Page 1

SERVICE MANUAL

VHX BOILER BASE SERIES

HIGH EFFICIENCY

ELECTRIC STEAMER

VHX24E ML-126852

VHX24E5 ML-126853

MHB24E ML-126857 (BASE ONLY)

VHX24E SHOWN

- NOTICE This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly qualified.

If you have attended a Vulcan Service School for this product, you

may be qualified to perform all the procedures described in this

manual.

This manual is not intended to be all encompassing. If you have not

attended a Vulcan Service School for this product, you should read,

in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do not

have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

For additional information on Vulcan-Hart or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanhart.com.

A product of VULCAN-HART LOUISVILLE, KY 40201-0696

F25154 (February 2004)

Page 2

VHX SERIES STEAMERS

TABLE OF CONTENTS

GENERAL ................................................................................4

Installation, Operation and Cleaning ........................................................4

Introduction ............................................................................4

Steam Cooking.....................................................................4

Model Designations .................................................................4

Compartment Pan Capacity ...........................................................4

Cooking Compartments Control Panel ...................................................4

Boiler Control Panel ................................................................. 4

Boiler Code Descriptions .............................................................5

Water Conditioning ...................................................................... 5

Specifications ..........................................................................5

Boiler Pressure.....................................................................5

Water Supply ......................................................................5

Electrical..........................................................................6

Tools.................................................................................6

REMOVAL AND REPLACEMENT OF PARTS ....................................................7

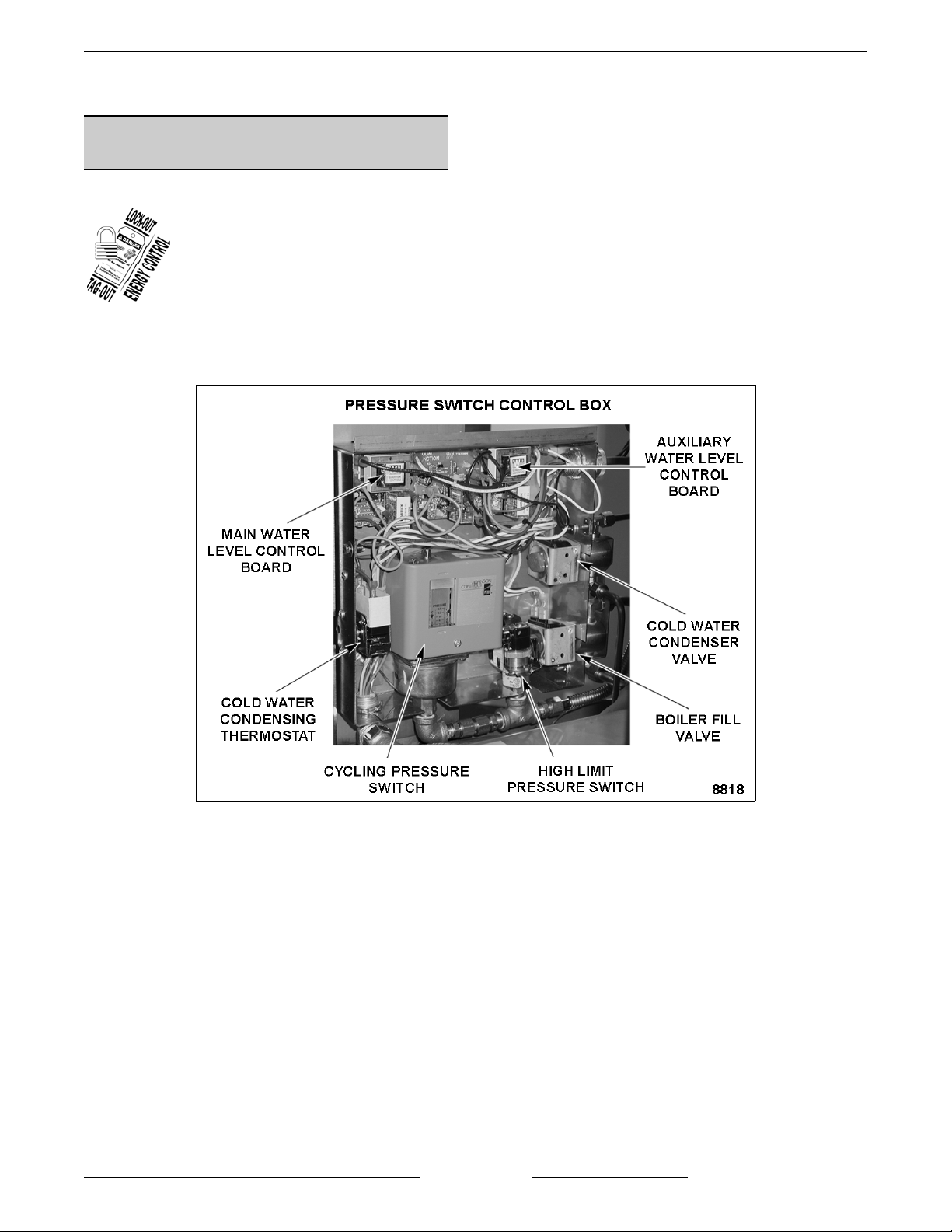

Pressure Switch Control Box Components ...................................................7

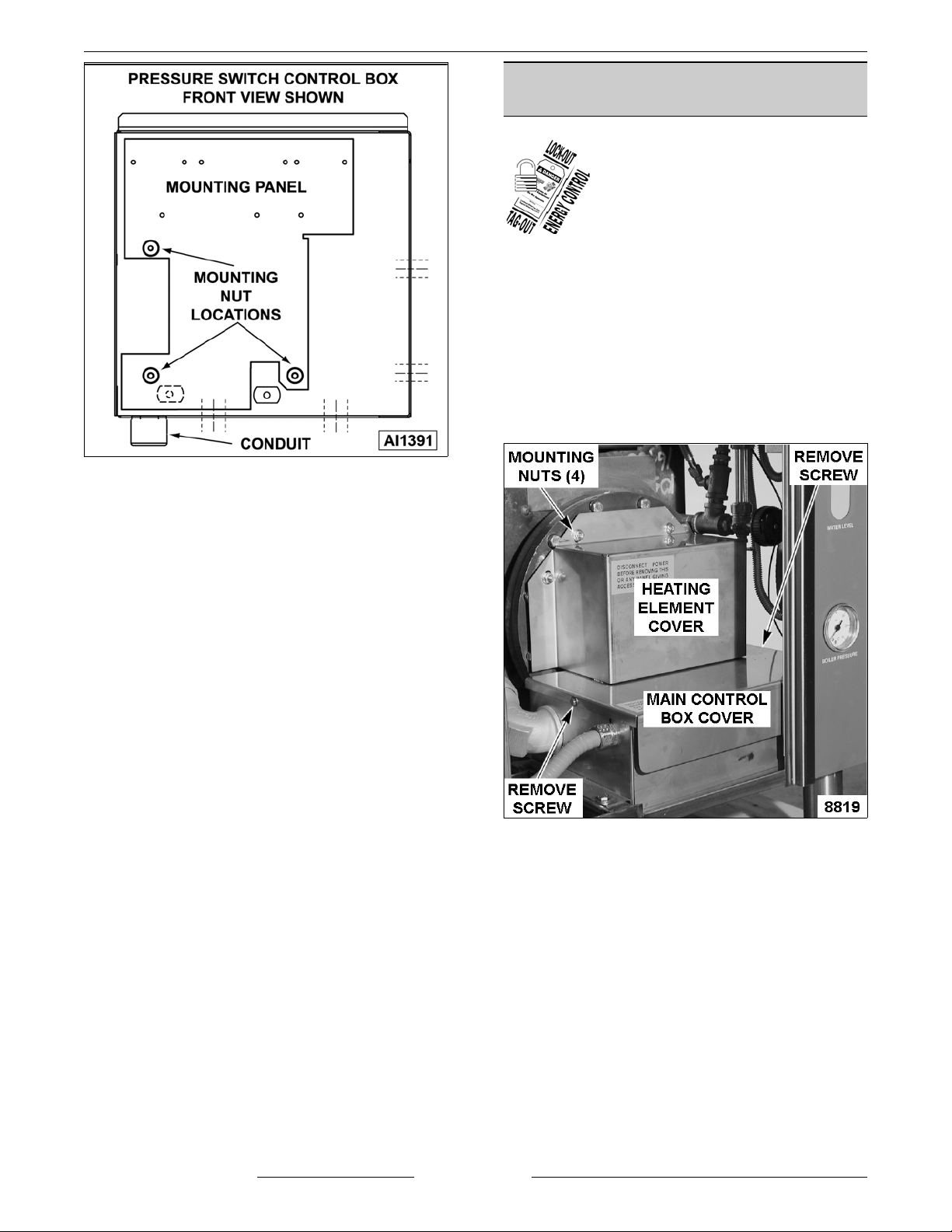

Main Control Box Components .............................................................8

Water Level Gauge Assembly .............................................................9

Heating Elements ..................................................................... 10

Heating Element Mounting Plate .......................................................... 11

Boiler Assembly .......................................................................12

Descaler (Cathodic Protector) ............................................................ 13

Cooking Compartment Door(s)............................................................14

SERVICE PROCEDURES AND ADJUSTMENTS.................................................16

Boiler ............................................................................... 16

Inspection ........................................................................16

Clean-Out ........................................................................ 16

Deliming .........................................................................16

Descaler (Cathodic Protector) ........................................................16

Water Level Probe Housing Blowdown ..................................................... 17

Water Level Controls Test ...............................................................17

Cycling Pressure Switch Adjustment .......................................................19

High Limit Pressure Switch Adjustment .....................................................20

Boiler Fill and Cold Water Condenser Solenoid Valves .........................................20

Cold Water Condenser Thermostat Adjustment ...............................................21

Heating Element Test...................................................................22

Cooking Compartment ..................................................................22

Intake Shut-Off Valve Adjustment (Steam Flow) .......................................... 22

Door Sealing Adjustment ............................................................23

Door Latch Adjustment..............................................................23

F25154 (February 2004) Page 2 of 48

Page 3

VHX SERIES STEAMERS

ELECTRICAL OPERATION.................................................................. 24

Component Function ................................................................... 24

Cabinet Base Boiler Controls .........................................................24

Cooking Compartment Controls ....................................................... 25

Component Locations ...................................................................26

Boiler Base Controls................................................................26

Cooking Compartment Controls ....................................................... 28

Water Level Controls ...................................................................29

Low Level Cut-Off & Differential Control................................................. 29

Auxiliary Low Level Cut-Off ..........................................................30

Relay Board ..........................................................................31

Layout, Legend & Diagnostic Test Points ................................................31

Schematic........................................................................ 32

Sequence of Operation ..................................................................33

Cooking Compartment Controls .......................................................34

Schematics ...........................................................................36

Boiler Base Controls................................................................36

Cooking Compartment Controls .......................................................37

Wiring Diagrams.......................................................................38

Boiler Base Controls................................................................38

Heating Element Circuits ............................................................40

Cooking Compartment Controls .......................................................41

TROUBLESHOOTING......................................................................42

CONDENSED SPARE PARTS LIST ........................................................... 48

© VULCAN 2004

F25154 (February 2004)Page 3 of 48

Page 4

VHX SERIES STEAMERS - GENERAL

GENERAL

INSTALLATION, OPERATION

AND CLEANING

Refer to the Installation and Operation Manual for

specific instructions.

INTRODUCTION

Steam Cooking

Convection cooking in pressure-less steaming

compartments will steam cook fresh foods or will

steam defrost and cook frozen foods providing the

maximum color, flavor and nutritional value with the

least expenditure of energy and labor. The pressureless steaming compartments on the VHX series,

allows the operator to open and close the door

anytime during a cooking cycle. The steam supply

will shut off when the door is opened, then re-start

when the door is closed.

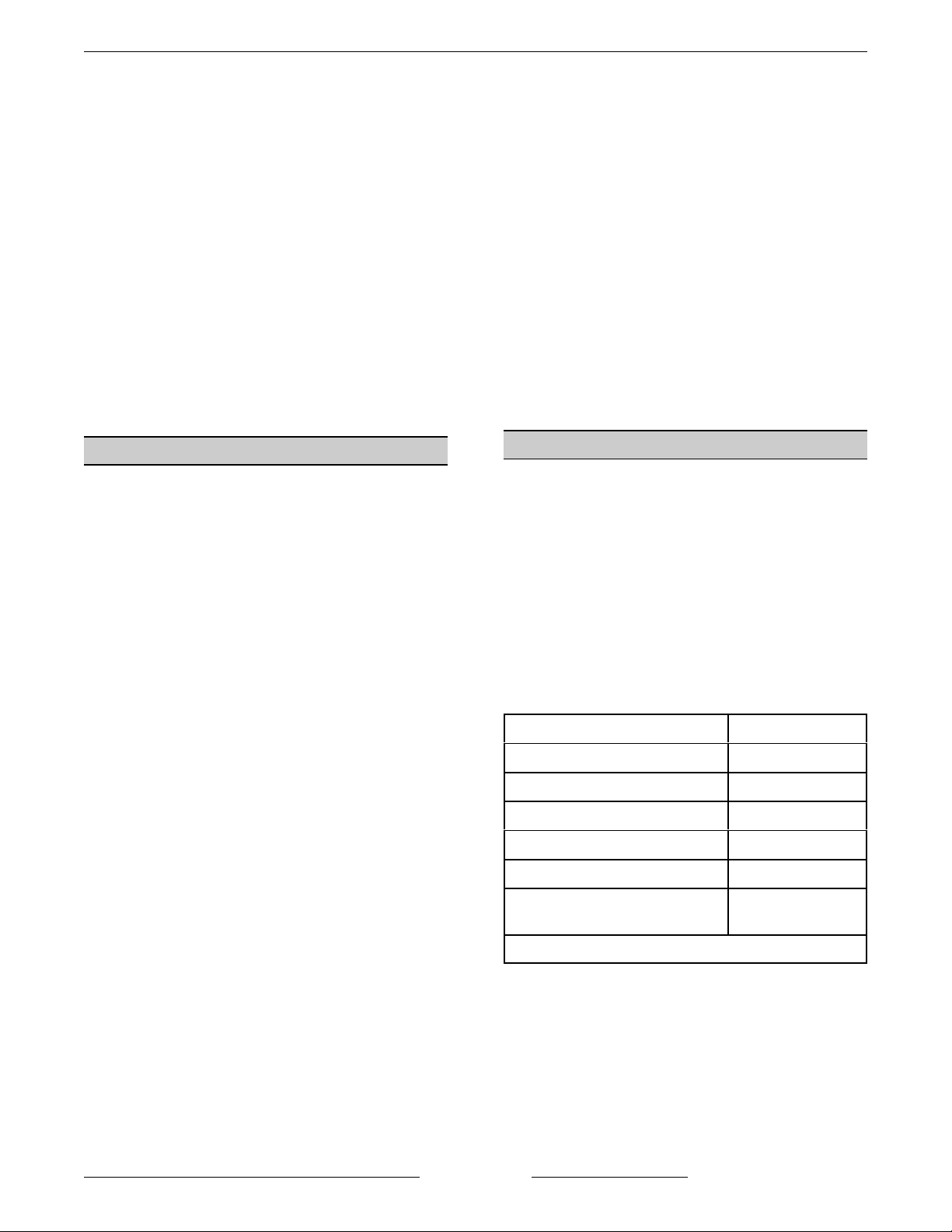

Model Designations

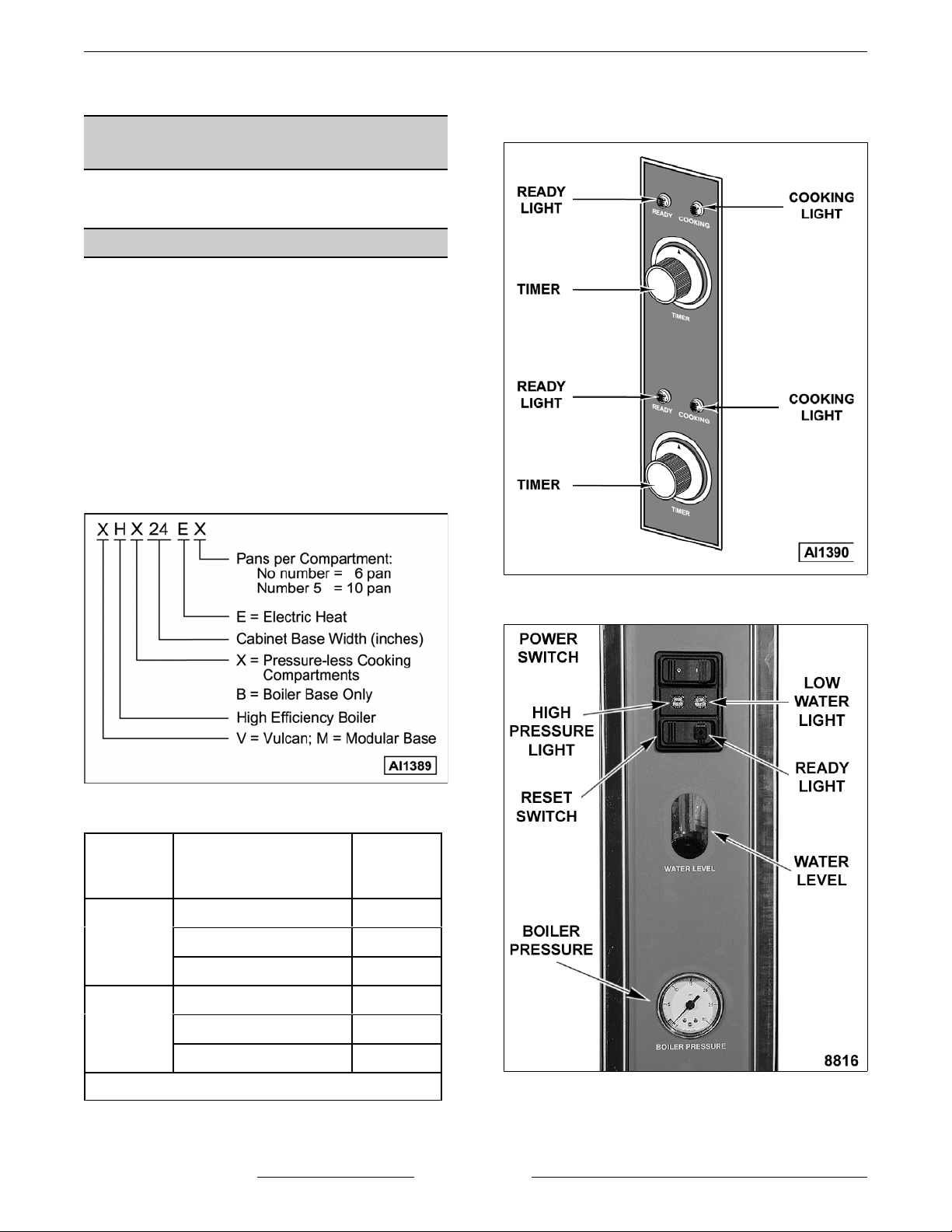

Cooking Compartments Control Panel

Compartment Pan Capacity

MODEL

VHX24E

VHX24E5

NUMBER OF PANS

PER COMPARTMENT

24.0

32.5

61.0

34.0

52.5

Boiler Control Panel

PAN

DEPTH

(INCHES)

10 1.0

Pan Size 12" x 20"

F25154 (February 2004) Page 4 of 48

Page 5

VHX SERIES STEAMERS - GENERAL

Boiler Code Descriptions

Vulcan-Hart incorporates redundant controls in

compliance with the CSD-1 controls and safety

devices for boiler construction on the high efficiency

steamer models. A description of the code is listed

below.

CSD-1 Construction - Redundant controls in the

electrical safety circuits that, if tripped, must

manually be reset after the condition causing the trip

subsides. The controls provide low water level cut-off

protection (LLCO), auxiliary low water level cut-off

protection (Aux LLCO), and high pressure protection

for the boiler. Additionally, the low water and high

pressure safety circuits have individual indicator

lights that will illuminate for a visual verification of the

shutdown mode.

CSD-1 construction requires operator intervention in

the event of a shutdown. The indicator lights show

the operator which safety system was shutdown.

WATER CONDITIONING

Furnishing the boiler with treated water to reduce

scale formation is advised. Scale formation will

reduce steam output, cause premature component

failure, and shorten equipment life. Most water

supplies contain scale producing minerals such as

calcium and magnesium. As steam is generated, the

minerals remain and dissolve into the water. As the

concentration of these minerals increases past a

certain point, they precipitate from the water and

coat the inside of the boiler, heating elements, and

water level sensors. Because of the high

temperature of these surfaces, the precipitated

minerals bake onto them and become very difficult to

remove.

This may cause several problems:

1. Reduced heat transfer efficiency.

2. Premature heating element failures.

3. False readings from water level sensors.

These problems are common to any steam

equipment manufacturer, regardless of design, but

can be minimized by furnishing the boiler with

treated water.

Other factors affecting steam generation are iron

content, amount of chlorination and dissolved gases.

The desired water properties can best be achieved

by using a properly maintained water treatment

system.

The water level probes in the boiler use ions in the

water to detect the water level. Do not use fully

demineralized or de-ionized water since it is non

conductive and the water level can not be

detected.

The use of strainers will not remove minerals from

the water.

Water supplies vary from state to state and from

locations within a state. Therefore, a water

treatment specialist should be consulted before

the installation of any steam generating equipment.

Steamers that operate over a long period of time

without the benefit of a water treatment system,

which have developed a heavy scale build-up,

should be cleaned before using the system.

SPECIFICATIONS

Boiler Pressure

Operating - 10 to 12 psi

Maximum - 15 psi

Water Supply

The fact that a water supply is potable is no

guarantee that it is suitable for steam generation.

The supply connection to the steam generator

should be treated water and must be within the

guidelines listed below. For drain water cooling only,

an untreated water supply connection should be

used.

Supply connection cold water

Supply pressure should be 20-60 psig

Hardness* less than 60 ppm

Silica less than 13 ppm

Total Chloride less than 4 ppm

PH Range 7 to 8

Un-dissolved Solids

*17.1 ppm = 1 grain of hardness

less than 5

microns

F25154 (February 2004)Page 5 of 48

Page 6

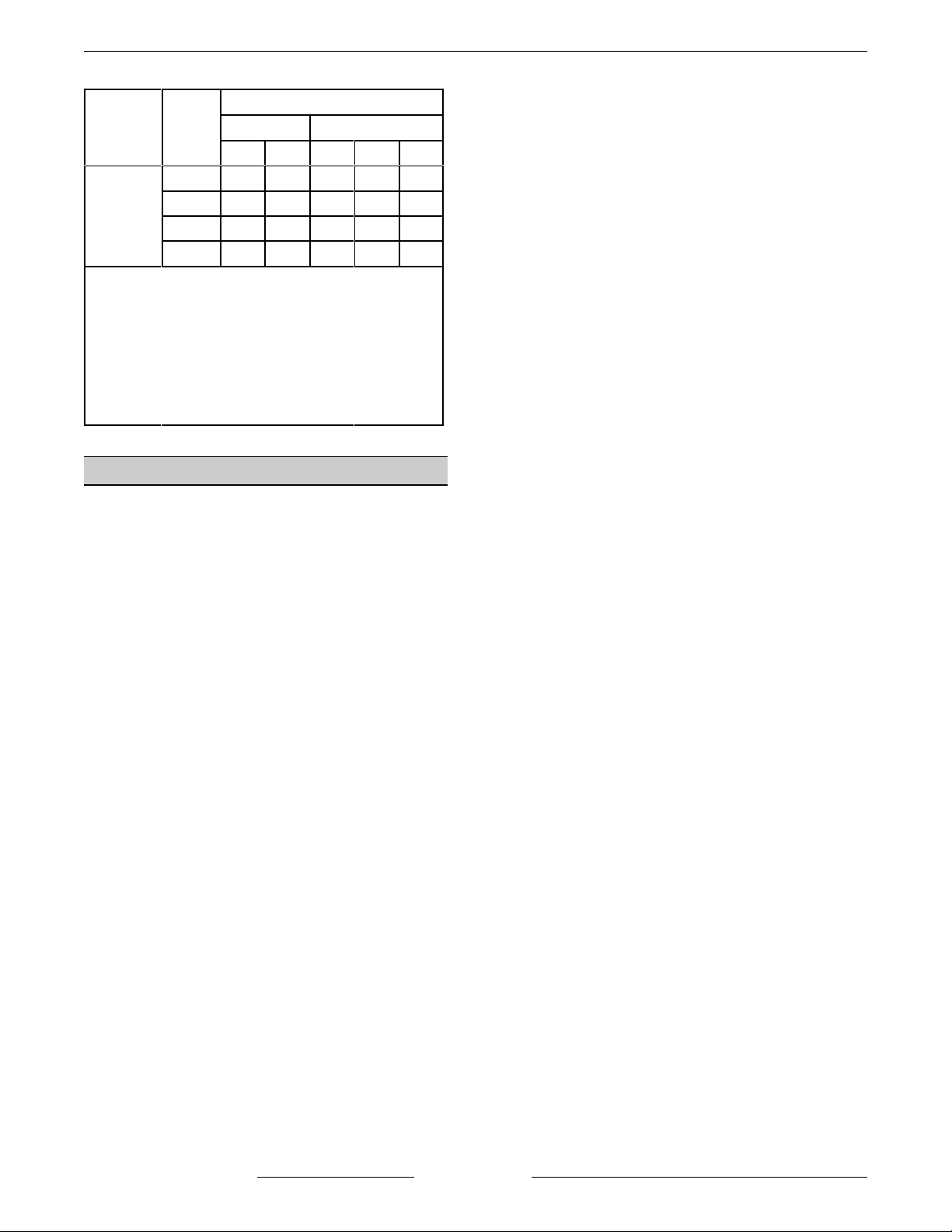

Electrical

MODELS

VHX24E,

VHX24E5,

MHB24E

NOTES:

VHX SERIES STEAMERS - COMPONENT FUNCTION

AMPERAGE

TOTAL

KW

24 116 100 67 58 29

36 --- --- 100 87 44

42 --- --- 117 --- --48 --- --- --- 116 58

1. Amperage values in the table are

nominal. Tolerance is +5/-10%.

2. Voltage values are @ 60HZ.

3. 24KW 3 phase is standard for both

models. If a 24KW single phase

connection is needed, the machine is

field convertible at the terminal block.

See heating element circuit diagram

AI1388.

1 PHASE 3 PHASE

208V 240V 208V 240V 480V

TOOLS

Standard

!

Standard set of hand tools.

!

VOM with AC current tester.

NOTE: Any quality VOM with a sensitivity of at

least 20,000 ohms per volt can be used.

Special

!

The recommended deliming chemical for the

water treatment system in use, for deliming of

the boiler.

!

Heat Exchanger Gasket (joint sealant strip,

Teflon) P/N 854058-1.

!

Loctite 242 thread sealant or equivalent

P/N 520228. Used on the top and bottom

cooking compartment door screws.

!

3/8 x 16 tap. Used for cleaning out threads on

front boiler flange.

F25154 (February 2004) Page 6 of 48

Page 7

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

PRESSURE SWITCH CONTROL

BOX COMPONENTS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

CAUTION: Certain components in this system are subject to damage by electrostatic discharge during

field repairs. A field service grounding kit is available to prevent damage. The field service grounding kit

must be used anytime a control board is handled.

1. Open the cabinet base door.

2. Remove cover from pressure switch control box.

3. Disconnect lead wires from component being replaced.

4. To remove:

A. Cycling pressure switch.

1) Disconnect compression fittings in the pressure supply line leading to the switch.

2) Remove mounting nuts from pressure switch mounting panel.

3) Disconnect conduit from box.

F25154 (February 2004)Page 7 of 48

Page 8

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

4) Disconnect lead wires from other

components as necessary then

remove pressure switch mounting

panel.

MAIN CONTROL BOX

COMPONENTS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

CAUTION: Certain components in this system

are subject to damage by electrostatic discharge

during field repairs. A field service grounding kit

is available to prevent damage. The field service

grounding kit must be used anytime a control

board is handled.

1. Open the cabinet base door.

2. Remove heating element cover then main

control

box cover.

5) Remove screws securing switch to

panel.

B. High limit pressure switch.

1) Disconnect compression fittings from

switch then remove from box.

C. Boiler fill or cold water condenser valve.

1) Turn water supply off and disconnect

compression fittings from valve.

2) Remove valve bracket mounting

screws.

D. Main or auxiliary water level control board

1) Compress locking tab on the board

mounting standoffs and remove

control board.

5. Reverse procedure to install.

NOTE: Before installing the cycling pressure switch,

use pressure scale on the switch to preset the

approximate cut-out (off) and cut-in (on) set points.

A. Adjust the installed pressure switch

(cycling or high limit) as outlined in

SERVICE PROCEDURES AND

ADJUSTMENTS.

3. Disconnect lead wires from component being

replaced.

6. Check for proper operation.

F25154 (February 2004) Page 8 of 48

Page 9

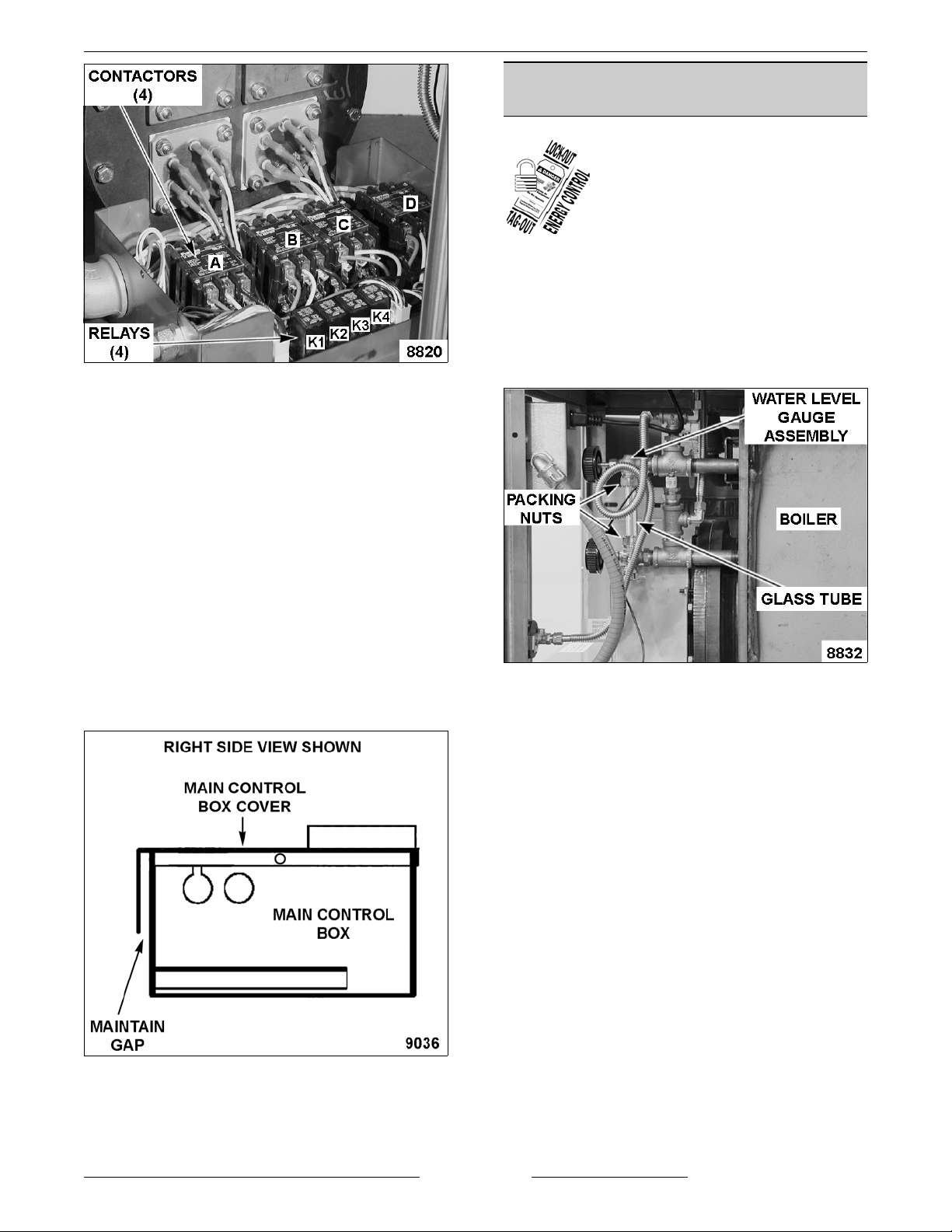

4. To remove:

A. Contactors.

1) Release catch at the base of

B. Relays.

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

WATER LEVEL GAUGE

ASSEMBLY

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Remove right side panel.

NOTE: If right side panel is not accessible, open the

cabinet door and remove control panel to access

from front.

2. Loosen packing nuts on glass tube until threads

disengage then slide nut toward center of tube.

contactor and remove from DIN rail.

1) Remove from socket.

C. Relay Board.

1) Compress locking tab on the board

mounting standoffs and remove

control board.

5. Reverse procedure to install and check for

proper operation.

NOTE:

installed, the gap between the front lip of cover and

main control box must be maintained for adequate

ventilation. Do not seal the gap.

When the main control box cover is properly

LEFT SIDE VIEW SHOWN

3. Slide glass tube up until it clears the bottom

fitting, tilt out at the bottom and slide glass tube

down to remove.

NOTE: Clean glass tube if cloudy or replace if chips

or cracks are noticed.

4. Remove packing nuts from glass tube.

A. A single rubber washer is installed inside

each packing nut. Clean debris from

washer and inspect the rubber for cracks

or hardening.

1) If rubber washer needs replacing,

install a replacement rubber washer in

each packing nut.

NOTE: When installing, ensure friction

washer (flat) is installed inside the packing

nut before rubber washer.

5. To Install:

A. Slide packing nuts onto glass tube and

position each nut approximately 1" from

open end on tube.

F25154 (February 2004)Page 9 of 48

Page 10

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

B. Insert one end of glass tube into top gauge

fitting then align opposite end of tube with

bottom gauge fitting.

C. Lower the glass tube into bottom gauge

fitting then center the tube between top &

bottom gauge fittings.

D. Hold glass tube in place and hand tighten

the bottom packing nut then top.

E. Tighten each packing nut and additional

1/2 turn.

CAUTION: Do not over tighten packing nuts or

damage to glass tube may occur.

6. Re-connect power to the machine.

7. Turn power switch on and allow boiler to fill.

A. Press reset switch to begin heating (green

ready light on).

8. Check gauge glass for water and steam leaks.

A. If necessary, slowly tighten packing nuts

until leak stops.

9. Install right side panel or front control panel (if

removed).

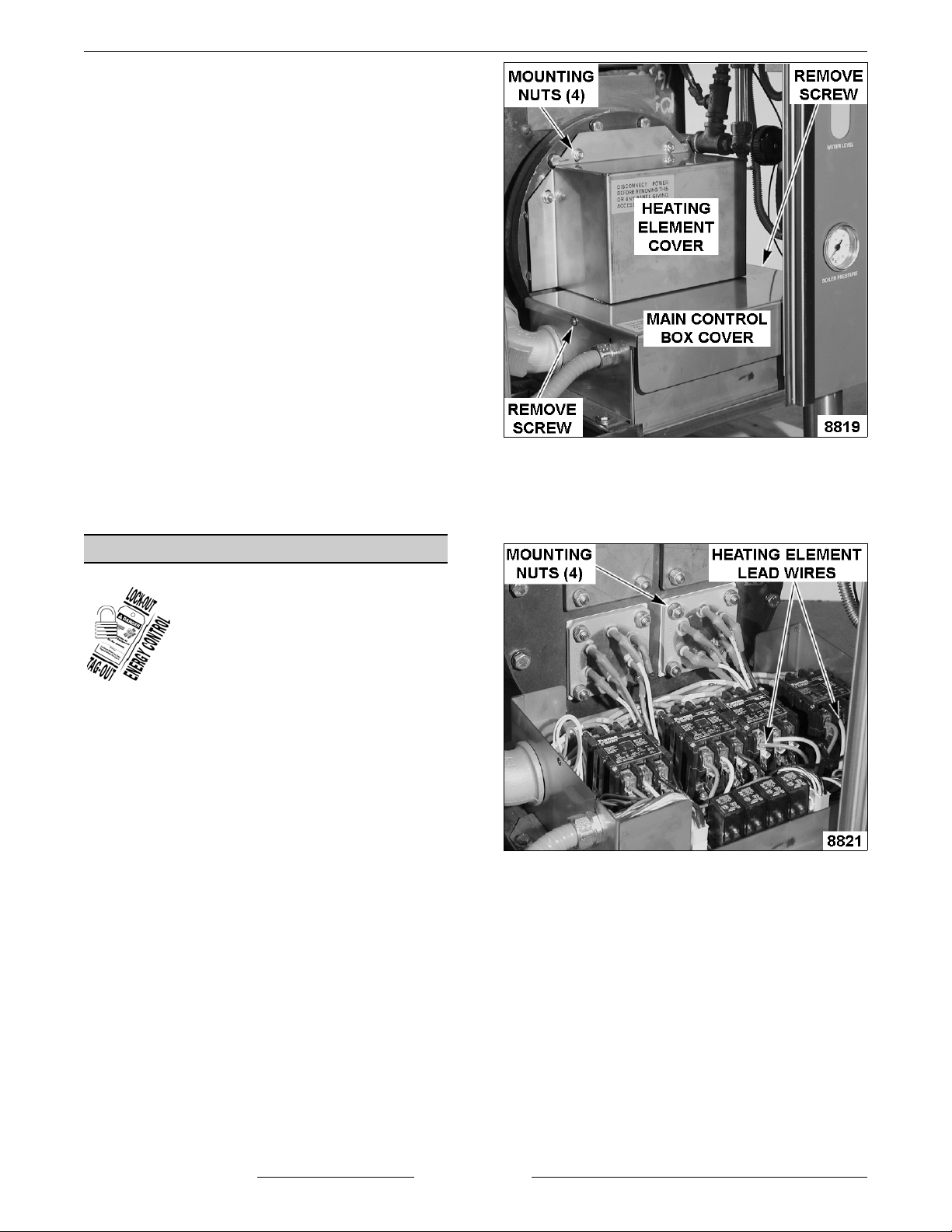

HEATING ELEMENTS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Turn power switch off and allow boiler to

blowdown/drain.

2. Open the cabinet base door.

3. Remove heating element cover then main

control box cover.

4. Disconnect lead wires from heating element at

the contactor terminals.

5. Remove mounting nuts from heating element

and remove the element from boiler.

6. Clean the mating surface on mounting plate

then install a replacement gasket and heating

element.

7. Reverse procedure to install and check for

NOTE: When installing heating element, route the

lead wires between the contactors.

F25154 (February 2004) Page 10 of 48

proper operation.

Page 11

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

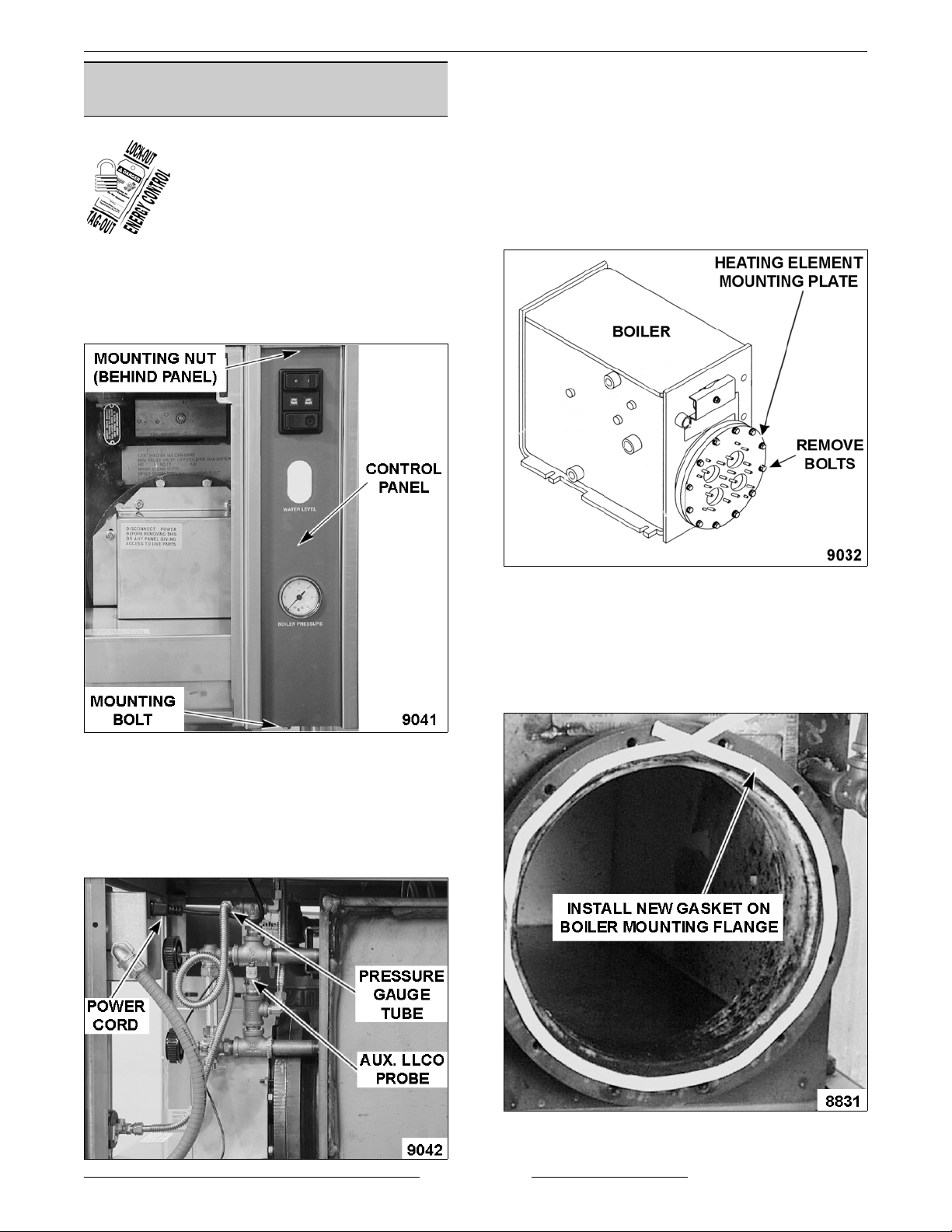

HEATING ELEMENT MOUNTING

PLATE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Remove heating elements as outlined under

HEATING ELEMENTS.

Loosen mounting hardware securing control

2.

panel to frame and lower the panel.

6.

Loosen both conduit locking nuts (1 1/2" & 3/8")

in main control box.

7. Loosen conduit nut (1 1/2") on elbow connected

to main control box.

8. Remove mounting bolts for main control box.

A. Lift main control box to remove from the

frame and position it to the left side.

9. Remove heating element mounting plate.

3.

On models with cooking compartments

disconnect power cord from power switch box

(rear of control panel).

4.

Disconnect pressure gauge tube

tee.

5.

Disconnect lead wire from Aux LLCO probe.

from fitting at

only,

10. To install:

A.

Clean the mating surfaces on heating

element mounting plate and boiler.

B. Install new gasket on boiler side of

mounting flange.

F25154 (February 2004)Page 11 of 48

Page 12

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

C. Position heating element mounting plate

with mounting studs for the element cover

at the top.

NOTE: When installing heating element

mounting plate

bolts as indicated to ensure the mounting plate

is flush with boiler flange and gasket is evenly

compressed. If bolt is not threading properly by

hand, clean out the threads with a 3/8 x 16 tap.

D. Align mounting holes then press and hold

heating element mounting plate against the

gasket. Install two bolts at the top and two

bolts at the bottom. Hand Tighten Only.

E. Starting with the bottom bolts, tighten each

bolt a few turns at a time and alternate

between the bottom and top bolts.

F. Install two bolts at the left and two bolts at

the right on the heating element mounting

plate. Tighten each bolt a few turns at a

time and alternate between the left and

right bolts.

G. Install the four remaining bolts. Tighten

each bolt a few turns at a time and

alternate between the four remaining bolts.

, install and tighten the mounting

RIGHT SIDE VIEW SHOWN

8. Remove gauge glass as outlined under

WATER LEVEL GAUGE ASSEMBLY.

9. Disconnect water level probe lead wires.

10. Remove coil from blowdown/drain valve.

11. Disconnect boiler fill and cold water condenser

valve water lines and remove lines.

11. To complete heating element mounting plate

installation, reverse procedure from main

control box removal.

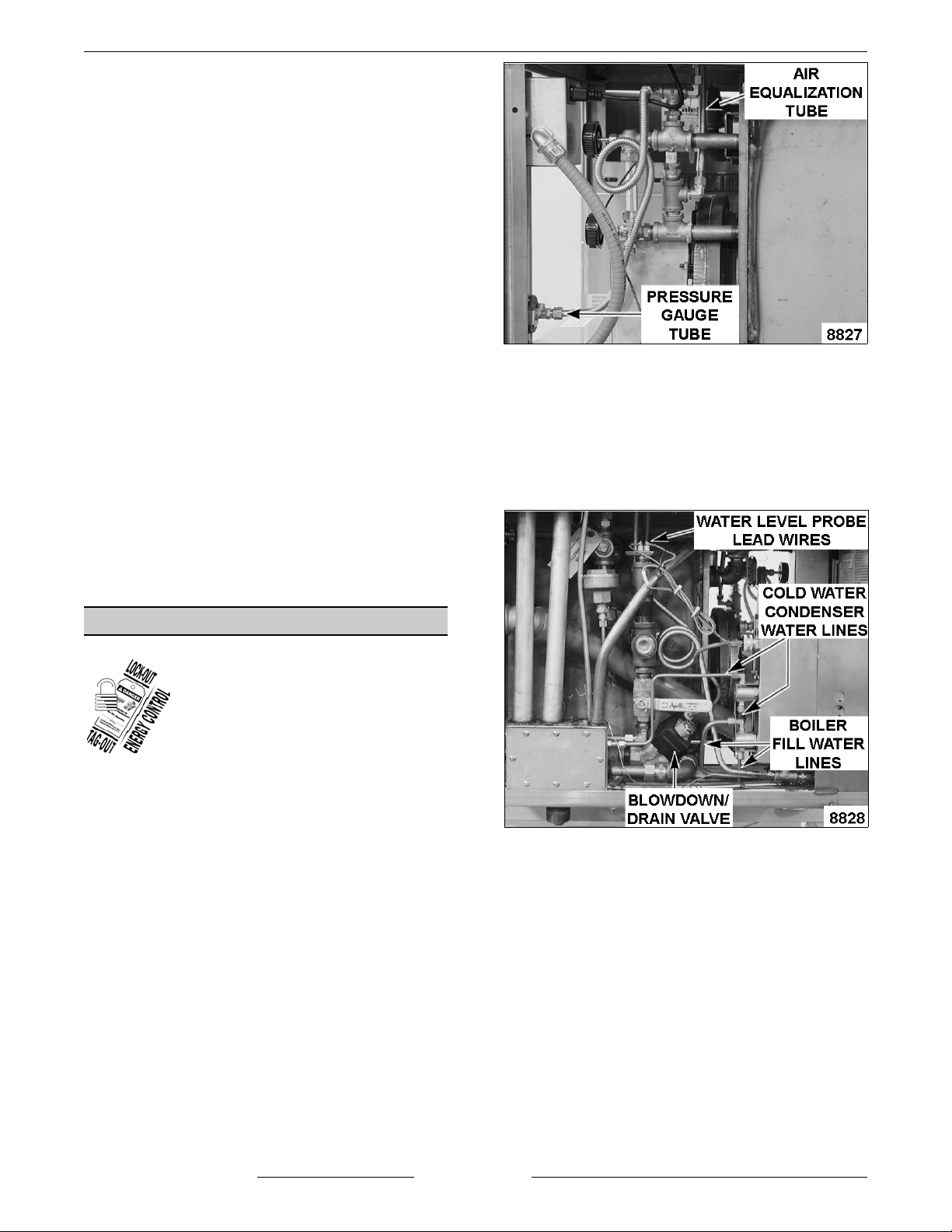

BOILER ASSEMBLY

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

NOTE: To perform this procedure, the steamer must

be accessible from all sides.

1. Turn power switch off and allow boiler to

blowdown/drain.

2. Turn water supply off.

3. Remove left and right side panels.

4. Raise steamer from the bottom right side by

approximately three inches to drain the

remaining water from boiler. Lower steamer

when boiler is empty.

5. Remove heating element mounting plate as

outlined under HEATING ELEMENT

MOUNTING PLATE.

6. Disconnect pressure gauge tube from gauge.

7. Disconnect air equalization tube and remove.

LEFT SIDE VIEW SHOWN

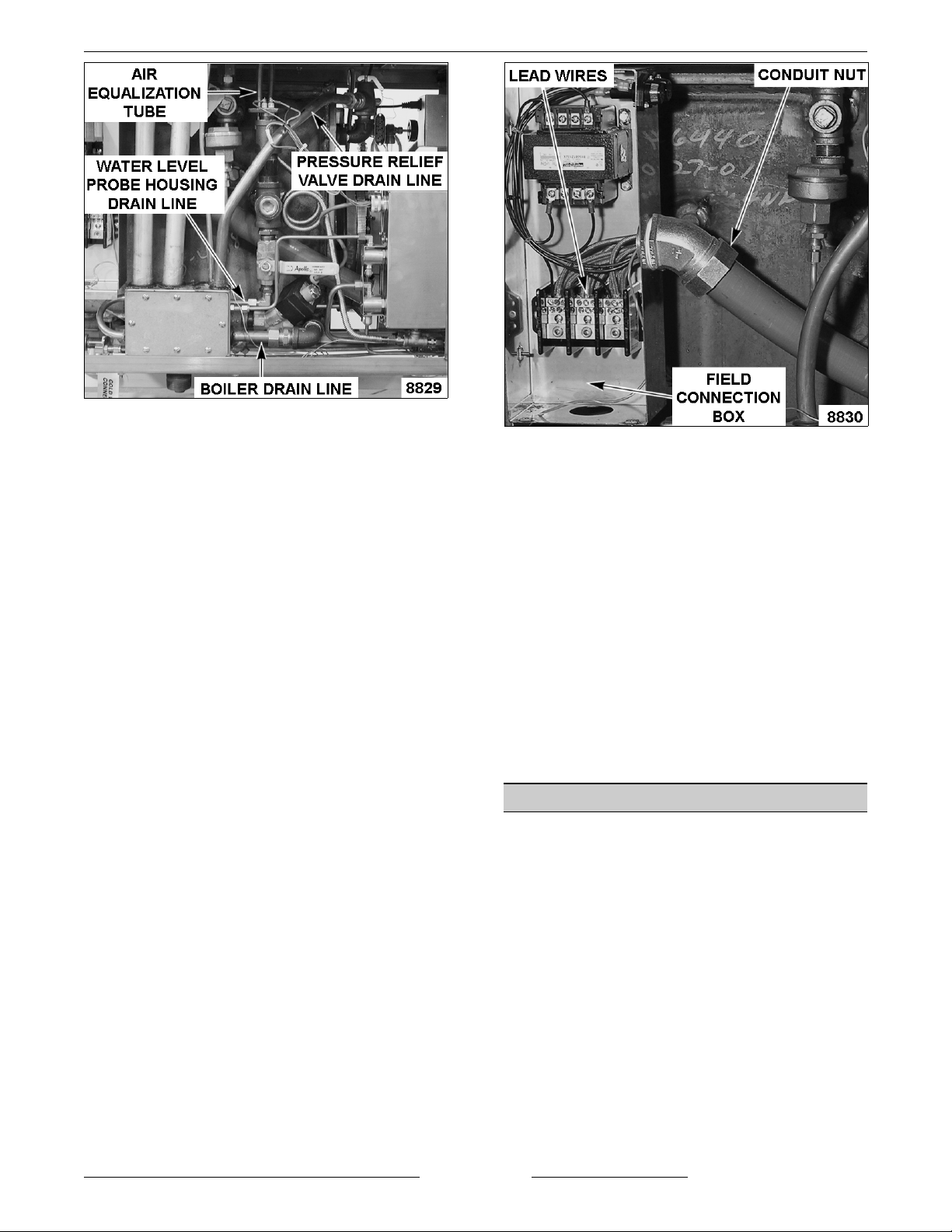

12. Remove cover from pressure switch control box

and loosen conduit locking nut.

13. Remove mounting screws for pressure switch

control box.

14. Disconnect pressure relief valve drain line at

the valve.

15. Disconnect water level probe housing air

equalization tube and remove tube.

16. Disconnect water level probe housing drain line

from condenser drain box.

17. Disconnect boiler drain line from condenser

drain box.

F25154 (February 2004) Page 12 of 48

Page 13

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

LEFT SIDE VIEW SHOWN

18. Separate union at boiler drain.

19. On models with cooking compartments:

A. Remove the left and right access panels

between the cooking compartments and

boiler base.

B. Disconnect flexible steam supply line from

boiler tee to cooking compartments and

remove the line.

C. Disconnect both drain lines from cooking

compartments to condenser drain box and

remove the lines.

20. On models

disconnect steam supply line from boiler tee.

21. Loosen conduit nut on field connection box and

slide nut down onto conduit.

22. Remove cover from field terminal box and

disconnect lead wires from terminal block.

with steam generator base only,

LEFT SIDE VIEW SHOWN

23. Remove main control box and pressure switch

control box from boiler base.

24. Remove bolts securing boiler to base frame

then slide boiler forward to remove.

25. Remove all plumbing components from boiler

and install on replacement boiler.

26. Install replacement boiler but hand tighten

mounting bolts only.

27. To complete boiler installation, reverse

procedure from main control box and pressure

switch control box removal.

28. When all connections to boiler are made,

tighten boiler mounting bolts to secure boiler to

base frame.

29. Check for proper operation.

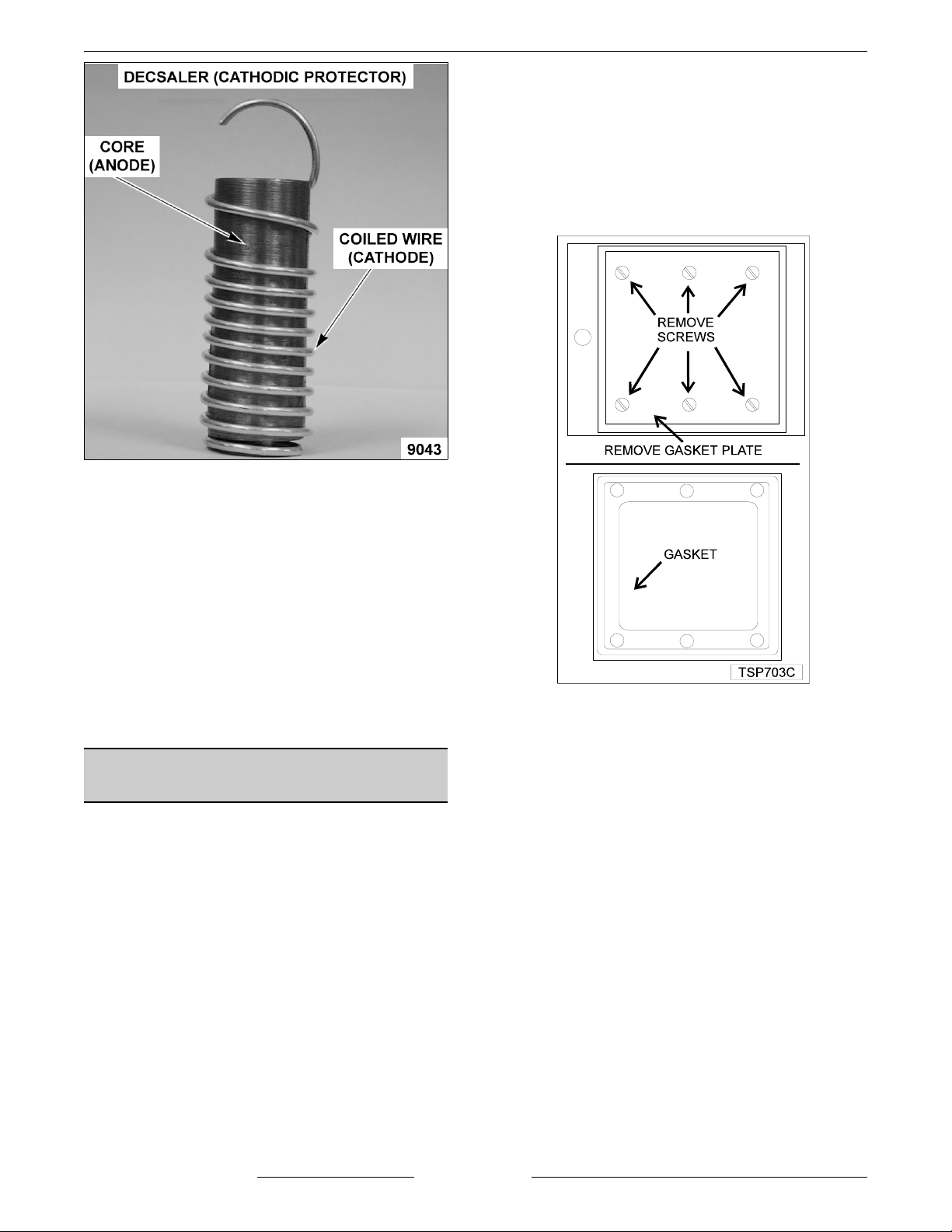

DESCALER (Cathodic Protector)

NOTE: The descalers are accessible only through

the heating element mounting plate opening in boiler.

1. Remove heating element mounting plate as

outlined under HEATING ELEMENT

MOUNTING PLATE.

2. Remove the two descalers hanging from the

front horizontal support rod.

F25154 (February 2004)Page 13 of 48

Page 14

3. To install:

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

5. Adjust the door as outlined in DOOR SEALING

ADJUSTMENT under COOKING

COMPARTMENT.

NOTE: Do not over tighten gasket plate screws as

this will compress the gasket excessively and

interfere with proper door sealing.

NOTE: Damage to the gasket sealing surface, such

as nicks or cuts, will cause steam leakage.

A. On the two replacement descalers, stretch

the coiled wire (cathode) at the top to

elongate the wire then form an open loop.

B. Hang the descalers on the front horizontal

support rod; one to the left of the heating

elements and one to the right.

C. Position the descalers so the core (anode)

is below the minimum water level in the

boiler and hanging freely.

NOTE: To function properly, the descalers must

not contact the interior surfaces of the boiler or

the heating elements.

COOKING COMPARTMENT

DOOR(S)

Removal

1. Remove top cover.

2. Open the door.

3. Pull hinge rod up.

4. Reverse the procedure to install, making sure

the door bushings are in place.

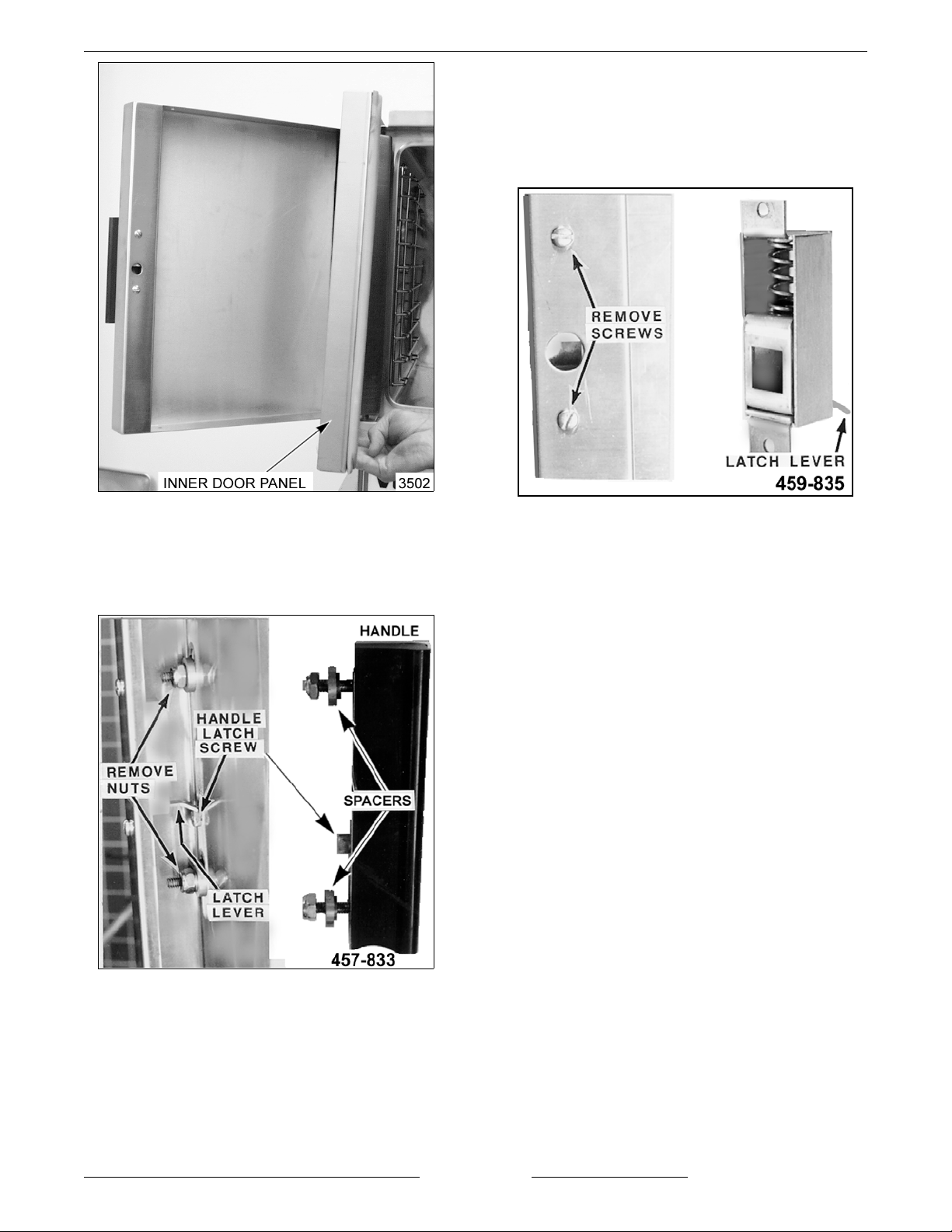

Handle

1. Open the door.

2. Remove screws from the top and bottom of the

door.

3. Pull the inner door panel out from the door

housing with the gasket plate and gasket still

attached.

Gasket

1. Open the door.

2. Remove screws from the gasket plate.

3. Pull the gasket plate out from the door housing

and remove the gasket.

4. Position the new gasket on the gasket plate and

reverse the procedure to install.

F25154 (February 2004) Page 14 of 48

Page 15

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

3. Pull the inner door panel out from the door

housing with the gasket plate and gasket still

attached.

4. Remove the screws from the side edge of the

door that secure the latch mechanism and

remove the latch from the door.

4. Remove the nuts and spacers from the handle

screws and remove the handle from the door.

NOTE: When installing the spacers, the smaller

diameter fits into the slot in the door and the latch

lever must rest on top of the handle latch screw.

NOTE: When installing, the latch lever must rest on

top of the handle latch screw.

5. Reverse procedure to install.

NOTE: When installing screws at the top and bottom

of door, apply thread sealant.

5. Reverse procedure to install.

NOTE: When installing screws at the top and bottom

of door, apply thread sealant.

Latch Assembly

1. Open the door.

2. Remove screws from the top and bottom of the

door.

F25154 (February 2004)Page 15 of 48

Page 16

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRES ELECTRICAL TEST OR

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POINTS ARE NOT EASILY ACCESSIBLE, DISCONNECT POWER AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES, ATTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST.

BOILER

Inspection

The boiler should be inspected for excessive lime

scale build-up in a time frame dependant on the

quality of the local water supply and steamer usage.

In hard water areas or for steamers heavily used, a

more frequent interval should be used. This

inspection consists of an internal examination and

cleaning of the boiler, an examination of the two

hanging descalers (cathodic protectors) and for lime

scale build-up on the water level probes. Also, check

all boiler controls, including the pressure switches.

Periodic service must be performed as outlined in

the BOILER procedures. See WATER

CONDITIONING under GENERAL.

Clean-Out

1. Turn power switch off and allow boiler to

blowdown/drain.

2. Remove heating element mounting plate as

outlined in REMOVAL AND REPLACEMENT

OF PARTS.

3. Inspect descalers (cathodic protectors) as

outlined under DESCALER (CATHODIC

PROTECTOR) in this section.

8. Install descalers (cathodic protectors).

9. Install heating element mounting plate.

10. Install heating elements.

11. Check for proper operation.

Deliming

Refer to the water filtration system manual supplied

with steamer for specific instructions.

Descaler (Cathodic Protector)

Two descalers are installed inside the boiler and are

used as a preventative measure to:

• Reduce scale deposit build-up

• Help remove existing scale deposits

• Inhibit boiler and component corrosion

The descaler has a coiled wire (cathode) wrapped

around a solid cylindrical core (anode) that hangs by

an open loop from the front horizontal support rod

inside the boiler.

The descaler materials serve as a sacrificial anode

and cathode combination that chemically react with

the contents of the boiler to meet the three objectives

outlined above.

4. Remove both descalers from boiler.

5. Clean interior of boiler using a wire brush or

equivalent.

A. Dislodge and remove all loose scale from

boiler. All loose debris must be removed

from the boiler.

B. Remove all loose scale form the heating

element mounting plate.

C. Clean the mating surfaces of the heating

element mounting plate and boiler.

6. Check boiler drain and drain line plumbing for

obstructions.

A. Remove cap and strainer screen from

strainer body. Separate screen from cap

and clean debris from screen.

B. Through the front opening in boiler, flush

out the boiler and drain line plumbing with

clean water.

7. Check probe housing and water level probes for

scale build-up and clean as necessary.

F25154 (February 2004) Page 16 of 48

Page 17

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

1. Access the descalers (cathodic protectors) as

outlined in REMOVAL AND REPLACEMENT

OF PARTS.

2. Inspect the two descalers hanging in boiler.

NOTE: As descalers erode over time, the diameter

decreases while the length increases.

NOTE: A new descaler is approximately 1 3/8"

diameter and 3 3/4" long at the core.

A. If either descaler has increased to

approximately 6" in length and the core is

breaking apart (pieces falling off), both

descalers should be replaced; or on an

annual basis.

WATER LEVEL PROBE

HOUSING BLOWDOWN

The water level probe housing fills to the same water

level in the boiler; and equalizes to the operating

pressure in the boiler. When the manual ball valve

on the probe housing assembly is opened, water and

steam are blown thru this valve and should be visible

exiting steamer drain. The probe housing blowdown

should be performed in a time frame dependant on

the quality of the local water supply and steamer

usage. In hard water areas or for steamers heavily

used, a more frequent interval should be used. The

blowdown procedure is essential to proper operation

and component life by removing sediment and

scalants that may be lodged in the probe housing.

1. Turn power switch on

completely fill (approximately 1" of water visible

in sight glass).

and allow boiler to

WATER LEVEL CONTROLS

TEST

A build-up of lime scale on or near the water level

sensing probes may cause them to retain moisture

on the probe surface and can give a false reading.

Also, a cracked or damaged insulator may give a

false reading.

These conditions may cause one or more of the

following to occur:

• Boiler no heat

• Boiler no fill

• Boiler overfill

• Boiler no fill and dry fire

NOTE: Dry firing may cause damage to heating

elements or boiler. If this condition is suspected, the

affected components should be inspected.

Main Water Level Control

NOTE: The main water level control is a dual

functioning control that provides low level cut-off

protection and differential water level control

1. Turn power switch on and verify:

A. Low water light is lit (front control panel).

B. HL LED is lit on the water level control

board.

C. Boiler is filling with water.

D. If boiler isn’t filling with water:

1) Verify 120VAC to boiler fill valve.

2. Press reset switch to begin heating and allow

boiler to reach operating pressure.

3. Remove left side boiler base panel to access

the manual ball valve.

WARNING: THE STEAMER AND ITS PARTS ARE

HOT. USE CARE WHEN OPERATING, CLEANING

OR SERVICING THE STEAMER. THE BOILER

CONTAINS LIVE STEAM. STAY CLEAR WHEN

OPENING THE VALVE.

4. Open the ball valve for approximately one

minute while under pressure to thoroughly flush

the probes and housing.

5. Close the ball valve and replace left side panel.

6. Press reset switch to resume heating and allow

boiler to reach operating pressure.

7. Steamer is ready for use.

2) Verify water supply is on and boiler fill

valve isn’t clogged.

2. At the end of the initial fill:

A. Verify approximately 1" of water visible in

sight glass.

B. Verify green ready light is lit (front control

panel).

C. Verify HL LED is not lit and LLCO LED is lit

on the water level control board.

3. Open the ball valve on probe housing assembly

(boiler left side) about half way. This will allow

boiler water to drain slowly and activate a fill

cycle. Do not press the reset switch to start

heating. The next step requires a visual sight

glass measurement that cannot be obtained if

there is boiling action in the vessel.

A. Verify water level in sight glass drops 1/4"

to 3/8" before a fill cycle is initiated. Repeat

at least twice to verify correct fill.

B. If proper fill wasn’t obtained:

F25154 (February 2004)Page 17 of 48

Page 18

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

1) Verify wire color connections are

correct at probe numbers 50, 51 & 52,

and at the water level control board.

2) Turn power switch off.

3) Remove probe assembly, clean lime

scale build-up from the probes and

compare probe lengths to drawing.

4) Disconnect 3/8” flexible line (air

equalization tube) from probe housing

assembly and from boiler tee. Check

flex line for obstructions and remove

as necessary.

A. Turn power switch on and allow boiler to

fill. Do not press the reset switch to start

heating.

B. Turn water supply off and open the ball

valve on probe housing assembly. This will

allow boiler water to drain.

C. When water level is no longer visible in

sight glass and is below LLCO probe;

LLCO LED should turn off, LLCO relay

should de-energize and return LLCO relay

contacts to there shelf state.

D. Repeat at least twice to verify correct

LLCO operation.

Auxiliary Low level Cut-Off Control

5. Turn power switch off.

6. Disconnect lead wire from Aux LLCO probe.

5) Disconnect 3/8” flexible line (pressure

switch tube) from boiler tee. Remove

boiler tee and check for obstructions

in the tee and in the mounting hole.

Remove obstructions as necessary.

NOTE: When replacing, boiler tee must be

mounted vertical to prevent a blockage due

to condensate build-up.

A. Set VOM to read resistance (ohms) and

connect meter leads to Aux LLCO probe

and boiler. If there is any measurable

resistance, remove and clean the Aux

LLCO probe.

B. Replace the probe and check resistance

again. If resistance is still present, install a

replacement probe.

C. Verify resistance measurement with new

probe installed.

7. Turn power switch on and allow boiler to begin

filling. Do not press the reset switch to start

heating.

8. With water below the lowest visible level in sight

4. Test LLCO circuit on water level control board.

F25154 (February 2004) Page 18 of 48

glass (below Aux LLCO probe) and boiler in

initial fill state:

A. Verify Aux LLCO LED is not lit on the Aux

water level control board.

Page 19

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

B. Verify Low Water light is lit (front control

panel).

C. Verify 120VAC is on Aux LLCO COM, and

0 volt is on Aux LLCO N.O. contacts.

9. When water level reaches Aux LLCO probe as

boiler continues to fill:

A. Verify Aux LLCO LED is lit on the auxiliary

low water board.

B. Verify the green ready light is lit (front

control panel).

C. Verify 120VAC is on the Aux LLCO

common and normally open contacts of the

auxiliary water level control board.

10. Open the ball valve on probe housing assembly.

This will allow boiler to drain.

11. When water level is no longer visible in sight

glass and is below LLCO probe; Aux LLCO

circuit should activate.

A. Low water light turns on (front control

panel).

B. Aux LLCO led turns off on the auxiliary low

water board.

C. Press reset switch to verify lockout

condition. Low water light should remain

on.

D. If lockout condition does not occur,

immediately turn power switch off.

1) Disconnect power to machine.

2) Replace auxiliary low level cut-off

control and check for proper

operation.

E. If lockout condition is ok, verify the auxiliary

water level control circuit is functioning

properly.

F. Close the ball valve on probe housing

assembly and allow boiler to fill.

1) Verify low water light turns off (front

control panel).

2) Press the reset switch and verify

auxiliary contactors A & C are

energized and boiler is heating.

3. Press reset switch and verify high pressure light

turns off.

4. When green ready light comes on, press reset

switch to begin heating (low water light turns

off).

A. Allow boiler to fully pressurize. Cycling

pressure switch opens and heating stops.

5. Turn one cooking compartment timer on to

exhaust steam from boiler.

6. Monitor boiler pressure gauge for two complete

cycles. Note pressure at which the heat comes

on and goes off.

The heat should come on at 10 PSI and go off

at 12 PSI.

A. If pressure readings differ, continue with

procedure to adjust.

7. Two pressure adjustment screws extend

through the top of switch cover. A clockwise

rotation increases pressure; a counterclockwise rotation decreases pressure.

A. Turn the adjustment screw above right side

pointer to obtain the proper cut-out (off)

pressure setting.

B. Turn the adjustment screw above the left

side pointer to obtain the proper cut-in (on)

pressure setting.

NOTE: The screw directly above the right side

pointer adjusts cut-out (off) and cut-in (on) set

points without changing the differential. The

screw directly above the left side pointer adjusts

cut-in (on) set point and changes the

differential.

8. Monitor boiler pressure gauge for two complete

cycles and note the pressure at which the heat

comes on and goes off.

A. If pressures are correct, pressure switch is

properly adjusted.

B. If pressures are not correct, repeat the

adjustment for up to three attempts.

9. If the above adjustment cannot be obtained,

install a replacement pressure switch and adjust

pressure settings as outlined in this procedure.

CYCLING PRESSURE SWITCH

ADJUSTMENT

1. Access cycling pressure switch as outlined

under PRESSURE SWITCH CONTROL BOX

COMPONENTS in REMOVAL AND

REPLACEMENT OF PARTS.

2. Turn power switch on (boiler begins to fill).

F25154 (February 2004)Page 19 of 48

Page 20

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

HIGH LIMIT PRESSURE

SWITCH ADJUSTMENT

NOTE: Before the high limit pressure switch can be

adjusted, the cycling pressure switch must be

temporarily removed from the boiler control circuit.

This allows the boiler to pressurize above the normal

operating range. After the high limit pressure switch

is properly adjusted, the cycling pressure switch

must be returned to its normal operating

condition. Follow the procedure as outlined in the

steps below.

1. Access cycling pressure switch as outlined

under PRESSURE SWITCH CONTROL BOX

COMPONENTS in REMOVAL AND

REPLACEMENT OF PARTS.

A. Remove cover from cycling pressure

switch.

B. Connect a jumper wire between the two

electrical terminals to

the cycling pressure switch from the boiler

control circuit.

2. Reconnect power to machine and turn power

switch on (boiler begins to fill).

3. Press reset switch and verify high pressure light

turns off.

4. When green ready light comes on, press reset

switch to begin heating (low water light turns

off).

NOTE: A

serves as back-up to the high limit pressure switch.

5. Monitor boiler pressure gauge. Note pressure at

CAUTION: While making the adjustment, do not

press on the wheel with extreme force. The

switch may rotate and develop a leak at the

compression fittings or in some cases, the rear

lead wire may touch the control box and create

an electrical short.

6. Turn adjustment wheel to change high limit

pressure relief valve with a 15 PSI setting,

which the high limit pressure switch opens (high

pressure light turns on).

The switch should open at boiler pressures no

less than 14.5 PSI but no greater than 15.0 PSI

(MAX).

A. If pressure reading differs, continue with

procedure to adjust.

pressure switch setting.

temporarily

remove

NOTE: For every click of the adjustment wheel,

the pressure setting is changed approximately

1/8 PSI.

NOTE: Make the adjustment in small

increments.

7. After adjusting high limit pressure switch, the

boiler pressure must be reduced to check the

pressure setting.

A. Remove left side boiler base panel to

access the manual ball valve on the probe

housing assembly.

WARNING: THE STEAMER AND ITS PARTS ARE

HOT. USE CARE WHEN OPERATING, CLEANING

OR SERVICING THE STEAMER. THE BOILER

CONTAINS LIVE STEAM. STAY CLEAR WHEN

OPENING THE VALVE.

B. Open the manual ball valve to release

boiler pressure and monitor the boiler

pressure gauge.

NOTE: High limit pressure switch resets at

approximately 12 PSI (not adjustable).

C. When pressure is reduced to

approximately 8 PSI, close the ball valve.

D. Press reset switch to reset the high

pressure safety circuit and begin heating

(high pressure light turns off).

Monitor boiler pressure gauge and note the

8.

pressure at which the high limit pressure switch

opens.

A. If pressure is correct, the high limit

pressure switch is properly adjusted.

B. If pressure is not correct, repeat the

adjustment for up to three attempts.

9. If the above adjustment cannot be obtained,

install a replacement high limit pressure switch

and adjust as outlined in this procedure.

10. After the high limit pressure switch is properly

adjusted, disconnect power to machine and

allow boiler to blowdown/drain.

11. Remove jumper wire from cycling pressure

switch to return the switch to its normal

operating condition.

12. Check for proper operation.

BOILER FILL AND COLD WATER

CONDENSER SOLENOID VALVES

A. A counterclockwise rotation lowers the

pressure switch set point; a clockwise

rotation raises the pressure switch set

point.

F25154 (February 2004) Page 20 of 48

1. Access boiler fill and cold water solenoid valves

2. Turn power switch on (boiler begins to fill).

as outlined under PRESSURE SWITCH

CONTROL BOX COMPONENTS in REMOVAL

AND REPLACEMENT OF PARTS.

Page 21

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

3. To check boiler fill valve:

A. Verify 120VAC to solenoid valve coil.

B. If voltage is correct but valve is not opening

(little or no water flow), turn power switch

off and disconnect power to machine.

1) Remove lead wires from coil and

check for continuity.

2) If no continuity is measured, install a

replacement solenoid valve and check

for proper operation.

3) If continuity is measured, the coil is

good.

C. If voltage is not correct, check main water

level control board as outlined under

WATER LEVEL CONTROLS TEST.

4. To check cold water condenser valve:

NOTE: Valve should energize only during cooking

cycles and at boiler blowdown/drain.

A. Verify 120VAC to solenoid valve coil.

B. If voltage is correct but valve is not opening

(little or no water flow), turn power switch

off and disconnect power to machine.

1) Remove lead wires from coil and

check for continuity.

2) If no continuity is measured, install a

replacement solenoid valve and check

for proper operation.

3) If continuity is measured, the coil is

good. Continue with procedure for

additional valve checks.

C. If voltage is not correct, check cold water

condenser thermostat as outlined under

COLD WATER CONDENSER

THERMOSTAT ADJUSTMENT.

5. To check valve ports for clogs or valve

component malfunction, continue with

procedure for disassembly and inspection of

internal components.

6. Turn water supply off, disconnect water line

from valve body then remove solenoid valve.

7. Remove coil assembly from valve stem

8. Secure the valve body to keep it from turning.

9. Scribe a line on stem nut to valve body for

proper re-tightening then remove stem locking

nut and remove the stem from valve body.

10. All parts are now accessible for inspection and

cleaning.

NOTE: If internal solenoid parts appear to be

damaged or worn, then replace the solenoid valve.

Do not reuse damaged or worn parts. No internal

solenoid parts are available as a service

replacement.

A. Check rubber seal on bottom of plunger.

B. Check plunger spring.

C. Check O-ring in valve body.

D. Check ports in valve body.

11. Reverse procedure to install and check for

proper operation.

COLD WATER CONDENSER

THERMOSTAT ADJUSTMENT

During a cooking

cold water condenser thermostat (N.O.) should

close and energize the cold water condenser

solenoid valve. The water from spray nozzle mixes

with the drain water in the condenser drain box to

reduce drain water temperature and condense

steam vapors.

If excessive steam vapors are seen exiting the drain,

adjust the cold water condenser thermostat as

outlined below.

1. Turn power switch off and allow boiler to

blowdown/drain.

2. Access cold water condenser

outlined under PRESSURE SWITCH

CONTROL BOX COMPONENTS in REMOVAL

AND REPLACEMENT OF PARTS.

3. Turn thermostat shaft fully counterclockwise to

energize the cold water condenser solenoid

valve.

A. Allow cold water to flow until condenser

drain box has completely cooled.

B. Slowly turn thermostat shaft clockwise until

thermostat opens and de-energizes the

solenoid valve. Turn shaft an additional 1/4

turn to prevent the thermostat from closing

near room ambient temperatures.

cycle or boiler blowdown/drain, the

thermostat as

4. Check for proper operation.

F25154 (February 2004)Page 21 of 48

Page 22

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

HEATING ELEMENT TEST

VOLTAGE

208 9.0 14.4 14.4

240 9.0 12.5 19.2

480 9.0 6.3 76.8

208 10.5 16.9 12.4

208 12.0 19.3 10.8

240 12.0 16.7 14.4

480 12.0 8.3 57.6

NOTES:

KW PER

ELEMENT

1. Values in the table are nominal.

Tolerance is +5/-10%.

2. Voltage values are @ 60HZ.

3. Resistance values (ohms) are @ room

temperature. If heating elements are

above room temperature, the measured

resistance will be greater.

4. Each heating element has 3 separate

internal elements.

AMPS PER

ELEMENT

OHMS PER

ELEMENT

COOKING COMPARTMENT

NOTE: Before proceeding with intake shut-off valve

adjustment, monitor boiler pressure gauge and verify

boiler is operating between 10-12 PSI. If boiler

pressure adjustment is necessary, refer to CYCLING

PRESSURE SWITCH ADJUSTMENT.

Intake Shut-Off Valve Adjustment (Steam Flow)

1. Remove right side compartment panel.

2. Allow boiler to fully pressurize (heat turns off).

NOTE: The intake shut-off valve adjustment should

be made while boiler pressure is at the upper cycling

limit.

3. Turn both cooking compartment timers on.

4. Open the intake shut-off valve completely.

5. Slowly begin to close the intake shut-off valve

and monitor manifold pressure gauge. Adjust

the valve until manifold pressure gauge reading

is between 8-10 PSI.

1. Access the heating elements as outlined in

REMOVAL AND REPLACEMENT OF PARTS.

2. Measure voltage at heating element terminals

and verify it against data plate voltage.

A. If voltage is incorrect, see

TROUBLESHOOTING.

B. If voltage is correct, continue with

procedure.

3. Check current draw (amps) through the heating

element lead wires.

NOTE: Checking current draw is the preferred

method over a resistance check when a clamp on

type amp meter is available.

A. If current draw is correct then heating

element is functioning properly. See table

for proper values.

B. If current draw is not correct, turn power

switch off and disconnect the electrical

supply.

1) Install a replacement heating element.

C. If unable to check current draw, a

resistance check may indicate a

malfunctioning element.

1) Turn power switch off and disconnect

power to machine.

2) Remove lead wires from heating

element and check resistance (ohms).

See table for proper values.

4. Check for proper operation.

6. Monitor manifold pressure gauge reading for

two complete boiler cycles.

A. If the manifold pressure gauge reading

stays within tolerance while the boiler is

cycling, the intake shut-off valve is set

correctly.

B. If the manifold pressure gauge reading is

outside of the tolerance repeat the

adjustment.

7. Once the steam supply manifold pressure is set

correctly, turn both cooking timers off and install

right side compartment panel.

F25154 (February 2004) Page 22 of 48

Page 23

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Door Sealing Adjustment

1. Check door gasket condition. If damaged or

worn, replace as outlined under COOKING

COMPARTMENT DOOR(S) in REMOVAL AND

REPLACEMENT OF PARTS.

2. Loosen screws until the screw heads no longer

touch gasket plate.

3. Tighten screws until the screw heads touch

gasket plate and begin counting turns. Tighten

all screws approximately two turns.

4. Close the door and check for proper operation.

A. If necessary, tighten all screws an

additional 1/2 turn.

B. Repeat as necessary, tightening all screws

by 1/2 turn until the door closes properly

and no steam leaks are seen around

gasket seal.

Door Latch Adjustment

Should cooking compartment door jam and cannot

be opened, do not force or pry the door or damage

may occur.

3. Open door and check the door strikers’ slot for

horizontal alignment. The slot on door striker

must be kept horizontal for the door latch to

<

catch on the door strikers

slot and latch.

Lift bottom of door at the handle end to disengage

latch. If door does not release, remove the right side

panel to access door striker.

The door striker mounting nut is located behind the

front panel of cooking cavity. Remove striker nut

from striker to release door.

Remove any burrs on door striker that may cause

door latch to stick. Reinstall door striker and adjust

as outlined below.

4. Place a cloth over the door striker to protect the

slot. Secure the door striker close to its base to

keep it from turning and tighten striker nut.

NOTE: Do not over tighten as the striker will begin to

turn and change alignment.

5. Check for proper operation.

CAUTION: When installing, do not damage the

slot in the door striker or door may not latch

properly.

To adjust:

1. Reinstall door striker with the slot pointing up

and hand tighten striker nut only.

2. Close door to center the door striker in the oval

mounting hole.

F25154 (February 2004)Page 23 of 48

Page 24

VHX SERIES STEAMER - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

CABINET BASE BOILER CONTROLS

Power Switch ................ Controls 120VAC to the boiler control circuit.

Reset Switch (Manual) ......... Resets the low water level safety circuit on initial startup or the occurrence of

a low water condition. Also, resets the high pressure level safety circuit on

initial startup or the occurrence of a high pressure condition which allows

heating to start.

Boiler Fill Valve ............... Allows water flow to the boiler when energized thru HL-3 contacts on the

water level control.

Cold Water Condenser

Valve ....................... Allows cold water to spray thru a nozzle inside the condenser drain box to

condense steam and cool the hot water before discharging into the drain.

Cold Water Condenser

Cycling Thermostat ........... Regulates cold water spray inside the condenser drain box during a cooking

cycle or boiler blowdown/drain.

Cycling Pressure Switch ....... Regulates boiler pressure between cut-out (off) and cut-in (on) pressure

settings of switch.

High Limit Pressure Switch ..... Prevents boiler from reaching pressures above 15 PSI by removing power

from heating circuit. The high limit automatically resets at approximately 12

psi (green ready light on).

Main Water Level Control ...... A dual function control that allows water to fill and maintain the proper level

in the boiler, providing differential level control; and removes power from

heating circuit if water level drops too low, providing low level cut-off

protection. The control uses three different probe lengths to monitor water

level (high level HL, low level LL, low level cut-off LLCO).

Auxiliary Water Level Control . . . A back up to the low level cut-off on the main water level control. Protects

boiler and heating system components from a low water cut-off condition by

opening the 120VAC voltage path to the heating circuit. The control uses a

single probe to monitor water level (auxiliary low level cut-off Aux LLCO).

Relay Board .................. Provides a centralized location for wire harness connections and power

transfer thru board relays (K1-K4) to the steamer controls. Also, provides

voltage test points (T1-T7) for verifying voltage to relay coils, N.O. relay

contacts closed, control panel lights and auxiliary contactor coils.

NOTE: The relay’s below are mounted on the relay board and are individually replaceable.

K1 Relay .................... Energized when water level reaches the Aux LLCO probe (water level

condition satisfied).

K2 Relay .................... Energized when high limit pressure switch is closed (high limit pressure

condition satisfied). When K1 & K2 are energized, ready light (green) will be

on.

K3 Relay .................... Energized when K1(2) N.O. contacts close and reset switch is activated.

When K3 is energized, K3(2) N.O. contacts close and low water light turns

off.

K4 Relay .................... Energized when K2(2) N.O. contacts are closed and reset switch is

activated. When K4 is energized, K4(2) N.O. contacts close and high

pressure light turns off. When K3 and K4 are energized, power is supplied to

auxiliary contactors A & C.

F25154 (February 2004) Page 24 of 48

Page 25

VHX SERIES STEAMER - ELECTRICAL OPERATION

Supply Voltage Transformer .... Provides 120VAC to the boiler control and cooking compartment control

circuits.

Cycling Contactors B & D ...... Supplies line voltage to one side of heating elements thru cycling pressure

switch N.C. contacts and LLCO-1 N.O. contacts.

Auxiliary Contactors A & C ..... Supplies line voltage to energize the heating elements thru relay K3 & K4

N.O. contacts.

Heating Elements ............. Heats water in boiler to generate steam.

Blowdown/Drain

Solenoid Valve ............... N.O. valve that closes when energized by the power switch to allow boiler to

fill and pressurize. When de-energized, valve opens to blowdown and drain

the boiler contents.

COOKING COMPARTMENT CONTROLS

The upper section of the steamer consists of two separate cooking compartments. Each compartment functions

independently with its own set of controls. Power is supplied to the controls only after the steam pressure rises

above the compartment pressure switch setting to close the N.O. contacts.

Ready Light (Green) ........... When lit, indicates steamer is ready to cook.

Cooking Light (Red) ........... When lit, indicates steamer is in a cooking cycle.

Cooking Timer ............... Use to set cooking time between 0-60 minutes. When timer is set, energizes

the steam solenoid valve to allow steam into the cooking compartment.

When time expires, energizes buzzer until turned off.

Buzzer ...................... Signals end of a cook cycle, must be turned off manually.

Door Switch ................. Removes power to cooking timer. If time is dialed on cooking timer and

compartments are steaming, removes power to steam solenoid valve when

compartment door is opened.

Steam Solenoid Valve ......... When energized, opens to allow steam into the cooking compartment

(normally closed valve).

Compartment Pressure Switch . . Supplies power to cooking compartment controls, after steam pressure rises

above approximately 3 psi to close the pressure switch. The pressure switch

remains closed as long as steam pressure is above the stated pressure.

F25154 (February 2004)Page 25 of 48

Page 26

VHX SERIES STEAMER - ELECTRICAL OPERATION

COMPONENT LOCATIONS

Boiler Base Controls

F25154 (February 2004) Page 26 of 48

Page 27

VHX SERIES STEAMER - ELECTRICAL OPERATION

Boiler Base Controls Continued

F25154 (February 2004)Page 27 of 48

Page 28

VHX SERIES STEAMER - ELECTRICAL OPERATION

Cooking Compartment Controls

F25154 (February 2004) Page 28 of 48

Page 29

VHX SERIES STEAMER - ELECTRICAL OPERATION

WATER LEVEL CONTROLS

Low Level Cut-Off & Differential Control

The steamer is equipped with three water level

sensing probes (high, low and low level cut-off) and

a water level control board. The water level control

board performs two functions: 1) Provide low level

cut-off protection to shut off the heat source in case

the water level drops below the low level cut-off

(LLCO) probe. 2) Perform as a differential level

control to maintain the water level between the low

and high water level probes.

The water level control (WLC) board has input

voltage (120VAC) across terminals 11 and 12 which

powers the primary side of the transformer. On one

side of the transformer secondary, power is provided

to the control by a series path through chassis

ground (terminal 10). The other side of the

transformer secondary (12VAC) is attached to the

probe that directs power to the other side of WLC

board relay coils (LLCO and HL) and to the inverse

latching relay (ILR) electronic circuit on the WLC

board. As water enters the boiler, it becomes part of

the WLC board circuit. When the water level in the

boiler reaches a probe, that circuit is completed.

When the water level drops below the low level (LL)

probe, power is removed from the inverse latching

relay, the HL relay energizes through ILR-2 and HL

contacts change state. The boiler fill solenoid is

energized through HL-1 to refill the boiler and the HL

LED is lit. The HL relay and LED will toggle on and

off during a cooking cycle as needed.

The inverse latching relay of the WLC board is deenergized, leaving the ILR-1 (N.O.) and ILR-2 (N.C.)

contacts in their shelf state.

When the main power switch is turned on, power is

supplied to the WLC board which energizes the high

level (HL) relay, closes HL-1 normally open contacts,

and illuminates the HL relay LED. With the HL-1

contacts closed, the boiler fill solenoid is energized

and water begins filling the boiler.

When the water level reaches the low level cut-off

(LLCO) probe, the LLCO relay is energized and

illuminates the LLCO LED. With the LLCO-1 contacts

closed, the heat source can be energized provided

the auxiliary control(s) in the heating circuit are

satisfied. The LLCO relay will remain energized and

its LED will stay lit until the water level in the boiler

drops below the LLCO probe.

When the water level reaches the low level (LL)

probe, power to terminal 2 on the WLC board is

present but no switching occurs.

After the water level reaches the high level (HL)

probe, the inverse latching relay of the WLC board is

energized and locked through the low level probe

(LL) and ILR-1 contacts. With ILR-2 contacts open,

HL relay is de-energized and the HL LED goes out.

With the HL-1 contacts open, the boiler fill solenoid is

de-energized, stopping the flow of water into the

boiler.

F25154 (February 2004)Page 29 of 48

Page 30

VHX SERIES STEAMER - ELECTRICAL OPERATION

Auxiliary Low Level Cut-Off

This control serves as a safety backup to the main

water level control (WLC) board to meet CSD-1 code

requirements. The operation of the auxiliary control

board is identical to the low level cut-off (LLCO)

function of the main WLC board but performs a

single function: 1) Provide auxiliary low level cut-off

protection to shut off the heat source in case the

water level drops below the auxiliary low level cut-off

(Aux LLCO) probe. A single Aux LLCO probe,

identical to the LLCO probe on the main WLC board,

is connected to the auxiliary control.

The auxiliary control board has input voltage

(120VAC) across terminals 11 and 12 which powers

the primary side of the transformer. On one side of

the transformer secondary, power is provided to the

control by a series path through chassis ground

(terminal 10). The other side of the transformer

secondary (12VAC) is attached to the Aux LLCO

probe that directs power to the other side of the

auxiliary control board relay (LLCO). As water enters

the boiler, it becomes part of the auxiliary water level

control’s circuit. When the water level in the boiler

reaches the Aux LLCO probe, the circuit is

completed.

When the main power switch is turned on, power is

supplied to the auxiliary control board but no

switching occurs. Also, the low water level indicator

light (amber) on the boiler base control panel comes

on.

When the water level reaches the auxiliary low level

cut-off (Aux LLCO) probe, the LLCO relay is

energized (LLCO-1 close) and the LLCO LED lights

up. The LLCO relay will remain energized and its

LED will stay lit until the water level in the boiler

drops below the Aux LLCO probe.

When the boiler stops filling, press the manual reset

switch on the boiler base control panel. This turns off

the low water light and energizes the heat source.

F25154 (February 2004) Page 30 of 48

Page 31

VHX SERIES STEAMER - ELECTRICAL OPERATION

RELAY BOARD

Layout, Legend & Diagnostic Test Points

The relay board provides a centralized location for wire harness connections and power transfer through board

relays (K1-K4) to the other steamer controls. Also, provides for condition or component troubleshooting by utilizing

seven voltage test points (T1-T7) on the board to verify the voltage status for the condition or component in the

<

operating sequence. When the condition for the component

120VAC can be measured between T1 (ref.) and T2 thru T7 test points to indicate whether the condition or

component is receiving voltage to energize and operate. If the voltage is not present, then the condition or

component has not been energized or is not activated.

s voltage measurement is satisfied or activated,

F25154 (February 2004)Page 31 of 48

Page 32

Schematic

VHX SERIES STEAMER - ELECTRICAL OPERATION

F25154 (February 2004) Page 32 of 48

Page 33

VHX SERIES STEAMER - ELECTRICAL OPERATION

SEQUENCE OF OPERATION

Refer to schematic diagram AI1385 for the electrical

sequence of operation.

Initial Fill and Preheat

1. Conditions.

A. Boiler connected to correct supply voltage

and is properly grounded.

1) Supply voltage transformer energized

and 120VAC is output from

transformer secondary.

2) 120VAC to compartment controls and

one side of the power switch.

B. Power switch off.

C. Cycling pressure switch closed.

D. High limit pressure switch closed.

E. Cold water condenser (CWC) thermostat

open.

F. Automatic blowdown/drain valve (A.B.D.)

open and boiler empty.

G. Water supply valve(s) on.

2. Turn power switch on.

A. Automatic blowdown/drain valve (N.O.) is

energized and closes.

B. Water level control (WLC) energized.

1) High level (HL) relay energized, HL-3

N.O. contacts close.

a. Boiler fill solenoid energized,

water begins filling the boiler (fill

time 4-11 min.).

2) LLCO-1 N.O. contacts remain open.

3) HL LED lit.

C. Auxiliary water level control (AUX WLC)

energized.

1) AUX LLCO-1 N.O. contacts remain

open.

D. 120VAC to common relay terminal on

K1(1) N.O., K3(1) N.O., K3(1) N.C., K3(2)

N.O. , K4(1) N.O., K4(1) N.C contacts.

E. Low Water light lit thru K3(1) N.C.

F. High Pressure light lit thru K4(1) N.C.

G. K2 energized through the high limit

pressure switch (N.C.).

1) K2 contacts K2(1) N.O. & K2(2) N.O.

close, no power transferred.

H. 120VAC to common terminal on AUX

LLCO-1 contacts.

I. 120VAC to common terminal on WLC

LLCO-1 contacts thru cycling pressure

switch (N.C.).

3. Water level reaches LLCO probe for the main

water level control and AUX LLCO probe for the

auxiliary water level control.

A. LLCO relay on water level control

energizes, LLCO-1 contacts (N.O.) close

1) LED on board lights.

2) Cycling contactors B & D energized.

Heating elements remain deenergized until manual reset switch

pressed.

B. AUX LLCO relay on AUX water level

control energizes, AUX LLCO-1 contacts

(N.O.) close.

1) LED on board lights.

2) K1 is energized thru AUX LLCO-1

N.O. contacts.

a. K1(1) N.O. and K1(2) N.O. close.

b. Ready light on manual reset

switch lit thru K1(1) N.O.

contacts.

NOTE: The LLCO and AUX LLCO relays will

remain energized and LLCO LED’S will remain

lit until the water level drops below the LLCO

probes or the power switch is turned off.

NOTE: The manual reset switch could be

pressed to energize the heating elements but

it’s preferred to let the boiler fill the to the high

level before continuing.

4. Water reaches LL (low level) probe.

5. Water reaches HL (high level) probe.

A. Boiler fill solenoid is de-energized.

B. HL LED goes out.

6. Manual reset switch pressed.

A. K3 is energized.

NOTE: Relay K3 remains energized through

K3(1) N.O. latching circuit.

1) K3(1) N.O. contacts close and K3(1)

N.C. contacts open.

2) Low water light goes out.

3) K3(2) N.O. contacts close.

a. 120VAC to common side of

K4(2) N.O. contacts.

B. K4 is energized.

NOTE: Relay K4 remains energized through

K4(1) N.O. latching circuit.

F25154 (February 2004)Page 33 of 48

Page 34

VHX SERIES STEAMER - ELECTRICAL OPERATION

1) K4(1) N.O. contacts close and K4(1)

N.C. contacts open.

2) High pressure light goes out.

3) K4(2) N.O. contacts close.

a. AUX contactors A & C energized,

heating elements powered.

NOTE: As boiler heats up and builds

pressure, some by-pass water/steam

is produced which runs into the steam

drain box. This causes the cold water

condenser (CWC) solenoid to cycle,

cooling the drain water and

condensing any steam vapors before

exiting the drain. The CWC solenoid is

powered through the CWC cycling

thermostat.

7. Boiler steam pressure reaches upper limit set

point of 12 PSI (Approx. 15 minutes).

A. Cycling pressure switch opens.

1) Cycling contactors B & D deenergized and power is removed from

heating elements.

2) Boiler fill valve is de-energized.

3) HL LED goes out.

4. The water refill cycle will occur whenever the

water level is below the low level probe and will

not affect the operation of either the preheat or

cook cycle.

Boiler Blowdown/drain

1. Power switch turned off.

A. Automatic blowdown valve (N.O.) is de-

energized and valve opens to drain the

boiler.

B. Power is removed from all components

except cold water condenser (CWC)

thermostat and solenoid valve. The CWC

thermostat cycles as necessary to lower

the discharge temperature of the water and

condense steam going into the drain.

COOKING COMPARTMENT CONTROLS

1. Conditions.

A. Doors shut (closes the N.O. door switch

contacts).

8. Boiler steam pressure drops below lower limit

set point of 10 PSI and the cycling pressure

switch closes.

A. Cycling pressure switch continues to cycle

between the upper and lower set point

limits. This energizes and de-energizes the

heating elements to maintain pressure in

the boiler.

This sequence continues until one of the

following occurs:

1) Power switch is turned off.

2) Boiler water level drops below the

LLCO probe for the main water level

control and the AUX LLCO probe for

the auxiliary water level control.

3) Boiler pressurizes to 15 PSI, causing

the high limit pressure switch to open.

Water Refill (After Initial Fill)

1. Water level drops below low level probe (LL).

A. HL relay is energized.

1) HL-3 (N.O.) contacts close.

2) Boiler fill valve is energized.

3) HL LED comes on.

2. Water reaches LL (low level) probe.

3. Water reaches high level probe.

A. HL relay is de-energized.

1) HL-3 (N.O.) contacts open.

B. Cooking timers off.

C. Compartment pressure switch contacts

open.

2. With boiler at operating pressure.

A. Cooking compartment pressure switch

closes (approx. 3 PSI).

1) Cooking compartment ready light

(green) comes on.

3. Start a cook cycle.

A. Insert product into steamer and close door.

B. Set a cook time.

NOTE: On initial startup, if a cooking timer is set

immediately after the ready light comes on,

steam solenoid chattering will be heard (oil

canning) and the ready lights will flash for

several seconds. This condition is caused by

the manifold steam pressure being on the fringe

of the pressure switch set point. When a cook

timer is set, the compartment steam solenoid

valve opens causing the manifold steam

pressure to drop, slightly below the pressure

switch set point. At the same time, steam

pressure is still increasing in the boiler. This

opposing condition causes a pressure bounce

to occur. After the steam pressure passes

approximately 4 psi this condition subsides.

During normal operation, this condition will not

be seen.

C. Contacts 1/3 of cook timer close and timer

motor is energized.

F25154 (February 2004) Page 34 of 48

Page 35

VHX SERIES STEAMER - ELECTRICAL OPERATION

1) Compartment steam solenoid valve

energized and steam begins to enter

the compartment.

2) Ready light (green) goes out and

Cooking light (red) comes on.

NOTE: Steam should not be seen entering

either compartment until a cook time is set.

This energizes the steam solenoid valve of

the cooking compartment to allow steam

flow.

4. Time expires on timer.

A. Timer contacts 1/3 open, timer motor de-

energized.

B. Steam solenoid valve de-energizes,

stopping the flow steam into compartment.

C. Timer contacts 4/1 close and energize

buzzer until manually turned off.

D. Cooking light (red) goes out and Ready

light (green) comes on.

5. Timer manually turned off.

A. Contacts 1/4 open.

B. Alarm Buzzer de-energized and stops

buzzing.

6. Steamer reverts to preheat cycle until time is

dialed on timer and the door is shut, water level

drops below low level cut-off probe or the power

switch is turned off.