Page 1

INSTALLATION &

OPERATION MANUAL

MG SERIES GAS RESTAURANT

MODULAR RANGE

MODEL

MG12 ML-52549

MG24 ML-52514

MG36 ML-52522

MG48 ML-52523

MG60 ML-52524

MODEL MG12

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 30832 Rev. E (Sept. 2000)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED,

SHUT DOWN UNITS AT MAIN SHUT-OFF VALVE

AND CONTACT THE LOCAL GAS COMPANY

OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY OR

DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE

INSTALLING OR SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO OPERATE THIS DEVICE.

– 2 –

Page 3

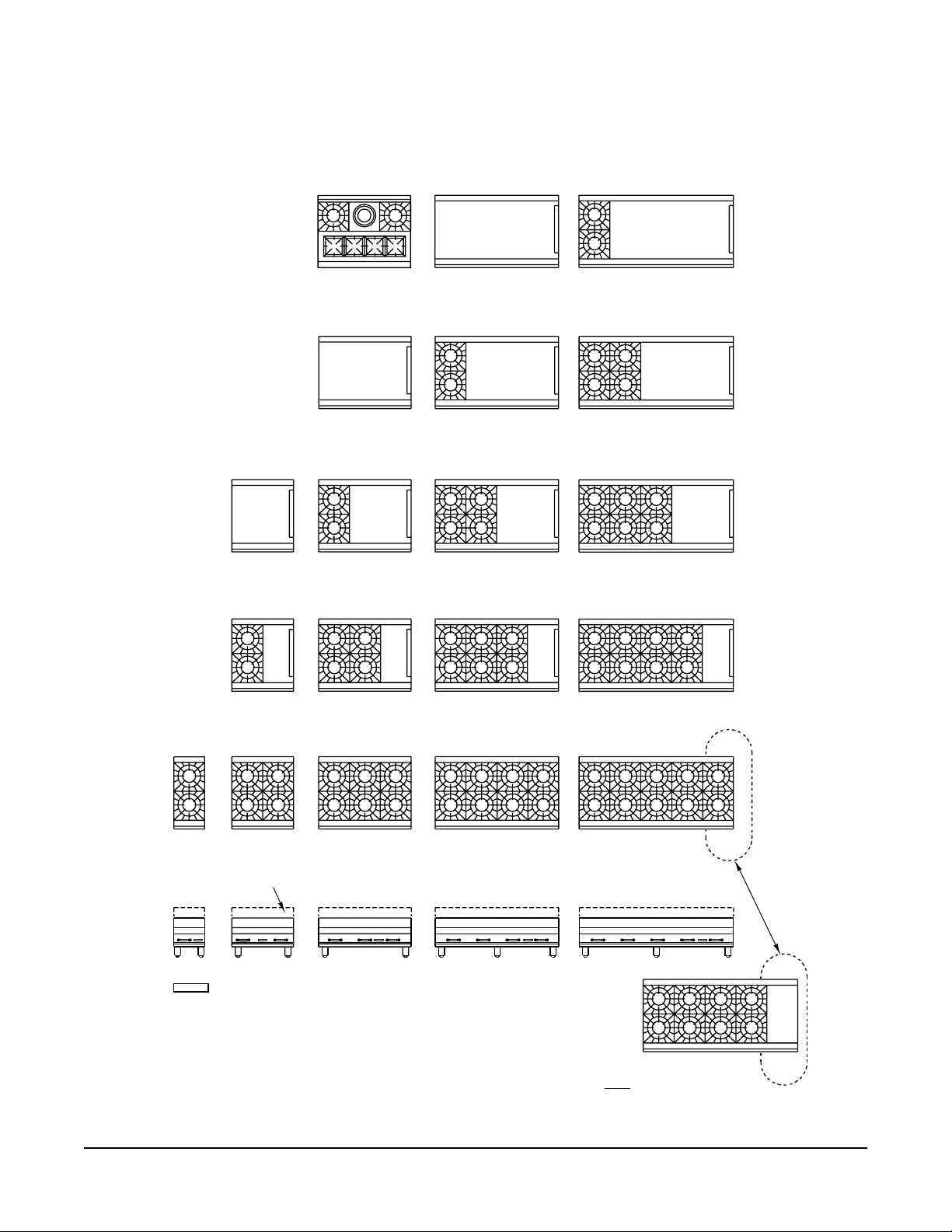

MG SERIES GAS RESTAURANT MODULAR RANGE

MODELS

TOP VIEWS

MG24F

MG24FT

MG24S

MG24ST

MG36ER

MG36X

MG36XT

MG36F

MG36FT

MG36S

MG36ST

MG48Z

MG48ZT

MG48X

MG48XT

MG48F

MG48FT

MG48S

MG48ST

MG60Z

MG60ZT

MG60X

MG60XT

MG60F

MG60FT

MG60S

MG60ST

Indicates step up

burner construction

PL-53565

MODEL SUFFIX DESIGNATIONS

S = 12" Griddle

F = 24" Griddle

X = 36" Griddle

Z = 48" Griddle

T = Thermostatic Control

MG48 MG36 MG24 MG12

FRONT VIEWS

MG48 MG36 MG24 MG12 MG60

– 3 –

MG60

NOTE:

RANGE MAY BE ORDERED WITH ONE 12" HOT TOP SECTION

IN PLACE OF TWO OPEN TOP BURNERS (FRONT TO REAR

ONLY)

Page 4

TABLE OF CONTENTS

MG SERIES GAS RESTAURANT MODULAR RANGE MODELS ................................................... 3

INSTALLATION ................................................................................................................................... 5

Uncrating ................................................................................................................................. 5

Location ................................................................................................................................... 5

Installation Codes and Standards .......................................................................................... 6

Assembly ................................................................................................................................. 6

Leveling ................................................................................................................................. 11

Gas Connections ................................................................................................................... 11

Testing the Gas Supply System ........................................................................................... 12

Flue Connections .................................................................................................................. 12

Lighting and Shutting Down Pilots ....................................................................................... 12

OPERATION ..................................................................................................................................... 14

Controls ................................................................................................................................. 14

Before First Use .................................................................................................................... 14

Preheating ............................................................................................................................. 14

Cleaning................................................................................................................................. 14

MAINTENANCE ................................................................................................................................16

OPTIONAL FIELD INSTALLABLE ACCESSORIES ....................................................................... 16

– 4 –

Page 5

Installation, Operation and Care of

MG SERIES GAS RESTAURANT MODULAR RANGE

KEEP THIS MANUAL FOR FUTURE REFERENCE

Vulcan ranges are produced with quality workmanship and material. Proper installation, usage and

maintenance of your range will result in many years of satisfactory performance.

The manufacturer suggests that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

INSTALLATION

UNCRATING

This range was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the range is found to be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

Carefully uncrate range and place in a work-accessible area as near to its final installed position as

possible. Remove all shipping wire and wood blocking.

Before installing, verify that the type of gas supply (natural or propane) agrees with the specifications

on the rating plate located under the left-hand cooking top, mounted to the side wall of the range.

If the supply and equipment requirements do not agree, do not proceed with the installation. Contact

your dealer or Vulcan-Hart Company immediately.

LOCATION

CAUTION: The equipment area must be kept free and clear of combustible substances.

A standard 20,000 BTU burner input range must have a minimum clearance from combustible

construction of 6" (15 cm) at the sides and 6" (15 cm) at the rear.

A standard 26,000 BTU burner input range must have a minimum clearance from combustible

construction of 10" (25 cm) at the sides and 6" (15 cm) at the rear.

Step-up ranges using 20,000 or 26,000 BTU input burners must have a minimum clearance from

combustible construction of 10" (25 cm) at the sides and 6" (15 cm) at the rear.

The installation location must allow adequate clearances for servicing and proper operation.

The range must be installed so that the flow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber must be provided. Make sure there

is an adequate supply of air in the room to allow for combustion of the gas at the burners.

– 5 –

Page 6

INSTALLATION CODES AND STANDARDS

For proper installation procedures in the United States of America, refer to:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1 (latest edition). Copies may be obtained from The

American Gas Assn., Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. National Electrical Code ANSI/NFPA-70 (latest edition). Copies may be obtained from The

National Fire Protection Assn., Batterymarch Park, Quincy, MA 02269.

In Canada, refer to:

1. Local codes.

2. CAN/CGA-B149.1 Installation for Natural Gas Burning Appliances and Equipment

(latest edition).

3. CAN/CGA-B149.2 Propane Installation Code (latest edition), available from The Canadian

Standards Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

ASSEMBLY

Installation of Standard Griddle Top Bricks

The griddle top section is extremely heavy. It will require three people to install the griddle and griddle

brick — two people to lift the griddle plate and one person to set the bricks and griddle thermostat

capillary bulb(s) in place.

The range griddle top section utilizes a two-fold baffle assembly to support the composite/mortar fire

1

bricks. There will always be only one small 6

order. There will be at least one 9

7

⁄8" (24 cm) wide baffle assembly per griddle, possibly more,

⁄2" (16 cm) wide baffle assembly with every griddle top

depending on the griddle width.

1

The 6

⁄2" (16 cm) wide baffle will utilize two 10" x 4" (25 cm x 10 cm), and two 7" x 4" (17 cm x 10 cm)

brick sets.

The 9

7

⁄8" (25 cm) wide baffle assembly will utilize two 10" x 4" (25 cm x 10 cm), and two 7" x 4"

(17 cm x 10 cm) brick sets.

1. The griddle bricks are shipped in a rectangular cardboard box. Locate the box and carefully

inspect quantities as explained above.

NOTE: If a brick has been broken into two pieces, it can still be used. Just place the pieces into

position as shown in Fig. 1. However, if a brick is broken into more than two pieces, it will need

to be replaced. Contact your local Vulcan servicer.

2. Clean anti-rust coating from top of griddle, following the procedures described in the

CLEANING - GRIDDLE PLATE section of this manual.

3. Remove griddle plate. With one person at either side of the griddle, gently lift griddle straight up.

DO NOT pull griddle forward until the third person has checked to ensure that the capillary

bulb(s) (thermostatically controlled models only) are freed from the underside of the griddle plate.

If bulb(s) are still attached to the griddle, pull capillary bulb(s) wire gently through the “V” shield(s)

until the bulbs are free.

– 6 –

Page 7

4. Rest the griddle plate in a secure place.

5. Thermostatically controlled griddles are shipped without the thermostat bulb in the “V” shield.

The bulb must be installed by the installer to prevent damage to the griddle and the thermostat

(not covered by the warranty). Exercise caution when placing brick in a thermostatically

controlled griddle section. DO NOT hit thermostat bulb while installing bricks. The thermostat

bulb is a sensitive device and may be easily knocked out of adjustment.

Into the 6

1

⁄2" (16 cm) wide baffle, install:

a. Two 10" x 4" (25 cm x 10 cm) bricks, placing the miter edge, one to each side of the front

burner baffle area (Fig. 1).

b. Two 7" x 4" (17 cm x 10 cm) bricks, one to each side of the rear burner baffle

area (Fig. 1).

Fig. 1

6. Into the 9

7

⁄8" (24 cm) wide baffle, install:

a. Two 10" x 4" (25 cm x 10 cm) bricks, placing the miter edge, one to each side of the front

burner baffle area (see Fig. 1).

b. Two 7" x 4" (17 cm x 10 cm) bricks, one to each side of the rear burner baffle area

(see Fig. 1).

7. If the burner has been strapped down, use wire cutters to remove the wire strapping

device.

– 7 –

Page 8

8. Check to ensure that all bricks and burners are secure.

9. Carefully replace the griddle top section. Be sure that the griddle capillary and bulb(s) are not in

a position to be damaged.

a. Gently pull the griddle capillary toward the front of the range and out from under the

griddle area.

b. While two people (one to each side of the griddle) are lowering the griddle into place,

the third person must gently feed the griddle thermostat bulb(s) through the “V” shield(s)

until completely covered. Ensure that the capillary is not positioned over the burner

flame pattern.

c. Continue to lower the plate into place until it is resting evenly on top of the range.

Installation of Hot Top Bricks

The range hot top sections utilize composite/mortar fire bricks for heat distribution to the burners.

Install these bricks before connecting the gas supply line or installing the back riser.

There should be one box of bricks per hot top section.

1. The composite/mortar bricks are shipped in a rectangular cardboard box. Locate the box and

carefully remove two 10" x 4" (25 cm x 10 cm), and two 7" x 4" (17 cm x 10 cm) bricks.

NOTE: If a brick has been broken into two pieces, it can still be used. Just place the pieces into

position as shown in Fig. 1. However, if a brick is broken into more than two pieces, it will need

to be replaced. Contact your local Vulcan servicer.

2. Rest the hot top plate in a secure area.

3. Install two 10" x 4" (25 cm x 10 cm) composite/mortar bricks, placing the miter edge, one to each

side of the front burner baffle area (see Fig.1).

4. Install two 7" x 4" (17 cm x 10 cm) bricks, one to each side of the rear burner baffle area

(see Fig. 1).

5. If the burner has been strapped down, use wire cutters to remove the wire strapping device.

6. Check to ensure that all bricks and the burner are secure. Carefully replace the hot top section

on top of the range.

– 8 –

Page 9

Backsplash

1. Remove the backsplash components from the crating materials.

2. Check the backsplash component parts against the list below to ensure that all the required

parts for the backsplash installation have been obtained.

• If any parts are missing, contact your dealer or closest parts depot immediately.

Backsplash Component Parts

MODELS

MG12 MG24 MG36 MG48 MG60 MG36ER

Std. 4" (10 cm) Std. 4" (10 cm) Std. 11" (27 cm) Std. 11" (27 cm) Std. 11" (27 cm) Std. 5" (12 cm)

High High High High High High

Backsplash (1) Backsplash (1) Backsplash (1) Backsplash (1) Backsplash (1) Backsplash (1)

Backsplash Backsplash Backsplash Backsplash Backsplash Backsplash

Channel (2) Channel (2) Channel (2) Channel (2) Channel (2) Channel (2)

Heat Shield (1) Heat Shield (1) Heat Shield (1) Heat Shield (1) Heat Shield (1) Heat Shield (1)

Fig. 2

3. Assemble the required components as shown in Fig. 2.

4. Lift the assembly up and slide the channels into the space provided at the rear of the range –

this may require two people.

– 9 –

Page 10

5. It may be necessary to pull the heat shield bottom out slightly in order to clear the flue box.

Be sure the backsplash is resting evenly and the channel holes are lining up with the holes

provided in the right- and left-hand body side (see Fig’s. 3 & 4).

PL-21424

Fig. 3 Fig. 4

PL-40045

PL-40045

Fig. 5

6. Install six #10 sheet metal screws (3 to each channel leg) (Fig. 5).

– 10 –

Page 11

LEVELING

Check the leveling of the range. Place a carpenter’s level across the range top plates. Level front to

back and side to side.

To adjust the leveling, tilt the range to one side and, using channel locks, unscrew the adjustable leg

insert as required. Repeat this procedure as necessary for each leg.

GAS CONNECTIONS

CAUTION: All gas supply connections and any pipe joint compound used must be resistant to

the action of propane gases.

Connect gas supply. Make sure the pipes are clean and free of obstuctions.

Codes require that a gas shutoff valve be installed in the gas line ahead of the range.

Standard ranges are equipped with fixed burner orifices which coincide with installation elevation.

Install the gas pressure regulator.

Before installing, ensure that regulator supplied agrees with rating plate gas supply.

The gas pressure regulator is NOT factory installed. The

regulator for this gas type is sealed within a plastic bag

and packaged with the range. This regulator must be field

installed by a qualified installer.

Natural gas regulators are preset for 4.0" W.C. (Water

Column); propane gas regulators for 10.0" W.C.

3

1. Locate

⁄4" (1.9 cm) gas connection pipe extending

from rear of range.

2. Cover pipe threads with leak sealant.

3. Screw regulator hand-tight onto pipe with

regulator arrow pointing towards range body

back (Fig. 6).

4. Using pipe wrench, tighten regulator securely in

an upright position (Fig. 6).

Fig. 6

The arrow on the regulator shows the direction of the gas flow (Fig. 6). The pressure regulator must

be mounted horizontally to ensure proper preset outlet pressure. If the regulator is installed in any other

position, the outlet pressure must be reset for proper operation.

A leak limiter is supplied with every regulator to allow excess gas pressure to escape. Do not obstruct

leak limiter on gas pressure regulator, because obstruction may cause regulator to malfunction.

– 11 –

Page 12

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

TESTING THE GAS SUPPLY SYSTEM

1

When gas supply pressure exceeds

⁄2 psig (3.45 kPa), the range and its individual shutoff valve must

be disconnected from the gas supply piping system.

When gas supply pressure exceeds 1⁄2 psig (3.45 kPa) or less, the range should be isolated from the

gas supply system by closing its individual manual shutoff valve until the range is ready for start-up.

FLUE CONNECTIONS

DO NOT obstruct the flow of flue gases from the flue located on the rear of the range. It is recommended

that the flue gases be ventilated to the outside of the building through a ventilation system installed by

qualified personnel.

From the termination of the flue to the filters of the hood venting system, a minimum clearance of 18"

(45 cm) must be maintained.

Information on the construction and installation of ventilating hoods may be obtained from the

standard, “Vapor Removal from Cooking Equipment,” NFPA No. 96 (latest edition), available from The

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

LIGHTING AND SHUTTING DOWN PILOTS

All adjustment procedures associated with initial start-up should be performed by an authorized

Vulcan-Hart installation or service person.

Hot Top and Griddle Top Burners

1. Turn main gas supply ON.

2. Turn all top burner valve knobs ON to purge gas line of air.

3. Turn top burner valve knobs OFF.

4. Wait 30 seconds.

5. Using a taper, light the hot top or griddle top pilot.

6. If pilot fails to light, wait 5 minutes and repeat Steps 1 through 5.

7. Turn one hot top or griddle top burner valve ON to ensure that all gas lines are completely purged

of air. Turn burner valve OFF when gas begins to flow.

– 12 –

Page 13

Nightly Shutdown: Turn burner valve OFF; pilot will remain lit.

Complete Shutdown

1. Turn burner valve OFF; pilot will remain lit.

2. Turn main gas supply OFF.

Open Top Burners

1. Turn main gas supply ON.

2. Turn all top burner valve knobs ON to purge gas line of air.

3. Turn top burner valve knobs OFF.

4. Wait 30 seconds.

5. Using a taper, light the open top pilot (Fig. 7).

Fig. 7

6. If pilot fails to light, wait 5 minutes and repeat Steps 1 thru 5.

7. Turn one open top burner valve ON to ensure that all gas lines are completely

purged of air. Turn burner OFF when gas begins to flow.

Nightly Shutdown: Turn burner valve OFF; pilot will remain lit.

Complete Shutdown

1. Turn burner valve OFF; pilot will remain lit.

2. Turn main gas supply OFF.

– 13 –

Page 14

OPERATION

WARNING: THE RANGE AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE RANGE.

CONTROLS

OPEN TOP BURNER KNOB — Regulates gas flow to top burners. To increase heat, turn knob

counterclockwise; to decrease, turn knob clockwise.

HOT TOP OR GRIDDLE TOP BURNER KNOB — Regulates gas flow to the hot top or griddle top

burner. To increase heat, turn knob counterclockwise; to decrease, turn knob clockwise.

BEFORE FIRST USE

Griddle Seasoning

CAUTION: This griddle plate is steel, but the surface is relatively soft and can be scored or

dented by the careless use of a spatula or scraper. Be careful not to dent, scratch, or gouge the

plate surface. Do not try to knock off loose food that may be on the spatula by tapping the corner

edge of the spatula on the griddle surface.

A new griddle surface must be seasoned to do a good cooking job. The metal surface of the griddle

is porous. Food tends to get trapped in these pores and stick; therefore, it is important to “season” or

“fill up” these pores with cooking oil before cooking. Seasoning gives the surface a slick, hard finish

from which the food will release easily.

To season, heat griddle top section at a low burner setting. Pour one ounce of cooking oil per square

foot of surface over the griddle top section. With an insulated cloth, spread the oil over the entire griddle

surface to create a thin film. Wipe off any excess oil with an insulated cloth.

Repeat this procedure 2 to 3 times until the griddle has a slick surface.

PREHEATING

Hot Top and Griddle Top Burners

Turn burner “ON” to highest heat to heat hot top section quickly. Hot top or griddle top will be ready to

cook on in about 10 minutes. After top section has reached operation temperature, turn some of the

burners down. You will save as much as 80% of gas consumption and notice very little difference in

cooking performance as long as you have allowed the entire hot top or griddle top section to preheat

properly.

Open Top Burners

Open top burners ignite quickly and do not require any preheating time. When food comes to a rolling

boil, cut back to slower boil to conserve energy, yet continue boiling. Turn burners ON only when in

use.

CLEANING

Do not use Dawn

®

dish detergent to clean the exterior or interior components of the range.

Do not use scouring powder; it is extremely difficult to remove completely and can build up

accumulations that will damage the oven.

– 14 –

Page 15

Vulcan painted surfaces may be cleaned using a soft cloth and mild detergent solution.

Ranges

Daily:

While still warm, wipe top with a soft cloth or other grease absorbing material to remove spillovers,

grease, etc., before they burn in. A crust on top of the hot top range looks unsightly and slows down

cooking speed because it reduces the flow of heat to the utensil.

Empty the grease pan daily or as often as necessary. CAUTION: Remove the grease pan slowly and

be careful of liquid wave action. It is recommended that the grease pan be emptied whenever it

3

is

⁄4 filled. The drip shield, grids and grease pan should be washed with a mild grease-dissolving

solution.

Clean cast iron open top grates with a mild soap and water solution. Rinse thoroughly and dry with a

clean, water-absorbent towel. Immediately after drying (with grates still removed from the range top),

season grates lightly with liquid vegetable or Pam

®

spray-type cooking oil.

After seasoning, replace grates onto the range. Turn all open top sections ON LOW and allow them

to burn for at least 15 minutes before using pots or pans on the range top.

Season the open top grates after each cleaning. Failure to season grates will cause grates to

rust.

Weekly:

Boil burners in a solution of washing soda. Rinse and dry parts thoroughly. Flash rusting may occur.

This is a normal condition and will not affect performance or the product.

When reinstalling the burner back onto the range, be sure the burner heads are properly connected.

Do not light the pilot or turn burner valve ON with the burner head removed.

Griddle Plate

Cleaning the griddle section will produce evenly cooked, perfectly browned griddle products and will

keep the cooking surface free from carbonized grease. Carbonized grease on the surface hinders the

transfer of heat to the food. This results in loss of cooking efficiency and spotty browning which gives

foods an unappetizing appearance. To keep the griddle clean and operating at peak efficiency, follow

these simple instructions:

After Each Use:

Carefully clean griddle with wire brush or flexible spatula.

Daily:

Thoroughly clean backsplash, sides and front. Remove grease drip tray and pan, empty and wash out

in the same manner as any ordinary cooking utensil.

Clean griddle surface thoroughly. If necessary, use a griddle stone, wire brush or steel wool over the

surface. Rub with the grain of the metal while still warm. A detergent may be used on the plate surface

to help clean it, but the cleaner must be thoroughly removed. After removal of detergent, the surface

of the plate must be reseasoned with a thin film of oil to prevent rusting and food sticking.

If the griddle is to be shut down for an extended period, put a heavy coat of grease over the griddle plate.

– 15 –

Page 16

MAINTENANCE

WARNING: THE RANGE AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE RANGE.

VENT

When cool, check the flue vent every six months for obstructions.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this modular range, contact the Vulcan-Hart

Service Agency in your area (refer to listing supplied with the modular range), or Vulcan-Hart Service

Department at the address or phone number shown on the front cover of this manual.

OPTIONAL FIELD INSTALLABLE ACCESSORIES

DESCRIPTION

Flue Devices

Flex Hose

and Quick

Disconnects

OPTIONS

1. Stainless steel backsplash.

2. Stainless steel 11" (28 cm) low riser.

3. Stainless steel 4" (10 cm) low riser (use with open tops only).

3

1.

⁄4" (1.9 cm) flex hose/disconnect – 3 ft. (0.9 m) long.

2.3⁄4" (1.9 cm) flex hose/disconnect – 4 ft. (1.2 m) long.

3.3⁄4" (1.9 cm) flex hose/disconnect – 5 ft. (1.5 m) long.

FORM 30832 Rev. E (Sept. 2000) PRINTED IN U.S.A.

– 16 –

Loading...

Loading...