Page 1

SERVICE MANUAL

C24GA SERIES

CONVECTION

STEAMERS

MODELS

C24GA6 ML-136021

C24GA10 ML-136022

- NOTICE -

This manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified. If you have attended a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this manual.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

For additional information on Vulcan-Hart or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

F35425 (February 2006)

Page 2

C24GA SERIES CONVECTION STEAMERS

TABLE OF CONTENTS

GENERAL................................................................................................................................................................ 4

Introduction....................................................................................................................................................... 4

Installation ........................................................................................................................................................ 4

Operation.......................................................................................................................................................... 4

Cleaning .......................................................................................................................................................... 4

Specifications ................................................................................................................................................... 4

Gas Line Pressures .................................................................................................................................. 4

Burner Pressure ........................................................................................................................................ 4

Electrical................................................................................................................................................... 4

Water Supply ............................................................................................................................................ 4

Tools................................................................................................................................................................. 4

Standard ................................................................................................................................................... 4

Special...................................................................................................................................................... 4

REMOV AL AND REPLACEMENT OF PARTS.......................................................................................................... 5

Covers and Panels............................................................................................................................................ 5

Cooking Compartment Right Side Panel.................................................................................................... 5

Cooking Compartment Flue Wrap ............................................................................................................. 5

Cooking Compartment Left Side Panel ...................................................................................................... 5

Cabinet Base Right Side Panel ................................................................................................................. 5

Cabinet Base Left Side Panel.................................................................................................................... 6

Cabinet Base Front Panel ......................................................................................................................... 6

Cabinet Base Rear Panel .......................................................................................................................... 6

Cooking Compartment Door.............................................................................................................................. 6

Door Assembly.......................................................................................................................................... 6

Door Gasket.............................................................................................................................................. 7

Door Handle .............................................................................................................................................. 7

Door Latch Assembly................................................................................................................................ 8

Compartment Controls...................................................................................................................................... 8

Main Burner...................................................................................................................................................... 9

Gas Combination Control V alve......................................................................................................................... 9

Generator Assembly ......................................................................................................................................... 9

Fill and Cold Water Solenoid Valves ................................................................................................................11

Pilot S park/Probe Flame Sensor..................................................................................................................... 12

SERVICE PROCEDURES AND ADJUSTMENTS ................................................................................................... 13

Blower Air Pressure Adjustment...................................................................................................................... 13

Air Pressure Switch Adjustment ..................................................................................................................... 13

Pilot Burner Adjustment.................................................................................................................................. 14

Operating Pressure Switch...................................................................................................................... 15

Thumb Wheel Adjustment ....................................................................................................................... 16

Inlet Water/S team Strainer ...................................................................................................................... 16

Automatic Ignition Systems............................................................................................................................ 17

Spark Ignition Control Test....................................................................................................................... 17

Ignition T est .................................................................................................................................................... 18

Manifold Pressure Adjustment ........................................................................................................................ 18

Cooking Compartment .................................................................................................................................... 19

Controls .................................................................................................................................................. 19

Door ............................................................................................................................................................... 19

Latch Adjustment .................................................................................................................................... 19

Striker Adjustment................................................................................................................................... 20

Deliming the Generator ................................................................................................................................... 20

Cooking Cycle T est......................................................................................................................................... 21

General ................................................................................................................................................... 21

Probe Inspection............................................................................................................................................. 21

F35425 (February 2006) Page 2 of 40

Page 3

C24GA SERIES CONVECTION STEAMERS

ELECTRICAL OPERA TION .................................................................................................................................... 22

Water Level Controls ...................................................................................................................................... 22

Low Level Cut-Off & Differential Control.................................................................................................... 22

Sequence of Operation ................................................................................................................................... 22

Initial Fill and Preheat Conditions ............................................................................................................ 22

Schematics .................................................................................................................................................... 25

Component Location Cabinet Base Generator ................................................................................................ 28

Component Function Cabinet Base Generator ................................................................................................ 29

Component Location Cooking Compartment ................................................................................................... 31

Component Function Cooking Compartment ................................................................................................... 32

General ................................................................................................................................................... 32

TROUBLESHOOTING ............................................................................................................................................ 33

General ................................................................................................................................................... 33

Water Not Being Supplied to Generator................................................................................................... 33

Pilot Or Main Burner Will Not Light.......................................................................................................... 33

Drain Solenoid Valve Does Not Drain....................................................................................................... 33

Water Accumulating in Compartment ...................................................................................................... 33

Cooking Cycle Cannot be Activated......................................................................................................... 33

Steamer Achieves Pressure Slower Than Normal .................................................................................... 33

Troubleshooting Sequence Of Operation ......................................................................................................... 34

TROUBLESHOOTING CHART................................................................................................................................35

CONDENSED SPARE P AR TS LIST ....................................................................................................................... 38

©VULCAN 2005

F35425 (February 2006)Page 3 of 40

Page 4

C24GA SERIES CONVECTION STEAMERS - GENERAL

GENERAL

INTRODUCTION

Procedures in this manual will apply to all models

unless specified. Pictures and illustrations can be of

any model unless the picture or illustration needs to

be model specific.

INSTALLATION

Refer to the Installation and Operation Manual for

detailed installation instructions on steamers.

OPERATION

Refer to the Installation and Operation Manual for

specific operating instructions.

CLEANING

Refer to the Installation and Operation Manual for

specific cleaning instructions.

SPECIFICATIONS

TOOLS

Standard

• S tandard set of hand tools.

• VOM with A.C. current tester (Any quality VOM

with a sensitivity of at lease 20,000 ohms per volt

can be used.)

Special

• Gas leak detection equipment.

• Gas Manometer.

• Loctite 271

• Screwdriver , 1/8 X 4 cabinet tip

Gas Line Pressures

• Operating Pressure

Natural - Recommended 2.5” W .C.

Propane - Recommended 10.0” W .C.

• Incoming Pressure

Natural - Recommended 7.0” W.C. min.

Propane - Recommended 1 1.0” W.C. min.

Burner Air Pressure

0.4” W .C.

Electrical

Volt age: 120/60/1

Amps: 2.5 Amps

Frequency: 50/60 Hz

Water Supply

Supply pressure: 20-60 psig

Hardness*: Less than 3 grains

Silica: Less than 13 ppm

T ot al Chloride: Less than 4.0 ppm

pH Range: 7 to 8

Undissolved Solids: Less than 5 microns

(*17.1 ppm = 1 grain of hardness)

F35425 (February 2006) Page 4 of 40

Page 5

C24GA SERIES CONVECTION STEAMERS - REMOV AL AND REPLACEMENT OF P ARTS

REMOVAL AND REPLACEMENT OF PARTS

COVERS AND PANELS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

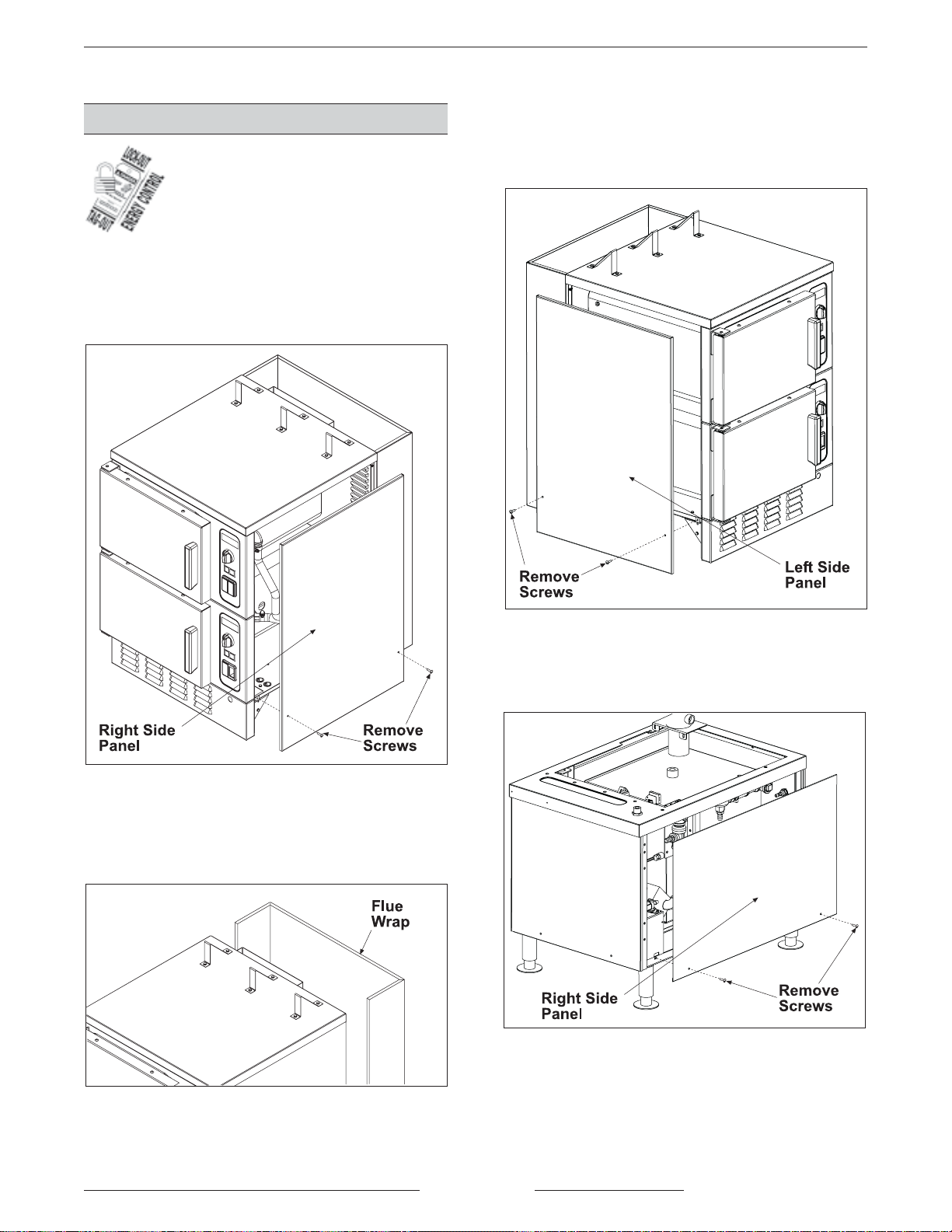

Cooking Compartment Right Side Panel

1. Remove the screws then remove the right side

panel from the compartment.

Cooking Compartment Left Side Panel

1. Remove the screws then remove the left side

panel from the compartment.

Cooking Compartment Flue Wrap

1. Remove left and right side panels from

compartment. Remove screws that secure flue

wrap.

Cabinet Base Right Side Panel

1. Remove the screws then remove the right side

panel from the cabinet base.

F35425 (February 2006)Page 5 of 40

Page 6

C24GA SERIES CONVECTION STEAMERS - REMOV AL AND REPLACEMENT OF P ARTS

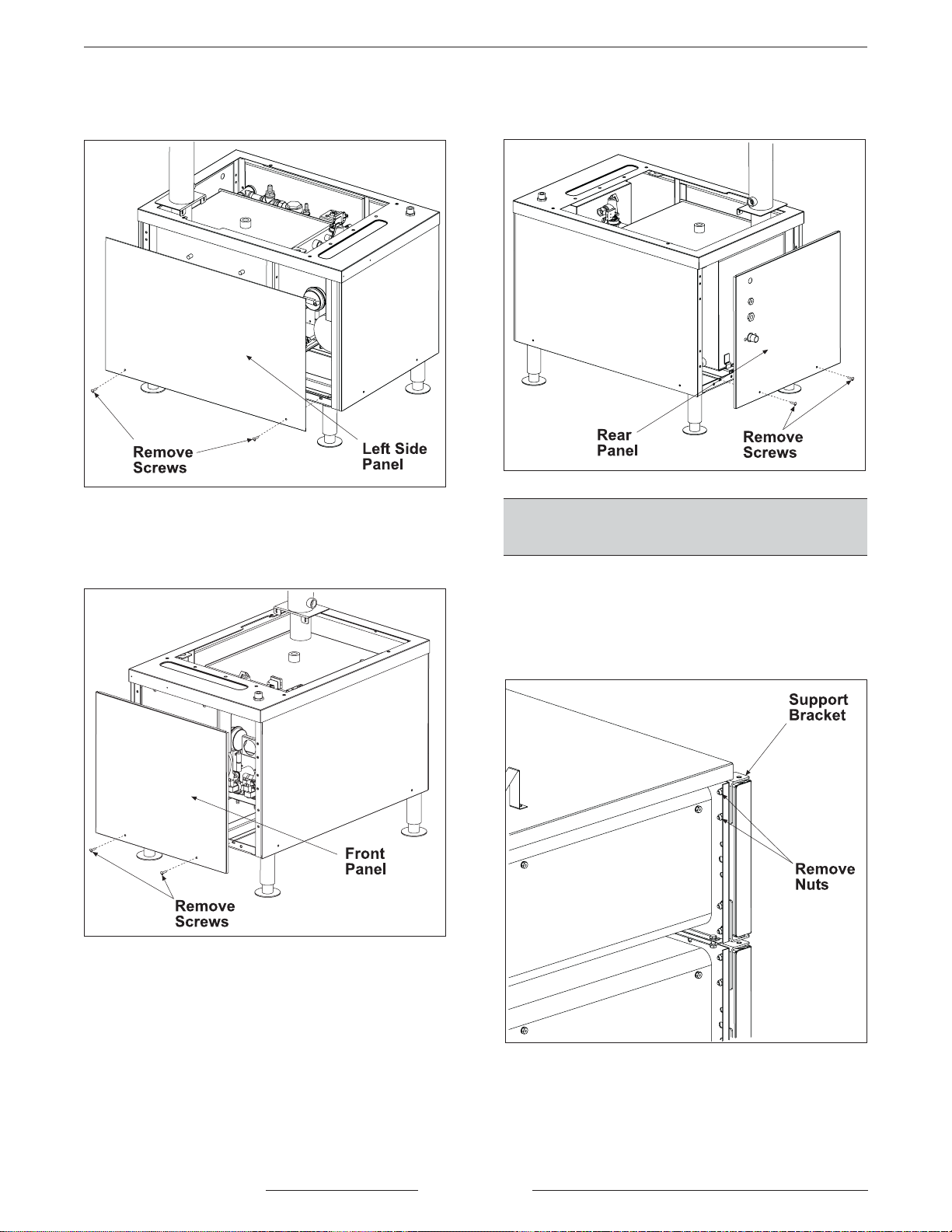

Cabinet Base Left Side Panel

Cabinet Base Rear Panel

1. Remove the screws then remove the left side

panel from the cabinet base.

Cabinet Base Front Panel

1. Remove the screws then remove the front panel

from the cabinet base.

1. Remove the screws then remove the rear panel

from the cabinet base.

COOKING COMPARTMENT

DOOR

Door Assembly

1. Remove compartment left side panel as outlined

under COVERS AND P ANELS.

2. Remove nuts from top door support bracket.

3. Open the door and lift from bottom hinge.

4. Reverse the procedure to install and check for

F35425 (February 2006) Page 6 of 40

proper operation.

Page 7

C24GA SERIES CONVECTION STEAMERS - REMOV AL AND REPLACEMENT OF P ARTS

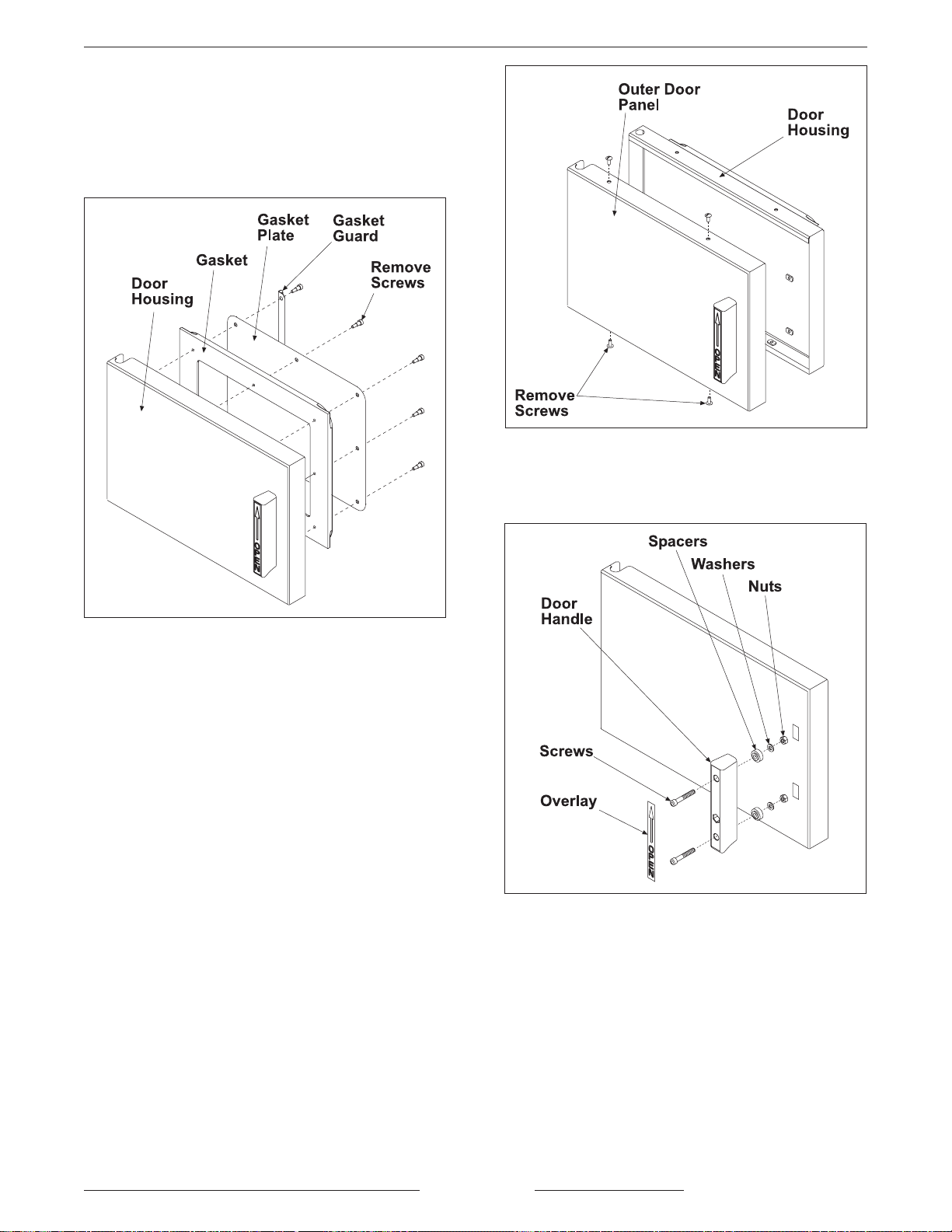

Door Gasket

1. Open the door.

2. Remove screws from the gasket guard and

gasket plate.

3. Remove the gasket guard and the gasket plate.

4. Remove the plate, nuts, washers and spacers

from the handle screws and remove the door

handle from the door.

4. Position the new gasket on the gasket plate.

5. Reverse the procedure to install.

6. Adjust the door as outlined under SERVICE

PROCEDURES AND ADJUSTMENTS.

Damage to the gasket sealing surface, such as nicks

or cuts, will cause steam leakage.

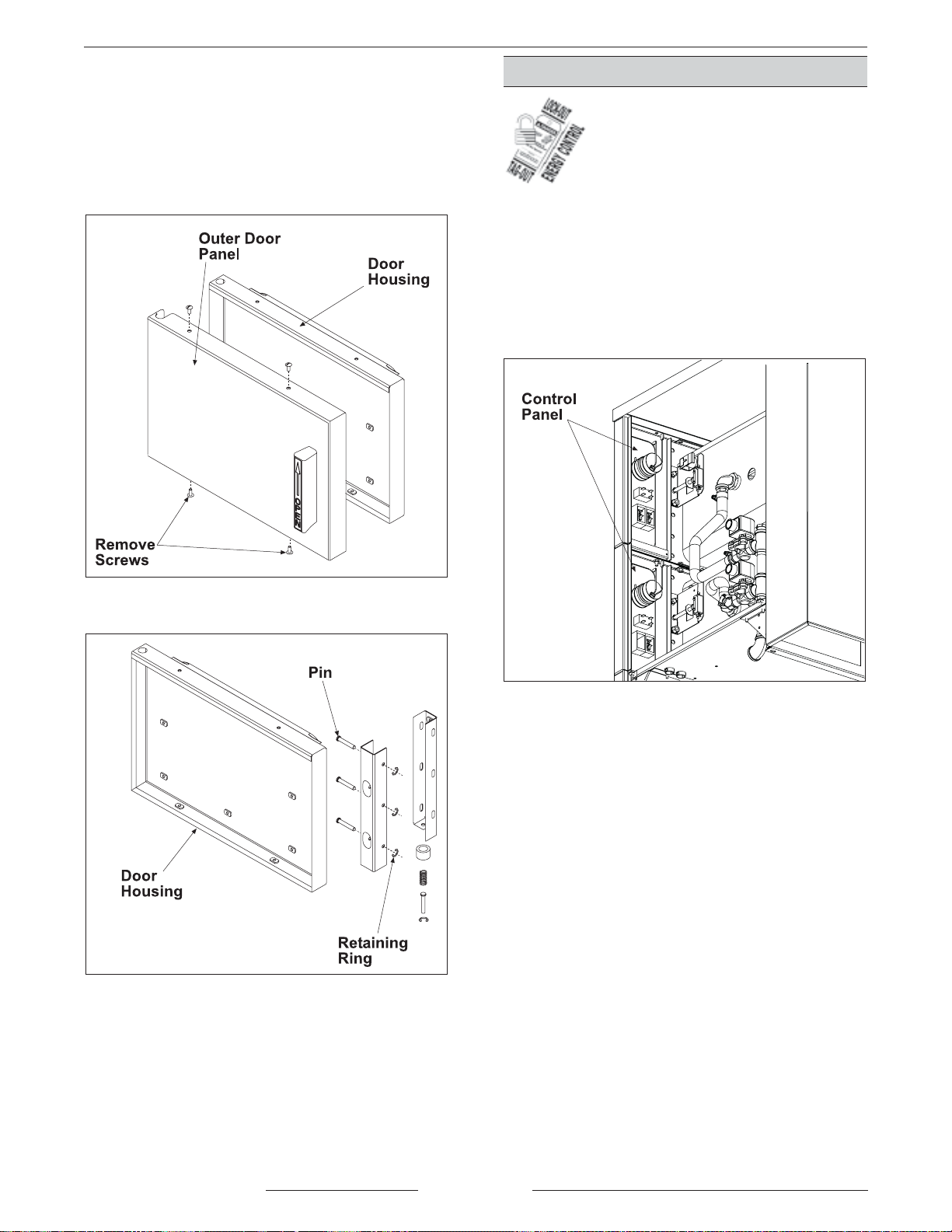

Door Handle

1. Open the door.

2. Remove screws from the top and bottom of the

door.

3. Pull the outer door panel out from the door

housing.

5. Reverse procedure to install. When installing the

spacers, the smaller diameter fits into the slot in

the door and the latch. Use Loctite 271 to secure

fasteners.

F35425 (February 2006)Page 7 of 40

Page 8

C24GA SERIES CONVECTION STEAMERS - REMOV AL AND REPLACEMENT OF P ARTS

Door Latch Assembly

1. Open the door.

2. Remove screws from the top and bottom of the

door.

3. Pull the outer door panel out from the door

housing.

COMPARTMENT CONTROLS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

1. Remove compartment right side cover as

outlined under COVERS AND PANELS.

2. Remove the component being replaced.

3. Reverse the procedure to install the replacement

component, then check steamer for proper

operation.

4. Remove the pins and retaining rings.

5. Remove the latch assembly from the door .

6. Reverse procedure to install. Use Loctite 271 to

secure fasteners.

F35425 (February 2006) Page 8 of 40

Page 9

C24GA SERIES CONVECTION STEAMERS - REMOV AL AND REPLACEMENT OF P ARTS

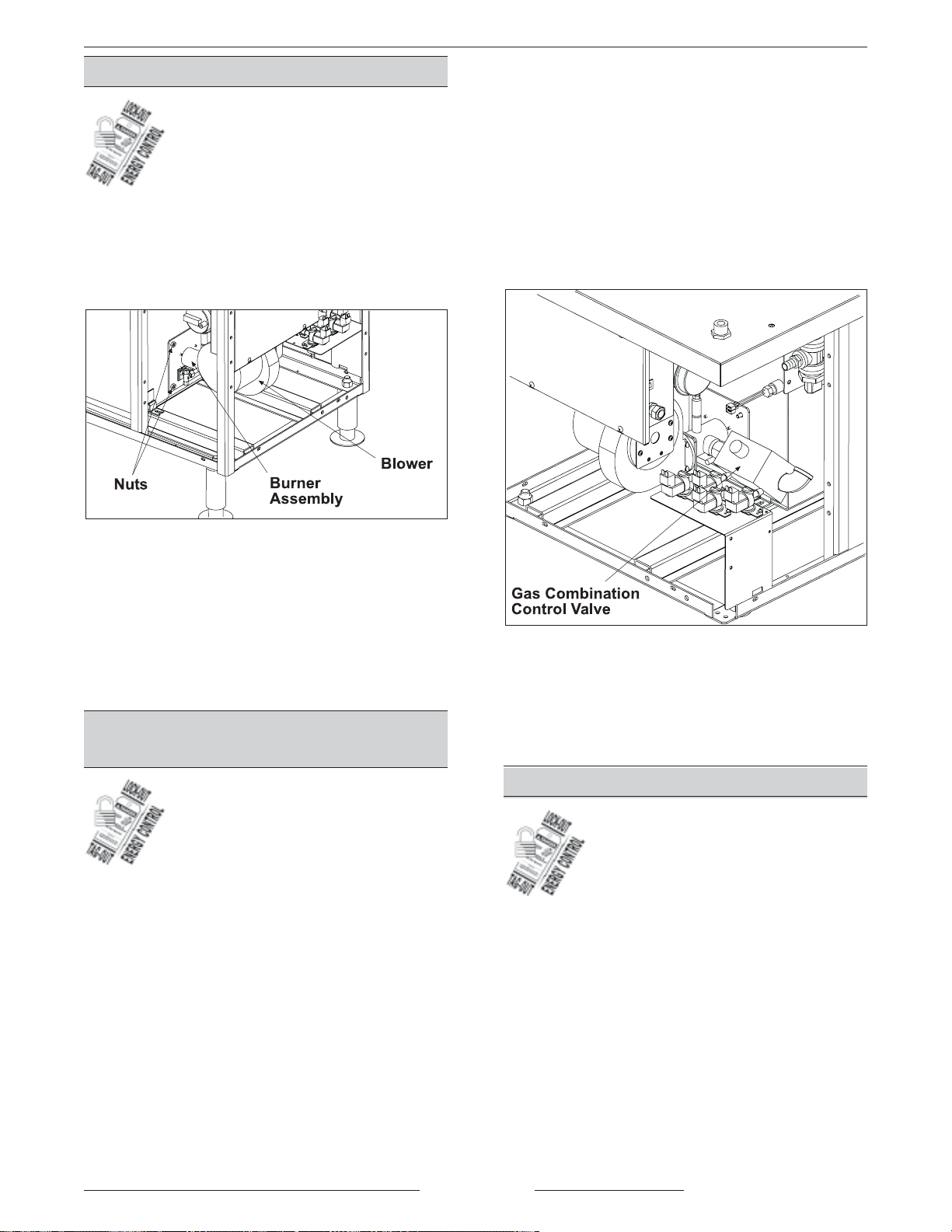

MAIN BURNER

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

1. Remove front and side covers as outlined under

COVERS AND PANELS.

2. Disconnect the gas line at gas combination

control valve.

Gas combination control valves are not serviceable

and should not be disassembled. Once the problem

has been isolated to this control, replace it. Do not

attempt to repair the assembly .

1. Remove the front and right side panels as

outlined under COVERS AND P ANELS.

2. Remove main burner as outlined in MAIN

BURNER.

3. Disconnect electrical supply wires running to the

gas combination control valve.

3. Disconnect wires to burner assembly .

4. Remove the nuts securing burner to tank.

5. Drop blower end of burner assembly slightly

down to clear control box and push all interfering

wires out of the way so that burner can be pulled

out of tank.

6. Reverse procedure to install burner assembly .

GAS COMBINATION

CONTROL VALVE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS SUPPL Y BEFORE

SERVICING THE UNIT .

W ARNING: ALL GAS JOINTS DISTURBED DURING

SERVICING MUST BE CHECKED FOR LEAKS.

CHECK WITH A SOAP AND WA TER SOLUTION

(BUBBLES). DO NOT USE AN OPEN FLAME.

A. CHECK A LL JOINTS PRIOR TO THE GAS

V ALVE (SOLENOID) BEFORE LIGHTING

THE UNIT .

B. CHECK ALL JOINTS BEYOND GAS V AL VE

(SOLENOID) AFTER UNIT IS LIT .

4. Disconnect the pilot gas supply tube from the

control and pipe connections on each side of the

gas combination control valve.

5. Reverse procedure to install and check unit for

proper operation.

GENERATOR ASSEMBLY

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS SUPPL Y BEFORE

SERVICING THE UNIT .

W ARNING: ALL GAS JOINTS DISTURBED DURING

SERVICING MUST BE CHECKED FOR LEAKS.

CHECK WITH A SOAP AND WA TER SOLUTION

(BUBBLES). DO NOT USE AN OPEN FLAME.

A. CHECK A LL JOINTS PRIOR TO THE GAS

V ALVE (SOLENOID) BEFORE LIGHTING

THE UNIT .

B. CHECK ALL JOINTS BEYOND GAS V AL VE

(SOLENOID) AFTER UNIT IS LIT.

F35425 (February 2006)Page 9 of 40

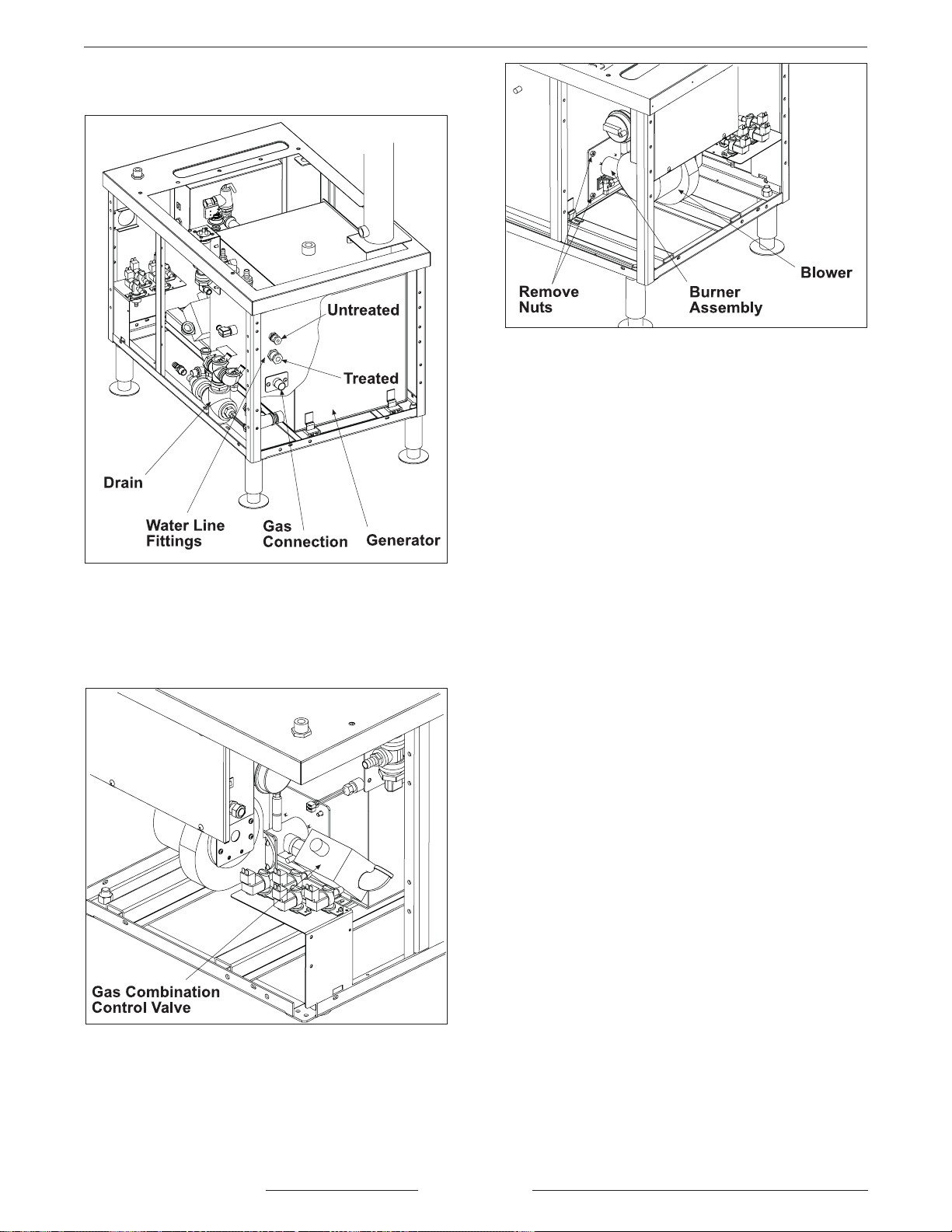

Page 10

C24GA SERIES CONVECTION STEAMERS - REMOV AL AND REPLACEMENT OF P ARTS

1. Drain the generator and allow steamer to cool, if

necessary.

4. Disconnect wires to burner assembly .

5. Disconnect wires from gas combination control

valve.

6. Remove the nuts securing the burner to

generator .

7. Drop blower end of burner assembly slightly

down to clear control box and push all wires out

of the way so that burner can be pulled out of

tank.

2. Remove rear and side panels as outlined under

COVERS AND PANELS.

3. Disconnect gas line at gas combination control

valve.

8. Disconnect wires from the 195°F thermostat

mounted to the generator and operating pressure

switch.

9. Loosen hose clamp attaching lower flexible

water line at back panel and use a wrench to

disconnect barb fitting from main inlet water

connection.

10. Loosen hose clamp attaching upper flexible

water line at back panel and use a wrench to

disconnect barb fitting from main inlet water

connection.

1 1. Remove water line from generator. Remove

steam hoses from steam trap and supply to

super heater.

12. Disconnect gas tubing from rear panel

13. Remove steel drain tube at tank.

14. Disconnect union between tank and drain.

15. Loosen cable clamp screws securing electrical

cable at rear panel so that cable is free to move.

16. Remove screws to free super heater and lift

super heater off flue pipe.

F35425 (February 2006) Page 10 of 40

Page 11

C24GA SERIES CONVECTION STEAMERS - REMOV AL AND REPLACEMENT OF P ARTS

16. Rotate pressure relief valve coupling to allow

pressure relief valve to be rotated about 90° so

that valve is below generator top level.

19. Move any interfering components out of the way ,

then push generator slightly forward to disengage

feet and remove generator from rear of cabinet.

20. Reverse procedure to install generator.

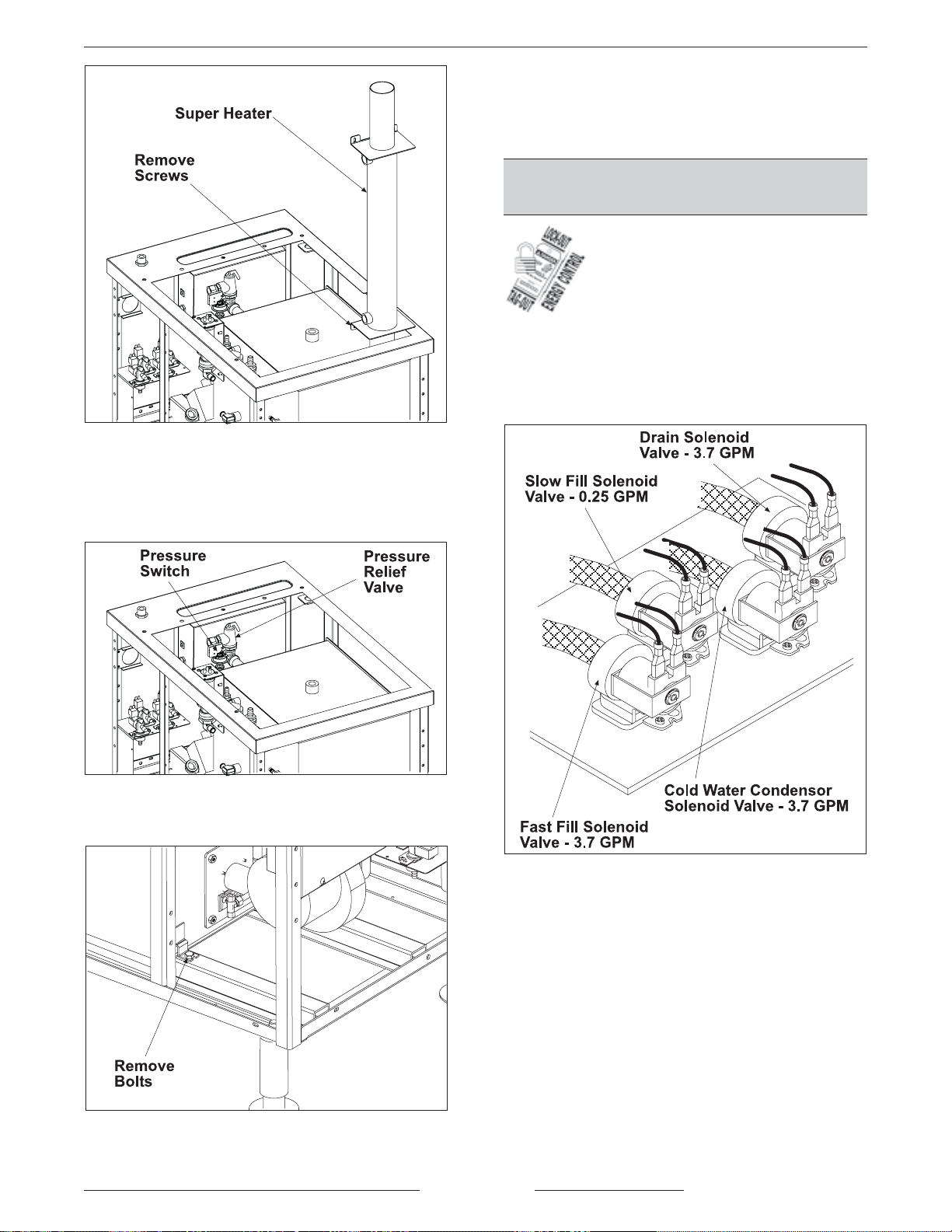

FILL AND COLD WATER

SOLENOID VALVES

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

1. Turn of f the water supply to the steamer .

2. Remove front and side covers as outlined under

COVERS AND PANELS.

17. Remove pressure switch from generator.

18. Remove bolts attaching front of generator to

frame.

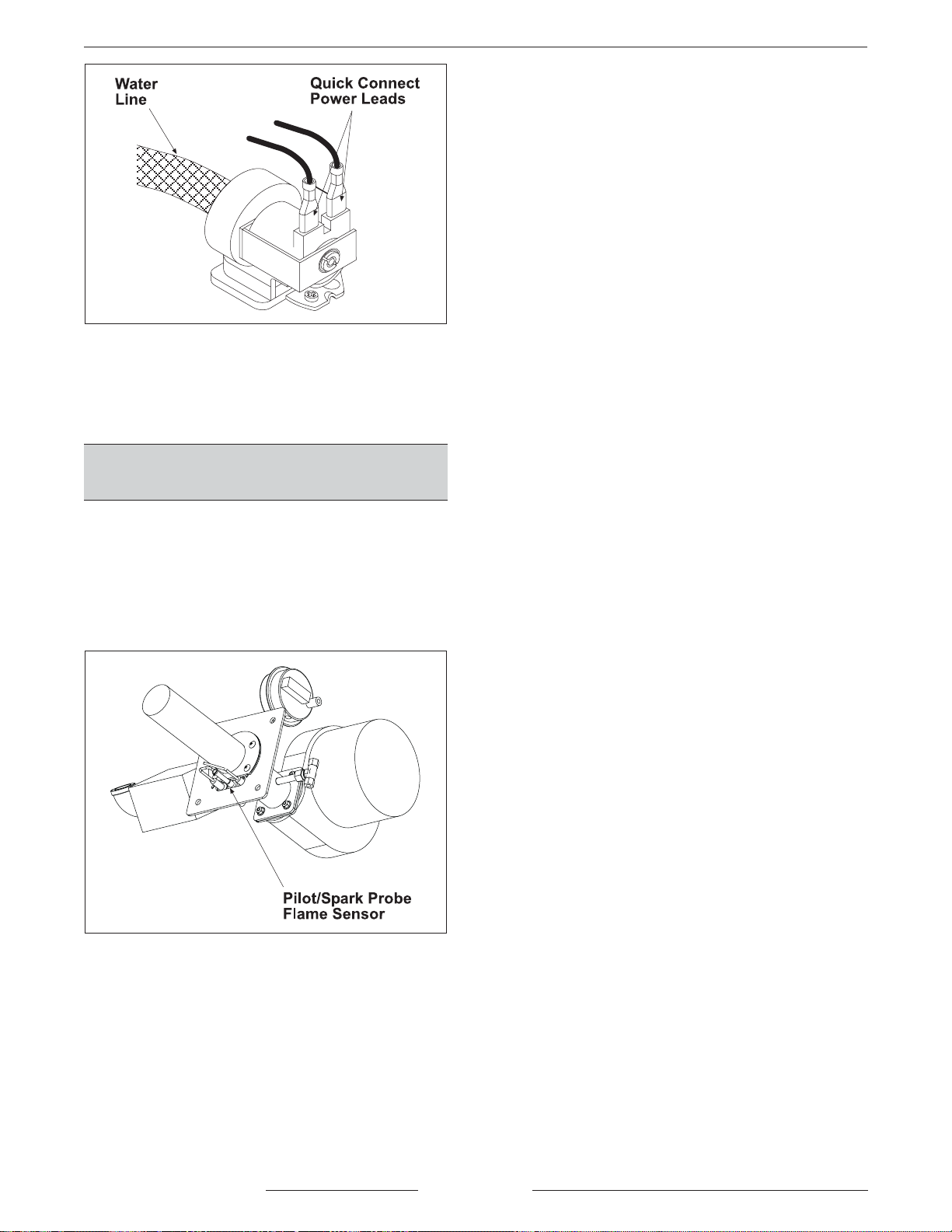

3. Pull the quick connect power leads off the

solenoid valve being serviced.

F35425 (February 2006)Page 11 of 40

Page 12

C24GA SERIES CONVECTION STEAMERS - REMOV AL AND REPLACEMENT OF P ARTS

4. Disconnect the water lines for the solenoid valve

being serviced and remove the solenoid valve

from the unit.

5. Reverse procedure to install solenoid valve.

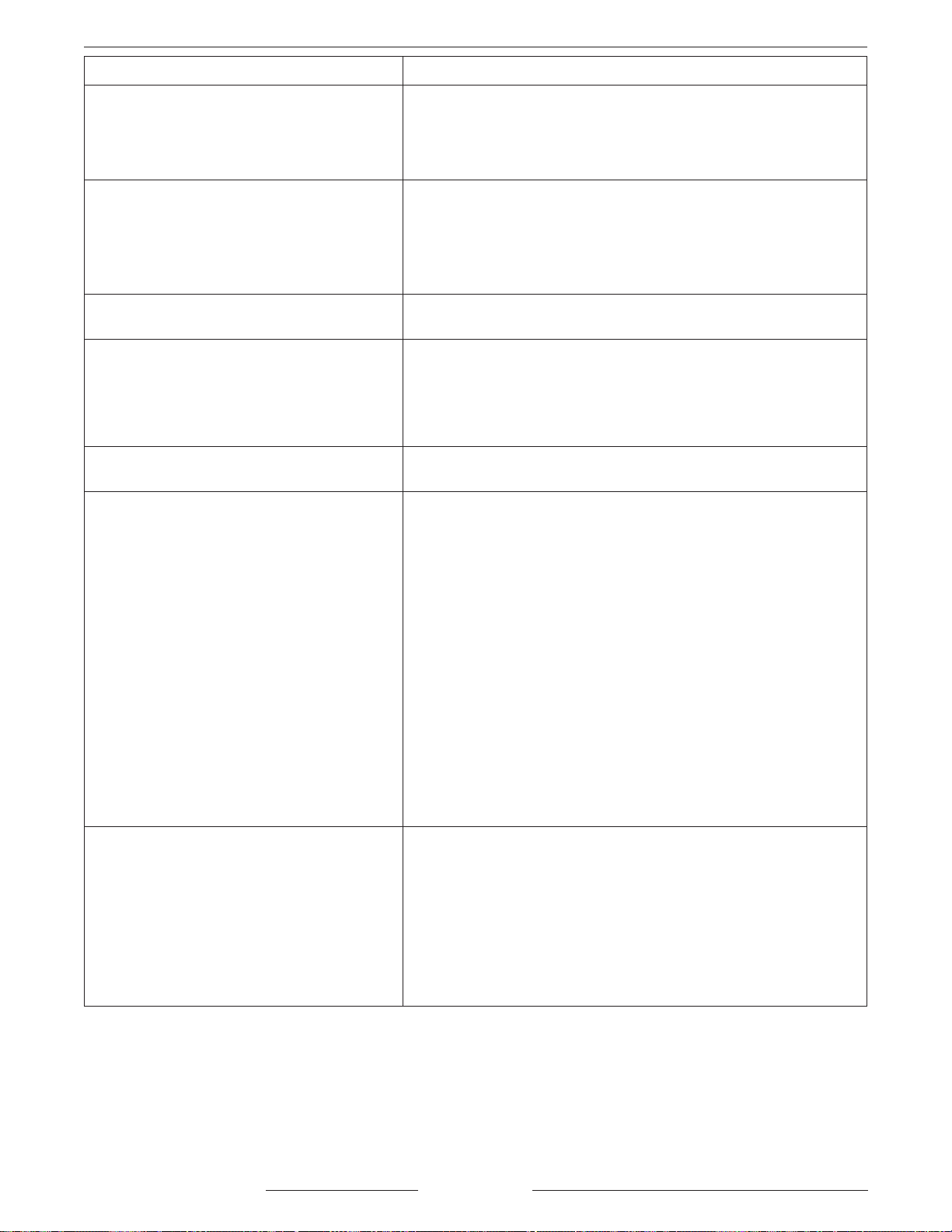

PILOT/SPARK PROBE

FLAME SENSOR

1. Remove main burner assembly as outlined under

MAIN BURNER in REMOVAL AND REPLACEMENT

OF P ARTS.

2. Remove the pilot assembly by disconnecting

gas tube to the pilot burner and remove screws

holding pilot assembly .

3. Replace the malfunctioning flame sensor or pilot

assembly.

4. Reverse procedure to install a new flame sensor

or pilot assembly .

5. Check for proper operation.

F35425 (February 2006) Page 12 of 40

Page 13

C24GA SERIES CONVECTION STEAMERS - SER VICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING: CER T AIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR MEASURE-

MENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL TIMES.

IF TEST POINTS ARE NOT EASIL Y ACCESSIBLE, DISCONNECT POWER AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES, A TTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST.

BLOWER AIR PRESSURE

ADJUSTMENT

Adjust the blower air pressure at the gas combination

manifold pressure tap. Turn the gas valve off. Remove

pipe plug from pressure tap on the outlet side of the

gas combination valve and install a gas manometer .

The air pressure should be 0.35"W .C. (0.09 kPa) to

0.4"W.C. (1 kPa). If the reading is not correct adjust

blower speed control adjustment screw clockwise to

increase and counter-clockwise to decrease.

AIR PRESSURE SWITCH

ADJUSTMENT

Blower air pressure adjustment must be performed

before proceeding with this procedure.

The air pressure switch senses the pressure level

produced by the blower for combustion. When the

pressure is sufficient, the switch closes and supplies

power to the ignition control module. The gas ignition

sequence starts to light the gas pilot and then main

burner . If gas pilot is not lighting (valve not energized),

the ignition control module may not be receiving

power, assuming the minimum water level is satisfied.

Check the air pressure switch operation then adjust if

necessary as outlined in the procedure below .

1. Turn the power switch off.

2. Remove the front panel from the cabinet base.

A. Inspect the air intake to the blower for

debris build up and clogging.

1 ) If debris is found, clean it away from

the air intake.

B. Turn the power switch on and verify main

burner ignition.

1 ) If burner ignites no adjustment to the

pressure switch setting is necessary .

2 ) If burner does not ignite, proceed to

step 3.

3. Turn the main gas valve to off.

4. Adjust the air pressure switch setting as follows:

A. Turn the adjustment screw fully clockwise

to the highest setting.

B. Slowly turn the adjustment screw counter-

clockwise until main gas valve energizes

then add 1/2 turn to the adjustment.

F35425 (February 2006)Page 13 of 40

Page 14

C24GA SERIES CONVECTION STEAMERS - SER VICE PROCEDURES AND ADJUSTMENTS

The screw head should not extend out past

the screw housing.

1) If gas valve energizes, proceed to

step 5.

2 ) If gas valve does not energize, check

the following:

a. Remove the lead wires from the

switch and verify with a meter that

the switch contacts are closing

with the blower on. If necessary ,

continue to turn the adjustment

screw several turns counterclockwise to close the switch

contacts.

b. If the switch contacts are not

closing, turn the power switch off,

remove the pressure switch from

the manifold and check the air

orifice for debris build up and

clogging. If debris is found, clean

it away from the orifice.

PILOT BURNER ADJUSTMENT

1. Shut the gas off at combination gas valve.

2. Remove cover from manifold pressure tap.

3. Install a barb fitting and connect manometer .

4. Turn on the steamer , let generator fill.

5. V erify air pressure setting is between 0.35" and

0.4" W.C.

6. V erify air pressure switch adjustment.

c. Replace the orifice, pressure

switch and connect the lead wires

to the switch. Turn the power

switch on and adjust the pressure

switch again as outlined in steps

4A and 4B. Verify the pilot gas

valve is energizing.

d. If the pilot gas valve is not

energizing and power is available

to the pressure switch, turn the

power switch off. Replace with a

new air pressure switch and

adjust the switch as outlined from

step 3 thru the end of this

procedure.

5.

Restart the ignition sequence by turning the power switch

off, waiting 3 seconds, then back on.

A. Listen or use a meter for gas pilot ignition

to verify operation.

1 ) If gas pilot ignition is successful, listen

for main gas burner ignition to verify

operation.

B. Verify the pilot and main burner both ignite

in succession.

1 ) Restart the ignition sequence by

rapidly turning the power switch off

then back on. A rapid switching is

needed to keep the generator from

starting automatic blowdown.

7. Turn off the steamer .

8. Remove pilot assembly from burner.

9. Remove cap from pilot adjustment screw.

10. Using cabinet tip screwdriver turn pilot

adjustment screw all the way in.

1 1 . Back out pilot adjustment screw 1 (one) turn

counter clockwise.

12. Remove the wire from main valve (wire # 35).

13. Turn on the steamer , let generator fill.

14. Turn on combination gas valve.

15. Observe pilot flame; adjust pilot flame length

using pilot adjustment screw. Set flame to

approx. 2" long (Pilot flame should be a nice blue

flame; with slight touch of yellow permissible at

tip.)

C. Listen for main gas burner ignition to verify

operation.

F35425 (February 2006) Page 14 of 40

Page 15

C24GA SERIES CONVECTION STEAMERS - SER VICE PROCEDURES AND ADJUSTMENTS

16. Turn off the machine.

17. Re-install pilot, reconnect wire # 35.

2. Turn the power on and let the generator come up

to pressure.

3. After the ready light comes on, turn one of the

cooking compartment timers on to exhaust

steam from the generator.

18. Turn on the machine, let generator fill

19. Observe proper functioning of gas burner.

Operating Pressure Switch

1. Remove the cabinet base front panel as outlined

under COVERS AND P ANELS. Pressure switch

is located behind control box.

4. Observe generator pressure gauge reading for

several cycles and verify that the burner is

cycling off at 3.5 to 4 psi.

F35425 (February 2006)Page 15 of 40

Page 16

C24GA SERIES CONVECTION STEAMERS - SER VICE PROCEDURES AND ADJUSTMENTS

Thumb Wheel Adjustment

The thumb wheel directly below the microswitch

changes both the cut-out (off) and the cut-in (on)

points of the operating Pressure Switch.

Turn the thumb wheel to obtain the proper cut-out (off)

setting. Turning thumb wheel clockwise increases the

pressure. The cut-out (off) off setting should be 3.5 to

4 psi.

Inlet Water/Steam Strainer

1. Unscrew the cap from the body .

2. Remove the screen and any foreign particles

3. Rinse the screen thoroughly to remove

4. Reinstall the cap.

F35425 (February 2006) Page 16 of 40

trapped in the opening.

accumulated debris and replace the screen in

the valve body . If the screen cannot be

thoroughly cleaned, replace it with a new one.

Page 17

C24GA SERIES CONVECTION STEAMERS - SER VICE PROCEDURES AND ADJUSTMENTS

AUTOMATIC IGNITION SYSTEMS

When the main power switch is turned on and the

water level is above LLCO, the ignition control module

is energized with 24 volts between terminals five and

six. High voltage is sent from terminal nine to the

spark electrode and an output of 24 volts is sent from

terminals two and three to the pilot coil in the combination valve, allowing gas to flow to the pilot. The

sparking will continue for 90 seconds or until the

flame sensor has confirmed that an adequate pilot

flame is present.

Once the pilot flame is confirmed, a 24 volt output

from terminal one will be sent to the gas combination

control valve.

TERMINAL

NO. DESCRIPTION

1 Voltage (24 VAC) will be present on MV

terminal #1 with the pilot sensing

electrode sensing an adequate pilot

flame. This output will remain present

as long as the pilot flame remains

adequate.

2 Common MV/PV .

3 The Pilot Voltage (24 VAC) will be

present on terminal #3 at the instant

an input voltage is supplied to the

module. This voltage will remain

present on terminal #3 providing an

adequate pilot flame is established

within 90 seconds. In the event that an

adequate pilot flame is not established

within 90 seconds this output voltage

will drop out.

4 Ground (burner).

5 Ground (24 VAC Neutral).

6 24 V AC Input.

8 Flame Sensor.

9 High Voltage to spark electrode.

Spark Ignition Control Test

The ignition control module and ignition control

module transformer are located in the electronics

enclosure behind the generator base front cover.

1. Check for earth ground.

2. Check to ensure that all electrical terminal

connections on the ignition control module and

the igniter are clean and tight.

3. V erify that the ignition control module and the

igniter have good ground wire connections. The

igniter mounting bracket should have good metal

to metal contact to its mounting surface.

4. Turn the main power switch on. Make sure LLCO

light is on.

5. Check for 24V AC output on the ignition control

module transformer.

F35425 (February 2006)Page 17 of 40

Page 18

C24GA SERIES CONVECTION STEAMERS - SER VICE PROCEDURES AND ADJUSTMENTS

A. If 24V AC is present, then replace ignition

control module and retest. It may take up to

3 seconds for the module to reset if main

power is turned off then back on.

B. If 24V AC is not present, then ensure that

transformer is receiving 120V AC input. If

ignition control module transformer is

receiving proper voltage, then replace

ignition control module transformer and

retest.

WARNING: SHUT OFF THE GAS SUPPL Y BEFORE

SERVICING THE UNIT .

MANIFOLD PRESSURE

ADJUSTMENT

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

IGNITION TEST

1. The gap between the spark probe and the pilot

burner should be approximately 1/8". If the gap

appears to be excessive or poor sparking is

occurring, remove the electronic ignition pilot and

adjust gap.

W ARNING: ALL GAS JOINTS DISTURBED DURING

SERVICING MUST BE CHECKED FOR LEAKS.

CHECK WITH A SOAP AND WA TER SOLUTION

(BUBBLES). DO NOT USE AN OPEN FLAME.

A. CHECK A LL JOINTS PRIOR TO THE GAS

V ALVE (SOLENOID) BEFORE LIGHTING

THE UNIT .

B. CHECK ALL JOINTS BEYOND GAS V AL VE

(SOLENOID) AFTER UNIT IS LIT.

1. Remove front, right and left side panels from

cabinet base as outlined under COVERS AND

PANELS.

2. Turn the gas combination control valve off.

2. Inspect the ceramic flame rod insulator for

cracks or evidence of exposure to extreme heat,

which can permit leakage to ground. If either of

these conditions exist, then replace the pilot

igniter assembly .

3. Check the ignition cable for tightness or

damaged insulation.

4. Check unit for proper operation.

Inspect the pilot burner orifice. This should be approximately 1/8" in diameter and free of debris.

F35425 (February 2006) Page 18 of 40

3. T o measure the manifold pressure, remove the

4. Turn the gas supply valve and the main power

1/8" NPT plug (pressure tap) on the outlet side of

the gas combination control valve and attach a

manometer.

switch on. Allow generator to fill.

Page 19

C24GA SERIES CONVECTION STEAMERS - SER VICE PROCEDURES AND ADJUSTMENTS

5. V erify burner air pressure is 0.35" to 0.4" W .C.

6. Turn the gas combination control valve on and

wait until main burner lights.

7. Observe the manometer pressure reading and

compare to the pressure chart below .

GAS PRESSURE READINGS (INCHES W.C.)

MANIFOLD LINE*

GAS TYPE RECOMMENDED MI N MAX

Natural 2.5 7.0 5.0 14

Propane 10.0 11.0 11.0 14

5. Check wiring for damaged insulation (no short

circuit).

6. Check that all connections and terminals are

securely fastened (no open circuits).

7. Check that all connections are made according

to compartment control wiring diagram.

DOOR

Latch Adjustment

If the cabinet door jams and cannot be opened, do not

force or pry the door , as damage will occur.

* If the incoming line pressure is less than the

minimum stated, then the manifold pressure cannot

be set correctly .

8. Once the correct pressure has been set, turn the

power switch and gas supply off, replace the

adjustment screw cap and 1/8" NPT plug

(pressure tap) on the outlet side of the valve.

COOKING COMPARTMENT

Controls

1. For access to compartment controls, remove the

right side panel from the cooking compartment

as outlined under COVERS AND P ANELS.

2. Check door switch for proper operation.

First, try lifting up on the bottom of the door at the

handle end to disengage the latch. If that does not

work, remove the right side panel from the cooking

compartment as outlined under COVERS A ND

PANELS.

The striker that catches on the door latch is located

behind the front face of the cooking cavity . Remove

the nut from the striker to release it from the panel.

3. Check cooking timer function and contact

position. See SCHEMA TICS under ELECTRICAL

OPERA TION.

4. Check that timer motor operates when

connected to power. If a problem is found in

timer , replace it, do not t ake timer apart.

Once the nut and washer have been removed, door

will open freely .

Remove any burrs on the striker that may cause the

latch to stick. Reinstall the striker and adjust so door

will not jam.

F35425 (February 2006)Page 19 of 40

Page 20

C24GA SERIES CONVECTION STEAMERS - SER VICE PROCEDURES AND ADJUSTMENTS

Striker Adjustment

• Safety goggles or face shield.

1. Reinstall the striker with the slot pointing

upwards and hand tighten nut only .

2. Close the door to center the striker in the oval

mounting hole.

3. Open the door and check the striker’s slot for

horizontal alignment. The slot on the striker must

be kept horizontal in order for the door latch to

catch it properly and latch.

4. Once the proper slot alignment has been set,

hold the striker close to its base using an open

end wrench, add Loctite to the threads, then

tighten the striker nut. Be careful not to damage

the striker slot when tightening or door may not

latch properly . Do not over tighten as the striker

will begin to turn and change alignment.

• Measuring cup.

• 1 gallon container for mixing deliming solution.

• Petrol-Gel Lubricant or equivalent food grade

grease for coating deliming port threads.

NOTE: Deliming solution may cause the surface of

aluminum measuring tools to tarnish or

etch.

C24GA (Automatic Drain)

11 US GAL Capacity Steam Generator.

NOTE: This procedure is not intended to take the

place of a water treatment program.

1. Turn power switch off. Wait 5 minutes for steam

generator to completely drain and the drain valve

to close.

2. Turn cooking timers to off.

3. Prepare deliming solution according to the

instructions on the deliming material package.

Follow all manufacturers’ instructions.

4. Remove delime port cap on top of unit and insert

funnel into delime port.

5. If door does not open easily , add shims as

necessary between striker and cabinet front.

6. Repeat steps 2 thru 4.

DELIMING THE GENERATOR

WARNING: READ AND FOLLOW THE INSTRUC-

TIONS ON THE DELIMING MA TERIAL P ACKAGE.

A VOID CONT ACT WITH SKIN AND EYES. WEAR

PLASTIC OR RUBBER GLOVES AND SAFETY

GOGGLES WHEN HANDLING . WASH THOROUGHL Y AFTER HANDLING . IF DELIMING SOLUTION COMES IN CONTACT WITH THE SKIN OR

EYES, RINSE THOROUGHL Y WITH CLEAN WATER.

WARNING: THE STEAMER AND ITS P ARTS ARE

HOT . USE CARE WHEN OPERA TING, CLEANING

OR SERVICING THE STEAMER. THE COOKING

COMP ARTMENT CONT AINS LIVE STEAM. ST A Y

CLEAR WHEN OPENING DOOR.

Items Required (not provided)

• Deliming material.

• Funnel.

5. Pour deliming solution into the steam generator

slowly to avoid spillage.

6. Remove funnel from delime port then rinse port

with clean water .

7. Lightly coat delime port threads with Petrol-Gel

then install delime port cap. Cap must be

installed and tightened securely at all times.

8. Turn power switch on. When ready light comes

on, allow steamer to remain on for 40 minutes.

9. After 20 minutes, turn cooking timers on for 1

minute to delime the steam tubes and nozzles.

• Plastic or rubber gloves.

F35425 (February 2006) Page 20 of 40

Page 21

C24GA SERIES CONVECTION STEAMERS - SER VICE PROCEDURES AND ADJUSTMENTS

10. After 40 minutes, turn power switch off and allow

steam generator to completely drain, 5 minutes.

1 1. Rinse steam generator with clean water:

A. Turn power switch on. When ready light

comes on, turn cooking timers on for 30

seconds to rinse the steam tubes and

nozzles.

B. Turn power switch off and allow steam

generator to completely drain.

C. Turn cooking timers to off.

D. Repeat steam generator rinse one time.

12. Clean exterior and interior using a mild solution

of soap and water. Rinse with clean water then

dry with a soft cloth. Leave compartment doors

open when not in use.

13. The steamer is ready for operation or shutdown.

COOKING CYCLE TEST

General

During a cooking cycle, the gas heating system will

cycle on and off as necessary to maintain steam

pressure in the generator. When the steam pressure

in the steam generator reaches 4 psi for the first time

after machine is switched on, the steam header

pressure relay latches on and supplies power to

compartment controls. Ready light will illuminate

(header pressure relay remains latched until the

machine is switched off).

10. Observe the floor drain to ensure that live steam

from the compartments is being cooled by cold

water from the cold water condenser solenoid

valve.

1 1 . When the timer knobs reach 0, confirm that the

buzzers sound, steam delivery ceases, cooking

lights go off, and ready lights come on.

12. To silence the buzzers, turn the timer knobs to

off position.

13. Turn the main power switch off to remove power

from the steamer, and confirm that the red light

goes out and generator drains.

PROBE INSPECTION

It is recommended that the generator be thoroughly

inspected for excessive scale and lime build-up on a

quarterly basis. In hard water areas or for units heavily

used, a shorter interval should be used. This inspection consists of the following:

Drain Plug - Remove clean-out port plug to check

for scale.

Probe - A check of lime build-up on the water

level probe assembly.

Controls - A check of all generator controls,

including the pressure switches.

T est operation of the cooking compartment controls.

1. With both timer knobs at the off position, open

the compartment doors.

2. Observe that no steam has entered the cooking

compartments.

3. Close the doors.

4. Set both timer knobs at 2 minutes.

5. Confirm that the ready lights go off, the cooking

lights come on, and steam begins to enter the

compartments.

6. After one minute, open both doors.

7. Observe that steam has ceased to enter each

compartment, cooking lights go back to ready ,

and one minute is remaining on each cook timer .

8. Close the doors.

9. Confirm that steam delivery and cook timing

resume.

F35425 (February 2006)Page 21 of 40

Page 22

C24GA SERIES CONVECTION STEAMERS - ELECTRICAL OPERA TION

ELECTRICAL OPERATION

WATER LEVEL CONTROLS

Low Level Cut-Off and Differential Control

The steamer is equipped with three water level

sensing probes (high, low and low level cut-off) and a

single water level control board. The water level

control board performs two functions:

1. Provide low level cut-off protection to shut off the

heat source in case the water level drops below

the low level cut-off (LLCO) probe.

2. Perform as a differential level control to maintain

the water level between the low and high water

level probes.

The input voltage (120V AC) is applied across terminals 1 1 and 12 of the Water Level Control (WLC). This

is applied to the primary of the transformer . On one

side of the transformer secondary power is provided to

the control by a series path through chassis ground

(terminal 10). The other side of the transformer

secondary (12V AC) is attached to the probe that

directs power to the other side of the internal relays

(LLCO, HL, and ILR). As water enters the generator , it

becomes part of the water level control’s circuit.

When the water level in the generator reaches a

probe, that circuit is completed.

contacts open, the generator fill solenoid is deenergized, stopping the flow of water into the

generator .

When the water level drops below the low level (LL)

probe, power is removed from the inverse latching

relay , the HL relay energizes through ILR-2, and HL

contacts change state. The fill solenoid is energized

through HL-3 to refill the generator and the HL LED is

lit. The HL relay and LED will toggle on and off during

a cooking cycle as needed.

The inverse latching relay (ILR) of the board is deenergized, leaving the ILR-1 (N.O.) and ILR-2 (N.C.).

When the main power switch is turned on, power is

supplied to the water level control (WLC) board which

energizes the high level (HL) relay and illuminates the

HL relay LED. With the HL-3 contacts closed, the

generator fill solenoid is energized and water begins

filling the generator.

When the water level reaches the low level cut-off

(LLCO) probe, the LLCO relay is energized and

illuminates the LLCO LED. With the LLCO-2 contacts

closed the heat source is then energized. The LLCO

relay will remain energized and its LED will stay lit

until the water level in the generator drops below the

LLCO probe.

When the water level reaches the low level (LL) probe,

power to terminal 2 on the WLC board is present but

no switching occurs.

After the water level reaches the high level (HL) probe,

the inverse latching relay on the board is energized

and locked through the low level probe (LL) and ILR-1

contacts. With ILR-2 contacts open, this de-energizes

the HL relay and the HL LED goes out. With the HL-3

SEQUENCE OF OPERATION

Refer to schematic diagrams 00855693 , 00855424

and 00856656.

Initial Fill and Preheat

Conditions:

A. Power switch off.

B. Cold water thermostat open.

C. Drain cold water condenser solenoid

de-energized.

D. Timer delay output open.

E. Normally closed solenoid de-energized.

F. Generator connected to correct voltage

(120VAC).

G. Generator properly grounded.

H. Gas and water supply valve(s) on.

I. Main gas valve manual valve in on position.

J. Cycling pressure switch closed.

K. Air pressure switch open.

F35425 (February 2006) Page 22 of 40

Page 23

C24GA SERIES CONVECTION STEAMERS - ELECTRICAL OPERA TION

1. Turn power switch on.

1) V oltage is removed from:

A. Timer de-energized.

1) Operating voltage applied to control

compartment after cavity relay is

latched on.

B. Water level control (WLC) energized.

1 ) Low level (LL) relay N.C. contacts

provide operating voltage to fast-fill

solenoid.

a. Fast-fill solenoid energized, water

begins filling the generator.

2 ) Water reaches low level probe.

a. LL relay N.C. contacts open and

N.O. contacts close.

b. Volt age applied to normally closed

pressure switch (opens at 4.0 psi).

c. Voltage applied through HL

contacts to hold thermostat

(closes at 190°F).

d. Volt age through pressure switch

applied to blower and to normally

open air switch (closes at

0.4" W.C.).

e. Fast-fill solenoid de-energized.

C. Air switch closes at 0.4" W.C.

1 ) Voltage applied to step-down

transformer primary (120 V AC).

Transformer steps voltage down to 24

VAC to operate ignition module.

a. Air pressure switch.

b. Blower motor.

c. Step-down transformer which

removesvoltage from ignition

module.

F. Voltage through the N.O. contact s of the

pressure switch is applied to the cavity

relay in the compartments.

1 ) Volt age applied to compartment

controls after cavity relay is energized.

Relay remains energized until main

power is removed.

Compartment control (Units before Dec. 1, 2005)

Refer to schematic diagrams 00855693 & 00855424.

1. Compartment door closed causing door switch

to close and READY light to illuminate.

A. 120 V AC applied through door switch to

timer contact 1.

B. Timer manually set to desired time period.

C. Volt age applied through contacts 1 and 3.

1) Timer begins countdown.

2) Steam solenoid energized allowing

steam into compartment.

3) Cavity relay 1 energized, energizing

the CWC solenoid.

4 ) Cook Light illuminated.

D. Timer times out.

2 ) V oltage applied to PV terminal of gas

valve and applying voltage to pilot valve

and high voltage spark lead to ignite

pilot.

3 ) Flame sensor sends signal to MV

relay . 1 micro-amp or higher is required

to maintain pilot.

4 ) MV relay contacts close and

energizes main valve.

5 ) Main burner ignites.

D. When temperature reaches 190°F , hold

thermostat closes energizing the slow-fill

solenoid to keep generator full.

E. When generator pressure reaches 4 psi, the

pressure switch N.C. contacts open, the

N.O. contacts close.

1 ) Timer contacts 1 – 3 open turning off

steam solenoid and cook light.

2 ) Timer contacts 1 – 4 close, turning on

buzzer.

E. Buzzer manually shut off by rotating timer

to off position.

2. Power switch set to off position.

A. Power removed from compartment controls

and generator control circuit.

B. Time delay relay energized.

1 ) Delay relay starts 1000-second

countdown.

2) Drain solenoid energized for 1000

seconds.

3) Water drained from generator.

F35425 (February 2006)Page 23 of 40

Page 24

C24GA SERIES CONVECTION STEAMERS - ELECTRICAL OPERA TION

Compartment control (Units after Dec. 1, 2005)

Refer to schematic diagrams 00855693 & 00856656.

1. Compartment door closed causing door switch

to close and Ready Light to illuminate.

A. 120 VAC applied through door switch to

timer contact 1 1 and 21.

B. Timer manually set to desired time period.

C. Volt age applied through contacts 1 1 and 13.

1) Timer begins countdown.

2 ) Volt age applied through contacts 21

and 23.

3) Steam solenoid energized allowing

steam into compartment.

4) Cavity relay 1 energized, energizing

the CWC solenoid.

5 ) Cook Light illuminated.

D. Timer times out.

1 ) Contacts 1 1 – 13 open and cont act s

1 1 and 14 close energizing the buzzer.

2 ) Timer contacts 21 – 23 open turning off

steam solenoid and COOK light.

E. Buzzer manually shut off by rotating timer

to off position.

F. If timer is set to the HOLD position,

contacts 21 – 23 remain closed keeping the

steam solenoids energized and COOK

lights turned on.

2. Power switch set to off position.

A. Power removed from compartment controls

and generator control circuit.

B. Time delay relay energized.

1 ) Delay relay starts 1000-second

countdown.

2) Drain solenoid energized for 1000

seconds.

3) Water drained from generator.

F35425 (February 2006) Page 24 of 40

Page 25

C24GA SERIES CONVECTION STEAMERS - ELECTRICAL OPERA TION

SCHEMATIC DIAGRAMS

Generator Schematic Diagram

F35425 (February 2006)Page 25 of 40

Page 26

C24GA SERIES CONVECTION STEAMERS - ELECTRICAL OPERA TION

Schematic Diagram - Compartment Controls (Standard)

F35425 (February 2006) Page 26 of 40

Page 27

C24GA SERIES CONVECTION STEAMERS - ELECTRICAL OPERA TION

Schematic Diagram - Compartment Controls (Constant Steam)

F35425 (February 2006)Page 27 of 40

Page 28

C24GA SERIES CONVECTION STEAMERS - ELECTRICAL OPERA TION

COMPONENT LOCATION

CABINET BASE GENERATOR

F35425 (February 2006) Page 28 of 40

Page 29

C24GA SERIES CONVECTION STEAMERS - ELECTRICAL OPERA TION

COMPONENT FUNCTION

CABINET BASE GENERATOR

Water Level Control and

Level Sensing Probes................... The Water Level Control circuit board and Level Sensing Probe Assembly

allow water to enter the generator to fill and maintain the proper water level.

These probes will also shut off the heat source to the generator if the water

level drops too low .

The water level control works by using three different probe lengths to monitor

the water level. The probes consist of a high level (HL), low level (LL), and low

water cut-off (LLCO) probe. The level sensing probes may easily be removed to

inspect for lime build up. As a rule, the condition of these devices will indicate

the overall water condition of the generator. Clean the probes, if necessary .

Generator Fast Fill

Solenoid Valve............................. The Generator Fast Fill Solenoid Valve is located on the right side of the

base and admits water at rate of 3.7 GPM to the generator when demanded by

the water level control to maintain the correct water level in the generator .

Generator Slow Fill

Solenoid Valve............................. The Generator Slow (Trickle) Fill Solenoid Valve is located on the right side of

the base and admits water to the generator at a rate of 0.25 GPM when

demanded by the water level control to maintain the correct water level in the

generator .

The output of the Fast Fill and Slow Fill valves are connected in a “Y” to provide

a single feed to the generator.

Cold Water Condenser (CWC)

Solenoid Valve............................. The Cold Water Condenser (CWC) Solenoid Valve allows cold water to flow

into the generator drain to condense steam and cool the hot water before it is

discharged into the drain.

Cavity Cold Water

Solenoid Valve............................. The Cavity Cold Water Solenoid Valve allows cold water to flow into the

cavity drain and cool the hot water before it is discharged into the drain.

Operating Pressure Switch........... The Pressure Switch is located on the front upper right corner of the

generator and is accessible through the left side panel. This switch controls

generator pressure between prescribed limits by turning the heat source on

and off.

Drain Solenoid Valve.................... The Drain Solenoid Valve (Drain V alve) is located on the right side of the base

and is plumbed into the drain pipe of the generator. The generator will

automatically drain for 1000 seconds when power is turned off by using a

normally closed solenoid valve. Daily generator draining is essential to proper

operation and component life by removing sediment and scalants that may be

lodged in the chamber of the generator .

Strainers.......................................Strainers are used in the water inlet line to prevent foreign matter from

becoming lodged in the fill or cold water condenser solenoid valves and to keep

unwanted particles out of the system. S trainers are also located in the steam

line and drain line.

Pressure Gauge

(If applicable)................................The Pressure Gauge is located on the upper right front of the base andindi-

cates generator steam pressure.

Cold Water Thermostat................. The Cold Water Thermostat is located on the lower right side of the base and

maintains drain temperature below 140°F by controlling the drain CWC

solenoid.

F35425 (February 2006)Page 29 of 40

Page 30

C24GA SERIES CONVECTION STEAMERS - ELECTRICAL OPERA TION

Hold Thermostat........................... The Hold Thermostat energizes the Generator Slow Fill Solenoid V alve when

generator temperature reaches the non-adjustable setpoint at 190°F .

Drain.............................................The Drain is located on the lower right of the base and removes steam conden-

sate and water from cooking compartments and generator .

Metal Fiber Main Burner............... The Metal Fiber Main Burner is accessible from the front. This burner heats the

water in the generator to generate steam.

Gas Combination Control Valve....The Gas Combination Control V alve is part of the Burner Assembly and is a

gassolenoid that opens to allow gas flow when a call for heat is made and that

also regulates the manifold gas pressure.

Blower Motor................................ The Blower Motor is part of the Burner Assembly and provides airflow for the

metal fiber burner . The blower is accessible through the front of the base.

Blower Air Pressure Switch.......... The Blower Air Pressure Switch is part of the Burner Assembly and closes at

0.4" W.C. to apply operating voltage to the ignition module.

Gas Orifice.................................... The Gas Orifice is part of the Blower Assembly and controls the flow of gas to

the burner.

Ignition Control Module................ The Ignition Control Module controls the ignition of the gas pilot and main

burner.

24 VAC Transformer.......................The 24 VAC T ransformer reduces the input 120 V AC to the 24 V AC required by

the Ignition Module.

Super Heater Assembly.................The Super Heater Assembly (Heat Exchanger) is located at the rear of the

base surrounding the flue and is used to raise the temperature of the steam by

passing the steam around the flue assembly .

Drain Valve Timer.........................The Drain V alve Timer turns on for 1000 seconds when Power On/Of f Switch

is set to off position to operate the Drain Solenoid.

5 PSI Pressure Relief Valve.......... The 5 psi Pressure Relief V alve opens if the generator pressure exceeds 5 psi

to prevent further pressure rise.

F35425 (February 2006) Page 30 of 40

Page 31

C24GA SERIES CONVECTION STEAMERS - ELECTRICAL OPERA TION

COMPONENT LOCATION

COOKING COMPARTMENT

F35425 (February 2006)Page 31 of 40

Page 32

C24GA SERIES CONVECTION STEAMERS - ELECTRICAL OPERA TION

COMPONENT FUNCTION

COOKING COMPARTMENT

General

The upper section of the steamer consists of two separate cooking compartments. Each compartment functions

independently with its own set of controls. Power is supplied to the controls only after the steam pressure rises

above 4 psi to energize the compartment latching relay . The relay remains energized as long as Main Power Switch

is on.

Ready Light (Green)......................When the Green Ready Light is lit, it indicates steamer is ready to cook.

Cooking Light (Red)...................... When the Red Cooking Light is lit, it indicates steamer is in a cooking cycle.

Cooking Timer.............................. The Cooking Timer is used to set desired cooking cycle time between 0 – 60

minutes. When a timer is set, the steam supply solenoid valve is energized to

allow steam into the cooking compartment, but only after the generator has

reached its operating pressure. Also, the timer energizes the buzzer when time

expires. The timer can be set to the constant steam position. This allows

steam to flow into the cooking compartment continuously .

Power On/Off Switch.................... The Power On/Off Switch located on the lower compartment control panel,

supplies power to the controls when in the on position, and causes the steam

generating process to start in the generator .

Power Indicator Light................... The Power Indicator Light, located to the left of the Power On/Off Switch, is

illuminated when the Power On/Off Switch is in the on position.

Buzzer...........................................The Buzzer signals the end of a cook cycle and must be turned off manually .

Door Switch.................................. The Door Switch removes electrical power to the timer.

Steam Solenoid Valve.................. The Steam Solenoid Valve is normally closed, and when energized, opens to

allow steam into the cooking compartment.

Steam Supply Header...................The Steam Supply Header is the main steam supply line from the generator for

each cooking compartment. The header supplies steam up to the steam

solenoid valve.

F35425 (February 2006) Page 32 of 40

Page 33

C24GA SERIES CONVECTION STEAMERS - TROUBLESHOOTING

TROUBLESHOOTING

General

The following paragraphs provide descriptive information

of the most common troubles that can occur in the

steamer . The Troubleshooting Chart provides a list of

other typical fault conditions. The left-hand column of

the table lists typical symptoms and the right-hand

column lists probable causes and the suggested

remedies.

Water Not Being Supplied to Generator

Turn the steamer on. Check that water supply is

available to the steamer. After approximately 10

minutes, if no water is present, then check for a

problem with the water solenoid valve or water level

control probe.

Scalants may be covering the water level control probe

giving a false indication of a sufficient water level in the

generator . Detach, remove and thoroughly clean the

water level probe assembly to remove scalants and lime

build-up. This condition indicates extremely poor water

quality being supplied to the generator and/or generator

clean out and deliming has not been performed. The

water condition must be cleared up immediately with a

proper water conditioner to avoid further problems with

the steamer. Replace the water level probes and

canister assembly . Water may be draining through an

open generator solenoid valve as quickly as it’s fed to

the generator. Particles of scale trapped in the generator solenoid valve seat may prevent the valve from

closing.

Pilot Or Main Burner Will Not Light

Check blower air pressure, air pressure switch adjustment, pilot burner adjustment, gas inlet and manifold

pressures. The pilot burner orifice should be a 1/8" hole.

Drain Solenoid Valve Does Not Drain

Water Accumulating in Compartment

Water accumulation on the bottom of the cooking

compartment(s) is primarily condensed steam. Failure

to drain out quickly and completely may be due to

debris in the compartment drain screen. Pull screen

straight out and thoroughly clean, then replace. Failure

to drain completely may also be due to improper

leveling of the steamer.

Cooking Cycle Cannot Be Activated

Inspect all wire terminals to ensure they are positive

and secure before assuming any other problem. When

the power switch on generator control box is in the on

position, set the timer knob to 2 minutes. Both Ready

lights should go off, Cooking lights should come on and

steam should be entering both compartments.

Steamer Achieves Pressure Slower Than Normal

If the generator requires more than 18 minutes to

achieve normal operating pressure of 3 – 4 psi, then

check the following conditions.

A. A heavy build-up of scalants has possibly coated

the interior of the generator. The insulating effect of

the scalants hampers heat transfer . Unscrew and

remove the clean-out port plug on the bottom of

the generator. Using a small mirror examine

interior of generator and if scalants and/or lime

build-up is apparent, perform a generator clean-out

and deliming procedure (see DELIMING THE

GENERA TOR). If considerable scalants are

evident, both the generator drain solenoid valve and

the water level control must also be examined.

B. Low incoming gas pressure. Check the incoming

line and manifold gas pressures as outlined in

MANIFOLD PRESSURE ADJUSTMENT under

SERVICE PROCEDURES AND ADJUSTMENTS.

The drain solenoid valve is normally closed when the

main power switch is in the on position. When the main

power switch is set to off, the solenoid valve is energized and the generator drain valve opens for 1000

seconds.

Water contained in the generator , being under pressure,

should be draining through this valve and be noticeable

exhausting out the steamer drain.

If the drain operation appears to function sluggishly or

not at all, scalants may be lodged in the drain pipe and/

or the valve. Disconnect the drain solenoid valve from

the drain line and inspect both the valve and the drain

pipe fixed to the generator. If considerable scalants or

lime build-up is apparent, then not only the drain

solenoid valve, but also the generator and water level

control must be thoroughly cleaned.

C. Gas combination control valve malfunction. Check

the incoming and manifold gas pressures as

outlined in MANIFOLD PRESSURE

ADJUSTMENT under SERVICE PROCEDURES

AND ADJUSTMENTS.

If pressure adjustments are made and manifold pressure remains low, replace the gas combination control

valve and test the steamer for proper operation.

D. Gas orifice clogged or obstructed around air

shutter. It is possible for debris to become lodged

in the small gas orifice opening over time. Clean

out the gas orifice using a round metal instrument

of the same hole diameter or slightly smaller.

Clean as needed. If clogging reappears, the orifice

should be removed, cleaned, and reinstalled.

Remove any other foreign objects that appear to

be obstructing the gas orifice or air shutter.

F35425 (February 2006)Page 33 of 40

Page 34

C24GA SERIES CONVECTION STEAMERS - TROUBLESHOOTING

TROUBLESHOOTING

SEQUENCE OF OPERATION

STEP FUNCTION DESCRIPTION

1 Power On Power Switch is switched to the on position.

2 Fill Stage 1 Boiler fills with fast fill water valve, (3.7 GPM).

3 Low Level Probe Confirmation Low Level Probe, (LLCO), is confirmed then power is applied to

burner system, fast fill valve is turned off.

4 Burner Operation Power is supplied to operating pressure switch.

5 Blower Blower is turned on by operating pressure switch.

6 Blower Pressure Switch Blower air pressure switch is closed when fan is up to speed,

(0.35" to 0.4" WC) and supplies 24 V AC to the ignition module.

7 Pilot Ignition Module turns on spark ignition and supplies power to combination

valve pilot valve, (PV & PV/MV terminals).

8 Flame Sense Flame sense probe confirms pilot flame.

9 Main Burner Ignition module supplies power to gas combination control valve,

(MV & PV/MV terminals), burner ignites.

10 Generator Initial Heat Up Generator heats up.

1 1 Fill Stage 2 Generator 190°F thermostat supplies signal to water level control

to continue filling with trickle valve, (0.25 GPM).

12 Generator Full Boiler will fill till high water probe is confirmed.

13 Ready Operating pressure switch activates ready light and supplies timer

motor power at 3.5 to 4.0 PSI.

14 Full Pressure Generator burner system is terminated at 3.5 to 4.0 PSI.

15 Low Pressure Generator burner system will turn on at 2.5 to 3.5 PSI and operate

till generator pressure reaches 3.5 to 4.0 PSI.

16 Water Level Water level is electronically controlled between the upper and

middle probe operating the trickle fill valve, 0.25 GPM.

17 Cooking Timer is set and door switch is closed power will be supplied to

steam valve, cavity drain valve relay , and cook light.

18 Cold Water Condensate Thermostat located in drain assembly will supply power to cold

water condensate valve to maintain drain temp below 140°F .

19 End Cook Cycle Timer supplies power to buzzer , removes power from steam valves,

cook light, & cavity drain valve relay .

20 Power Off Power Switch is switched to the off position.

21 Power Down Power is removed from burner and water level controls.

22 Drain Power is supplied to drain timer, drain valve is powered for

approximately 16 minutes.

F35425 (February 2006) Page 34 of 40

Page 35

C24GA SERIES CONVECTION STEAMERS - TROUBLESHOOTING

TROUBLESHOOTING CHART

SYMPTOM POSSIBLE CAUSES

Compartment leaks steam or water 1. Steamer not level.

around door. 2. Worn or damaged gasket.

3. Cavity rear strainer clogged.

4. Drain line obstructed.

5. Drain not to an open gap drain.

Cold water condenser not operating properly . 1. Cold water condenser solenoid inoperative or plugged.

2. Lack of water supply.

3. Cold water condenser thermostat malfunction.

4. No power to cold water condenser solenoid.

5. Plugged spray nozzle.

Steam visible inside compartment when 1. Steam supply solenoid not fully closing (clogged or dirty).

unit is not in cook mode. 2. Timer contacts 1 & 3 closed.

Heat coming on without water in. 1. Scale on water level probes (shorted to ground).

2. Retention of water in probe canister assembly.

Pressure relief valve opening or leaking. 1. Cycling pressure switch set too high.

2. Pressure relief valve malfunction.

3. Dirt or scale on valve seat.

Generator will not heat or build pressure. 1. Incorrect input voltage.

2. Generator not filled.

3. Water Level Control malfunction.

4. Water too “pure” for probes to properly conduct electricity .

5. Cycling pressure switch open or set too high or set

too low.

6. High limit thermostat open.

7. Power switch malfunction.

Steam output low or slow cooking. 1. Blocked steam injector ports.

2. Steam solenoid valve not fully opening or blocked.

3. Steam intake shut-of f valve closed.

4. Cycling pressure switch malfunction or needs adjustment.

5. Steam header line (supply) blockage.

6. Pressure relief valve leaking.

7. Steam supply lines leaking badly .

8. Steam strainer clogged.

9. Superheater plumbed incorrectly.

10. Superheater cracked or clogged.

Unit leaks water . 1. Loose water, steam or drain line connections (top or

base).

2. Water line connection clamp leaking.

Generator water level too high. 1. Fast fill or slow fill solenoid does not shut off.

2. High level probe dirty or scaled (open circuit).

3. Water level control malfunction.

F35425 (February 2006)Page 35 of 40

Page 36

C24GA SERIES CONVECTION STEAMERS - TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSES

Generator does not fill. 1. Water supply not on.

2. Fill solenoid not opening or plugged.

3. Water level control malfunction.

4. Filter clogged.

Timer motor does not run. 1. Door open.

2. Door switch inoperative.

3. Timer not getting power.

4. Timer motor inoperative.

5. Ready light circuit malfunction.

Door not closing properly . 1. Door latch assembly malfunction or out of adjustment.

2. Striker adjustment.

Door won’t open or hard to open. 1. Latch won’t release.

2. Door held shut by internal vacuum due to improper

drain connection.

3. Striker adjustment.

4. Door held shut by internal pressure.

Buzzer not operating. 1. Timer malfunction.

2. Buzzer malfunction.

Burner won’t light or won’t stay lit. 1. Gas not on.

2. Combustion air pressure switch malfunction.

3. Ignition module not receiving power.

4. Unit not properly grounded and/or polarity of incoming

power is incorrect on automatic ignition systems.

5. Low incoming gas pressure.

6. Ignition module malfunction.

7. Gas combination control valve malfunction.

8. Generator not filling.

9. Water level control malfunction.

10. Water too “pure” for probes to properly conduct electricity .

1 1. Generator pressure switch open or set too low .

12. Supply line gas pressure too low.

13. Ignition module malfunction.

14. Obstruction in gas orifice.

Pilot not lit or goes out. 1. Gas not on.

2. Low incoming gas pressure.

3. Flame sense current too low; dirty or failed pilot

assembly.

4. Burners ignite too violently.

5. Flame sense wire connection corroded.

6. No sparking.

7. Wrong pilot assembly used.

F35425 (February 2006) Page 36 of 40

Page 37

C24GA SERIES CONVECTION STEAMERS - TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSES

Sp ark igniter not sparking. 1. Incorrect spark gap setting.

2. Poor ground between pilot bracket and burner.

3. Loose, broken or damaged lead wires (including ground)

from ignition module to ignitor.

4. Ignitor boot on ignition cable loose, damaged or missing

causing excessive ignition voltage leakage.

5. Ceramic flame rod insulator on ignitor cracked or damaged

from extreme heat.

6. Ignition module not receiving power.

7. Ignition module malfunction.

8. Combustion burner not operating.

9. Air pressure switch.

F35425 (February 2006)Page 37 of 40

Page 38

C24GA SERIES CONVECTION STEAMERS - CONDENSED SP ARE P A RTS LIST

CONDENSED SPARE PARTS LIST

C24GA SERIES CONVECTION STEAMERS

PART NO. DESCRIPTION

419315 POWER CORD

419359 CABLE, IGNITOR, HIGH VOL T AGE

842049 DOOR SWITCH

41 1500-12 TRANSFORMER 120V/24V

41 1690-1 TIMER COMP ARTMENT

416535-4 SWITCH RELAY

416535-6 RELAY CA VITY COLD WATER CONDENSATE

423813-3 CABLE, FLAME SENSE

423987-1 CIRCUIT BREAKER 3 AMP

435968-1 SOLENOID, DRAIN (NC)

844069-1 LOW WATER CONTROL BOARD

844133-1 GAS VAL VE, NA TURAL

844133-2 GAS VALVE, PROPANE

850778-1 PRESSURE SWITCH, AIR

852984-10 MAIN BURNER ORIFICE, PROP ANE

852984-9 MAIN BURNER ORIFICE, NATURAL

855268-1 DOOR GASKET (C24GA6)

855286-2 DOOR GASKET (C24GA10)

855373-1 SOLENOID, SLOW-FILL 0.25 GPM

855373-2 SOLENOID, FAST-FILL AND CONDENSATE 3.7 GPM

855395-1 STEAM INLET VAL VE

855421-1 PRESSURE SWITCH, BOILER (4PSI)

855605-1 BLOWER, BURNER, VARIABLE SPEED

855606-1 PRESSURE RELIEF VAL VE (5 PSI)

855607-1 THERMOSTA T , COLD W ATER CONDENSA TE 135°F

855608-1 THERMOSTA T , HOLD 190°F

850736-2 PROBES, WATER LEVEL

855627-1 PILOT IGNITOR

855628-1 GASKET , PILOT

855646-1 MAIN BURNER, ACONIT

855659-1 IGNITOR MODULE

855661-1 RELAY ,TIME DELA Y

855666-1 ORIFICE, PILOT AIR NA TURAL

855666-2 ORIFICE, PILOT AIR PROPAN E

855677-1 POWER SWITCH ON/OFF

855625-1 BURNER GASKET

F35425 (February 2006) Page 38 of 40

Page 39

F35425 (February 2006)Page 39 of 40

Loading...

Loading...