Vulcan-Hart GR65F, GR65, GR85, GR85F, GR35 User Manual

...

SERVICE MANUAL

GR SERIES GAS FRYERS WITH

MILLIVOLT CONTROLS

MODEL ML MODEL ML

GR25 126988 GR35F 126998

GR35 126989 GR45F 126999

GR45 126990 GR65F 135534

GR65 126991 GR85F 135535

GR85 126992

GR35 SHOWN

- NOTICE This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified. If you have attended a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this manual.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

For additional information on Vulcan-Hart Company or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com.

A product of VULCAN-HART LOUISVILLE, KY 40201-0696

F25125 (March 2003)

GR SERIES GAS FRYERS

TABLE OF CONTENTS

GENERAL ................................................................................ 3

Introduction ............................................................................ 3

Single Floor Model or Battery Fryers ........................................................ 3

Model Designations ................................................................. 3

Models and Features ................................................................ 3

Kleenscreen Filtering System .............................................................. 4

Model Designations ................................................................. 4

Models and Features ................................................................ 4

Specifications ..........................................................................5

Electrical .......................................................................... 5

Gas Pressures ..................................................................... 5

Input BTU Rating ................................................................... 5

Tools ................................................................................. 5

REMOVAL AND REPLACEMENT OF PARTS .................................................... 5

Front Panel ............................................................................ 5

Door ................................................................................. 5

Control Thermostat...................................................................... 6

High Limit Thermostat ................................................................... 6

Main Burners .......................................................................... 7

Main Burner Orifice...................................................................... 8

Gas Combination Valve .................................................................. 8

Pilot Burner ............................................................................ 9

Thermopile ............................................................................9

Fry Tank Assembly..................................................................... 10

Filter Valve and Discard Valve Switches .................................................... 11

Pump and Motor ....................................................................... 11

SERVICE PROCEDURES AND ADJUSTMENTS ................................................. 12

Control Thermostat Calibration............................................................ 12

Gas Manifold Pressure Adjustment ........................................................ 13

Pilot Burner Flame Adjustment............................................................ 13

Millivolt Controls Test ................................................................... 14

ELECTRICAL OPERATION .................................................................. 15

Component Function ................................................................... 15

Component Location ................................................................... 16

Sequence of Operation .................................................................. 17

Millivolt Controls ................................................................... 17

Kleenscreen Filtering System ......................................................... 17

Schematic Diagram .................................................................... 18

Millivolt Controls ................................................................... 18

Wiring Diagrams ....................................................................... 19

Millivolt Controls ................................................................... 19

Junction Box, Kleenscreen Filtering System ............................................. 20

Frymate (Dump Station) ............................................................. 21

TROUBLESHOOTING ...................................................................... 22

All Models ............................................................................ 22

Frymate (Dump Station) with Optional Heater ................................................ 23

Kleenscreen Filtering System ............................................................. 23

CONDENSED SPARE PARTS LIST ........................................................... 24

© VULCAN 2003

F25125 (March 2003) Page 2 of 24

GR SERIES GAS FRYERS - GENERAL

GENERAL

INTRODUCTION

This Service Manual covers specific service information related to the models listed on the front cover.

SINGLE FLOOR MODEL OR

BATTERY FRYERS

Fryers with the Filter-Ready option installed, use the Mobile Filter. For service information related to the Mobile

Filter, refer to F24599 MOBILE FILTERS. Filter-Ready fryers are available as single floor models only.

The information in the GR Series Service Manual also applies to Non-Filter Ready fryers. Non-Filter Ready fryers

are available in batteries of two to six.

An RO Frymate (dump station) can be configured in a battery with fryers 15 1/2" or 21" in width.

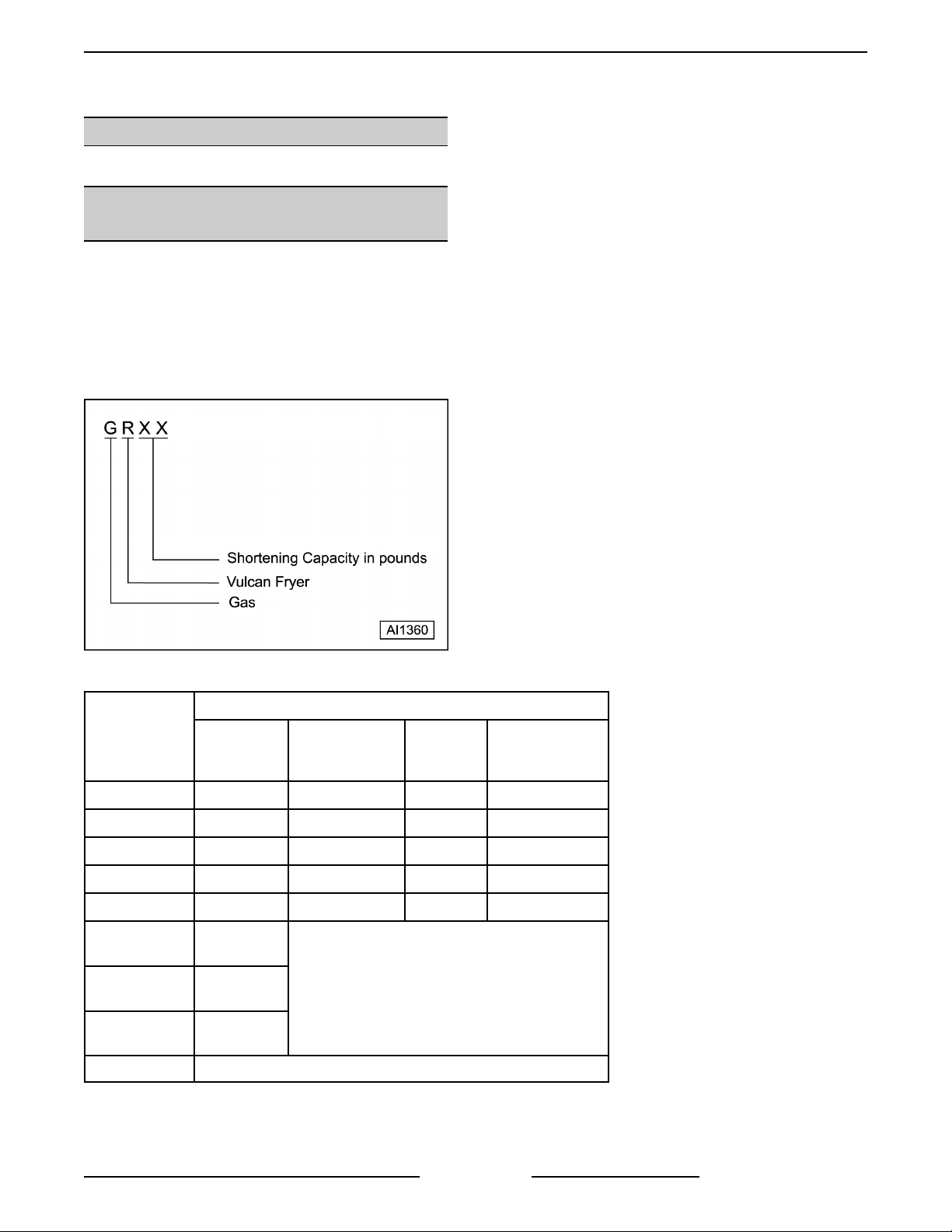

Model Designations

Models and Features

MODEL

1

GR25

GR35

GR45

GR65

GR85

RO15

(Frymate)

RO21

(Frymate)

RO21S

(Frymate)

NOTE:

FRYER

WIDTH

(INCHES)

10 1/2 25-30 Full Thermostat

15 1/2 35-40 Full Thermostat

15 1/2 45-50 Full Thermostat

15 1/2

1. Available in battery configurations only.

FEATURES

SHORTENING

CAPACITY

(POUNDS)

21 65-70 Full Thermostat

21 85-90 Full Thermostat

21

21

FRY

TANK

COOKING

CONTROL

Page 3 of 24

F25125 (March 2003)

GR SERIES GAS FRYERS - GENERAL

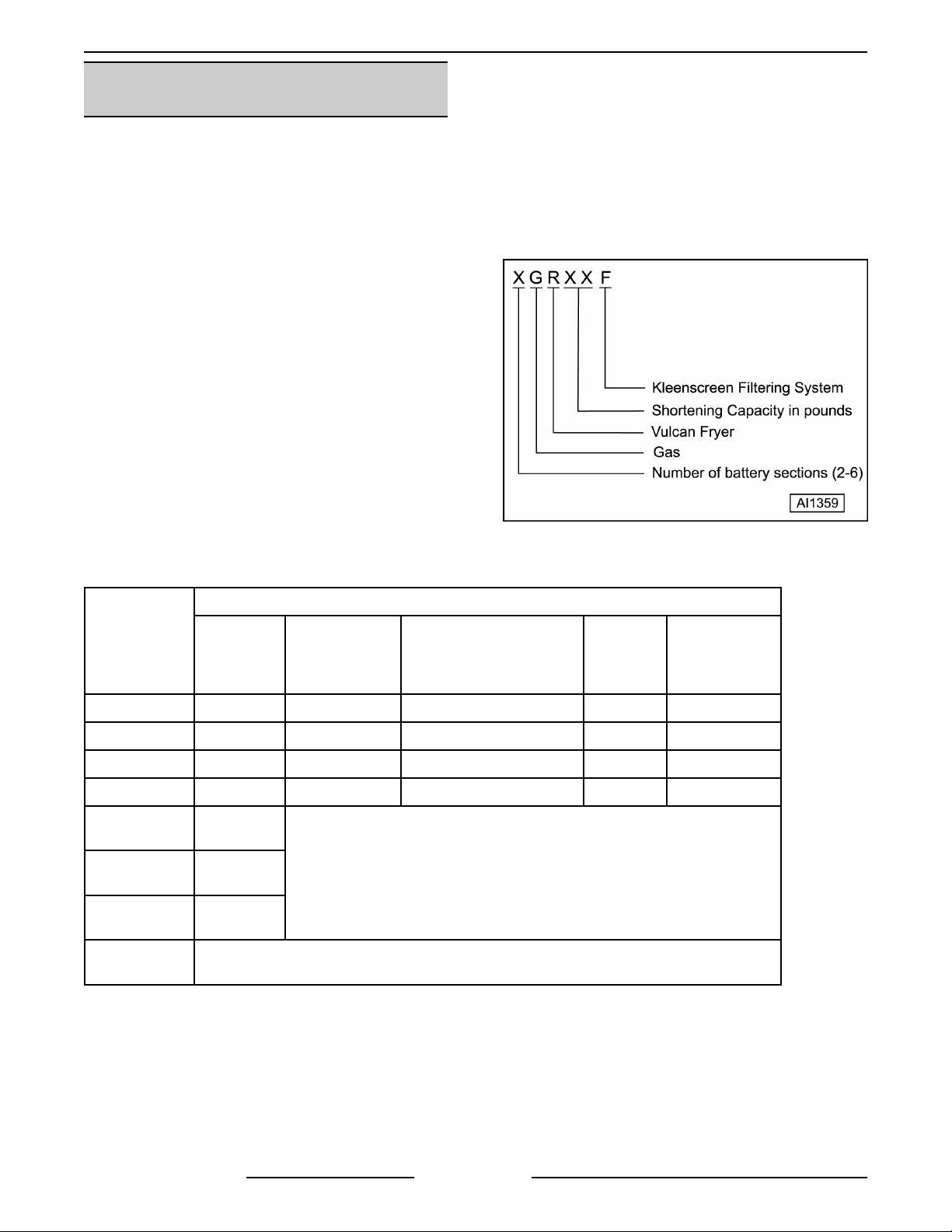

KLEENSCREEN FILTERING

SYSTEM

The new Kleenscreen filtering system has been

integrated into the GR Series fryer battery. The filter

is housed in a pull-out drawer assembly at the base

of the fryer. The filtering components in the drawer

include a stainless steel filter tank, crumb-catch

basket and a dual element mesh filter screen. With

the filter drawer closed, a self-seating oil return line

provides the path to return the filtered oil to the fry

tank.

This system is designed to provide a thorough and

easy method for filtering shortening.

Some of the benefits include:

• Self-contained system eliminating the use of

external filter equipment.

• Paperless filtering system.

• Easy to clean and low maintenance.

The Kleenscreen fryer battery still utilizes many of

the same components as the single floor model and

Non-Filter ready battery fryers.

Kleenscreen fryer batteries are available in a

minimum of two and a maximum of six fryer

sections. The fryer size of each section is identical.

An RO Frymate (dump station) can also be included

as one or more of the sections.

Model Designations

Models and Features

MODEL

2GR35F

2GR45F

2GR65F

2GR85F

RO15

(Frymate)

RO21

(Frymate)

RO21S

(Frymate)

NOTES:

1

1

2

2

FRYER

WIDTH

(INCHES)

15 1/2

1. For each additional fryer section, add 15 1/2" to the width.

2. For each additional fryer section, add 21" to the width.

FEATURES

SHORTENING

CAPACITY

PER FRYER

(POUNDS)

31 35-40 80 Full Thermostat

31 45-50 80 Full Thermostat

42 65-70 130 Full Thermostat

42 85-90 130 Full Thermostat

21

KLEENSCREEN FILTER

PAN CAPACITY

(POUNDS)

FRY

TANK

COOKING

CONTROL

21

F25125 (March 2003) Page 4 of 24

GR SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

SPECIFICATIONS

Electrical

• 120VAC supply for Filter-Ready fryers and

Kleenscreen filter models only. The filter pump

motor draws approximately 5 amps.

Gas Pressures

Manifold (per fryer section):

• Natural - 4" W.C.

• Propane - 10" W.C.

Building supply pressure (Min):

• Natural - 5" W.C. (7" W.C. battery units)

• Propane - 11" W.C. (12" W.C. battery units)

NOTE: Propane or Natural gases -14" W.C. (Max).

Input BTU Rating

GR SERIES

GR25, GR25F 2 60,000

GR35, GR35F 3 90,000

GR45, GR45F 4 120,000

GR65, GR65F 5 150,000

GR85, GR85F 5 150,000

NO. OF

TUBES

BTU/HR/SECTION

TOOLS

Standard

• Standard set of hand tools.

• VOM with AC current tester.

NOTE: Any quality VOM with a sensitivity of

20,000 ohms per volt can be used.

• Temperature tester (thermocouple type).

• U-Tube Manometer.

• Pipe joint compound suitable for use with

propane gas.

REMOVAL AND REPLACEMENT OF PARTS

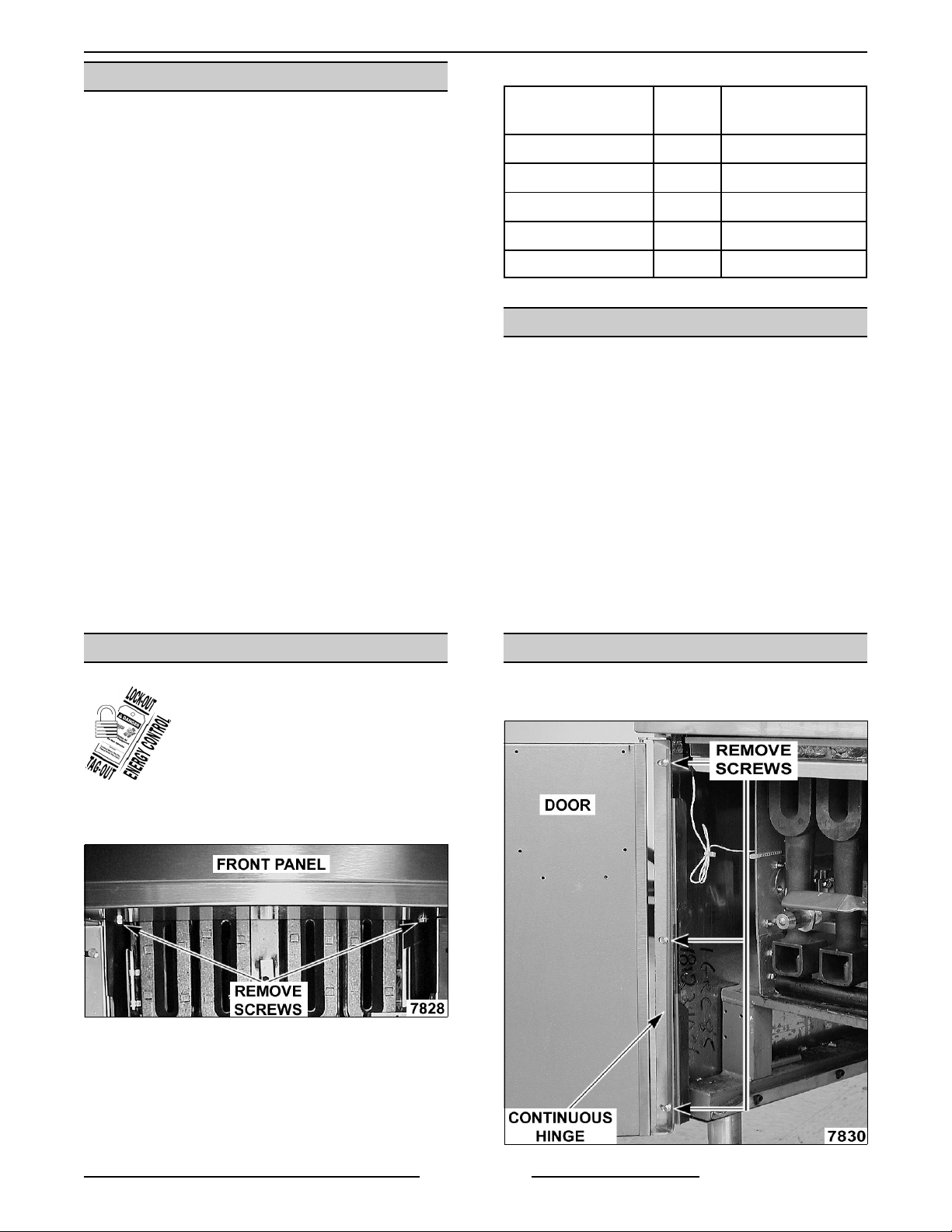

FRONT PANEL

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Open fryer door and remove screws from front

panel.

2. Lift front panel from fryer.

DOOR

1. Open the fryer door and remove screws

securing hinge & door assembly to fryer.

3. Reverse procedure to install.

Page 5 of 24

F25125 (March 2003)

GR SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

2. When replacing door, install screws and tighten

top and bottom screws enough to hold door in

place.

3. Close door, check alignment and adjust if

necessary.

4. Finish tightening screws to fully secure.

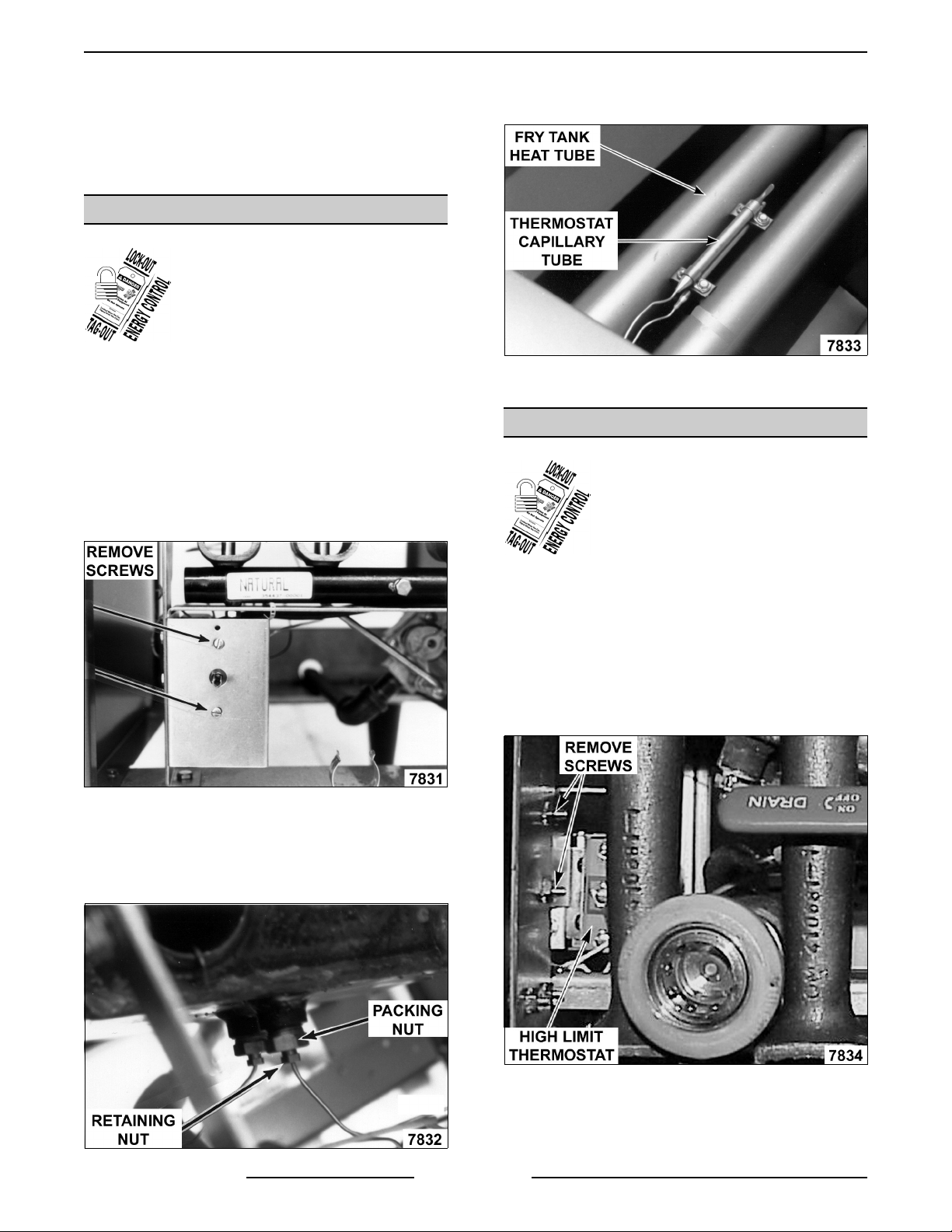

CONTROL THERMOSTAT

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

CAUTION: Do not sharply bend and kink the

capillary tube or damage may occur.

1. Drain shortening from fry tank.

2. Remove burners (as necessary) as outlined

under MAIN BURNERS.

3. Remove knob from control thermostat shaft

then remove control thermostat from mounting

bracket.

6. Remove screws securing capillary tube

mounting clips to the fry tank heat tube then

remove capillary tube.

7. Reverse procedure to install and check for

proper operation.

HIGH LIMIT THERMOSTAT

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

NON FILTER READY SHOWN

4. Disconnect lead wires from control thermostat.

5. Remove the capillary tube retaining and packing

nuts, from the bottom of fry tank.

CAUTION: Do not sharply bend and kink the

capillary tube or damage may occur.

1. Drain shortening from fry tank.

2. Remove burners (as necessary) as outlined

under MAIN BURNERS.

3. Remove screws securing the high limit

thermostat to mounting bracket.

4. Disconnect lead wires from high limit

F25125 (March 2003) Page 6 of 24

thermostat.

GR SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

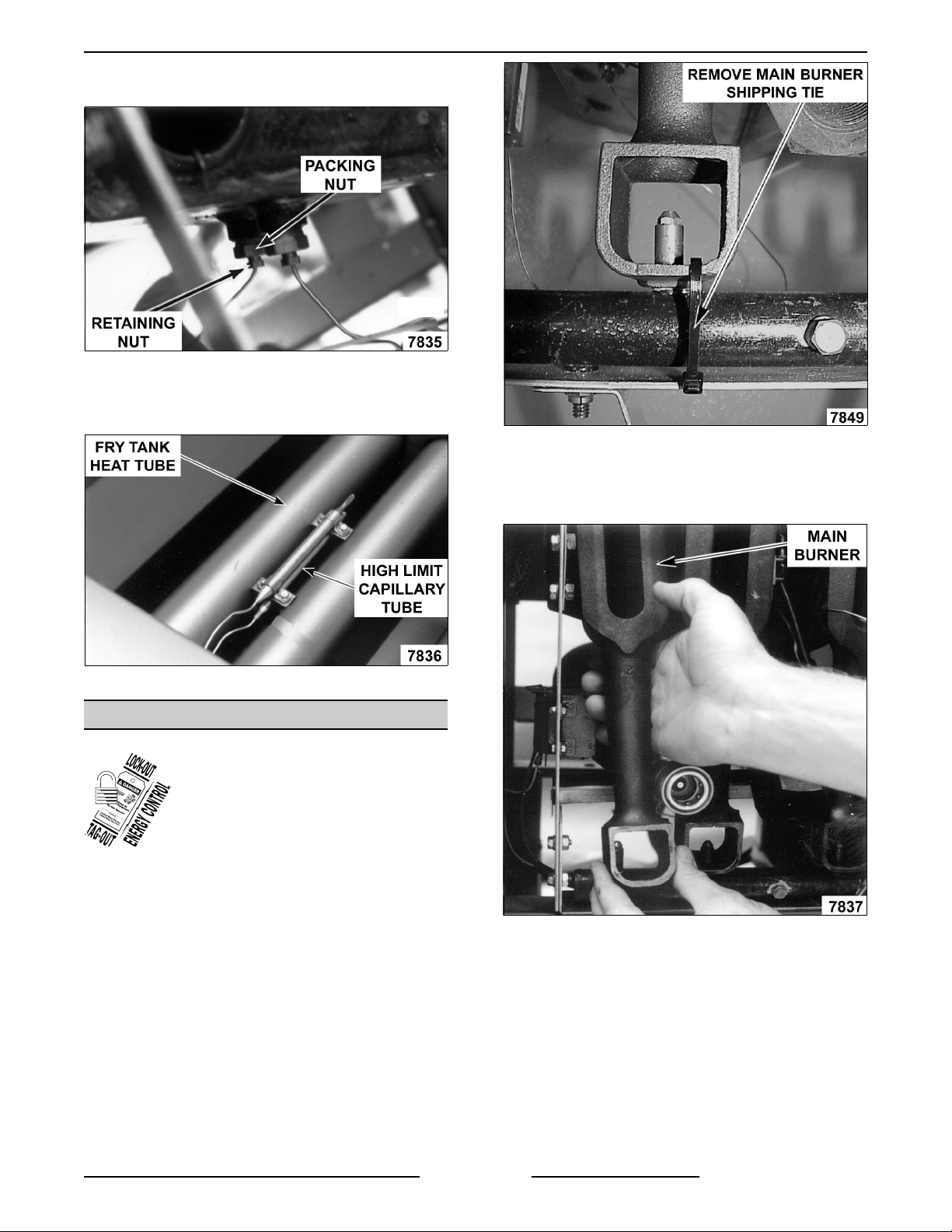

5. Remove the capillary tube retaining and packing

nuts, from the bottom of fry tank.

6. Remove screws securing capillary tube

mounting clips to the fry tank heat tube then

remove capillary tube.

3. Lift main burner up and tilt the top of burner

toward fry tank until it clears the gas orifice at

the bottom.

7. Reverse procedure to install.

MAIN BURNERS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

1. Open fryer door.

2. Remove main burner shipping ties (if installed).

NOTE: All shipping ties should be removed during

installation. Do not replace for normal operation.

A. Lift main burner from fryer.

NOTE: The main burners mount to the fryers’ burner

mounting bracket by shoulder bolts that rest in the

keyway slot.

Page 7 of 24

F25125 (March 2003)

GR SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

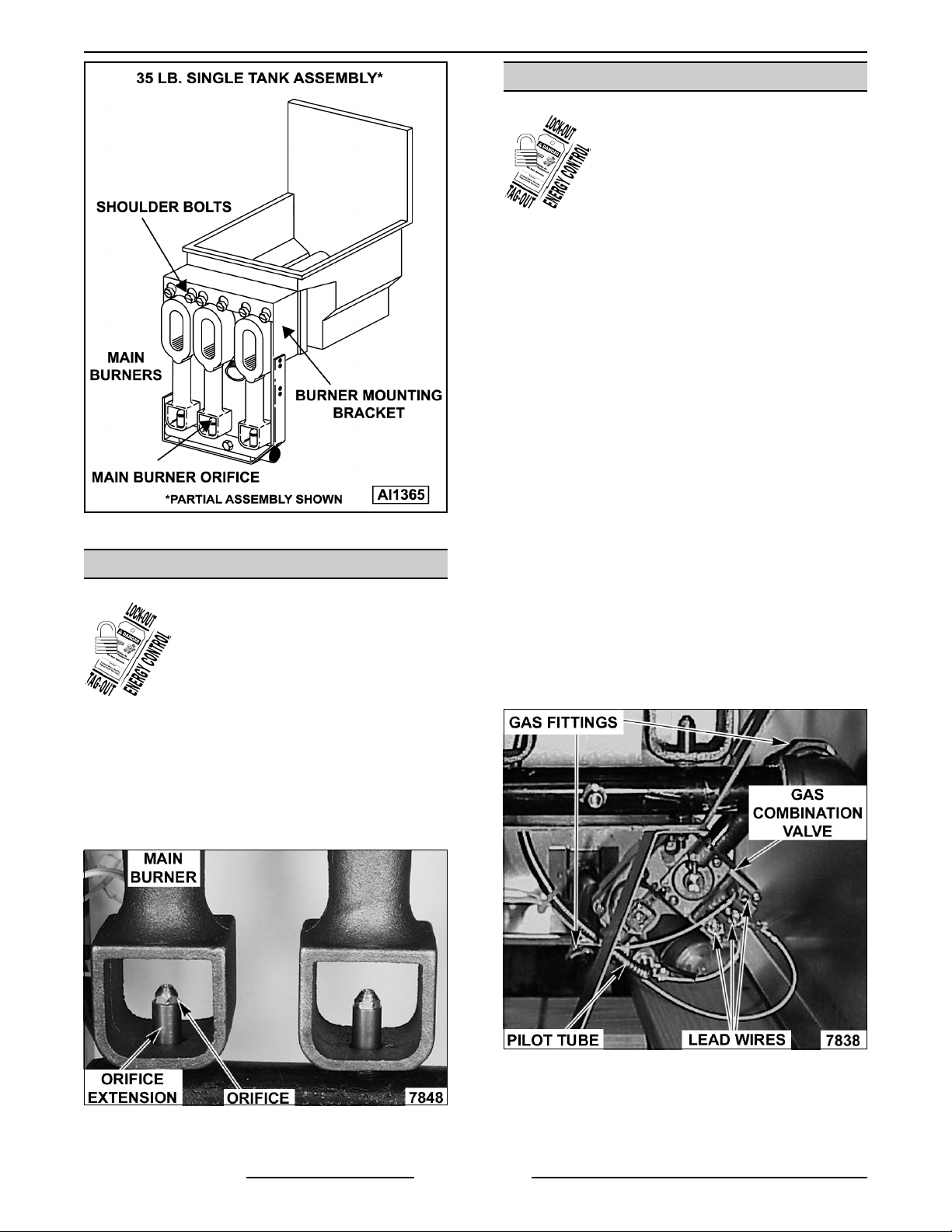

GAS COMBINATION VALVE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

NOTE: Gas combination valves are not serviceable

and should not be disassembled. Once the problem

has been isolated to this control, replace it. Do not

attempt to repair the assembly.

1. Remove burners (as necessary) as outlined

under MAIN BURNERS.

4. Reverse procedure to install.

MAIN BURNER ORIFICE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

1. Remove main burner orifice from orifice

extension.

NOTE: When installing, do not over tighten the

orifice or damage to the threads may occur.

2. Disconnect lead wires from gas combination

valve.

3. On filter ready and Kleenscreen fryers only,

remove cotter pin securing handle to gas

combination valve on/off knob. Pull handle (with

gas combination valve knob bracket attached)

away from valve assembly.

4. Disconnect pilot tube.

5. Separate gas line fittings then remove gas

combination valve assembly.

NOTE: Remove fittings and piping from gas

combination valve and install (in same orientation)

2. Reverse procedure to install.

F25125 (March 2003) Page 8 of 24

on the replacement valve.

NON FILTER READY SHOWN

Loading...

Loading...