5V

9 EVENT 2 (IN)

1

23456

1 NOT USED

+

2 TC

-

3 TC J TYPE (RED)

4 NOT LISTED

3J (FEMALE)

OPER. TEMP.

0-30 DEG. C

3J

12 9 6

3

11 8 5

2

10 7 4

1

1 NOT USED 7 NOT USED

2 SSRI 8 NOT USED

3 SSRI 9 L2 24V-

4 NOT USED 10 NOT USED

5 NOT USED 11 NOT USED

6 L1 24V- 12 NOT USED

5 NOT USED

6 NOT USED

PORCELAIN

BLOCK

ASSEMBLY

HEAT

RELAY

(R1)

COMPONENT PANEL

(FRONT VIEW)

NHIN

1T

TRANSFORMER

OUT

LOAD

21

34

INPUT

LOAD

21

34

INPUT

14

58

912

SOLID STATE

RELAY (SSR1)

SOLID STATE

RELAY (SSR2)

IGNITION

CONTROL

MODULE

2S

LIGHT

SWITCH

ELECTRONIC

BEEPER

1P (MALE)

2221

1817

1413

109

65

21

13 14

NH

PORCELAIN

12NO IGNITION

1LT

1S

ON/OFF/

COOLDOWN

SWITCH

BLOCK

ASSEMBLY

GROUND

GROUND

1J (FEMALE)

2122

2324

2423

2P (MALE)

3P (MALE)

2019

1615

1211

56 4

23 1

89

61

52

41

1297

118

107

1920

1516

1112

87

43

(PLUGS VIEWED FROM PIN SIDE)

1718

1314

(PLUGS VIEWED FROM

PIN SIDE)

910

56

78

12

34

PL-56082

– 32 –

Page 33

SEQUENCE OF OPERATIONS

2. Set temperature controller dial to desired

temperature.

SG4D/SG6D with Solid State Temperature

Controller

Schematic 424373-1 will be used to explain the

electrical sequence of operation.

Cook Cycle

1. Conditions

A. Oven connected to correct voltage.

1) L1 (HOT) to power switch (S1).

2) L2 (neutral or second line) to one

side of the following components: L1

of the power level control, power ON

light, heat light, temperature controller

board terminal 9 (120VAC) or terminal

10 (208-240 VAC), oven cavity lights,

buzzer, timer motor, heat relay coil

(R3), convection fan motor common

(C), transformer primary T1), motor

speed (Hi/Low) relay coil (R1), hold

relay coil (R2) and the component

cooling fan.

B. Oven properly grounded.

C. Gas supply valve ON.

D. Gas combination control valve ON.

E. Power switch (S1) OFF.

A. Contacts J3 and J5 close.

3. Power switch (S1) is turned ON.

NOTE: Power is available to the oven light switch

A. Component cooling fan energized.

B. ON light (amber) is lit.

C. Power to timer terminal C.

D. Transformer (T1) energized.

1) Power (24 VAC) to one side of the

following components: heat relay (R3)

normally open (N.O.) contact.

2) First valve (safety) on the gas valve

energized. Gas does not flow to the

burner until the 2nd valve (main) is

energized.

3) Ignition module energized.

E. Heating light is lit.

F. Power to one side of centrifugal switch.

G. Convection fan motor is energized through

(S3) high-low.

1) When the convection fan motor

reaches operating speed, the

centrifugal switch (N.O.) on the motor

closes.

F. Oven light switch (S2) ON/OFF (position

has no affect on the function of the

normal cooking cycle).

G. Temperature controller dial set to lowest

temperature (fully counterclockwise).

H. High limit switch closed (position has no

affect on the function of the normal

cooking cycle).

I. Timer in the OFF position.

J. Oven doors closed.

K. Door switch contacts closed.

L. Oven cavity temperature below 140°F.

M. Power level switch to 100%.

H. Heat relay is energized.

1) N.O. contacts close.

(Continued next page)

– 33 –

Page 34

4. Heating circuit is powered.

Timer Cycle

A. No ignition light (red) comes ON.

B. Module performs a self diagnostic test

for 4 seconds.

C. Second valve (main) on the gas valve is

energized. Gas starts to flow to burners.

D. Sparking begins, the no ignition light

goes out and burners light.

NOTE: Sparking continues for up to 7 seconds or until

a flame is established on both burners. If a flame is

sensed on both burners, the no ignition light stays out

and burner remains lit. If a flame is not sensed on both

burners after 7 seconds of sparking, the no ignition

light comes back on, second valve (main) on the gas

valve is de-energized and gas flow to the burner

stops. Ignition trial cycle repeats after a 15 second

purge between cycles for two additional tries before

locking out. To reset after a lockout, turn power

switch (S1) OFF then ON.

5. Oven reaches set temperature.

A. Temperature controller de-energizes

internal relay and the normally open (N.O.)

contacts open.

The timer operates independently of the heating

cycle. Additional time can be set or the timer can be

turned OFF throughout the cooking cycle.

1. With the master switch turned ON, power is

supplied to timer.

A. Set the timer to desired time.

B. Contacts 1 & 3 close, timer motor is

energized and timing down begins.

2. Time expires on timer.

A. Contacts 1 & 3 open, timer motor is

de-energized and timing stops.

B. Contacts 1 & 4 close.

1) Buzzer energized and sounds. The

buzzer continues to sound until the

timer dial is set to the OFF position

or additional time is set.

Cool Down Cycle (Solid State Temperature

Controller)

1. Conditions.

1) Heat light goes out.

B. Power removed from heat relay.

C. Heat relay normally open (N.O.) contacts

OPEN.

D. Power removed from heating circuit.

1) Second gas valve de-energized.

6. The oven will continue to cycle on the

temperature controller until the doors are

opened or master switch (S1) is turned to the

OFF or OVEN COOL position.

A. Oven is ON.

B. Oven cavity temperature needs to be

lowered.

C. Doors are open.

1) Convection fan de-energized.

2) Thermostat de-energized.

a. Heat light out.

b. Power removed from heat relay.

3) 24 V transformer de-energized.

4) Cooling fan de-energized.

– 34 –

Page 35

2. Power switch (S1) turned to COOL DOWN.

SG4C/SG6C with Computer Controller

A. Power to fan speed switch (S3). Set fan

speed switch to either HI or LO.

3. If door is closed, power is supplied to one

side of the following components:

A. Power ON light (Amber) comes ON.

B. Transformer (T1) energized.

1) Power (24 VAC) to one side of the

following components: heat relay (R3)

normally open (N.O.) contacts, high

limit connected through the normally

closed (N.C.) contacts to the first

valve (safety) on the dual solenoid

gas valve.

a. First valve (safety) on the gas

valve energized. Gas does not

flow to the burner until the second

valve (main) is energized.

C. Component cooling fan.

D. Power to timer and oven cavity lights.

4. The oven will remain in this condition until the

master switch (S1) is turned to the OFF or ON

position.

Schematic 426575-1 will be used to explain the

electrical sequence of operation.

Normal Cook Cycle

1. Conditions

A. Oven connected to correct voltage.

1) L1 (hot) to power switch (S1).

2) L2 (neutral or second line) to one side

of the following components: oven

cavity lights, convection fan motor

common (C), transformer primary

(T2), component cooling fan and the

heat relay coil (R1).

B. Oven properly grounded.

1) Ground (GND) to one side of the

following components: computer

control case, no ignition light,

transformer secondary (T2), ignition

control module, the first valve (safety)

and second valve (main) on the dual

solenoid gas valve and computer

control pin 9 (C3-9).

C. Gas supply valve ON.

D. Gas combination control valve ON.

E. Power switch (S1) OFF.

F. Computer control is set up properly and

ready to use.

G. Oven lights switch (S2) ON or OFF

(position has no affect on the function of

the normal cook cycle).

H. High limit thermostat closed.

I. Oven doors closed.

J. Oven cavity temperature below 140°F.

2. Power switch (S1) turned ON.

A. Power (120 VAC) to computer control pin

3 (C3-3). Power at pin 3 is not transferred

to other components until computer

control is energized and operation

conditions are met.

B. Power is available to the oven light switch

(S2).

– 35 –

Page 36

C. Power to terminal 1 on solid state relay 1

SSR1-load side and solid state relay 2

SSR2-load side.

D. Component cooling fan energized.

E. Transformer (T1) is energized, 24 volt

output.

1) Power (24 VAC) to one side of the

following components: heat relay (R1)

normally open (N.O.) contacts, high

limit connected through the normally

closed (N.C.) contacts to the first

valve (safety) on the dual solenoid

gas valve.

2) First valve (safety) on the gas valve

energized. Gas does not flow to the

burner until the second valve (main)

is energized.

3) Ignition module energized.

4) Power (24 VAC) to the oven computer

control.

3. Control is energized and performs a power on

self test before energizing outputs. If the

control passes self test, then the outputs are

energized and operation sequence continues,

If control does not pass self test, then the

corresponding error code is displayed.

NOTE: Control retains last temperature set.

B. Heat relay coil (R1) energized.

1) (R1) contacts (N.O.) close and the

heating circuit is powered.

2) Oven heat light on the control comes

on.

C. Ignition module is energized.

1) Heating circuit is powered.

2) No ignition light (red) comes ON.

3) Module performs a self-diagnostic

test for 4 seconds.

4) Second valve (main) on the gas valve

is energized. Gas starts to flow to

burners.

5) Sparking begins, the no ignition light

goes out and burners light.

NOTE: Sparking continues for up to 7 seconds or until

a flame is established on both burners. If a flame is

sensed on both burners, the no ignition light stays out

and burner remains lit. If a flame is not sensed on both

burners after 7 seconds of sparking, the no ignition

light comes back on, second valve (main) on the gas

valve is de-energized and gas flow to the burner

stops. Ignition trial cycle repeats after a 15 second

purge between cycles for two additional tries before

locking out. To reset after a lockout, turn power

switch (S1) OFF then ON.

A. Computer control senses oven cavity

temperature.

1) With the oven cavity temperature

below set point, the controls

120 VAC output from pin C3-2 is

activated and power is connected to

the common (C) side of the blower

switch contacts on the convection

fan motor.

2) The controls 5 VDC output from pins

C2-2 (-) and C2-8 (+) is activated and

SSR1 relay is energized.

a. Convection fan motor is

energized (fan speed on HI).

3) When the convection fan motor

reaches operating speed:

a. The blower switch (N.O.) on the

motor closes.

4. Oven reaches set point temperature.

A. Computer control deactivates the

120 VAC output to heat relay (R1).

1) Heat relay (R1) de-energized and the

normally open (N.O.) contacts open.

B. Power removed from ignition control

module.

1) The second valve (main) on the gas

valve is de-energized and gas flow to

the burner stops.

– 36 –

Page 37

2) Oven heat LED on the control goes out.

3) Oven ready LED on the control comes

ON.

4) Electronic beeper sounds momentarily.

C. The oven will continue to cycle on the

computer control until the doors are opened

or power switch (S1) is turned to the OFF or

COOL DOWN position.

Temperature and Time Cycle (Normal Cooking)

B. The computer control 5 VDC output from

pins C2-1 (-) and C2-8 (+) is activated and

SSR2 relay is energized.

1) Power (120 VAC) is applied to the

convection fan motor low speed

terminal.

3. At the end of the cook time, the electronic

beeper sounds momentarily to indicate the

end of the first stage cooking (oven operates

normally at the temperature and time selected