Vulcan-Hart ML-135311-948RX, ML-135309-924RX, ML-135310-936RX, ML-135313-972RX, ML-135312-960RX User Manual

Page 1

INSTALLATION & OPERATION MANUAL

900RX Heavy Duty Gas Griddles

M

ODEL

92 M

4RX L-135309-924RX

93 M

6RX L-135310-936RX

94 M

8RX L-135311-948RX

96 M

0RX L-135312-960RX

97 M

2RX L-135313-972RX

w

ww.vulcanhart.com

M

LS

936RX

ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-36968 (rev. 3-08)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury, or death. Read the

installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

-

2 -

Page 3

INSTALLATION, OPERATION AND CARE OF

HEAVY DUTY GAS GRIDDLES

GENERAL

Heavy Duty Gas Griddles are produced with quality workmanship and materials. Proper

installation, usage and maintenance of your griddle will result in many years of

satisfactory performance.

Thoroughly read this entire manual and carefully follow all of the instructions provided

Model Number of Burners BTU/hr Input Rating

924RX 2 54,000

936RX 3 81,000

948RX 4 108,000

960RX 5 135,000

972RX 6 162,000

INSTALLATION

Before installing, verify that the type of gas supply (natural gas or propane) agree with

the specifications on the rating plate located inside the griddle front panel. If the supply

and equipment requirements do not agree, do not proceed with the installation. Contact

your dealer immediately.

UNPACKING

This griddle was inspected before leaving the factory. The transportation company

assumes full responsibility for safe delivery upon acceptance of shipment. Check for

possible shipping damage immediately after unpacking. If the griddle is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Carefully unpack your griddle and make sure that no parts are discarded with packaging

material. A pressure regulator designed to operate with the griddle has been supplied and

must be installed before the griddle is placed into service (Refer to GAS PRESSURE

REGULATOR INSTALLATION in this manual).

LOCATION

The installation location must be kept free and clear of combustibles. When installing,

never enclose the bottom of the griddle with a raised curb or other constructions that

would obstruct flow of air into or out of the griddle. Adequate clearance for air openings

into the combustion chamber must be provided. Make sure there is an adequate supply of

air in the room to replace air taken out by the ventilation system.

Do not permit air to blow directly at the griddle. Avoid open windows next to the griddle

wherever possible. Avoid wall-type fans which create air cross-currents within the room.

3 -

-

Page 4

This griddle is Design Certified for installation on a non-combustible counter with 4” legs,

or combustible floor with 25” high stand.

INSTALLATION CLEARANCES

COMBUSTIBLE CONSTRUCTION NON-COMBUSTIBLE CONSTRUCTION

Back: 6” 0”

Right 6” 0”

Left Side 6” 0”

INSTALLATION CODES AND STANDARDS

The griddle must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall include but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

NOTE: In the Commonwealth of Massachusetts

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3

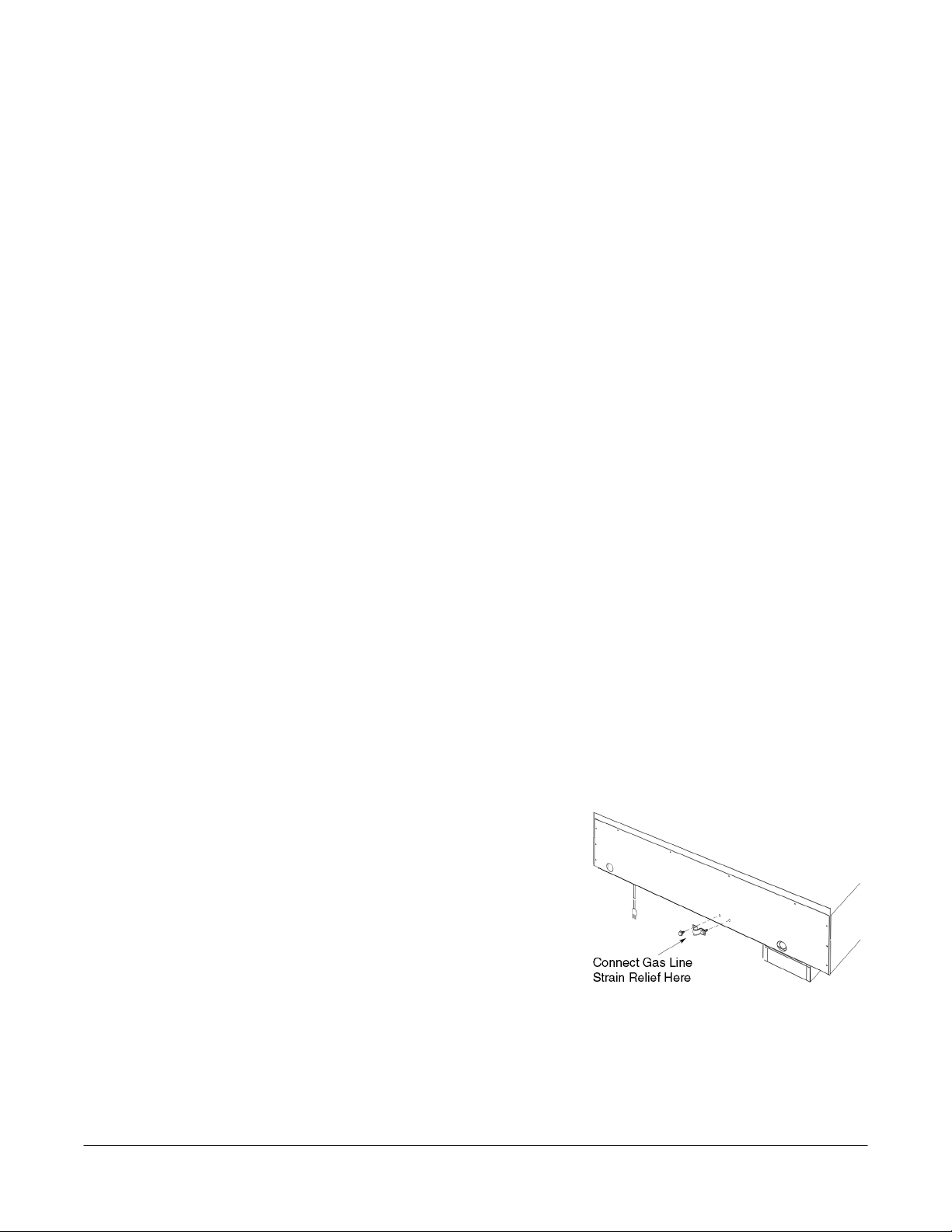

GRIDDLES MOUNTED ON STANDS WITH CASTERS

Griddles mounted on stands with casters must use a

flexible connector (not supplied) that complies with the

Standard for Connectors for Movable Gas Appliances

ANSI Z21.69•CSA6.16, and a quick-disconnect device

that complies with Gas Fuel, ANSI Z21.3•CSA6.9. In

addition, adequate means must be provided to limit

movement of the appliance without depending on the

connector and the quick-disconnect device (or its

associated piping) to limit appliance movement. Attach

the restraining device at the rear of the griddle as

shown in Fig. 3.

Fig. 3.

If disconnection of the restraint is necessary, turn off the gas supply before

disconnecting. Reconnect the restraint prior to turning the gas supply on and returning

the griddle to its installation position.

-

4 -

Page 5

Casters are only supplied on a griddle stand. If the griddle is moved for any reason the

griddle should be re-leveled (see LEVELING in this manual).

FLUE CONNECTIONS

Do not obstruct the flow of flue gases from the flue, located at the rear of the griddle. It is

recommended that flue gases be ventilated to the outside of the building through a

ventilation system installed by qualified personnel.

From the termination of the flue to the filters of the hood venting system, a minimum

clearance of 18” must be maintained.

Information on the construction and installation of ventilating hoods may be obtained from

the standard for “Vapor Removal from Cooking Equipment”, NFPA No. 96 (latest edition),

available from the National Fire Protection Association, Batterymarch Park, Quincy, MA

02269.

STANDS

The griddle has an optional 25” high by 30” deep by 24”, 36”, 48”, 60” or 72” wide

stainless steel stand with casters. The two front casters lock. The stand includes a top

shelf with marine edges style lip and a lower shelf.

GAS CONNECTIONS

Gas supply connections and any pipe joint compound must be resistant to the

action of propane gases.

Use a ¾” NPT gas supply line for the griddle inlet, located at the rear of the griddle. All of

flexible and semi-rigid gas supply lines must comply with the applicable ANSI standard.

To ensure maximum operating efficiency this appliance must be connected with a gas

supply line of solid pipe or a commercial type Flexible Connector with the net inside

diameter (I.D.) as large as or larger than the gas pipe inlet on this appliance. Codes

require that a gas shutoff valve must be installed in the gas line upstream of the griddle.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

After checking for leaks all lines receiving gas should be fully purged to remove air.

TESTING THE GAS SUPPLY SYSTEM

When the gas supply pressure exceeds ½ psig (3.45 kPa), the griddle and its individual

shutoff valve must be disconnected from the gas supply piping system.

When the gas supply pressure is ½ psig (3.45 kPa) or less, the griddle should be isolated

from the gas supply system by closing its individual manual shutoff valve.

GAS PRESSURE REGULATOR INSTALLATION

Gas regulator pressure is preset at 5” Water Column (W.C.) for natural gas, and 10” W.C.

for propane gas. No further adjustment should be required.

Install the regulator as close to the griddle on the gas supply line as possible. Make sure

that the arrow on the underside of the regulator is oriented in the direction of gas flow to

5 -

-

Page 6

the griddle (Fig. 1) and the regulator is positioned with the vent plug and adjustment

screw upright (Fig. 2).

Fig. 1

The supply pressure (upstream of the regulator) should be 7-9” W.C. for natural gas and

11-12” W.C. for propane gas. At no time should the griddle be connected to supply

pressure greater than ½ psig (3.45 kPa) or 14” W.C.

ELECTRICAL CONNECTIONS

Electrical and grounding connections must comply with the

applicable portions of the National Electrical Code and/or other local electrical

codes.

Disconnect the electrical power to the griddle and follow lockout /

tagout procedures.

Appliances equipped with a flexible electric supply cord are provided

with a three-prong grounding plug. It is imperative that this plug be connected into

a properly grounded three-prong receptacle. If the receptacle is not the proper

grounding type, contact an electrician. Do not remove the grounding prong from

this plug.

Fig. 2

Power supply for electric ignition is 120 volts, 1 amp, 50/60 Hertz, 1 phase.

Do not connect the griddle to electrical supply until after gas connections are made.

OPERATION

The griddle and its parts are hot. Use care when operating, cleaning

or servicing the griddle.

BEFORE FIRST USE

Before leaving the factory the griddle is coated with vegetable oil as a rust inhibitor.

Remove this film when the griddle plate is being cleaned prior to its first cooking use.

Heat the griddle to 200-300°F to loosen and melt the coating, then clean the surface with

a non-corrosive, grease dissolving commercial cleaner, following the manufacturer’s

directions. Rinse thoroughly and wipe dry with a soft clean cloth. Clean all accessories.

6 -

-

Page 7

SEASONING THE GRIDDLE

Season the griddle to avoid possible surface corrosion before first use, and after every

cleaning. Heat griddle to a low temperature (300-350°F) and apply a small amount of

cooking oil – about one ounce per square foot of surface. Use a soft lint-free cloth to

spread the oil over the entire griddle surface to create a thin film. Wipe off any excess oil

with a cloth. Repeat the procedure until the griddle has a slick, mirror-like finish.

CONTROLS

There is one pilot and one safety valve for every two burners except on the 36” and 60”

models. The 36” and 60” models have an odd number of main burners, therefore one of

the sets of pilots and safety valves in these models will control only one main burner.

The pilot burners are aligned with the safety valve bush buttons and pilot sight holes. The

pilot burners are inset 12” from the front panel.

This model features an electric ignition system that is controlled by the power switch. The

power switch turns the electric ignition system off and on only. It is recommended that

the power switch stay in the ON position while the unit is running. The burners and pilots

will continue to work with the power switch in the OFF position until the gas supply to the

unit is cut off.

The pilots are monitored by thermocouples and pilot safety valves. If the pilot goes out

and the corresponding power switch is in the ON position, the igniter will immediately

reignite the pilot. If the pilot does not achieve reignition in a short period of time, the

safety valve will shut-off the gas supply to the pilot and main burners. In the event of a

failure of the electronic ignition system, it is possible to ignite the pilots with an outside

ignition source (such as a lit taper, etc). See pilot lighting procedure on page 8.

Each 12” section of the griddle is independently controlled by a mechanical snap-action

thermostatic valve. The thermostats have an operating range of 200 to 550 degrees.

Once pilots are lit, turning the thermostats to the desired setting is all that is required to

put the unit into service.

7 -

-

Page 8

p

900RX PILOT LIGHTING PROCEDURE

1. Turn all thermostats to the OFF position. Wait 5 minutes to allow any gas that may have

accumulated in the burner compartment to escape.

2. Turn on the main gas shut-off valve.

3. Push the power switches to ON. The switches will illuminate and you will hear a “clicking” sound.

4. Depress and hold the red buttons on the pilot safety valves while the electric igniters light the

corresponding pilots. You will have to monitor the pilot burners through the pilot sight holes. The

pilot burners are aligned with the red buttons on the pilot safety valves and the pilot sight holes.

The

ilot burners are inset 12” from the front of the unit.

PILOT BURNER

PILOT SIGHT HOLE

12”

PILOT SAFETY VALVE BUTTON

POWER SWITCH

CUTAWAY VIEW

4. Watch for the pilot burners to ignite. When the gas at the pilot has been burning for about 45

seconds, release the corresponding red button. If the pilot does not remain lit, repeat the

procedure allowing more time before releasing the button.

5. The pilot burners can be lit manually in the event of a failure of the electronic ignition system. If

this happens, repeat steps 1-4 with the power switch in the OFF position. You will have to reach

under the front of the unit and through the pilot cutout to ignite the pilots with an outside ignition

source(such as a lit taper, etc.) while again depressing the corresponding red button.

5. If after completing steps 1 -5 and the pilot does not light, turn off the main gas shut-off to the

unit and contact an authorized service agency.

8 -

-

Page 9

USING THE GRIDDLE

To preheat, turn the burners on about 20-25 minutes before cooking.

A uniform and systematic approach to loading the griddle will produce the most consistent

product results.

The griddle plate is steel, but the surface is relatively soft and can be scored or dented by

careless use of a spatula or scraper. Be careful not to dent, scratch, or gouge the plate

surface. Do not try to knock off loose food that may be on the spatula by tapping the

corner or the edge of the spatula on the griddle surface.

ZONE COOKING

This griddle features a tubular U-shaped burner in 12” sections, each controlled by

independent thermostats. Each 12” section is a separate cooking zone, and allows

cooking a wide variety of products over a single griddle plate. The chart below is a

suggested usage of zone cooking.

When zone cooking, it is suggested that you start with your lowest temperature setting at

either side of the griddle, increasing the zone temperature as you move up the zone line.

These zone cooking guidelines will vary depending on product temperatures, size and

shape. This guide should be adjusted to suit your product and operational cooking

preference.

ZONE 1

(300°F)

PRODUCT

Sausage

Eggs (Hard Fried)

Eggs (Scrambled)

Burger (Well Done)

Steak (Well Done)

Chicken Breast

Frozen Foods

Pork Chops

ZONE 2

(350°F)

ZONE 3

(350°F)

PRODUCT

Pancakes

French Toast

Bacon

Eggs (Sunny Side Up)

Boiled Ham

Steak (Medium Well)

Fresh Burger (Medium Well)

Small Frozen Burger (Medium Well)

Omelet

Hash Browns

Canadian Bacon

9 -

-

ZONE 4

(400°F)

PRODUCT

Steak (Rare)

Stir Fry Vegetables

Salmon

Fish Cakes

Lobster

Scampi

Page 10

CLEANING THE GRIDDLE

Empty the grease drawer as needed throughout the day and regularly clean at least once

daily.

Clean the griddle regularly. A clean griddle always looks better, lasts longer and performs

better. To produce evenly cooked, perfectly browned griddle products keep the griddle

plate clean and free of carbonized grease. Carbonized grease on the surface hinders the

transfer of heat from the griddle surface to the food, resulting in spotty browning and loss

of cooking efficiency. Carbonized grease tends to cling to griddle foods, giving them a

highly unsatisfactory and unappetizing appearance.

To keep the griddle clean and operating at peak efficiency, follow these procedures:

AFTER EACH USE

Clean the griddle with a wire brush of flexible spatula.

ONCE PER DAY

Thoroughly clean the griddle back splash, sides and front. Remove, empty and wash the

grease drawer in the same manner as an ordinary cooking utensil.

ONCE PER WEEK

Clean the griddle surface thoroughly. Use a griddle stone, screen, or Scotch Bright pad

on the surface as necessary. Rub with the grain of the metal while the griddle is still

warm (not hot). A detergent may be used on the plate surface to help clean it, but be sure

the detergent is thoroughly removed by flushing with clear water.

After removal of detergent the surface of the plate the griddle should be seasoned

according to the instructions in this manual.

Clean stainless steel surfaces with a damp cloth and polish with a soft dry cloth. To

remove discoloration, use a griddle cleaner.

If the griddle usage is very high, consider conducting this weekly cleaning procedure

more than once per week.

CLEANING A CHROME GRIDDLE PLATE

AFTER EACH USE

Clean the griddle with a palmetto brush of flexible spatula. NEVER USE AN ABRASIVE

SCOURING PAD OR GRIDDLE STONE ON A CHROME PLATE SURFACE.

ONCE PER DAY

Thoroughly clean backsplash, sides, and front. Do not hit the backsplash with a spatula

or any other tool. This may create a gap between the splash and griddle plate that is

hard to clean.

Clean stainless steel and chrome surfaces with a damp cloth and polish with a soft dry

cloth.

10 -

-

Page 11

ADJUSTMENTS

CALIBRATION

1. Each thermostat controls a 12” zone of the

griddle. Using a Surface Probe temperature

measurement device, observe the temperatures

at the center points of the cooking zones.

These points are located by starting 6” from the

side splash (left or right) and every 12” across

the width of the griddle, with all points located

12” back from the front edge of the griddle

plate.

NOTE: Use of infrared thermometers is not

recommended. These devices are highly

sensitive to surface color (clean or dirty), angle

of reading and distance from the unit.

2. Set thermostats to 350°F and allow to stabilize,

allowing the indicator light to cycle ON and

OFF at least two times.

3. Watch for indicator light to cycle OFF, then

measure the temperature for that zone. The

temperature should be 350°F ±15°F. If not,

continue to Step 4.

4.

a. Carefully loosen the knob set

screw. DO NOT allow the knob to

turn. Carefully remove the knob

from the thermostat shaft,

exposing the temperature dial.

b. Loosen screws on the temperature

dial and adjust to that the

temperature indicated by the knob

arrow matches the griddle plate

temperature reading. Knob will

have to be placed back on the

shaft to verify adjustment.

IMPORTANT: NEVER ADJUST THE

SCREW IN THE CENTER OF THE

THERMOSTAT SHAFT. This will ruin the

factory calibration; the thermostat will no

longer operate properly and will need to

be replaced.

5. Once calibration is achieved, tighten the

temperature dial screws and knob set

screws.

Step 4a. Set knob &

check Temperature.

Remove knob

Step 4b. – Adjust

temperature dial &

verify temperature

setting

Step 5 –Replace

knob & tighten

screws

11 -

-

Page 12

LEVELING

The griddle must be level (side-to-side and front-to-back) during operation to ensure

proper performance. Improper leveling can result in uneven temperature distribution, cold

spots, and possibly damage electrical components.

1. Place a level on the griddle.

2. Adjust legs by turning the bullet feet at the bottom of each leg. Using pliers or a

crescent wrench, turn the feet counter-clockwise to increase height, and clockwise to

decrease height until leveling is achieved. Do not extend the legs more than 1-¾”.

PILOT ADJUSTMENT

Using a flathead screwdriver, turn the slotted hex-head pilot adjustment screw clockwise

to decrease the flame, and counterclockwise to increase the flame. Pilot adjustments

should only be performed by Service Personnel.

SHUTDOWN OF GRIDDLE WITH ELECTRIC IGNITION SYSTEM

1. Turn thermostats to the OFF position to cut off burners.

2. Push the power switches to OFF. This will cause electrical power to be turned off to

the igniters.

3. The pilots will remain lit and monitored by the safety valve as long as the main gas

supply is on.

EXTENDED SHUTDOWN

1. Shut off the main gas supply valve.

2. Unplug the griddle electrical supply cord.

3. Apply a heavy coat of vegetable oil over the griddle plate to inhibit rust.

MAINTENANCE

The griddle and its parts are hot. Use care when operating, cleaning

or servicing the griddle.

LUBRICATION

There are no parts on this unit that require lubrication.

VENT

Daily, when the griddle is cool, check the flue and clear any obstructions.

12 -

-

Page 13

SERVICE AND PARTS INFORMATION

Contact the Service Agency in your area to obtain service and parts information. For a

complete listing of Service and Parts depots refer to or www.vulcanhart.com

.

When calling for service the following information should be available from the appliance

serial plate: Model Number, Serial Number and Gas Type.

ACCESSORIES

STANDS

The griddle has an optional 24” high by 30” deep by 24”, 36”, 48”, 60” or 72” wide

stainless steel stand with casters or flanged legs. The front casters lock, and flanged legs

may be bolted to the floor. The stand includes a top shelf with marine edges style lip and

a lower shelf. When mounted on a stand with standard legs and properly leveled, the

griddle plate cooking surface should approximately 36” from the floor.

CUTTING BOARDS & TOWEL BARS

Refer to the installation instructions provided with the cutting board or towel bar kit.

FRONT GREASE

STANDARD

BULLNOSE

FRONT GREASE

TOWEL BAR

FRONT GREASE

CUTTING

REAR GREASE

STANDARD

BULLNOSE

REAR GREASE

TOWEL BAR

13 -

-

Page 14

PROBLEM POSSIBLE CAUSES

Heat does not come on

when the thermostat is

turned on

Pilot burner will not light

Pilot burner will not stay

lit

Fat appears to smoke

excessively

Food sticks to griddle or

burned around edges or

contains dark specs

Food under-cooked inside

Food tastes greasy or has

objectionable off-flavor

Noticeable build-up of

gum on griddle

TROUBLESHOOTING

1. Problem with thermostat. (Call for service)

2. Pilot burner not lit. (Call for service)

3. Problem with gas valve (Call for service)

1. Manual gas valve not turned on.

2. Obstructed pilot orifice. (Call for service)

3. Pilot gas turned off at pilot. (Call for service)

4. Problem with pilot safety valve. (Call for service)

5. Problem with thermocouple. (Call for service)

6. ON/OFF switch not in the ON position

1. Obstructed or wrong size pilot orifice. (Call for service)

2. Gas supply not purged of air. (Call for service)

3. Air blowing pilot out. (Call for service)

4. Problem with pilot safety valve. (Call for service)

5. Thermocouple not in flame. (Call for service)

1. Temperature set too high.

2. Moisture in food may be turning into steam

1. Temperature set too high.

2. Griddle surface requires cleaning and/or seasoning.

3. Surface under food not covered with enough cooking oil.

1. Temperature set too high.

2. Food not cooked for long enough time.

1. Food itself may have off-flavor.

2. Food stored improperly before cooking.

3. Too much griddle fat used.

4. Temperature set too low.

1. Temperature set too high.

2. Griddle surface needs cleaning and/or seasoning.

3. Too much griddle fat used.

14 -

-

Loading...

Loading...