Vulcan-Hart VG30, VE40, ML-126847, ML-126848, ML-152047 Installation & Operation Manual

...Page 1

INSTALLATION &

OPERATION MANUAL

VG30, VG40, VE30 & VE40 BRAISING PANS

MODELS

VG30 ML-126847

VG40 ML-126848

VE30 ML-152047

VE40 ML-152048

For additional information on Vulcan or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanequipment.com

Model VE40

VULCAN

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANEQUIPMENT.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

FORM 31227 Rev. B (January 2018)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND ADJUSTMENTS

OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED FROM THE

LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS

AT MAIN SHUTOFF VALVE AND CONTACT THE LOCAL GAS

COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

©VULCAN, 2018

RETAIN THIS INSTRUCTION MANUAL FOR FUTURE REFERENCE

– 2 –

Page 3

TABLE OF CONTENTS

GENERAL ..............................................................................................................................................................4

INSTALLATION .....................................................................................................................................................4

Unpacking ........................................................................................................................................................4

Location ...........................................................................................................................................................4

Installation Codes and Standards ....................................................................................................................6

Leveling and Anchoring the Tilting Braising Pan ..............................................................................................6

Service Connections ........................................................................................................................................6

Gas Connections .............................................................................................................................................7

Testing the Gas Supply System .......................................................................................................................7

Ventilation ........................................................................................................................................................7

Control Circuit Power Connection — Gas Braising Pans ................................................................................7

Electrical Connections .....................................................................................................................................8

Installation Diagram .........................................................................................................................................9

OPERATION .......................................................................................................................................................10

Before First Use .............................................................................................................................................10

Gas Heat Braising Pans .................................................................................................................................10

Electric Heat Braising Pans ...........................................................................................................................12

Operation of the Lifting System ......................................................................................................................12

Unloading Prepared Foods ............................................................................................................................13

Steaming Inserts (Optional) ...........................................................................................................................14

Suggested Uses For Your Braising Pan .........................................................................................................14

CLEANING ..........................................................................................................................................................15

COOKING GUIDELINES (Domestic Measurements) ........................................................................................16

COOKING GUIDELINES (Metric Measurements) ..............................................................................................19

MAINTENANCE ..................................................................................................................................................22

Lubrication .....................................................................................................................................................22

Adjustments ...................................................................................................................................................22

Flue ................................................................................................................................................................22

Service and Parts Information ........................................................................................................................22

TROUBLESHOOTING .......................................................................................................................................23

Gas Heat Braising Pans .................................................................................................................................23

Electric Heat Braising Pans ...........................................................................................................................23

– 3 –

Page 4

INSTALLATION, OPERATION AND CARE OF

TILTING BRAISING PANS

MODELS VG30, VG40, VE30 & VE40

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

Vulcan Tilting Braising Pans are available in two sizes. Models VG30 and VE30 have a 30-gallon (114 L)

capacity, and Models VG40 and VE40 have a 40-gallon (151 L) capacity.

The tilting braising pan is a versatile piece of equipment. It allows you to stew, simmer, pan fry, braise,

grill or sauté, and all with a very uniform heat pattern.

Standard features on all models include thermostat, manual lift, drop-away food pan support and four

anged feet.

Optional features include automatic power lift and casters.

Your Vulcan braising pan is produced with quality workmanship and material. Proper installation, usage

and maintenance will result in many years of satisfactory performance.

Vulcan suggests that you thoroughly read this entire manual and carefully follow all of the instructions

provided.

INSTALLATION

Before installing, verify that the electrical service and gas supply (natural or propane) agree with the

specications on the rating plate located on the left front edge of the table top.

UNPACKING

This braising pan was carefully inspected before leaving the factory. The transportation company assumes

full responsibility for safe delivery upon acceptance of this shipment.

Immediately after unpacking, check for possible shipping damage. If the tilting braising pan is found to be

damaged, save the packaging material and contact the carrier within 5 working days of delivery.

LOCATION

For Gas-Powered Braising Pans Only

The braising pan must be kept free and clear from combustible substances. The braising pan, when

installed, must have minimum clearance from combustible construction of 2" (5 cm)

and 6" (15 cm) from the rear. Minimum clearance from noncombustible construction is 0" from the sides

and 6" (15 cm) from the rear.

from the sides

– 4 –

Page 5

The installation location must allow adequate clearances for servicing and proper operation. Recommended

HOLES PROVIDED

FOR RESTRAINT

PL-56652

clearances are 24" (61 cm) on the sides and back (for servicing), and 36" (91 cm) on the front.

The braising pan must be installed so that the ow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber must be provided. Make sure there

is an adequate supply of air in the room suitable for the amount of combustion gas feeding the braising

pan burners.

Do not permit fans to blow directly at the braising pan. Wherever possible, avoid open windows next to

the braising pan. Avoid wall-type fans which create air crosscurrents within the room.

Gas-Powered Braising Pans Equipped with Casters (Optional)

If casters are assembled to the braising pan, the installation must be made using:

1. A connector (not supplied by Vulcan) that complies with the Standard for Connectors for Movable

Gas Appliances, ANSI Z21.69 (latest edition) or Connectors for Movable Gas Appliances, CAN/

CGA-6.16 (latest edition).

2. A quick-disconnect device that complies with the Standard for Quick-Disconnect Devices for

With Gas Fuel, ANSI Z21.41 or Quick-Disconnect Devices for Use with Gas Fuel, CAN1-

Use

6.9

(latest edition).

Adequate means must be provided to limit the movement of the appliance, without depending on the

connector and/or any quick-disconnect device or its associated piping to limit braising pan movement.

Attach the restraint at the rear of the braising pan (Fig. 1).

Fig. 1

If disconnection of the restraint is necessary, turn o the gas supply before disconnection. Reconnect this

restraint prior to turning the gas supply on and prior to returning the braising pan to its originally installed

position.

– 5 –

Page 6

INSTALLATION CODES AND STANDARDS

Your Vulcan tilting braising pan must be installed in accordance with:

In the United States:

1. State and local codes, or in the absence of local codes, with:

2. National Fuel Gas Code ANSI-Z223.1 (latest edition), available from The American Gas Association,

Inc., 1515 Wilson Boulevard, Arlington, VA 22209.

3. National Electrical Code ANSI/NFPA-70 (latest edition).

4. ANSI NFPA Standard #96 Vapor Removal from Cooking Equipment (latest edition), available from

The National Fire Protection Association, Batterymarch Park, Quincy, MA 01169.

In Canada:

1. Local codes.

2. CAN/CGA-B149.1 National Fuel Gas Code (latest edition), available from The Canadian Gas

Association, 178 Rexdale Boulevard, Etobicoke, Ontario, Canada M9W 1R3.

3. Canadian Electrical Code Part 1 CSA-C22.1 (latest edition), available from The Canadian Standards

Association, 178 Rexdale Boulevard, Etobicoke, Ontario, Canada M9W 1R3.

LEVELING AND ANCHORING THE TILTING BRAISING PAN

1. Place the braising pan in the nal installed position.

2. Place a carpenter's level on the braising pan table top and turn the adjustable feet to level the braising

pan table top side-to-side and front-to-back. Do not attempt to level the braising pan base.

3. Mark hole locations on the oor through the anchoring holes provided in the rear, anged adjustable

feet.

4. Remove the tilting braising pan from the installation location and drill holes in the locations marked

on the oor. Insert proper anchoring devices (not supplied).

5. Place the tilting braising pan back in the installation location.

6. Place a carpenter's level on top of the braising pan, and re-level side-to-side and front-to-back.

7. Bolt and anchor the tilting braising pan securely to the oor.

8. Seal bolts and anged feet with Silicon sealant or equivalent compound.

SERVICE CONNECTIONS

To access service and utility connections, remove the left side panel. To remove, hold the panel from

underneath and lift it up. While holding the panel up, swing out the lower part of the panel until it clears

the bottom ange and remove the panel. If required, the rear panel can also be removed using the same

procedure.

The gas-powered braising pan is supplied with a 120-volt power cord.

The electrical connection for the electric braising pan can be accessed from the rear or the left panel.

– 6 –

Page 7

GAS CONNECTIONS (See Fig. 2)

All gas supply connections and any pipe joint compound used must be resistant to the action of propane gases.

Connect a 3/4" (nominal) gas supply to the braising pan. Recommended incoming gas line pressure is 7"

W.C. (Water Column) (48.3 kPa) for natural gas or 11" W.C. (75.8 kPa) for propane gas.

Make sure the pipes are clean and free of obstructions, dirt and piping compound.

Codes require that a gas shuto valve be installed in the gas line ahead of the tilting braising pan.

Natural gas and propane gas braising pans are equipped with xed orices, and no adjustment is necessary.

The manifold is set at 3.7 W.C. (Water Column) (25.5 kPa) for natural gas and 10" W.C. (68.9 kPa) for

propane gas.

Prior to lighting, check all joints in the gas supply line for leaks. Use soap and water

solution. Do not use an open ame.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

The electrical control circuit must be connected (see CONTROL CIRCUIT POWER CONNECTION in this

manual).

TESTING THE GAS SUPPLY SYSTEM

1

When test pressures exceed

/2 psig (3.45 kPa), the tilting braising pan and its individual shuto valve

must be disconnected from the gas supply piping system.

1

When test pressures are

/2 psig (3.45 kPa) or less, the tilting braising pan must be isolated from the gas

supply system by closing its individual manual shuto valve.

VENTILATION

DO NOT obstruct the ow of ue gases from the ue duct located on the rear of the tilting braising pan.

It is recommended that the ue gases be ventilated to the outside of the building through a ventilation

system installed by qualied personnel.

From the termination of the braising pan ue vent to the lters of the hood venting system, an 18"

cm) minimum clearance must be maintained. The ue is not to be directly connected to the ventilation

(46

system.

Local jurisdictions may require a ventilation system to exhaust the steam from this appliance. Clearance

should be provided for the lid to be raised without interference with the hood. A ceiling that is too low may

not allow for an installation of a hood to meet this requirement.

CONTROL CIRCUIT POWER CONNECTION — GAS BRAISING PANS (See Fig. 2)

Appliances equipped with a exible electric supply cord are provided with a three-

prong grounding plug. It is imperative that this plug be connected into a properly grounded three-

prong receptacle. If the receptacle is not the proper grounding type, contact an electrician. Do

not remove the grounding prong from this plug.

– 7 –

Page 8

ELECTRICAL CONNECTIONS (SEE FIG. 2)

Electrical and grounding connections must comply with the national electrical code

and/or other local codes.

Disconnect the electrical power to the machine and follow lockout / tagout procedures.

The eld connection box for eld wire connection of Models VE30 and VE40 is located at the back of the

braising pan. A knockout hole is provided for a 1" (2.5 cm) conduit connection.

1. Remove the eld connection box cover plate. Mount suitable 1" (2.5 cm) conduit tting in the conduit

opening provided on the bottom surface.

2. Connect eld wire to the terminal block as indicated on the wiring diagram. The wiring diagram is

located on the inside of the eld box lid. Wire must be of the type suitable for 75°C service and at

the suitable gauge for loads shown on the data plate.

3. After making the connections, replace the control box cover plate.

4. The braising pan must be grounded by installing a properly grounded lead to the ground lug located

inside the eld connection box.

ELECTRICAL DATA CHART

Model

Number

V (L-L)

Rated Line Current (A)

3Ø 1Ø

L1 L2 L3

Rated

Power

(kW)

208 33.3 33.3 33.3 57.7 12

VE30-FB

240 28.9 28.9 28.9 50.0 12

480 14.4 14.4 14.4 - 12

208 45.9 41.6 45.9 76.9 16

VE40-FB

240 39.7 36.1 39.7 66.7 16

480 19.9 18.0 19.9 - 16

These values are nominal ratings. Field wire connections must be capable of withstanding anticipated

surges.

– 8 –

Page 9

INSTALLATION DIAGRAM

76"

(1930 mm)

36.761"

(934 mm)

.501"

(12.7 mm)

46"

(1168 mm)

36"

(914 mm)

40.75"

(1040 mm)

12"

(305 mm)

14"

(355 mm)

35.5"

(900 mm)

6"

(153 mm)

8.75"

(222 mm)

5"

(127 mm)

SERVICE CONNECTIONS:

ELECTRICAL: Machine is supplied with 120-VAC,

1-phase, 15-amp. power cord.

GAS INPUT: 3/4" N.P.T., Nat.6"-14" W.C.,

IMPORTANT

1. A pressure regulator sized for this unit is included. Natural gas 7"

W.C., propane gas 11" W.C. supply pressure.

propane gas 11" - 18" W.C., See capacity chart.

2. Gas line connecting to appliance must be

3

/4" or larger. If flexible

connectors are used, the inside diameter must be at least the same

as the

3

/4" iron pipe.

3. An adequate ventilation system is required for commercial cooking

equipment. Information may be obtained by writing to the National

Fire Protection Association, Batterymarch Park, Quincy, MA 02289.

When writing, refer to NFPA No. 96.

4. These units are manufactured for installation in accordance with

ANSZ223.1A (latest edition), National Fuel Gas Code. Copies may

be obtained from the American Gas Association, 1515 Wilson Blvd.,

Arlington, VA 22209.

5. Clearances: Combustible Noncombustible

Rear 6 6

Sides 2 0

6. This appliance is manufactured for commercial installation only and

is not intended for home use.

ELECTRICAL CONNECTION: 1" dia. conduit, fitting

to be installed by installer.

Cooking 4 oz.

MODEL Surface Area Capacity Portions

VE/VG30 29" x 23" 30 gal./114 liters 960

VE/VG40 39" x 23" 40 gal./152 liters 1280

BTU/hr.

MODEL Input

VG30 90,000

VG40 120,000

208

VAC

MODEL

VE30

VE40

12 KW

16 KW

12 KW

16 KW

12 WK

16 KW

240

VAC

480

VAC

PL-56638

GAS BRAISING PAN:

1.

ELECTRICAL BRAISING PAN:

2.

Fig. 2

– 9 –

Page 10

OPERATION

The tilting braising pan and its parts are hot. Use care when operating, cleaning

or servicing the braising pan.

BEFORE FIRST USE

Use a noncorrosive, grease-dissolving commercial cleaner to clean the protective metal oils from all

surface parts and the interior of the tilting braising pan. Follow the cleaner manufacturer's directions.

Rinse thoroughly and drain the pan. Wipe dry with a soft, clean cloth.

GAS HEAT BRAISING PANS

Controls (Fig. 3)

THERMOSTAT

AMBER

LIGHT

ON / OFF

SWITCH

[O] = OFF

[I] = ON

RED HEATLIGHT

Fig. 3

MANUAL LIFT CRANK

HANDLE

Thermostat — Sets desired cooking temperature.

On/O Switch (Black) — Turns the braising pan on and o.

OPTIONAL

AUTOMATIC

POWER

LIFT

PL-41750-1

Amber Light — When lit, indicates the machine is turned on.

Heat Light (Red) — When lit, indicates the thermostat is calling for heat.

Auto. Power Lift (Gray) — (Optional). Push the upper part of the switch to raise the braising

pan; push the lower part to lower the braising pan. Always remove

the manual lift crank handle before operating the automatic power lift.

Manual Lift Crank Handle

— Use to manually raise and lower the braising pan.

– 10 –

Page 11

Lighting and Shutdown of Pilot

Lighting instructions are also located on the front panel.

1. Turn main gas supply to the braising pan to the ON position at the shuto valve.

2. Lower the braising pan (see OPERATION OF LIFTING SYSTEM in this manual). The braising pan

will not operate with the pan in the UP position (5 degrees or higher from horizontal).

3. Turn the black on/o switch to the ON position. The ON position is indicated by a glowing amber

light on the control panel.

4. Turn the thermostat to the desired cooking temperature.

5. If pilot is extinguished, turn the gas supply and the on/o switch to the OFF position. Wait 5 minutes

before relighting.

Nightly Shutdown

Turn the on/o switch to the OFF position.

Extended Shutdown

Turn the on/o switch to the OFF position and turn o the gas supply.

Operating the Gas Braising Pan

The braising pan does not require any adjustments before startup.

The entire ue duct opening (located across the rear of the braising pan) must be left uncovered.

Turn the on/o switch to the ON position and turn the thermostat to the desired temperature to put the

braising pan into operation.

To prevent discoloration of the stainless steel cooking surface, do not turn the heat on unless the braising

pan is covered with a uid, a thin layer of cooking oil or food to be cooked.

DO NOT use the braising pan as a deep fat fryer; use it only for shallow pan frying (cooking oil lm not

1

more than

/8" [0.3 cm] thick). Its use for deep frying could result in a re hazard. See SUGGESTED

USES FOR YOUR BRAISING PAN in this manual for additional information.

Do not overheat the clad stainless steel plate by setting the temperature well above recommended

temperatures or by operating the braising pan without any uid inside the pan to absorb heat. Overheating

the plate may cause warping and will carbonize any cooking oil on the plate and cause sticking.

In case of a power failure, there will be no ames because the combination control valve will shut o the

gas ow. In the event of a power failure, immediately turn the on/o switch to the OFF position. Once

power is restored, turn the on/o switch to the ON position to resume cooking.

The lid is spring-loaded and will stay in any position at which it is placed. After some time, the springs

may need to be tightened. Call your local Vulcan-authorized servicer to make these adjustments.

– 11 –

Page 12

ELECTRIC HEAT BRAISING PANS

Controls (see Fig. 3)

Thermostat — Sets desired cooking temperature.

On/O Switch (Black) — Turns the braising pan on and o.

Amber Light — When lit, indicates the machine is turned on.

Heat Light (Red) — When lit, indicates the thermostat is calling for heat.

Auto. Power Lift (Gray) — (Optional). Push the upper part of the switch to raise the braising pan;

push the lower part to lower the braising pan. Always remove the manual

lift crank handle before operating the automatic power lift.

Manual Lift Crank Handle

— Use to manually raise and lower the braising pan.

Operating the Electric Braising Pan

The braising pans do not require any adjustments before startup.

Turn the black on/o switch to the ON position.

Lower the braising pan (see OPERATION OF LIFTING SYSTEM in this manual). The braising pan will

not operate with the pan in the UP position (5 degrees or higher from horizontal).

Turn the thermostat to the desired cooking temperature.

To prevent discoloration of the stainless steel cooking surface, do not turn the heat on unless the braising

pan surface is covered with a uid, a thin layer of cooking oil or food to be cooked.

DO NOT use the braising pan as a deep fat fryer; use it only for shallow pan frying (cooking oil lm not

1

more than

/8" [0.3 cm] thick). Its use for deep frying could result in a re hazard. See SUGGESTED

USES FOR YOUR BRAISING PAN in this manual for additional information.

Do not overheat the clad stainless steel plate by setting the temperature well above recommended

temperatures or by operating the braising pan without any uid inside the pan to absorb heat. Overheating

the plate may cause warping and will carbonize any cooking oil on the plate and cause sticking.

The lid is spring-loaded and will stay in any position at which it is placed. After some time, the springs

may need to be tightened. Call your local Vulcan-authorized servicer to make these adjustments.

OPERATION OF THE LIFTING SYSTEM

Keep the area underneath and around the braising pan clear of your hands or any other objects when

operating the lifting system.

Do not obstruct any of the moving parts of the lift system located underneath the table top on the right and/

or left side of the braising pan. This area must be kept clear of any objects or obstructions at all times.

Do not leave the braising pan in the UP position for extended periods (e.g., overnight or during a shutdown

period between cooking times).

– 12 –

Page 13

Braising Pans with Manual Lift (Standard)

1. The crank for the manual lift system is shipped separately.

2. There are two pins on one end of the crank. Insert the crank through the hole on the control panel

so that the two pins engage in the slots of the speed reducer coupling located behind the panel.

3. Turn the crank handle clockwise to lift the braising pan and counterclockwise to lower the braising

pan.

4. This lift system is not aected by a power failure and can be operated during a power failure.

5. Refer to the MAINTENANCE section of this manual for lubrication and maintenance instructions.

Braising Pans with Automatic Power Lift (Optional)

1. The automatic lift cannot raise the braising pan unless the lid is fully opened.

2. The pan lift is controlled by the gray rocker switch located on the control panel (see Fig. 3).

3. Always remove the manual crank handle before operating the automatic power lift.

4. Press the upper half of the gray rocker switch to raise the braising pan and the lower half of the gray

rocker switch to lower the braising pan. The switch must be held for continuous raising or lowering

of the braising pan.

5. In case of a power failure, use the hand crank (shipped separately) to lower or raise the pan (same

as the braising pans with manual lift).

UNLOADING PREPARED FOODS

All braising pans are provided with a frame support (Fig. 4) for holding a food receiving pan when unloading

prepared foods.

Pull the frame support out and up until it locks. The support will accept food receiving pans of 12" x 20"

(30 cm x 50 cm) up to 6" (15 cm) deep.

When lowering the frame support, push in on the hinges until they bend, then lower the support.

FRAME

SUPPORT

HINGE

PL-41751-1

Fig. 4

– 13 –

Page 14

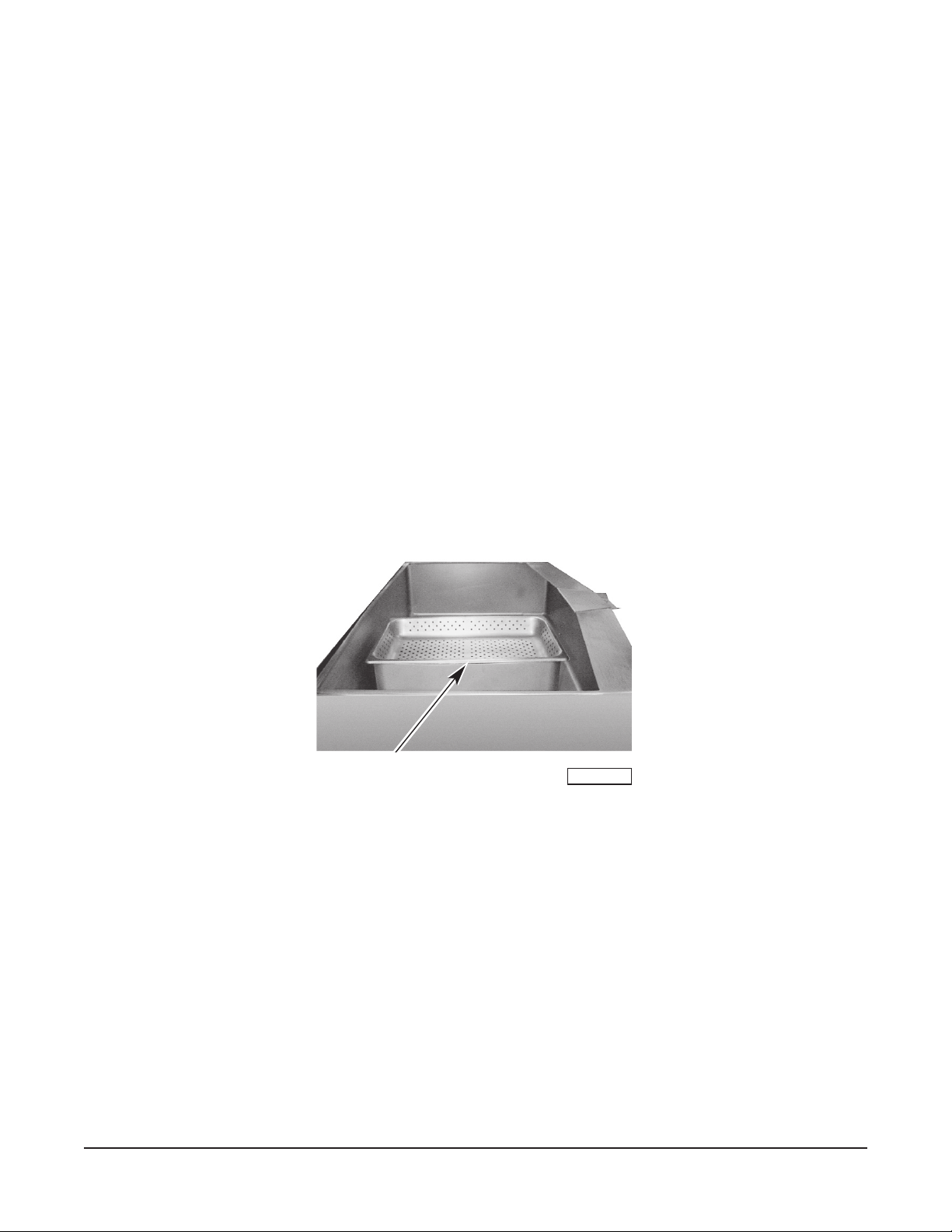

STEAMING INSERTS (Optional)

Your tilting braising pan can be used for steaming frozen and fresh foods. The 30-gallon (114 L) pans

(Models VE30 or VG30) can be loaded with a maximum of two 12" x 20" x 4"

(30 cm x 50.8 cm x

10 cm) deep steaming pans. The 40-gallon (151 L) pan (Models VE40 or VG40) will accept up to three

steam pans of this same size.

To use the braising pan for steaming, ll the pan with 6 to 7 gallons (23 to 26 L) of water (approximately

2" [5 cm] deep) for 30-gallon (114 L) models and 8 to 9 gallons (30 to 34 L) of water (approximately 2"

[5 cm] deep) for 40-gallon (151 L) models.

Turn the braising pan ON. Set the thermostat at 212°F (100°C). Allow the water to come to a boil. Then

change the thermostat setting to 250°F (121°C) and carefully place the steaming inserts into the pan as

shown in Fig. 5. Place the pan with product into the steaming insert. Close the lid and allow steaming

for the desired time.

Periodically inspect the water level inside the braising pan. Add water if the water level is less than

1

/2"

(1 cm) deep.

To use the braising pan as a food warmer or bain marie, follow the same procedure as for steaming, but

increase the depth of the water to allow the bottom and part of the sides of the steaming inserts to be

immersed in water. Set the thermostat for the holding or warming temperature desired.

The steaming inserts can be ordered from your dealer.

STEAMING INSERT

Fig. 5

PL-41752-1

SUGGESTED USES FOR YOUR BRAISING PAN

DO NOT use the braising pan for deep fat frying. Restrict frying activity to shallow pan frying (oil lm not

1

more than

/8" [0.3 cm] thick) or sautéing.

A tilting braising pan is quite versatile. It can be used for roasting, simmering, boiling, sautéing, searing,

frying, warming, holding, proong, thawing, browning, steaming, braising, griddling or stewing. It can

be used as an oversized skillet, as a bain marie, as a proong oven, as a stock pot, as a kettle or as an

even-heat range top. It can be used for cooking breakfasts, lunches and dinners.

Your Vulcan tilting braising pan is a multi-purpose unit that can be used for virtually any type of cooking,

except deep fat frying, with great speed, in large volume and with considerable savings in labor and energy.

– 14 –

Page 15

CLEANING

Disconnect the electrical power to the machine and follow lockout / tagout procedures

before cleaning.

Clean your braising pan regularly. Keep the plate surface clean. To produce evenly cooked, perfectly

braised products, keep the pan surface free from carbonized grease. Carbonized grease on the surface

hinders the transfer of heat from the pan surface to the food. This results in spotty browning and loss

of cooking eciency. Worst of all, carbonized grease tends to cling to the foods, giving them a highly

unsatisfactory and unappetizing appearance.

After Each Use

Clean the pan surface with a brush or exible spatula.

Remove the strainer (Fig. 6) at the pouring lip of the braising pan by pulling it toward the back of the pan.

Clean the strainer in a sink. Rinse thoroughly and dry with a soft, clean cloth. Replace strainer.

PL-41753

Fig. 6

Once a Day

Thoroughly clean the back, sides and front of the pan. Also clean the inside and outside surfaces of the lid.

Once a Week

Clean the pan surface thoroughly. If necessary, use a griddle stone or brush on the surface. A detergent

may be used on the pan surface to help clean it, but be sure the detergent is thoroughly removed.

Clean other stainless steel surfaces with a damp cloth and polish with a soft, dry cloth. To remove

discolorations, use a nonabrasive cleaner. If the braising pan usage is very high, consider going through

the weekly cleaning procedures more often than once a week.

When cleaning the braising pan, it is helpful to ll the pan with approximately 10 gallons (38 L) of warm

water and add detergent. After cleaning, raise the braising pan to drain all water (place a bucket or

container under the pouring lip). Then repeat the procedures for rinsing with clean water.

– 15 –

Page 16

COOKING GUIDELINES (Domestic Measurements)

The guidelines given below are suggested quantities, temperature settings and estimated numbers of

orders per load and per hour. When two temperatures are given, the rst is to start the product and the

second is to nish the product.

The following temperatures should be used:

Temperature

(°F)

Simmering 200 Max.

Sautéing 225 to 275

Searing 300 to 350

Frying 325 to 375

Grilling 350 to 425

BATCHES

PORTION

ITEM

BREAKFAST FOODS

Bacon 3 Slices 350 12 2 lb. 10 3 lb. 15

Eggs

–Boiled-Hard 1 egg 225 5 50 eggs 50 75 eggs 75

–Boiled-Soft 1 egg 225 8 50 eggs 50 75 eggs 75

–Fried 1 egg 400 4 30 eggs 30 45 eggs 45

–Poached 1 egg 225 5 36 eggs 36 60 eggs 60

–Scrambled 1

French Toast 3 slices 425 7 35 slices 12 50 slices 17

Regular Oatmeal

Pancakes 2 each 400 10 30 ea. 15 50 ea. 25

FISH

Clams 1 pt. 400 10 10 qts. 20 15 qts. 30

Fish Cakes 2 to 3 oz. 400 5 70 – 3 oz. 35 110 – 3 oz. 55

Haddock Fillet 4 oz. 400 4 60 – 4 oz. 60 90 – 4 oz. 90

Halibut Steak 5 oz. 425 3 60 – 4 oz. 60 90 – 4 oz. 90

Lobster 1 – 1 lb. 350 4 20 – 1 lb. 20 30 – 1 lb. 30

Swordsh 5 oz. 425 3 50 – 5 oz. 50 75 – 5 oz. 75

SIZE

1

/2 eggs 300 – 200 1 18 gal. 720 28 gal. 1100

1

/2 cup 250 2

TEMP.

(°F)

PER

HOUR

20 lb (100 cups)

VG30/VE30

PER LOAD

QTY. PORTIONS QTY. PORTIONS

500 40 lb (200 cups) 1000

VG40/VE40

PER LOAD

SAUCES, GRAVIES, SOUPS

Brown Gravy 1 oz. 350 – 200 2 30 gal. 3840 40 gal. 5120

Cream Sauce 2 oz. 250 – 175 1 30 gal. 1920 40 gal. 2560

Cream Soup 6 oz. 200 1 30 gal. 640 40 gal. 853

French Onion Soup 6 oz. 225 1 30 gal. 640 40 gal. 853

Meat Sauce 4 oz. 350 – 200 1 30 gal. 960 40 gal. 1280

– 16 –

Page 17

ITEM

PORTION

SIZE

TEMP.

(°F)

BATCHES

PER

HOUR

VG30/VE30

PER LOAD

VG40/VE40

PER LOAD

QTY. PORTIONS QTY. PORTIONS

VEGETABLES

CANNED 3 oz. 400 6 30 lb. 125 45 lb. 200

FRESH

Beans, Wax, Green 3 oz. 400 3 25 lb. 125 50 lb. 250

Beets 3 oz. 400 1 30 lb. 125 60 lb. 300

Broccoli 3 oz. 400 3 25 lb. 125 40 lb. 200

Cabbage 3 oz. 400 5 20 lb. 80 30 lb. 125

Carrots 3 oz. 400 2 35 lb. 150 70 lb. 300

Cauliower 3 oz. 250 5 15 lb. 75 25 lb. 125

Corn 1 Ear 400 8 50 ears 50 75 ears 75

Potatoes 3 oz. 400 2 40 lb. 200 60 lb. 300

Spinach 4 oz. 250 10 6 lb. 25 9 lb. 35

Turnips 4 oz. 400 2 20 lb. 100 30 lb. 150

FROZEN

Beans, French Green 3 oz. 400 6 15 lb. 60 22

Lima Beans 3 oz. 250 4 15 lb. 60 22

1

/2 lb. 90

1

/2 lb. 90

Broccoli 3 oz. 400 8 12 lb. 50 18 lb. 75

Sliced Carrots 3 oz. 250 6 15 lb. 60 22

Small Whole Carrots 3 oz. 250 3 15 lb. 50 22

Corn 3 oz. 250 18 15 lb. 50 22

Small Whole Onions 3 oz. 250 7 15 lb. 50 22

Peas 3 oz. 400 10 15 lb. 75 22

Spinach 3 oz. 400 3 15 lb. 75 22

1

/2 lb. 90

1

/2 lb. 90

1

/2 lb. 90

1

/2 lb. 90

1

/2 lb. 110

1

/2 lb. 110

DESSERTS, PUDDINGS, SWEET SAUCES

Butterscotch Sauce 1 oz. 200 1 30 gal. 3840 40 gal. 5120

Cherry Cobbler 3 oz. 200 1 30 gal. 1280 40 gal. 1707

Chocolate Sauce 1 oz. 200 1 30 gal. 3840 40 gal. 5120

Cornstarch Pudding 4 oz. 200 1 30 gal. 960 40 gal. 1280

Fruit Gelatin 3 oz. 250 2 30 gal. 1280 40 gal. 1707

MEAT – POULTRY

Bacon 3 Slices 350 12 2 lb. 10 3 lb. 15

BEEF

Amer. Chop Suey 6 oz. 400 – 225 2 30 gal. 640 40 gal. 853

Beef Stew 8 oz. 300 — 30 gal. 480 40 gal. 640

Corned Beef Hash 5 oz. 400 5 20 lb. 60 30 lb. 90

Cheeseburger 3 oz. 300 12 7 lb. 35 10 lb. 50

Hamburger 3 oz. 300 15 7 lb. 35 10 lb. 50

Meatballs 1 oz. 400 – 225 3 12

1

/2 lb. 65 18 lb. 100

Pot Roast 2 oz. 350 – 200 120 lb. 500 180 lb. 750

Salisbury Steak 5 oz. 400 3 16 lb. 50 24 lb. 75

Sirloin Steak 6 oz. 400 5 15 lb. 40 22

1

/2 lb. 60

Swiss Steak 4 oz. 300 – 200 1 25 lb. 110 40 lb. 160

– 17 –

Page 18

ITEM

CHICKEN

PORTION

SIZE

TEMP.

(°F)

BATCHES

PER

HOUR

VG30/VE30

PER LOAD

VG40/VE40

PER LOAD

QTY. PORTIONS QTY. PORTIONS

Pan Fried 2 –

1

/4's 350 3 50 pieces 25 80 pieces 40

Whole 2 oz. 350 – 200 16 – 5 lb. 200 24 – 5 lb. 265

FRANKFURTERS

Grilled 2 oz. 300 8 22 lb. 176 33 lb. 264

Boiled 2 oz. 250 12 16 lb. 128 25 lb. 200

PORK

Ham Steak 3 oz. 400 8 10 lb. 50 15 lb. 75

Pork Chops 5 oz. 350 4 15 lb. 50 25 lb. 75

Sausage Links 3 links 350 7 30 lb. 120 45 lb. 180

TURKEY

O Carcass 2 oz. 400 – 200 — 3–26 to 30 lb. 200 4–26 to 30 lb. 275

On Carcass 2 oz. 400 – 200 — 4–16 to 20 lb. 175 6–16 to 20 lb. 265

MISCELLANEOUS

Grilled Cheese Sandwich 1 sand. 400 8 40 sand. 40 50 sand. 50

Macaroni & Cheese 8 oz. 200 2 30 gal. 480 40 gal. 640

Rice 4 oz. 350 – 225 1 20 lb. raw 320 40 lb. raw 650

Spaghetti 4 oz. 350 – 225 2 8 lb. raw 200 12 lb. raw 300

– 18 –

Page 19

COOKING GUIDELINES (Metric Measurements)

The guidelines given below are suggested quantities, temperature settings and estimated numbers of

orders per load and per hour. When two temperatures are given, the rst is to start the product and the

second is to nish the product.

The following temperatures should be used:

Temperature (°C)

Simmering 93.3 Max.

Sautéing 107 to 135

Searing 149 to 177

Frying 163 to 191

Grilling 177 to 218

BATCHES

PORTION

ITEM

BREAKFAST FOODS

Bacon 3 Slices 177 12 0.9 kg 10 1.4 kg 15

Eggs

–Boiled-Hard 1 egg 107 5 50 eggs 50 75 eggs 75

–Boiled-Soft 1 egg 107 8 50 eggs 50 75 eggs 75

–Fried 1 egg 204 4 30 eggs 30 45 eggs 45

–Poached 1 egg 107 5 36 eggs 36 60 eggs 60

–Scrambled 1

French Toast 3 slices 218 7 35 slices 12 50 slices 17

Regular Oatmeal 118 mL 121 2 9 kg 500 18 kg 1000

Pancakes 2 each 204 10 30 ea. 15 50 ea. 25

FISH

Clams 473 mL 204 10 9 L 20 14 L 30

Fish Cakes 57 to 85 g 204 5 70 – 85 g 35 110 – 85 g 55

Haddock Fillet 113 g 204 4 60 – 113 g 60 90 – 113 g 90

Halibut Steak 142 g 218 3 60 – 113 g 60 90 – 113 g 90

Lobster 1 – 0.5 kg 177 4 20 – 0.5 kg 20 30 – 0.5 kg 30

Swordsh 142 g 218 3 50 – 142 g. 50 75 – 142 g 75

SIZE

1

/2 eggs 149 – 93 1 68 L 720 106 L 1100

TEMP.

(°C)

PER

HOUR

VG30/VE30

PER LOAD

QTY. PORTIONS QTY. PORTIONS

VG40/VE40

PER LOAD

SAUCES, GRAVIES, SOUPS

Brown Gravy 28 g 177 – 93 2 114 L 3840 151 L 5120

Cream Sauce 57 g 121 – 79 1 114 L 1920 151 L 2560

Cream Soup 170 g 93 1 114 L 640 151 L 853

French Onion Soup 170 g 107 1 114 L 640 151 L 853

Meat Sauce 113 g 177 – 93 1 114 L 960 151 L 1280

– 19 –

Page 20

BATCHES

PORTION

ITEM

VEGETABLES

CANNED 85 g 204 6 14 kg 125 20 kg 200

FRESH

Beans, Wax, Green 85 g 204 3 11 kg 125 23 kg 250

Beets 85 g 204 1 14 kg 125 27 kg 300

Broccoli 85 g 204 3 11 kg 125 18 kg 200

Cabbage 85 g 204 5 9 kg 80 14 kg 125

Carrots 85 g 204 2 16 kg 150 32 kg 300

Cauliower 85 g 121 5 7 kg 75 11 kg 125

Corn 1 Ear 204 8 50 ears 50 75 ears 75

Potatoes 85 g 204 2 18 kg 200 27 kg 300

Spinach 113 g 121 10 3 kg 25 4 kg 35

Turnips 113 g 204 2 9 kg 100 14 kg 150

FROZEN

Beans, French Green 85 g 204 6 7 kg 60 10 kg 90

Lima Beans 85 g 121 4 7 kg 60 10 kg 90

Broccoli 85 g 204 8 5 kg 50 8 kg 75

Sliced Carrots 85 g 121 6 7 kg 60 10 kg 90

Small Whole Carrots 85 g 121 3 7 kg 50 10 kg 90

Corn 85 g 121 18 7 kg 50 10 kg 90

Small Whole Onions 85 g 121 7 7 kg 50 10 kg 90

Peas 85 g 204 10 7 kg 75 10 kg 110

Spinach 85 g 204 3 7 kg 75 10 kg 110

SIZE

TEMP.

(°C)

PER

HOUR

VG30/VE30

PER LOAD

QTY. PORTIONS QTY. PORTIONS

VG40/VE40

PER LOAD

DESSERTS, PUDDINGS, SWEET SAUCES

Butterscotch Sauce 28 g 93 1 114 L 3840 151 L 5120

Cherry Cobbler 85 g 93 1 114 L 1280 151 L 1707

Chocolate Sauce 28 g 93 1 114 L 3840 151 L 5120

Cornstarch Pudding 113 g 93 1 114 L 960 151 L 1280

Fruit Gelatin 85 g 121 2 114 L 1280 151 L 1707

MEAT – POULTRY

Bacon 3 Slices 177 12 0.9 kg 10 1 kg 15

BEEF

Amer. Chop Suey 170 g 204 – 107 2 114 L 640 151 L 853

Beef Stew 0.2 kg 149 — 114 L 480 151 L 640

Corned Beef Hash 142 g 204 5 9 kg 60 14 kg 90

Cheeseburger 85 g 149 12 3 kg 35 5 kg 50

Hamburger 85 g 149 15 3 kg 35 5 kg 50

Meatballs 28 g 204 – 107 3 6 kg 65 8 kg 100

Pot Roast 57 g 177 – 93 54 kg 500 82 kg 750

Salisbury Steak 142 g 204 3 7 kg 50 11 kg 75

Sirloin Steak 170 g 204 5 7 kg 40 10 kg 60

Swiss Steak 113 g 149 – 93 1 11 kg 11 0 18 kg 160

– 20 –

Page 21

ITEM

CHICKEN

PORTION

SIZE

TEMP.

(°C)

BATCHES

PER

HOUR

VG30/VE30

PER LOAD

VG40/VE40

PER LOAD

QTY. PORTIONS QTY. PORTIONS

Pan Fried 2 –

1

/4's 177 3 50 pieces 25 80 pieces 40

Whole 57 g 177 – 93 16 – 2 kg 200 24 – 2 kg 265

FRANKFURTERS

Grilled 57 g 149 8 10 kg 176 15 kg 264

Boiled 57 g 121 12 7 kg 128 11 kg 200

PORK

Ham Steak 85 g 204 8 5 kg 50 7 kg 75

Pork Chops 142 g 177 4 7 kg 50 11 kg 75

Sausage Links 3 links 177 7 14 kg 120 10 kg 180

TURKEY

O Carcass 57 g 204 – 93 — 3 –

12 to 14 kg

200 4 – 12 to 14 kg 275

On Carcass 57 g 204 – 93 — 4 – 7 to 9 kg 175 6 – 7 to 9 kg 265

MISCELLANEOUS

Grilled Cheese Sandwich 1 sand. 204 8 40 sand. 40 50 sand. 50

Macaroni & Cheese 0.2 kg 93 2 114 L 480 151 L 640

Rice 113 g 177 – 107 1 9 kg raw 320 18 kg raw 650

Spaghetti 113 g 177 – 107 2 4 kg raw 200 5 kg raw 300

– 21 –

Page 22

MAINTENANCE

The tilting braising pan and its parts are hot. Use care when operating, cleaning

or servicing the braising pan.

Disconnect the electrical power to the machine and follow lockout / tagout procedures

before performing any maintenance.

LUBRICATION

Lid Mechanism

1. The lid lift mechanism and tension spring are located behind the backsplash (sheet metal panel

behind the braising pan) on both the left and right rear corners of the braising pan.

2. Take the cover o by prying and lifting up (Fig. 7).

3. For smooth operation of the lid, lubricate these mechanisms with 8 to 10 drops of lubricating machine

oil every 6 months. Place a few drops of oil between the lid arm and stationary block, and a few

drops on the shaft around which the spring is coiled.

4. Replace the cover to maintain smooth operation.

COVER

LUBRICATE

Fig. 7

PL-41754-1

ADJUSTMENTS

At least twice a year, have a Vulcan authorized service person clean and adjust the tilting braising pan

for maximum performance.

FLUE

When cool, annually check the ue. Clean the ue of any grease buildup or other obstructions that can

aect the ow of the ue gases from the braising pan.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning the tilting braising pan, contact the Vulcan service

agency in your area (refer to listing supplied with the braising pan) or Vulcan service department at the

address or phone number shown on the front cover of this manual.

– 22 –

Page 23

TROUBLESHOOTING

GAS HEAT BRAISING PANS

Problem Possible Cause

Burners do not come on. 1. The power supply is o.

2. The gas supply to the braising pan is o.

3. The thermostat is not turned on.

4. The gas valve is o.

5. The pan is not in the lowest position.

6. Problem with the gas control system. Contact your Vulcan

authorized servicer.

Burners produce carbon

deposits.

ELECTRIC HEAT BRAISING PANS

1. Braising pan frame is not level.

2. Wrong size orices.

3. Burner air is not adjusted properly.

4. Wrong gas supply

5. Incorrect pressure at supply.

Problem Possible Cause

Heating elements do not

come on.

1. The power supply is o.

2. The thermostat is not turned on.

3. Blown fuse in eld electrical box.

4. Pan is not in the lowest position.

5. Problem with the control circuits. Contact your Vulcan

authorized servicer.

– 23 –

Page 24

— NOTES —

FORM 31227 Rev. B (January 2018) PRINTED IN U.S.A.

– 24 –

Page 25

– 24 –

FORMULAIRE 31227 Rév. B (janvier 2018) IMPRIMÉ AUX É.-U.

— NOTES —

Page 26

– 23 –

technicien d’entretien agréé Vulcan.

5. Problème avec les circuits de commande. Contactez votre

4. La braisière n'est pas dans sa position la plus basse.

3. Fusible grillé dans le boîtier électrique sur site.

2. Le thermostat est éteint.

1. L'alimentation électrique est coupée.

5. Pression incorrecte à l'alimentation.

4. Mauvaise alimentation en gaz

3. L'air du brûleur n'est pas réglé correctement.

2. Orifi ces de mauvaises tailles.

1. Le cadre de la braisière n’est pas de niveau.

votre technicien d’entretien agréé Vulcan.

6. Problème avec le système de commande du gaz. Contactez

5. La braisière n'est pas dans sa position la plus basse.

4. Le robinet d’alimentation en gaz est fermé.

3. Le thermostat est éteint.

2. L'alimentation en gaz de la braisière est coupée.

1. L'alimentation électrique est coupée.

s'allument pas.

Les éléments chauff ants ne

Problème Cause possible

BRAISIÈRES ÉLECTRIQUES

dépôts de carbone.

Les brûleurs produisent des

pas.

Les brûleurs ne s'allument

Problème Cause possible

DÉPANNAGE

BRAISIÈRES À GAZ

Page 27

– 22 –

Fig. 7

de ce manuel.

service auxiliaire de Vulcan à l’adresse ou au numéro de téléphone indiqués sur la page de couverture

l’agence de service Vulcan de votre région (reportez-vous à la liste fournie avec la braisière) ou avec le

Pour obtenir des renseignements sur l’entretien et les pièces concernant la braisière, communiquez avec

RENSEIGNEMENTS SUR L’ENTRETIEN ET LES PIÈCES

de graisse ou d'autres obstructions pouvant aff ecter l'écoulement des gaz de combustion de la braisière.

Une fois refroidi, vérifi ez chaque année le conduit de fumée. Nettoyez le conduit de toute accumulation

CONDUIT DE FUMÉE

basculante afi n d’assurer une performance maximale.

Au moins deux fois par an, demandez à un technicien Vulcan autorisé de nettoyer et de régler la braisière

RÉGLAGES

PL-41754-1

LUBRIFIER

CACHE

4. Replacez la cache pour maintenir le bon fonctionnement.

bloc fi xe, et quelques gouttes sur l'arbre autour duquel le ressort est enroulé.

d'huile lubrifi ante tous les 6 mois. Placez quelques gouttes d'huile entre le bras du couvercle et le

3. Pour assurer un bon fonctionnement du couvercle, lubrifi ez ces mécanismes avec 8 à 10 gouttes

2. Forcez l’ouverture de la cache et enlevez-la (fi g. 7).

(panneau de tôle derrière la braisière) sur les deux coins arrière gauche et droit de la braisière.

1. Le mécanisme de levage du couvercle et le ressort de tension sont situés derrière le dosseret

ENTRETIEN

Mécanisme du couvercle

LUBRIFICATION

d'étiquetage avant d’eff ectuer l’entretien.

Coupez l'alimentation électrique à la braisière et suivez les procédures de verrouillage/

A VERTISSEMENT

nettoyez ou entretenez la braisière.

La braisière et ses pièces sont chaudes. Faites attention lorsque vous utilisez,

A VERTISSEMENT

Page 28

– 21 –

650

cuit)

Spaghetti 113 g 177 – 107 2 4 kg (non cuit) 200 5 kg (non cuit) 300

Riz 113 g 177 – 107 1 9 kg (non cuit) 320 18 kg (non

Macaroni au fromage 0,2 kg 93 2 114 L 480 151 L 640

Sandwich au fromage fondu 1 sandwich 204 8 40 sandwichs 40 50 sandwichs 50

DIVERS

Sur carcasse 57 g 204 – 93 — 4 – 7 à 9 kg 175 6 – 7 à 9 kg 265

200 4 – 12 à 14 kg 275

12 à 14 kg

Hors carcasse 57 g 204 – 93 — 3 –

DINDE

Chapelet de saucisses 3 chapelets 177 7 14 kg 120 10 kg 180

Côtes de porc 142 g 177 4 7 kg 50 11 kg 75

Tranche de jambon 85 g 204 8 5 kg 50 7 kg 75

PORC

Bouillie 57 g 121 12 7 kg 128 11 kg 200

Grillée 57 g 149 8 10 kg 176 15 kg 264

SAUCISSES FUMÉES

Entier 57 g 177 – 93 16 – 2 kg 200 24 – 2 kg 265

/4 177 3 50 morceaux 25 80 morceaux 40

1

Poêlé 2 –

PAR CHARGE

VG40/VE40

QTÉ PORTIONS QTÉ PORTIONS

PAR CHARGE

VG30/VE30

HEURE

PAR

LOTS

(°C)

TEMP.

TAILLE

PORTION

POULET

ALIMENT

Page 29

– 20 –

Bifteck à la suisse 113 g 149 – 93 1 11 kg 110 18 kg 160

Bifteck de surlonge 170 g 204 5 7 kg 40 10 kg 60

Bifteck Salisbury 142 g 204 3 7 kg 50 11 kg 75

Morceau à braiser 57 g 177 – 93 54 kg 500 82 kg 750

Boulettes de viande 28 g 204 – 107 3 6 kg 65 8 kg 100

Hamburger 85 g 149 15 3 kg 35 5 kg 50

Hamburger au fromage 85 g 149 12 3 kg 35 5 kg 50

Hachis de bœuf 142 g 204 5 9 kg 60 14 kg 90

Ragoût de bœuf 0,2 kg 149 — 114 L 480 151 L 640

Chop suey américain 170 g 204 – 107 2 114 L 640 151 L 853

BŒUF

Bacon 3 tranches 177 12 0,9 kg 10 1 kg 15

VIANDE – VOLAILLE

Gélatine aux fruits 85 g 121 2 114 L 1 280 151 L 1 707

Pudding de fécule de maïs 113 g 93 1 114 L 960 151 L 1 280

Sauce au chocolat 28 g 93 1 114 L 3 840 151 L 5 120

Cobbler cerise 85 g 93 1 114 L 1 280 151 L 1 707

Sauce caramel 28 g 93 1 114 L 3 840 151 L 5 120

DESSERTS, PUDDINGS, SAUCES SUCRÉES

Épinards 85 g 204 3 7 kg 75 10 kg 110

Pois 85 g 204 10 7 kg 75 10 kg 110

Petits oignons entiers 85 g 121 7 7 kg 50 10 kg 90

Maïs 85 g 121 18 7 kg 50 10 kg 90

Petites carottes entières 85 g 121 3 7 kg 50 10 kg 90

Carottes tranchées 85 g 121 6 7 kg 60 10 kg 90

Brocoli 85 g 204 8 5 kg 50 8 kg 75

Haricots de Lima 85 g 121 4 7 kg 60 10 kg 90

Haricots verts à la française 85 g 204 6 7 kg 60 10 kg 90

CONGELÉ

Navets 113 g 204 2 9 kg 100 14 kg 150

Épinards 113 g 121 10 3 kg 25 4 kg 35

Pommes de terre 85 g 204 2 18 kg 200 27 kg 300

Maïs 1 épi 204 8 50 épis 50 75 épis 75

Chou-fl eur 85 g 121 5 7 kg 75 11 kg 125

Carottes 85 g 204 2 16 kg 150 32 kg 300

Chou 85 g 204 5 9 kg 80 14 kg 125

Brocoli 85 g 204 3 11 kg 125 18 kg 200

Betteraves 85 g 204 1 14 kg 125 27 kg 300

Haricots, jaune, vert 85 g 204 3 11 kg 125 23 kg 250

FRAIS

CONSERVES 85 g 204 6 14 kg 125 20 kg 200

PAR CHARGE

VG40/VE40

QTÉ PORTIONS QTÉ PORTIONS

PAR CHARGE

VG30/VE30

HEURE

PAR

LOTS

(°C)

TEMP.

TAILLE

PORTION

LÉGUMES

ALIMENT

Page 30

– 19 –

Sauce à la viande 113 g 177 – 93 1 114 L 960 151 L 1 280

Soupe à l'oignon 170 g 107 1 114 L 640 151 L 853

Potage crème 170 g 93 1 114 L 640 151 L 853

Sauce crème 57 g 121 – 79 1 114 L 1 920 151 L 2 560

Sauce brune 28 g 177 – 93 2 114 L 3 840 151 L 5120

SAUCES ET SOUPES

Espadon 142 g 218 3 50 – 142 g 50 75 – 142 g 75

Homard 1 – 0,5 kg 177 4 20 – 0,5 kg 20 30 – 0,5 kg 30

Darne de fl étan 142 g 218 3 60 – 113 g 60 90 – 113 g 90

Filet d'églefi n 113 g 204 4 60 – 113 g 60 90 – 113 g 90

Fricadelle de poisson 57 à 85 g 204 5 70 – 85 g 35 110 – 85 g 55

Myes 473 mL 204 10 9 L 20 14 L 30

POISSON

Crêpes 2 chaque 204 10 30 ch 15 50 ch 25

Gruau régulier 118 mL 121 2 9 kg 500 18 kg 1 000

Pain doré 3 tranches 218 7 35 tranches 12 50 tranches 17

/2 œufs 149 – 93 1 68 L 720 106 L 1100

1

– brouillé 1

– poché 1 œuf 107 5 36 œufs 36 60 œufs 60

– poêlé 1 œuf 204 4 30 œufs 30 45 œufs 45

– bouilli – à la coque 1 œuf 107 8 50 œufs 50 75 œufs 75

– bouilli – dur 1 œuf 107 5 50 œufs 50 75 œufs 75

Œufs

Bacon 3 tranches 177 12 0,9 kg 10 1,4 kg 15

PAR CHARGE

VG40/VE40

QTÉ PORTIONS QTÉ PORTIONS

PAR CHARGE

VG30/VE30

Température (°C)

HEURE

PAR

LOTS

(°C)

TEMP.

Griller 177 à 218

Faire frire 163 à 191

Saisir 149 à 177

Sauter 107 à 135

Mijoter 93,3 max.

TAILLE

PORTION

DÉJEUNER

ALIMENT

Les températures suivantes devraient être utilisées :

première consiste à démarrer la cuisson du produit et la seconde à terminer la cuisson du produit.

nombres estimés de commandes par charge et par heure. Lorsque deux températures sont données, la

Les directives données ci-dessous sont des quantités suggérées, des réglages de température et des

DIRECTIVES DE CUISSON (mesures métriques)

Page 31

– 18 –

300

650

cuit)

cuit)

Spaghetti 4 oz 350 – 225 2 8 lb (non cuit) 200 12 lb (non

cuit)

320 40 lb (non

Riz 4 oz 350 – 225 1 20 lb (non

Macaroni au fromage 8 oz 200 2 30 gal 480 40 gal 640

Sandwich au fromage fondu 1 sandwich 400 8 40 sandwichs 40 50 sandwichs 50

DIVERS

Sur carcasse 2 oz 400 – 200 — 4-16 à 20 lb 175 6-16 à 20 lb 265

Hors carcasse 2 oz 400 – 200 — 3–26 à 30 lb 200 4–26 à 30 lb 275

DINDE

Chapelet de saucisses 3 chapelets 350 7 30 lb 120 45 lb 180

Côtes de porc 5 oz 350 4 15 lb 50 25 lb 75

Tranche de jambon 3 oz 400 8 10 lb 50 15 lb 75

PORC

Bouillie 2 oz 250 12 16 lb 128 25 lb 200

Grillée 2 oz 300 8 22 lb 176 33 lb 264

SAUCISSES FUMÉES

PAR CHARGE

VG40/VE40

QTÉ PORTIONS QTÉ PORTIONS

PAR CHARGE

VG30/VE30

HEURE

PAR

LOTS

(°F)

TEMP.

/4 350 3 50 morceaux 25 80 morceaux 40

1

TAILLE

PORTION

Entier 2 oz 350 – 200 16 – 5 lb 200 24 – 5 lb 265

Poêlé 2 –

POULET

ALIMENT

Page 32

– 17 –

Bifteck à la suisse 4 oz 300 – 200 1 25 lb 110 40 lb 160

/2 lb 60

1

/2 lb 65 18 lb 100

1

Bifteck de surlonge 6 oz 400 5 15 lb 40 22

Bifteck Salisbury 5 oz 400 3 16 lb 50 24 lb 75

Morceau à braiser 2 oz 350 – 200 120 lb 500 180 lb 750

Boulettes de viande 1 oz 400 – 225 3 12

Hamburger 3 oz 300 15 7 lb 35 10 lb 50

Hamburger au fromage 3 oz 300 12 7 lb 35 10 lb 50

Hachis de bœuf 5 oz 400 5 20 lb 60 30 lb 90

Ragoût de bœuf 8 oz 300 — 30 gal 480 40 gal 640

Chop suey américain 6 oz 400 – 225 2 30 gal 640 40 gal 853

BŒUF

Bacon 3 tranches 350 12 2 lb 10 3 lb 15

VIANDE – VOLAILLE

Gélatine aux fruits 3 oz 250 2 30 gal 1 280 40 gal 1 707

Pudding de fécule de maïs 4 oz 200 1 30 gal 960 40 gal 1 280

Sauce au chocolat 1 oz 200 1 30 gal 3 840 40 gal 5120

Cobbler cerise 3 oz 200 1 30 gal 1 280 40 gal 1 707

Sauce caramel 1 oz 200 1 30 gal 3 840 40 gal 5120

DESSERTS, PUDDINGS, SAUCES SUCRÉES

/2 lb 110

1

/2 lb 110

1

/2 lb 90

1

/2 lb 90

1

/2 lb 90

1

/2 lb 90

1

Épinards 3 oz 400 3 15 lb 75 22

Pois 3 oz 400 10 15 lb 75 22

Petits oignons entiers 3 oz 250 7 15 lb 50 22

Maïs 3 oz 250 18 15 lb 50 22

Petites carottes entières 3 oz 250 3 15 lb 50 22

Carottes tranchées 3 oz 250 6 15 lb 60 22

Brocoli 3 oz 400 8 12 lb 50 18 lb 75

/2 lb 90

1

/2 lb 90

1

Haricots de Lima 3 oz 250 4 15 lb 60 22

Haricots verts à la française 3 oz 400 6 15 lb 60 22

CONGELÉ

Navets 4 oz 400 2 20 lb 100 30 lb 150

Épinards 4 oz 250 10 6 lb 25 9 lb 35

Pommes de terre 3 oz 400 2 40 lb 200 60 lb 300

Maïs 1 épi 400 8 50 épis 50 75 épis 75

Chou-fl eur 3 oz 250 5 15 lb 75 25 lb 125

Carottes 3 oz 400 2 35 lb 150 70 lb 300

Chou 3 oz 400 5 20 lb 80 30 lb 125

Brocoli 3 oz 400 3 25 lb 125 40 lb 200

Betteraves 3 oz 400 1 30 lb 125 60 lb 300

Haricots, jaune, vert 3 oz 400 3 25 lb 125 50 lb 250

FRAIS

CONSERVES 3 oz 400 6 30 lb 125 45 lb 200

PAR CHARGE

VG40/VE40

QTÉ PORTIONS QTÉ PORTIONS

PAR CHARGE

VG30/VE30

HEURE

PAR

LOTS

(°F)

TEMP.

TAILLE

PORTION

LÉGUMES

ALIMENT

Page 33

1 000

tasses)

– 16 –

Sauce à la viande 4 oz 350 – 200 1 30 gal 960 40 gal 1 280

Soupe à l'oignon 6 oz 225 1 30 gal 640 40 gal 853

Potage crème 6 oz 200 1 30 gal 640 40 gal 853

Sauce crème 2 oz 250 – 175 1 30 gal 1 920 40 gal 2 560

Sauce brune 1 oz 350 – 200 2 30 gal 3 840 40 gal 5120

SAUCES ET SOUPES

Espadon 5 oz 425 3 50 – 5 oz 50 75 – 5 oz 75

Homard 1 – 1 lb 350 4 20 – 1 lb 20 30 – 1 lb 30

Darne de fl étan 5 oz 425 3 60 – 4 oz 60 90 – 4 oz 90

Filet d'églefi n 4 oz 400 4 60 – 4 oz 60 90 – 4 oz 90

Fricadelle de poisson 2 à 3 oz 400 5 70 – 3 oz 35 110 – 3 oz 55

Myes 1 chop 400 10 10 ptes 20 15 ptes 30

POISSON

Crêpes 2 chaque 400 10 30 ch 15 50 ch 25

tasses)

500 40 lb (200

20 lb (100

/2 tasse 250 2

1

/2 œufs 300 – 200 1 18 gal 720 28 gal 1100

1

Gruau régulier

Pain doré 3 tranches 425 7 35 tranches 12 50 tranches 17

– brouillé 1

– poché 1 œuf 225 5 36 œufs 36 60 œufs 60

– poêlé 1 œuf 400 4 30 œufs 30 45 œufs 45

– bouilli – à la coque 1 œuf 225 8 50 œufs 50 75 œufs 75

– bouilli – dur 1 œuf 225 5 50 œufs 50 75 œufs 75

Œufs

Bacon 3 tranches 350 12 2 lb 10 3 lb 15

PAR CHARGE

VG40/VE40

QTÉ PORTIONS QTÉ PORTIONS

PAR CHARGE

VG30/VE30

(°F)

Température

HEURE

PAR

LOTS

(°F)

TEMP.

Griller 350 à 425

Faire frire 325 à 375

Saisir 300 à 350

Sauter 225 à 275

Mijoter 200 max.

TAILLE

PORTION

DÉJEUNER

ALIMENT

Les températures suivantes devraient être utilisées :

première consiste à démarrer la cuisson du produit et la seconde à terminer la cuisson du produit.

nombres estimés de commandes par charge et par heure. Lorsque deux températures sont données, la

Les directives données ci-dessous sont des quantités suggérées, des réglages de température et des

DIRECTIVES DE CUISSON (mesures impériales)

Page 34

– 15 –

un seau ou un récipient sous le bec verseur). Répétez ensuite ces étapes pour le rinçage à l'eau propre.

chaude et d'ajouter du détergent. Après le nettoyage, soulevez la braisière pour vider toute l'eau (placez

Lorsque vous nettoyez la braisière, il est utile de remplir la braisière d'environ 10 gallons (38 L) d'eau

fois par semaine.

braisière très souvent, envisagez de passer par les procédures de nettoyage hebdomadaires plus d'une

doux et sec. Pour éliminer toute décoloration, utilisez un agent nettoyant non abrasif. Si vous utilisez la

Nettoyez les autres surfaces en acier inoxydable avec un chiff on humide et polissez avec un chiff on

vous que le détergent est complètement enlevé.

surface. Du détergent peut être utilisé sur la surface de la braisière pour aider à la nettoyer, mais assurezNettoyez la surface de la braisière à fond. Si nécessaire, utilisez un bloc ou une brosse à grille sur la

Une fois semaine

intérieures et extérieures du couvercle.

Nettoyer soigneusement le dos, les côtés et l'avant de la braisière. Nettoyez également les surfaces

Une fois par jour

PL-41753

Fig. 6

Replacez la passoire.

Nettoyez la passoire dans un évier. Rincez abondamment la braisière avec un chiff on doux et propre.

Retirez le passoire (fi g. 6) sur le bec verseur de la braisière en la tirant vers l'arrière de la braisière.

Nettoyez la surface de la braisière avec une brosse ou une spatule fl exible.

Après chaque utilisation

très insatisfaisante et peu appétissante.

pire de tout, la graisse carbonisée a tendance à s'accrocher aux aliments, leur donnant une apparence

braisière à la nourriture. Ceci entraîne un brunissement irrégulier et une perte d'effi cacité de cuisson. Le

carbonisée. La graisse carbonisée sur la surface empêche le transfert de chaleur de la surface de la

produits parfaitement cuits et parfaitement braisés, gardez la surface de la braisière exempte de graisse

Nettoyez votre braisière régulièrement. Gardez la surface de la plaque propre. Pour produire des

d'étiquetage avant de nettoyer.

Coupez l'alimentation électrique à la braisière et suivez les procédures de verrouillage/

A VERTISSEMENT

NETTOYAGE

Page 35

– 14 –

Fig. 5

des économies considérables de main-d'œuvre et d'énergie.

n'importe quel type de cuisson, à l'exception de la friture, à grande vitesse, en grande quantité et avec

Votre braisière basculante Vulcan est un appareil polyvalent qui peut être utilisé pour pratiquement

Elle peut être utilisée pour la préparation des déjeuners, dîners et soupers.

fermentation, comme une marmite, comme une bouilloire ou comme une cuisinière de chaleur uniforme.

cuire. Elle peut être utilisée comme une poêle surdimensionnée, comme un bain-marie, comme un four à

réchauff er, maintenir au chaud, fermenter, décongeler, faire dorer, cuire à la vapeur, braiser, griller ou

Une braisière est très polyvalente. Elle peut être utilisée pour rôtir, mijoter, bouillir, sauter, saisir, frire,

pas plus de 1/8 po [0,3 cm] d'épaisseur) pour frire ou sauter.

N’utilisez PAS la braisière pour la friture. Restreignez l’activité de friture au bac peu profond (fi lm d'huile

UTILISATIONS SUGGÉRÉES POUR VOTRE BRAISIÈRE

PL-41752-1

ACCESSOIRE À VAPEUR

/2 po

(1 cm) de profondeur.

1

Les accessoires à vapeur peuvent être commandés auprès de votre revendeur.

ou de réchauff ement désirée.

accessoires à vapeur d'être immergés dans l'eau. Réglez le thermostat pour la température de maintien

cuisson à la vapeur, mais augmentez la profondeur de l'eau pour permettre au fond et aux côtés des

Pour utiliser la braisière comme chauff e-plats ou bain-marie, suivez la même procédure que pour la

d’eau est inférieur à

Inspectez périodiquement le niveau d'eau à l'intérieur de la braisière. Ajoutez de l’eau si le niveau

le couvercle et laissez cuire à la vapeur pendant le temps désiré.

braisière comme indiqué à la fi gure 5. Placez le plat avec le produit dans l'accessoire à vapeur. Fermez

ensuite le thermostat à 250 °F (121 °C) et placez soigneusement les accessoires à vapeur dans la

Mettez en marche la braisière. Réglez le thermostat à 212 °F (100 °C). Laissez l'eau bouillir. Réglez

2 po [5 cm] de profondeur) pour les modèles de 40 gallons (151 L).

de profondeur) pour les modèles de 30 gallons (114 L) et de 8 à 9 gallons (30 à 34 L) d'eau (environ

Pour utiliser la braisière, remplissez la braisière de 6 à 7 gallons (23 à 26 L) d'eau (environ 2 po [5 cm]

(151 L) (modèles VE40 ou VG40) acceptera jusqu'à trois bacs à vapeur de cette même taille.

bacs à vapeur de 12 po x 20 po x 4 po (30 cm x 50,8 cm x 10 cm). La braisière de 40 gallons

(modèles VE30 ou VG30) peuvent être chargées avec un maximum

de deux

braisières de 30 gallons (114 L)

Votre braisière basculante peut être utilisée pour cuire à la vapeur des aliments congelés et frais. Les

ACCESSOIRES DE VAPEUR (facultatifs)

Page 36

PL-41751-1

– 13 –

Fig. 4

CHARNIÈRE

DE CADRE

SUPPORT

abaissez le support

Lorsque vous abaissez le support de cadre, appuyez sur les charnières jusqu'à ce qu'elles se plient, puis

des bacs de réception de nourriture de 12 po x 20 po (30 cm x 50 cm) jusqu'à 6 po (15 cm) de profondeur.

Tirez le support de cadre vers l'extérieur et vers le haut jusqu'à ce qu'il se verrouille. Le support acceptera

nourriture aux fi ns de déchargement des aliments préparés.

Toutes les braisières sont munies d'un support de cadre (fi g. 4) pour contenir un bac de réception de

DÉCHARGEMENT DES ALIMENTS PRÉPARÉS

braisière (comme pour les braisières avec levage manuel).

5. En cas de panne de courant, utilisez la manivelle (fournie séparément) pour abaisser ou lever la

appuyé pour le levage ou l'abaissement continu de la braisière.

inférieure de l'interrupteur à bascule gris pour abaisser la braisière. L'interrupteur doit être maintenu

4. Appuyez sur la partie supérieure de l'interrupteur à bascule gris pour lever la braisière et la partie

3. Retirez toujours la manivelle de levage manuel avant d'utiliser l’interrupteur de levage automatique.

(voir fi g. 3).

2. Le levage de la braisière est contrôlé par l'interrupteur à bascule gris situé sur le panneau de commande

ouvert.

1. Le levage automatique ne peut pas lever la braisière à moins que le couvercle ne soit complètement

Braisières avec levage automatique (facultatif)

5. Reportez-vous à la section ENTRETIEN de ce manuel pour les instructions de lubrifi cation et d'entretien.

panne de courant.

4. Ce système de levage n'est pas aff ecté par une panne de courant et peut être utilisé pendant une

abaisser la braisière.

3. Tournez la manivelle dans le sens horaire pour lever la braisière et dans le sens antihoraire pour

situé derrière le panneau.

commande de sorte que les deux broches s'engagent dans les fentes de l’accouplement du réducteur

2. Il y a deux broches à une extrémité de la manivelle. Insérez la manivelle dans le trou du panneau de

1. La manivelle du système de levage manuel est expédiée séparément.

Braisières avec levage manuel (standard)

Page 37

– 12 –

ou pendant une période d'arrêt entre les heures de cuisson).

Ne laissez pas la braisière en position HAUTE pendant des périodes prolongées (p. ex., pendant la nuit

de la braisière. Cette zone doit être dégagée de tout objet ou obstruction en tout temps.

N’obstruez pas les pièces mobiles du système de levage situées sous le dessus côté droit et/ou gauche

utilisez le système de levage.

Gardez vos mains ou tout autre objet à l’écart de la zone sous et autour de la braisière lorsque vous

UTILISATION DU SYSTÈME DE LEVAGE

agréé Vulcan local pour eff ectuer ces réglages.

un certain temps, les ressorts peuvent avoir besoin d'être resserrés. Appelez le technicien d’entretien

Le couvercle fonctionne à ressorts et restera dans n'importe quelle position à laquelle il est placé. Après

l'huile de cuisson sur la plaque et provoquer un collage.

absorber la chaleur. La surchauff e de la plaque peut provoquer un gauchissement et carboniser toute

recommandées ou en faisant fonctionner la braisière sans aucun liquide à l'intérieur de la braisière pour

Ne surchauff ez pas la plaque en acier inoxydable en réglant la température bien au-dessus des températures

BRAISIÈRE dans ce manuel pour plus d'informations.

pourrait entraîner un risque d'incendie. Consultez la section UTILISATIONS SUGGÉRÉES POUR VOTRE

/8 po [0,3 cm] d’épaisseur). Son utilisation pour la friture

1

fi lm d'huile de cuisson ne doit pas dépasser

N'utilisez PAS la braisière comme une friteuse. Utilisez-la uniquement pour la friture peu profonde (le

à cuire.

surface de la braisière ne soit recouverte d'un liquide, d'une fi ne couche d'huile de cuisson ou d'aliments

Pour éviter la décoloration de la surface de cuisson en acier inoxydable, ne chauff ez pas à moins que la

Tournez le bouton du thermostat à la température de cuisson désirée.

à l’horizontale).

braisière ne fonctionnera pas lorsque la braisière est en position HAUTE (5 degrés ou plus par rapport

Abaissez la braisière (voir FONCTIONNEMENT DU SYSTÈME DE LEVAGE dans ce manuel). La

Mettez le bouton Marche/Arrêt à la position de marche.

Les braisières ne nécessitent aucun réglage avant le démarrage.

Utilisation de la braisière électrique

— Pour élever et abaisser la braisière.

Manivelle de levage manuel

l’interrupteur de levage automatique.

braisière. Retirez toujours la manivelle de levage manuel avant d'utiliser

braisière; appuyez sur la partie inférieure du bouton pour abaisser la

— (facultatif). Appuyez sur la partie supérieure du bouton pour élever la

— Lorsqu'il est allumé, indique que le thermostat eff ectue un appel de chaleur.

levage automatique (gris)

Auto. Interrupteur de

Voyant de chauff age (rouge)

Voyant ambré — Lorsqu’allumé, indique que l’appareil est en marche.

Bouton Marche/Arrêt (noir) — Pour mettre en marche ou à l’arrêt la braisière.

Thermostat — Pour régler la température de cuisson désirée.

Commandes (voir fi g. 3)

BRAISIÈRES ÉLECTRIQUES

Page 38

– 11 –

agréé Vulcan local pour eff ectuer ces réglages.

un certain temps, les ressorts peuvent avoir besoin d'être resserrés. Appelez le technicien d’entretien

Le couvercle fonctionne à ressorts et restera dans n'importe quelle position à laquelle il est placé. Après

la cuisson.

d’arrêt. Une fois le courant rétabli, mettez le bouton Marche/Arrêt à la position de marche pour reprendre

débit de gaz. En cas de panne de courant, mettez immédiatement le bouton Marche/Arrêt à la position

En cas de panne de courant, il n'y aura pas de fl ammes car la vanne de régulation combinée arrêtera le

l'huile de cuisson sur la plaque et provoquer un collage.

absorber la chaleur. La surchauff e de la plaque peut provoquer un gauchissement et carboniser toute

recommandées ou en faisant fonctionner la braisière sans aucun liquide à l'intérieur de la braisière pour

Ne surchauff ez pas la plaque en acier inoxydable en réglant la température bien au-dessus des températures

BRAISIÈRE dans ce manuel pour plus d'informations.

pourrait entraîner un risque d'incendie. Consultez la section UTILISATIONS SUGGÉRÉES POUR VOTRE

/8 po [0,3 cm] d’épaisseur). Son utilisation pour la friture

1

fi lm d'huile de cuisson ne doit pas dépasser

N'utilisez PAS la braisière comme une friteuse. Utilisez-la uniquement pour la friture peu profonde (le

braisière ne soit recouverte d'un liquide, d'une fi ne couche d'huile de cuisson ou d'aliments à cuire.

Pour éviter la décoloration de la surface de cuisson en acier inoxydable, ne chauff ez pas à moins que la

désirée pour mettre en marche la braisière.

Mettez le bouton Marche/Arrêt à la position de marche et tournez le bouton du thermostat à la température

L'ouverture complète du conduit de fumée (situé à l'arrière de la braisière) doit être laissée à découvert.

La braisière ne nécessite aucun réglage avant le démarrage.

Utilisation de la braisière à gaz

Mettez le bouton Marche/Arrêt à la position d’arrêt et coupez l'alimentation en gaz.

Arrêt prolongé

Mettez le bouton Marche/Arrêt à la position d’arrêt.

Mise en arrêt la nuit

d’arrêt. Attendez 5 minutes avant de rallumer.

5. Si la veilleuse est éteinte, coupez l’alimentation en gaz et mettez le bouton Marche/Arrêt en position

4. Tournez le bouton du thermostat à la température de cuisson désirée.

voyant ambré allumé sur le panneau de commande.

3. Mettez le bouton Marche/Arrêt à la position de marche. La position de marche est indiquée par le

rapport à l’horizontale).

braisière ne fonctionnera pas lorsque la braisière est en position HAUTE (5 degrés ou plus par

2. Abaissez la braisière (voir FONCTIONNEMENT DU SYSTÈME DE LEVAGE dans ce manuel). La

1. Tournez le robinet d'alimentation principale en gaz de la braisière vers la position ON (marche).

Les instructions d'allumage sont également situées sur le panneau avant.

Allumer et éteindre la veilleuse

Page 39

– 10 –

PL-41750-1

EN OPTION

AUTOMATIQUE

DE LEVAGE

INTERRUPTEUR

— Pour élever et abaisser la braisière.

d'utiliser l’interrupteur de levage automatique.

la braisière. Retirez toujours la manivelle de levage manuel avant

la braisière; appuyez sur la partie inférieure du bouton pour abaisser

— (facultatif). Appuyez sur la partie supérieure du bouton pour élever

chaleur.

— Lorsqu'il est allumé, indique que le thermostat eff ectue un appel de

Fig. 3

VOYANT DE CHAUFFAGE ROUGE

Manivelle de levage manuel

automatique (gris)

Interrupteur de levage

(rouge)

Voyant de chauffage

Voyant ambre — Lorsqu’allumé, indique que l’appareil est en marche.

Bouton Marche/Arrêt (noir) — Pour mettre en marche ou à l’arrêt la braisière.

Thermostat — Pour régler la température de cuisson désirée.

[I] = MARCHE

[O] = ARRÊT

MARCHE/ARRÊT

BOUTON

LEVAGE MANUEL

MANIVELLE DE

AMBRE

VOYANT

THERMOSTAT

Commandes (fi g. 3)

BRAISIÈRES À GAZ

de nettoyant. Rincez bien et videz la braisière. Essuyez la braisière avec un chiff on doux et propre.

de métal sur toutes les parties de la surface et l'intérieur de la braisière. Suivez les instructions du fabricant

Utilisez un nettoyant dégraissant et non corrosif de type commercial pour nettoyer les huiles de protection

AVANT LA PREMIÈRE UTILISATION

nettoyez ou entretenez la braisière.

La braisière et ses pièces sont chaudes. Faites attention lorsque vous utilisez,

A VERTISSEMENT

FONCTIONNEMENT

Page 40

(900 mm)

35,5 po

– 9 –

Fig. 2

(1 168 mm)

46 po

(914 mm)

36 po

PL-56638

16 kW

12 kW

V CA

480

(127 mm)

5 po

16 kW

12 kW

V CA

240

16 kW

12 kW

V CA

208

cuisson 4 oz

VE40

VE30

MODÈLE

(934 mm)

36,761 po

(1 930 mm)

76 po

VE/VG40 39 po x 23 po 40 gal/152 L 1 280

VE/VG30 29 po x 23 po 30 gal/114 L 960

MODÈLE Surface de Capacité Portions

(12,7 mm)

,501 po

(222 mm)

8,75 po

(305 mm)

12 po

(153 mm)

6 po

(355 mm)

14 po

(1 040 mm)

40,75 po

0

6

Non combustible

BTU/h

VG40 120 000

VG30 90 000

MODÈLE Entrée

il n’est pas conçu pour une utilisation domestique.

6. Cet appareil est conçu pour une utilisation commerciale seulement,

Côtés 2

Arrière 6

5. Dégagements : Combustible

Gas Association, 1515 Wilson Blvd., Arlington, VA 22209.

Des exemplaires peuvent être obtenus auprès de l'American

ANSZ223.1A (dernière édition), National Fuel Gas Code.

4. Ces appareils sont fabriqués pour l’installation en conformité avec

mentionnez le nº 96 NFPA.

Quincy, MA 02289. Lors de votre communication à l’écrit,

diamètre; son raccord doit être installé par l’installateur.

RACCORDEMENT ÉLECTRIQUE :conduit de 1 po de

2.

BRAISIÈRE ÉLECTRIQUE :

auprès de la National Fire Protection Association, Batterymarch Park,

de cuisson commercial. Des renseignements peuvent être obtenus

3. Un système de ventilation adéquat est requis pour cet équipement

intérieur doit être d’au moins le même que le tuyau en fer de ¾ po.

de ¾ po ou plus. Si des raccords flexibles sont utilisés, le diamètre

2. Le tuyau de gaz de raccordement à l’appareil doit être de diamètre

est de 11 po CE.

d’alimentation pour le gaz naturel est de 7 po CE et le gaz propane

d’alimentation de 120 V CA, 1 phase, 15 A.

ÉLECTRIQUE :cet appareil est doté d’un cordon

le tableau concernant les capacités.

de 6 à 14 po CE, gaz propane de 11 à 18 po CE, voir

ENTRÉE DE GAZ :raccord de 3/4 po N.P.T., gaz naturel

1.

BRAISIÈRE BASCULANTE À GAZ :

1. Un régulateur de pression pour cet appareil est inclus. La pression

IMPORTANT

BRANCHEMENTS D'ALIMENTATION :

SCHÉMA D’INSTALLATION

Page 41

(kW)

nominale

Puissance

3Ø 1Ø

– 8 –

L1 L2 L3

Courant nominal de ligne (A)

480 19,9 18,0 19,9 - 16

240 39,7 36,1 39,7 66,7 16

208 45,9 41,6 45,9 76,9 16

480 14,4 14,4 14,4 - 12

240 28,9 28,9 28,9 50,0 12

208 33,3 33,3 33,3 57,7 12

V (L-L)

supporter les surtensions prévues.