Page 1

SERVICE MANUAL

900RE SERIES

HEAVY DUTY

GAS GRIDDLES

MODELS

924RE ML-135221-00G24

936RE ML-135222-00G36

948RE ML-135223-00G48

960RE ML-135224-00G60

972RE ML-135225-00G72

- NOTICE -

This manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly qualified.

If you have attended a Vulcan Service School for this product, you

may be qualified to perform all the procedures described in this

manual.

This manual is not intended to be all encompassing. If you have not

attended a Vulcan Service School for this product, you should

read, in it's entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

P.O. BOX 696, LOUISVILLE, KY 40201-0696

TEL. (502) 778-2791

F35628 (10-04)

Page 2

TABLE OF CONTENTS

GENERAL ........................................................................................................................................3

Introduction ................................................................................................................................3

Installation ..................................................................................................................................3

Operation....................................................................................................................................3

Cleaning .....................................................................................................................................3

Lubrication..................................................................................................................................3

Specifications............................................................................................................................. 3

Tools ...........................................................................................................................................3

REMOVAL AND REPLACEMENT OF PARTS ..............................................................................4

Component Location ................................................................................................................. 4

Control Panel ............................................................................................................................. 5

Covers and Panels .................................................................................................................... 5

Bullnose Weld Assembly ..........................................................................................................5

Heat Shield.................................................................................................................................5

Back Panel .................................................................................................................................5

Power On/Off Switch .................................................................................................................6

Indicator Light ............................................................................................................................ 6

Thermostat .................................................................................................................................6

Flame Switch..............................................................................................................................7

Ignitor Module ............................................................................................................................ 7

Gas Burner .................................................................................................................................8

Pilot Solenoid .............................................................................................................................8

Pilot .............................................................................................................................................9

Dual Solenoid.............................................................................................................................9

SERVICE PROCEDURES AND ADJUSTMENTS...................................................................... 10

Thermostat Calibration ........................................................................................................... 10

Main Burner Adjustment ........................................................................................................ 10

Gas Pressure Measurement .................................................................................................. 11

Extended Shutdown ............................................................................................................... 11

ELECTRICAL OPERATION ......................................................................................................... 12

Component Description.......................................................................................................... 12

Sequence of Operation .......................................................................................................... 12

SCHEMATIC DIAGRAMS ............................................................................................................ 13

TROUBLESHOOTING GUIDE..................................................................................................... 18

F35628 (10-04)

© VULCAN-HART, 2004

— 2 —

Page 3

GENERAL

INTRODUCTION

Procedures in this manual will apply to all

models unless specified. Pictures and

illustrations can be of any model unless the

picture or illustration needs to be model

specific. All models are equipped with 30,000

BTU/HR burners as standard equipment. One

burner is used for every 12 inches of griddle

surface.

All models use an automatic spark igniter to

light the burners.

INSTALLATION

Generally, installations are made by the dealer

or contracted by the dealer or owner. Detailed

installation instructions are included in the

Installation & Operation Manual which is sent

with each unit.

SPECIFICATIONS

Electrical Data

Model Volts Hertz Phase Amps

924RE 120 60 1 0.5

936RE 120 60 1 0.5

948RE 120 60 1 0.5

960RE 120 60 1 0.5

972RE 120 60 1 0.5

Gas Data

Model Input BTU/HR Manifold Pressure

Natural LP Gas Natural LP Gas

924RE 60,000 60,000 5.0” W.C. 10” W.C.

936RE 90,000 90,000 (1.1 kPa) (2.2 kPa)

948RE 120,000 120,000

960RE 150,000 150,000

972RE 180,000 180,000

TOOLS

OPERATION

Detailed operation instruction are included in

the Installation and Operation Manual which

is sent with each unit.

CLEANING

Detailed cleaning procedures are included in

the Installation and Operation Manual which

is sent with each unit.

LUBRICATION

No lubrication is required on this equipment.

Standard

· Hand tools (standard set)

· VOM with AC current tester (any

quality VOM with a sensitivity of at least

20,000 ohms per volt can be used)

· Temperature tester (thermocouple type)

· Manometer

— 3 —

F35628 (10-04)

Page 4

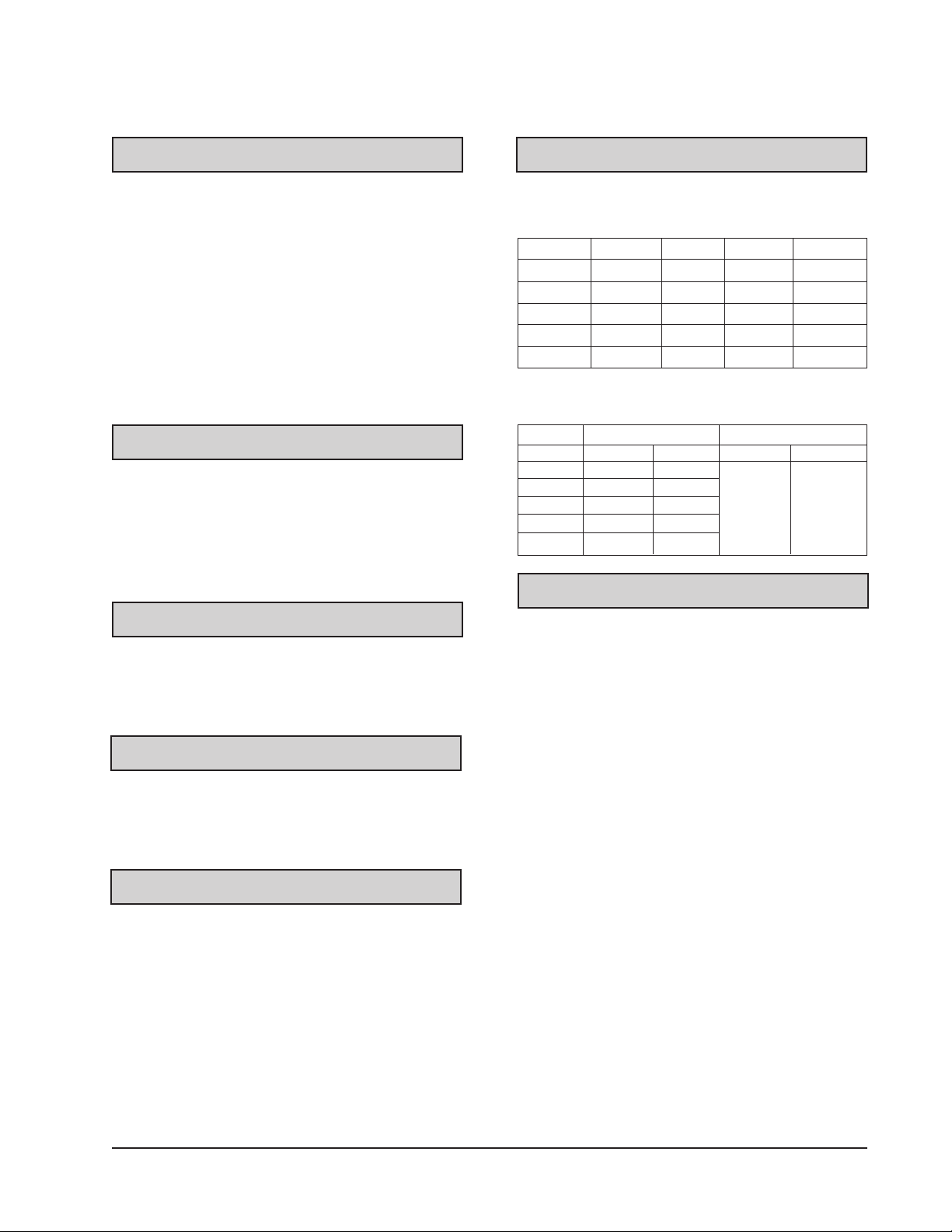

Back Panel

Griddle

REMOVAL AND REPLACEMENT OF PARTS

COMPONENT LOCATION

Bullnose

Deflector Plate

Heat Shield

Control Plate

Control Panel

Grease Drawer

Flame

Switch

Dual

Solenoid

Ignitor

Module

Panel

Connector

Ignitor

Module

Flame

Switch

Dual

Solenoid

Pilot

Solenoid

F35628 (10-04)

Figure A

— 4 —

Page 5

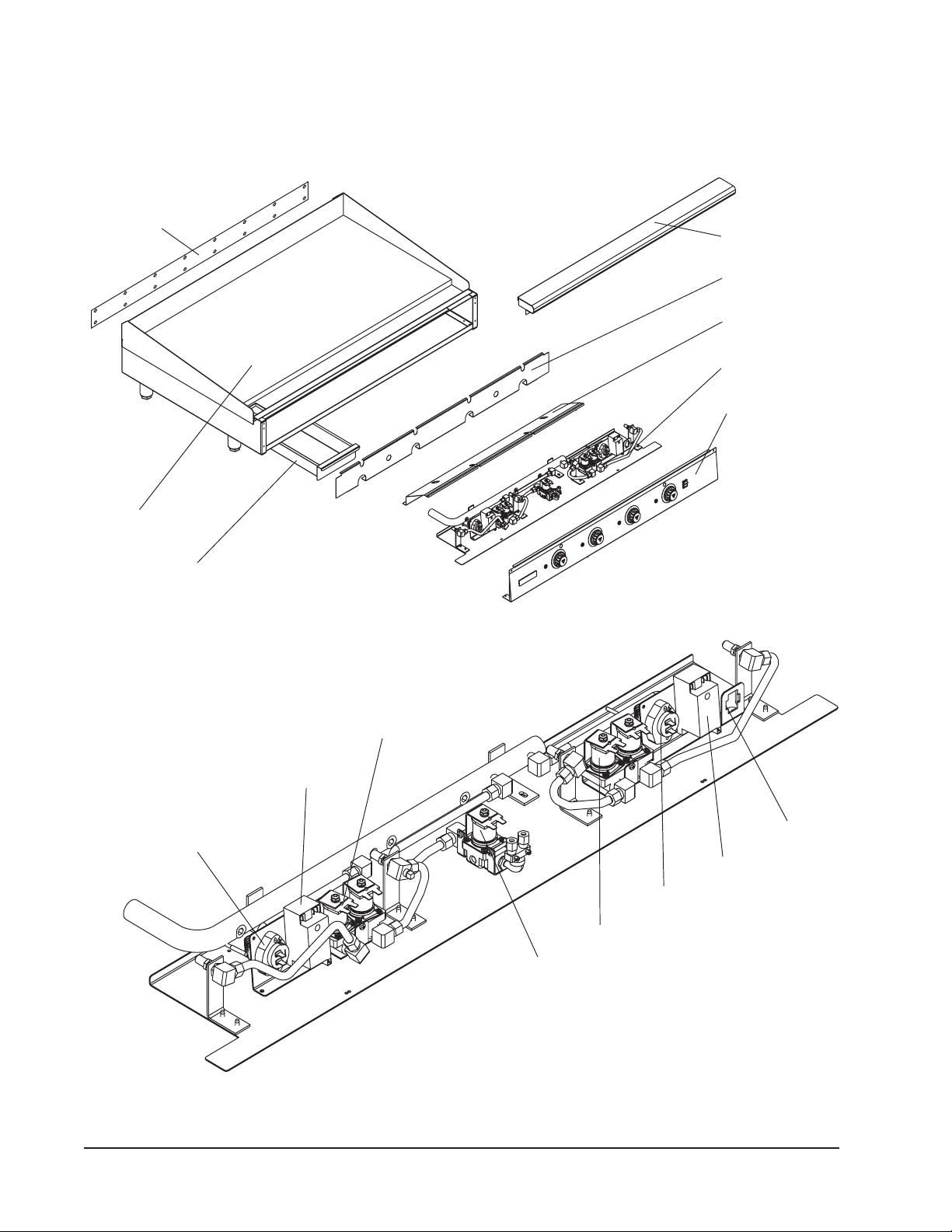

CONTROL PANEL

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES.

1. Remove the two screws securing the

control panel. One screw is located at

each end of the control panel.

2. Pull the control panel forward and

disconnect the electrical connector near

the right end.

Panel

Connector

Griddle

Bullnose

Figure C

3. Reverse the procedure to install.

Heat Shield

1. Remove control panel.

2. The heat shield clamps on the front of the

griddle and can be removed by grasping

the top of the shield and pulling forward.

Remove

Screw

Control

Panel

Figure B

3. Reverse the procedure to install.

COVERS AND PANELS

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES.

Bullnose Weld Assembly

1. Remove control panel.

2. The bullnose weld assembly is secured

with two screws, one on each side of the

bottom of the assembly. Remove these

screws, then remove the bullnose weld

assembly from the griddle.

Back

Panel

Griddle

Deflector

Plate

Heat

Shield

Figure D

3. Reverse the procedure to install.

Back Panel

1. Remove all screws from rear of griddle

securing the back panel.

2. Remove the back panel. (See Figure D)

3. Reverse procedures to install.

— 5 —

F35628 (10-04)

Page 6

POWER ON/OFF SWITCH

INDICATOR LIGHT

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES.

1. Remove the control panel.

2. Label and disconnect the wires to the

power ON/OFF switch.

3. Squeeze the switch retainer and slide the

switch out through the front of the control

panel.

ON/OFF

Switch

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES.

1. Remove the control panel.

2. Label and disconnect the wires to the Red

indicator light.

3. Squeeze the light retainers and slide the

indicator light out through the front of the

control panel.

4. Reverse procedures to install and check

for proper operation.

THERMOSTAT

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES.

Figure E

4. Reverse procedures to install and check

for proper operation.

1. Remove the control panel.

2. Remove the knob.

3. Remove the two screws and two washers

securing the thermostat and thermostat

dial to the control panel, then remove the

thermostat and thermostat dial.

4. When installing a new thermostat reverse

the procedure and be sure to position the

thermostat dial with OFF at the top.

5. Check calibration. Refer to the Service

Procedures and Adjustments section of

this manual.

F35628 (10-04)

— 6 —

Page 7

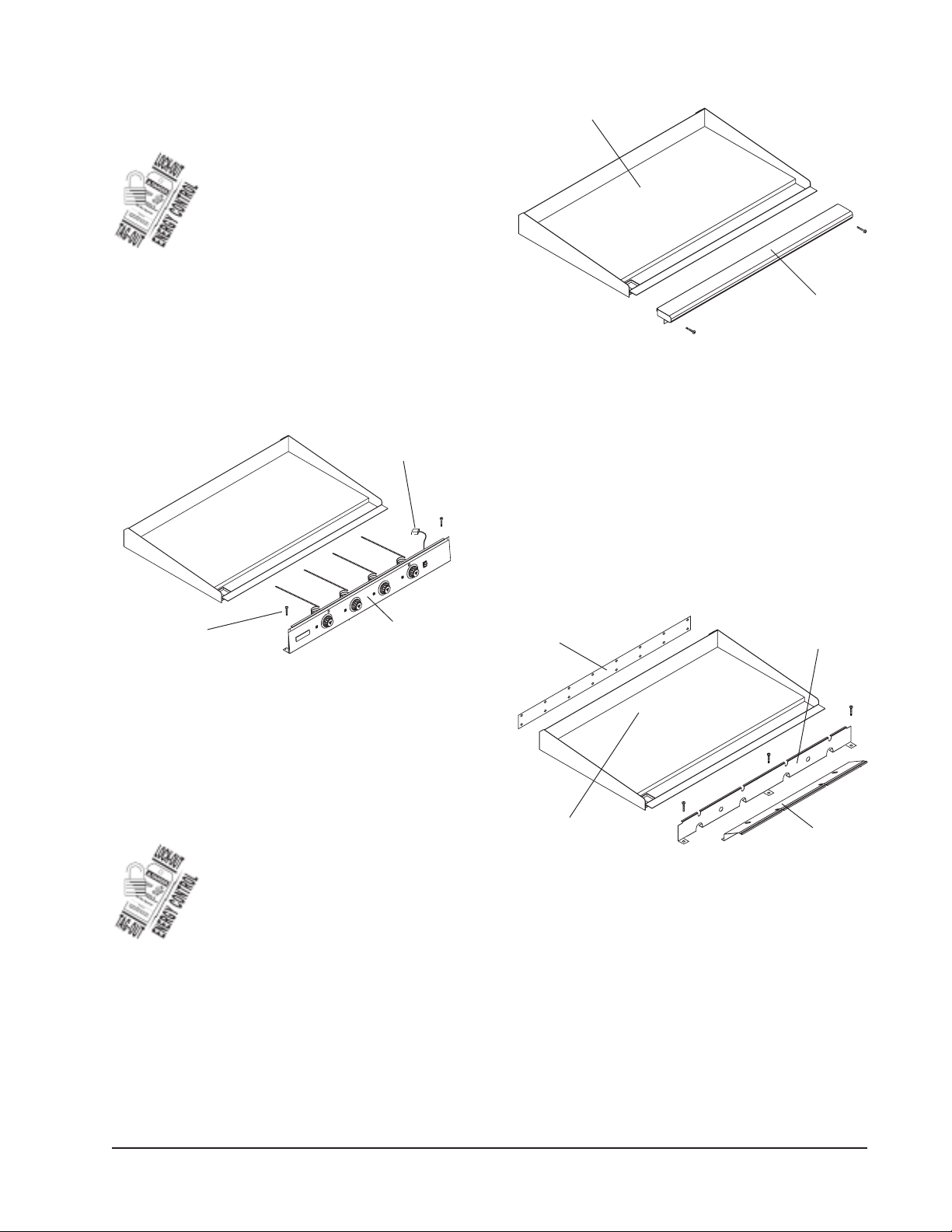

FLAME SWITCH

IGNITOR MODULE

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES.

1. Remove the control panel.

2. Label and disconnect the wires to the

flame switch.

3. Remove the two screws securing flame

switch to control plate.

4. Remove sensor from the pilot assembly.

Sensor can be accessed from the front of

unit or from underneath the unit via the

pilot assembly access cut out opening.

The sensor is a snap in fit device.

5. When installing a new flame switch,

reverse the procedure. Be sure to carefully

route and attach the sensor to the pilot

assembly and check for proper operation.

Remove

Probe

From Pilot

Assembly

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES.

1. Remove the control panel.

2. Label and disconnect the black, green,

and white wires from the ignitor module.

3. Disconnect the ignitor cable from the

bottom of the ignitor module.

4. Remove the two screws securing ignitor

module to module bracket.

5. Remove ignitor module from module

bracket.

6. When installing a new ignitor module

reverse the procedure and check for

proper operation.

Disconnect

Wires

Ignitor

Module

Flame

Switch

Sensor

Remove

Screws

Module

Bracket

Figure F

Ignitor

Electrode

Flame

Switch

Disconnect

Wires

— 7 —

Module

Bracket

Remove

Screw

Figure G

Disconnect

Wire

F35628 (10-04)

Page 8

GAS BURNER

PILOT SOLENOID

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES.

1. Remove the back panel.

2. Cut shipping tie from burner.

3. To remove the burner, reach through the

back of the unit and lift the burner up over

the guide screw then pull the burner out

through the back of the unit.

4. Replace the burner by inserting the burner

through the rear of the unit, engaging the

burner venturi onto the burner valve orifice

at the front of unit. From the front of the

unit, remove the control panel to check

that the venturi is properly fitted over the

orifice.

5. Reassemble the control and back panels

then check for proper operation.

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE GRIDDLE.

1. Remove the control panel.

2. Label and disconnect the two wires

connected to the solenoid.

3. Disconnect the input compression fitting

and the two output compression fittings.

4. Remove the two screws attaching solenoid

to single solenoid bracket and remove

solenoid.

Input

Compression

Fitting

Guide

Screw

Burner

Figure H

Orifice

Output

Remove

Screws

Compression

Fittings

Figure I

5. Reverse procedure to install the

replacement gas solenoid.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE

CHECKED FOR LEAKS. CHECK

WITH SOAP AND WATER

SOLUTION (BUBBLES).

DO NOT USE AN OPEN FLAME.

6. Verify gas pressure as outlined under the

GAS PRESSURE ADJUSTMENT in

Service Procedures and Adjustments.

Check for proper operation.

F35628 (10-04)

— 8 —

Page 9

PILOT

DUAL SOLENOID

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE GRIDDLE.

1. Remove control panel and heat shield for

visual access of the pilot.

2. Reaching underneath the front of the

griddle remove the pilot tube fitting and

disengage the pilot tube from the pilot.

3. Reaching up through the square pilot

access cut out, remove the screw retaining

the pilot bracket to the unit and slip the

entire pilot assembly out from under the

front section of the unit.

4. Remove the pilot from the bracket.

5. Reverse procedures to install new pilot.

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE GRIDDLE.

1. Remove the control panel.

2. Label and disconnect the two wires

connected to each solenoid.

3. Disconnect the input compression fitting

and the two output compression fittings.

4. Remove the screw securing solenoids to

solenoid bracket and remove solenoid.

Disconnect

Wires

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE

CHECKED FOR LEAKS. CHECK

WITH SOAP AND WATER

SOLUTION (BUBBLES). DO

NOT USE AN OPEN FLAME.

6. Verify gas pressure as outlined under the

GAS PRESSURE ADJUSTMENT in the

Service Procedures and Adjustments section

of this manual. Check for proper operation.

Pilot

Bracket

Pilot

Assembly

Remove

Screw

Figure J

Disconnect

Screw

Fittings

Figure K

5. Reverse procedure to install the

replacement dual solenoid.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE

CHECKED FOR LEAKS. CHECK

WITH SOAP AND WATER

SOLUTION (BUBBLES).

DO NOT USE AN OPEN FLAME.

6. Verify gas pressure as outlined under the

GAS PRESSURE ADJUSTMENT in

Service Procedures and Adjustments.

Check for proper operation.

— 9 —

F35628 (10-04)

Page 10

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING: CERTAIN PROCEDURES IN

THIS SECTION REQUIRE

ELECTRICAL TEST OR

MEASUREMENTS WHILE

POWER IS APPLIED TO THE

MACHINE. EXERCISE

EXTREME CAUTION AT ALL

TIMES. IF TEST POINTS ARE

NOT EASILY ACCESSIBLE,

DISCONNECT POWER AND

FOLLOW LOCKOUT / TAGOUT

PROCEDURES, ATTACH TEST

EQUIPMENT AND REAPPLY

POWER TO TEST.

THERMOSTAT CALIBRATION

1. Set the thermocouple in the center of the

burner section to be calibrated.

2. Set the ON/OFF switch to the ON position.

Adjust the thermostat knob of the burner

to be calibrated to 350 degrees.

3. Allow the burners to cycle on and off at

least twice. Observe the griddle heat light

and thermocouple readings. The

thermocouple reading should be 350

degrees plus or minus 15 degrees the

instant the heating light comes on.

If the unit is not within these calibration

specifications follow the steps below.

4. Gently, remove the thermostat knob from

the unit without rotating the thermostat

shaft.

5. Loosen (2) screws securing the

temperature dial plate to the unit. Gently,

replace the thermostat knob onto the unit

without moving the thermostat shaft.

6. Hold the thermostat knob in place and

rotate the dial plate so that the 350 degree

position aligns with the knob temperature

indicator mark.

7. While holding the dial plate in position,

gently remove the knob without moving

the shaft . Tighten down the (2) dial plate

securing screws.

8. Replace the thermostat knob and verify

that thermocouple reading, knob indicator

and dial setting all agree.

9. Turn the knob and ON/OFF switch to the

OFF position.

10. Remove the thermocouple.

Thermostat

Dial

Loosen

Screws

Knob

Figure L

MAIN BURNER ADJUSTMENT

For efficient burner operation, it is important

that a proper balance of gas volume and

primary air supply is maintained, to give

complete combustion. Insufficient air supply

results in a yellow streaming flame. Primary

air supply is controlled by the air shutter on

the front of the burner venturi. Loosen the

screws on the venturi and adjust the air

shutter to just eliminate yellow tips on burner

flames. Lock the air shutter in place by

tightening the screws. Repeat this procedure

with all burners.

1. All units are equipped with fixed orifices

for use with natural or propane gas and

no adjustment is necessary.

F35628 (10-04)

— 10 —

Page 11

2. Units for operation of natural or propane

gas are also equipped with a factory preset

pressure regulator with an outlet pressure

of 5” W.C. (Water Column) for natural gas

supply and 10” W.C. for propane gas

supply, and should not require further

adjustment.

3. The burners and pilot flames may be

observed through round holes in the front

panel.

GAS PRESSURE MEASUREMENT

1. Set the power ON/OFF switch to the OFF

position.

2. Turn the gas supply off at manual shutoff

valve.

3. Remove the screws securing the control

panel and move the panel forward

sufficiently to access the plug on the

manifold pressure port.

4. Remove the plug from the manifold

pressure port.

5. Install hose barb adapter and attach

manometer tube.

WARNING: THE FOLLOWING STEPS

REQUIRE POWER TO BE

APPLIED TO THE UNIT

DURING TEST. USE EXTREME

CAUTION AT ALL TIMES.

6. Turn the power switch to the ON position.

7. Turn only one burner on to the maximum

temperature.

8. Check gas pressure.

9. Turn all burners on to the maximum

temperature.

10. Check gas pressure.

11. Turn all other equipment on same supply

line on.

12. Check gas presssure.

NOTE: Pressure drop should not be greater

than ±½” W.C. If gas pressure requires

adjustment, the adjustment screw is

located under a cap on the regulator.

PRESSURE READINGS (IN W.C.)

Gas Type

Natural Propane

Manifold 5 10

Recommended 7-9 (Line) 11-12 (Line)

Minimum 6 (Line) 11 (Line)

Maximum 14 (Line) 14 (Line)

Manifold

Pressure

Port

Figure M

Plug

— 11 —

13. Turn off all burners.

14. Turn ON/OFF switch to OFF position.

15. Disconnect manometer and reinstall plug.

F35628 (10-04)

Page 12

ELECTRICAL OPERATION

COMPONENT DESCRIPTION

Power Switch ON/OFF – Switch turns power

ON or OFF.

Ignition Control Module – Provides ignition

spark. Turned on when ON/OFF switch is set

to the ON position and turned off when flame

switch closes.

Burner On Lights – Illuminates to indicate

burner is turned on.

Thermostats – Turns burner on and sets

operating temperature.

Flame Switch – When the flame switch is

heated by the pilot the switch contacts close

and turn on the single and/or dual burner

solenoids.

Gas Valve (Single Solenoid) – Contains one

valve. The valve controls a single burner. The

solenoid is turned on when the ON/OFF switch

is in the ON position and the corresponding

thermostat is rotated out of the OFF position.

When the solenoid is turned on (operated)

gas flows to the burners.

Gas Valve (Dual Solenoid) – Contains two

valves. Each valve controls a separate burner.

Solenoids are turned on when the ON/OFF

switch is in the ON position and the

corresponding thermostat is rotated out of

the OFF position.

Pilot Gas Valve (Single Solenoid) – Contains

one valve. The valve controls the gas to the

pilot. The solenoid is turned on when the

ON/OFF switch is in the ON position and

turned off when the flame switch closes.

SEQUENCE OF OPERATION

Operation of all size griddles is the same.

The following discussion is for the 48” griddle.

This griddle has four thermostats, two flame

switches, two dual solenoids and one pilot

solenoid.

The neutral wire from the power source is

directly connected to the following terminals:

• A terminal on each thermostat

• The N terminal on each ignition module

• One terminal on the pilot solenoid

When the power ON/OFF switch is set to the

ON position, voltage is applied to the following

terminals:

• Terminal L1 on each ignition module

turning the module on

• One side of each flame switch

• The remaining terminal on the pilot

solenoid energizing the solenoid

The ignition module which is now connected

across the power lines turns on and provides

the voltage for the ignition spark. The pilot

valve solenoid is energized allowing gas to

flow to the pilot where it is ignited by the

spark. The pilot flame heats up the flame

switch. When the flame switch is sufficiently

hot, the switch closes. The voltage through

the flame switch is applied to one side of

each burner solenoid and one side of the

burner ON light.

When the pilot flame is sensed, the ignition

module will shut off automatically.

F35628 (10-04)

When a thermostat is rotated out of the OFF

position the neutral return wire is connected

to the other side of the burner light causing

the light to be illuminated. At the same time

the neutral is connected to the other side of

the burner solenoid causing the solenoid to

operate and allowing gas to flow to the burner.

— 12 —

Page 13

SCHEMATIC DIAGRAMS

Schematic Drawing for 24” Griddle

— 13 —

EMPLOYER DES FILS D’ALIMENTATION ADEQUATS 200°C OR EQUIVALENT

1. USE SUPPLY WIRES SUITABLE FOR 200°C OR EQUIVALENT

2. HARNESS PART NO. 723526-1

B NOTE:

F35628 (10-04)

Page 14

SCHEMATIC DIAGRAMS

F35628 (10-04)

Schematic Drawing for 36” Griddle

— 14 —

EMPLOYER DES FILS D’ALIMENTATION ADEQUATS 200°C OR EQUIVALENT

1. USE SUPPLY WIRES SUITABLE FOR 200°C OR EQUIVALENT

2. HARNESS PART NO. 723527-1

B NOTE:

Page 15

SCHEMATIC DIAGRAMS

Schematic Drawing for 48” Griddle

— 15 —

EMPLOYER DES FILS D’ALIMENTATION ADEQUATS 200°C OR EQUIVALENT

1. USE SUPPLY WIRES SUITABLE FOR 200°C OR EQUIVALENT

2. HARNESS PART NO. 723528-1

B NOTE:

F35628 (10-04)

Page 16

SCHEMATIC DIAGRAMS

F35628 (10-04)

Schematic Drawing for 60” Griddle

— 16 —

EMPLOYER DES FILS D’ALIMENTATION ADEQUATS 200°C OR EQUIVALENT

1. USE SUPPLY WIRES SUITABLE FOR 200°C OR EQUIVALENT

2. HARNESS PART NO. 723529-1

B NOTE:

Page 17

SCHEMATIC DIAGRAMS

Schematic Drawing for 72” Griddle

— 17 —

EMPLOYER DES FILS D’ALIMENTATION ADEQUATS 200°C OR EQUIVALENT

1. USE SUPPLY WIRES SUITABLE FOR 200°C OR EQUIVALENT

2. HARNESS PART NO. 723530-1

B NOTE:

F35628 (10-04)

Page 18

TROUBLESHOOTING GUIDE

SYMPTOM

Indicator light fails to light

when power ON/OFF

switch is set to ON

position

Indicator light fails to go

out when power ON/OFF

switch is set to the OFF

position

Griddle does not heat

when thermostat is turned

on

CAUSE

Not plugged in

Faulty ON/OFF switch

Store circuit breaker tripped

Faulty lamp

Faulty power ON/OFF switch

Not plugged in

Faulty ON/OFF switch

Store circuit breaker tripped

Faulty thermostat

Problem with pilot valve

REMEDY

Plug griddle into correct voltage

outlet

Replace ON/OFF switch

Reset circuit breaker

Replace lamp

Replace switch

Plug griddle into correct voltage

outlet

Replace ON/OFF switch

Reset circuit breaker

Replace thermostat

Check operation of pilot valve

Igniter stays on too long

after pilot flame is

established

Igniter fails to light

Problem with igniter

Problem with flame switch

Loose wire connection

Flame switch has not had enough

time to heat up

Flame switch bulb not hot enough

Problem with igniter

Unit not plugged in

Store circuit breaker tripped

Check operation of igniter

Check operation of flame switch

Check for bad connection and

correct

Allow more time for flame switch to

heat up

Check alignment of pilot and flame

switch

Check for obstruction or wrong size

orifice

Check for proper gas pressure

Replace igniter

Plug griddle into correct voltage

outlet

Reset circuit breaker

F35628 (10-04)

Problem with power ON/OFF switch

Loose wire connection

— 18 —

Replace ON/OFF switch

Check and repair wire connection

Page 19

TROUBLESHOOTING GUIDE

SYMPTOM

Pilot does not light after

igniter has been on

several minutes

Pilot fails to remain lit

after igniter goes out

(Pilot may cycle on and

off normally several times

after cold start-up before

the pilot heats up.)

CAUSE

Problem with pilot valve

Gas supply not purged of air

No gas supply

Loose wire connection

Obstructed or wrong size pilot orifice

Problem with alignment of pilot and

igniter

Loose wire connection

Air blowing pilot out

Obstructed or wrong size pilot orifice

Problem with alignment of pilot and

flame switch

REMEDY

Check operation of pilot valve

Purge gas lines

Check that gas supply is on

Check and repair wire connection

Check for obstruction or wrong size

orifice

Realign pilot and igniter

Check and repair wire connection

Correct air flow

Check for obstruction or wrong size

orifice

Realign pilot and igniter

Burner does not come on

(burner light does not

come on)

Heat does not turn off,

burner light is off,

temperature is above

thermostat setting

Heat does not turn off,

burner light is on,

temperature is above

thermostat setting

Temperature varies

Problem with flame switch

Thermostat setting too low

Problem with thermostat sensor

Problem with temperature controller

Problem with thermostat gas valve

Loose wire connection

Problem with thermostat gas valve

Problem with temperature controller

Low gas pressure

Check operation of flame switch

Adjust thermostat to a high

temperature setting

Replace sensor

Check or replace controller

Check thermostat gas valve

Check and repair wire connection

Check or replace thermostat gas

valve

Check or replace temperature

controller

Check and adjust proper gas

pressure

Faulty thermostat sensor

— 19 —

Replace faulty thermostat and sensor

F35628 (10-04)

Page 20

FORM 35628 (10-04)

PRINTED IN U.S.A.

Loading...

Loading...