Page 1

GAS 2/3 JACKETED

INSTALLATION &

OPERATION MANUAL

STATIONARY

AND

TILTING KETTLES

MODELS

K20GL ML-136090

K40GL ML-136091

K60GL ML-136092

K20GLT ML-136094

K40GLT ML-136095

K60GLT ML-136096

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanequipment.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANEQUIPMENT.COM

K40GL

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

FORM 35461 (June 2012)

Page 2

GAS KETTLES

IMPORTANT FOR YOUR

SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORT

ANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN

GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

SHUTOFF VALVE

AND CONTACT THE LOCAL

FOR YOUR

SAFETY

DO

NOT STORE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ

THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

OR USE

IMPROPER INSTALLATION, ADJUSTMENT,

GASOLINE

OR OTHER FLAMMABLE

IN THE EVENT OF A POWER FAILURE, DO

OPERATE THIS DEVICE.

RETAIN THIS INSTRUCTION MANUAL FOR FUTURE

REFERENCE

NOT

ATTEMPT TO

— 2 —

Page 3

GAS KETTLES

— 3 —

CONTENTS

GENERAL

INSTALLATION

Unpacking......................................................................................................................................5

Installation Codes and Standards..................................................................................................5

Draw-Off Valves.............................................................................................................................5

Gas Connections ...........................................................................................................................6

Gas Connection Data ....................................................................................................................7

Testing the Gas Supply System.....................................................................................................7

Gas and Altitude Conversion .........................................................................................................8

Flue................................................................................................................................................9

Faucet Bracket ..............................................................................................................................9

Electrical Connection .....................................................................................................................9

Location .......................................................................................................................................10

Leveling

Before First Use

OPERATION......................................................................................................................................

Controls and Indicators................................................................................................................12

Before Operation .........................................................................................................................13

Operation .....................................................................................................................................13

Daily Shut Down ..........................................................................................................................13

Extended Shut Down ...................................................................................................................13

Venting.........................................................................................................................................14

Reservoir Jacket Water Level Check...........................................................................................14

Tilting Kettles ...............................................................................................................................14

Operating Data ............................................................................................................................14

STAINLESS STEEL EQUIPMENT CARE AND CLEANING

CLEANING

Compression Draw-Off Valve Cleaning Instructions....................................................................17

Plug Valve Cleaning Instructions .................................................................................................18

MAINTENANCE

Venting.........................................................................................................................................19

Filling The Reservoir Jacket ........................................................................................................19

Shutdown.....................................................................................................................................19

Service.........................................................................................................................................19

TROUBLESHOOTING ......................................................................................................................

...........................................................................................................................................

...................................................................................................................................

.......................................................................................................................................

...........................................................................................................................

..............................................................

........................................................................................................................................

................................................................................................................................

4

5

11

11

12

15

17

19

20

Page 4

GAS KETTLES

INSTALLATION, OPERATION AND

MAINTENANCE O F KGL AND KGLT

GAS

KETTLES

SERIES

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

V

ulcan gas 2/3 jacketed kettles are produced with quality workmanship and material. Proper installation,

usage and maintenance will result in many years of satisfactory performance. It is suggested that you

thoroughly read this entire manual and carefully follow all of the instructions provided.

Model K40GL Model K40GLT

MODEL CHART

Model Gallons Quarts Liters

K20GL & K20GLT 20 80 76

K40GL & K40GLT 40 160 152

K60GL & K60GLT 60 240 228

— 4 —

Page 5

GAS KETTLES

— 5 —

INSTALLATION

UNPACKING

This kettle was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment.

Immediately after unpacking, check for possible shipping damage. If kettle damage is found, save the

packaging material and contact the carrier within 15 days of delivery. Freight damage is not covered

under Vulcan Warranty.

INSTALLATION CODES AND STANDARDS

In the United States, Vulcan kettles must be installed in accordance with:

1. State and local codes.

2. National Fuel

Gas

Code, ANSI-Z223.1 (latest edition). Copies may be obtained from the American

Gas Association, Inc.; 1515 Wilson Blvd.; Arlington, VA 22209.

3. National Electrical Code, ANSI/NFPA-70 (latest edition).

4. NFPA Standard NFPA-96, Vapor Removal from Cooking Equipment, latest edition, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada, Vulcan ket tles must be installed in accordance with:

1. Local codes.

2. CAN/CGA-B149.1 National Fuel Gas Code (latest edition), available from the Canadian Gas

Association; 178 Rexdale Blvd.; Etobicoke, Ontario; Canada M9W 1R3.

3. CSA C22.2 No. 3 Canadian Electrical Code (latest edition), available from the Canadian Standards

Association, 178 Rexdale Boulevard, Etobicoke, Ontario, Canada M9W1R3

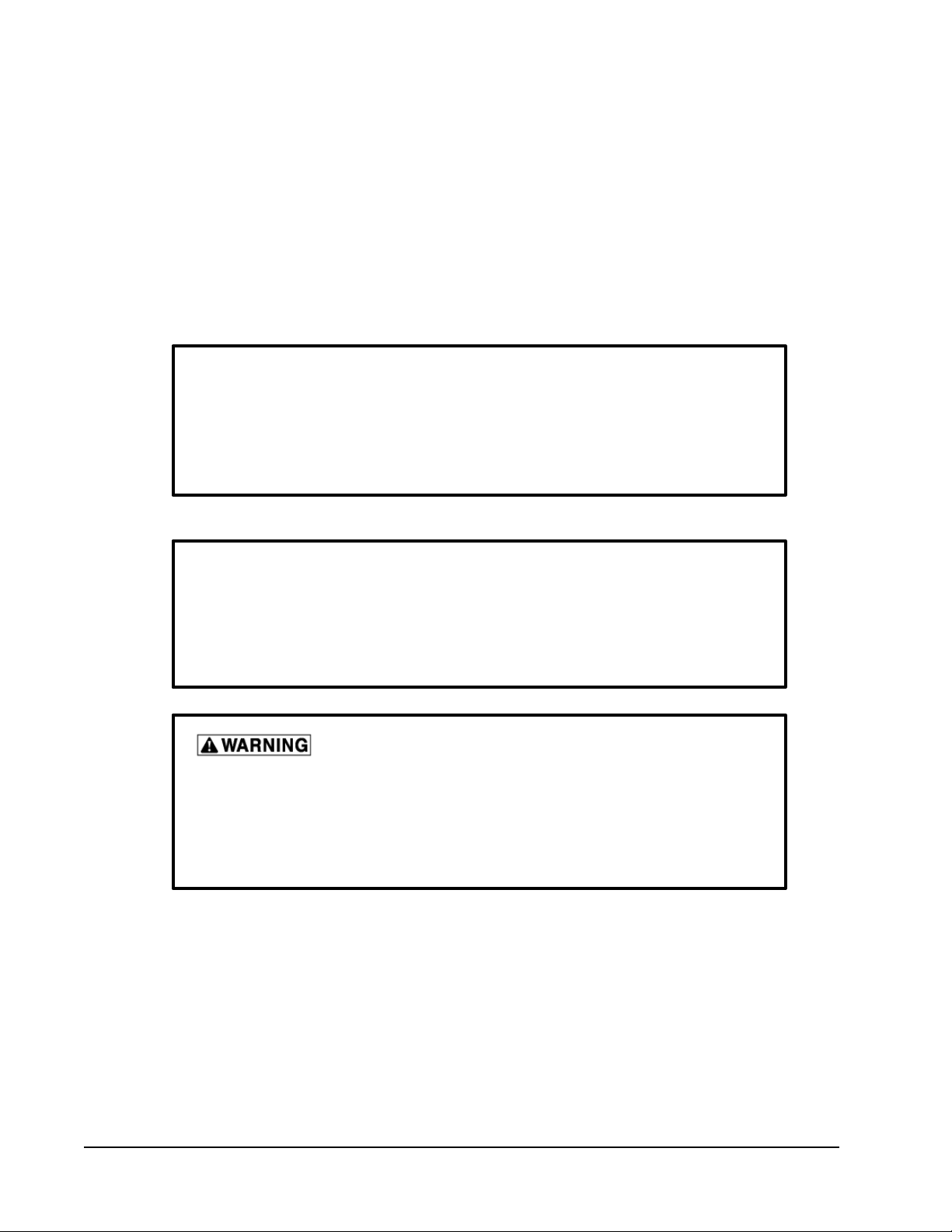

DRAW-OFF VALVES

Install the draw-off valve, if equipped. Install items 1 thru 5 for the plug style valve or items 1 thru 3

and item 6 for the compression style valve.

3

3

4 6

2

1

1

2

5

PLUG

DRAW-OFF VALVE

COMPRESSION

DRAW-OFF VALVE

Page 6

GAS KETTLES

GAS CONNECTIONS

Gas supply connections and any pipe joint compound must be resistant to the action of

propane gases.

Codes require that a gas shutoff valve be installed in the gas line ahead of the kettle.

Connect the gas supply line to the gas valve on the kettle. Make sure the pipes are clean and free of

obstructions, dirt and piping compound.

The gas line must be capable of delivering gas to the kettle without excessive pressure drop at the rate

specified on the nameplate. Suggested gas supply line pressure is 7" Water Column (1.75 kPa) for

natural gas and 11" Water Column (2.75 kPa) f or propane. Burner manifold pressure is (-)1.4" Water

Column (0.350kPa) for natural gas and (-)1.4" Water Column (0.350 kPa) for propane.

The proper sizing and installation of the gas connection is important for the machine to operate within

its design specifications. In some installations, the gas supply may not be sufficient enough to allow

all the gas equipment to operate properly at peak loads; or when other equipment with a high BTU/

hr. input requirement is operating. The connection to the machine becomes even more important in

this type of location. Flexible gas connectors with quick disconnect or swivel fittings (when used) and

gas connectors beyond the length necessary will reduce the BTU/hr. flow capacity to the machine.

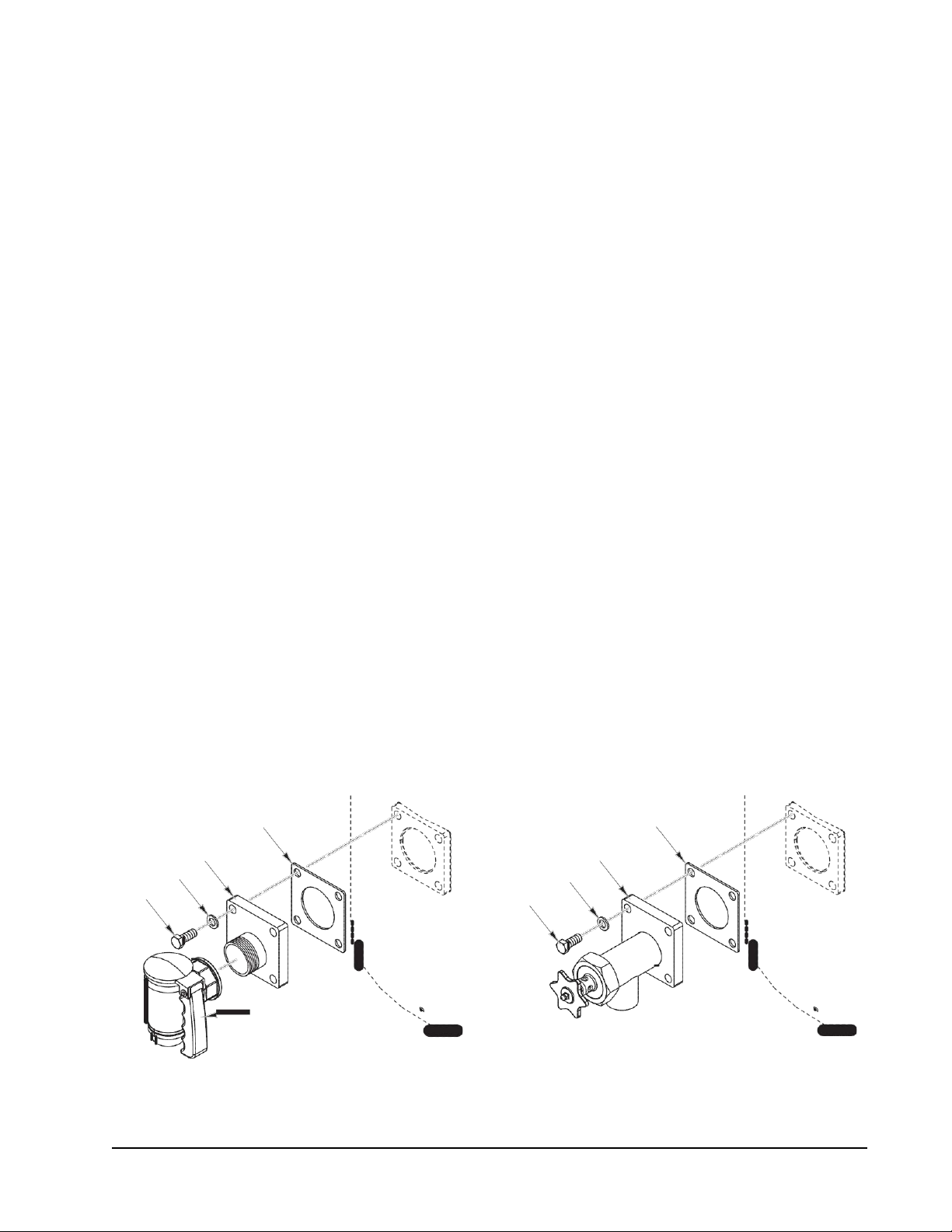

NOTE: Do not use corrugated stainless steel tubing

for

commercial gas equipment supply connections.

NOTE: A straight gas connection is the ideal condition for the rated BTU/hr. flow capacity of the

connector. If a straight connection is not possible and a flexible gas connector is used, do not twist,

kink or excessively flex the connector beyond a U shape. Flexing the gas connector as described will

restrict gas flow or may damage the connector.

Changing a flexible gas connector may raise the BTU/hr. flow capacity enough to allow the machine

to

operate within its design specifications.

(i.e.

Removing the quick disconnect

fitting, installing a

shorter

gas connector or installing a larger diameter gas connector.) An alternative may be to move the

equipment to a different gas supply location in the kitchen. (i.e. Clos er to the main supply into the

kitchen or away from other equipment with high BTU/hr. input requirements.)

KETTLE WALL KETTLE WALL

INCORRECT INSTALLATION CORRECT INSTALLATION

Prior to lighting, check all joints in the gas supply line for leaks. Use soap and

water

solution.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

Do not use an open flame.

— 6 —

Page 7

GAS KETTLES

— 7 —

are

will

used,

registered

Gas Connection Data

FLEXIBLE GAS CONNECTORS BTU/hr. FLOW CAPACITY

LENGTH

3

LENGTH

End Fittings - (1) Quick Disconnect

& (1)

Threaded

End Fittings - Both Threaded

1, 2

3

ID 36" 48" 60" 72" 36" 48" 60" 72"

1

/2"

3

/4"

1"

11/4"

77,000 68,000 60,000 55,000 120,000 106,000 93,000 86,000

218,000 180,000 158,000 139,000 256,000 225,000 198,000 175,000

379,000 334,000 294,000 279,000 512,000 451,000 397,000 350,000

615,000 541,000 476,000 419,000 946,000 833,000 733,000 645,000

1. Flow rating BTU/hr. 0.64 SP. GR @ 0.5 inch W.C. pressure drop.

2. BTU/hr. flow capacities are based on Dormont Mfg. Co. Supr-Safe gas line connectors and

provided

for

reference. Additional quick disconnect fi

ttings,

swivels, or manual shut

off

reduce the BTU/hr. flow capacities listed in this table. If other flexible gas connectors are

check the manufacturer’s specifications for BTU/hr. flow capacities. Supr-Safe is a

trademark of the Dormont Manufacturing Company.

3. The maximum length for a flexible gas connector is 72" per National Fuel Code standards.

BLACK IRON PIPE BTU/hr. FLOW CAPACITY

1, 2, 3

Natural Gas Nominal Inside Diameter of Pipe

Pipe Length

15'

30'

45'

60'

75'

90'

1

/

2"

76,000 172,000 345,000 750,000 1,220,000 2,480,000

52,000 120,000 241,000 535,000 850,000 1,780,000

43,000 99,000 199,000 435,000 700,000 1,475,000

38,000 86,000 173,000 380,000 610,000 1,290,000

3

/

4" 1" 1

1

/

4" 1

1

/

2" 2"

77,000 155,000 345,000 545,000 1,120,000

70,000 141,000 310,000 490,000 1,000,000

1. Flow rating BTU/hr. 0.64 SP. GR @ 0.3 inch W.C. pressure drop.

2.

BTU/hr.

flow capacities are based on Schedule 40 pipe, include a tolerance for pressure losses

in gas piping systems are provided for reference.

3. Count each 90° elbow as 3' of gas pipe for the purpose of calculating total pipe length.

valves

TESTING THE G AS SUPPLY SYSTEM

When gas supply pressure exceeds 1/2 psig (3.45 kPa), the kettle and its individual shutoff valve must

be disconnected from the gas supply piping system.

When gas supply pressure is 1/2 psig (3.45 kPa) or less, the kettle should be isolated from the gas

supply system by closing its individual manual shutoff valve.

Page 8

GAS KETTLES

GAS AND ALTITUDE CONVERSION

The kettle can be field converted to propane

gas or for operation at altitudes above 2000ft

elevation.

manometer

that

reads in 1/100" WC

A

and portable combustion analyzer are required.

Natural gas to Propane gas conversion:

1. Remove the right side controls

compartment side panel.

2. Locate the gas combination valve located

of

in the bottom

the controls compartment.

3. Turn S1 screw located right of manifold

pressure port (Fig. 1) clockwise to

completely close position. Then turn

counter clockwise 10 turns.

4. Pressure at inlet port should be between

11" and 13" WC.

5. Turn the unit on.

6. Fill the unit half way with cold water.

7. Run the unit for ½ hour to burn off any

residue in combustion chamber.

8. Using the combustion analyzer check

the flue gases. If the analyzer reads Co

Free Air the combustion gases should

not exceed 0.04 % or 400 PPM. If the

Fig. 1

analyzer does not read Co Free verify the

Co reading is below 100 PPM. If the reading is above, verify your settings and retest. If readings

are still high, call tech support at the number located on the front of this manual.

9. Attach the conversion data plate located in the bottom of the controls compartment with rivets

provided. The plate is to be mounted next to the kettle’s factory data plate.

10. Replace the controls compartment panel.

Propane gas to Natural gas

conversion:

1. Remove the right side controls compartment side panel.

2. Locat e the gas combination valve located in the bottom of the controls compartment.

3. Turn S1 screw located right of manifold pressure port (Fig. 1) clockwise to completely close

position. Then turn counter clockwise 16 turns.

4. Pressure at inlet port should be between 5" and 10.5" WC.

5. Turn the unit on.

6. Fill the unit half way with cold water.

7. Run the unit for ½ hour to burn off any residue in combustion chamber.

8. Using the combustion analyzer check the flue gases. If the analyzer reads Co Free Air the

combustion gases should not exceed 0.04 % or 400 PPM. If the analyzer does not read Co Free

verify the Co reading is below 100 PPM. If the reading is above verify your settings and retest.

If readings are still high call tech support at the number located on the front of this manual.

9. Attach the conversion data plate located in the bottom of the controls compartment with rivets

provided. The plate is to be mounted next to the kettle’s factory data plate.

10. Replace the controls compartment panel.

— 8 —

Page 9

— 9 —

GAS KETTLES

Altitude:

1. Remove the right side controls compartment side panel.

2. Locat e the gas combination valve located in the bottom of the controls compartment.

3. Turn S2 screw (Fig. 1) (using 5/64” Allen wrench), ½ turn clock wise

4. Turn the unit on.

5. Try five (5) times igniting the burner, if burner fails to ignite repeat step 3.

6. I nlet pressure setting:

a. Natural Gas: 5-7” WC

b. Propane: 11-13” WC

7. Fill the unit half way with cold water.

8. Run the unit for ½ hour to burn off any residue in combustion chamber.

9. Using the combustion analyzer check the flue gases. If the analyzer reads Co Free Air the

combustion gases should not exceed 0.04 % or 400 PPM. If the analyzer does not read Co Free

verify the Co reading is below 100 PPM. If the reading is above verify your settings and retest.

If reading is still high call tech support at the number located on the front of this manual.

10. Replace the controls compartment panel.

FLUE

DO NOT obstruct the flow of flue gases from the flue located on the rear of the kettle. It is required

that the flue gases be ventilated to the outside of the building through a ventilation system installed by

qualified personnel. The flue on the kettle should not be directly connected to any ventilation system.

From the termination of the flue to the filters of the hood venting system, a minimum clearance of 18"

(116 cm) must be maintained.

Information on the construction and installation of ventilating hoods may be obtained from Vapor

Removal from Cooking Equipment, NFPA-96 (latest edition), available from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

FAUCET BRACKET

A bracket is provided for mounting a faucet on the kettle; this would allow the addition of water to the

kettle for the convenience of the food preparer. A faucet is available as an accessory.

NOTE: Do not use tap water from faucet to fill kettle jacket. Refer to Jacket Water & Jacket Water

Treatment.

ELECTRICAL CONNECTION

Electrical and

grounding connections

must comply with the

applicable

portions

of the national electrical code and/or other local electrical codes.

Electrical Grounding Instruction

This appliance is equipped with a three-prong (grounding) plug

for

your protection against shock hazard

and should be plugged directly into a properly grounded three-prong receptacle. Do not cut or remove

the grounding prong from this plug.

Disconnect the electrical power to the machine and follow lockout / tagout

procedure, before cleaning or servicing..

All kettles are supplied with a 120 Volt power cord.

Page 10

GAS KETTLES

A B C D

H J K

N

LOCATION

Position the kettle in its final location. Check that there are sufficient clearances for operating and

servicing the kettle, and for proper clearance of the cover when raised. Keep the kettle free and

clear from all combustible substances. Minimum clearance from combustible and non-combustible

construction is 2" (5.0 cm) at the rear and 6" (15.2 cm) at each side.

The kettle draw off valve should be located near a floor drain.

Do not obstruct the flow

of

air into and around the

kettle.

This air flow is necessary

for

proper combustion

of gases and for ventilation of the kett le. Provisions for ventilation and incoming air supply for the

equipment in the room must be in accordance with the National Fuel Gas Code ANSI Z223.1 (latest

edition).

Stationary Kettle

FLUE

"E"

"D"

"P"

GAS CONNECTION

1.6

[41]

ELEC CONNECTION

"M"

12.0

[305]

"F"

ADD 2" FOR

PLUG VALVE

5.2[132]

ADD 2" FOR OPEN POSITION

8.0 FOR 3" DOV. ADD 3" FOR OPEN POSITION

"A"

"B"

"C"

"G"

CONNECTION

GAS

"H"

"J"

"N"

7.6

[192]

"L"

12.0

[305]

DRAIN TROUGH

"K"

MODEL

K20GL

K40GL

K60GL

TRUE

WORKING

CAPACITY

20 gallons

76 liters

40 gallons

152 liters

60 gallons

227 liters

21.6

549

660

29.5

749

E

In.

15.2

In.

36.8

In.

32.7

In.

18.6

In.

15.6

mm

386

mm

935

mm

831

mm

472

mm

396

26

In.

21.2

In.

39.2

In.

36.7

In.

19.8

In.

17.8

mm

538

mm

996

mm

932

mm

503

mm

451

In.

24.2

In.

39.5

In.

40.9

In.

21.7

In.

19.8

mm

615

mm

1003

mm

1039

mm

551

mm

502

= FLOOR DRAIN FOR DRAW-OFF VALVE

F

G

In.

mm

In.

mm

In.

mm

495

406

422

19.5

16.0

16.6

In.

mm

In.

mm

In.

mm

6.4

In.

17.0

In.

32.6

163

mm

432

mm

828

6.4

In.

18.0

In.

69.0

163

mm

457

mm

1753

6.0

In.

19.9

In.

76.6

152

mm

505

mm

1946

In.

mm

In.

mm

In.

mm

488

396

411

19.2

15.6

16.2

L

In.

mm

In.

mm

In.

mm

M

531

584

673

20.9

23.0

26.5

In.

mm

In.

mm

In.

mm

211

295

13.8

351

8.3

11.6

In.

mm

In.

mm

In.

mm

371

358

348

14.6

14.1

13.7

P

In.

mm

In.

mm

In.

mm

— 10 —

Page 11

— 11 —

GAS KETTLES

A B C D

"Q"

"P"

Tilting Kettle

"E"

"M"

ADD 2" FOR

PLUG VALVE

"F"

"C"

"B"

SHOWN WITH OPTIONAL DRAW-OFF VALVE

( 2" COMPRESSION VALVE)

"N"

"A"

"D"

12.0 [305]

CONNECTION

9.3 [235]

4.1

[104]

ELEC

"J"

GAS

CONNECTION

1.8

[45]

GAS CONNECTION

"L"

SHOWN WITH OPTIONAL DRAW-OFF VALVE

( 2" PLUG VALVE)

17.6 [446]

"G"

"H"

"S"

"R"

SHOWN WITH OPTIONAL DRAW-OFF VALVE

AND LID (3" COMPRESSION VALVE)

= FLOOR DRAIN FOR

DRAW-OFF VALVE

AND POUR PATH

"K"

TRUE

MODEL

K20GLT 20 gallons 21.6 15.2 38.3 41.8 25.8 16 21 8.2 22.3 67.1 20.7 28 11 15 9.4 20 28

K40GLT 40 gallons 25.8 21.2 39.9 45.1 28.8 17.75 16.7 7.3 23 71 16 33 12.8 18.8 9.6 15.7 32

K60GLT 60 gallons 29.5 23.9 43.7 49.6 30.8 20.4 17.6 6.8 26.7 78.7 17.2 36 14.8 21 10.3 16.9 36

WORKING

CAPACITY

76 liters 549 386 973 1062 655 406 533 208 566 1704 526 711 279 381 239 508 711

152 liters 655 538 1013 1146 732 451 424 185 584 1803 406 838 325 478 244 399 813

227 liters 749 607 1110 1260 782 518 447 173 678 1999 437 914 376 521 262 429.3 914

E

F

G

H J K L

M N P

Q

R S

LEVELING

Place a spirit level on the rim of the kettle with the cover open. Turn the feet in or out to level the kettle

in both the left-to-right and front-to-rear directions.

BEFORE FIRST USE

Use a non-corrosive, grease-dissolving commercial cleaner to clean the protective metal oils from

all surface parts and the interior of the kett le. Follow the cleaner manufacturer's directions. Rinse

thoroughly with warm water to remove all traces of the cleaner. Drain the kettle's interior cooking

area. Wipe dry with a clean cloth.

Page 12

GAS KETTLES

Control Function

the kettle.

CONTROLS AND INDICATORS

The kettle and its parts are hot. Use care when operating, cleaning or servicing

OPERATION

Vacuum/Pressure Gauge Indicates the vacuum (in inches) and pressure (in PSI)

inside the kettle jacket.

Thermostat Regulates kettle temperature from warm to rolling boil.

Low Water Indicator (Red) When lit, indicates insufficient water in the kettle jack et

and the sensing probe has interrupted power supply to

the controls and to the burners.

Power ON/OFF Switch Controls power to the kettle.

Power ON indicator (Amber) When lit, indicates machine on/powered.

Heater Light (Amber) When lit, indicates the burner is turned on.

Ignition Failure Indicator (Red) When lit, indicates the burner has failed to ignite.

Water Level Sight Glass Visually shows the water level in the jacket.

Crank Handle Rotate the crank handle to tilt.

AMBER HEAT ON

INDICATOR

WATER

SIGHT

LEVEL

GLASS

Model K40GL

AMBER HEAT ON

INDICATOR

Model K40GLT

THERMOSTAT

LOW

RED

WATER INDICATOR

POWER ON/OFF

SWITCH

IGNITION FAILURE

INDICATOR

VACUUM/PRESSURE GAUGE

THERMOST

RED

WATER INDICATOR

POWER ON/OFF

SWITCH

IGNITION FAILURE

INDICATOR

CRANK

WATER

SIGHT

LEVEL

GLASS

VACUUM/PRESSURE GAUGE

LOW

HANDLE

A

T

— 12 —

Page 13

— 13 —

GAS KETTLES

BEFORE OPERATION

1. Check Gauge Pressure – should read 20-30 In. Hg. below zero when cold. (Higher reading

indicates air in jacket. See Venting instructions.)

2. Check to make sure gas supply valve is turned on.

3. Check water level in sight glass. Water level should be in the middle of the sight glass. If level

is less than ¼ of the sight glass or the low water light is illuminated, water must be added to the

jacket (See Jacket Water Level.) Do not over fill.

4. Check the flue at the rear of the kettl e fo r any obstructions before operating.

NOTE: Use only distilled water to refill the jacket. Refilling the kettle with tap water will damage the

kettle jacket and void the warranty.

OPERATION

1. Turn power switch to the “ON” position and set ther mo s tat to maximum.

2. The heat light will illuminate.

3. If ignition failure light is illuminated then turn the power switch to the “OFF” position.

4. Wait five minutes then turn the power switch to the “ON” position.

Preheat

1. Set the thermostat to Simmer/Boil and wait until the heat light cycles off.

Cooking

1. Verify that the draw-off valve is closed.

2. Set thermosta t to desired cooking temperature, warm, simmer, or boil.

NOTE: Food products with milk or egg base should be placed into a cold kettle before cooking. Avoid

sudden contact of these food products to a hot kettle surface because they stick to the surface.

3. Pour the food to be cooked into the kettle.

Tilting

1. Set the thermostat to the minimum.

2. Turn power switch off.

3. Rotate the crank handle clockwise to tilt or counter clockwise to return.

DAILY SHUT DOWN

1. Set thermosta t to minimum and turn the power switch off.

2. Clean and dry kettle thoroughly.

EXTENDED SHUT DOWN

1. Turn manual gas supply valve off.

2. Disconnect power form the kettle.

Page 14

GAS KETTLES

VENTING

While the kettle is cold, check the vacuum/pressure gauge. The gauge should be in the vacuum zone

measuring between 20 to 30 in. Hg (84 to 100kPa). If not, there is air in the jacket and it must be

removed by venting for proper heating. Perform the venting procedure located in the Maintenance

section of this manual.

RESERVOIR JACKET WATER LEVEL CHECK

During use, the reservoir water level must be maintained high to cover the entire heating zone. If the

low water light is illuminated during use, perform the Filling the Reservoir Jacket procedure located in

the Maintenance section of this manual.

TILTING KETTLES

The low water indicator light (red) should not be lit when kettle is in upright position during operation.

This light indicates that the burner has been automatically shut off by the kettle’s safety circuitry. It

is, however, normal for the low water light (red light) to come on when the kettle is in a tilted position.

OPERATING DATA

MODEL NO. GALLONS OF WATER BURNER

WORKING

CAPACITY

JACKET

CHARGE

INPUT

BTU/HR

HEAT UP TIME-MINUTES

EMPTY

TO 5 PSI

2/3

130˚F

FULL

RISE

K20GLT/K20GLT 20 7 100,000 10 20

K40GLT/K40GLT 40 7 100,000 10 40

K60GL/K60GLT 60 8 100,000 15 60

— 14 —

Page 15

— 15 —

GAS KETTLES

STAINLESS STEEL EQUIPMENT CARE AND CLEANING

(Supplied courtesy of NAFEM. For more information, visit their web site at www.nafem.org)

Contrary to popular belief, stainless steels ARE susceptible to rusting.

Corrosion on metals is everywhere. It is recognized quickly on iron and steel as unsightly yellow/

orange r ust. Such metals are called “active” because they actively corrode in a natural environment

when their atoms combine with oxygen to form ru st.

Stainless steels are passive metals because they contain other metals, like chromium, nickel and

manganese that stabilize the atoms. 400 series stainless steels are called ferritic, contain chromium,

and are magnetic; 300 series stainless steels are called austenitic, contain chromium and nickel; and

200 series stainless, also austenitic, contains manganese, nitrogen and carbon. Austenitic types of

stainless are not magnetic, and generally provide greater resistance to corrosion than ferritic types.

With 12-30 percent chromium, an invisible passive film covers the steel’s surface acting as a shield

against corrosion. As long as the film is intact and not broken or contaminated, the metal is passive

and stain-less. If the passive film of stainless steel has been broken, equipment starts to corrode. At

its end, it rusts.

Enemies of Stainless Steel

There are three basic things which can break down stainless steel’s passivity layer and allow corrosion

to occur.

1. Mechanical abrasion

2. Deposits and water

3. Chlorides

Mechanical abrasion means those things that will scratch a steel surface. Steel pads, wire brushes

and scrapers are prime examples.

Water comes out of the faucet in varying degrees of hardness. Depending on what part of the country

you live in, you may have hard or soft water. Hard water may leave spots, and when heated leave

deposits behind that if left to sit, will break down the passive layer and r ust stainless steel. Other

deposits from food preparation and service must be properly removed.

Chlorides are found nearly everywhere. They are in water, food and table salt. One of the worst

chloride perpetrators can come from household and industrial cleaners.

So what does all this mean? Don’t Despair!

Here are a few steps that can help prevent stainless steel rust.

1. Use the proper tools.

When cleaning stainless steel products, use non-abrasive tools. Soft cloths and plastic scouring

pads will not harm steel’s passive layer. Stainless steel pads also can be used but the scrubbing

motion must be in the direction of the manufacturers’ polishing marks.

2. Clean with the polish lines.

Some stainless steel comes with visible polishing lines or “grain.” When visible lines are present,

always scrub in a motion parallel to the lines. When the grain cannot be seen, play it safe and

use a soft cloth or plastic scouring pad.

3. Use alkaline, alkaline chlorinated or non-chloride containing cleaners.

While many traditional cleaners are loaded with chlorides, the industry is providing an ever-

increasing choice of non-chloride cleaners. If you are not sure of chloride content in the cleaner

used, contact your cleaner supplier. If your present cleaner contains chlorides, ask your supplier

if they have an alternative. Avoid cleaners containing quaternary salts; it also can attack stainless

steel and cause pitting and rusting.

Page 16

GAS KETTLES

Job

Cleaning Agent

Comments

4. Treat your water.

Though this is not always practical, softening hard water can do much to reduce deposits. There

are certain filters t hat can be installed to remove distasteful and corrosive elements. To insure

proper water treatment, call a treatment specialist.

5. Keep your food equipment clean.

Use alkaline, alkaline chlorinated or non-chloride cleaners at recommended strength. Clean

frequently to avoid build-up of hard, stubborn stains. If you boil water in stainless steel equipment,

remember the single most likely cause of damage is chlorides in the water. Heating cleaners that

contain chlorides have a similar effect.

6. Rinse, rinse, rinse.

If chlorinated cleaners are used, rinse and wipe equipment and supplies dry immediately. The

sooner you wipe off standing water, especially when it contains cleaning agents, the better. After

to

air

dry;

wiping equipment down, allow it

oxygen helps maintain the stainless steel’s passivity film.

7. Never use hydrochloric acid (muriatic acid) on stainless steel.

8. Regularly restore/passivate stainless steel.

Routine cleaning Soap, ammonia,

Apply with soft cloth or sponge.

detergent, Medallion

Fingerprints and smears Arcal 20, Lac-O-Nu Ecoshine Provides barrier film

Stubborn stains and

discoloration

Grease and fatty acids,

blood, burnt-on foods

Grease and Oil Any good commercial

Cameo, Talc, Zud,

Rub in direction of polish lines.

First Impression

Easy-off, DeGrease It Oven Aid Excellent removal

on all finishes

Apply with soft cloth or sponge.

detergent

Restoration/Passivation Benefit, Super Sheen

Review

1. Stainless steels rust when passivity (film-shield) breaks down as a result of scrapes,

scratches, deposits and chlorides.

2. Stainless steel rust starts with pits and cracks.

3. Use the proper tools. Do not use steel pads, wire brushes or scrapers to clean stainless

steel.

4. Use non-chlorinated cleaners at recommended concentrations. Use only chloridefree

cleaners.

5. Soft en your water. Use filters and softeners whenever possible.

6. Wipe off cleaning agent(s) and standing water as soon as possible. Prolonged contact

causes eventual problems.

T

o learn more about chloride-stress corrosion and how to prevent

or cleaning materials supplier.

it,

contact the equipment manufacturer

Developed by Packer Engineering, Naperville, Ill., an independent testing laboratory.

— 16 —

Page 17

— 17 —

GAS KETTLES

CLEANING

The kettle and its parts are hot. Use care when operating, cleaning or servicing

the kettle.

Disconnect the electrical power to the machine and follow lockout / tagout

procedure, before cleaning or servicing..

Never spray the exterior of the kettle or control box with water under any condition. Failure

to comply will void the warranty.

The kettle interior and exterior should be thoroughly washed after each use when a different food is

to be cooked next or when cooking is completed for t he day. If the unit is used continuously through

the day, it should be cleaned and sanitized once every 12 hours.

Empty the kettle. Close draw-off valve and add water to the kettle for cleaning to prevent residue from

drying and sticking to the inside of the kettle.

• Never use harsh or corrosive cleaning chemicals.

• Never scrape the inside of the kettle with abrasive cleansers, metal tools or steel scouring pads,

to

which will scratch the surface, spoil the appearance and make it more difficult

thoroughly clean.

• Add mild, non-chlorine, non-chloride, and non-bleach detergent and scrub the kettle interior

with a nylon brush.

• Loosen stuck-on food by allowing it to soak at a low temperature setting.

• Thoroughly rinse the interior and dry with a soft cloth.

• Rinse the exterior and dry with a soft cloth.

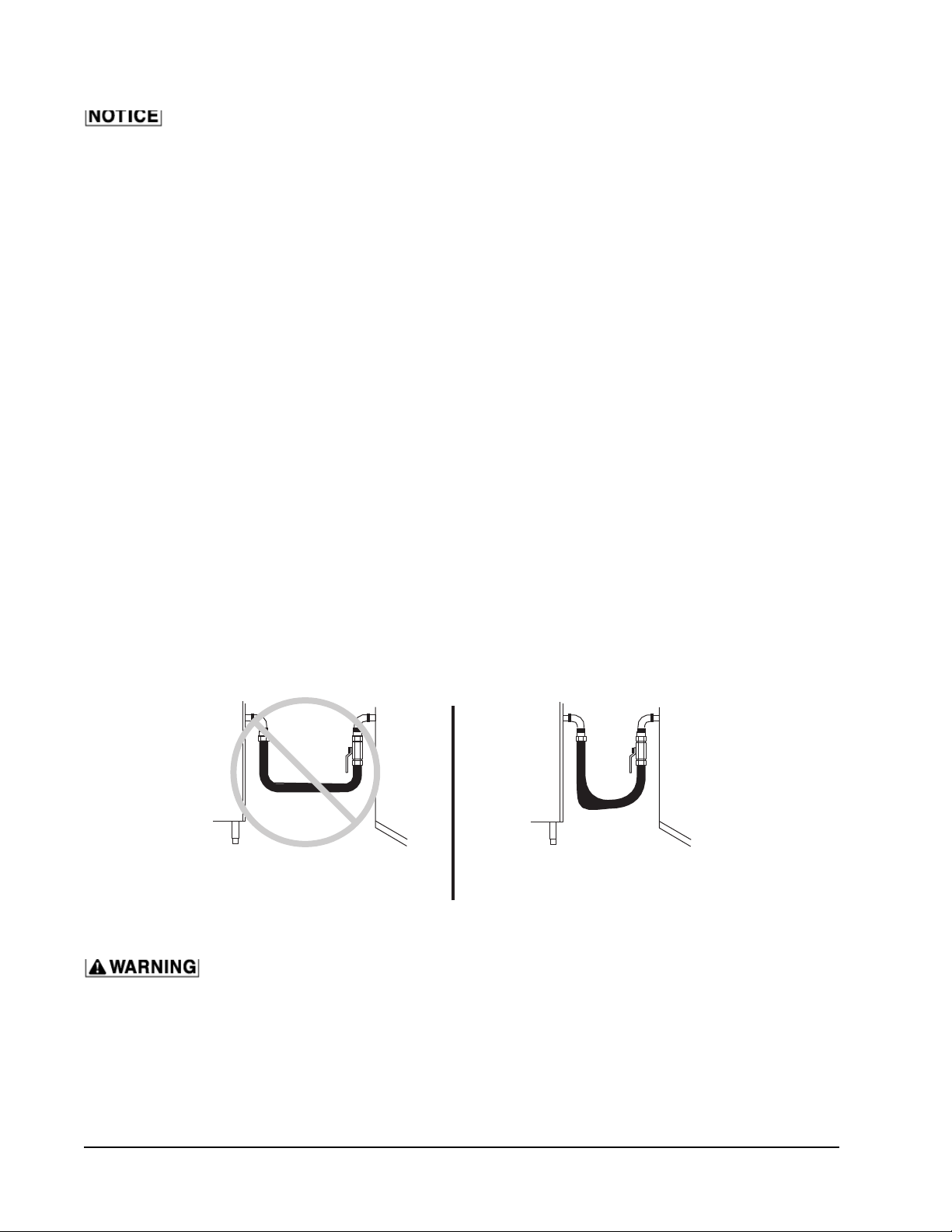

COMPRESSION DRAW-OFF VALVE CLEANING INSTRUCTIONS

Daily After Use

Remove

(Fig. 2).

Install draw-off valve assembly:

draw-off valve stem

Turn the valve handle

1.

assembly

for

counterclockwise

cleaning

until it stops.

2. Pull the valve handle back until it stops.

3. Turn large hex nut counterclockwise

until the valve stem assembly is loose.

4. Pull the assembly straight out of the

valve body.

5. Remove wing nut and handle. Unscrew valve stem from bonnet.

6. Wash valve body and stem assembly with mild soap and water, and then rinse. Make sure

all food residue is removed from inside valve body.

7. Leave assembly apart to air dry.

Valve Stem

Stem

O-Ring

Fig. 2

1. Apply PetroGel lubricant to valve stem threads, O-Ring, rubber plug face and large hex nut

threads.

2. T hread the valve stem into bonnet till valve stem can be pulled through bonnet.

3. Insert valve stem into valve body.

4. Ins t all large hex nut hand tight.

5. Ins t all valve handle, lock washer and wing nut onto the valve stem.

6. Turn valve handle clockwise until closed. Do not overtighten.

Page 18

GAS KETTLES

PLUG VALVE CLEANING INSTRUCTIONS

Daily After Use

Remove draw-off valve plug for cleaning (Fig. 3).

1. Unscrew the retaining ring and remove

it and the bottom washer.

2. Pull the valve plug straight up

to

remove

from valve body.

3. Wash valve body, plug, washer and

retaining ring with mild soap and water,

and then rinse.

4. Leave assembly apart to air dry.

Care should be taken not to scratch, ding or dent

the valve plug to prevent valve leakage.

If multiple kettles are in use, care should be taken

to keep each plug separate and returned to its

original valve body.

Install draw-off valve plug.

1. Apply PetroGel lubricant to valve plug

face.

2. Holding the valve handle, slide the plug

down into the valve body.

3. Install the bottom washer, making sure

to align the key with the groove in the

valve plug.

4. Install the retaining ring and hand tighten.

If the valve is hard to open, then the ring has been

overtightened.

Fig. 3

Valve Plug

Valve Body

Bottom Washer

Retaining Ring

— 18 —

Page 19

— 19 —

GAS KETTLES

MAINTENANCE

The kettle and its parts are hot. Use care when operating, cleaning or servicing

the kettle.

VENTING

When cold, the pressure gauge vacuum measuring zone should be between 20 to 30 In. Hg (84 to

100kPa). If the vacuum indicator is not within this range, perform the following:

1. Ensure t hat the water level in the jacket is approx. 1/2 in the sight glass.

2. With the kettle empty, place the power switch to the ON position.

3. Set the temperature control to the max heat setting. Let the kettle heat until the jacket pressure

reaches 10 PSI.

Hot steam. The kettle and its parts are hot. Use care when operating, cleaning

or servicing the kettle.

4. Pull the pressure relief valve lever to relieve pressure for 10 seconds. Allow valve to s nap shut

to seal.

5. Turn kettle off and let cool. Check for a correct vacuum reading of 20 to 30 In. Hg (84 to 100kPa).

If the reading is not correct, repeat steps 1 through 3.

FILLING THE RESERVOIR JACKET

Use ionized distilled water with sodium (no tap water). Equipment failure caused by inadequate water

quality is not covered under warranty. To fill the reservoir jacket, perform the following:

1. Set the thermostat and power switch to OFF position.

2. Release any pressure by lifting the lever on the pressure relief valve.

3. Insert a funnel into the fill valve and fill the jacket with water and anti-freeze mix until water level

in the sight glass is 1/2 full.

4. Turn on the kettle.

If the low water light turns on, turn off the unit and repeat steps 3 and 4. If low water light is off, follow

the venting procedure (see VENTING) to vent air from reservoir.

SHUTDOWN

Turn the thermostat dial to the OFF position. Turn power switch off. For extended shutdown, close

the gas shutoff valve.

SERVICE

To obtain service and parts information concerning this unit, contact t he Vulcan-Hart Service Agency

in your area (refer to listing supplied with the kettle), or contact the Vulcan-Hart Service Department

at the address or phone number shown on the front cover of this manual.

Parts and service are also available at www.vulcanequipment.com.

Page 20

GAS KETTLES

F-35461 (June 2012)

— 20 —

PRINTED IN U.S.A.

Problem

Possible Causes / Suggested Corrective Action

Will Not Turn On, no power

light

Low Water Light On or Low

water in Sight Glass

Not Heating, Ignition Fail

Light Is On

Kettle not in vacuum when

cold or will not boil when up

to pressure

TROUBLESHOOTING

Kettle is not plugged in / Plug in power cord.

Power switch is off / Turn on power switch.

Circuit Breaker tripped / Reset Breaker

Ground Fault Receptacle is tripped / Reset Ground Fault

Receptacle

Hood system with power interrupt is not on / Turn on hood system.

Tilt kettle not in the fully lower position / Lower kettle with crank to

the level position

Note: If the kettle still does not come ON verify that there is power

at the receptacle by plugging in another electrical device such

at a lamp. If the device does not come ON call an electrician or

maintenance personel. If the alternate device does come ON, call

your authorized Vulcan Servicer.

Water level to low / Fill jack et per instructions in this manual.

Relief valve is not seated and leaking / With no pressure on gauge,

lift lever on relief valve and allow it to snap closed, refill jacket per

instructions in this manual

Fill port is not fully closed and leaking / Close tightly fill port valve,

refill jacket per instructions in this manual.

Jacket was refilled with deionized water / Add a pinch of salt to

jacket water.

Gas Supply Valve is off / Turn on gas valve

Combo Valve is off / Turn on combo valve

Quick connect hose not connected or fully inserted / Connect quick

connect hose or push connector in till quick connect snaps and

locks.

Gas line, f lex hose, or quick connect undersize and not delivering

enough gas / Increase gas line size to 125% of kettel r ated BTU

input.

Gas supply pressure to low / Have plumber Increase gas supply

pressure

Air in jacket / Vent per instructions in this manual.

Relief valve is not seated and leaking / With no pressure on gauge,

lift lever on relief valve and allow it to snap closed, vent jacket per

instructions in this manual

Fill port is not fully closed and leaking / Close tightly the fill port

valve, vent jacket per instructions in this manual.

Note: If the kettle jacket continues to loose vacuum or requires

frequent refilling of the jacket call your authorized Vulcan Servicer.

Loading...

Loading...