Page 1

INSTALLATION &

OPERATION MANUAL

GPC SERIES GAS PASTA COOKERS

MODELS

GPC12

GPC12S

ML-126881

ML-126883

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

P.O. BOX 696, LOUISVILLE, KY 40201-0696

TEL. (502) 778-2791

F-31173 Rev. A (02-04)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION OR MODIFICATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE

INSTALLING OR SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

– 2 –

Page 3

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Gas Pressures and Orifices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Testing the Gas Supply System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Leveling the Pasta Cooker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flue Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Plumbing Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Water Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Drain Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Before First Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Using the Pasta Cooker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Swivel Head Faucet (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

High Limit Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Overflow/Skim Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Deliming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Service and Parts Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

– 3 –

Page 4

Installation, Operation and Care of

MODEL GPC SERIES GAS PASTA COOKER

KEEP THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

Your Vulcan Gas Pasta Cooker is produced with quality workmanship and material. Proper installation,

usage and maintenance of your pasta cooker will result in many years of satisfactory performance.

It is suggested that you thoroughly read this entire manual and carefully follow all of the instructions

provided.

Each gas burner tube has 30,000 BTU input rating.

Model GPC12S is equipped with a chill tank (no burners) which is plumbed to both hot and cold water.

The chill tank is used for cooling pasta quickly. It is the same width as the pasta cooker.

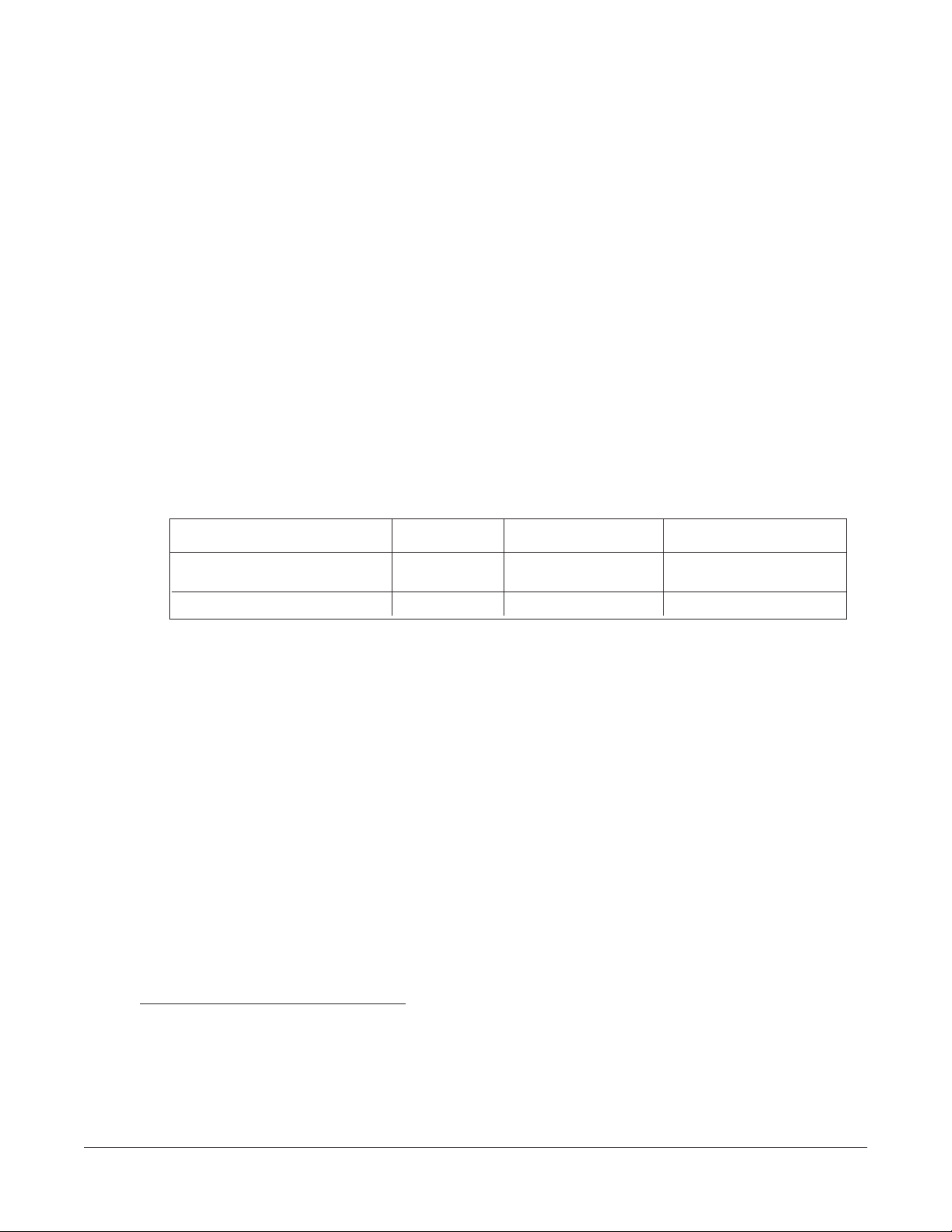

Model No. Tubes BTU Input Width

GPC12 3 90,000 151/2" (394 mm)

GPC12S 3 90,000 31" (787 mm)

Standard Features include:

• stainless steel tank, sides, door, and flue wrap

• mechanical thermostat

• electronic ignition

Model GPC12S is equipped with a foam zone overflow strainer. All models are equipped with a basket

hanger.

Optional accessories for all models include a basket hanger and stainless steel legs.

Optional accessories for only Model GPC12S include a stainless steel vat cover/tray, and a faucet

assembly.

The retherm basket with portion cups allows reheating of 12 servings at a time. The portion cups hold

a serving-size portion.

Accessories Factory Installable

(Must be requested at the time the original cooker is ordered.)

Basketlift

Cooker/Chill Tank Combo

– 4 –

Page 5

Accessories Field Installable

Casters Round Angel Hair Pasta Baskets (set of 6)

Bulk Single Cook Basket Bulk Single Angel Hair Pasta Basket

Retherm Basket S/S Vat Cover/Tray (Cooker/Chill Tank Combo Only)

Portion Cups (set of 12) Spray Assembly (Cooker/Chill Tank Combo Only)

Retherm Basket with cups

INSTALLATION

Before installing, verify that the type of gas supply (natural or propane) and electrical service agree with

the specifications on the rating plate which is located on the inside of the door panel. If the supply and

equipment requirements do not agree, contact your dealer or Vulcan-Hart immediately.

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the pasta cooker is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Do not use the door or its handle to lift or move the pasta cooker.

For pasta cookers shipped on a pallet: Before removing the cooker from the pallet, assemble

casters or legs (see ASSEMBLY in this manual).

The pasta cooker is shipped without the swivel head attached. Look for the swivel head in the tank of

the cooker and screw it onto the faucet before hooking up the water.

LOCATION

Do not install pasta cooker next to a deep fat fryer because a splash-over of water into the hot oil may

cause a flash fire.

The equipment must be kept free and clear of combustible substances.

The pasta cooker, when installed, must have minimum clearance from combustible construction of 6"

(152 mm) from the sides and 6" (152 mm) from the rear. Clearance requirement from non-combustible

construction is 0" at the sides and rear. The pasta cooker may be installed on combustible floors.

The installation location must allow adequate clearances for servicing and proper operation.

A minimum front clearance of 36" (914 mm) is required.

The pasta cooker must be installed so that the flow of combustion and ventilation air will not be

obstructed. Adequate clearance for air openings into the combustion chamber must be provided.

Make sure there is an adequate supply of air in the room suitable for the amount of combustion gas

feeding the burners.

Do not permit fans to blow directly at the pasta cooker. Avoid open windows next to the pasta cooker.

Avoid wall-type fans which create air cross currents within the room.

– 5 –

Page 6

INSTALLATION CODES AND STANDARDS

Your Vulcan-Hart gas pasta cooker must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1 (latest edition), available from the American Gas Association,

Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. National Electrical Code ANSI/NFPA-70 (latest edition). Copies may be obtained from the National

Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CGA-B149.1 (latest edition) Natural Gas Installation Code.

3. CAN/CGA-B149.2 (latest edition) Propane Installation Code, available from the Canadian Standards

Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

4. Canadian Electric Code, CSA Standard C22.2 No.3 (latest edition). Copies may be obtained from

The Canadian Standards Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

ASSEMBLY

The cooker must be restrained to prevent tipping when installed in order to avoid the splashing of hot

liquid. The means of restraint may be the manner of installation, such as connection to a battery of

appliances or installing the cooker in an alcove, or by separate means, such as adequate ties.

Legs

1. Position the pasta cooker in an open space near the final installation area.

2. Tilt pasta cooker on its side. Be careful not to scratch the finish.

3. Thread legs into mounting holes provided on the bottom of the pasta cooker by screwing in a

clockwise rotation until tightened.

4. Carefully raise pasta cooker to its normal position and place it in the installing location.

– 6 –

Page 7

Casters

1. Position the pasta cooker in an open space near the final installation area.

2. Tilt pasta cooker on its side. Be careful not to scratch the finish.

3. Thread casters into mounting holes provided on the bottom of the pasta cooker by screwing in a

clockwise rotation until tightened.

4. Carefully raise pasta cooker to its normal position and place it in the installing location.

NOTICE: When the pasta cooker is mounted on casters, it must be installed with the casters supplied,

a connector (not supplied by Vulcan-Hart) complying with either ANSI Z21.69 (latest edition) or CAN/

CGA-6.16 (latest edition), and a quick disconnect device complying with either ANSI Z21.41 (latest

edition) or CAN1-6.9 (latest edition). It must also be installed with restraining means to guard against

transmission of strain to the connector, as specified in the appliance manufacturer's instructions.

Attach the restraining device at the rear of the oven. (Fig. 1).

Provide a gas line strain relief to limit movement of the pasta cooker without depending on the

connector and any quick-disconnect device or its associated piping to limit the pasta cooker's

movement. Attach the strain relief to the rear of the pasta cooker (Fig. 1).

Should it be necessary to disconnect the gas line strain relief, turn off the gas supply before

disconnection. Reconnect this restraint before turning the gas supply on and returning the pasta

cooker to its installation position.

STRAIN RELIEF

FITTING FOR GAS LINE

THIS SIDE ONLY.

(Strain relief fitting

supplied by Vulcan-Hart.

Chain to be supplied by

others.)

PL-51493

Fig. 1

Instructions for installing casters to the pasta cooker are included with the casters. Pasta cooker/chill

tank combination units are shipped with legs or casters already assembled.

– 7 –

Page 8

GAS CONNECTIONS

CAUTION: Gas supply connections and any pipe joint compound used must be resistant to the

action of propane gases.

Codes require that a gas shutoff valve be installed in the gas line ahead of the pasta cooker.

Connect gas supply to the pasta cooker. The gas inlet is located at the rear of the pasta cooker on the

lower right when facing the rear of the machine.

The gas supply line must be at least the equivalent of 1/2" (13 mm) iron pipe. If using the optional quickdisconnect flex hose, 3/4" (19 mm) iron pipe must be used unless 3/4" to 1/2" (19 to 13 mm) reducing fittings

are used. Make sure the pipes are clean and free of obstructions, dirt, and piping compound.

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

GAS PRESSURES AND ORIFICES

The standard orifices are set at 4" W.C. (Water Column) (1 kPa) manifold pressure for natural gas and

10" W.C. (Water Column) (2.5 kPa) manifold pressure for propane gas. A pressure regulator is

supplied as part of the gas control valve.

TESTING THE GAS SUPPLY SYSTEM

1

When test pressures exceed

/2 psig (3.45 kPa), the pasta cooker and its individual shutoff valve must

be disconnected from the gas supply piping system.

When test pressures are 1/2 psig (3.45 kPa) or less, the pasta cooker must be isolated from the gas

supply system by closing its individual manual shutoff valve.

LEVELING THE PASTA COOKER

Once gas connections have been made:

1. Place a spirit level on top of the pasta cooker.

2. Adjust the legs or casters to ensure that the pasta cooker is level front-to-back and side-to-side

in the final installed position.

Adjust casters:

1. Loosen the set screws in the caster extension.

2. Adjust the height.

3. Tighten the set screws.

– 8 –

Page 9

FLUE CONNECTIONS

The pasta cooker must be located under a hood which has an adequate connection to an exhaust duct.

The hood must extend 6" (152.4 mm) beyond the sides of the pasta cooker.

Adequate ventilation must be provided and must comply with NFPA Standard #96 (latest edition), and

with local codes.

Clearance above the pasta cooker should be adequate for products of combustion to be removed

efficiently. An 18" (457 mm) minimum clearance should be maintained between the flue vent and the

filters of the hood venting system.

Never make flue connections directly to the pasta cooker. DO NOT obstruct the flow of flue gases from

the flue duct located on the rear of the pasta cooker.

Adequate air should be provided in the kitchen to replace air taken out by the ventilating system. This

will prevent the pasta cooker from being affected by a reduced atmospheric pressure.

It is recommended that the flue gases be ventilated to the outside of the building through a ventilation

system installed by qualified personnel.

Information on the construction and installation of ventilating hoods may be obtained from the standard

for "Vapor Removal from Cooking Equipment," NFPA No. 96 (latest edition), available from the

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE NATIONAL

ELECTRICAL CODE AND/OR OTHER LOCAL CODES.

WARNING: APPLIANCES EQUIPPED WITH ELECTRICAL SUPPLY CORD(S) ARE PROVIDED

WITH A THREE-PRONG GROUNDING PLUG WHICH MUST BE CONNECTED TO A PROPERLY

GROUNDED RECEPTACLE. IF THE RECEPTACLE IS NOT THE PROPER GROUNDING TYPE,

CONTACT AN ELECTRICIAN. DO NOT REMOVE THE GROUNDING PRONG FROM THE PLUG.

The pasta cooker is equipped with a 120 Volt / 60 Hz. / 1 Phase cord and plug which requires only that

it be plugged into a properly grounded 120 volt receptacle.

Do not connect the pasta cooker to electrical supply until after gas connections have been made.

The wiring diagram is located on the inside of the door panel.

– 9 –

Page 10

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY

AND PLUMBING CODES.

3

/4" (19 mm) male hose connection is provided at the rear of the pasta cooker. On single body pasta

A

cookers GPC12, the water connection hookup is located in the rear of the cooker, in the leg channel

of the base frame. Note that the GPC12 models have only a hot water valve on the front control panel;

therefore, it is recommended that the hot water rear connection hookup be used.

The double body pasta cookers GPC12S, have hot

and cold water valves and should be hooked up

utilizing the appropriate rear connections as shown in

Fig 2.

A water hammer arrestor (meeting ASSE-1010

Standard) must be supplied (by other than VulcanHart Company) in the water supply line at the service

connection.

PL-41145

MODEL GPC12S

Fig. 2

WATER QUALITY

The water supply connected to this pasta cooker should contain no more than 2.0 grains of hardness

per gallon with pH from 6.5 to 8.0. This degree of hardness and pH can easily be obtained with the use

of a properly maintained water softener.

Water supplies vary from one location to another. A local water treatment specialist should be

consulted before installing the pasta cooker.

Untreated water contains scale producing minerals which can precipitate onto the surfaces in the

cooker and its components. This can result in early component failure and reduced product life.

Strainers and filters will NOT remove minerals from the water. Refer to DELIMING in this manual.

DRAIN CONNECTIONS

The pasta cooker 1" NPT Discharge Drain Pipe must be connected to the floor drain of the installation

site.

1. For standard discharge connection, using 1" NPT pipe directing the discharge drain from the

front of the cooker straight down into the floor. An alternate rear drain diverter method may also

be used. It is recommended that when using the diverter method a 1" capped tee be installed

for ease of cleaning. This method entails 1" pipe and fittings from the discharge at the front of

the unit to a rear drain. It will be necessary to use a combination of 1" tee, elbows and nipples

to access the drain location (the installer must determine what will be required).

– 10 –

Page 11

OPERATION

WARNING: HOT WATER AND PARTS CAN CAUSE BURNS. USE CARE WHEN OPERATING,

CLEANING AND SERVICING THE PASTA COOKER.

WARNING: SPILLING HOT/BOILING WATER CAN CAUSE SEVERE BURNS. DO NOT MOVE

PASTA COOKER WITHOUT DRAINING ALL WATER FROM THE TANK.

CAUTION: This pasta cooker is designed exclusively for use with water. NEVER add oil with

the intent of frying in this cooker. (Oil on partially cooked pasta is OK.)

BEFORE FIRST USE

Clean the Pasta Cooker

1. Use a non-corrosive, grease-dissolving commercial cleaner to clean the protective metal oils from

all surface parts and the tank interior.

2. Follow the cleaner manufacturer's directions.

CAUTION: Be careful not to disturb the thermostat and high limit capillaries (Fig. 6) when

cleaning down inside the tank.

3.

Rinse thoroughly and drain by opening the drain valve accessible when the door is opened (Fig. 7).

4. Wipe tank completely dry with a soft clean cloth.

5. Clean all pasta cooker accessories.

6. Rinse all parts thoroughly after cleaning.

7. Wipe dry.

Thermostat

High Limit

Device

Overflow / Skim

Port

PL-40199-1

Fig. 6 Fig. 7

– 11 –

Page 12

CONTROLS (Fig's. 8 & 9)

HIGH LIMIT

ON

P

O

W

E

R

OFF

TROUBLE

15 MIN. TIMER

15

14

13

12

11

BASKET LIFT CONTROL

TIMED BASKETLIFT

0

1

2

3

4

5

6

7

8

10

9

OPTION

B

HEATING

PUSH TO

TIME

I

O

L

S

HOT

I

M

M

E

R

ON

OFF

TIMED BASKETLIFT

HIGH LIMIT

ON

P

O

W

E

R

OFF

HEATING

TROUBLE

15 MIN. TIMER

PUSH TO

0

1

2

TIME

3

15

4

14

5

13

6

12

7

11

8

10

9

BASKET LIFT CONTROL

OPTION

I

O

L

B

S

I

M

M

E

R

Model GPC12 / GPC16 Model GPC12S / GPC16S

Fig. 8

THERMOSTAT —

Controls temperature of water in tank. Temperature at "simmer"

setting i

At "boil" setting,

s approximately 190°F (88°C); burners will cycle on and off.

temperature is 212°F (100°C); the burners will

remain on 100% of the time.

HOT

ON

OFF

COLD

ON

OFF

PL-53524

POWER SWITCH —

Turns electric power to the pasta cooker on or off.

• ON position opens the combination gas valve which allows the

ignitor to light the pilot. This

will happen every time the power

switch is turned on.

• OFF position shuts

off all gas to the burners and pilot.

INDICATOR LIGHTS:

ON — When lit, electric power to the machine is on.

TROUBLE — When lit, the electronic igniter has not been able to light the pilot.

HEATING — When lit, burners are supplying heat, warming water in tank per

thermostat.

HIGH LIMIT — When lit, there is not enough water in the tank; system has shut

down.

MANUAL FILL VALVES — Model GPC12 has one hot water fill valve. Model GPC12S has one

hot water fill valve, and one cold water fill valve on the chill tank. Turn

fill valves counterclockwise to open and clockwise to close.

GAS VALVE (Fig. 9) — Turns gas supply to the pasta cooker on or off.

– 12 –

Page 13

USING THE PASTA COOKER

Fig. 9

The tank warranty may be voided by improper operation. Turn the power switch

OFF when draining

or filling the pasta cooker.

CAUTION: Before turning the pasta cooker on, the tank must be filled with water. If this is not

done, the tank walls can be damaged. Warpage can cause leaks.

Turning the Pasta Cooker ON

1. Fill the pasta cooker tank to the water fill level line on the back wall, which is approximately

5" (127 mm) above the tank tubes (Fig. 10). The manual fill valve(s) are located on the front

control panel.

a. Turn handle counterclockwise to open and clockwise to close to operate.

b. Do not overfill tank.

c. Add water as needed.

FILL LEVEL

Fig. 10

– 13 –

PL-51431

Page 14

2. Connect the power cord to an appropriate grounded receptacle.

3. Turn the gas valve (located inside the cabinet door - see Fig. 9) to the ON position.

4. Push the power switch to the ON position. A "snapping" noise will be heard. This is the igniter

lighting the pilot.

• If the pilot fails to light within 90 seconds, the ignition system will automatically shut down and

the TROUBLE light will illuminate.

a. Push the power switch to the OFF position.

b. Wait 5 minutes.

c. Repeat Steps 2 and 3.

• If the pilot still fails to light, contact a qualified Vulcan-Hart service representative.

5. Make sure the tank is full of water.

6. Turn the thermostat control knob to the desired setting.

Turning the Pasta Cooker OFF

CAUTION: If you drain the tank at the end of the day, it is imperative that you turn off the pilot

by pushing the power switch to the OFF position.

1. Push the power switch to the OFF position.

2. Turn the gas valve to the OFF position to shut off all gas to the system.

Extended Shutdown

1. Push the power switch to the OFF position and unplug the pasta cooker.

2. Turn gas valve to OFF position.

3. Drain tank by opening the drain valve (Fig. 11) located inside the cabinet door.

– 14 –

Page 15

Fig. 11

Cooking

Do not overfill basket.

Recommended capacities are:

Model Pounds of Spaghetti*

GPC12 / GPC12S 7 (3 kg)

*Amounts of different pasta, such as rigatoni, tortellini, or shells, may vary.

1. Fill tank with hot water to correct level.

2. Turn thermostat to "BOIL."

3. Bring water to full rolling boil.

With Basketlift:

1. Turn the timer to the desired setting.

2. Set basket on basketlift arm.

3. Push button to lower.

• The basketlift arm will automatically raise when time is up.

• If you wish to raise the basketlift arm before time is up, turn the timer knob to zero.

– 15 –

Page 16

Without Basketlift:

1. Carefully lower basket into water.

2. Stir product often using a long utensil and protective mitt.

3. Remove basket when cooking is completed.

4. Hang basket on rear basket hanger to drain.

Model GPC12S Only:

If desired, the cooked pasta may be submerged in the chill tank to arrest cooking and quickly lower its

temperature for storage.

1. Fill chill tank with cold water to fill line (you may wish to add ice). Do not fill above fill line.

2. Stir often to help quickly lower the temperature of the pasta.

Other foods, such as corn-on-the-cob, may be cooked in the pasta cooker. It must be submerged to

cook uniformly.

1. Place corn in bottom of basket.

2. Stack an empty basket on top of corn to keep it submerged.

SWIVEL HEAD FAUCET (Optional)

The pasta cooker is shipped without the swivel head attached. Look for the swivel head in the tank of

the cooker and screw it onto the faucet. The swivel head faucet (Fig. 12) can be moved left to right

for use over either the hot or cold tank section. The left faucet handle controls hot running water, while

the right controls cold running water.

SWIVEL HEAD FAUCET

HOT

COOKER

COLD

RINSE

STATION

COOKER CONTROLS

COOKER FILL

VALVE (HOT)

Fig. 12

– 16 –

RINSE STATION

FILL VALVE

(COLD)

PL-41473-1

Page 17

HIGH LIMIT DEVICE

If the water level goes below the thermostat and high limit location (Fig. 13), the high limit will turn the

pasta cooker off and extinguish the pilot. DO NOT relight the pilot until the tank has been refilled with

water.

OVERFLOW/SKIM PORT

An overflow/skim port is provided at the front of the tank (Fig. 13) and a fill port spray nozzle is provided

at the right rear of the tank just above the fill line (Fig. 14).

Thermostat

High Limit

Device

Overflow / Skim

Port

FILL LINE

The overflow/skim port serves two functions:

PL-40199-1

Fig. 13

FILL PORT SPRAY NOZZLE

PL-41474-1

Fig. 14

1. Allows operator to skim foam and starch debris from the product while cooking and also while

filling with fresh water.

2. Keeps the tank from overflowing during filling.

– 17 –

Page 18

The fill port spray nozzle allows the operator to see the tank filling with water. The fill port spray nozzle

also forces the foam and starch debris over to the skim hole where the operator can skim off starches

and any unwanted debris while the tank is filling with fresh water.

To start filling the cooker tank, turn the left (hot) black manual fill valve handle on the front of the control

panel counterclockwise to the open position. To fill the rinse station side, use the right (cold) black

manual fill valve handle. Water will begin to fill into the tank through the fill port spray nozzle.

Note that the GPC12 will have only one valve handle for hot water fill of the cooker. The

have a hot and a cold valve handle (Fig. 15). The left handle of the GPC12S

controls hot water flow

GPC12S will

to the cooker and the right handle controls cold water flow to the rinse station. To stop flow and close

valve(s), turn handle(s) clockwise.

Be sure proper water level is maintained. Add water if necessary.

HOT WATER

FILL VALVE

TO COOKER

Fig. 15

COLD WATER

FILL VALVE

TO RINSE STATION

PL-41475-1

CLEANING

WARNING: UNPLUG THE PASTA COOKER AND TURN THE GAS VALVE OFF BEFORE CLEANING.

1. Clean the tank daily with a mild detergent and water.

• DO NOT use "Dawn" dish detergent.

a. Rinse thoroughly.

b. Wipe dry with a soft clean cloth.

CAUTION: Be careful not to disturb (crimp or bend) the high limit or thermostat

capillaries (see Fig. 13).

2. Wash all exterior surfaces at least once daily.

a. Use a cloth with warm water and a mild soap or detergent.

b. Rinse thoroughly

c. Wipe dry with a soft clean cloth.

– 18 –

Page 19

3. Make sure drains (tank and overflow/skim) are unobstructed. Dried cooked pasta can clog

drains.

4. Clean-out Brush

• The clean-out brush is used to clean the space at the rear section of the battery between the

cooker and

the rinse station.

a. Insert the brush into the opening and run brush up and down along the opening to

remove any

debris that may have settled in this area (Fig. 17).

b. The brush can also be used on the front of the cooker for clean-out between the two control panel

plates.

PL-41476

Fig. 17

– 19 –

Page 20

MAINTENANCE

WARNING: HOT WATER AND PARTS CAN CAUSE BURNS. USE CARE WHEN OPERATING,

CLEANING AND SERVICING THE PASTA COOKER.

WARNING: SPILLING HOT/BOILING WATER CAN CAUSE SEVERE BURNS. DO NOT MOVE

PASTA COOKER WITHOUT DRAINING ALL WATER FROM THE TANK.

LUBRICATION

Motors used on basketlift are permanently lubricated.

VENT

Annually, when pasta cooker is cool, check the flue and clear any obstructions.

DELIMING

The pasta cooker MUST be delimed periodically (depending upon usage, every 3-4 weeks). Follow the

deliming agent manufacturer's instructions. Rinse thoroughly at least 3 times before using pasta

cooker.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning the pasta cooker, contact the Vulcan-Hart Service

Depot in your area (refer to listing supplied with the pasta cooker or visit our website at

www.VulcanHart.com).

F-31173 Rev. A (02-04) PRINTED IN U.S.A.

– 20 –

Loading...

Loading...