Page 1

SERVICE MANUAL

VHX BOILER BASE SERIES

HIGH EFFI CIENCY GAS

STEAMERS

VHX24G ML-114795

VHX24G5 ML-126590

MHB24G ML-114954 (BASE ONLY)

VHX24G SHOWN

This Manual is prepared for th e use of trained Vulcan Service

Technicians and should not be used by those not properly

qu alif ied. If yo u have attend ed a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this man ual.

Thi s manu al i s no t i nten ded to be al l en comp assi ng . I f you have

not attende d a Vulcan S ervic e School for this produ ct , you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e n ecessary too ls, in strument s and skills should be

performed b y a trained Vu lcan Service Technician .

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

- NOTICE -

A product of VULCAN-HART LOUISVILLE , KY 40201-0696

F24700 (October 2001)

Page 2

VHX SERIES STEAMERS

TABLE OF CONTENTS

GENERAL............................................................................. 4

Installation......................................................................... 4

Maintenance ....................................................................... 4

Cleaning .......................................................................... 4

Introduction ........................................................................ 4

Steam Cooking.................................................................. 4

Compartment Pan Capacity ........................................................ 4

Model Designations .............................................................. 4

Boiler Code Descr iptions .......................................................... 4

Boiler Control Styles.............................................................. 5

Water Conditi oning .................................................................. 6

Specifications ...................................................................... 6

Water Supply ................................................................... 6

Electrical ...................................................................... 6

Boiler Pressure.................................................................. 6

Gas Supply ..................................................................... 7

Tools ............................................................................. 7

STEAMER OPERATION.................................................................. 8

Cabinet Base Boiler .................................................................. 8

Cooking Compartment Controls......................................................... 8

Boiler Blowdown and Steamer Shut off ................................................... 9

Component Func tion ................................................................ 10

Cabinet Base Boiler Controls ...................................................... 10

Cooking Compartment Controls .................................................... 12

REMOVAL AND REPLACEMENT OF PARTS ................................................ 13

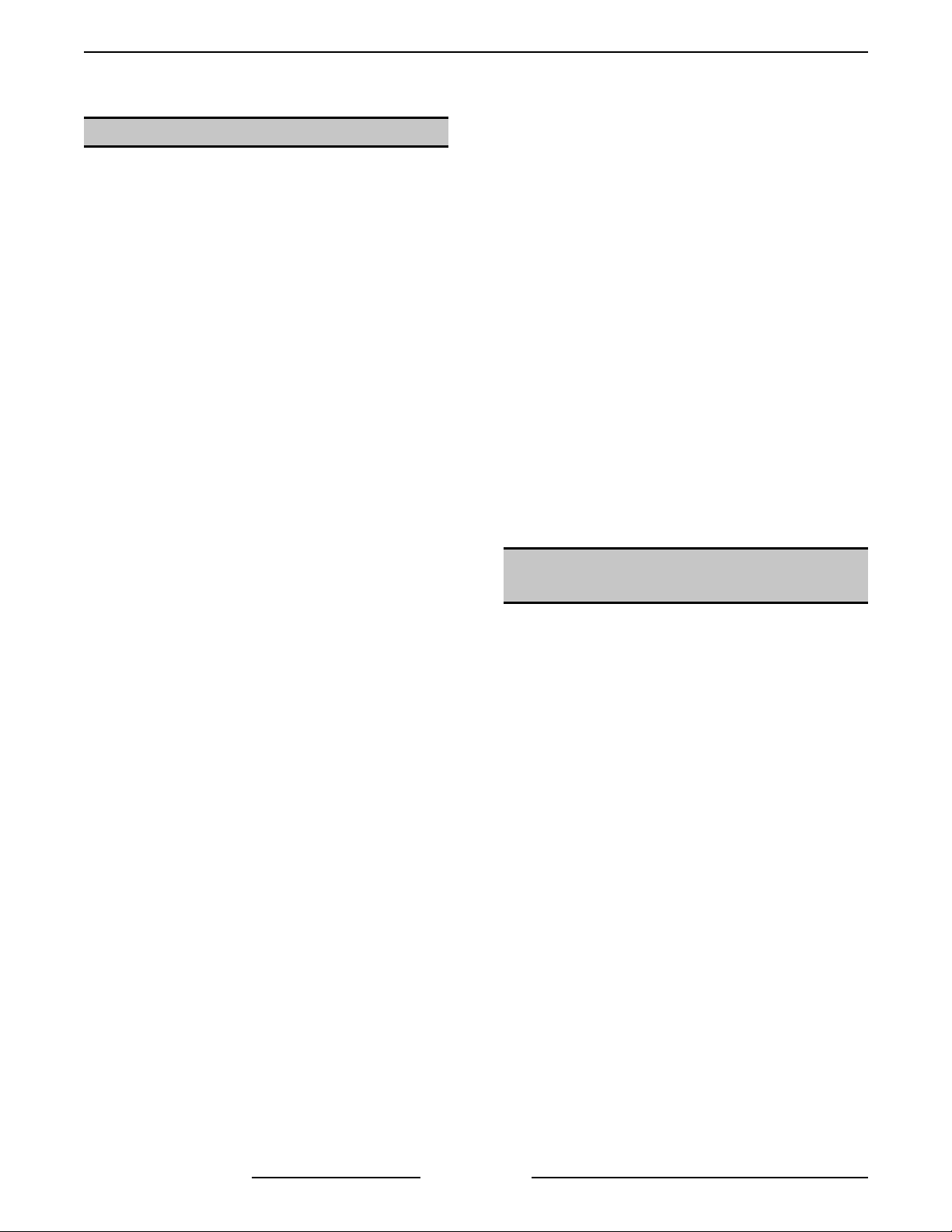

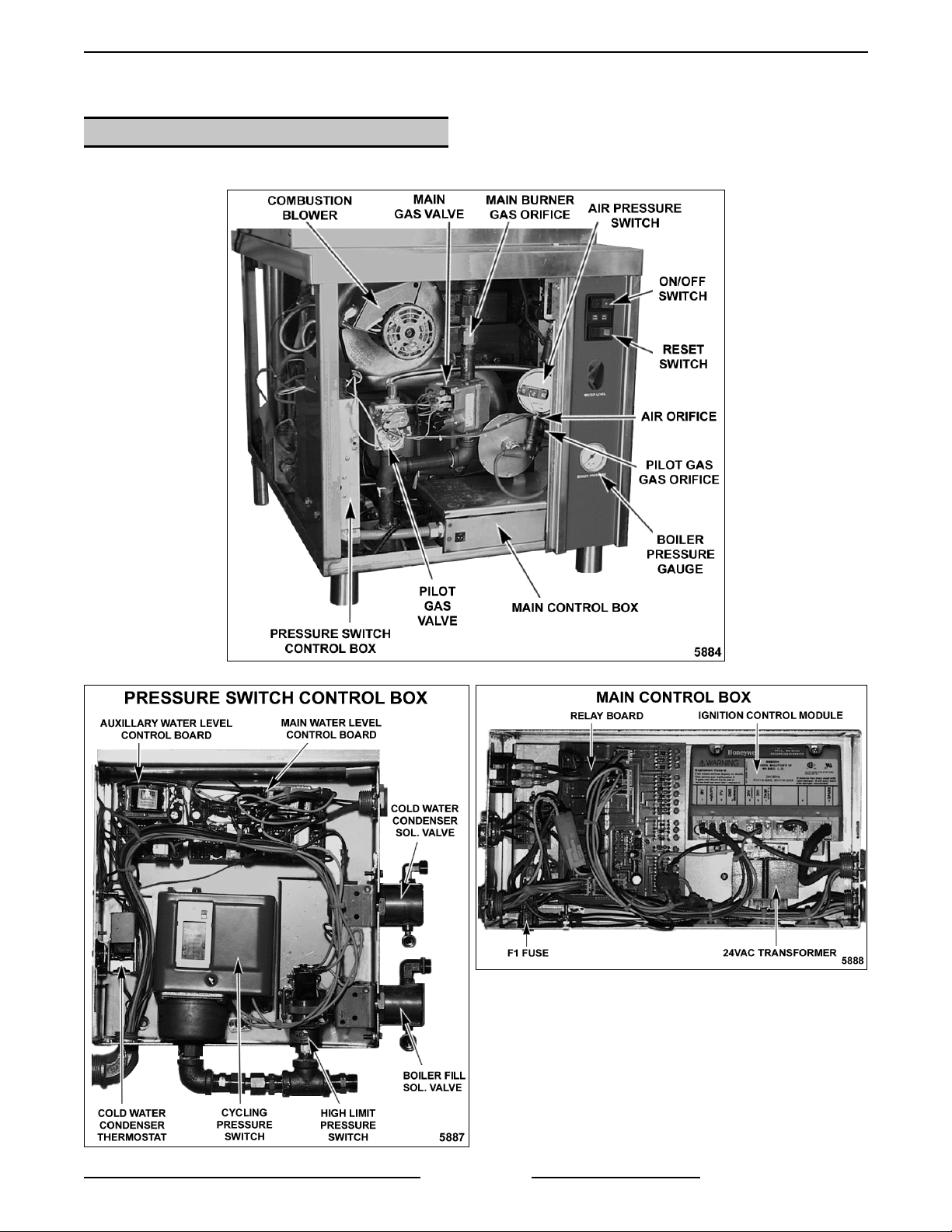

Component Locat ions ............................................................... 13

Cabinet Base Boiler Controls ...................................................... 13

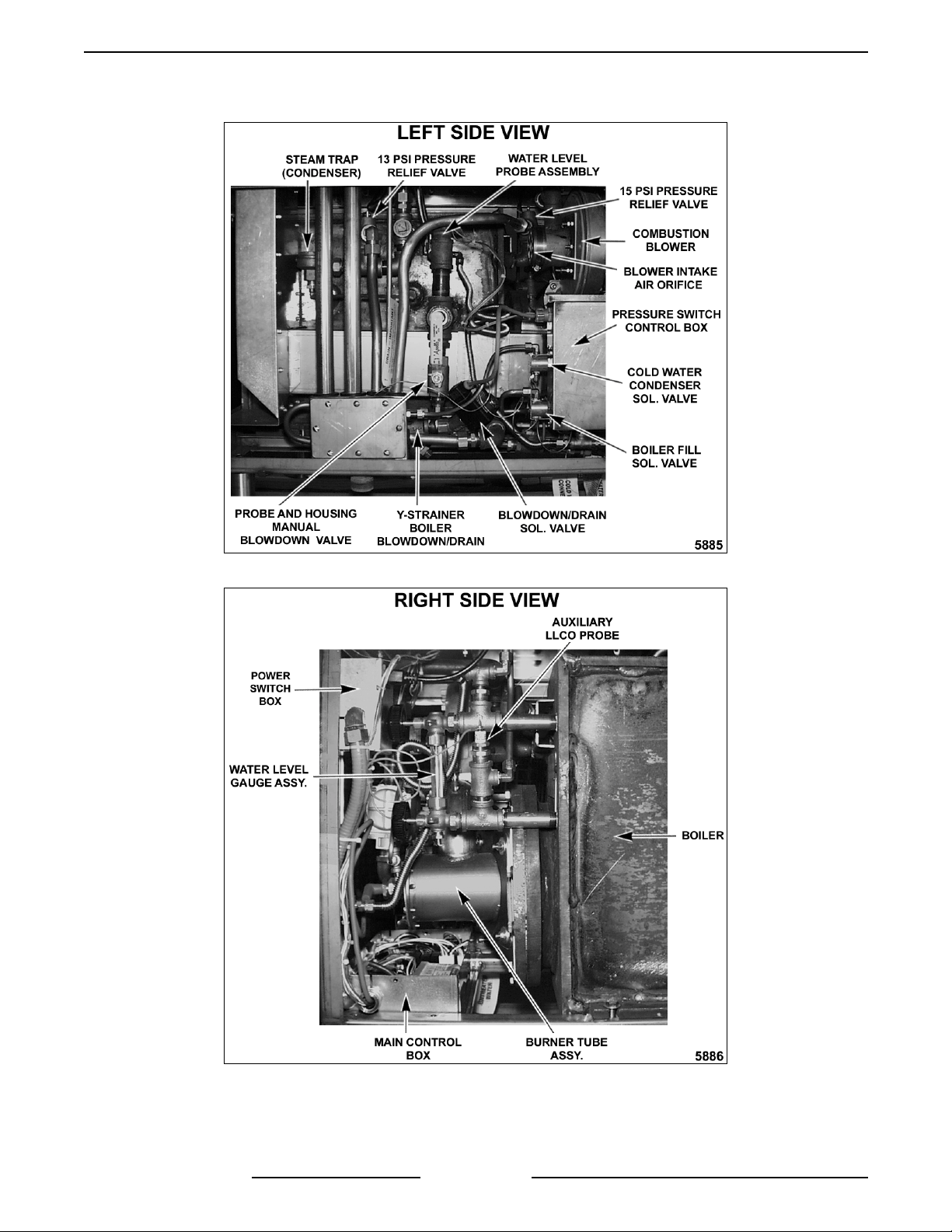

Cooking Compartment Controls .................................................... 15

Water Level Controls

(Main or Auxiliary LLCO) ......................................................... 15

Relay Board....................................................................... 15

Water Level Gauge Assembly ......................................................... 16

Pressure Switches .................................................................. 16

Boiler Assembly.................................................................... 16

Boiler Fill and Cold Water Condenser Solenoi d V alves ...................................... 17

Pilot Gas Valve .................................................................... 17

Main Gas Valve.................................................................... 17

Burner Head Assembly .............................................................. 18

Complete Burner Assembly ........................................................... 18

Heat Exchanger .................................................................... 19

Cooking Compartment Door(s)......................................................... 21

SERVICE PROCEDURES AND ADJUSTMENTS .............................................. 23

Boiler............................................................................ 23

Inspection..................................................................... 23

Clean-Out ..................................................................... 23

Deliming...................................................................... 23

Descaler (Cathodic Protector ) ...................................................... 24

Water Level Probe Housing Blowdown .................................................. 24

Water Level Controls Test ............................................................ 25

Pressure Switches .................................................................. 27

Fill and Cold W ater Solenoid V alves .................................................... 28

Boiler Blowdown/drain Solenoid Valve .................................................. 29

Inline Water S trainer Cleaning ......................................................... 29

Main Burner Ignition Checks .......................................................... 30

F24700 (October 2001) Page 2 of 68

Page 3

VHX SERIES STEAMERS

Air Pressure Switch Adjustment........................................................ 33

Gas Pilot Pressure Adjustment......................................................... 34

Gas Manifold Pressure Adjustment ..................................................... 36

Ignition Control Module Checks ........................................................ 37

Cooking Compartment............................................................... 39

Intake Shut-Off Valve Adjustment (Steam Flow)........................................ 39

Door Sealing Adjustment ......................................................... 39

Door Latch Adjustment........................................................... 40

ELECTRICAL OPERATION .............................................................. 41

Water Level Controls................................................................ 41

Low Level Cut-Off & Differential Control.............................................. 41

Auxiliary Low Level Cut-Off ....................................................... 42

Relay Board....................................................................... 43

Board Layout and LED Legend ..................................................... 43

Boiler Operational Status (LED Indicator) ............................................. 44

Sequence of O per ation .............................................................. 46

New Style Controls - Boiler........................................................ 46

Old Style Controls - Boiler ........................................................ 48

Cooking Compartment Controls .................................................... 50

Schematics ....................................................................... 52

Models Built After 5/25/00 (New Style Boiler Controls) ................................... 52

Models Built Befor e 5/25/00 (Old S tyle Boiler Controls) .................................. 54

Cooking Compartment Controls .................................................... 55

Wiring Diagrams ................................................................... 56

Models Built After 5/25/00 (New Style Boiler Controls) ................................... 56

Models Built Befor e 5/25/00 (Old S tyle Boiler Controls) .................................. 58

Cooking Compartment Controls .................................................... 60

TROUBLESHOOTING .................................................................. 61

CONDENSED SPARE PARTS LIST ........................................................ 68

© VULCAN 2001

F24700 (October 2001)Page 3 of 68

Page 4

VHX SERIES STEAMERS - GENERAL

GENERAL

INSTALLATION

Refer to the Installation and Operation Manual for

detailed installation instructions.

MAINTENANCE

Refer to the Installation and Operation Manual for

specific maintenance instruct ions.

CLEANING

Refer to the Installation and Operation Manual for

specific cleani ng instructions.

INTRODUCTION

Steam Cooking

Convection cooking in pressure-less steaming

compartments will steam cook fresh foods or will

steam def rost and cook froz en foods prov iding the

maximum c olor, flav or and nutritional value with the

least expenditure of energy and labor. T he pr essureless steaming compartm ents on the VHX series

allows the operator to open and close the door,

anytim e during a cooking cycle. T he steam supply

will shut off when the door is opened, then re-start

when the door is closed.

Compartment P an Capacity

PAN

DEPTH

(INCHES)

MODEL

VHX24G

NUMBER OF PANS

PER COMPARTMENT

24.0

32.5

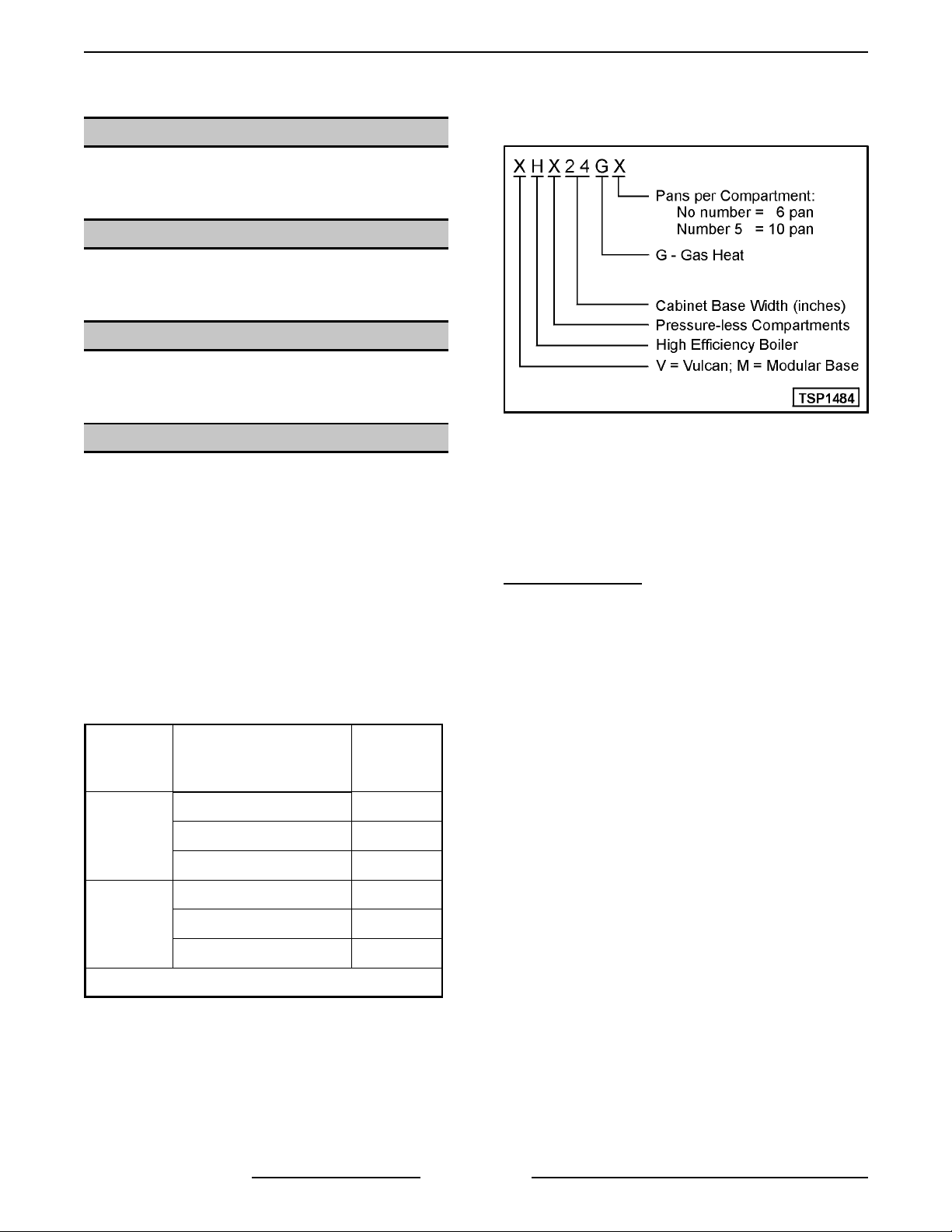

Model Desi gnations

Boiler Code Descriptio ns

Vulcan-Hart incorporates redundant c ontrols in

compliance with the CSD-1 controls and safet y

devices for boiler construction on these High

Efficienc y S team models. A Description of the c ode

is listed below.

CSD-1 Constructi on

electrical safety circuits that, i f tri pped, must

manually be reset after the condit ion causing the trip

subsides. These controls consist of - (1) dual

function water level cycling and low level cut off

control and ( 1) si ngle funct ion low water level cut-off

control ( A ux LLCO) and a high pr essure rel ief switch

in conjunction with a mechanical pr essure rel ief

valve. A dditional ly, both circuits have indi vidual

indicat or lights for low water and high pressure that

will illuminate for a visual verification of the

shutdown mode.

CSD-1 construction requires operator intervention i n

the ev ent of a shutdown. The i ndicator l ights show

the operator which safety system was shutdown.

- Redundant controls in the

61.0

34.0

VHX24G5

Pan Size 12" x 20"

F24700 (October 2001) Page 4 of 68

52.5

10 1.0

Page 5

VHX SERIES STEAMERS - GENERAL

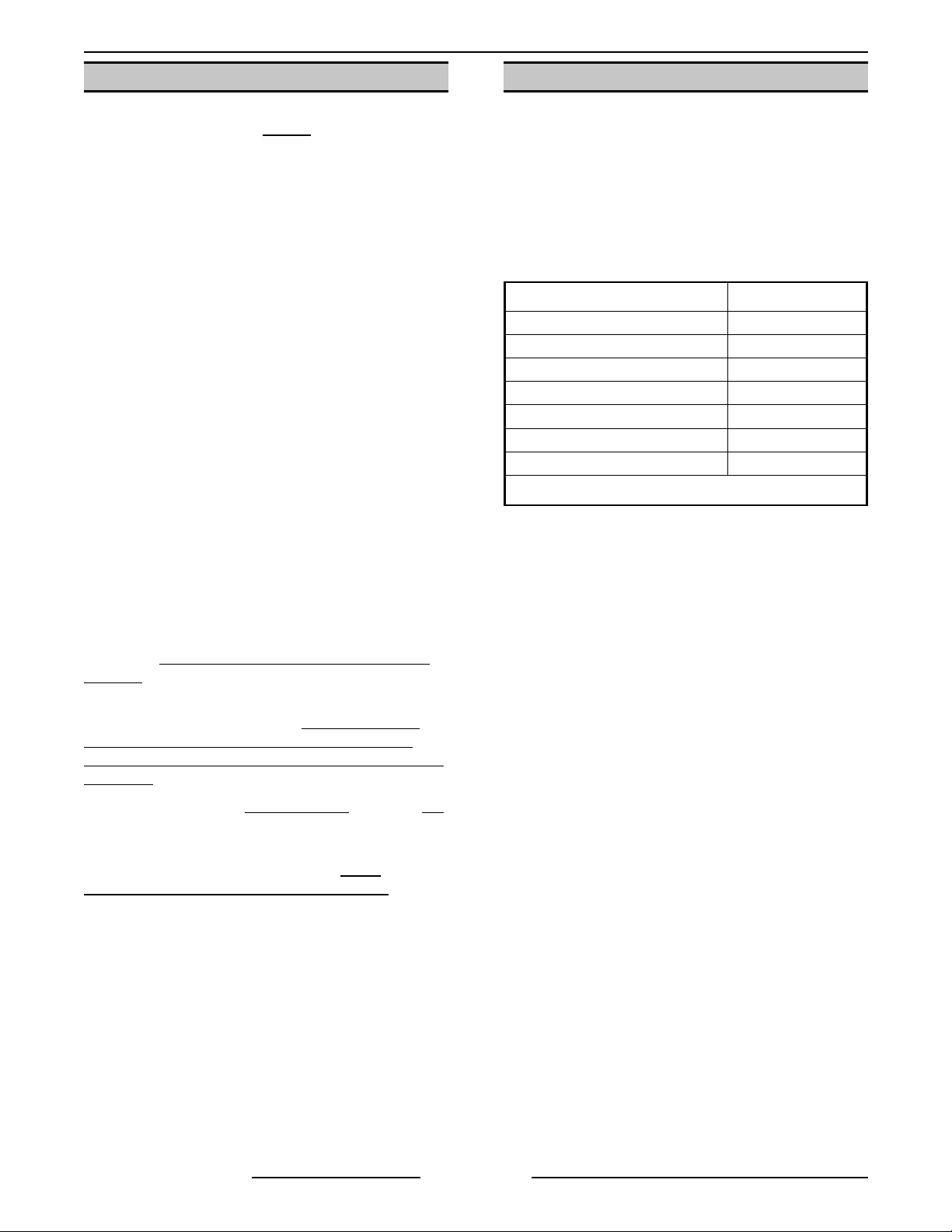

Boiler Control Styles

VHX Steamers manufactur ed usi ng the old style boiler controls ended on 5/19/00. Steamers that were in stock at

the time of the boiler contr ol changeov er were removed and equipped with the new style c ontrols without

recording t he serial number for track ing.

Refer to the pictures bel ow to differentiate between the old style and new style boiler controls.

F24700 (October 2001)Page 5 of 68

Page 6

VHX SERIES STEAMERS - GENERAL

WATER CONDITIONING

Furnishing the boiler wit h treated water to reduce

scale formation is import ant. Scale format ion will

reduce steam out put, cause prematur e c omponent

failure, and shorten equi pment life. Most water

supplies contai n scale producing m inerals such as

Calcium and Magnesium. As steam is generated,

the mi nerals remai n and dissolve into the water. As

the concentrat ion of these minerals i nc r eases past a

certain point, they pr ec ipitate from the water and

coat the inside of the boi ler, heating element s, and

water level sensors. Because of the high

temperat ure of these surf ac es, the precipitated

minerals bake onto them and bec ome v er y difficult

to remove.

This may c ause several probl ems:

1. Reduced heat transf er eff iciency.

2. Premature heating element failures.

3. False readings from water l evel sensors.

These problem s are common to any manufacturer's

steamer regardless of design, but t hey c an all be

minimized by furnishing the boiler with treated

water.

Other factors affecting steam generati on ar e iron

content, amount of c hlorination and dissolved

gases.

SPECIFICATIONS

Water Supply

The fact that a water supply is potable is no

guarantee that it is suitable for steam generation.

The supply connect ion to the steam gener ator

should be “treated” water and must be within t he

guideli nes listed below. For dr ain water cooling only,

an “untreated“ water suppl y c onnec tion should be

used.

Supply pressure should be 20-60 psig

In line strainer f or suppl y line (Not Supplied)

Supply connection cold

Total dissolved solids (TDS)* less than 60 ppm

Total alkalinity less than 20 ppm

Silica less than 13 ppm

Chloride less than 30 ppm

PH fact or 7 to 8

(*17.1 ppm = 1 grain of har dness)

Electrical

Voltage - 120/ 60/1

Amps - 3.0 (max)

The desired water propert ies can best be achieved

by using a

system.

The water level probes in the boiler use ions i n the

water to detect the water level.

demineralized or de-ionized water since it is

"non conductive" and the water level can not be

detected.

The use of strainers or

remove mi nerals from the water.

Water supplies vary fr om state to state and from

locati ons wit hin a state. Therefore, a

treatment specialist should be consulted

the installation of any steam generating equipment.

Steamers that operate over a long peri od of time

without the benefit of a water treatment system,

which have developed a heavy scale build up,

should be cleaned before using the system.

properly maintained water treatment

Do not use fully

non approved

filters will not

water

before

Boiler Pressu re

Operating - 8 to 10 psi

Maximum - 15 psi

F24700 (October 2001) Page 6 of 68

Page 7

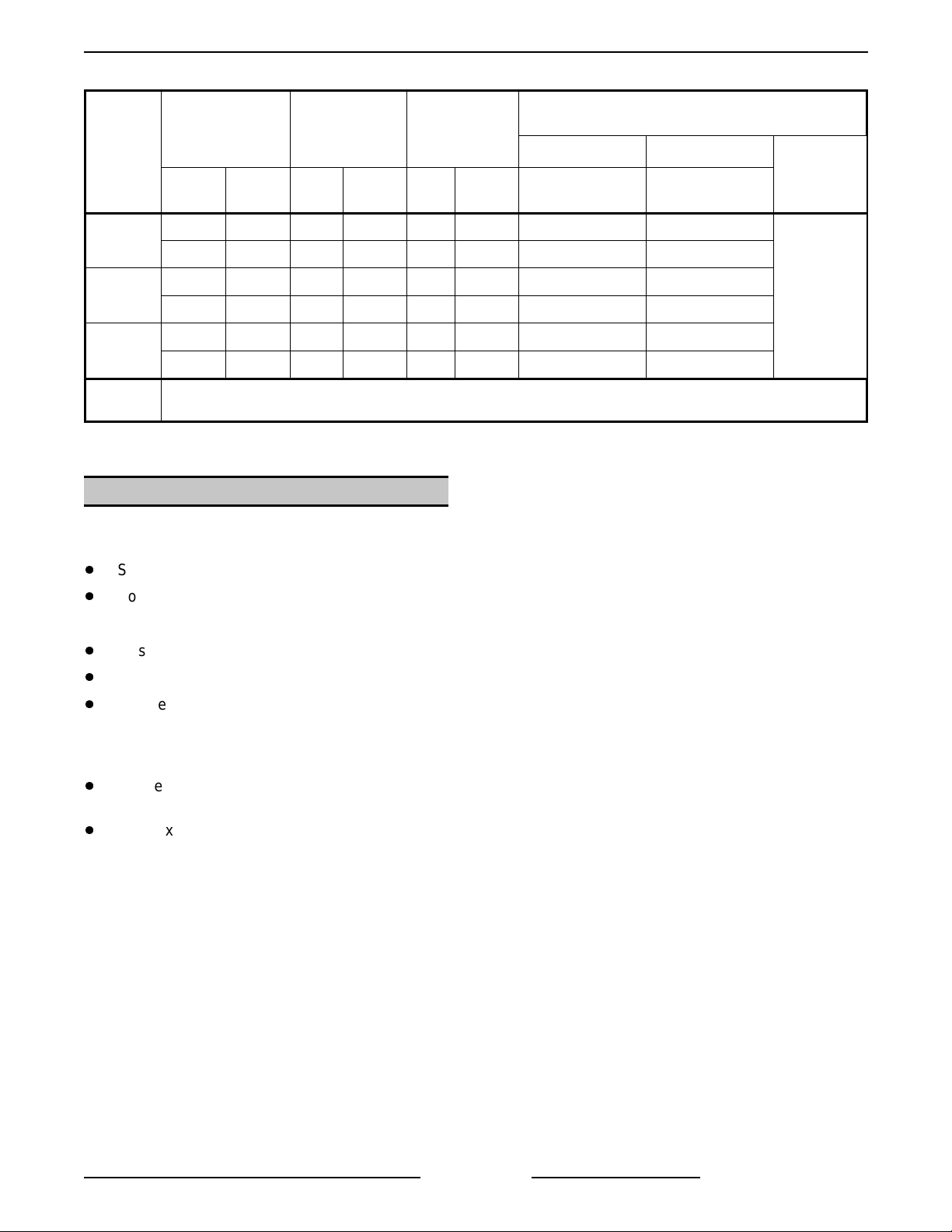

Gas Supply

VHX SERIES STEAMERS - GENERAL

MODEL

VHX24G

VHX24G5

MHB24G

NOTE

Standard

INPUT

(BTU/HR)

NAT. PROP. NAT. PROP. NAT. PROP.

200,000 200,000 3.0 3.0 3.5 3.5 7.0 11.0

270,000 270,000 3.0 3.0 3.5 3.5 7.0 11.0

200,000 200,000 3.0 3.0 3.5 3.5 7.0 11.0

270,000 270,000 3.0 3.0 3.5 3.5 7.0 11.0

200,000 200,000 3.0 3.0 3.5 3.5 7.0 11.0

270,000 270,000 3.0 3.0 3.5 3.5 7.0 11.0

1. Output Boiler Horsepower (BHP): 4.3 BHP for 200,000 BTU; 5.5 BHP for 270,000 BTU.

:

2. Input BTU/HR difference is based on gas orifice size and air orifi c e size.

MANIFOLD

PRESSURE

(INCHES W.C. )

PILOT

PRESSURE

(INCHES W.C. )

NATURAL PROPANE

MINIMUM

RECOMMENDED

LINE PRESSURE

(INCHES W.C. )

RECOMMENDED

TOOLS

MINIMUM

MAXIMUM

ALLOWED

14.0

Standard set of hand tools.

Volt-Ohm-Meter (VOM) with AC current tester.

(Any quality VOM wit h a sensit ivity of at least 20,000 ohm s per volt c an be used)

Gas leak checking equipment.

Gas pressure manomet er

Temperat ure meter and t her mocouple.

Special

The recommended deli ming chemical for the water treatment system in use, for deliming of the boiler.

Contact Vul c an A uthorized Service Centers.

Heat Exchanger Gasket (joi nt sealant strip, Teflon) P /N 854058-1.

F24700 (October 2001)Page 7 of 68

Page 8

VHX SERIES STEAMERS - OPERATION

STEAMER OPERATION

CABINET BASE BOILER

Ensure that all utility connections to the steamer

have been made and are turned ON and t hat the

knob on the main gas valve is i n the ON positi on.

The VHX Series steam er s are CSD- 1 c ompliant and

are equipped with amber colored lights on the boiler

control panel for Hi gh P ressure and Low Water level

that illuminate and stay on until the boiler is full and

the manual reset switch pressed.

1. Turn power switch ON.

A. Amber colored lights on the boiler control

panel for High Pressure and Low Water

level will illuminate. and stay on until t he

boiler is full and the reset switch is

pressed.

B. Water will begin filling the boiler and the

blowdown solenoid v alve will close. The

boiler shoul d fill, in four to eleven minutes.

C. As water fills the boiler, observe water

level gauge glass to verify that water i s i n

boiler. See "WATER LEVEL GAUGE

ASSEMBLY" in "COMPONENT

FUNCTION” and COMPONENT

LOCATION “ under "REMOVAL AND

REPLACEMENT OF PARTS".

D. Onc e the water in the boiler reaches the

minimum level, the green ready light on

the boiler control panel will illuminate.

NOTE: If the fill has stopped, one visible inc h

of water should be in the gauge glass.

2. Press the reset switch on the boiler control

panel.

A. Low water level safety circuit will be reset

and the Low Wat er lev el light (amber) will

turn off.

B. High pressure safety circuit will be reset

and the High Pressure light (amber ) will

turn off.

C. Sparking will begin three seconds later to

light the pilot bur ner.

1) I f the pilot burner lights, a signal is

sent back through the igniti on c able

indicat ing the presence of pilot burner

flame and sparking stops.

2) I f pil ot burner flame is not

established immedi ately, sparki ng will

continue for 90 seconds. After that

duration, the ignition control module

will lock out and needs to be reset to

start the pilot and main burner li ghting

cycle again.

New Style Controls

Pilot gas valve operates on a "timer"

circuit allowing gas flow to the pilot

for approximately 15 seconds, during

ignition trial, then turns off.

D. Main gas valve opens, burner ignites and

begins to heat the water in the boil er . After

approximately 15 minutes, steam should

be present for c ook ing product. O bserve

that the boi ler pressure gauge indicates a

steam pressure of 8- 10 psi before the

burner shuts OFF.

3. The cycling pressure switch will maintain steam

pressure in the boiler by cycling the main

burner ON and OF F.

- Power to the

COOKING COMPARTMENT

CONTROLS

When the steam pressure in the c ook ing

compartment manifol d reaches approximately 3 psi,

the cooking compartment pressure switch closes,

suppling power to the ot her c ook ing compart ment

controls. The ready lights will illuminate and after

approximately one minute, the steam pressure in

the boiler will reach the upper limit of 10 psi. If the

pressure drops below approximately 3 psi, the

pressure switch will open, removing power fr om the

controls.

NOTE:

immediatel y after t he ready light c omes on, steam

solenoid chattering will be heard (oil canning) and

the ready lights will flash for several seconds. This

conditi on is caused by the mani fold steam pressure

being on the “fringe” of the pressure switch set point.

When a c ook timer is set, the compar tment steam

solenoid valve opens causing the manifold st eam

pressure to drop, slightly below the pressure switch

set point. At the same time, steam pressure is still

increasing in the boiler . This opposing condition

causes a pressure “bounce” to occur. After the

steam pressure passes approxim ately 4 psi this

conditi on subsides. Dur ing normal oper ation, this

conditi on will not be seen.

On initial startup, if a cooking ti mer is set

F24700 (October 2001) Page 8 of 68

Page 9

VHX SERIES STEAMERS - OPERATION

1. With both timer knobs at the off posi tion, open

the compartment doors and observe that no

steam has entered the c ook ing compart ments,

then close the doors.

2. Set both timer knobs at 2 minutes. The r eady

lights will go off, the cooking lights will come

on, and steam will begin to enter the

compartments.

3. After one minute, open eac h door and observe

that steam has ceased to enter each

compartment, cooking lights go back to ready,

and one minut e is remaining on each cook

timer.

4. Close doors and steam generation and cook

timing will resume. Observe the floor drain to

ensure that live steam from compart ments is

being cooled by cold water fr om the cold water

condenser solenoid valve.

5. When timer k nobs reac h " 0" , buzzers will

sound, steam generation will cease, cooking

lights will go off and ready lights will come on.

To silence buz z er s, turn timer knobs to off

position.

BOILER BLOWDOWN AND

STEAMER SHUT OF F

Turn the steamer off at least once daily to bl owdown

the boiler. This will aid in the removal of sediment

and scale buil d- up in the boil er .

NOTE

: Boil er should be with-in normal operating

pressures.

1. Turn power switch OFF .

2. Boiler blowdown sequence starts.

A. The blowdown/drain solenoid valve will be

de-energized and t he boiler will begin to

drain.

B. The cold water condenser solenoid will

operate, as needed, to condense steam

and to cool the water going into the dr ain.

6. During idle t ime or a cooking cycle, the heating

system will cycle on and off as necessary to

maint ain steam pressure in t he boiler.

7. Turn power switch off to remove power from

the steamer.

A. Boiler blowdown starts.

F24700 (October 2001)Page 9 of 68

Page 10

VHX SERIES STE A M E RS - COMPONENT FUNCTION

COMPONENT FUNCTION

CABINET BASE BOILER CONTROLS

Power Switch (ON/OFF)

Reset Switch (Manual)

Boiler Fill Solenoid Valve

Cold Water Condenser

Solenoid Valve

Blowdown/Drain

Solenoid Valve

Cycling P ressure Switch

High Limit Pressure Sw itch

................. Allows cold water flow into the boiler blowdown drain box to condense

................. A normally open valve (N.O.) that closes to allow boiler to fill and

......... When turned ON, supplies power to the control cir c uit.

.......... Resets the low water level safety circuit on initial startup or the

......... Controls boiler pressure between prescribed limits by turning the heat

occurrence of a low water condition and allows the boil er to fill with

water. Also, resets the high pressure lev el safety circuit on initial startup

or the occurrenc e of a high pressure condition and all ows the gas

ignition cycle to start.

........ Admits water to the boiler when dem anded by the water level control to

maintain the correct water level in the boiler.

steam and cool the hot water befor e its discharge int o the drain.

pressurize when power switch is turned ON and opens when power

switch is turned off to blowdown and drain the boiler. This valve is

plumbed into the drain line of the boiler.

source on and off.

...... Protects the boiler from pressures above 15 psi by removing power from

the heating ci rcuit. Thi s pressure setting is higher than the cycling

pressure switch in order to t ur n off the heat source before the boiler

pressure reaches its limit. A fter the pr essure drops below approximat ely

12psi, press the rest switch of the front control panel to rest the safety

circuit.

Main Water Level Control

Auxiliary Water Level Control

Transformer

Ignition Control Module

Main Gas Valve

Pilot Gas Valve

................... Provides 24VAC power to ignition control modul e and heating circ uit.

................ A gas solenoid valve that opens to allow gas flow to the main burner

................ A gas solenoid valve that opens to allow gas flow to the pilot to ignite the

........ A dual functioning control that allows water to fill and maintain the

......... Controls and m onitors gas heating. E ner gizes pilot valve coi l to supply

proper level in the boiler pr oviding dif ferenti al water level control; and

shuts off the main gas valve if the water level drops too low providing

low level cut-off protection. The water level control works by using three

different probe lengths to moni tor the water level. The probes consist of

a high level (HL) , low level (LL) and low water cut- off ( LLCO).

..... A back up to the low level cut-off on the main control. Protects the boiler

and heating system c omponents from a low water cut-off condition by

opening the 24VAC volt age path to the heati ng system circuit. Al so,

energizes the l ow water "l ight" on the front contr ol panel.

gas to pilot, generates spark to ignite gas at the pilot, monitors the

presence of flame and energizes the main and pilot valve coi ls on the

main gas valve upon a call for heat.

after the successful ignition of the pil ot burner when a call for heat is

made.

main burner when a call f or heat is made. T he valve is energized by a

tim e delay circ uit on the rel ay boar d dur ing ignit ion trial for

approximately 15 seconds. New styl e c ontrols only.

Combustion Blower

F24700 (October 2001) Page 10 of 68

............ Provides forced air to the gas/air mixture for gas pilot and m ain burner

combustion.

Page 11

VHX SERIES STE A M E RS - COMPONENT FUNCTION

Relay Board

................... Provides a centralized location for wire harness connections and power

transfer through board relays (K1-K 7) to the steamer controls. Also,

provides a condition or component t r oubleshooting indicator by utilizing

seventeen LED’S on the board to represent the status of the condi tion or

component in the operation sequence. For an LED legend, see "RELA Y

BOARD" under "E LE CTRICAL OPERATION". New style c ontrols only.

: The relay’s below are mounted on the relay board and are not

NOTE

K1 Relay

...................... Energized when Aux LLCO is satisfied and turns ready light ( gr een) ON

if high limit pressure switch i s closed. Also, K1 allows K3 to be energized

when the reset switch is pressed.

K2 Relay

...................... Energized when high li mit pressure switch is closed (high limit pressure

conditi on sat isfied). When K 1 & K 2 ar e ener gized, the ready light (green)

will be ON.

K3 Relay

...................... When Aux LLCO is satisfied and the m anual reset switch is activat ed,

K3 is energized. When K 3 is energized, tur ns water error light OFF and

allows the ignition sequence to begi n. K3 must be energi z ed for ignition

sequence to begin.

K4 Relay

...................... Energized when K2 contacts are closed and manual reset switch is

activated. When K4 i s energized, the high pressure light is OFF. When

K3 and K4 are both energized, power to the ignition system is supplied.

K5 Relay

...................... Energized when operating conditions are m et and reset switch is

activated. Pr ovides power to start combustion blower.

individual ly replaceable.

K6 Relay

...................... Energized by time delay circuit for approx imately 15 seconds. When K 6

and K7 are energized, power is supplied to the pilot gas valve.

K7 Relay

...................... Energized when pilot voltage (PV) f r om the ignition module is present.

Also used in the time delay c ircuit.

......................... Ignites to light the main burner upon a call f or heat.

Pilot

Main Burner

................... Heats the water in the boiler to gener ate steam.

Water Level

Gauge Assembly

............... Permits a visual confirmation the water level is being maintained in

boiler dur ing operation. The correct water l evel is approximately one

visible inch in the glass. The manual valves at the top and bott om of this

assembly m ust be full y open and only closed if the glass tube is

damaged.

Water Inlet Valve (manual)

....... The water inlet valve is used to stop water flow to the steamer when the

steamer i s bei ng serviced. This valve should remai n open dur ing normal

operation.

Inline Water Strainer

............ A "Y" strainer is installed upstream of the blowdown solenoid valve to

prevent forei gn matter from becoming lodged in the valve. A strainer

(not supplied) shoul d also be installed in the water supply line to prevent

forei gn matter from becoming l odged in the fill or cold water condenser

solenoid valves and to keep unwanted partic les out of the system.

Pressure Relief V alve

........... A mechani c al device that opens to relieve steam pressure in the boiler if

the pressure exceeds 13 psi.

High Pressu re Relief Valve

Descaler

Boiler Pressu re Gauge

...................... Hangs below the water level inside the boi ler and is used to help cont r ol

.......... Indicates the amount of steam pressure in the boi ler.

Steam Header Assembly

....... A back-up mechanical device that opens to relieve steam pressure in

the boiler if the pressure exceeds 15 psi.

boiler surface scaling. Two descalers are used in each boiler.

......... Main steam supply line fr om the boiler to the steam header inlet in the

cooking control compar tment.

F24700 (October 2001)Page 11 of 68

Page 12

VHX SERIES STE A M E RS - COMPONENT FUNCTION

COOKING COMPARTMENT CONTROLS

The upper section of the steam er c onsi sts of two separate cooking compartm ents. Each compartment functions

independently wi th its own set of contr ols. Power is supplied to the controls only after the steam pressure rises

above t he c ompartm ent pressure switch setting to close the N.O. contacts.

Ready Light (Green)

Cooking Light (Red)

Cooking Timer

Buzzer

Door Switch

Steam Solenoid Valve

Compartment P r essure Switch

Manifold Pressure Gau ge

Steam Supply Manifold

....................... Signals end of a cook cycle, must be turned off manual ly.

................... Removes electrical power to the timer. If time is dialed on the cooking

............ When lit, indicates steamer is ready to cook.

............ When lit, indicates steamer is in a cooking cycle.

................. Use to set desired cooking cycle time between 0-60 minutes. When a

........... When energi zed, opens to allow steam into the cooking compartment

........ Indicates the amount of steam pressure in manifold. The intak e shut- off

.......... Main steam supply line fr om the boiler for eac h c ook ing compart ment.

tim er is set, the steam suppl y sol enoid valve is energized to al low steam

into the cook ing compartment but only after the boiler has reached its

operating pressure. Also, energizes the buzzer when time expires.

tim er and compartments are steaming, removes power to the steam

solenoid valve when the compart ment door is opened.

(normally closed valve).

.... Supplies power to the controls only after the steam pressure ri ses above

approximately 3 psi to close the compartment pressure switch. The

switch remains closed as long as steam pressure stays above this

pressure.

valve should be adjusted so manifold pressure remains at 9 psi with both

compartments on.

Supplies steam up to the steam sol enoid valve.

Intake Shut-Off Valve

........... Main steam supply shut-off from the boiler t o the steam supply manif old.

This valve should NOT be left fully O P E N to boiler steam supply. See

“INTAKE SHUT-OFF VALVE ADJUSTMENT (STEAM FLOW)" in

“SERVICE PROCEDURES AND ADJUSTMENTS".

F24700 (October 2001) Page 12 of 68

Page 13

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

COMPONENT LOCATIONS

Cabinet Base Bo iler Contro ls

F24700 (October 2001)Page 13 of 68

Page 14

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

Cabinet Base Bo iler Contro ls Contin ued

F24700 (October 2001) Page 14 of 68

Page 15

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

Cooking Compartment Controls

WATER LEVEL CONTROLS

(MAIN OR AUXILIARY LLCO)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base door.

2. Remove the cover from the pressure switch

control box to access the water level controls.

Refer to "CABINET BASE BOILER

CONTROLS" under "COMPONENT

LOCATIONS" in "REMOVAL AND

REPLACEMENT OF PARTS".

3. Disconnect l ead wir es from the boar d being

replaced.

4. Compress the lock ing tab on the board

mounti ng "standoffs" and remove the water

level control.

5. Reverse proc edur e to install and c hec k for

proper operati on.

DISCONNECT THE ELECTRICAL

RELAY BOARD

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base door.

2. Remove the cover from the main control box to

access the relay board. Refer to "CAB INET

BASE BOILER CONTROLS" under

"COMPONENT LOCATIONS" in "REMOVAL

AND REPLACEMENT OF PARTS".

3. Disconnect all lead wires f r om the board.

4. Compress the lock ing tab on the board

mounti ng "standoffs" and remove the relay

board.

5. Reverse proc edur e to install and c hec k for

proper operati on.

DISCONNECT THE ELECTRICAL

F24700 (October 2001)Page 15 of 68

Page 16

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

WATER LEVEL GAUGE

ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base door and remove the

right side panel.

2. Close the valve at the top and at the bottom of

the gauge assembly.

3. Unscrew the packing nuts at t he top and bottom

of the glass tube.

4. Slide t he glass tube upwards until the bottom of

the tube is clear of the fitt ing and lift it out.

NOTE

damaged or broken.

NOTE:

gauge glass may break.

5. Install the tube using new sealing washers.

6. Open the top and bottom valves.

7. Turn the power switch ON and allow boiler t o

come up to pressure.

8. Check gauge glass for water/steam leaks and i f

necessary, graduall y tighten packing nuts until

leak stops.

DISCONNECT THE ELECTRICAL

: Clean tube if dir ty or clogged and replace if

Do not ov er tighten the pack ing nuts or

PRESSURE SWITCHES

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open the cabinet base door and remove the

left side panel.

2. Remove the cover from the pressure switch

control box to access the pressure switches.

Refer to "CABINET BASE BOILER

CONTROLS" under "COMPONENT

LOCATIONS" in "REMOVAL AND

REPLACEMENT OF PARTS".

3. The pressure switches are located at the

bottom of the box . The pressure switch on the

left is the cycling

the right is the high limit

4. If replacing:

A. Cycling control - remove cov er from

DISCONNECT THE ELECTRICAL

or primary control ; the one on

control.

pressure switch and disconnect the lead

wires.

1) Remove the mounti ng screws on the

back side of the control box and lift

out the pressure switch. Proc eed to

step 5.

B. High li mit control - disconnec t the lead

wires.

5. Disconnect the pressure fittings at the bottom

of the switc h.

6. Preset the new pressure switch to the

approximate cut-out (OFF) and cut-in (O N) set

points befor e installing. Refer to "PRESSURE

SW ITCHES" in " S E RV ICE PROCEDURES

AND ADJUSTMENTS".

7. Reverse proc edur e to install .

8. Adjust the pressure switch(s) final set points as

outlined under "P RESSURE SWITCHES" in

"SERVICE PROCEDURES AND

ADJUSTMENTS".

BOILER ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Blowdown the boiler and, if nec essary, allow to

cool.

2. Disconnect the steam supply line, power leads

and drain lines from the cooking compartment

top to the boi ler base.

3. Refer to " HE A T EXCHANGER" and perform

steps 3 through 12A.

4. Remove bolts securing the boiler t o frame.

5. Drain any remaining water from t he boiler.

A. The suggested methods are:

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS BEFORE

ALL GAS JOINTS DISTURBED

1) Where the dr ain line exits the boiler

on the lower left side, separate the

drain line union.

2) Remove the access panel between

the boiler and the cooking

compartment on the right side.

3) Disconnect the steam supply hose

from the cooking compartment steam

manifold.

F24700 (October 2001) Page 16 of 68

Page 17

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

a. From t he bottom right side, raise

the boiler two to three inches so

it tilts to the left. When the

remaining water has drained out,

lower the boiler before.

proceeding.

B. Remove the drain/ scale clean-out plug

from the bottom of the boiler.

6. Slide t he boiler forward and remove it from

base frame.

7. Install a new boi ler and secure it t o frame.

8. Refer to " HE A T EXCHANGER" and perform

steps 13 through 15.

9. Reconnect all steam, water, dr ain and power

connections and check for proper operat ion.

BOILER FILL AND COLD WATER

CONDENSER SOLENOID VALVES

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Turn off the water supply to the steamer.

2. Open the cabinet base door and remove the

cover from the pressure switch control box to

access the solenoid valves. Both solenoi d

valves are l oc ated side by side at the r ear of

the box with the boiler fill near the bottom and

the cold water condenser near the middle.

Refer to "CABINET BASE BOILER

CONTROLS" under "COMPONENT

LOCATIONS" in “REMOVAL AND

REPLACEMENT OF PARTS”.

3. Disconnect the power l ead wir es from the

solenoid valve being serviced.

4. Disconnect the water lines for the valve bei ng

servi ced and remove the valve.

5. Reverse proc edur e to install .

DISCONNECT THE ELECTRICAL

PILOT G AS VALVE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

SERVICING THE UNIT.

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS BEFORE

WARNING:

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

NOTE:

servi ceable and should not be di sassembl ed. Once

the problem has been isolated to t his component,

replace it. Do not attempt to repair the assembly.

1. Open the cabinet door to access the Pilot gas

valve.

2. Disconnect the lead wires.

3. Remove pilot gas tubing from the top of the

valve (outlet side).

4. Remove the valve from the gas supply piping.

5. Reverse proc edur e to install and adjust pilot

pressure as outlined under "G A S P ILOT

PRESSURE ADJUSTMENT" in "SERVICE

PROCEDURES AND ADJUSTMENTS".

ALL GAS JOINTS DISTURBED

Gas combination control valves are not

MAIN GAS VALVE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

NOTE:

servi ceable and should not be di sassembl ed. Once

the problem has been isolated to t his component,

replace it. Do not attempt to repair the assembly.

1. Open the cabinet base door to access the mai n

gas valve.

2. Disconnect the lead wires.

3. Separate the uni on above the gas valve (outlet

side).

4. Remove the valve from the gas supply piping.

5. Reverse proc edur e to install and adjust

manifold pressure as outlined under "GAS

MANIFOLD PRESSURE ADJUSTMENT" in

"SERVICE PROCEDURES AND

ADJUSTMENTS".

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

ALL GAS JOINTS DISTURBED

Gas combination control valves are not

F24700 (October 2001)Page 17 of 68

Page 18

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

BURNER HEAD ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

1. Remove the pressure gauge tubing and power

cable f r om the rear of the control panel then

remove the panel.

2. Disconnect the spark igniti on c able from the

ignitor termi nal.

3. Disconnect pilot gas tubing from the air

pressure switch tee.

4. Separate the uni on above the main gas v alve

and remove the gas v alve piping assembly .

NOTE

assumes the use of a gas line quick connect or

union at the gas supply inlet to the steamer.

5. Remove the screws from the burner head

assembly end plate and pull the assembly out

from the complete burner assembly .

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

: Removal of the gas valve piping assembly

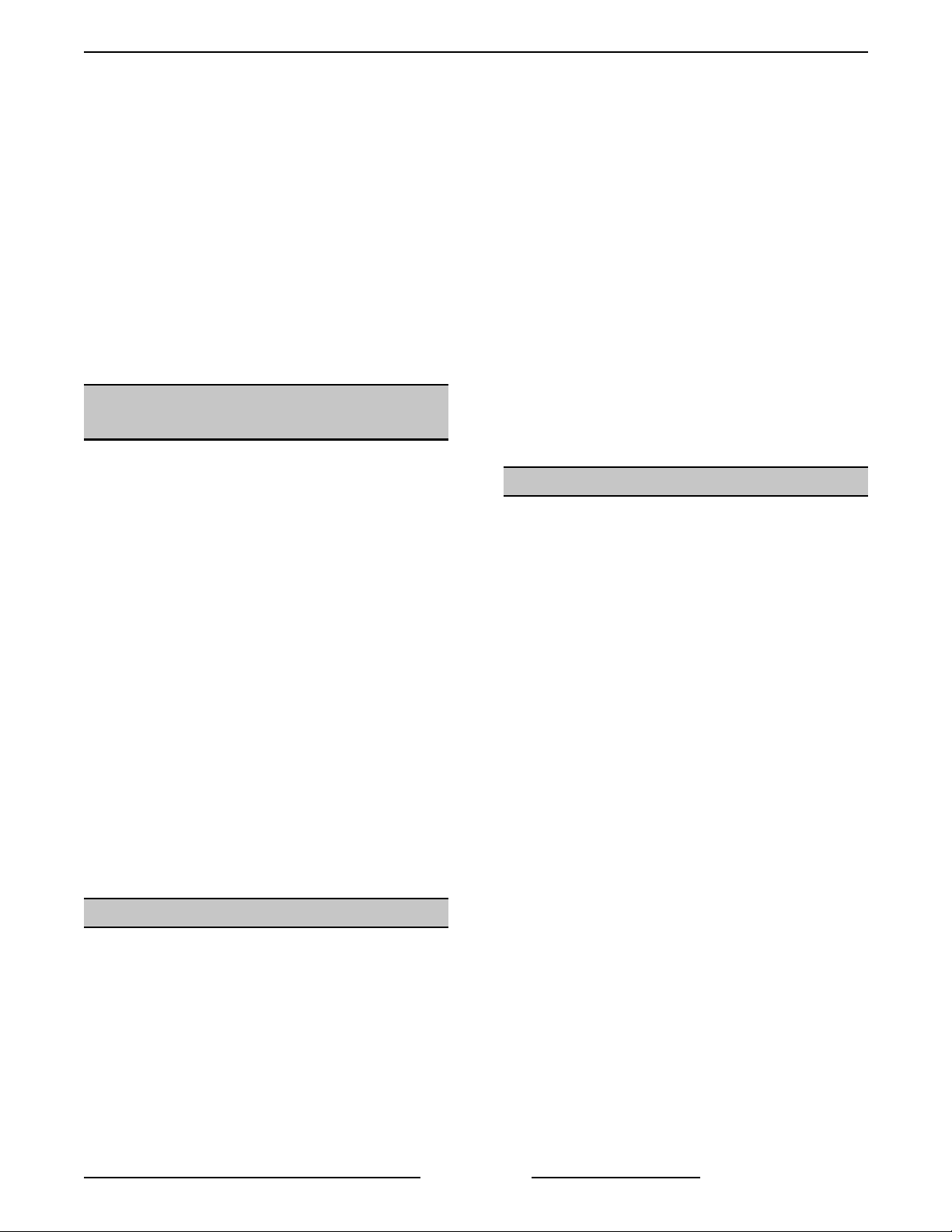

3. Remove the four nuts from the burner tube

assembly then slowly

out from the heat exchanger.

pull the assem bly straight

6. Reverse proc edur e to install and c hec k for

proper operati on.

COMPLETE BURNER

ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

1. Refer to steps 1 thr ough 4 under "BURNER

HEAD ASSEMBLY".

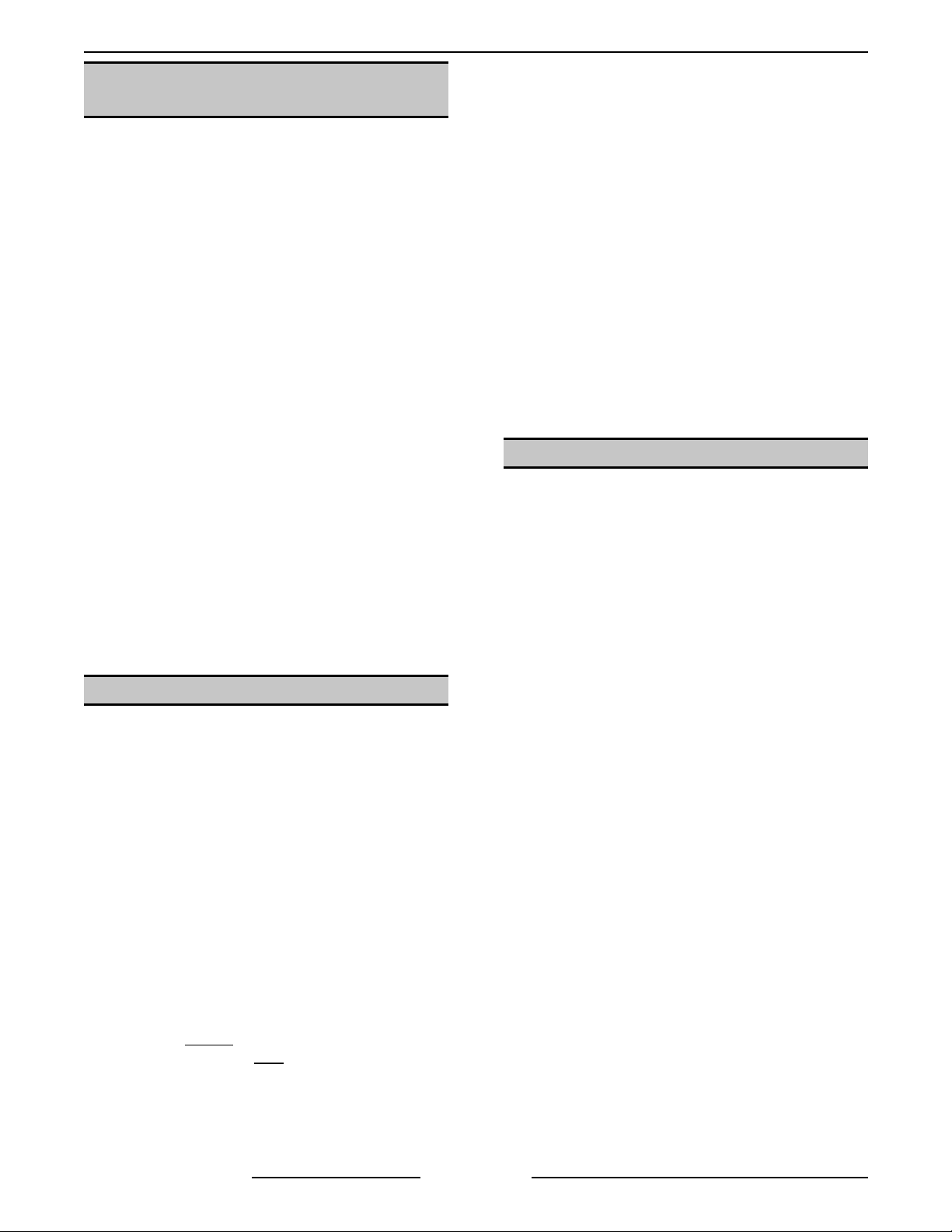

2. Remove the four nuts from c ombustion bl ower

mounti ng flange and remove blower from

burner tube assembly .

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

CAUTION: Use care w hile removing as to no t

damage the ceramic insulation surrounding the

burner.

4. Reverse proc edur e to install and c hec k for

proper operati on.

F24700 (October 2001) Page 18 of 68

Page 19

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

HEAT EXCHANGER

WARNING:

SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Blowdown the boiler and, if nec essary, allow to

cool.

2. Disconnect the electric al power to the machine

at the main circuit box. Place a tag on the

circuit box indicating the circui t is being

serviced.

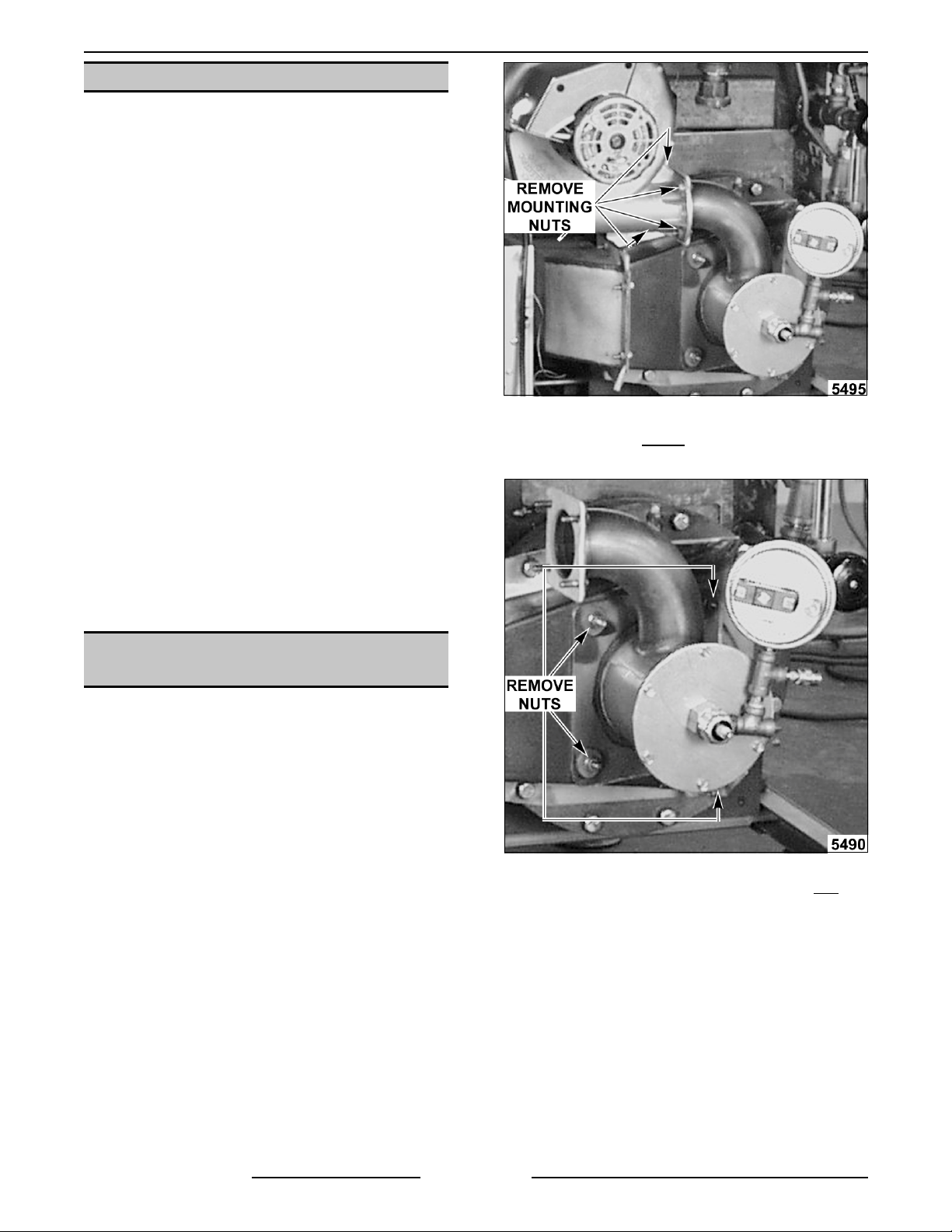

3. Remove the pressure gauge tubing and power

cable f r om the rear of the control panel then

remove the panel.

4. Disconnect the electric al lead wires exiting the

boiler control box from:

SHUT OFF THE GAS BEFORE

ALL GAS JOINTS DISTURBED

NOTE

: Removal of the gas valve piping assembly

assumes the use of a gas line quick connect or

union at the gas supply inlet to the steamer.

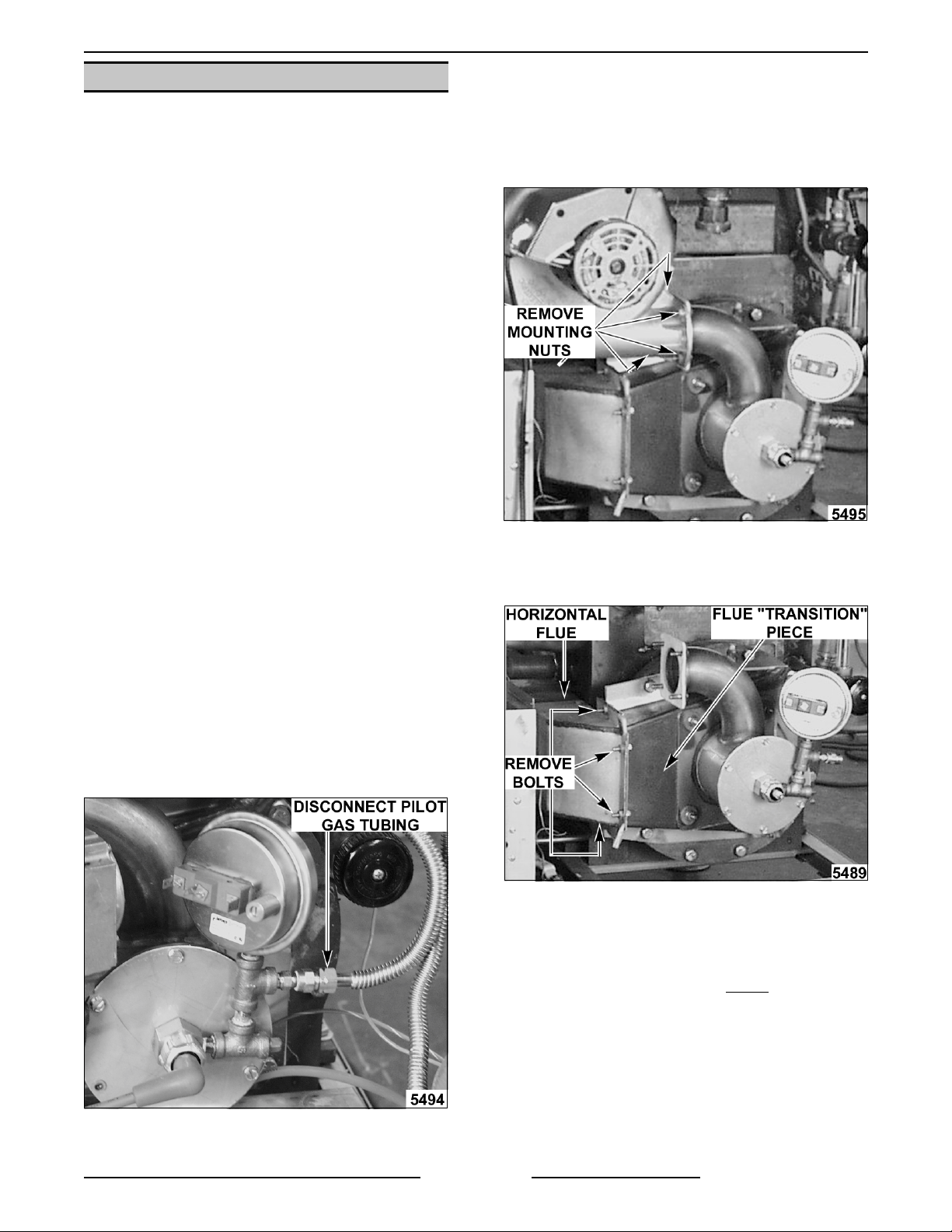

8. Remove the four nuts from c ombustion bl ower

mounti ng flange and remove blower from

burner tube assembly .

A. Auxiliary LLCO probe (Orange).

B. Burner ground (green).

C. Air pressure switch (yellow & yellow/white

stripe).

D. Main gas valve (purple & grey).

E. Pilot burner valve (red & grey).

F. Spar k ignition cable.

5. Remove bolts securing the boiler control box

(front ) to the base frame.

A. Lift up on left side of box and slide out.

6. Disconnect pilot gas tubing from the air

pressure switch tee.

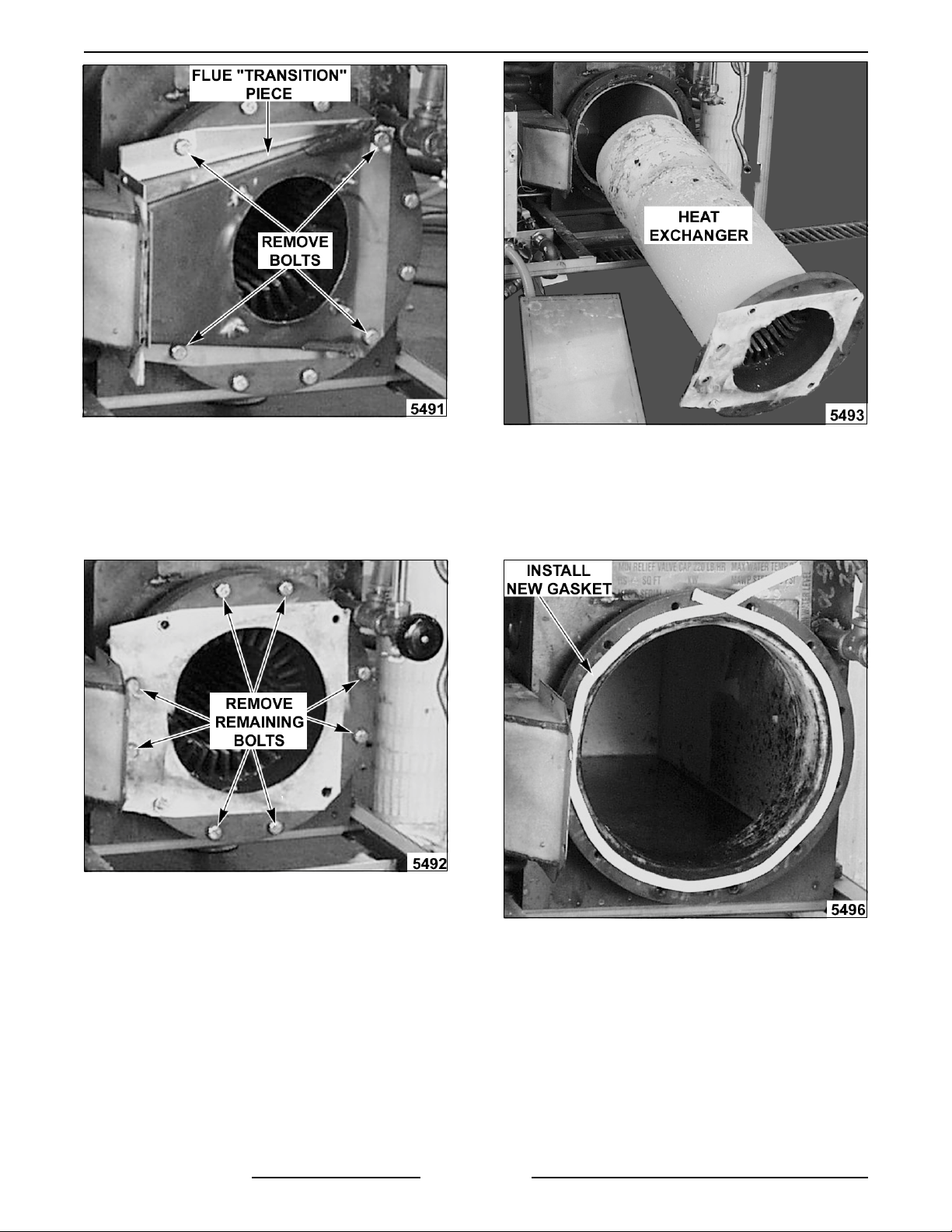

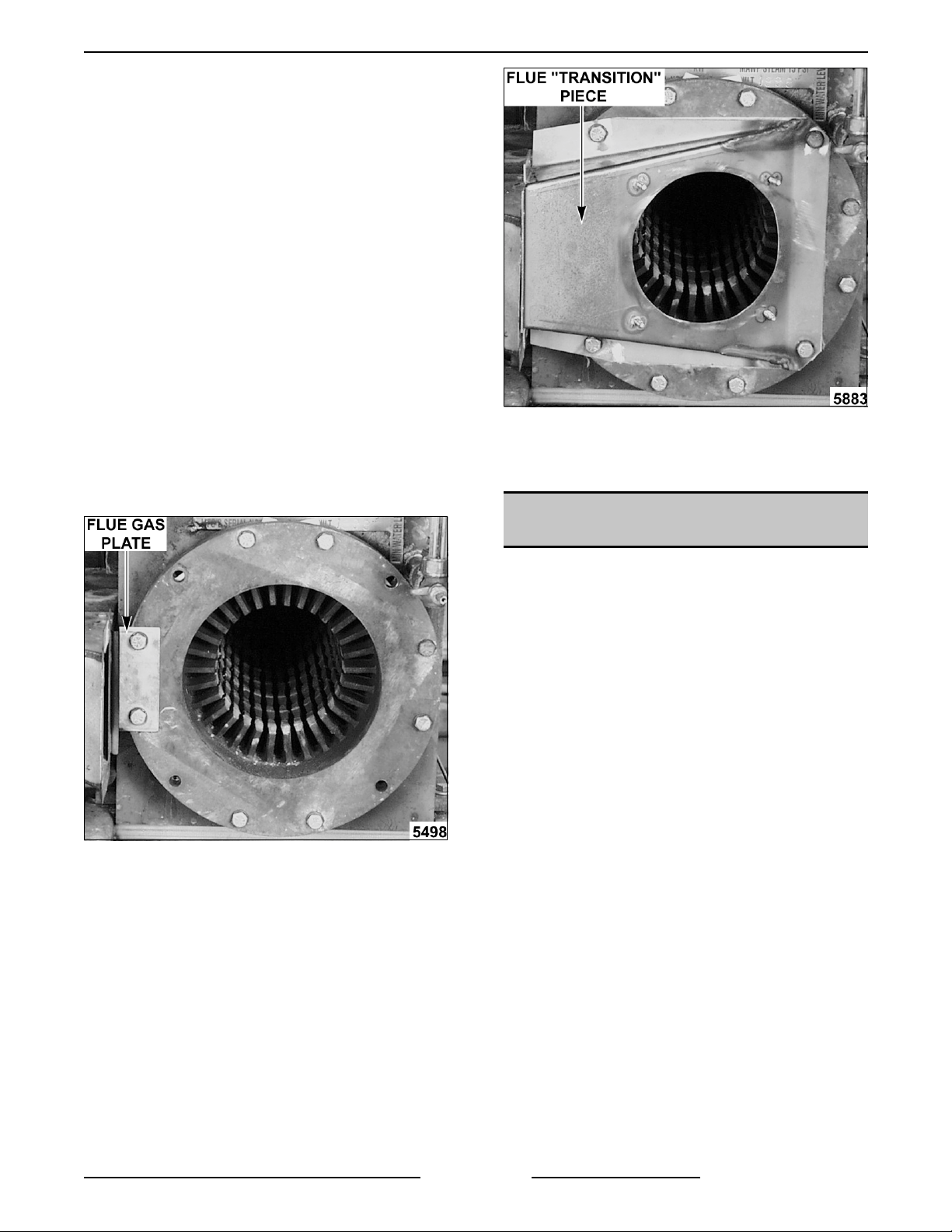

9. Remove the four bolts connecting the

horizontal flue (left of boil er) to the flue

"transition" piece.

A. Separate the horizontal flue f rom flue

"transition" piece, leaving the horizontal

flue in place.

7. Separate the uni on above the main gas v alve

and remove the gas v alve piping assembly .

10. Rem ove the four nuts fr om the com plete

burner tube assembly then slowly

assembly strai ght out from the heat exchanger.

CAUTION: Use care w hile removing as to no t

damage the ceramic insulation surrounding the

burner.

11. Rem ove the flue "tr ansi tion" piec e from the

heat exchanger.

F24700 (October 2001)Page 19 of 68

pull the

Page 20

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

12. For c learance of the heat exchanger only,

remove the drain nut (petcock) and the lower

adjustment knob from the water level gauge.

A. Remove the remaining bolt s on the heat

exchanger then pull heat exchanger

straight out from the boiler.

13. To install heat exchanger:

A. Clean the m ating surfaces on the heat

exchanger and boi ler.

B. Install a new gasket on t he boiler side of

the mounting fl ange.

F24700 (October 2001) Page 20 of 68

C. Insert the heat exchanger bac k into the

boiler and line up the mounting holes

being careful not to disturb gasket.

D. At tach a 2" C-Clamp between the heat

exchanger mounting flange and the boiler

side mounting flange. Tighten clamp only

enough to allow start ing of bottom bolt into

mounti ng hole.

Page 21

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

: It may be necessary to use two clamps

NOTE

to draw the bottom of the heat exchanger cl ose

enough to be clamped. Start one c lamp at a 3

o’clock position then instal l other clamp near

the bottom. Once the bolts are tight enough, CClamp will fall away.

E. Install two bolts at the bott om and two

bolts at the t op on the heat exchanger

flange and tighten the bolts a few turns at

a tim e. Starti ng wi th the bottom bolts,

tighten t he bolts in an alternating pattern

between the bottom and top for a flush

mounti ng of the heat exchanger flange

and an even compression of the gasket.

NOTE:

hand, clean out the threads with the proper si z e

tap.

F. O nc e those bolts are tight, install the two

If a bolt is not threading in properly by

bolts to the left and t he two bolts to the

right on the heat exchanger flange. On the

left side, be sure to install the rectangular

flue gas pl ate then tight en the bolts in an

alternating pattern.

15. Star ting at step 12, reverse procedure t o install

the remaining components.

16. Check for water leaks and proper oper ation.

COOKING COMPARTMENT

DOOR(S)

Removal

1. Remove top cover.

2. Open the door.

3. Pull hinge rod up.

4. Reverse the procedure to install, m ak ing sure

the door bushings are in place.

Gasket

1. Open the door.

14. To install flue "transition" pi ec e:

A. Clean the m ating surfaces on the

"transition" piece and the heat exchanger

face.

B. Install new gasket on t he " transition" piece

then secure to the heat exchanger using

the remaining bolts.

2. Remove screws from t he gasket plate.

3. Pull t he gasket plate out from the door housing

and remove the gasket.

4. Position the new gasket on the gasket plate

and rever se t he pr oc edur e to install . Adjust the

door as outlined in " DOOR SEALING

ADJUSTMENT" under "COOKING

COMPARTMENT".

NOTE:

this will compress the gasket excessively and

interfere with proper door seal ing.

NOTE:

as nicks or cuts, will cause steam leakage.

Do not ov er tighten gasket plate screws as

Damage to the gasket sealing surface, such

F24700 (October 2001)Page 21 of 68

Page 22

VHX SERIES STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

Handle

1. Open the door.

2. Remove screws from t he top and bottom of the

door.

3. Pull t he inner door panel out from the door

housing with the gasket plate and gasket stil l

attached.

NOTE:

diamet er fit s into the slot in the door and the latch

lever must rest on t op of the handle latch screw.

5. Reverse proc edur e to install .

Latch Assembly

1. Open the door.

2. Remove screws from t he top and bottom of the

3. Pull t he inner door panel out from the door

4. Remove the screws from the side edge of the

When installing the spacers, the smaller

door.

housing with the gasket plate and gasket stil l

attached.

door that secure the latch mec hanism and

remove the lat c h from the door.

NOTE:

top of t he handle latch screw.

5. Reverse proc edur e to install .

4. Remove the nuts and spacers from the handle

screws and remove the handle fr om the door.

F24700 (October 2001) Page 22 of 68

When installing, the lat ch lev er must rest on

Page 23

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING:

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POI NT S ARE NOT EASI LY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST

EQUIPMENT AND REAPPLY POWER TO TEST .

Inspection

It is recommended the boiler be inspect ed for

excessive lime scale build up in a time frame

dependant on the quality of the local water suppl y

and steamer usage. In har d water ar eas or for

steamers heavily used, a frequent i nterval should be

used. This inspection consists of an i nternal

examination and cleaning of the boiler, an

examination of the two hanging descaler s, and for

lime build up on the water level probes. Also, a

check of all boiler control s, including the pressure

switches.

Periodic servi c e must be perfor med as outlined in

these procedures. See “WATER CONDITIONING”

under “GENERAL”.

Clean-Out

1. Turn power switch OFF .

A. Boiler should automatically star t

2. Remove the burner assembl y and heat

exchanger as outlined under "HEAT

EXCHANGER" in "REMOVAL AND

REPLACEMENT OF PARTS".

NOTE:

the hand hole cover is very limited on this model

and is recommended to be rem oved for deliming

purposes only.

3. Remove old descalers (cathodic protectors).

4. With a wire brush or equivalent:

A. Dislodge and remove al l loose scale from

B. Remove all loose scale form the heat

C. Cl ean the mati ng surfaces of the heat

5. Check probe housing and water level pr obes

for scale build up and cl ean as necessary.

Refer to "WAT ER LEVEL CONTROLS TEST".

6. Check the drain line exiting the boiler for

obstructions.

CERTAIN PROCEDURES IN THIS SECTION REQUIRES ELECTRICAL TEST OR

BOILER

blowdown/drain cycle.

Access to the int er ior of t he boiler through

boiler shel l. The loose material must be

scooped from the boiler or flushed through

the washout drain.

exchanger.

exchanger and boiler.

A. Remove the strainer clean out plug, turn

the steamer on and allow the boil er " fil l

water" to f lush-out the drain line. Tur n the

steamer off, remov e the cap and strainer

screen and clean, if necessary, before

replacing the screen and clean-out plug.

7. Inspect condition of t he descalers as outlined

under "DESCALER (Cathodic Protec tor)" in t his

section, and replace if necessary.

8. Install a new gasket and replace the burner

assembly and heat exchanger by reversing the

removal procedur e from step 2.

9. Delime the boiler as outlined under

"DELIMING" in this section.

Deliming

Boiler deliming should be perf or med in a time f r ame

dependant on the quality of the local water suppl y

and steamer usage. In har d water ar eas or for

steamers heavily used, a frequent i nterval should be

used. See “W A TER CONDITI ONING” under

“GENERAL”.

On steamers using a water t r eatment system , follow

the instructions for t hat system to delime the boiler.

Only use the type of chem ical recommended or

described in t he instructions for deliming with t his

type of system.

If a water t reatment system is not

instructions for deliming the boiler as outlined in the

steps below.

1. Turn power switch OFF .

A. Boiler should automatically star t

blowdown/drain cycle.

2. Remove hand hole plat e and gasket (top front)

from the boiler by removing the nut and clamp,

then tap the cover lightly t o free it . Hold the

stud in the plate while tappi ng to prevent the

plate from droppi ng into boiler.

3. Clean the m ating surfac es of the hand hole

opening and plate.

4. Delime the boiler :

A. If t he boiler was delimed through a water

treatm ent system, proceed to step 7.

B. If t he boiler has not

proceed to step 5.

used, follow the

been delimed,

F24700 (October 2001)Page 23 of 68

Page 24

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

WARNING

INSTRUCTI ONS FOR THE DE- LIMING CHEMI CA L

BEING USED. USE PLASTIC OR RUBBER

GLOVES TO AVOID SKIN CONTACT. IF T HE

CHEMICAL COME S IN CONTACT WITH S K IN,

RINSE WITH CLEAN WATE R.

5. Mix deliming solution ac c or ding to the

NOTE:

gallons.

NOTE:

steamer components, li ghtly rinse off with c lean

water.

6. Install a new gasket on t he hand hole plate then

7. Ensure cooking compartment tim er s are O FF.

8. Turn power switch ON and open water supply

9. Allow the boiler to reach oper ating pressure

10. Steps 9A and 9B

11. Steamer is now ready for normal operation.

Descaler (Cathodic Protector)

Two descalers are installed inside the boiler shell

and are used to as a preventative measure to:

• Reduce scale deposit buildup

• Help remove ex isting scale deposits

• Inhibit boiler and component corrosi on

The type of descaler used has a coiled wire

(Cathode) wrapped around a solid c y lindric al core

(Anode) that hangs by an open loop from the front

horizontal support rod inside t he boiler.

: READ AND FOLLOW THE

instructions for the chemical being used.

Boiler water c apac ity is approximat ely seven

If deliming solution comes in contact with

A. Turn OFF water supply.

B. Turn power switch ON to close the drain

valve.

C. Pour deliming solution into the boiler shell.

position and tighten the plate to the boiler.

valve.

and run for 90 minutes or per t he instructions

for the deliming chemi cal in use.

A. Turn power switch OFF and allow the

boiler t o complet ely drain.

B. Turn power switch ON to refill boiler and

allow to heat until fully pr essuriz ed.

be repeated three times

must

to thoroughly rinse the boil er .

The descaler material s serve as a sacrificial

"Anode" and "Cathode" c ombination that chem ically

reacts with the contents of the boiler to meet the

three object ives outlined above.

If t he c oiled wire has eroded away or if the

cylindrical cor e of the descaler has eroded away to

approximately half i ts original diameter, a new

descaler should be installed. The si z e of a new

descaler is approximat ely: 1 3/8" diameter and 3

3/4" long at the core.

NOTE:

decreases through erosion, the length of the

descaler will increase. If the descaler has increased

to a length t hat is touching the bottom of the boiler

shell, the descaler should be replaced.

The descalers are accessibl e through the "heat

exchanger" opening in the boi ler only. For removal

of the heat exchanger refer to "HEAT

EXCHANGER" under "REM OVAL AND

REPLACEMENT OF PARTS".

To install a new descaler, stretch the coiled wire at

the top to el ongate the wire and form an open loop.

Hang the descaler on the front horizontal support

rod so that its core will be completely below the

minimum

The descaler must not

heat exchanger c ast ing.

While the di ameter of the descaler

water level in the boiler but hanging free.

contact the boiler shell or the

WATER LEVEL PROBE

HOUSING BLOWDOWN

The water contai ned in the probe housing, being

under pressure, should be "blown through" this

manual valve and be noti c eably v isible ex haust ing

out the steamer drain. The pr obe housi ng blowdown

should be perfor med in a time f r ame dependant on

the quality of the local water supply and steamer

usage. In hard water areas or f or steamers heavily

F24700 (October 2001) Page 24 of 68

Page 25

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

used, a frequent interval should be used. This

blowdown procedure is essential

and component life by removing sedim ent and

scalants that may be lodged in the probe housing.

NOTE:

pressures.

1. Remove the left side boiler base panel to

2. Turn the power switch ON and allow the boiler

WARNING:

HOT. USE CARE WHEN OPERATING, CLEANING

OR SERVICING THE STEAMER. THE BOILER

CONTAINS LIVE STEAM. STAY CLEAR WHEN

OPENING THE VALVE.

3. Open the ball valve for approximately one

4. Close the ball val ve and repl ace left side panel.

5. Press the reset switch (manual) on the boiler

6. Steamer is now ready for use.

Boiler should be within normal operati ng

access the ball valve.

to reach operating pressure.

THE STEAMER AND ITS PARTS ARE

minut e whi le under pressure to thoroughly flush

the probes and housing.

control panel and allow boiler to reach

operating pressure.

to proper operation

WATER LEVEL CONTROLS

TEST

The procedure bel ow applies to the water level

control boar ds for both the ol d and new styl e boiler

controls. For additi onal inf or mation related to the

new style control s, r efer to "RELA Y B OARD" and

"SEQUENCE O F OPERATI ON" under

"ELECTRICAL OPERATIO N". For specific

infor mation related to the water level controls

operation, refer to "WATER LEVEL CONTROLS"

under "ELECTRICAL OPERATION".

Loose electri c al connections may prev ent the

steamer from operat ing properly.

An accumulation of lime scale on or near the water

level sensing probes may cause them to retain

water (moi st) on the probe surface and gi ve a false

reading. Also, a cracked or damaged insulator may

give a false reading.

These conditions may cause one or more of the

following to occur:

• Gas burner no igni tion

• Boiler no fill

• Boiler overfill.

• Boiler no fill and dry fire

: Dry f iring m ay cause damage to the heat

NOTE

exchanger, burner assembly or the boiler. I f this

conditi on is suspect, the affected components

should be inspected.

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE TEST. USE EXTREME CAUTION AT ALL

TIMES.

Main Water Level Control

NOTE:

functioning control that provides f or low level cut-off

protecti on and differential water level control

1. Turn power switch ON and verify:

A. Low water light is illuminated (front control

B. HL LED is illuminated on the water level

C. Boiler is filling with water.

2. At the end of the initial fill:

A. Verify approxi mately one inch of water

B. Verify "green" ready light in the reset

THE FOLLOWI NG ST EPS REQUIRE

The mai n water level control is a dual

panel).

control boar d.

1) If boiler isn’t filling with water:

a. Verify 120 Volt AC is being

applied to the fill valve.

b. Verify fill valve isn’t clogged.

c. Ver ify 120 Volt AC is on main

water level control board.

2) I f water level cont rol board doesn’t

have 120 Volt AC:

a. Check it’s power source at the

10 pin J3 connector, pin 1

(white) and pin 2 ( black).

Disconnect the 10-pin J3

connector from the r elay board

in the m ain boiler c ontrol box.

b. If no volt age is measured on J3

pins 1and 2, check t he F1 fuse

(resettable c ircuit br eak er ) in the

main control box, and the power

switch connecti ons i n the power

switch box.

c. I f 120 volt AC was measured on

J3 connector pins 1 and 2 but

not on the water level control

board, verif y wi r e c onnec tions.

There should be continuity

between L1 on the water level

control boar d and J 3 pin 7.

There should also be cont inuity

between L2 on the water level

control boar d and J 3 pin 6. This

path incl udes connec tions thru

the J1 connector.

visible in t he boiler sight glass.

switch is illuminated.

F24700 (October 2001)Page 25 of 68

Page 26

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

C. Verify LED’s on the water level control

board, HL LED should be off, and LLCO

LED should be illuminated.

3. Open the ball valve in the probe housing

assembly (boi ler left side) about hal f way, to

gradually remove boiler water and ac tivate a fill

cycle.

Do not

the ignition cycle.

press the reset sw itch to start

The next step requires a

visual sight glass measurement that cannot be

obtained, if there is boili ng ac tion in the vessel.

A. Verify water level in the boiler sight glass

drops 1/4" to 3/8" before a fill cycle is

initiated. Repeat at least twice to verify

correct fill.

1) I f proper fill wasn’t obtained:

a. Verify probes 50, 51, and 52

have t he c or rect colored wir e to

them and to the water level

control boar d.

b. Remove the 3 probe assembly ,

clean lime scale build-up f r om

the probes and compare pr obe

lengths to drawing.

C. Repeat at least twice to veri fy correct

LLCO operation.

Auxiliary Low level Cut-Off Co ntrol

5. Conti nued testing with focus on the auxiliary

LLCO circuit. With water below the lowest

visible level in the sight glass (bel ow Aux LLCO

probe), and boiler in state of initial fill:

A. Verify Aux LLCO LE D is off on the Aux

water level control board.

B. Verify Low Water light is illuminated (front

control panel).

C. Verify 24 volt A C is on Aux LLCO COM,

and 0 volt is on Aux LLCO N.O. contacts.

1) With the water level above the Aux

LLCO probe and in the initi al fill state:

a. Verify Aux LLCO LE D is

illuminated on the auxiliary low

water board.

b. Verify N2 on the relay board is

illuminated (new style boiler

controls onl y ) .

c. Ver ify t he "green" ready light in

the reset switch is illuminated.

c. Remove 3/8” flex line from t he

probe housing assembly t o the

boiler and r emove any

obstructions. The 1/4"

compression fitting elbow and

1/4" tee i nto the boiler shel l for

the balance tube ar e sloped 1/8"

so condensation drains into

boiler. When replacing, t he

assembly

have t his slope

must

to prevent a blockage from

condensate build- up.

4. Test the water level c ontrol board LLCO circuit.

A. With the boiler full with water, turn off the

water supply and open the ball valve in the

probe housing assembly.

B. Shortly after the water dr ops bel ow the

lowest visible level in the sight gl ass, the

LLCO LED on the water level c ontrol

board should turn off, LLCO relay should

de-energize and t he nor mally open

contacts should ret ur n there shelf stat e.

d. Verify 24 volt AC is on the Aux

LLCO common and normal ly

open contacts of the auxiliary

water level control board.

2) With the mai n gas valve turned off,

water supply valve turned off, and

probe housing assembly ball valve

opened, press the reset switch.

a. Verify low water light (front

control panel).

b. Blower comes on.

c. Gas pilot cycles at

approximately 15 seconds on

and 5 seconds off.

3) Shor tly af ter water level drops below

the lowest visible level in the sight

glass, the Aux LLCO circui t should be

activated.

a. Low water light tur ns on.

b. Aux LLCO led turns off.

c. Combustion blower i s de-

energized.

d. Gas pilot st ops cyc ling.

4) Press reset switch to verify lo ckout.

5) Disconnect lead wire from Aux LLCO

probe. If there is any measurable

resistance between the probe and the

F24700 (October 2001) Page 26 of 68

Page 27

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

boiler shel l, remove and cl ean the

Aux LLCO probe.

a. Replace the probe and check

resistance again. If resistance is

still present, install a new probe.

b. Replace lead wir e on pr obe and

repeat steps "2) thru 4)" to verify

proper operati on.

PRESSURE SWITCHES

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE TEST. USE EXTREME CAUTION AT ALL

TIMES.

Remove the cover from the pressure switch control

box to access the t wo pressure switches. The

pressure switch near the front is the cycling

switch and the one beside it is the high l imit

pressu re switch.

Cycling

1. If t he boiler is already operating, proceed to

step 2. If the boiler is not

start the boiler as outli ned under " CA B INET

BASE BOILER" in "STEAMER OPERATION".

2. Turn one of the cooking compartment tim er s

ON to exhaust st eam from the boiler.

3. Monitor the boiler pressure gauge for several

cycles and note the pressures at which the

burner comes ON and goes OFF.

A. The mai n burner should come O N at 8 PSI

THE FOLLOWI NG ST EPS REQUIRE

pressure

already operat ing,

and go OFF at 10 P S I. If the readings

differ, adj ust the pressure settings as

described below.

1) T wo pressure adjustment screws

extend thr ough the top of t he swit c h

case. The screw directly abov e the

side pointer r aises or lowers both

right

the cut-out ( OFF) and the cut-in (ON)

set points sim ultaneously, wit hout

affecting the differential.

The screw directly above the left

pointer raises or lowers the cut-in

(ON) set point and changes the

differential.

2) T ur n the adjustment screw above the

side pointer to obtain the proper

right

cut-out (OFF) setting fir st, then adjust

the other screw to obtain the proper

cut-in (ON) setting.

a. A clockwise

the pressure setting whil e a

counterclockwise

decreases the pressure setting.

rotation increases

rotation

side

4. The cycling pressure switch will maintain the

steam pressure setting in the boil er by c y c ling

the mai n burner ON and OFF .

High Limit

Adjusting t he High Limit pressure switch fr om a cold

startup is the preferred condi tion of the boiler. On

the initial cold startup, the highest over shoot

pressure (drift) is achiev ed aft er the burner cycles

OFF for the f irst time. If the boiler is already

operating, the pressure setting can still be made

after foll owing the procedures outlined below.

1. The high limit pressure switch should be

adjusted to allow a maximum pr essure in the

boiler of 14.5 to 15.0 P S I. Befor e making

adjustment s t o the high li mit pressure setting,

the 13 PSI pressure rel ief valve (PRV- l eft side)

must be

high enough pressure in the boiler to properly

set the switch.

A. The suggested methods to prevent t he

2. Turn the power switch ON and allow the boiler

to completely fill.

A. High Pressure and Low Water indicator

3. When water in the boiler reaches the minimum

level, the green light on the r eset switc h will

come ON.

A. Press the reset switch on the front control

4. Monitor the boiler pressure gauge and note t he

pressure at which the high limit switch opens.

NOTE

: In f r ont of the boiler there is an additional

temporarily

valve from releasing pressure are:

1) Use a wooden block, a hand tool or

other object to hold the valve plunger

down.

2) Use a m etal wire threaded through

the hole in the valve handle and tie

the pressure relief valve handle to the

piping bel ow i t.

3) I f neither of the two methods keep the

valve fully c losed without leaks, an

alternate method is:

a. Turn the power switch OF F and

b. Remove the discharge piping

lights (amber) com e ON.

panel to reset the High Pressure and Low

Water safety controls.

1) I gnition sequence start s, main burner

lights and water in the boiler begins to

heat.

disabled. This will allow a

allow the boi ler to blowdown.

from the v alve outlet and insert a

pipe plug for

only.

temporary

use

F24700 (October 2001)Page 27 of 68

Page 28

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Mechanical Pressure relief valve factory set to

approximately 15 P SI. If the pressure in the boi ler

reaches this level, the valve will OPEN.

A. High pressure light (amber) will come ON.

1) I f the pressure switch opens at a

pressure range other than 14.5 t o

15.0 PSI then an adjustment t o the

switch setting should be made.

a. Proceed to step 5.

CAUTION: While making the adjustment, do not

press on the wheel wi th extreme force. The

switch may ro tate and devel op a leak at the

compression fittings or in some cases, the rear

lead wire may t ouch the control b ox and create

an electrical short.

5. Turn the adjust ment wheel sev er al clic k s to

change the pressure switch set point.

A. A counterclockwise

pressure switch set point while a

clockwise

switch set point.

NOTE:

during rotation, the pressure setting is changed

approximately 1/8 PSI.

in small increments.

6. Raise the handle on the 15 PSI mechanical

pressure relief valve and open the val ve for

approximately 4 minutes. This will exhaust

steam down the drain line and lower the boiler

pressure.

A. High li mit pressure switch closes at

B. Lower the boiler pr essure to approxim ately

C. Ignition sequence starts, main burner

7. Repeat steps 4 through 6 until the High Li mit

Pressure Switch opens at the corr ec t pressure.

8. If t he 13 P S I pressure relief valve (P RV - left

side) was temporari ly disabled as outl ined in

step 1:

A. Turn the power switch OF F and allow the

B. Return the valve to it s original stat e.

9. Check steamer for proper operat ion.

For every click of the adjustment wheel

approximately 12 PSI (non-adjustable).

1) Press the reset switch to reset the

8 PSI.

lights and water in the boiler begins to

heat.

boiler t o blowdown.

rotation raises the pressure

High Pressure safety c ontrol.

a. High pressure light (amber) goes

out.

rotation lowers the

Make the adj ustment

FILL A ND COLD WATER

SOLENOID VALVES

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Check to ensure the solenoid valve is receiving

power.

A. If t he sol enoid valve is receiving power but

B. If t he sol enoid valve is receiving power

2. To check solenoid valve further, pr oc eed to

step 3 through 8 for disassembly and inspect ion

of internal com ponents.

3. Shut water supply off, disconnect the water line

from the v alve body then remove the solenoid

valve from t he steamer.

4. Remove the coil assembly from the valve stem

by lifting up on t he retaining c ap at the top of

the solenoid valve and sliding the metal cov er

plate off.

5. Clamp t he body of the valve in a vise.

6. Mark a scribe line on the stem nut to the valve

body for proper re-tight ening.

7. Remove the stem locking nut t o remove the

stem f rom the valve body.

8. All parts are now accessible for inspection and

cleaning.

NOTE:

damaged or worn, then r eplace the solenoid valve.

Do not reuse damaged or worn parts.

solenoid parts are avail able as a service

replacement.

A. Check rubber seal on bottom of plunger.

B. Check plunger spri ng.

C. Check O-ring in valve body.

DISCONNECT THE ELECTRICAL

the v alve is not opening, the c oil may be

malfunctioning.

1) Remove the lead wires from the

solenoid coi l and check f or c ontinuity .

a. If continuity is measured,

proceed to step "1. B .".

b. If no continuity is measured,

replace the sol enoid valve and

check for proper operation.

and the v alve appear s to be opening but

little or no water is flowing through it, then

the v alve por ts may be clogged with debris

or a valve c omponent malfunct ioning.

If internal solenoid parts appear to be

No internal

F24700 (October 2001) Page 28 of 68

Page 29

VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

D. Check por ts in valve body .

9. Reverse proc edur e to install .

BOILER BLOWDOWN/DRAIN

SOLENOID VALVE

The water contai ned in the boil er , being under

pressure, should be "blown through" this valve and

be noticeabl y vi sible exhausting out the steamer

drain. Dai ly boil er blowdown is essential

operation and component life by removing sediment

and scalants that may be lodged in the chamber of

the boiler .

The boiler blowdown/drain process is an automatic

function and should start whenever the power switch

is turned OFF after a normal operating cycle. The

blowdown solenoid is a normally open (N.O.) valve

that CLOSES when energized by the power switch.

When the power switch is turned OFF, the