VULCAN Pool Heater

Installation & Operating Manual

Important Notes!

Thank you for purchasing the VULCAN direct electric swimming pool

heater manufactured in England to the highest standards.

To ensure your new heater will give years of trouble free service please

carefully read the following instructions. Incorrect installation will

a ect your warranty.

Do not discard this manual, please retain for future reference.

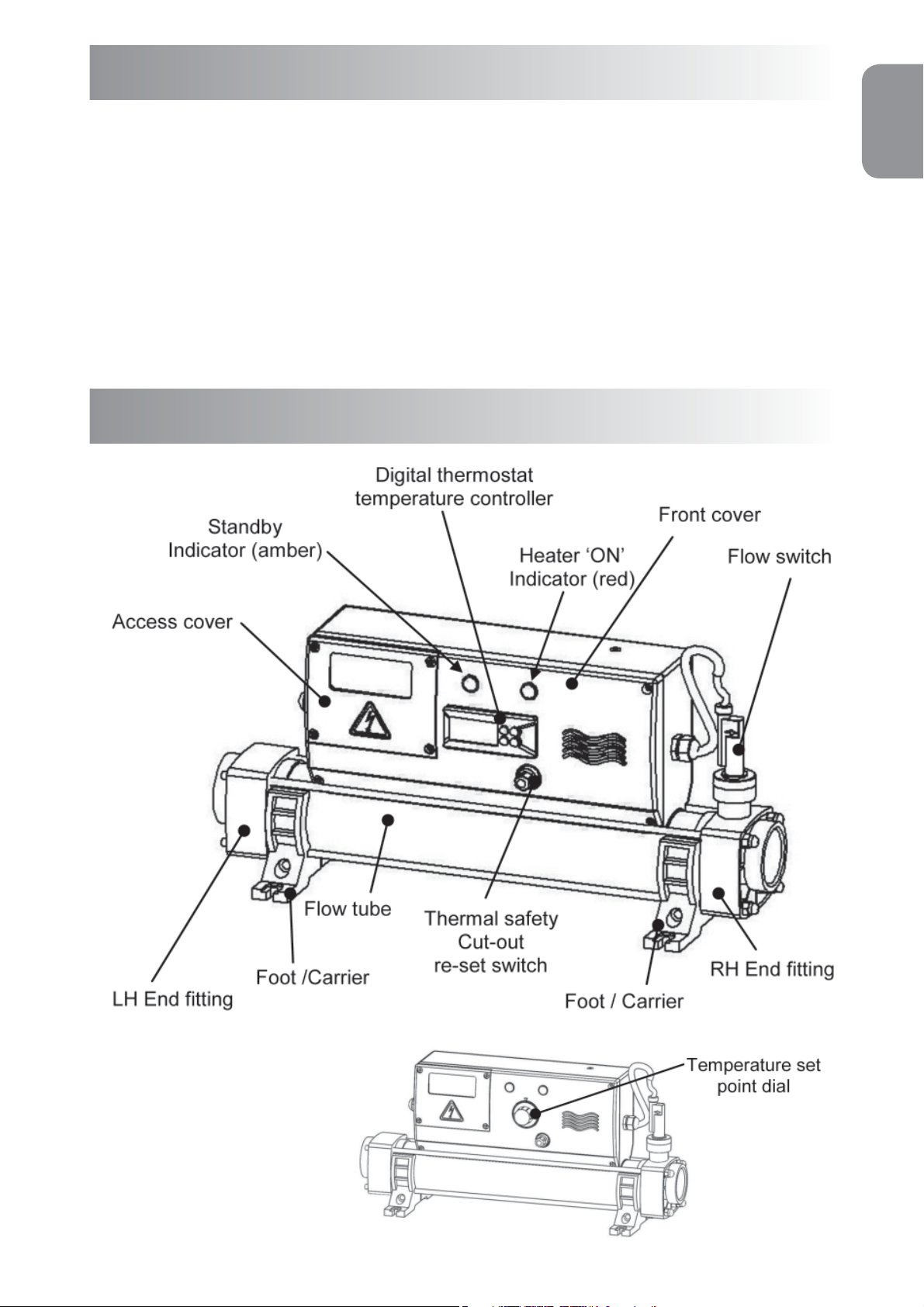

Product Overview

ENGLISH

DIGITAL

Version

ANALOGUE

Version

Fig 1.

1

ENGLISH

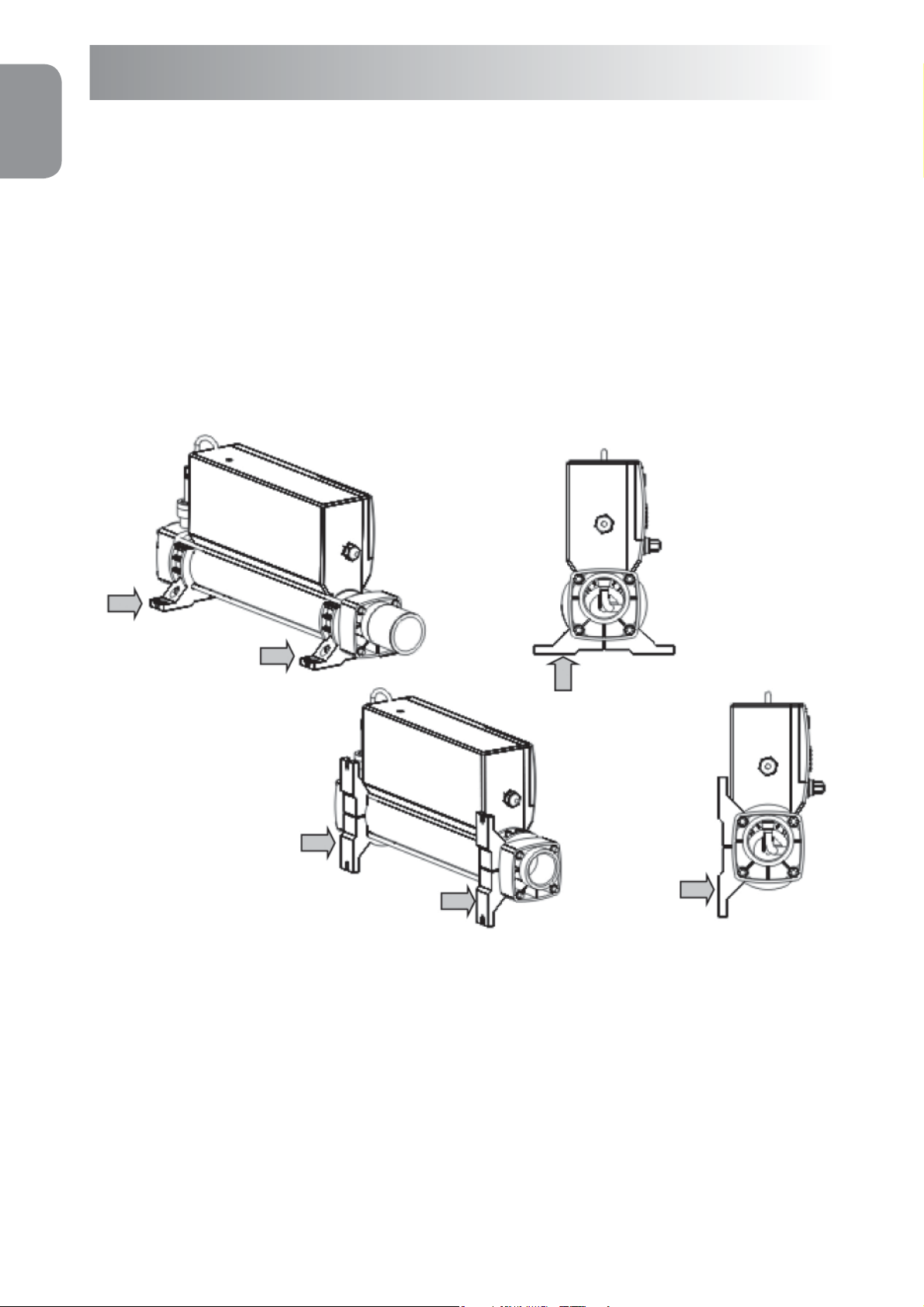

Positioning

Your heater must be horizontally or vertically sited allowing su cient

space for pipe connections and wiring, it should be screw xed securely to

a rm base or wall.

NOTE: See gure 2 for details of the foot arrangement when securing

to the wall or oor.

Floor mount ‘Foot position’

Fig 2.

Factory set oor

mount ‘Foot position’

To reset for wall

mount option,

undo the bolts and

re-assemble in the

vertical position as

shown.

Wall mount ‘Foot position’

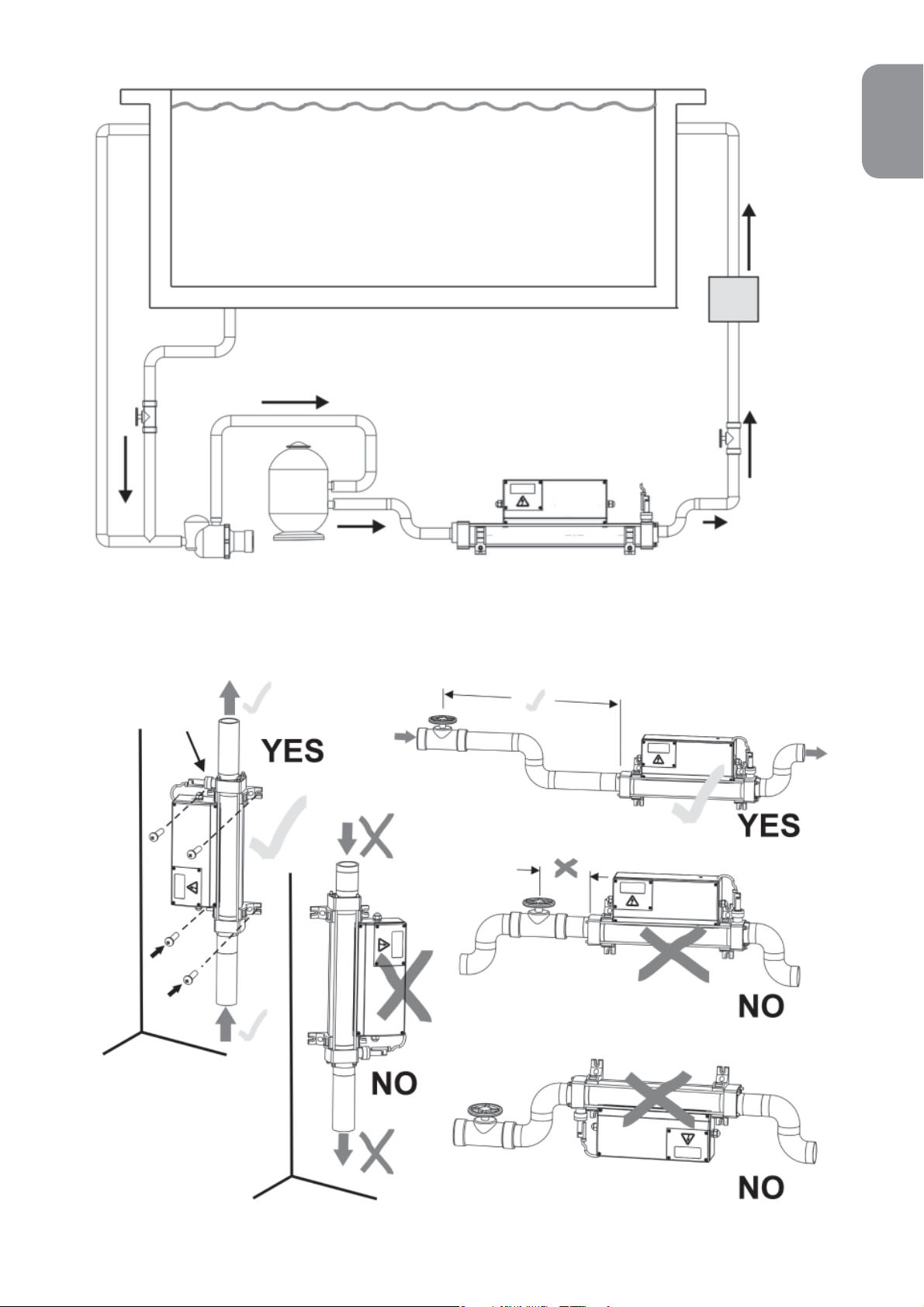

The heater should be installed at a low point in the ltration system.

It should be positioned downstream (after) of the lter and upstream

(before) of any dosing or other water treatment plant. (see g.3)

NOTE : If the ow direction is reversed (explained later in this

booklet) the heater must remain sited after the lter.

2

Fig 3.

PUMP

FILTER

POOL

ENGLISH

WATER

TREATMENT

VALVE

NON RETURN

VULCAN HEATER

Flow switch

at top

For vertical wall

mounting water

must always enter

at the bottom

Fig 4.

3

ENGLISH

Pipe Work

It is essential that the pipe work connecting to and from the heater

has a minimum bore (internal diameter) of 1¼” (32mm). To assist correct air

purging and to ensure the heater remains completely full of water during

operation, the return pipe which carries the water back to the pool must

incorporate a safety loop or ‘kick-up’ in the pipe as close as possible to the

heater (see g 4)

NOTE: When coupling to a exible pipe a safety loop can simply be

created by routing the pipe up and over an obstacle.

Remember to use pipe clips to securely fasten all hose connections.

Weather Protection

The heater must be installed within a dry weather proof enclosure.

Caution! If the heater is not used during winter months it must be drained to

prevent frost damage.

Electrical Connection

The heater must be installed in accordance with the country / regional

requirements & regulations. In any event the work must be carried out by

a quali ed electrician, who will provide a certi cate of conformity upon

completion of the work. The power supply must be tted with a RCD. If

required your electrician may replace the supplied cable entry gland with a

larger size to secure the cable powering the heater, this will not a ect your

warranty if carried out by a quali ed electrician.

Cable section: This should be calculated at 5-amp / mm for distances

up to 20 metres (these sections are indicative and should be checked and

adapted if necessary for cable lengths over 20 metres.

Remove Access Cover

to make the electrical

connections

(Quali ed electricians only)

Fig 5.

4

Power Requirements

Power

Output

3 - kW 230 13

4.5 - kW 230 20

6 - kW 230 27

9 - kW 230 40

12 - kW 230 53

15 - kW 230 66

Voltage

Amp

(V)

3 Phase

Power

Output

6 - kW 400 / 230V 9 / 15

9 - kW 400 / 230V 13 / 23

12 - kW 400 / 230V 18 / 31

15 - kW 400 / 230V 22 / 38

400 V Star /

230 V Delta

Amp

Flow Requirements

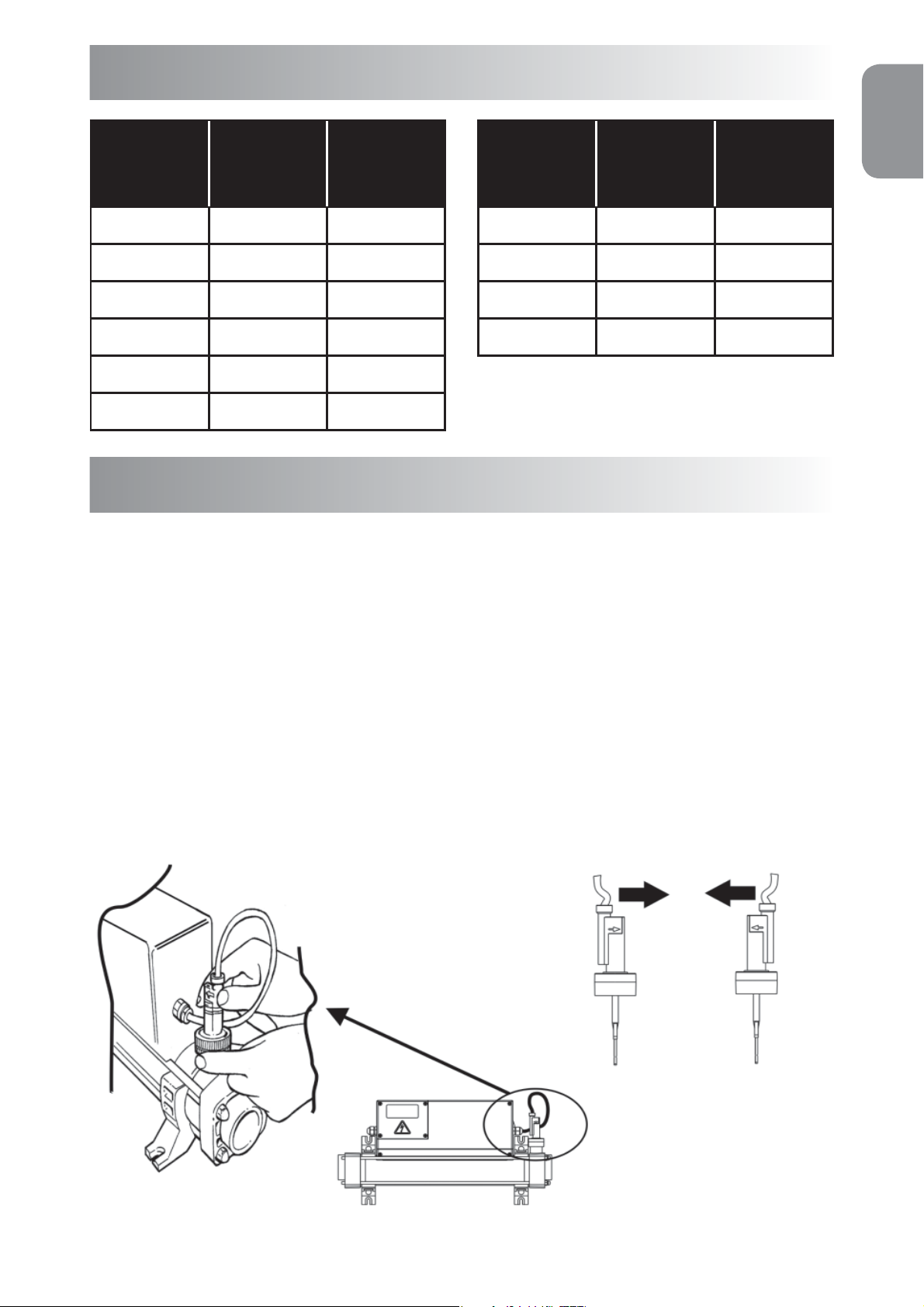

Your heater is factory set to accept input water ow entering on the left

and exiting on the right, this can be reversed by rotating the ow switch

ENGLISH

180 degrees (ie:½ turn, see g 6)

Warning! The ow switch paddle can be damaged when reversing the ow

direction if it is lifted by more than 5mm from its housing and turned with

force. If the ow switch has been rotated it is important to ensure that it is

nally locked in the correct orientation perpendicular (at right angles) to the

ow of water.

To reverse ow:

Loosen cap and rotate

Flow switch by 180 degrees

as shown. Always ensure

the arrow marked on the

plastic ow switch body is

in the same direction as the

water ow.

Factory set ow

Flow

Optional reverse

o w

Fig 6.

5

Loading...

Loading...