Page 1

INSTALLATION & OPERATION MANUAL

GAS INFRARED CHEESEMELTER

MODEL

ICM24 ML-52470, 52476

ICM36 ML-52471, 52477

ICM48 ML-52472, 52478

ICM60 ML-52473, 52479

ICM72 ML-52474, 52480

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-30908 (2-14)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

adjustment, alteration, service or maintenance

can cause property damage, injury, or death.

Read the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

Improper installation,

-

2 -

Page 3

Installation, Operation, and Care of

MODELS ICM24, ICM36, ICM48, ICM60 & ICM72

GAS INFRARED CHEESE MELTERS

KEEP THIS MANUAL FOR FUTURE USE

GENERAL

Vulcan Gas Infrared Cheese Melters use efficient gas heat and are available in 24, 36,

48, 60, or 72 inch widths. Each model has one or two burners; each burner has its own

pilot light and control knob.

GAS RATINGS

Model ICM24 ICM36 ICM48 ICM60 ICM72

BTU Rating

20,000 BTU/hr 35,000 BTU/hr 40,000 BTU/hr 55,000 BTU/hr 70,000 BTU/hr

INSTALLATION

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the Cheese Melter is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Before installing, verify that the gas (natural or propane) agrees with the specifications on the rating

plate located on the front.

LOCATION

The area around the appliance must be kept free and clear from combustibles. The area in front of and

above the Cheese Melter must be clear to avoid any obstruction to the flow of combustion and

ventilation air. Means must be provided for adequate air supply and adequate clearance for air

openings into the combustion chamber.

Adequate clearance must be provided in front and at the sides of the appliance for servicing and proper

operation.

The Cheese Melter can be installed in combustible or noncombustible locations. Clearance from

combustible construction must be a minimum of 6 inches from the sides and 0 inches from the back.

There are no minimum clearances from noncombustible construction.

The Cheese Melter can be installed on a noncombustible counter, with or without 4" legs, or mounted

on a combustible or noncombustible wall: Leg kits and wall mounting brackets are available from your

Vulcan-Authorized Service Office for your model Cheese Melter. If installing the Cheese Melter on a

combustible counter, the 4" legs are required.

-

3 -

Page 4

ASSEMBLY — Legs (optional)

If using legs, four legs are required on 24, 36, and 48" models; six legs are required on 60 and 72"

models. Assemble legs to the bottom of the unit through threaded holes in the four corners of the unit;

on 60 and 72" models, the extra two legs mount at the middle of the front and back rails.

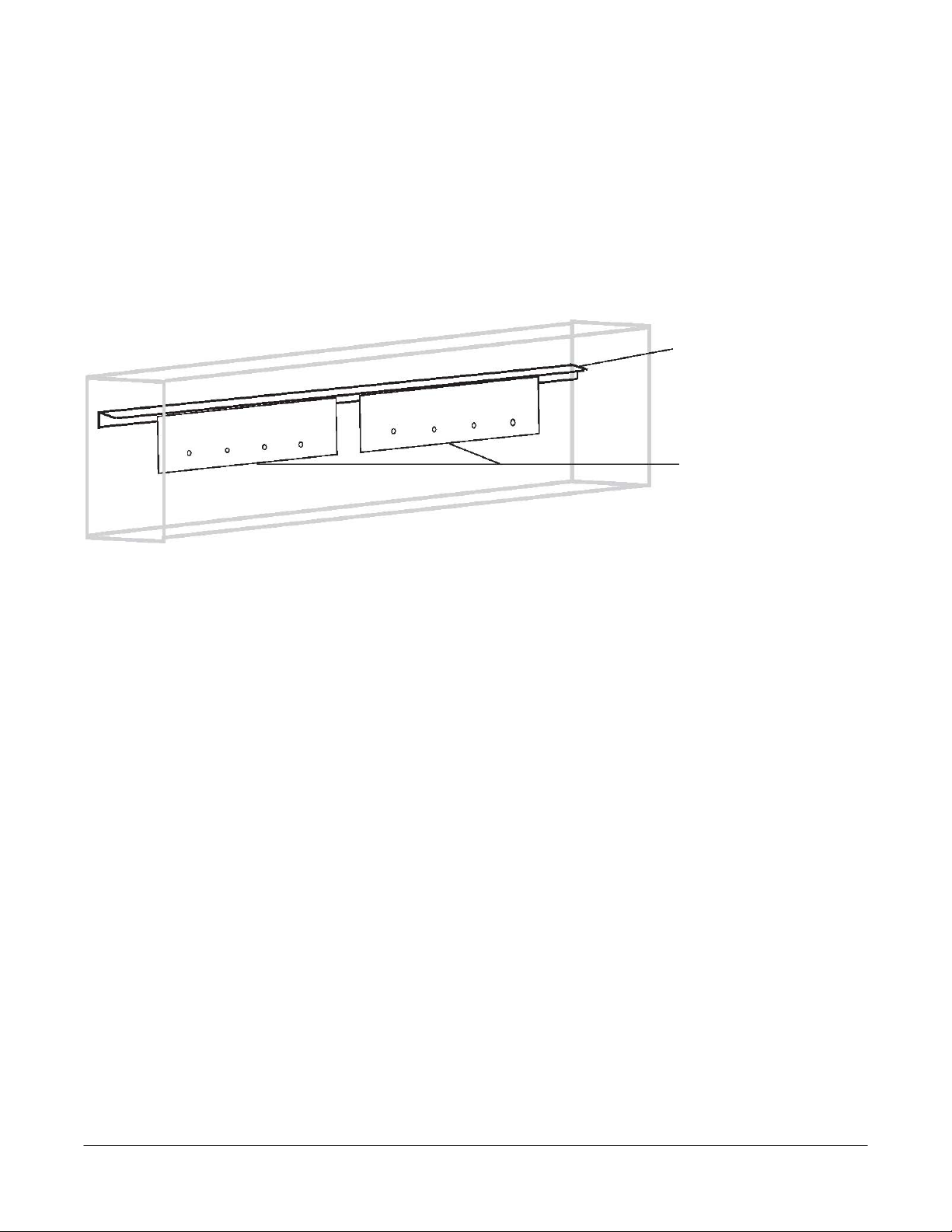

ASSEMBLY — Wall Mounting Brackets (optional)

If mounting the Cheese Melter on a wall: Attach the wall mounting bracket(s) to the wall with suitable

fasteners (not supplied with the kit); hang the Cheese Melter from its angle iron rail on the wall

mounting bracket(s) (Fig. 1).

Angle Iron on Rear of

Cheese Melter Frame

Wall Mounting Brackets

Fig. 1

INSTALLATION CODES AND STANDARDS

The Cheesemelter must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall include but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

NOTE: In the Commonwealth of Massachusetts

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3

-

4 -

Page 5

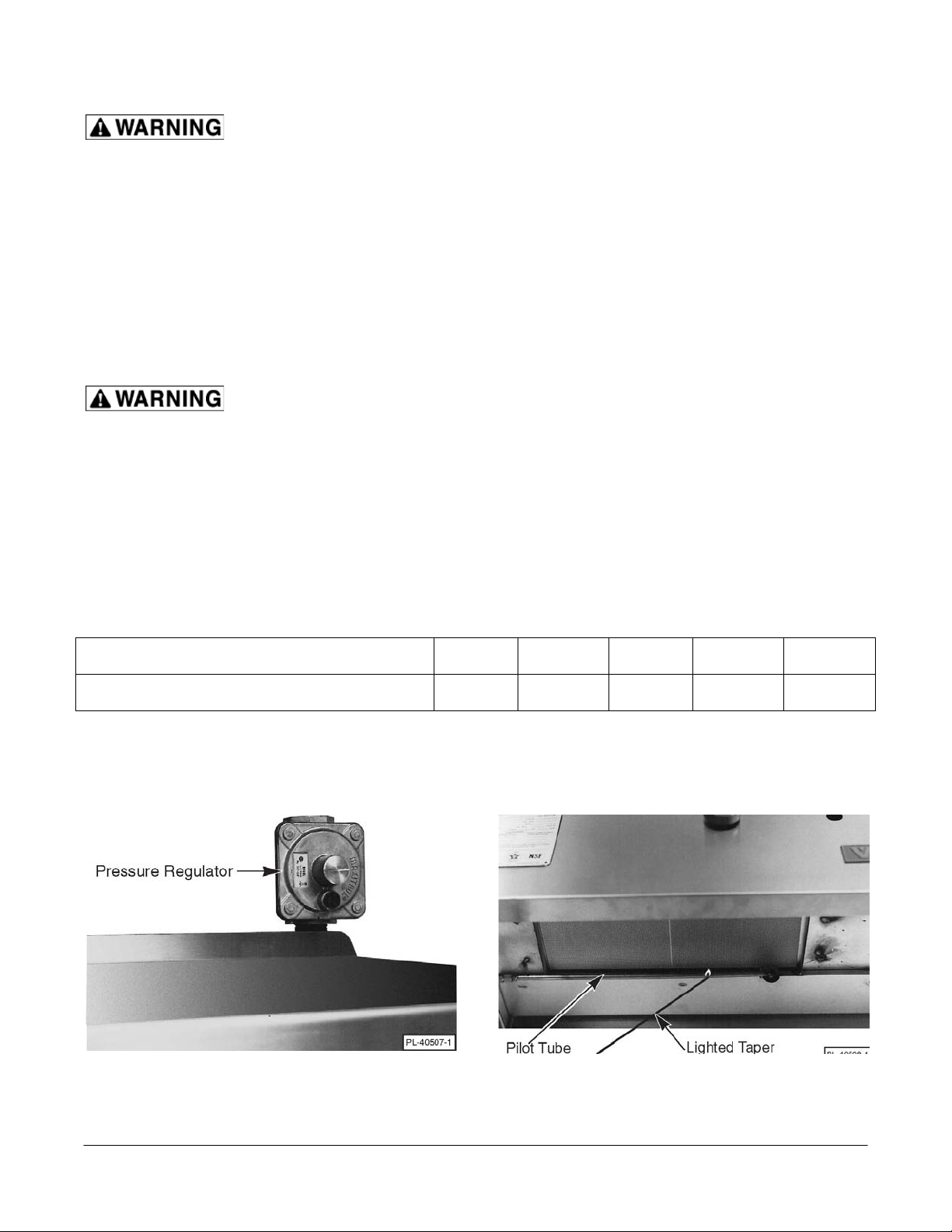

GAS CONNECTION

Gas supply connections and any pipe joint compound must be

resistant to the action of propane gases.

Codes require that a manual gas valve be installed in the gas supply line ahead of the appliance. Make sure the

pipes are clean and free of obstructions, dirt, and piping compound. A pressure regulator is supplied loose with

the Cheese Melter for installation in the gas supply line. The Natural gas regulator requires a pressure of 5" Water

Column. The Propane gas regulator requires a pressure of 10" Water Column. The arrow on the rear of the

pressure regulator indicates the direction of gas flow. The regulator (Fig. 2) must be installed so the arrow points

down. If it is installed so the arrow is not pointing down, the pressure must be reset. Connect the Cheese Melter

to the gas supply with a

tap is located on the manifold for checking the gas pressure. Natural or Propane gas conversion and orifice

changes for various altitudes can be performed by Vulcan-authorized servicers.

Use soap and water solution. Do not use an open flame.

TESTING THE GAS SUPPLY PIPING

When test pressures exceed ½ psig (3.45 kPa) the Cheese Melter and its individual shut-off valve must be

disconnected from the gas supply piping system during any pressure testing of the system. When test pressures

are 1/2 psig (3.45 kPa) or less, the Cheese Melter must be isolated from the gas supply piping system by closing

its individual shut-off valve during any pressure testing of the system.

3

/4" iron pipe or larger. If a flexible connector is used, it must be 3/4" I.D. A 1/8" pressure

Prior to lighting, check all joints in the gas supply line for leaks.

EXHAUST FAN

A mechanical exhaust hood must be installed above the appliance; the exhaust blower must have a capacity of

200 CFM per square foot of broiler area, check local code for specific requirements.

Model

Minimum Exhaust Fan Rating

ICM24

388 CFM 604 CFM 821 CFM 1038 CFM 1255 CFM

ICM36

ICM48

ICM60

ICM72

LIGHTING THE GAS PILOT TUBE(S)

Before lighting the Cheese Melter, make sure that all burners are turned off. Wait 5 minutes. Turn on the manual

gas valve and use a taper to light the gas pilot tube(s). A gas pilot tube is located below each burner (Fig. 3).

Fig. 2 Fig. 3

-

5 -

Page 6

The cheesemelter and its parts are hot. Use care when operating,

cleaning or servicing the cheesemelter.

CONTROLS (FIG. 4)

Burner Valve — Turn fully ON or

PilotAdjustmentScrew

OFF by rotating the control knob 1/4 turn.

Burnervalve

OFF

ON

The Cheese Melter rack can be positioned in one of the three operating levels.

Complete Shut Down

For complete shut-down: Turn the Burner Valve(s) off. Shut the manual gas valve off and the pilot tubes

will go out.

CLEANING

Cheese Melter must be cool before cleaning. Cheese Melter rack should be cleaned daily by washing

in hot water and detergent. Use non-abrasive type cleaning pads to remove burned on particles. After

washing, rinse with hot water.

Aluminized Steel Interior — clean with mild detergent (or soap) and water solution. Heavy soil can be

loosened with a wooden tool or use a non-etching cleaner recommended for aluminized steel. DO NOT

use steel wool, wire brush, or caustic solutions such as lye, soda ash, or ammonia. Rinse with clear

water and dry with a soft cloth.

Stainless Steel Interior — for routine cleaning use detergent (or soap) and water solution. Burned-on

foods and grease can be removed with an abrasive cleanser (scouring powder) mixed into a paste.

Apply with stainless steel wool — always rub with the grain. Rinse with clear water; dry with a soft cloth.

Vent System — At least once a year the exhaust hood (venting system) should be examined and

cleaned.

SERVICE

Contact your local Vulcan-authorized service office for repairs or adjustments needed on this

equipment.

-

6 -

Page 7

-

7 -

Page 8

-

8 -

Page 9

8 -

-

Page 10

7 -

-

requis sur cet appareil.

Communiquez avec votre bureau de service autorisé de Vulcan pour toute réparation ou ajustement

SERVICE

doit être examinée et nettoyée.

Système d’évacuation — au moins une fois par année, la hotte d’aspiration (le système d’évacuation)

grain. Rincez avec de l'eau propre, puis séchez avec un linge doux.

(poudre à récurer) mêlé en pâte. Appliquez à l’aide d’une laine d’acier; frottez toujours dans le sens du

(ou du savon) et d’eau. Les aliments brûlés et la graisse peuvent être enlevés avec un nettoyant abrasif

Partie interne en acier inoxydable — pour les nettoyages réguliers, utilisez une solution de détergent

propre, puis séchez avec un linge doux.

tels que de l’hydroxyde de sodium, de la soute du commerce et de l’ammoniac. Rincez avec de l'eau

décapant recommandé pour l’acier aluminié. N’utilisez PAS de laine d’acier ni de solutions caustiques

et d’eau. -Les grosses saletés peuvent être enlevées à l’aide d’un outil en bois ou d’un nettoyant non

Partie interne en acier aluminié — nettoyez à l’aide d’une solution de détergent doux (ou du savon)

rincez à l’eau.

Utilisez des tampons à récurer non abrasifs pour enlever les particules brûlées. Après le nettoyage,

La grille du four à gratiner doit être nettoyée quotidiennement avec de l'eau chaude et du détergent.

Le four à gratiner doit être froid avant de le nettoyer.

NETTOYAGE

soupape de gaz manuelle et les tubes de flamme pilote s’éteindront d’eux-mêmes.

Pour une mise à l’arrêt complet : mettez les soupapes de brûleur en position d’arrêt. Fermez la

Mise à l’arrêt complet

La grille du four à gratiner peut être placée à l’une des trois positions d’utilisation.

Page 11

6 -

-

ON

MARCHE

ARRÊT

Soupape de brûleur

Burnervalve

flamme pilote

Vis d’ajustement de

commande de ¼ de tour.

Soupape de brûleur — Placer entièrement à la position de marche ou d’arrêt en tournant le bouton de

COMMANDES (FIG. 4)

lors de l'utilisation, du nettoyage et de l'entretien du four à gratiner.

Le four à gratiner et ses pièces sont chauds. Soyez prudent

Fig. 3

flamme pilote

Briquet long

ON

Tube de

Fig. 2

Fig. 2

Burnervalve

pression

Régulateur de

tubes de flamme pilote au gaz. Un tube de flamme pilote au gaz est situé sous chaque brûleur (Fig. 3).

minutes. Tournez la soupape à gaz manuelle en position de marche et utilisez un briquet long pour allumer les

Avant d’allumer le four à gratiner, assurez-vous que tous les brûleurs sont à la position d’arrêt. Attendez 5

ALLUMAGE DES TUBES DE FLAMME PILOTE AU GAZ

Page 12

pi3/min

1 255

ICM72

/min

3

pi

1 038

ICM60

5 -

-

pi3/min

821

ICM48

pi3/min

604

ICM36

/min

3

388

pi

ICM24

/min par pied carré de la zone du grilloir; vérifiez le code local au sujet des exigences

3

Capacité minimum de la hotte d’aspiration

Modèle

spécifiques.

une capacité de 200 pi

Une hotte d’aspiration mécanique doit être installée au-dessus de l’appareil; la soufflerie d’aspiration doit avoir

VENTILATEUR D’ÉVACUATION

pression du système.

moins, le four à gratiner doit être isolé du système par la fermeture du robinet d’arrêt pour effectuer tout test de

pression du système. Lorsque les pressions de test d'alimentation sont de 1/2 psi manométrique (3,45 kPa) ou

individuel doivent être débranchés du système de conduite d'alimentation de gaz pour effectuer tout test de

Lorsque les pressions de test dépassent 1/2 psi manométrique (3,45 kPa), le four à gratiner et son robinet d'arrêt

TEST DES CONDUITES D'ALIMENTATION DE GAZ

solution de savon et d'eau. N'utilisez pas une flamme nue.

d'alimentation de gaz pour vous assurer qu'il n'y a pas de fuite. Utilisez une

Avant l'allumage, vérifiez tous les raccords de la conduite

différentes altitudes peuvent être effectués par les techniciens autorisés de Vulcan.

vérification de la pression du gaz. La conversion du gaz naturel ou propane et un changement d’orifice pour

interne du boyau doit être de ¾ pouce. Une prise sous pression de1/8 po est située sur le collecteur pour la

l’alimentation de gaz à l’aide d’un tuyau en fer de ¾ po ou plus. Si vous utilisez un boyau flexible, le diamètre

la flèche ne pointe la vers le bas, la pression devra alors être réinitialisée. Branchez le four à gratiner à

régulateur (Fig. 2) doit être installé de sorte que la flèche pointe vers le bas. Si régulateur est installé de sorte que

colonne d’eau de 10 po. La flèche à l’arrière du régulateur de pression indique le sens de la circulation du gaz. Le

régulateur de gaz naturel nécessite une colonne d’eau de 5 po. Le régulateur de gaz propane nécessite une

est fourni en pièce détaché avec le four à gratiner. Il doit être installé sur la conduite d'alimentation de gaz. Le

Assurez-vous que les tuyaux sont libres d'obstruction, de poussières et de pâte à joint. Un régulateur de pression

Les codes exigent qu'une soupape de gaz manuelle soit installée dans la conduite de gaz à l'avant de l’appareil.

doivent être résistantes à l'action du gaz propane.

Les connexions de l'alimentation du gaz et les pâtes à joints

BRANCHEMENT DU GAZ

Page 13

4 -

-

Ontario, Canada M9W 1R3

disponible auprès de l'Association Canadienne du Gaz 178 Rexdale Blvd., Etobicoke,

3. CAN/CSA-B149.2 Code d'Installation du gaz propane (plus récente édition),

2. CAN/CSA-B149.1 Installation du gaz naturel (plus récente édition)

1. Codes locaux.

Au Canada :

MA 02269.

disponible auprès de National Fire Protection Association, Batterymarch Park, Quincy,

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, plus récente édition,

doivent être conformes à 248 CMR.

système d'échappement avec un registre ou des dispositifs motorisé d'échappement

Tous les appareils fonctionnant au gaz et ayant une hotte de ventilation ou un

REMARQUE : Dans le Commonwealth du Massachusetts

Secretary Standards Council, NFPA, 1 Batterymarch Park Quincy, MA 02169-7471.

Standards Committee Z223, @ 400 N. Capital St. NW, Washington, DC 20001 ou du

exemplaires sont disponibles auprès de The American Gas Association Accredited

inclure, mais sans s'y limiter: NFPA #54 Section 10.3.5.2 pour la ventilation. Des

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (plus récente édition). Ceci doit

1. Codes d'État et locaux.

Aux États-Unis d'Amérique :

Le four à gratiner doit être installé conformément à :

CODES ET NORMES D'INSTALLATION

Fig. 1

muraux

Supports de montage

four à gratiner

l’arrière du châssis du

Pièce à angle en fer à

son rail à angle en fer aux supports muraux (Fig. 1)

des pièces de fixation appropriées (non comprises avec la trousse); suspendez le four à gratiner avec

Pour le montage du four à gratiner sur un mur : fixez les supports de montage muraux au mur à l’aide

ASSEMBLAGE — Supports de montage muraux (en option)

arrière.

60 et de 72 pouces, les deux pattes supplémentaires doivent être installées au milieu des rails avant et

l’appareil à l’aide des trous filetés se trouvant dans les quatre coins de l'appareil; pour les modèles de

po alors que six pattes sont requises pour les modèles de 60 et de 72 po. Installez les pattes au bas de

Si vous devez utiliser des pattes, quatre pattes sont alors requises pour les modèles de 24, 36 et de 48

ASSEMBLAGE — Pattes (en option)

Page 14

3 -

-

Les pattes de 4 po sont requises pour une installation du four à gratiner sur un comptoir combustible.

disponibles auprès de votre bureau de service autorisé Vulcan pour votre modèle de four à gratiner.

un mur combustible ou incombustible : La trousse de pattes et de supports de montage muraux sont

Le four à gratiner peut être installé sur un comptoir incombustible, avec ou sans pattes de 4 po, ou sur

INSTALLATION

n'y a pas de dégagement minimum pour une construction incombustible.

de la construction combustible doit être d’au moins 6 pouces sur les côtés et de 0 pouce à l’arrière. Il

Le four à gratiner peut être installé dans des endroits combustibles et incombustibles. Le dégagement

fonctionnement de l’appareil.

Un dégagement suffisant doit être prévu à l'avant et sur les côtés de l'appareil pour l'entretien et un bon

pour les ouvertures d'air de la chambre de combustion.

d’aération. Des moyens doivent être prévus pour une circulation d’air adéquate et un espace suffisant

dessus du four à gratiner doit être libre de toute obstruction à la circulation de l’air de combustion et

La zone entourant l'appareil doit être gardée libre de substances combustibles. La zone à l’avant et au-

EMPLACEMENT

indiquées sur la plaque signalétique située sur la partie avant.

Avant l'installation, vérifiez que le type de gaz (naturel ou propane) est conforme aux spécifications

avec le transporteur dans les 15 jours de la livraison.

dommages sont trouvés sur le four à gratiner, conservez les matériaux d'emballage et communiquez

Vérifiez immédiatement après le déballage si des dommages sont survenus lors du transport. Si des

DÉBALLAGE

20 000 BTU/h 35 000 BTU/h 40 000 BTU/h 55 000 BTU/h 70 000 BTU/h

Cote BTU

Modèle ICM24 ICM36 ICM48 ICM60 ICM72

PUISSANCE DU GAZ

bouton de commande.

d’un ou de deux brûleurs et chaque brûleur est muni de sa propre flamme pilote et d’un

sont disponibles dans des largeurs de 24, 36, 48, 60 et 72 po. Les modèles sont dotés

Les fours à gratiner par infrarouge à gaz Vulcan utilisent la chaleur efficiente du gaz et

GÉNÉRALITÉS

CONSERVEZ CE GUIDE À DES FINS DE RÉFÉRENCE ULTÉRIEURE

DE FOURS À GRATINER PAR INFRAROUGE À GAZ

MODÈLES ICM24, ICM36, ICM48, ICM60 ET ICM72

Installation, utilisation et entretien des

Page 15

2 -

pp

-

areil.

LORS D’UNE PANNE ÉLECTRIQUE.

NE PAS TENTER D'UTILISER CET APPAREIL

faire l'entretien de cet a

d'utilisation et d'entretien avant d'installer ou de

attentivement les directives d'installation,

dommages, des blessures ou la mort. Lire

un entretien inapproprié peut entraîner des

ajustement, une modification, une réparation ou

Une installation, un

AVERTISSEMENT

AUTRE APPAREIL.

DANS LES ENVIRONS DE CET APPAREIL OU DE TOUTE

D'AUTRES VAPEURS OU LIQUIDES INFLAMMABLES

NE PAS RANGER NI UTILISER DE GAZOLINE OU

POUR VOTRE SÉCURITÉ

IMPORTANT

SÉCURITÉ

GAZ POUR LA RÉPARATION DE L'APPAREIL.

COMPAGNIE DE GAZ OU LE FOURNISSEUR DE

PRINCIPALE ET COMMUNIQUER AVEC LA

L'APPAREIL À L’AIDE DE LA SOUPAPE

EN PRÉSENCE D'ODEUR DE GAZ, ARRÊTER

AUPRÈS D’UN FOURNISSEUR LOCAL DE GAZ.

D’ODEUR DE GAZ. CES RENSEIGNEMENTS PEUVENT AUSSI ÊTRE OBTENUS

AFFICHEZ À UN ENDROIT VISIBLE LES DIRECTIVES À SUIVRE EN PRÉSENCE

COUVERT PAR CE MANUEL.

MARCHE INITIALE SUR LE SITE ET DES AJUSTEMENTS DE L'APPAREIL

L’INSTALLATION D’UN APPAREIL FONCTIONNANT AU GAZ, DE LA MISE EN

CE MANUEL A ÉTÉ ÉLABORÉ POUR DU PERSONNEL QUALIFIÉ EN VUE DE

RENSEIGNEMENTS IMPORTANTS POUR VOTRE

Page 16

FORMULAIRE F-30908 (2-14)

RÉFÉRENCE ULTÉRIEURE

CONSERVER CE GUIDE À DES FINS DE

Modèle ICM-48

Baltimore, MD 21222

3600 North Point Blvd.

©ITW Food Equipment Group, LLC

ICM72 ML-52474, 52480

ICM60 ML-52473, 52479

ICM48 ML-52472, 52478

ICM36 ML-52471, 52477

ICM24 ML-52470, 52476

MODÈLE

INFRAROUGE À GAZ

DU FOUR À GRATINER PAR

D’UTILISATION

GUIDE D’INSTALLATION ET

Loading...

Loading...