Vulcan-Hart CEM10U ML-138077, CEM20U, CEM6U ML-138076, CEM6U, ML-138076 Installation & Operation Manual

...Page 1

ELECTRIC

COMBINATION OVEN

MODELS

CEM6U ML-138076

CEM10U ML-138077

INSTALLATION &

OPERATION MANUAL

CEM20U ML-138078

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanequipment.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANEQUIPMENT.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

FORM 37466 (09-10)

Page 2

ELECTRIC COMBI OVEN

— 2 —

Page 3

ELECTRIC COMBI OVEN

TABLE OF CONTENTS

INSTALLATION, OPERATION AND CARE OF ELECTRIC COMBI OVEN ..................................5

GENERAL...................................................................................................................................5

UNPACKING ...............................................................................................................................5

INSTALLATION ...........................................................................................................................5

INSTALLATION CODES AND STANDARDS ...........................................................................5

COMBINATION OVEN STAND ASSEMBLY INSTRUCTIONS ................................................ 6

Unpacking ............................................................................................................................. 6

Assembly ..............................................................................................................................6

LOCATION ..................................................................................................................................7

LEVELING ................................................................................................................................... 7

ELECTRICAL SPECIFICATIONS ..............................................................................................7

Power Supply .......................................................................................................................8

Grounding .............................................................................................................................8

WATER REQUIREMENTS ........................................................................................................8

Water Treatment .................................................................................................................. 8

Water Supply Connection....................................................................................................9

Filter System ........................................................................................................................9

Drain Connection .............................................................................................................. 10

VENT HOOD ........................................................................................................................... 10

BEFORE FIRST USE ............................................................................................................. 10

OPERATION ................................................................................................................................. 11

OPERATING CONTROLS LOCATION.................................................................................. 11

Optional Internal Product Probe ....................................................................................... 11

Oven Vent Valve ................................................................................................................ 12

Oven Convection Fan ....................................................................................................... 12

Cooking Selector Knob ..................................................................................................... 12

Warming - Rethermalization Mode .................................................................................. 13

Combined Cooking............................................................................................................ 13

Convection Cooking .......................................................................................................... 13

Steam Cooking .................................................................................................................. 14

Thermostat Controlled Steam Cooking ........................................................................... 14

Oven Temperature Display .............................................................................................. 14

Oven Temperature Button ................................................................................................ 15

Oven Temperature Selector Knob ................................................................................... 15

Oven Timer Button............................................................................................................ 15

Oven Timer Knob .............................................................................................................. 15

Humidity Control ................................................................................................................ 16

Oven Light Button ............................................................................................................. 16

— 3 —

Page 4

ELECTRIC COMBI OVEN

TABLE OF CONTENTS (CONTINUED)

Fan Speed Selector .......................................................................................................... 16

Product Probe Temperature Selector Knob .................................................................... 17

Internal Product Temperature Probe Button ................................................................... 17

COOKING ................................................................................................................................18

Cooking with The Internal Product Probe ........................................................................ 18

Cook and Hold ................................................................................................................... 19

Displaying and Modifying Cooking Settings ..................................................................... 19

Cooking Settings ............................................................................................................... 19

CHANGE COOKING SETTINGS ............................................................................................ 20

Manually Lowering The Oven Temperature..................................................................... 20

Automatically Lowering Oven Temperature .................................................................. 20

DAILY SHUTDOWN ................................................................................................................ 20

EXTENDED SHUTDOWN ...................................................................................................... 20

CLEANING ..................................................................................................................................... 22

OVEN DRAINS ........................................................................................................................ 22

OVEN COMPARTMENT ......................................................................................................... 22

Daily ................................................................................................................................... 22

Weekly ............................................................................................................................... 22

DOOR GASKET ...................................................................................................................... 22

STAINLESS STEEL EQUIPMENT CARE AND CLEANING .................................................. 23

Recommended cleaners for specific situations ............................................................. 24

Review ............................................................................................................................... 24

MAINTENANCE ............................................................................................................................. 25

WATER TREATMENT SYSTEM ............................................................................................ 25

DOOR GASKET REPLACEMENT ......................................................................................... 25

OVEN LIGHT REPLACEMENT............................................................................................... 25

REMOVAL OF LIME SCALE DEPOSITS .............................................................................. 25

MESSAGES AND ALARMS .......................................................................................................... 26

MESSAGES ............................................................................................................................. 26

ALARMS................................................................................................................................... 26

TROUBLESHOOTING .................................................................................................................. 27

SERVICE AND PARTS INFORMATION ...................................................................................... 28

— 4 —

Page 5

ELECTRIC COMBI OVEN

INSTALLATION, OPERATION AND CARE OF

ELECTRIC COMBI OVEN

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

GENERAL

Vulcan electric combination ovens are

produced with quality workmanship and

material. Proper installation, usage and

maintenance will result in many years of

satisfactory performance. It is suggested that

you thoroughly read this entire manual and

carefully follow all of the instructions provided.

It is a convection oven and a pressureless

steam oven combined into one. The steam is

generated inside the oven and circulated by a

fan. With the combined oven/steamer, three

cooking processes are available: Steam, hot

air, and combination. The combined oven

may be used to perform these types of cooking:

• Steam Cooking

• Baking

• Stewing

• Browning

INSTALLATION

Before installing, verify that the electrical supply

agrees with the specifications on the data

plate located on the lower front corner of the

right side panel. If the supply and equipment

requirements do not agree, do not proceed

with the installation. Contact your dealer or

Vulcan-Hart immediately.

This oven is shipped pre-wired with one of

the following voltages: 208/60/3, 240/60/3 or

480/60/3 VAC.

INSTALLATION CODES AND

STANDARDS

In the United States of America, the oven must

be installed in accordance with:

1. State and local codes.

2. National Electrical Code, ANSI/NFPA-70

(latest edition). Copies may be obtained

from The National Fire Protection

Association, Batterymarch Park, Quincy,

MA 02269.

• Grilling

• Braising

• Pre-Cooking

• Reheating

• Defrosting

Unpacking

Each oven is inspected before leaving the

factory. The transportation company assumes

full responsibility for safe delivery upon

acceptance of the shipment.

Immediately after delivery, unpack and check

for shipping damage. If the oven is damaged,

save the packing material and contact the

carrier immediately. There is a fifteen-day

limitation on filing freight damage claims with

the freight company. Freight damage is not

covered under warranty.

3. Vapor Removal from Cooking Equipment,

(NFPA-96, latest edition) available from NFPA.

In Canada, Vulcan-Hart ovens must be

installed in accordance with:

1. Local Codes

2. Canadian Electrical Code (CSA C22.2

No. 3, latest edition) available from the

Canadian Standards Association, 5060

Spectrum Way, Mississauga, Ontario,

Canada L4W 5N6

— 5 —

Page 6

ELECTRIC COMBI OVEN

COMBINATION OVEN STAND

ASSEMBLY INSTRUCTIONS

Unpacking

Each Combination Oven Stand is inspected

before leaving the factory. The transportation

company assumes full responsibility for safe

delivery upon acceptance of the shipment.

Immediately after delivery unpack and check

for shipping damage. If the stand is damaged,

save the packing material and contact the

carrier immediately. There is a fifteen-day

limitation on filing freight damage claims with

the freight company. Freight damage is not

covered under warranty.

Assembly

NOTE: Discard washers from kit.

Follow these procedures to properly assemble

the Adjustable Combination Oven Stand.

1. Remove the adjustable feet from the

bottom of the stand.

Allen Cap Screw

Figure 2: Allen Cap Screw Location

3. Push the leg onto the leg support and turn

the leg until the threaded holes are visible.

Insert the bolts and tighten them. Repeat

this step on each leg.

4. Once the legs are installed each leg must

be rotated so that the threaded holes, for

the tray support, face each other (front

and rear). These holes are used to mount

a tray support once the oven is installed on

the stand. The tray support will be installed

after the oven is installed on the stand. If

tray support is not used, insert the plastic

plugs into the four holes in the base.

Remove

adjustable

feet

Figure 1: Stand Foot Removal

2. Using the 10 mm Allen wrench, loosen but

do not remove the cap screw securing the

leg support to the stand base.

Align holes

Make sure

holes are

facing

each other

FRONT

Figure 3: Leg with Threaded Holes

in Proper Position

5. Tighten the Allen Cap screws in the base

of each leg.

6. Reattach the adjustable feet. The stand is

now ready for oven installation.

— 6 —

Page 7

ELECTRIC COMBI OVEN

7. Install tray support (if supplied) after oven

is installed onto stand. Use the four knurled

screws to secure the support to the legs.

FRONT

Figure 4: Assembled

Combination Oven Stand

LOCATION

Allow space for operating the oven. Do not

obstruct the ventilation port above the oven.

To provide ventilation access, allow 1" of

1

clearance on the left side of the oven and 2

/2"

clearance on the rear side of the oven. A

minimum of 18" must be provided on the right

side of the oven for operation, cleaning and

service. An optional heat shield assembly is

required if the clearance is less than 18" on

the right side of the oven.

LEVELING

Position the oven in its final installed location.

Place a level on the horizontal area of the

cabinet. Adjust the feet to level the oven in

both the left-to-right and front-to-rear

directions.

ELECTRICAL SPECIFICATIONS

The data plate is located on the front lower

right side of the oven.

Electrical Specifications Chart

Model Voltage Amperage Kilowatts Phase

CEM6U 208 26 9.4 3

CEM6U 240 25 10.3 3

CEM6U 480 11 9.4 3

CEM10U 208 43 15.5 3

CEM10U 240 40 16.8 3

CEM10U 480 19 15.5 3

CEM20U 208 54 19.5 3

CEM20U 240 48 24.0 3

CEM20U 480 27 22.1 3

— 7 —

Page 8

ELECTRIC COMBI OVEN

POWER SUPPLY

Connect the power supply as follows:

Electrical and grounding

connections must comply with applicable

portions of the National Electrical Code

and/or other local electrical codes.

Disconnect

the electrical power to the

machine and follow Lockout/

Tagout procedures.

1. Remove the right side panel from the oven.

The panel is held on by two screws on the

bottom and one screw on the top near the

back edge.

2. Wire to be sized per the National Electric

Code. Use copper wire rated for 125°C max.

3. Route the power supply cable through the

cable strain relief.

4. Connect the power supply cable to the

terminal block as shown on the label below

the terminal block.

5. Fasten the cable clamp firmly.

6. Reinstall the right side panel.

Plumbing connections must

comply with applicable sanitary, safety and

plumbing codes.

WATER REQUIREMENTS

Proper water quality can improve the taste of

the food prepared in the oven, reduce liming in

the oven cavity and extend equipment life.

Local water conditions vary from one location

to another. Ask your municipal water supplier

for details about your local water supply prior

to installation.

Presence of sediment, silica, excess chlorides or

other dissolved solids may lead to a

recommendation for alternate form(s) of water

treatment. Test the water with a TDS meter or the

test strip included with the oven. Other factors

affecting steam generation are iron content, amount

of chlorination and dissolved gasses.

Water Treatment

A local water treatment specialist should be

consulted before installing steam generating

equipment. It is recommended that you have

your water tested.

Supply Pressure 20-60 psig

L1 L2 L3

Power

Cord

L1 L2 L3

1234567

¥L1¥L2¥

PE

PE

89

L3

Terminal Block

10

Wiring Label

Figure 5: Power Supply Cable Connection

Grounding

The oven must be properly grounded.

Connect the ground conductor to the

terminal block in the position indicated on

the terminal block label.

Hardness* Less than 3 grains

Silica Less than 13 ppm

Total Chlorine/ 0 ppm

Chloramine**

Chlorides*** Less than 30 ppm

PH Range 7 – 8

Undissolved Solids Less than 5 microns

* 17.1 ppm = 1 grain of hardness

** Total Chlorine of 4.0 ppm is the max limit for the

building water supply. A carbon block filter must still be

used to remove all Chlorine and Chloramines from the

water. Failure to do so will result in corrosion and rust in

the cooking cavity which is not covered under warranty.

*** If the Chlorides exceed 30 ppm and the oven is

used more than 8 hours during the day in steam or

combination mode the cavity will require rinsing every

8 hours. Failure to do so will result in corrosion and

rusting of the oven cavity and interior parts. RO water

treatment system can be installed to eliminate

chlorides from the water and reduce the hardness.

— 8 —

Page 9

ELECTRIC COMBI OVEN

If the water supply fails to meet these

standards, it will be necessary to install a

water treatment system.

The use of strainers or filters will not remove

minerals from the water

Water Supply Connection

Connect the treated cold water supply line,

3

min of

/8" ID, to the 3/4" garden hose inlet on

the underside of the Combi Oven. Connect

3

the untreated cold water supply line to the

/4"

garden hose, also on the underside of the

Combi Oven. Refer to Figures 6 and 7.

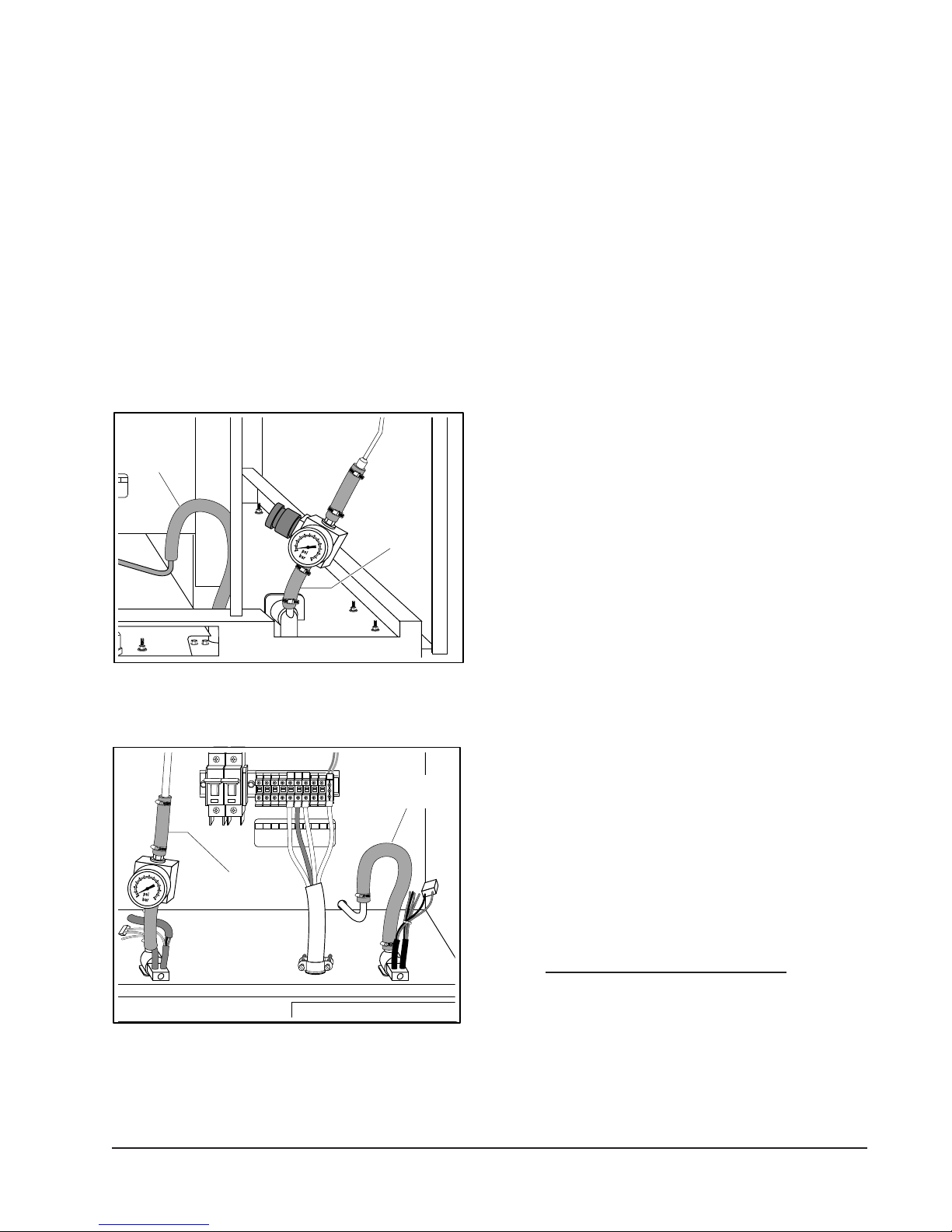

Unfiltered

water

supply

9

10

Filtered

water

supply

A water filter system is required for the water

supply line going to the treated water inlet of your

Combi Oven. Follow the recommendations for

use and installation instructions shipped with

the water filter. If a water filter is not installed, the

Combi Oven warranty is limited.

NOTE: Failure to properly connect the water

lines will result in equipment failure

that is not covered under warranty.

A manual shutoff valve must be provided in a

convenient location near the Combi Oven.

Filter System

• In addition to filtration for the control of

solids, you must have a carbon block filter

installed and maintained. Carbon block

filters remove the chlorine and chloramines

disinfectants from the water. Chlorine/

chloramines will erode the oven cavity,

rack guides, racks, and internal

components, which is not covered under

warranty. Check with your local water

treatment specialist for proper sizing and

replacment intervals for the carbon block

cartridge.

Figure 6: Water Supply Connection

for CEM6U and CEM10U

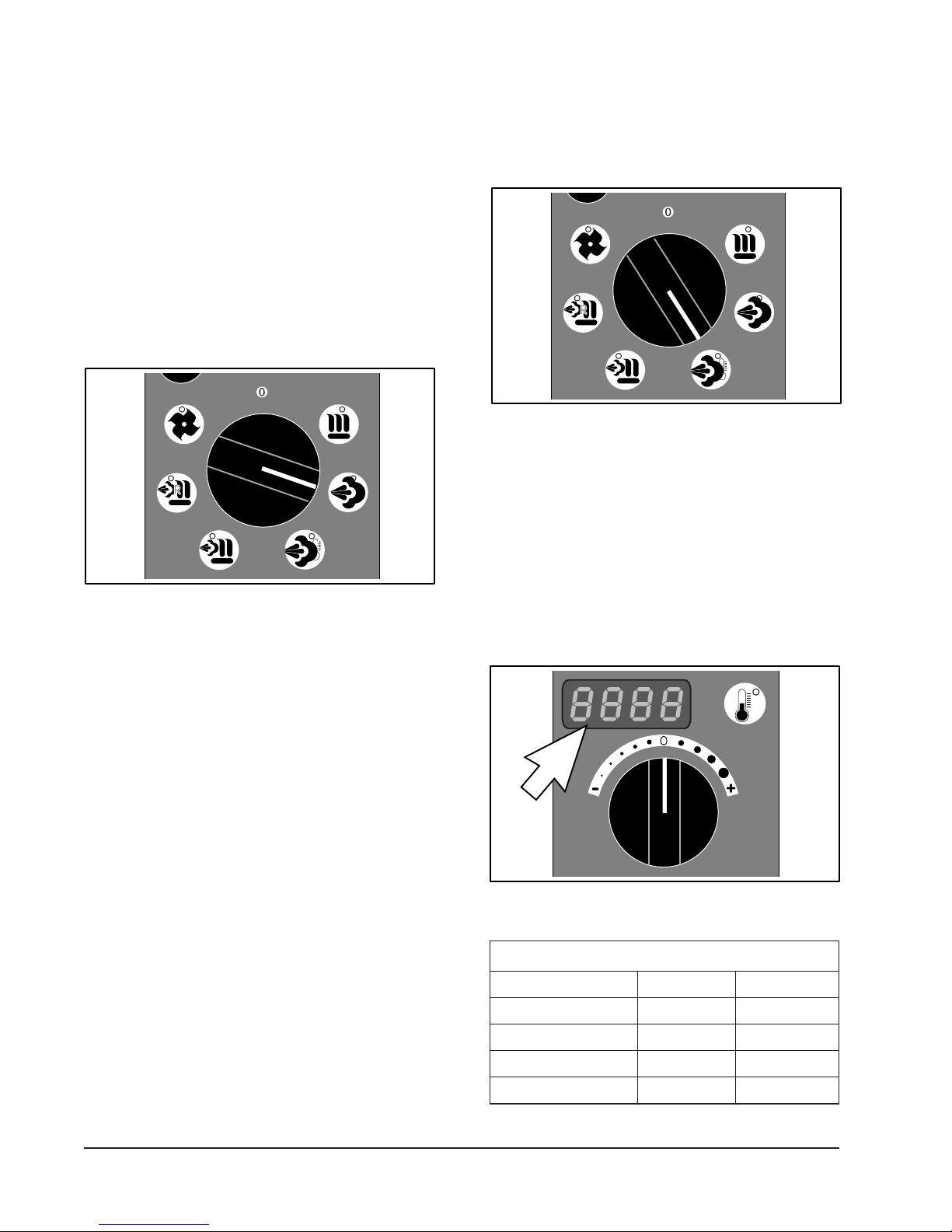

L1 L2 L3

PE

Unfiltered Water

Connection

PE

L1 L2 L3

1234567

Filtered Water

Connection

¥L1¥L2¥

89

10

L3

Figure 7: Water Supply Connections

for CEM20U

• Water feed lines to the oven must be flushed

before final connection. Particles in the water

could clog tubing and components that

supply water for steam production and drain

cooling. If the water supply is not free of

sediment or cloudy after several minutes of

flushing, a sediment filter must be installed

before use.

• If you have purchased a water filter

system from Vulcan-Hart, please follow

the instructions provided with the filter

system. At the time of installation you

must register your Combi Oven at

www.vulcanhart.com/filterreg or use the

reply card supplied with your unit. You will

need to register your Combi Oven at each

filter change to insure your standard and

extended warranty is maintained.

Filter purchase invoices and maintenance

records must be provided with warranty claims.

— 9 —

Page 10

ELECTRIC COMBI OVEN

DRAIN CONNECTION

In order to avoid any backpressure

in the oven, do not make a solid connection to

any drain. Failure to do so can damage the

oven and will void the warranty.

OR

12" (305 mm)

min.

Figure 8: Drain Connection

The 1¼" NPT threaded fitting on the drain

outlet must be extended a minimum of 12"

(305 mm) – maximum of 72" (1829 mm)

away from the Comb Oven base, to an open

air gap type drain. Do not reduce the 1¼"

NPT drain piping throughout its length.

Not supplied

VENT HOOD

Local codes may require the oven to be located

under an exhaust hood. Information on the

construction and installation of ventilating

hoods may be obtained from Vapor Removal

from Cooking Equipment, NFPA Standard No.

96 (latest edition).

BEFORE FIRST USE

Before using the oven for the first time, it must

be “burned in” to release any odors that might

result from heating the new surfaces in the

oven. Remove the racks and rack guides and

thoroughly clean in sink with soap and water.

Thoroughly clean with soap and water the

interior of the oven. Refer to cleaning

instructions in this manual. Operate the oven

at maximum thermostat setting for 45 minutes

in Convection Mode.

Make sure the hinged back of the oven cavity

is completely closed and the thumb screws

are secured properly.

Install the rack guides and racks.

Provide a suitable floor sink with a minimum

depth of 12" (305 mm). The floor sink is NOT

to be directly under the oven and should be at

a distance so that steam vapors will not enter

the Combi Oven from underneath. The drain

should slope down away from the oven ¼" for

every foot of drain pipe length. The drain pipe

should be either iron or copper. DO NOT use

PVC pipe; PVC pipe may lose its rigidity or

glue may fail.

In order to avoid any back pressure in the

oven, do not connect solidly to any drain

connection.

— 10 —

Page 11

6

7

8

9

12

15

17

18

21

2

3

4

5

10

11

13

14

19

20

1

16

OPERATION

The oven and its parts are

hot. Use care when operating, cleaning or

servicing the oven. The cooking

compartment contains live steam. Stay

clear while opening the door.

OPERATING CONTROLS LOCATION

The Control Panel consists of the following

controls, which are explained in the

OPERATING CONTROLS FUNCTION section

of this manual:

1. Oven Vent Valve

2. Oven Convection fan

3. Cooking Selector Knob

4. Warming - Rethermalization

5. Combination Cooking

6. Off

7. Convection Cooking

8. Steam Cooking

9. Thermostat Controlled Steam Cooking

10. Oven Temperature Display (LED)

11. Oven Temperature Adjustment Knob

12. Oven Temperature Button

13. Oven Time Display (LED)

14. Oven Time Adjustment Knob

15. Oven Timer Button

16. Humidity Control (Spritzer), (Humidity

Injector)

17. Oven Light Button

18. Fan Speed Selector Button (Full & Half

Speed)

ELECTRIC COMBI OVEN

Optional Internal Product Probe

19. Internal Product Probe Temperature

Display (LED)

20. Internal Product Probe Temperature

Adjustment Knob

21. Internal Product Probe Button Control

panel.

Figure 9: Operating Control Location

— 11 —

Page 12

ELECTRIC COMBI OVEN

Oven Vent Valve

The Oven Vent Valve opens or closes the Vent

to adjust the amount of steam venting from the

oven. Pull the Oven Vent Valve out to open it.

Push it in to close it.

Figure 10: Oven Vent Valve

Oven Convection Fan

Cooking Selector Knob

The Cooking Selector Knob has seven

selectable positions corresponding to the

different cooking modes of the oven, or the off

position as shown. When a cooking mode is

selected, the respective LED light will flash

and after a few seconds, the control panel will

illuminate, indicating that the oven is prepared

for cooking.

NOTE: Select the desired cooking mode at

least ten minutes prior to cooking to

allow the oven to pre-heat and be

ready for cooking.

When the Oven Convection Fan is on, the LED

will be illuminated. The Oven Convection Fan

can be used to rapidly lower the oven

temperature. The Oven Timer Adjustment Knob

must be set to continuous, or a specific time

must be set, and the door must be closed in

order for the Oven Convection Fan to operate.

For quicker cool down, press the Humidity

Control button twice. This injects approximately

5 gal/h of water into the oven, cooling it faster.

Figure 12: Cooking Selector Knob

Figure 11: Oven Convection Fan

— 12 —

Page 13

ELECTRIC COMBI OVEN

Warming - Rethermalization Mode

Use the rethermalization mode to warm-up

(rethermalize) refrigerated foods. Warming is

accomplished in the combined mode at a

temperature range of 210°F (100°C) to 518°F

(270°C) on low speed.

Cold food shall not be added to the unit for

rethermalization while hot food is being held.

The Oven Timer Adjustment Knob must be

set to continuous, or a specific time must be

set, and the door must be closed in order for

the Oven Convection Fan to operate.

NOTE: It is recommended that the Vent Valve

remain open while warming food.

Foods cook quickly and brown evenly while

keeping the product moist and flavorful.

The Oven Timer Adjustment Knob must be

set to continuous, or a specific time must be

set, and the door must be closed in order for

the Oven Convection Fan to operate.

Figure 14: Combined Cooking

Convection Cooking

Figure 13: Warming - Rethermalization

Combined Cooking

The temperature range for combined cooking

is from 212°F (100°C) to 518°F (270°C). The

default value is 302°F (150°C). This cooking

method combines the benefits of steam and

convection. With combined cooking, cooking

time can be reduced from 5% to 50% even for

foods such as potatoes, carrots, etc. With

combined cooking it is possible to steam

foods and then glaze them to make them

crispy. Foods such as roasts, hams, etc.,

minimize their loss of weight and moisture.

For cooking temperatures ranging from 68°F

(20°C) to 518°F (270°C), hot air is evenly

distributed in the oven by a convection fan.

The default value is 302°F (150°C). This

method of cooking is ideal for baking, roasting,

toasting and grilling.

The Oven Timer Adjustment Knob must be

set to continuous, or a specific time must be

set, and the door must be closed in order for

the Oven Convection Fan to operate.

Figure 15: Convection Cooking

— 13 —

Page 14

ELECTRIC COMBI OVEN

Steam Cooking

The main advantage of steaming is the

nutritional values are maintained. It is the

most efficient means of cooking and the food

does not lose its moisture. Steaming is

conducted at 212°F (100°C). In the steam

mode the convection fan does not start until

the oven reaches 176°F (80°C).

The Oven Timer Adjustment Knob must be

set to continuous, or a specific time must be

set, and the door must be closed in order for

the Oven Convection Fan to operate.

Adjustment Knob must be set to continuous,

or a specific time must be set, and the door

must be closed in order for the Oven

Convection fan to operate.

Figure 17: Thermostat Controlled

Steam Cooking

Oven Temperature Display

Figure 16: Steam Cooking

Thermostat Controlled Steam Cooking

The temperature range for thermostatically

controlled steam cooking is from 68°F (20°C)

to 210°F (99°C). This method of cooking is

ideal for foods that have already been

processed, portioned and vacuum packaged.

The main advantages of this method of cooking

are the ability to cook in batches, food is

preserved longer, there is minimal weight

loss and the nutritional values are maintained.

After selecting the desired cooking method,

the Oven Temperature Display will display the

default temperature. The default temperature

is 302°F (150°C) During cooking, the display

will indicate the set temperature of the oven.

Figure 18: Oven Temperature Display

Temperature Ranges

Mode °F °C

Steam 212°F 100°C

Rethermalization 210–518°F 100–270°C

Combined 212–518°F 100–270°C

Convection 68–518°F 20–270°C

— 14 —

Page 15

ELECTRIC COMBI OVEN

Oven Temperature Button

During a cooking cycle, press the Oven

Temperature Button to display current oven

temperature.

Figure 19: Oven Temperature Button

Oven Temperature Selector Knob

The Oven Temperature Selector Knob is used

to change the desired oven cooking

temperature. Press the Oven Temperature

Button, then turn the Oven Temperature

Selector Knob clockwise to increase or counter

clockwise to decrease setting. The Oven

Temperature Button must be pressed to

change the temperature during operation.

Oven Timer Button

The Oven Timer button is used to change the

timer display and to silence the audible end of

the cook cycle alarm. During cooking, the

timer displays the remaining time. Pushing

the Oven Timer button toggles the display to

the oven set time.

Figure 21: Oven Timer Button

Oven Timer Adjustment Knob

The Oven Timer Adjustment Knob is used to

change the desired oven cooking time. To

adjust the time, turn the timer knob clockwise

to increase the time or counterclockwise to

decrease the time. The oven can also be

placed in continuous cooking mode by turning

the Oven Timer Adjustment Knob

counterclockwise until “Cont” displays.

Figure 20: Oven Temperature

Selector Knob

Figure 22: Oven Timer Adjustment Knob

— 15 —

Page 16

ELECTRIC COMBI OVEN

Humidity Control

The Humidity Control button controls the

level of moisture in the oven. This is essential

for cooking products with low moisture

content such as bread, biscuits, cakes and

soft items. The Humidity Control button is

also used to prevent roasts from burning or

losing their moisture. The Humidity Control

button has two positions. Pressing the

button once (the left LED will illuminate)

injects approximately 1 Gal/h (4 l/h) of water

into the oven while cooking. Pressing the

button again (the right LED will illuminate)

injects approximately 5 Gal/h (18 l/h) of

water into the oven while cooking. To turn

the Humidity Control off, press the button

again (both LED lights will extinguish).

NOTE: The humidity control button only works

in Convection Cooking and Oven

Convection Fan modes.

LED

Figure 23: Humidity Control

Oven Light Button

The Oven Light button turns the oven light on

or off when the oven is on.

LED

Figure 24: Oven Light

Fan Speed Selector

The Fan Speed Selector controls the speed of

the Oven Convection Fan. This makes it

possible to reduce the amount of air in the

oven for cooking delicate items that require

less airflow. The button has two positions;

Low speed and High speed. High is used for

fast cooking while Low is used for cooking

delicate items or for steaming. The LED lights

in the corner of the button correspond to the

fan speed selected. Pressing the button once

will select the Low Speed setting and the left

LED will be illuminated. Pressing the button

again will select the High Speed setting and

the right LED will be illuminated.

LED

Figure 25: Fan Speed Selector

— 16 —

Page 17

ELECTRIC COMBI OVEN

Internal Product Probe Temperature

Selector Knob

The optional Internal Product Probe that can

be attached to maintain specific internal

cooking temperatures. The temperature range

is from 68°F (20°C) to 210°F (99°C). For such

items as roast-beef, pâté, etc., the internal

cooking temperature is important to maintain.

By using the Internal Product Probe, the oven

will switch off when the desired internal cooking

temperature is reached. Setting the

temperature for the Internal Product Probe

disables the cook time timer. The Internal

Product Probe can be used with all the optional

cooking methods: steaming, convection

cooking, combined cooking. The internal

temperature guide for cooking with the Internal

Product Probe can be found on page 21.

The Internal Product Probe Temperature

Selector Knob controls the desired internal

cooking temperature sensed by the Internal

Product Probe. To adjust the desired internal

temperature, turn the selector knob clockwise

to increase the internal temperature or

counterclockwise to decrease the internal

temperature.

Internal Product Temperature

Probe Button

Press the Internal Product Temperature Probe

Button to display the current internal

temperature of the product being cooked.

Figure 27: Internal Product Temperature

Probe Button (if Installed)

Figure 26: Internal Product Probe

Temperature Selector Knob (if Installed)

— 17 —

Page 18

ELECTRIC COMBI OVEN

COOKING

Make sure the hinged back of the oven cavity

is completely closed and the thumb screws

are secured properly.

To start up oven:

1. Select the desired cooking mode.

2. Select the desired cooking time by turning

the selector knob clockwise to the desired

time. The Oven Timer Adjustment Knob

must be set to continuous, or a specific

time must be set, and the door must be

closed in order for the Oven Convection

Fan to operate.

Turning the timer knob counterclockwise until

“Cont” displays will place the oven in

continuous cooking mode.

When the desired time is reached the oven will

stop, an audible alarm will sound for one (1)

minute and the display will change to “End”.

2. Place the product with probe in place, in or

near the center of the oven.

3. Remove the protective cap and insert the

probe electrical connector into the probe

connection on the oven as shown below

(Figure 28).

Internal

Product

Temperature

Probe

Probe

Electrical

Connector

3. To cancel the audible alarm, press the

Timer Display button.

In order to set a new cooking time, the Timer

Display button must first be pressed.

4. To cancel continuous cooking, place the

Oven Timer Knob to zero or turn the

Cooking Selector Knob to 0.

In the 212°F (100°C) steam mode, the

convection fan will not come on until the oven

temperature reaches 176°F (80°C). This

allows the product to be cooked when the fan

is not on.

The oven is equipped with a cooling fan for the

internal components. It will start when the

oven is on and stop approximately ten (10)

minutes after the oven is turned off.

Cooking with the Internal Product

Temperature Probe

To cook using the Internal Product

Temperature Probe:

1. Insert the probe into the product to be

cooked. Place the tip of the probe in or

near the center of the product.

Figure 28: Cooking with the

Internal Product Temperature Probe

4. Close the oven door.

5. Select the desired cooking method.

6. Push the Internal Product Temperature

Probe LED button. The button LED will

illuminate. The display will show a pre-set

temperature and the minute counter

display will be deactivated.

7. Select the desired internal cooking

temperature. After a few seconds, the

oven will begin cooking and the product

internal temperature will be displayed.

8. During the cooking cycle, the minute

counter will display the amount of elapsed

time.

9. Cooking will stop when the product internal

temperature reaches the desired set

temperature.

If the probe exceeds 212°F (100°C) “Ovl”

(Overtemp) will show in the display.

The oven will automatically enter the Cook

and Hold Mode when the desired product

internal temperature is reached.

— 18 —

Page 19

ELECTRIC COMBI OVEN

If the Internal Product Temperature Probe is

hot at the start of the cooking cycle due to

oven pre-heating, the display will flash until

the actual temperature of the food is displayed

and then cooking will commence.

Cook and Hold

Cook and Hold is only available when using

the Internal Product Temperature Probe. At

the end of the cooking cycle, the product is

kept warm without its temperature falling below

158°F (70°C). The oven will maintain 158°F

(70°C) as long as the product is in the hold

mode. The display will flash “Hold” for ten (10)

minutes. If the oven is not switched off or the

product removed after ten (10) minutes, the

display will change to a steady “Hold”. The

Timer Display button can be pressed to see

how long the product has been in Hold mode.

To exit the Cook and Hold mode, turn the

Selector Knob to 0.

DISPLAYING AND MODIFYING

COOKING SETTINGS

NOTE: If probe is removed without changing

the cooking mode alarm PGno will

display. When changing from probe to

time cooking, you must switch the

mode to time or PGnu will display.

Figure 29: Cooking Settings

Cooking Settings

The setting can be changed at any time by

pressing one of the buttons displayed in Figure

29. When selected, the appropriate LED will

illuminate. The display will show either the

oven temperature, the set time or the Internal

Product Temperature Probe temperature.

After a few seconds, the LED will extinguish

and the display will change back to the

previous display.

— 19 —

Page 20

ELECTRIC COMBI OVEN

Change Cooking Settings

To change either the set temperature, timer or

internal temperature while cooking:

1. Press the relevant button and the LED will

illuminate.

2. Turn the knob.

After a few seconds, the new parameter will

be accepted and the LED will extinguish.

Manually Lowering The Oven Temperature

To manually lower the oven temperature:

1. Close the oven door.

2. Turn selector knob to Oven Convection

Fan position and open vent.

3. Select the desired temperature.

4. The oven temperature will lower to the

desired temperature set.

DAILY SHUTDOWN

1. Place the Selector Knob to 0 (OFF).

2. Clean the oven interior.

3. Leave door open.

EXTENDED SHUTDOWN

1. Perform DAILY SHUTDOWN procedure.

2. Turn off the circuit breakers.

3. Turn off the water supply.

4. Thoroughly clean the oven interior, door

seals, etc.

5. Leave door open.

Automatically Lowering Oven Temperature

If steaming or thermostatic steaming is

selected while the oven is still hot, water is

injected into the oven. This is so that the oven

temperature can be lowered quickly and

prevents food from being cooked at too high of

a temperature.

— 20 —

Page 21

ELECTRIC COMBI OVEN

Safe Cooking Temperatures

After desired cooking temperature is reached, remove meat from heat source and let stand 10 to 15 minutes before

carving. The amount of time required for resting varies with the size of the cut of your meat. During this resting time, the

meat continues to cook (meat temperature will rise 5 to 20 degrees after it is removed from the heat source) and the

juices redistribute.

NOTE: For additional information on safe cooking temperatures, refer to USDA Safe Food Handling.

Beef and Lamb

Roasts, Steaks & Chops

Rare 120 to 125°F (49 to 52°C) Center is bright red, pinkish toward the exterior portion.

Medium Rare 130 to 135°F (55 to 57°C) Center is very pink, slightly brown toward the exterior portion.

Medium 140 to 145°F (60 to 63°C) Center is light pink, outer portion is brown.

Medium Well 150 to 155°F (66 to 68°C) Not pink.

Well Done 160°F (71°C) and above Steak is uniformly brown throughout.

Ground Meat 160 to 165°F (71 to 74°C) No longer pink but uniformly brown throughout.

Beef Brisket 160°F (71°C) and above

Casseroles and Left overs 165°F (74°C)

Poultry

Poultry (Chicken & Duck) 165°F (74°C) Cook until juices run clear.

Turkey 165°F (74°C) Juices run clear – leg moves easily.

Stuffing (cooked alone or in turkey) 165°F (74°C)

Pork

Roasts, Steaks & Chops

Medium 140 to 145°F (60 to 63°C) Pale pink center.

Well Done 160°F (71°C) and above Steak is uniformly brown throughout.

Pork ribs, pork shoulders,

and pork loin 160°F (71°C) and above Medium to well done.

Sausage (raw) 160°F (71°C) No longer pink.

Ham

Raw 160°F (71°C)

Pre cooked 140°F (60°C)

Seafood

Fish (steaks, filleted or whole) 140°F (60°C) Flesh is opaque, flakes easily.

Tuna, Swordfish, & Marlin 125°F (52°C) Cook until medium rare.

Shrimp

Medium size, boiling 3 to 4 minutes Cook until medium rare.

Large size, boiling 5 to 7 minues Cook until medium rare.

Jumbo size, boiling 7 to 8 minutes Cook until medium rare.

Lobster

Boiled, whole 1 lb. 12 to 15 minutes Meat turns red and opaque in center when cut.

Broiled, whole 1 1/2 lbs. 3 to 4 minutes Meat turns red and opaque in center when cut.

Steamed, whole 1 1/2 lbs. 15 to 20 minutes Meat turns red and opaque in center when cut.

Baked, tails each 15 minutes Meat turns red and opaque in center when cut.

Broiled, tails each 9 to 10 minutes Meat turns red and opaque in center when cut.

Scallops

Bake 12 to 15 minutes Milky white or opaque, and firm.

Broil Milky white or opaque, and firm.

Clams, Mussels & Oysters Point at which their shells open – throw away any that do not open.

(Do not overcook or the meat will become dry and lose its flavor.)

(Do not overcook or the meat will become dry and lose its flavor.)

(Do not overcook or the meat will become dry and lose its flavor.)

(Do not overcook or the meat will become dry and lose its flavor.)

— 21 —

Page 22

ELECTRIC COMBI OVEN

CLEANING

NOTE: Do not use any cleaners (soaps,

detergents, disinfectants) that contain

chlorine or chlorides.

OVEN DRAINS

To keep the oven drain free of blockage:

1. Inspect the oven drain daily for any

blockage.

2. Remove any particles or debris from the

perforated strainer daily (more often if

needed).

After cooking greasy foods or seafood:

1. Make a solution of warm water and

detergent and pour ½ gallon (1.9 liters) of

it down into the compartment drain.

2. Rinse by pouring ½ gallon (1.9 liters) of hot

water down the drain.

Weekly

1. Thoroughly clean the exposed surfaces

(sides, front, door and top) with a damp

cloth.

2. Polish with a clean cloth.

3. To remove discolorations, use a

nonabrasive cleaner.

Door Gasket

1. Clean the gasket-sealing surface of the

oven doors to remove food acids for

maximum gasket life. Do not use any

solvents or sharp instruments.

2. Wash with a cloth moistened in a solution

of mild detergent and warm water.

3. Rinse with a fresh cloth moistened with

warm water to remove all traces of

detergent.

OVEN COMPARTMENT

Daily

1. Remove the oven racks and rack guides.

2. Wash the inside of the oven compartment

with a solution of warm water and detergent.

3. Rinse with warm water.

4. Remove the drain hole cover and wash

with a solution of warm water and nonchloride detergent.

5. Rinse with warm water.

4. Wipe dry with a clean cloth.

Never apply food oils or petroleum

lubricants directly to the door gasket.

Petroleum-based solvents and lubricants will

reduce the gasket life.

Leave Oven Door Open

Leave the oven door slightly open when the

oven is not in use. When the oven is idle, never

latch the door and apply pressure to the door

gasket. Leaving the gasket under pressure

can cause permanent deformation and reduce

the gasket life.

— 22 —

Page 23

ELECTRIC COMBI OVEN

STAINLESS STEEL EQUIPMENT

CARE AND CLEANING

Contrary to popular belief, stainless steels

ARE susceptible to rusting.

Corrosion on metals is everywhere. It is

recognized quickly on iron and steel as

unsightly yellow/orange rust. Such metals are

called “active” because they actively corrode

in a natural environment when their atoms

combine with oxygen to form rust.

Stainless steels are passive metals because

they contain other metals, like chromium,

nickel and manganese that stabilize the atoms.

400 series stainless steels are called ferritic,

contain chromium, and are magnetic; 300

series stainless steels are called austenitic,

contain chromium and nickel; and 200 series

stainless, also austenitic, contains

manganese, nitrogen and carbon. Austenitic

types of stainless are not magnetic, and

generally provide greater resistance to

corrosion than ferritic types.

With 12-30 percent chromium, an invisible

passive film covers the steel’s surface acting as

a shield against corrosion. As long as the film is

intact and not broken or contaminated, the metal

is passive and stainless. If the passive film of

stainless steel has been broken, equipment

starts to corrode. At its end, it rusts.

steel. Other deposits from food preparation and

service must be properly removed.

Chlorides are found nearly everywhere. They

are in water, food and table salt. One of the

worst chloride perpetrators can come from

household and industrial cleaners.

So what does all this mean?

Don’t Despair!

Here are a few steps that can help prevent

stainless steel rust.

1. Use the proper tools.

When cleaning stainless steel products,

use non-abrasive tools. Soft cloths and

plastic scouring pads will not harm steel’s

passive layer. Stainless steel pads also

can be used, but the scrubbing motion

must be in the direction of the

manufacturer’s polishing marks.

2. Clean with the polish lines

Some stainless steel comes with visible

polishing lines or “grain.” When visible

lines are present, always scrub in a motion

parallel to the lines. When the grain cannot

be seen, play it safe and use a soft cloth or

plastic scouring pad.

3. Use alkaline, alkaline chlorinated or

non-chloride-containing cleaners.

Enemies of Stainless Steel

There are three basic things which can break

down stainless steel’s passivity layer and

allow corrosion to occur.

1. Mechanical abrasion

2. Deposits and water

3. Chlorides

Mechanical abrasion means those things that

will scratch a steel surface. Steel pads, wire

brushes and scrapers are prime examples.

Water comes out of the faucet in varying degrees

of hardness. Depending on what part of the

country you live in, you may have hard or soft

water. Hard water may leave spots, and when

heated leave deposits behind that if left to sit, will

break down the passive layer and rust stainless

While many traditional cleaners are loaded

with chlorides, the industry is providing an

ever-increasing choice of non-chloride

cleaners. If you are not sure of chloride

content in the cleaner used, contact your

cleaner supplier. If your present cleaner

contains chlorides, ask your supplier if

they have an alternative. Avoid cleaners

containing quaternary salts; it also can

attack stainless steel and cause pitting

and rusting.

4. Treat your water.

Though this is not always practical,

softening hard water can do much to

reduce deposits. There are certain filters

that can be installed to remove distasteful

and corrosive elements. To insure proper

water treatment, call a treatment specialist.

— 23 —

Page 24

ELECTRIC COMBI OVEN

5. Keep your food equipment clean.

Use alkaline, alkaline chlorinated or nonchloride cleaners at recommended strength.

Clean frequently to avoid build-up of hard,

stubborn stains. If you boil water in stainless

steel equipment, remember the single most

likely cause of damage is chlorides in the

water. Heating cleaners that contain chlorides

has a similar effect.

6. Rinse, rinse, rinse.

immediately. The sooner you wipe off

standing water, especially when it contains

cleaning agents, the better. After wiping

equipment down, allow it to air dry; oxygen

helps maintain the stainless steel’s

passivity film.

7. Never use hydrochloric acid (muriatic

acid) on stainless steel.

8. Regularly restore/passivate stainless

steel.

If chlorinated cleaners are used, rinse and

wipe equipment and supplies, and dry

Recommended cleaners for specific situations

JOB CLEANING AGENT COMMENTS

Routine cleaning Soap, ammonia, Apply with cloth or sponge

detergent, Medallion

Fingerprints & smears Arcal 20, Lac-O-Nu Ecoshine Provides barrier film

Stubborn stains & Cameo, Talc, Zud, Rub in direction of polish lines

discoloration First Impression

Grease & fatty acids, Easy-off, De-Grease It Oven Aid Excellent removal on all

blood, burnt-on-foods finishes

Grease & oil Any good commercial detergent Apply with sponge or cloth

Restoration/Passivation Benefit, Super Sheen

Review

1. Stainless steels rust when passivity (filmshield) breaks down as a result of scrapes,

scratches, deposits and chlorides.

2 Stainless steel rust starts with pits and

cracks.

3. Use the proper tools. Do not use steel

pads, wire brushes or scrapers to clean

stainless steel.

5. Soften your water. Use filters and softeners

whenever possible.

6. Wipe off cleaning agent(s) and standing

water as soon as possible. Prolonged

contact causes eventual problems.

To learn more about chloride-stress corrosion

and how to prevent it, contact the equipment

manufacturer or cleaning materials supplier.

4. Use non-chlorinated cleaners at

recommended concentrations. Use only

chloride- free cleaners.

Developed by Packer Engineering, Naperville, Ill., an

independent testing laboratory.

Provided courtesy of NAFEM.

— 24 —

Page 25

MAINTENANCE

Light Lens

Lens Gasket

Light Bulb

ELECTRIC COMBI OVEN

The oven and its parts are

hot. Use care when operating, cleaning or

servicing the oven. The cooking

compartment contains live steam. Stay

clear while opening the door.

Water Treatment System

A water treatment system is recommended

for the combination oven. Refer to the

supplier’s manual for normal maintenance

procedures for proper scale-free operation.

Removal of Lime Scale Deposits

The oven cavity should be delimed when symptoms

occur (see Troubleshooting Chart). This is in

accordance with the minimum preventive

maintenance schedule required by warranty.

Items required (not provided):

• Deliming material (Recommended product

Scale Release™)

Door Gasket Replacement

Call your local service agent to replace the

gasket.

Oven Light Replacement

Do not touch new bulb glass with

bare hand.

1. Remove the oven rack and rack guides to

gain access to the light/s.

2. Remove the screws securing the light

lens to the cabinet.

3. Carefully remove the lens avoid damaging

the lens gasket.

4. Remove and replace the defective light bulb.

5. If the gasket has come loose, secure it.

6. Reinstall the lens cover making sure the

gasket is properly seated.

• Plastic or rubber gloves

• Safety goggles or face shield

• Measuring cup

• 1-gallon container for mixing the deliming

solution

Deliming solution may cause the surface

of aluminum measuring tools to tarnish or etch.

Figure 30: Oven Light

— 25 —

Page 26

ELECTRIC COMBI OVEN

MESSAGES AND ALARMS

Messages

When applicable, the Oven Timer LED will display the following messages:

LCD DISPLAY MESSAGE DESCRIPTION

door The oven door is open, or the door drip tray is not in place or is missing.

Cont The Selector Knob has been rotated counterclockwise and

the oven has been placed in continuous operation mode.

HoLd (Flashing) Cook cycle is complete and oven is entering the Cook and

Hold mode.

HoLd (Steady) The oven is in Cook and Hold mode.

End Cooking has ended.

Alarms

When applicable, the Control Panel LED will display the following alarms:

LCD ALARM DISPLAY DESCRIPTION

P1NO Oven temperature sensor broken or disconnected.

P6NO Internal Product Probe is broken and/or disconnected (it is still

possible to operate the oven without the Internal Product Probe).

P7NO Oven internal electrical compartment temperature has

exceeded 158°F (70°C).

NOT Convection Fan Motor failure

*OUL Internal Product Probe temperature has exceeded 210°F (99°C).

*VOLT The power supplied to the oven is either too high or too low

for proper operation.

*EEP Invalid parameter entry.

OVF The internal product probe temperature has exceeded

212°F (use symbol)/ 100°C.

* IMPORTANT: If any of the last three alarms are displayed, it is recommended that an Authorized

Vulcan-Hart service provider be called to examine and/or repair the oven.

— 26 —

Page 27

ELECTRIC COMBI OVEN

TROUBLESHOOTING

Problem Possible Cause / Suggested Corrective Action

Oven not heating/steaming No main power source / Check power source or circuit breaker.

Cooking Selector Knob in 0 position / Turn Selector Knob to

the desired cooking operation.

Door is open / Close the door.

Oven door leaks Damaged door gasket / Check door gasket for damage. If

adjustment or replacement is needed, contact your Authorized

Vulcan-Hart service provider.

Damage to gasket sealing surface / Contact your Authorized

Vulcan-Hart service provider.

Oven does not cook evenly Products may be too close together / Check to make sure

there is good air circulation between the products.

Product is dry Product humidity too high / Set Humidity Control to proper

setting.

Oven temperature too high / Set oven to correct temperature to

product being cooked.

Water accumulates in the oven Plugged drain or screen / Remove the cover from the oven drain

compartment and check for any obstructions.

Oven not leveled properly / See leveling instructions in the

INSTALLATION section of this manual.

Water not being supplied to the oven Water Manual Shutoff Valve is off / Turn the Manual Shutoff

Valve on.

Water pressure too low / Check water supply pressure.

Water filter is plugged / Refer to water filter manual. If symptom

persists, contact your Authorized Vulcan-Hart service provider.

Valve inlet screen is clogged / Contact your Authorized

Vulcan-Hart service provider.

Unit shuts down while operating Hi Limit trip / Contact your Authorized Vulcan-Hart service

provider.

— 27 —

Page 28

ELECTRIC COMBI OVEN

SERVICE AND PARTS INFORMATION

To obtain service and parts information, contact the Vulcan-Hart Service Agency

in your area or refer to our website www.vulcanequipment.com for a complete listing of authorized

service and parts providers.

When calling for service the following information must be available:

• Model Number

• Serial Number

• Manufacture Date (MD)

• Voltage

(09-10)

— 28 —

PRINTED IN U.S.A.

Loading...

Loading...