Page 1

SERVICE MANUAL

HEAVY DUTY GAS BROILER

MODELS

GHCB40 ML-052211

GHCB44 ML-052213

GHMCB44 ML-052214

HCB1 ML-052202

HCB2(B) ML-052208

IR1 ML-052200

IR2(B) ML-052201

GHIR44 ML-052210

GHCB40 SHOWN

– NOTICE –

This Manual is prepared for the use of trained Vulcan Service Technicians and should not be used by those not properly

qualified. If you have attended a Vulcan Service School for this product, you may be qualified to perform all the procedures

described in this manual.

This manual is not intended to be all encompassing. If you have not attended a Vulcan Service School for this product,

you should read, in its entirety, the repair procedure you wish to perform to determine if you have the necessary tools,

instruments and skills required to perform the procedure. Procedures for which you do not have the necessary tools,

instruments and skills should be performed by a trained Vulcan Service Technician.

Reproduction or other use of this Manual, without the express written consent of Vulcan, is prohibited.

For additional information on Vulcan-Hart Company or to locate an authorized

parts and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 35608 (Aug. 2003)

Page 2

TABLE OF CONTENTS

GENERAL ................................................................................................................................................................ 4

Introduction ................................................................................................................................................. 4

Installation and Operation ............................................................................................................................ 4

Cleaning ...................................................................................................................................................... 4

Lighting Pilot ............................................................................................................................................... 4

Data Plate Location ..................................................................................................................................... 4

GHCB40 ............................................................................................................................................... 4

HCB1/2(B) ............................................................................................................................................ 4

GHIR44 ................................................................................................................................................. 4

IR1/2(B) ................................................................................................................................................ 4

Specifications ............................................................................................................................................. 4

Gas Data .............................................................................................................................................. 4

Tools ........................................................................................................................................................... 4

Standard ............................................................................................................................................... 4

IMPORTANT ............................................................................................................................................................ 5

REMOVAL AND REPLACEMENT OF PARTS .......................................................................................................... 6

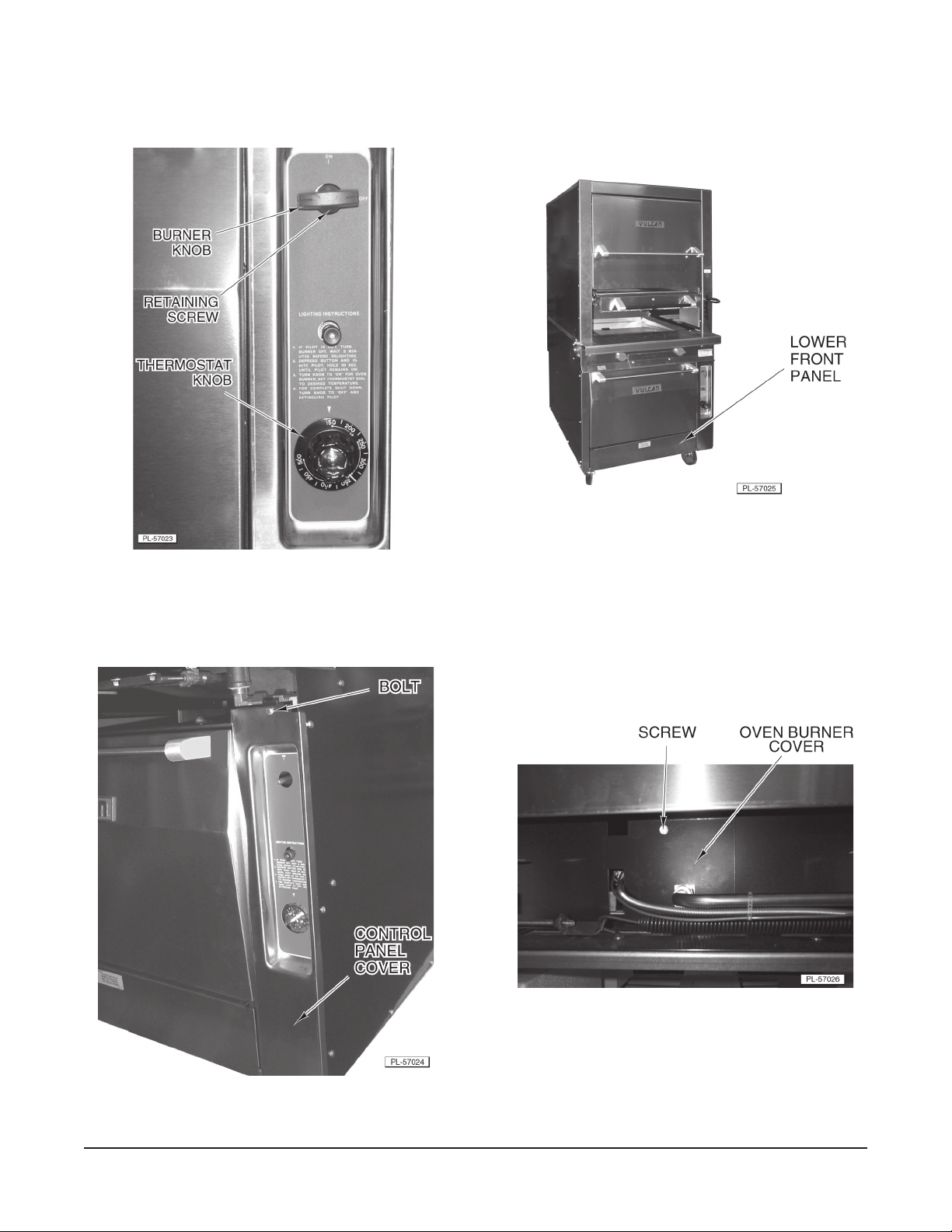

Covers, Panels and Handles ....................................................................................................................... 6

Burner Box Cover (GHCB40, GHCB44, GHIR44) .................................................................................. 6

Burner Shield Cover [HCB2(B), IR1, IR2(B)] ......................................................................................... 6

Manifold Cover Assembly (GHCB40 & GHIR44) ................................................................................... 7

Burner Knob Cover Plate [HCB2(B), IR1 and IR2(B)] ............................................................................ 7

Control Panel Cover (GHCB40) ............................................................................................................. 8

Lower Front Panel (GHCB40) ................................................................................................................ 8

Oven Burner Cover (GHCB40) .............................................................................................................. 8

Oven Bottom Assembly (GHCB40) ...................................................................................................... 9

Augratin Oven Bottom Assembly (GHCB40) ....................................................................................... 10

Oven Door Handle (GHCB40) .............................................................................................................. 10

Broiler Grid Tray (All Models) ..................................................................................................................... 11

Grid Carriage Assembly (All Models) ......................................................................................................... 11

Burner Ceramics (GHCB40) ..................................................................................................................... 12

Burner Assembly ...................................................................................................................................... 13

GHCB40 & HCB2(B) ........................................................................................................................... 13

GHIR44 ............................................................................................................................................... 13

Heat Shield (GHIR44) ................................................................................................................................14

Pilot Elbow Nozzle .................................................................................................................................... 14

Sub-Manifold Assembly ............................................................................................................................ 14

GHCB40 ............................................................................................................................................. 14

GHIR44 ............................................................................................................................................... 15

Burner Sub-Manifold (GHIR44) ................................................................................................................. 15

Pilot Manifold (GHIR44) ............................................................................................................................. 16

Oven Burner Assembly (GHCB40) ............................................................................................................ 17

Pilot Burner Nozzles (GHIR44) ................................................................................................................. 17

– 2 –

Page 3

Gas Valves, Tubing, Thermostats, Regulators and Solenoids .................................................................... 18

Burner Manifold Assembly (GHCB40) ................................................................................................. 18

Burner Manifold Assembly (GHIR44) .................................................................................................. 19

Oven Pilot Valve (GHCB40) .............................................................................................................. 19

Oven Burner Valve (GHCB40) ............................................................................................................ 19

Pilot Outage Protection Valve (GHCB40) ........................................................................................... 20

Thermostat (GHCB40) ....................................................................................................................... 21

Oven Burner Nozzle (GHCB40) .......................................................................................................... 22

Burner Valve [(IR2(B) and HCB2(B)] .................................................................................................... 22

Burner Valve (GHIR44) ........................................................................................................................ 23

Regulator (GHIR44) ............................................................................................................................. 23

Regulator [HCB2(B)] ........................................................................................................................... 24

Solenoid (GHIR44) .............................................................................................................................. 24

Lever Arm Assembly (All Models) ............................................................................................................. 25

Upper .................................................................................................................................................. 25

Lower .................................................................................................................................................. 25

Blower and Motor ...................................................................................................................................... 26

GHIR44 ............................................................................................................................................... 26

IR1 and IR2(B) .................................................................................................................................... 27

Blower Switch (GHIR44) ..................................................................................................................... 27

Light (GHIR44) .................................................................................................................................... 28

SERVICE PROCEDURES AND ADJUSTMENTS .................................................................................................. 28

Gas Supply Checks .................................................................................................................................. 28

Regulator Adjustment (All Models) ............................................................................................................ 28

Pilot Adjustment (All Models) .................................................................................................................... 29

Burner Venturi Air Shutter Adjustment [GHCB40 and HCB2(B)] ................................................................. 29

Burner Service (All Models) ....................................................................................................................... 30

Burner Orifice Service (All Models) ........................................................................................................... 30

TROUBLESHOOTING ............................................................................................................................................ 31

– 3 –

Page 4

GENERAL

INTRODUCTION

This service manual was specially written for the

Heavy Duty Gas Broilers.

INSTALLATION AND OPERATION

Detailed installation and operation instructions are

included in the Installation and Operation Manual

which is sent with each Broiler.

CLEANING

Detailed cleaning instructions are included in the

Installation and Operation Manual for the appropriate

model.

LIGHTING PILOT

Detailed lighting pilot instruction are included in the

Installation and Operation Manual for the appropriate

model.

SPECIFICATIONS

Gas Data

Dimensions No. of Total

Model

Width Depth Height

GHCB40 34” 391/8” 79” 4 100,000

GHCB44 34” 391/8” 79” 4 100,000

GHMCB44 34” 391/8” 57” 4 100,000

HCB1 36” 383/8” 68” 4 50,000

HCB2(B) 36” 383/8”801/2” 4 100,000

IR1 36” 383/8” 69” 4 80,000

IR2(B) 36” 383/8”801/2” 4 160,000

GHIR44 34” 381/4” 82” 4 80,000

Burners BTU

per

Section

/hr

TOOLS

DATA PLATE LOCATION

GHCB40

Behind the oven kick panel riveted to left corner of

the oven burner box. (Removal of the kick panel is

necessary to access plate.)

HCB1/2(B)

Riveted to front right-hand corner of the lower shelf.

GHIR44

Riveted to the door liner behind the left hand door

panel.

IR1/2(B)

Riveted to lower cabinet bottom shelf.

Standard

• Hand tools (standard set)

• Volt-Ohmmeter (VOM) with AC current tester

(any quality VOM with a sensitivity of at least

20,000 ohms per volt can be used).

• Gas test kit

• Temperature tester (thermocouple or digital

pyrometer)

• Temperature tester (thermocouple type).

• Manometer

– 4 –

Page 5

IMPORTANT

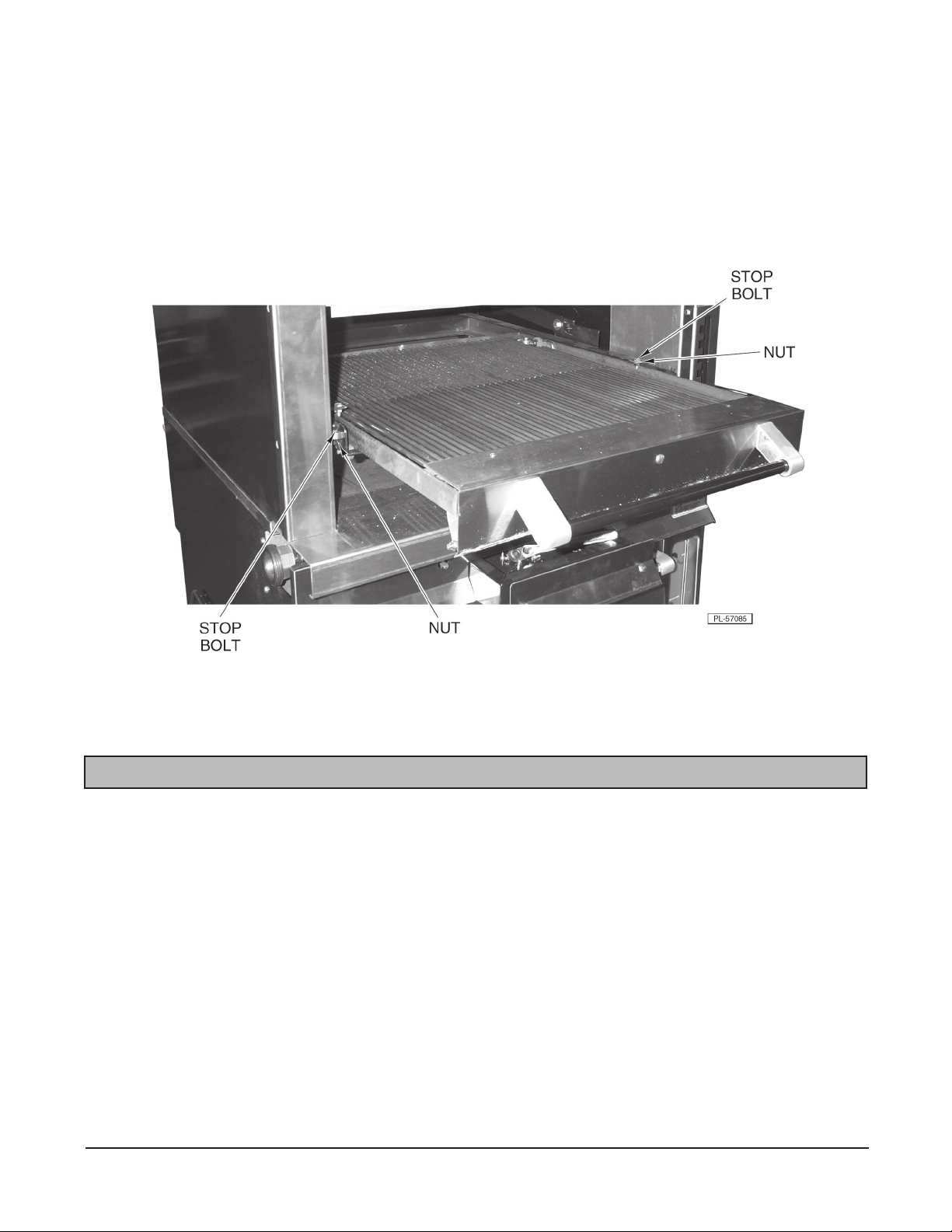

STOP BOLTS MUST BE IN POSITION FOR SAFE OPERATION OF GRID. IF DAMAGED OR MISSING,

REPLACE AT ONCE. DO NOT OPERATE GRID WITHOUT BOLTS.

Two (2) broiler grid 1/4-20 stop bolts and nuts are supplied with each broiler grid to ensure that the grid is not

accidentally pulled completely from the broil section while hot. One (1) stop bolt and nut are mounted to the grid

carriage RT. and LT. HD. side member through a 0.281 diameter hole directly in front of the grid stop tab. The

stop nuts and bolts are screwed tightly against the side members and are properly adjusted extending

approximately 1/2” below the stop tab as shown in the above photo.

– 5 –

Page 6

REMOVAL AND REPLACEMENT OF PARTS

COVERS, PANELS AND HANDLES

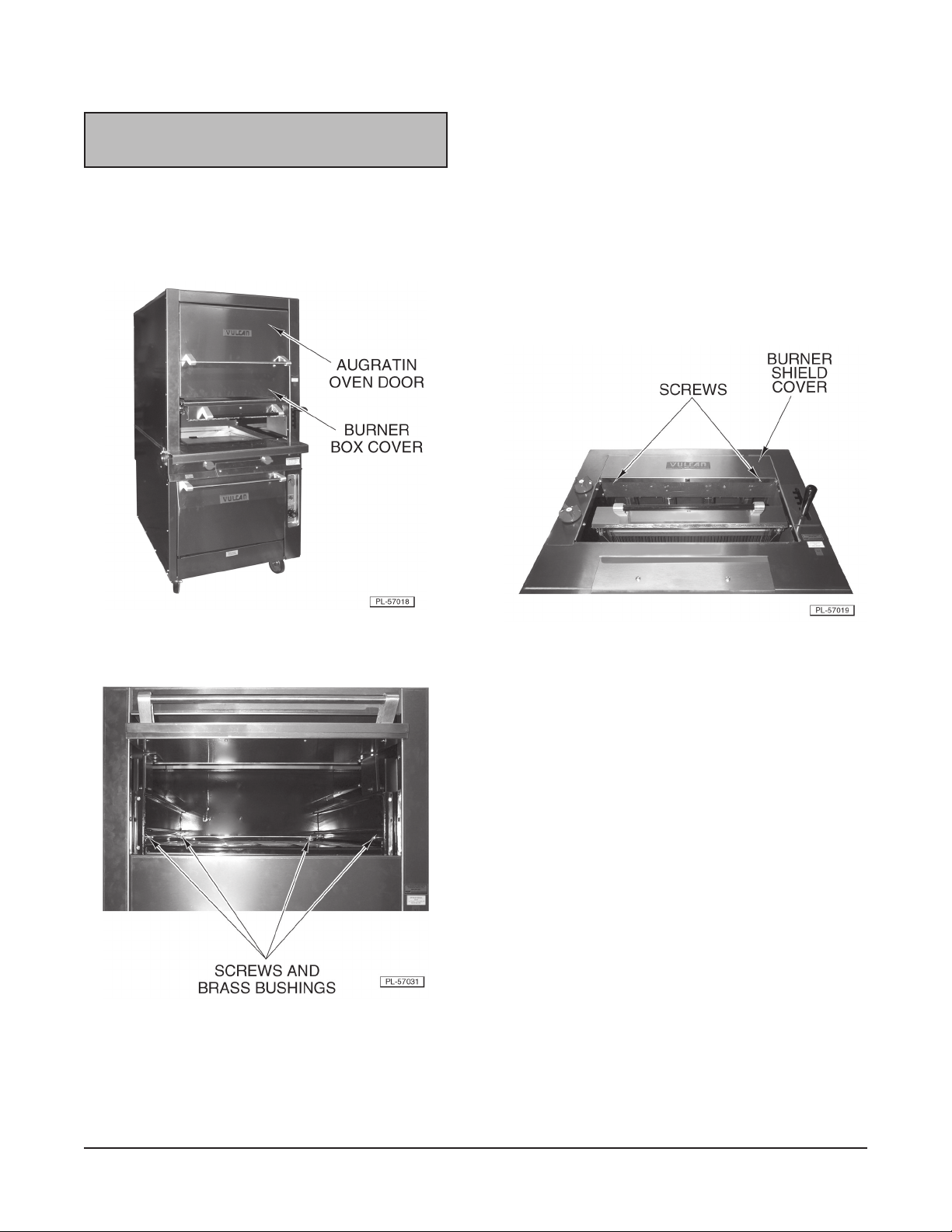

Burner Box Cover (GHCB40, GHCB44, GHIR44)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

5. Lift and remove the burner box cover from the

broiler.

6. Reverse the procedure to install.

Burner Shield Cover [HCB2(B), IR1, IR2(B)]

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

NOTE: The models HCB2(B) and IR2(B) have two

burner shield covers.

1. Open the augratin oven door.

2. Remove the oven rack.

3. Remove the four screws and bushings from

the oven.

4. Remove the augratin oven bottom assembly

as outlined in Augratin Oven Bottom Assembly.

1. Remove the two screws from the burner shield

cover and the broiler.

2. Lift and remove the burner shield cover from

the broiler.

3. Reverse the procedure to install.

– 6 –

Page 7

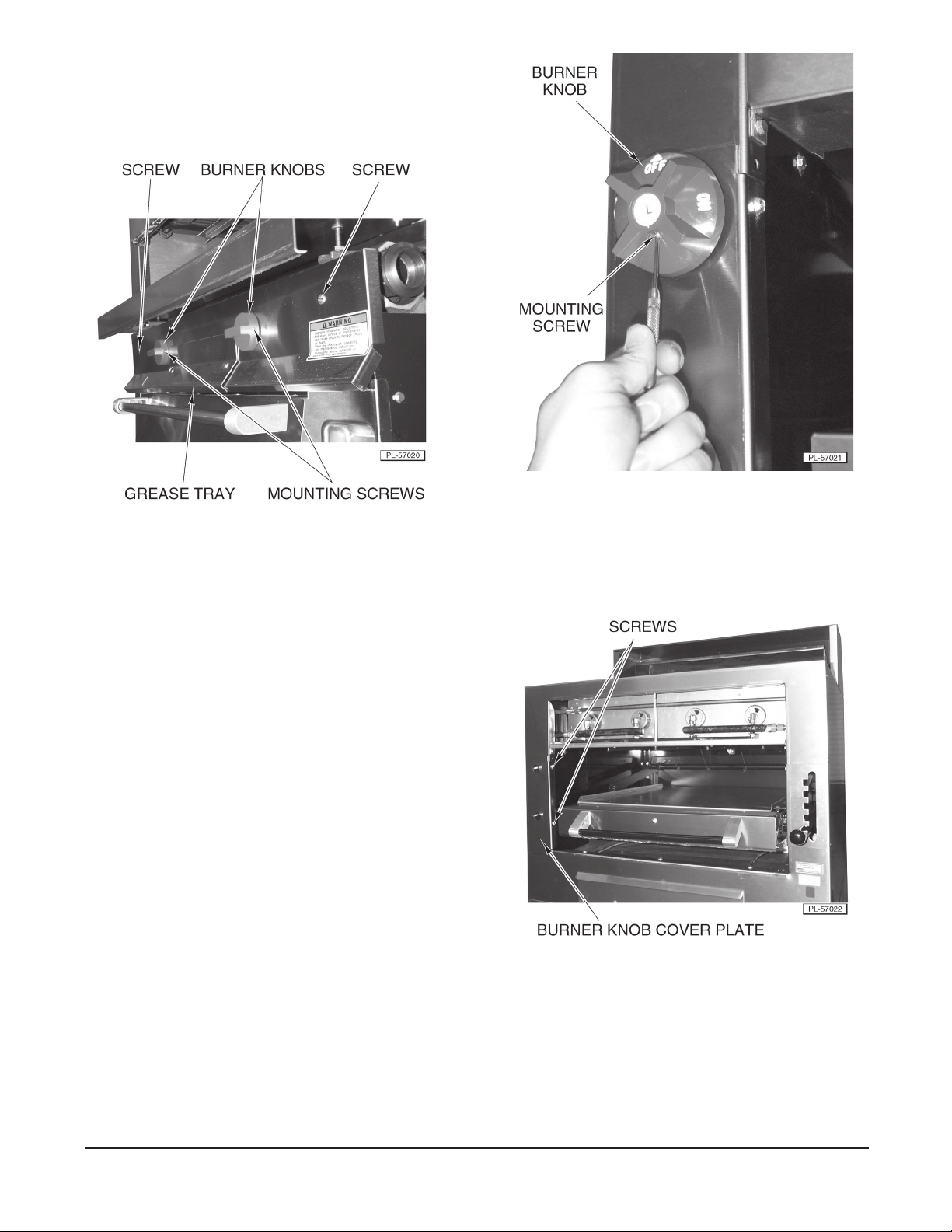

Manifold Cover Assembly (GHCB40 & GHIR44)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

1. Remove the grease tray from the broiler

(GHCB40 only).

NOTE: The GHIR44 manifold cover assembly has

a chain to protect switch wiring.

2. Loosen the mounting screw in each burner

knob.

3. Remove the two burner knobs from the broiler.

4. Remove the two screws from the manifold

cover assembly.

5. Remove the manifold cover assembly from

the broiler.

6. Reverse the procedure to install.

Burner Knob Cover Plate [ HCB2(B), IR1 and IR2(B)]

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

1. Loosen the mounting screw in each burner

knob.

2. Remove the burner knob.

3. Remove two screws from the burner knob

cover plate and the broiler.

– 7 –

4. Slide the burner knob cover plate out and

remove it from the broiler.

5. Reverse the procedure to install.

Page 8

Control Panel Cover (GHCB40)

1. Remove the manifold cover assembly as

outlined in Manifold Cover Assembly.

4. Remove the bolt and the control panel cover

from the broiler.

5. Reverse the procedure to install.

Lower Front Panel (GHCB40)

2. Loosen the retaining screw and remove the

burner knob from the broiler.

3. Pull the thermostat knob to remove it from the

broiler.

1. Grasp the bottom of the lower front panel.

2. Pull the lower front panel out to remove it from

the broiler.

3. Reverse the procedure to install.

Oven Burner Cover (GHCB40)

1. Remove the lower front panel as outlined in

Covers, Panels and Handles.

– 8 –

2. Remove the screw from the oven burner cover.

3. Remove the oven burner cover from the

broiler.

4. Reverse the procedure to install.

Page 9

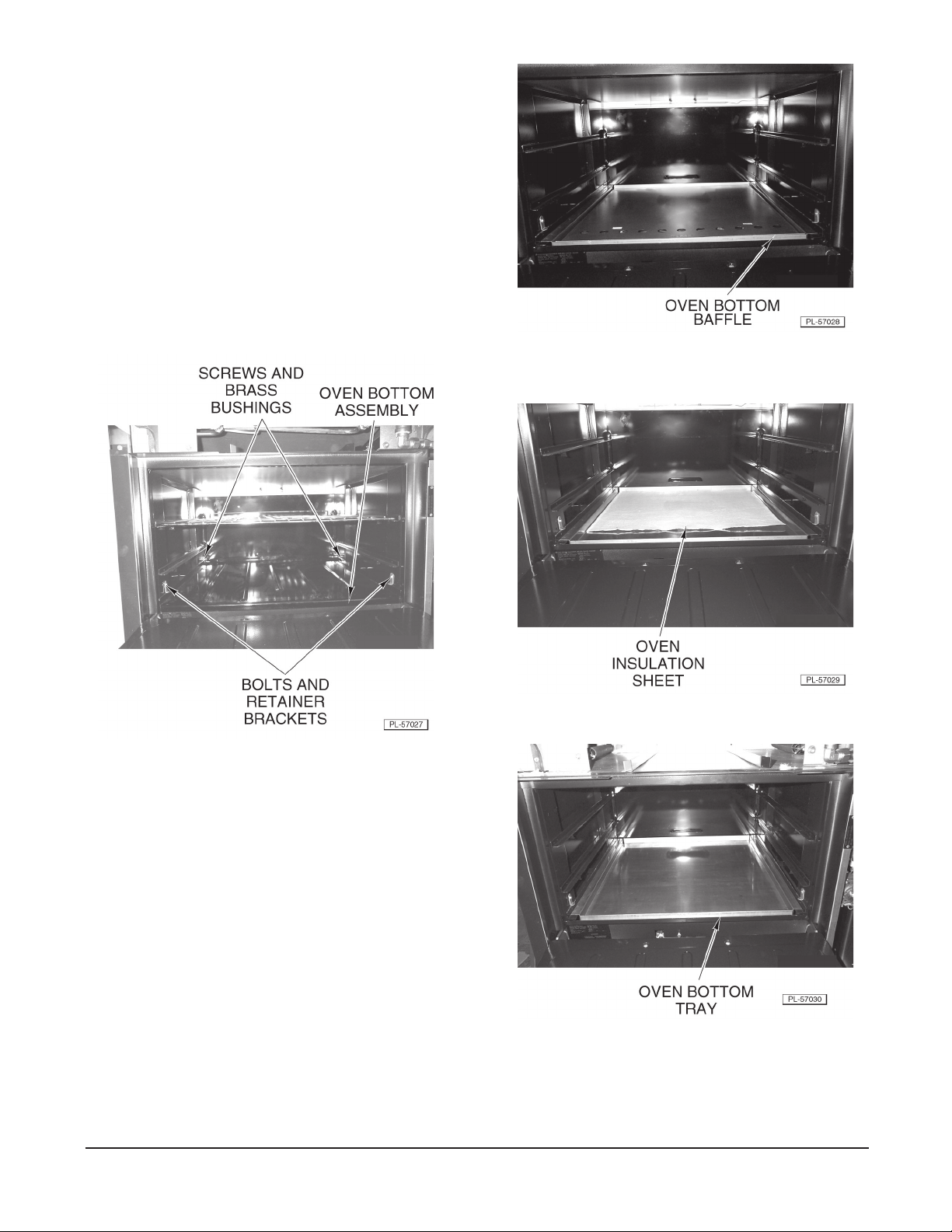

Oven Bottom Assembly (GHCB40)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the lower front panel as outlined in

Covers, Panels and Handles.

2. Open oven door.

3. Remove rack if necessary.

7. Remove the oven bottom baffle from the

broiler.

4. Remove the two screws and brass bushings

from the broiler.

5. Loosen the two bolts on the retainer brackets.

6. Remove the oven bottom assembly from the

broiler.

8. Remove the oven insulation sheet.

9. Remove the oven bottom tray.

10. Reverse the procedure to install.

– 9 –

Page 10

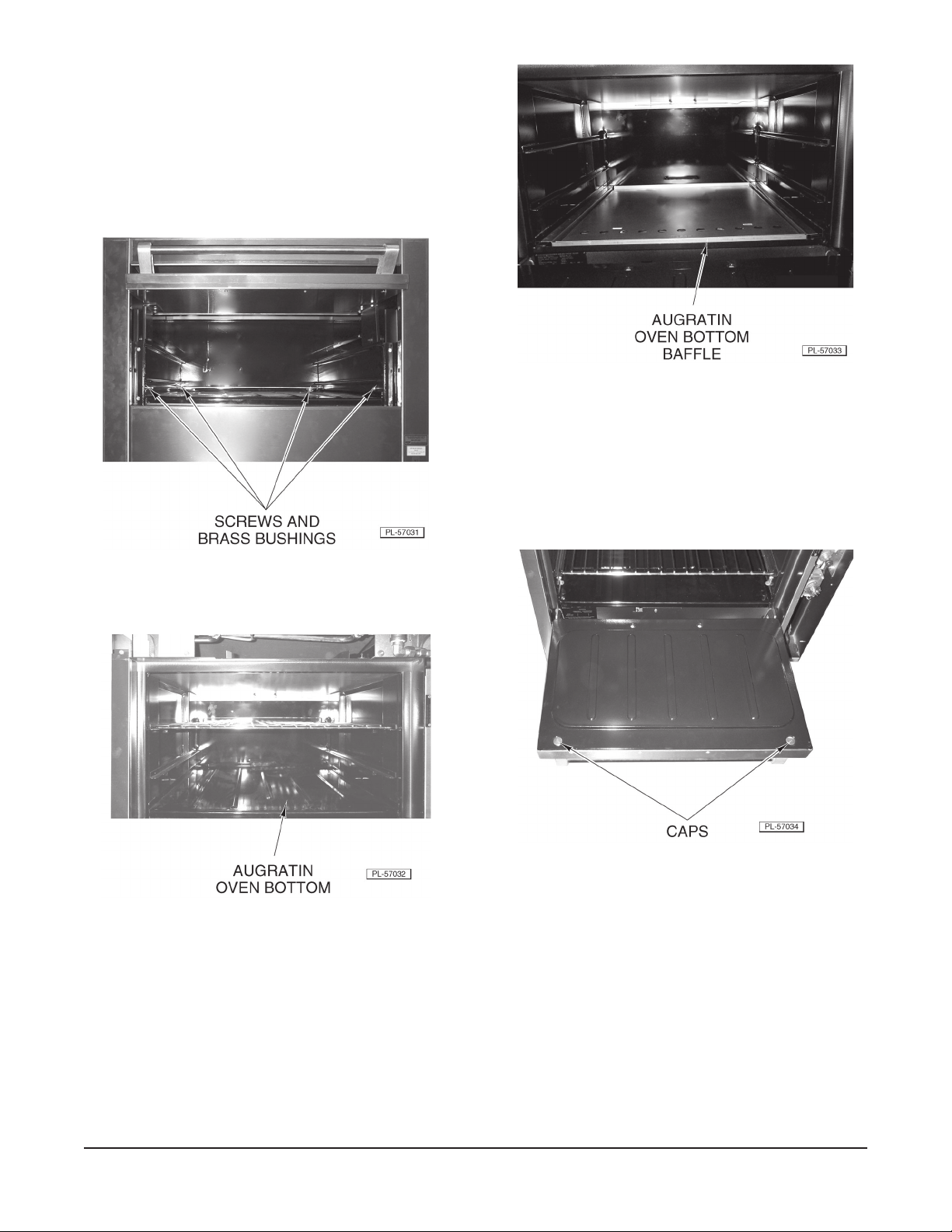

Augratin Oven Bottom Assembly (GHCB40)

WARNING: ALL GAS JOINTS DISTURED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

3. Remove the augratin oven bottom baffle from

the broiler.

4. Reverse the procedure to install.

NOTE: When installing bottom assembly, angle

metal should be at the rear of the oven.

1. Remove the four screws and brass bushings

from the broiler.

2. Slide the augratin oven bottom assembly from

the broiler.

Oven Door Handle (GHCB40)

1. Remove the caps from the oven door.

– 10 –

Page 11

2. Remove two screws and the oven door handle

from the oven door.

3. Reverse the procedure to install.

BROILER GRID TRAY (ALL MODELS)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

GRID CARRIAGE ASSEMBLY

(ALL MODELS)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

WARNING: SPRING AND HOOK BOLT ARE

UNDER TENSION.

1. Remove the broiler grid tray as outlined in

Broiler Grid Tray.

2. Remove cover manifold cover assembly as

outlined in Covers, Panels and Handles.

1. Allow the broiler grids to cool.

2. Remove the two broiler grids from the broiler

grid tray.

3. Carefully remove the two springs from the

threaded hook bolts and the lower lever arm

assembly.

3. Remove two stop bolts and nuts from the

broiler.

4. Carefully pull out the broiler grid tray to remove

it from the grid carriage.

5. Reverse the procedure to install.

– 11 –

Page 12

4. Remove the grid handle from the grid arm

lifting assembly.

5. Remove two bolts, six washers and two nuts

from the grid arm lifting assembly and the grid

carriage assembly.

6. Remove the grid arm lifting assembly from

the grid carriage assembly and the broiler.

BURNER CERAMICS (GHCB40)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

NOTE: Lower broiler pan for easier access.

1. Allow the burner ceramics to cool.

7. Remove the four cotter pins and bolts (two

each side) from the lever arm bracket and

upper and lower lever arm assemblies.

NOTE: When installing grid arm lifting assembly,

install washers between grid arm lifting assembly

and grid carriage assembly.

2. Carefully push up on the side and center

ceramics to remove from the broiler.

3. Reverse the procedure to install.

8. Reverse the procedure to install.

– 12 –

Page 13

BURNER ASSEMBLY

GHCB40 & HCB2(B)

GHIR44

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

1. Remove the burner ceramics as outlined under

Burner Ceramics.

2. Remove burner box cover as outlined in

Controls, Panels and Handles.

1. Allow the burner assembly to cool.

2. Lift the rear of the burner assembly off the

alignment pins.

3. Allow the burner assembly to cool.

4. Lift the rear of the burner assembly and remove

it from the broiler.

CAUTION: Make sure that you do not damage the

pilot nozzle when you remove the burner

assembly.

5. Reverse the procedure to install.

3. Carefully move the burner assembly to the

rear of the broiler and then remove burner

from the broiler.

CAUTION: Make sure that you do not damage the

pilot burner nozzle when you remove the burner

assembly.

4. Reverse the procedure to install.

– 13 –

Page 14

HEAT SHIELD (GHIR44)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

1. Remove burner assemblies as outlined in

Burner Assembly.

4. Remove the pilot elbow nozzle from submanifold assembly.

5. Reverse the procedure to install.

SUB-MANIFOLD ASSEMBLY

2. Remove the cotter pin from the shaft of the

heat shield.

3. Remove the heat shield from the broiler.

4. Reverse the procedure to install.

PILOT ELBOW NOZZLE

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the burner box cover as outlined in

Covers, Panels and Handles.

2. Remove the burner assemblies as outlined in

Burner Assemblies.

GHCB40

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the burner box cover as outlined in

Covers, Panels and Handles.

2. Remove the burner assemblies as outlined in

Burner Assemblies.

3. Remove the pilot elbow nozzles as outlined in

Pilot Elbow Nozzle.

3. Allow the pilot elbow nozzles to cool.

– 14 –

Page 15

4. Disconnect the burner tubing fitting from the

sub-manifold assembly.

5. Loosen the two nuts on the sub-manifold

assembly and the brackets.

6. Remove the sub-manifold assembly from the

broiler.

7. Reverse the procedure to install.

3. Remove the two nuts and washers from the

sub-manifold and the bracket.

4. Disconnect the sub-manifold from the elbow.

5. Remove the sub-manifold from the broiler.

6. Reverse the procedures to install.

BURNER SUB-MANIFOLD (GHIR44)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

NOTE: These procedures apply to the left and right

side burner subassemblies.

1. Remove the burner box cover as outlined in

Covers, Panels and Handles.

2. Remove the burner assemblies as outlined in

Burner Assemblies.

3. Remove the elbow pilot nozzles as outlined in

Pilot & Elbow Nozzle.

GHIR44

1. Remove the manifold cover assembly as

outlined in Covers, Panels and Handles.

2. Disconnect the burner valves from the submanifold as outlined in Burner Valves

(GHIR44).

4. Disconnect the burner tubing fitting from the

burner sub-manifold.

– 15 –

Page 16

5. Loosen the two nuts on the burner submanifold.

6. Remove the burner sub-manifold from the

broiler.

7. Reverse the procedure to install.

PILOT MANIFOLD (GHIR44)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the burner box cover as outlined in

Covers, Panels and Handles.

3. Disconnect the four pilot burner nozzles from

the pilot manifold.

4. Remove the two washers and nuts from the

pilot manifold.

5. Remove the pilot manifold from the broiler.

2. Disconnect the pilot tube from the pilot

manifold.

6. Reverse the procedure to install.

– 16 –

Page 17

OVEN BURNER ASSEMBLY (GHCB40)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the oven bottom assembly as outlined

in Covers, Panels and Handles.

3. Remove the two screws and plate from the

broiler.

2. Lift and remove the oven burner assembly

from the broiler.

3. Reverse the procedure to install.

PILOT BURNER NOZZLES (GHIR44)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the burner box cover as outlined in

Covers, Panels and Handles.

2. Remove the pilot manifold as outlined in Pilot

Manifold.

4. Remove the two screws and the pilot burner

nozzle from the pilot support housing.

5. Remove the pilot burner nozzle from the

broiler.

6. Reverse the procedure to install.

– 17 –

Page 18

GAS VALVES, TUBING,

THERMOSTATS, REGULATORS

AND SOLENOIDS

Burner Manifold Assembly (GHCB40)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the manifold cover assembly as

outlined in Covers, Panels and Handles.

6. Disconnect the oven gas supply tube from the

burner manifold assembly.

NOTE: For proper alignment of the gas tubing,

make sure you do not change the position of the stop

nuts.

2. Disconnect the burner tubing from the burner

valves.

3. Disconnect the pilot supply tubing from the

pilot valve.

4. Remove the two burner valves from the burner

manifold assembly.

5. Remove the pilot valve from the burner

manifold assembly.

7. Remove the two nuts and two washers from

the threaded rod.

8. Hold the burner manifold assembly and

remove the two bolts, manifold holding bracket

and two washers from the broiler.

9. Reverse the procedure to install.

– 18 –

Page 19

Burner Manifold Assembly (GHIR44)

Oven Pilot Valve (GHCB40)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the manifold cover assembly as

outlined in Covers, Panels and Handles.

2. Disconnect the drop pipe from the burner

manifold assembly

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the control panel cover as outlined in

Covers, Panels and Handles.

NOTE: For proper alignment of the gas tubing,

make sure you do not change the position of the stop

nuts.

3. Remove the two nuts and two washers from

the threaded rod.

4. Hold the burner manifold assembly and

remove the two bolts, manifold holding bracket

and two washers from the broiler.

2. Disconnect the pilot tubing from the oven pilot

valve.

3. Remove the oven pilot valve from the gas

supply tube.

4. Reverse the procedure to install.

Oven Burner Valve (GHCB40)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the control panel cover as outlined in

Covers, Panels and Handles.

5. Reverse the procedure to install.

– 19 –

Page 20

2. Disconnect the oven burner valve from the

oven gas supply tube and the union.

3. Reverse the procedure to install.

Pilot Outage Protection Valve (GHCB40)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the control panel cover as outlined in

Covers, Panels and Handles.

2. Remove the lower front panel as outlined in

Covers, Panels and Handles.

3. Disconnect the pilot valve tubing from the pilot

outage protection valve.

4. Remove the oven bottom assembly as outlined

in Covers, Panels and Handles.

5. Loosen the b-nut and remove the ignitor wire

from the bracket.

– 20 –

Page 21

6. Remove the two bolts from the pilot outage

protection valve and the bracket.

7. Disconnect the pilot outage protection valve

from the union and the thermostat.

8. Remove the pilot outage protection valve and

the ignitor wire from the broiler.

9. Reverse the procedure to install.

Thermostat (GHCB40)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

3. Disconnect the thermostat from the pilot

outage protection valve and from the oven

burner tubing.

1. Remove the control panel cover as outlined in

Covers, Panels and Handles.

2. Note the location and position of the

temperature probe in the oven.

4. Remove the temperature probe from the oven.

5. Remove the thermostat with the temperature

probe from the broiler.

6. Reverse the procedure to install.

– 21 –

Page 22

Oven Burner Nozzle (GHCB40)

Burner Valve [(IR2(B) and HCB2(B)]

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the oven burner cover as outlined in

Covers, Panels and Handles.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the burner knob cover plate as

outlined in Covers, Panels and Handles.

2. Disconnect the oven burner tubing from the

oven burner nozzle.

3. Remove the oven burner nozzle from the

bracket.

4. Remove the oven burner nozzle from the

broiler.

5. Reverse procedure to install.

2. Disconnect the burner valve from the elbow

and the burner tubing.

3. Reverse the procedure to install.

– 22 –

Page 23

Burner Valve (GHIR44)

Regulator (GHIR44)

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the manifold cover assembly as

outlined in Covers, Panels and Handles.

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Open the lower doors to gain access to the

regulator.

2. Disconnect the burner tubing from the burner

valve.

3. Disconnect the burner valve from the submanifold.

4. Remove the burner valve from the broiler.

5. Reverse the procedure to install.

2. Disconnect the regulator from the pipe elbow

and the solenoid.

3. Remove the regulator from the broiler.

4. Reverse the procedure to install.

– 23 –

Page 24

Regulator [HCB2(B)]

Solenoid (GHIR44)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Disconnect the gas supply tube and the burner

tube.

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Open the lower doors to get access to the

solenoid.

2. Remove the regulator from the broiler.

3. Reverse the procedure to install.

2. Note the location and connection of the

electrical wires.

3. Disconnect the electrical wires.

4. Disconnect the solenoid from the burner pipe

and the regulator.

5. Remove the solenoid from the broiler.

6. Reverse the procedure to install.

– 24 –

Page 25

LEVER ARM ASSEMBLY

(ALL MODELS)

Upper

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the grid carriage assembly as

outlined in Grid Carriage Assembly.

Lower

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove the grid carriage assembly as

outlined in Grid Carriage Assembly.

2. Remove the two cotter pins and washers from

the upper lever arm assembly.

3. Remove the upper lever arm assembly from

the two brackets.

4. Reverse the procedure to install.

2. Remove two screws and the lower lever cover

from the broiler.

– 25 –

Page 26

3. Remove the two cotter pins and washers from

the lower lever arm assembly.

4. Remove the lower lever arm assembly from

the two brackets.

5. Reverse the procedure to install.

BLOWER AND MOTOR

GHIR44

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

2. Remove the four screws from the bracket and

blower and motor.

3. Move the bracket away from the blower and

motor.

4. Remove the four screws and nuts from the air

duct and the blower and motor.

1. Open the lower doors to get access to the

blower and motor.

5. Carefully remove the six screws from the

blower and motor and the brackets.

6. Remove the air duct from the broiler.

7. Note the location and connection of the

electrical wires.

– 26 –

Page 27

8. Disconnect the electrical wires.

9. Remove the blower and motor from the broiler.

10. Reverse the procedure to install.

Blower Switch (GHIR44)

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

1. Remove the manifold cover assembly as

outlined in Covers, Panels and Handles.

IR1 and IR2(B)

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

1. Remove the screws and the bracket and the

blower and motor.

2. Remove the screws and nuts from the air duct

and the blower and motor.

3. Carefully remove the screws from the blower

and motor and the brackets.

4. Carefully remove the air duct from the blower

and motor.

5. Note the location and connection of the

electrical wires.

6. Disconnect the electrical wires from the blower

and motor.

7. Remove the blower and motor from the broiler.

8. Reverse the procedure to install.

2. Remove the nut from the manifold cover

assembly and the switch.

3. Note the location and connection of the

electrical wires.

4. Disconnect the electrical wires.

5. Reverse the procedures to install.

– 27 –

Page 28

Light (GHIR44)

WARNING: DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

1. Remove the manifold cover assembly as

outlined in Covers, Panels and Handles.

2. Note the location and connection of the

electrical wires.

3. Disconnect the electrical wires from the light.

4. Reverse the procedure to install.

SERVICE PROCEDURES AND ADJUSTMENTS

GAS SUPPLY CHECKS

If the gas supply piping is to be tested at a test pressure in excess of 1/2 psi (3.45 kPa), the appliance and its

individual shutoff valve must be disconnected from the supply line. If the gas supply piping is to be tested at a

pressure equal to or less than 1/2 psi (3.45 kPa), the individual shutoff valve must be closed during testing.

REGULATOR ADJUSTMENT

(ALL MODELS)

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

Accurate gas pressure adjustment can only be made

with the gas on and the burner lit. In addition the

supply line pressure to the broiler must be at least

1.0” W.C. greater than what is stated on the broiler

unit rating plate.

Regulators are preadjusted for natural or propane gas

as specified on the broiler rating plate.

3. Light all burners and take a reading.

4. Light all the gas appliances on the same

supply line and take a reading.

A. At no time should the pressure drop more

than 1/2” W.C. A large pressure drop

could be an indication that the gas supply

line is too small or a blockage. Check

supply line pressure to ensure that it is at

least 1.0” greater than the specified

operating pressure of the broiler. Check

with the gas provider for the proper size

gas line.

1. Connect the manometer to the main gas

manifold pipe of the broiler. Turn on gas.

2. Light one burner and take a reading.

– 28 –

Page 29

PILOT ADJUSTMENT

(ALL MODELS)

1. Light the pilot as outlined under Lighting Pilot

in the Installation and Operation manual for

the appropriate model.

2. Locate the pilot adjustment screw on the

supply end of pilot manifold pipe.

3. With a flat blade screwdriver, turn the pilot

adjustment screw counterclockwise to

increase or clockwise to decrease gas flow.

The flame should only be high enough to

ignite the burner in less than 4 seconds.

BURNER VENTURI AIR SHUTTER

ADJUSTMENT

[GHCB40 AND HCB2(B)]

4. Turn the burner on . If the flame is soft, lazy or

yellow, there is not enough primary air and

the air shutter needs to be opened up. If the

flame is lifting off the burner, there is too

much primary air and the air shutter needs to

be closed down.

The gas burners have a disk type air shutter. The disk

type is used on cast iron burners. All burners are

tested and the air shutters are set at the factory prior

to shipment. However, fine tuning adjustments may

be necessary.

When using natural gas, the air shutter will be

approximately 50% open. On propane (LP), the air

shutter will be approximately 90% open.

1. For GHCB40 remove the burner box cover as

outlined under Covers, Panels and Handles

in Removal and Replacement of Parts Section

of this manual.

2. For HCB2(B) remove the burner box cover as

outlined under Covers, Panels and Handles in

Removal and Replacement of Parts Section of

this manual.

3. Loosen the air shutter adjustment screw.

5. Rotate the air shutter so that a blue flame

without any yellow tipping is seen across the

burner.

6. Once the proper adjustment is made, carefully

tighten the adjustment screw without moving

the air adjuster.

7. Install front covers when complete.

– 29 –

Page 30

BURNER SERVICE (ALL MODELS)

WARNING: SHUT OFF THE GAS BEFORE SERVICING THE OVEN.

If the burner ports become obstructed or the burner cracks, the burner will not operate properly.

1. Remove burner(s) as outlined under Burner Assemblies Section of this manual.

2. Check burner(s) for:

A. Obstruction in port holes.

1) Soak the burner(s) in warm, soapy water. If this does not solve the problem, the obstruction may

be removed by carefully inserting, by hand, the proper size drill bit. If severe clogging or damage

is evident, replace the burner(s).

B. Cracks in burner body.

1) Burner must be replaced.

BURNER ORIFICE SERVICE (ALL MODELS)

WARNING: SHUT OFF THE GAS BEFORE SERVICING.

1. Remove the burner associated with the orifice to be serviced as outlined under Burner Assemblies.

2. Remove the orifice tip and check for obstructions or damage.

3. Soak the orifice(s) in warm, soapy water. If this does not solve the problem, the obstructions may be

removed by carefully inserting, by hand, the proper size drill bit. If severe clogging or damage is evident,

replace the orifice(s).

4. Reverse the procedure to install.

– 30 –

Page 31

TROUBLESHOOTING

SYMPTOMS POSSIBLE CAUSES

Uneven heating, sides burning. A) Temperature too low.

B) Improper operation of broiler.

C) Fluctuating gas pressure.

Too much top heat. A) Temperature too high.

B) Faulty ventilation.

C) Excessive heat input.

D) Gas pressure too high or orifice too large.

Uneven heat front to back. A) Appliance not level front to back.

Dried out products. A) Broiling time too long or product too close to the burner.

B) Gas pressure too high or orifice too large.

Pilot outage. A) Pilot flame too low.

B) Restriction in pilot orifice.

Pilot will not light. A) Insufficient gas input.

B) Poor air to gas adjustment.

C) Restriction in pilot orifice.

D) Restriction in main burner port.

E) Pilot adjustment incorrect.

– 31 –

Page 32

FORM 35608 (Aug. 2003) PRINTED IN U.S.A.

– 32 –

Loading...

Loading...