Page 1

SERVICE MANUAL

GR SERIES GAS FRYERS WITH

MILLIVOLT CONTROLS

MODEL ML MODEL ML

GR25 126988 GR35F 126998

GR35 126989 GR45F 126999

GR45 126990 GR65F 135534

GR65 126991 GR85F 135535

GR85 126992

GR35 SHOWN

- NOTICE This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified. If you have attended a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this manual.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

For additional information on Vulcan-Hart Company or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com.

A product of VULCAN-HART LOUISVILLE, KY 40201-0696

F25125 (March 2003)

Page 2

GR SERIES GAS FRYERS

TABLE OF CONTENTS

GENERAL ................................................................................ 3

Introduction ............................................................................ 3

Single Floor Model or Battery Fryers ........................................................ 3

Model Designations ................................................................. 3

Models and Features ................................................................ 3

Kleenscreen Filtering System .............................................................. 4

Model Designations ................................................................. 4

Models and Features ................................................................ 4

Specifications ..........................................................................5

Electrical .......................................................................... 5

Gas Pressures ..................................................................... 5

Input BTU Rating ................................................................... 5

Tools ................................................................................. 5

REMOVAL AND REPLACEMENT OF PARTS .................................................... 5

Front Panel ............................................................................ 5

Door ................................................................................. 5

Control Thermostat...................................................................... 6

High Limit Thermostat ................................................................... 6

Main Burners .......................................................................... 7

Main Burner Orifice...................................................................... 8

Gas Combination Valve .................................................................. 8

Pilot Burner ............................................................................ 9

Thermopile ............................................................................9

Fry Tank Assembly..................................................................... 10

Filter Valve and Discard Valve Switches .................................................... 11

Pump and Motor ....................................................................... 11

SERVICE PROCEDURES AND ADJUSTMENTS ................................................. 12

Control Thermostat Calibration............................................................ 12

Gas Manifold Pressure Adjustment ........................................................ 13

Pilot Burner Flame Adjustment............................................................ 13

Millivolt Controls Test ................................................................... 14

ELECTRICAL OPERATION .................................................................. 15

Component Function ................................................................... 15

Component Location ................................................................... 16

Sequence of Operation .................................................................. 17

Millivolt Controls ................................................................... 17

Kleenscreen Filtering System ......................................................... 17

Schematic Diagram .................................................................... 18

Millivolt Controls ................................................................... 18

Wiring Diagrams ....................................................................... 19

Millivolt Controls ................................................................... 19

Junction Box, Kleenscreen Filtering System ............................................. 20

Frymate (Dump Station) ............................................................. 21

TROUBLESHOOTING ...................................................................... 22

All Models ............................................................................ 22

Frymate (Dump Station) with Optional Heater ................................................ 23

Kleenscreen Filtering System ............................................................. 23

CONDENSED SPARE PARTS LIST ........................................................... 24

© VULCAN 2003

F25125 (March 2003) Page 2 of 24

Page 3

GR SERIES GAS FRYERS - GENERAL

GENERAL

INTRODUCTION

This Service Manual covers specific service information related to the models listed on the front cover.

SINGLE FLOOR MODEL OR

BATTERY FRYERS

Fryers with the Filter-Ready option installed, use the Mobile Filter. For service information related to the Mobile

Filter, refer to F24599 MOBILE FILTERS. Filter-Ready fryers are available as single floor models only.

The information in the GR Series Service Manual also applies to Non-Filter Ready fryers. Non-Filter Ready fryers

are available in batteries of two to six.

An RO Frymate (dump station) can be configured in a battery with fryers 15 1/2" or 21" in width.

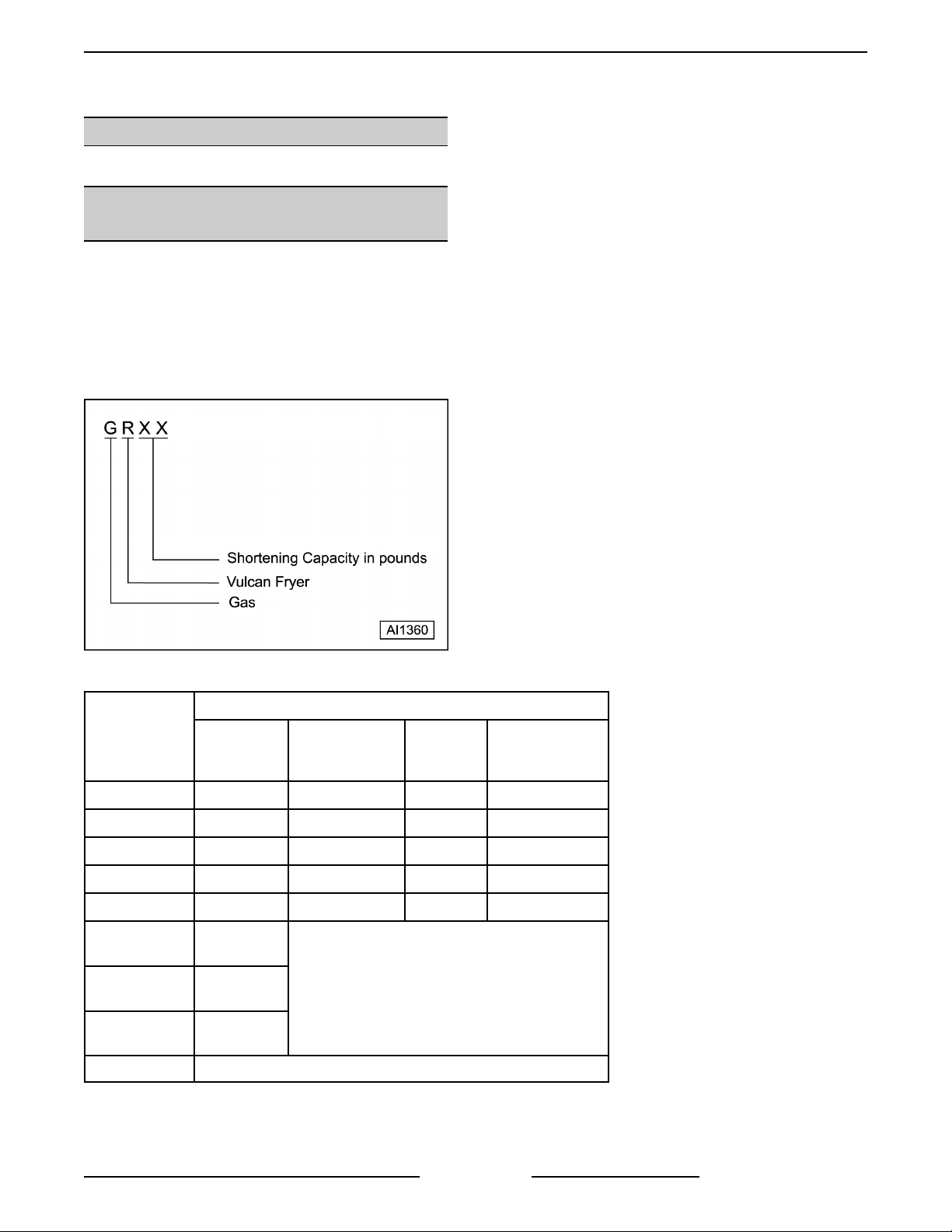

Model Designations

Models and Features

MODEL

1

GR25

GR35

GR45

GR65

GR85

RO15

(Frymate)

RO21

(Frymate)

RO21S

(Frymate)

NOTE:

FRYER

WIDTH

(INCHES)

10 1/2 25-30 Full Thermostat

15 1/2 35-40 Full Thermostat

15 1/2 45-50 Full Thermostat

15 1/2

1. Available in battery configurations only.

FEATURES

SHORTENING

CAPACITY

(POUNDS)

21 65-70 Full Thermostat

21 85-90 Full Thermostat

21

21

FRY

TANK

COOKING

CONTROL

Page 3 of 24

F25125 (March 2003)

Page 4

GR SERIES GAS FRYERS - GENERAL

KLEENSCREEN FILTERING

SYSTEM

The new Kleenscreen filtering system has been

integrated into the GR Series fryer battery. The filter

is housed in a pull-out drawer assembly at the base

of the fryer. The filtering components in the drawer

include a stainless steel filter tank, crumb-catch

basket and a dual element mesh filter screen. With

the filter drawer closed, a self-seating oil return line

provides the path to return the filtered oil to the fry

tank.

This system is designed to provide a thorough and

easy method for filtering shortening.

Some of the benefits include:

• Self-contained system eliminating the use of

external filter equipment.

• Paperless filtering system.

• Easy to clean and low maintenance.

The Kleenscreen fryer battery still utilizes many of

the same components as the single floor model and

Non-Filter ready battery fryers.

Kleenscreen fryer batteries are available in a

minimum of two and a maximum of six fryer

sections. The fryer size of each section is identical.

An RO Frymate (dump station) can also be included

as one or more of the sections.

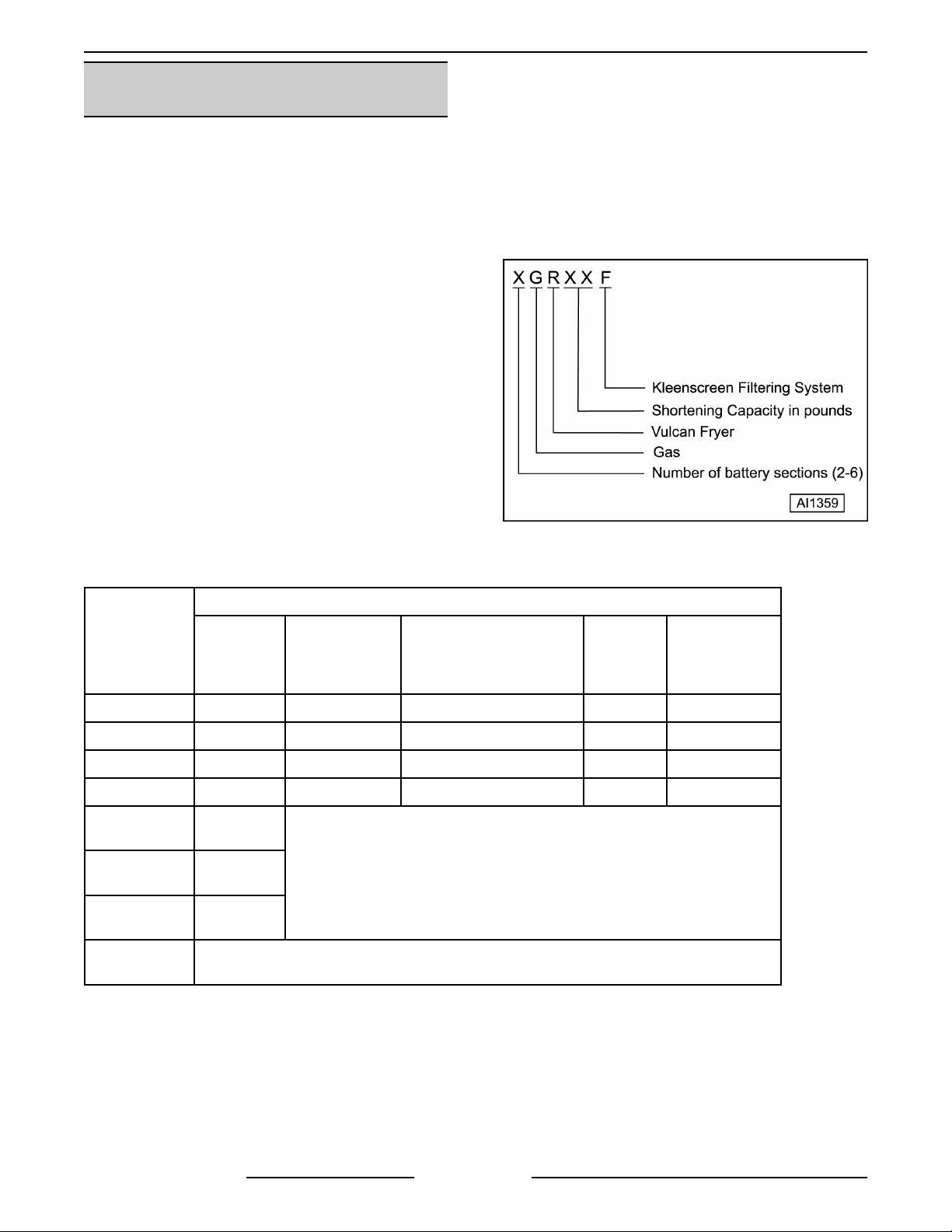

Model Designations

Models and Features

MODEL

2GR35F

2GR45F

2GR65F

2GR85F

RO15

(Frymate)

RO21

(Frymate)

RO21S

(Frymate)

NOTES:

1

1

2

2

FRYER

WIDTH

(INCHES)

15 1/2

1. For each additional fryer section, add 15 1/2" to the width.

2. For each additional fryer section, add 21" to the width.

FEATURES

SHORTENING

CAPACITY

PER FRYER

(POUNDS)

31 35-40 80 Full Thermostat

31 45-50 80 Full Thermostat

42 65-70 130 Full Thermostat

42 85-90 130 Full Thermostat

21

KLEENSCREEN FILTER

PAN CAPACITY

(POUNDS)

FRY

TANK

COOKING

CONTROL

21

F25125 (March 2003) Page 4 of 24

Page 5

GR SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

SPECIFICATIONS

Electrical

• 120VAC supply for Filter-Ready fryers and

Kleenscreen filter models only. The filter pump

motor draws approximately 5 amps.

Gas Pressures

Manifold (per fryer section):

• Natural - 4" W.C.

• Propane - 10" W.C.

Building supply pressure (Min):

• Natural - 5" W.C. (7" W.C. battery units)

• Propane - 11" W.C. (12" W.C. battery units)

NOTE: Propane or Natural gases -14" W.C. (Max).

Input BTU Rating

GR SERIES

GR25, GR25F 2 60,000

GR35, GR35F 3 90,000

GR45, GR45F 4 120,000

GR65, GR65F 5 150,000

GR85, GR85F 5 150,000

NO. OF

TUBES

BTU/HR/SECTION

TOOLS

Standard

• Standard set of hand tools.

• VOM with AC current tester.

NOTE: Any quality VOM with a sensitivity of

20,000 ohms per volt can be used.

• Temperature tester (thermocouple type).

• U-Tube Manometer.

• Pipe joint compound suitable for use with

propane gas.

REMOVAL AND REPLACEMENT OF PARTS

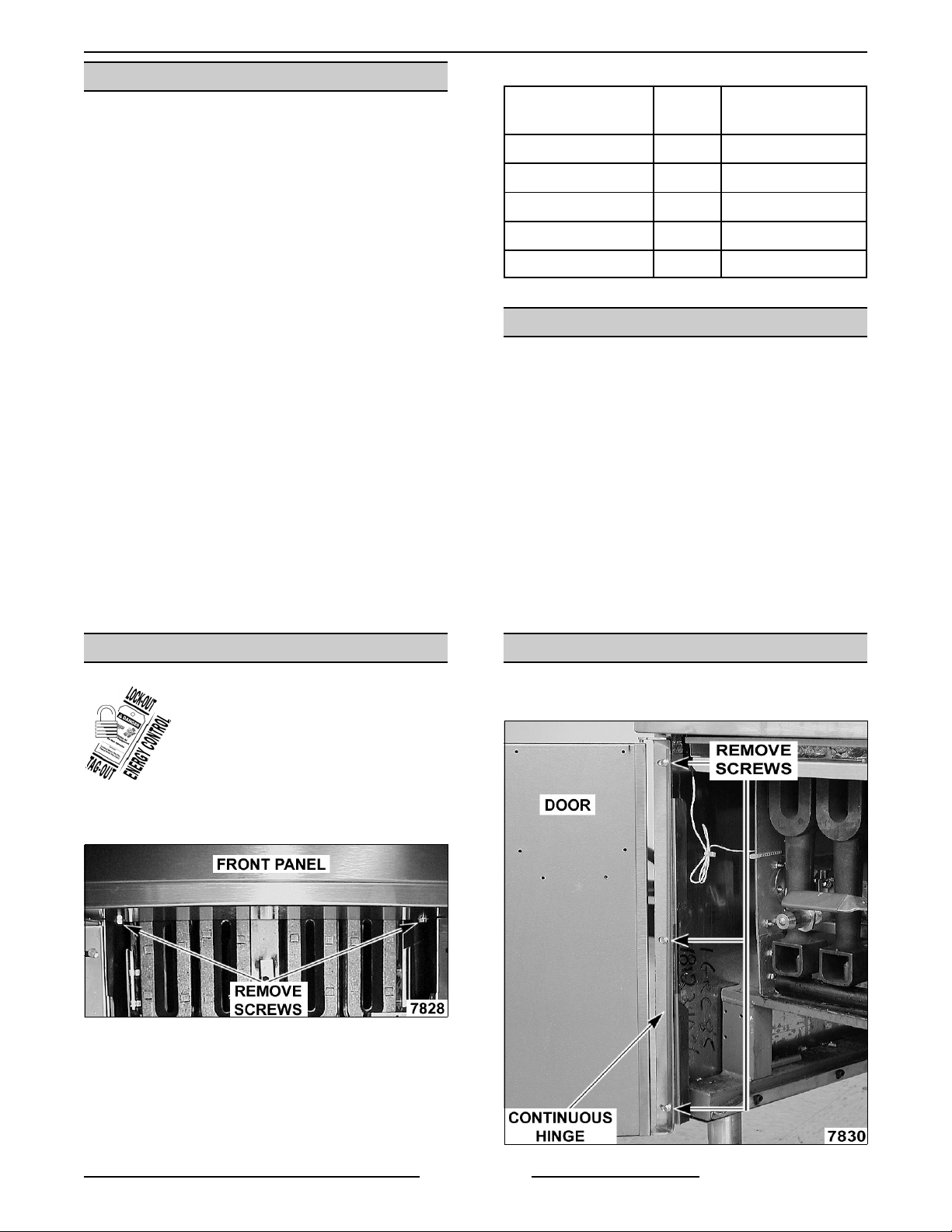

FRONT PANEL

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Open fryer door and remove screws from front

panel.

2. Lift front panel from fryer.

DOOR

1. Open the fryer door and remove screws

securing hinge & door assembly to fryer.

3. Reverse procedure to install.

Page 5 of 24

F25125 (March 2003)

Page 6

GR SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

2. When replacing door, install screws and tighten

top and bottom screws enough to hold door in

place.

3. Close door, check alignment and adjust if

necessary.

4. Finish tightening screws to fully secure.

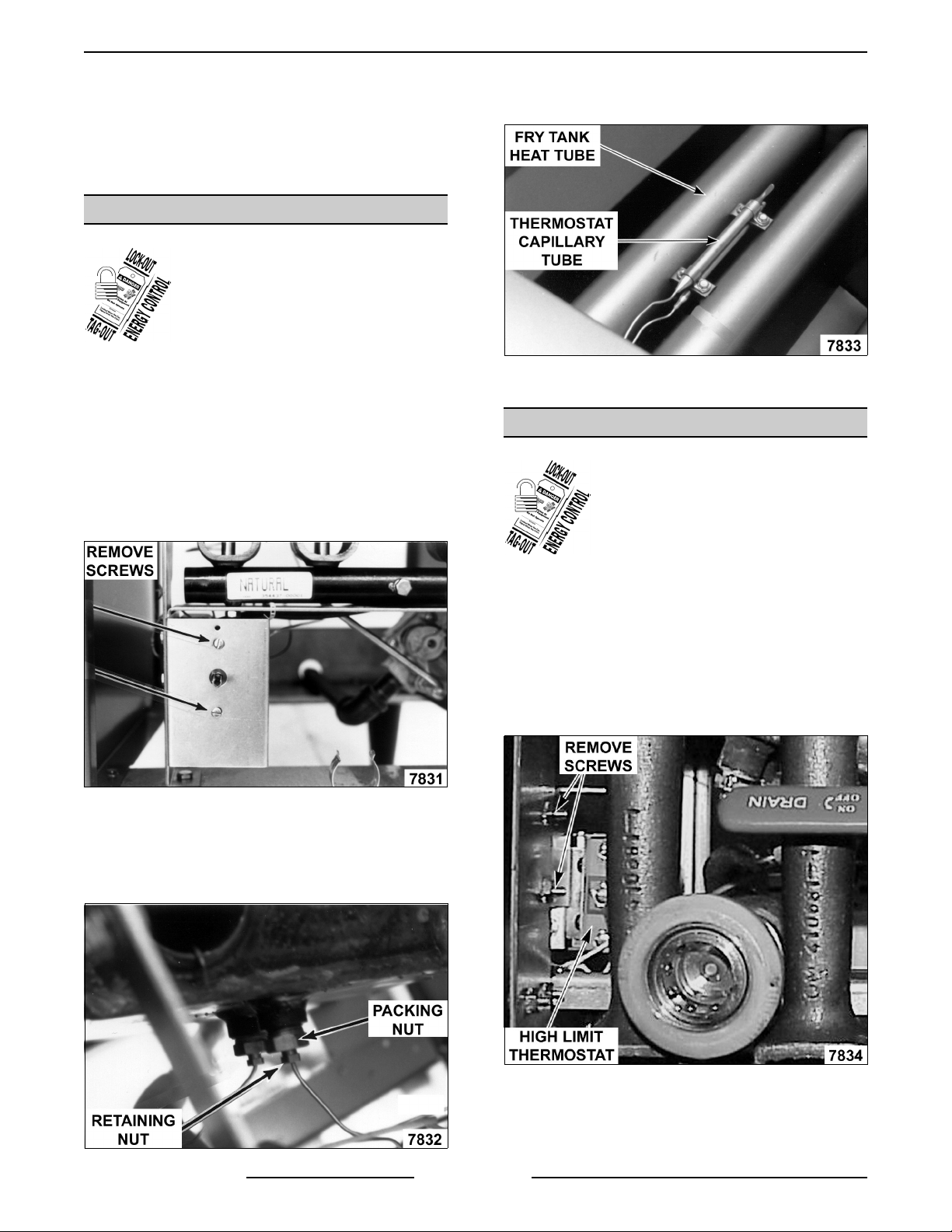

CONTROL THERMOSTAT

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

CAUTION: Do not sharply bend and kink the

capillary tube or damage may occur.

1. Drain shortening from fry tank.

2. Remove burners (as necessary) as outlined

under MAIN BURNERS.

3. Remove knob from control thermostat shaft

then remove control thermostat from mounting

bracket.

6. Remove screws securing capillary tube

mounting clips to the fry tank heat tube then

remove capillary tube.

7. Reverse procedure to install and check for

proper operation.

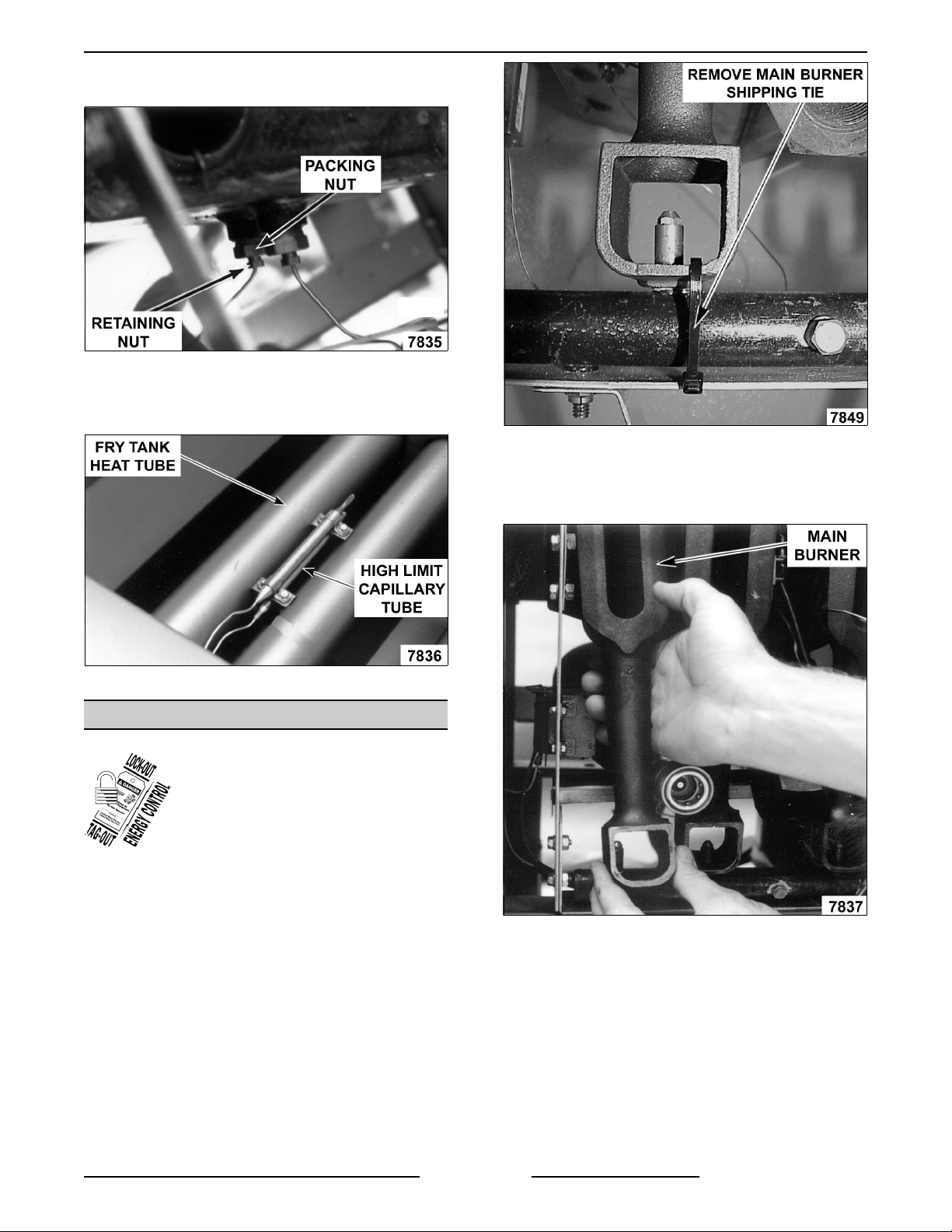

HIGH LIMIT THERMOSTAT

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

NON FILTER READY SHOWN

4. Disconnect lead wires from control thermostat.

5. Remove the capillary tube retaining and packing

nuts, from the bottom of fry tank.

CAUTION: Do not sharply bend and kink the

capillary tube or damage may occur.

1. Drain shortening from fry tank.

2. Remove burners (as necessary) as outlined

under MAIN BURNERS.

3. Remove screws securing the high limit

thermostat to mounting bracket.

4. Disconnect lead wires from high limit

F25125 (March 2003) Page 6 of 24

thermostat.

Page 7

GR SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

5. Remove the capillary tube retaining and packing

nuts, from the bottom of fry tank.

6. Remove screws securing capillary tube

mounting clips to the fry tank heat tube then

remove capillary tube.

3. Lift main burner up and tilt the top of burner

toward fry tank until it clears the gas orifice at

the bottom.

7. Reverse procedure to install.

MAIN BURNERS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

1. Open fryer door.

2. Remove main burner shipping ties (if installed).

NOTE: All shipping ties should be removed during

installation. Do not replace for normal operation.

A. Lift main burner from fryer.

NOTE: The main burners mount to the fryers’ burner

mounting bracket by shoulder bolts that rest in the

keyway slot.

Page 7 of 24

F25125 (March 2003)

Page 8

GR SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

GAS COMBINATION VALVE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

NOTE: Gas combination valves are not serviceable

and should not be disassembled. Once the problem

has been isolated to this control, replace it. Do not

attempt to repair the assembly.

1. Remove burners (as necessary) as outlined

under MAIN BURNERS.

4. Reverse procedure to install.

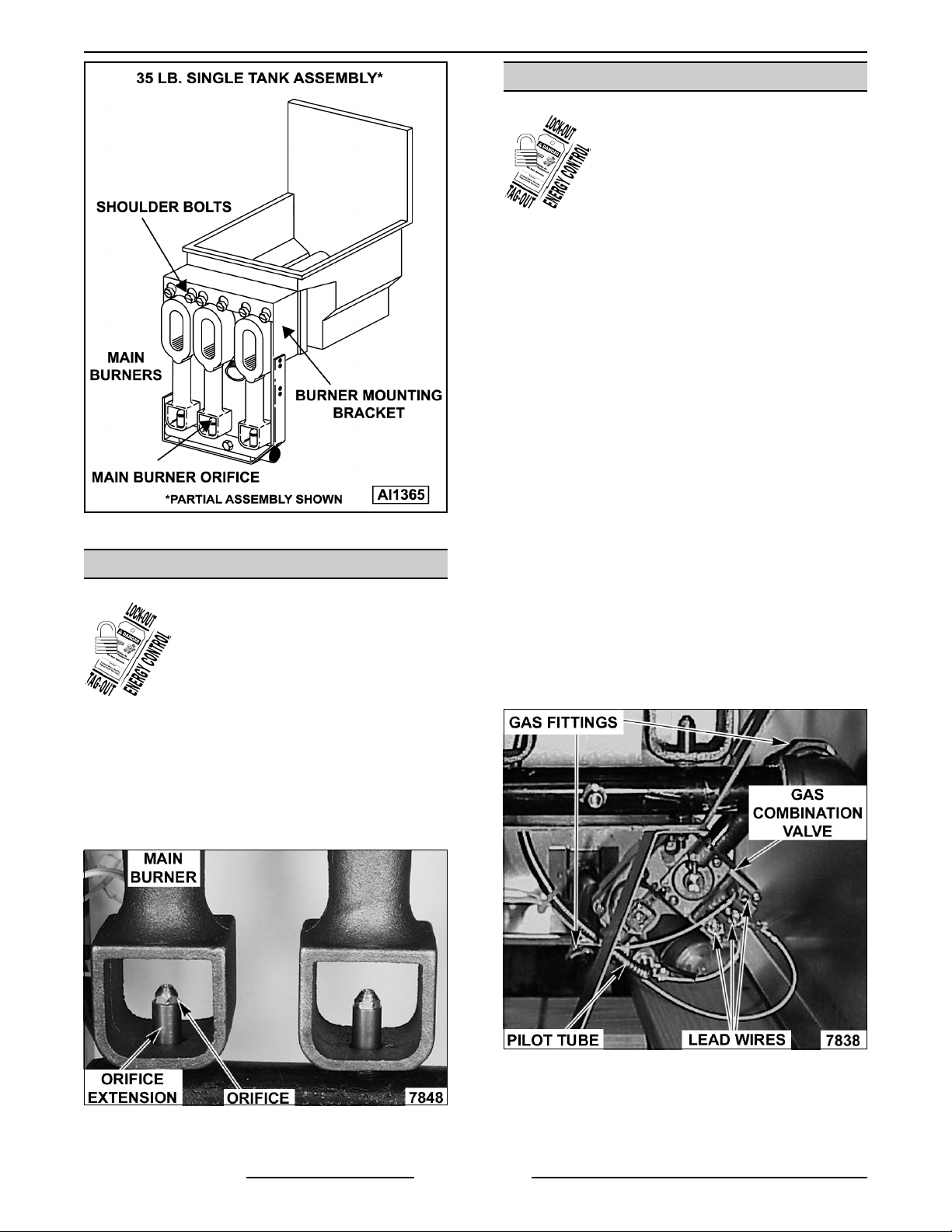

MAIN BURNER ORIFICE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

1. Remove main burner orifice from orifice

extension.

NOTE: When installing, do not over tighten the

orifice or damage to the threads may occur.

2. Disconnect lead wires from gas combination

valve.

3. On filter ready and Kleenscreen fryers only,

remove cotter pin securing handle to gas

combination valve on/off knob. Pull handle (with

gas combination valve knob bracket attached)

away from valve assembly.

4. Disconnect pilot tube.

5. Separate gas line fittings then remove gas

combination valve assembly.

NOTE: Remove fittings and piping from gas

combination valve and install (in same orientation)

2. Reverse procedure to install.

F25125 (March 2003) Page 8 of 24

on the replacement valve.

NON FILTER READY SHOWN

Page 9

GR SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

6. Reverse procedure to install and check for

proper operation.

PILOT BURNER

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove burners (as necessary) as outlined

under MAIN BURNERS.

2. Disconnect thermopile lead wires from N.O. and

COM terminals on the high limit thermostat.

6. Reverse procedure to install and check for

proper operation.

THERMOPILE

3. Disconnect pilot tube from pilot burner.

NOTE: With pilot tube disconnected from pilot

burner, the pilot orifice is accessible for inspection or

cleaning.

CAUTION: If orifice is clogged with debris, clean

with air or liquid only.

4. Remove pilot burner from pilot mounting

bracket stool (on fry tank).

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove pilot burner as outlined under PILOT

BURNER.

2. Remove mounting nut securing thermopile to

pilot burner.

5. Remove pilot burner from pilot mounting

bracket.

Page 9 of 24

F25125 (March 2003)

Page 10

GR SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

3. Reverse procedure to install and check for

proper operation.

FRY TANK ASSEMBLY

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Drain shortening from fry tank.

2. Disconnect the gas supply line to allow access

to fryer from all sides.

3. Remove fry baskets, crumb screen and basket

hanger.

NOTE: If the fryer is a battery section, remove

grease strip and split the silicone seal between the

fryer section tanks with a utility knife.

4. Remove front panel as outlined under FRONT

PANEL.

5. On Kleenscreen fryer sections only, remove

bolts securing the drain pipe flange to the

manual drain valve.

6. Remove main burners as outlined under MAIN

BURNERS.

7. Disconnect lead wires and pilot tube from the

gas combination valve.

8. Remove pilot burner as outlined under PILOT

BURNER.

9. Remove control thermostat as outlined under

CONTROL THERMOSTAT.

10. Remove high limit thermostat as outlined under

HIGH LIMIT THERMOSTAT.

11. Remove gas manifold and hanger assembly

from the fryer.

A. For fryer sections above the filter drawer

assembly on battery fryers or single floor

model fryers (filter ready), remove

mounting nuts securing gas manifold and

hanger assembly to the fryer’s base frame.

B. For other fryer sections in a battery and for

non-filter ready fryers, remove mounting

nuts securing gas manifold and hanger

assembly to the V shaped support bracket.

12. On Kleenscreen and filter ready fryers only,

separate the oil return line (hose or flexible

tubing) fitting at the elbow.

13. Separate gas line fitting at the inlet side of the

gas combination valve.

14. Remove bolts securing gas line support bracket

at the left side of gas manifold and hanger

assembly. Allow gas line support bracket to

swing out of way then replace bolts in the

frame. Hand tighten only.

15. Remove screws securing the top of fry tank to

the flue wrap.

CAUTION: Use care when lifting fry tank

assemblies from the fryer body. Exterior

surfaces of the fryer can be slippery and the

assemblies are heavy.

16. Grasp the fry tank at the top (by flue) and front

lip, then lift fry tank assembly from the fryer

body. Place the assembly on floor or table for

removal of the remaining components.

NOTE: If side access is not available, lift fry tank

assembly from the front of the fryer while rotating

the assembly upwards and toward the front.

17. On Kleenscreen fryers only, remove filter valve

assembly (as necessary) and oil return line

piping from fryer. If removing left side fry tank

above filter drawer assembly, disconnect oil

line and remove discard valve assembly from

fryer.

18. Remove bolts securing gas manifold hanger

assembly to the fry tank.

19. Remove screws securing flue box to fry tank

then remove flue box.

20. Remove drain valve.

F25125 (March 2003) Page 10 of 24

Page 11

GR SERIES GAS FRYERS - REMOVAL AND REPLACEMENT OF PARTS

21. Reverse procedure to install all the parts

removed from original fry tank onto

replacement fry tank, then install the assembly.

FILTER VALVE AND DISCARD

VALVE SWITCHES

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Open the door to the fryer section being

serviced.

2. Remove burners (as necessary) as outlined

under MAIN BURNERS.

3. Disconnect lead wire connector (2 pin) from the

appropriate switch.

4. Remove switch mounting screws.

NOTE: The remaining steps are written for front

removal of the pump assembly. If access to the back

of the fryer is available, it may be easier to remove

the pump from the rear.

3. Remove burners from the right side fryer

section above filter tank drawer as outlined

under MAIN BURNERS.

4. Disconnect the electrical connection to the

motor.

5. Separate the swivel hose connections at the

pump.

NOTE: When viewed from pump end, the right side

is the intake port and the left side is the discharge

port.

6. Remove motor mounting bolts.

7. Remove the motor and pump (pipe fittings

attached) from the fryer.

A. If replacing the pump and motor, remove

the existing pipe assemblies and reuse.

8. Reverse procedure to install.

NOTE: Ensure the rubber vibration pad or the

grommets are installed under the motor mounting

plate.

5. Reverse procedure to install and check for

proper operation.

NOTE: Switches are not adjustable.

PUMP AND MOTOR

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Open both fryer cabinet doors above the filter

tank drawer.

2. Pull the filter drawer out, remove the filter tank

assembly and push the tank support arms back

underneath the fryer.

Page 11 of 24

F25125 (March 2003)

Page 12

GR SERIES GAS FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POINTS ARE NOT EASILY ACCESSIBLE, DISCONNECT POWER AND FOLLOW LOCKOUT

/ TAGOUT PROCEDURES, ATTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST.

CONTROL THERMOSTAT

CALIBRATION

NOTE: Check the level of shortening in fry tank

before proceeding. When the oil temperature is

within normal operating range (325

level must

1. Place a thermocouple in the geometric center

2. Set

3. Allow the shortening temperature to stabilize

4. Record the temperature reading from the

5. Calculate the differential temperature by

[ Differential = Temp. (burners off) - Temp. (burners on) ]

6. Calculate the average temperature by adding

be between the MIN & MAX fill lines.

of the fry tank 1" below the oil surface.

control thermostat to 350°F.

(normally 3 cycles).

meter, at which the main burners turn off and

turn on for at least two complete heating

cycles.

subtracting the temperature reading when the

main burners turn off to the temperature

reading when the main

Example: 360/ (burners off) - 340/ (burners on) = 20/F.

The differential calculated should be less than

20/F.

A. If the differential is less

control thermostat is functioning properly.

B. If the differential is more

control thermostat is malfunctioning.

1) Install a replacement control

thermostat as outlined under

CONTROL THERMOSTAT in

REMOVAL AND REPLACEMENT OF

PARTS.

the temperature reading when the main burners

turn off to the temperature reading when the

main burners turn on and divide this answer by

2.

[ Temp. (burners off) + Temp. (burners on) ] ÷ 2 =

Average Temp.

Example: 360/ + 340/ ÷ 2 = 350/F.

The average temperature should be

350°F (± 10°F).

/F - 375/F), the

burners turn on.

than 20/F, the

than 20/F, the

A. If the average temperature reading is

within tolerance, the control thermostat is

properly calibrated.

B. If the average temperature reading is out

of tolerance, continue with procedure.

7. To adjust:

A. Remove control thermostat knob.

B. Hold control thermostat shaft and turn the

inner set screw clockwise

temperature or counterclockwise

increase temperature (1/4 turn = 18

C. Replace control thermostat

repeat step 6 for up to three attempts.

Allow the main burners to cycle at least two

times between adjustments before

performing the calculation.

1) When calibration is successful,

remove control thermostat knob and

apply a non-permanent

material to set screw head to secure

from rotation.

2) Replace control thermostat knob.

8. If the above adjustment cannot be obtained,

install a replacement control thermostat as

outlined under CONTROL THERMOSTAT in

REMOVAL AND REPLACEMENT OF PARTS.

to decrease

to

/F).

knob and

adhesive

F25125 (March 2003) Page 12 of 24

Page 13

GR SERIES GAS FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

GAS MANIFOLD PRESSURE

ADJUSTMENT

WARNING: SHUT OFF THE GAS SUPPLY

BEFORE SERVICING THE UNIT.

GAS PRESSURE (INCHES W.C.)

GAS

TYPE

Natural 4 7 5

Propane 10 11 11

NOTE: If the incoming line pressure is less than the

minimum stated, then the manifold pressure cannot

be set correctly.

1. Open the door and turn gas combination valve

2. Remove the 1/8" NPT plug (pressure tap) on

NOTE: Gas manifold pressure can also be

measured at the pressure tap in the manifold. On

Kleenscreen battery fryers only, the drain pipe may

need to be removed for access.

3. Turn the gas supply on.

4. Light the pilot burner and turn the gas

5. Set control thermostat to call for heat and verify

6. Observe the manometer pressure reading and

7. Remove the adjustment screw cap to access

MANIFOLD

knob/extension arm

the outlet side of the valve and attach a

manometer.

combination valve

the main burners light.

compare to the pressure chart near the end of

this procedure.

A. If other appliances are connected to the

same gas line, turn them all on and check

manometer pressure reading again. If a

pressure drop of 1/2" water column or

more is observed, then the gas supply

needs to be checked by the gas line

installer or the local gas company for

adequate sizing.

B. If adjustment is necessary, continue with

procedure.

the pressure adjustment screw.

RECOMMENDED MIN MAX

to off.

knob/extension arm to on.

LINE

14

NON FILTER READY SHOWN

A. To increase pressure, turn the screw

clockwise

screw counterclockwise

NOTE: Accurate gas pressure adjustments can only

be made with the gas on and the main burners lit.

8. Set pressure as outlined in gas pressure table.

9. Once the correct pressure has been set, turn

the gas combination valve

to off and shut off the gas supply.

10. Replace the adjustment screw cap and 1/8"

NPT plug (pressure tap) on the outlet side of

the valve.

11. Check fryer for proper operation.

. To decrease pressure, turn the

.

knob/extension arm

PILOT BURNER FLAME

ADJUSTMENT

NOTE: Verify the proper gas type (natural or

propane) is being supplied to the fryer

proceeding.

1. Turn control thermostat to off.

2. Light pilot burner and

valve knob/extension arm in the pilot position.

Allow pilot to burn for 3-4 minutes to stabilize

flame.

A. If pilot burner is not lighting or does not

remain lit when the gas combination valve

knob/extension arm is released, see

TROUBLESHOOTING. Wait 5 minutes

between pilot burner lighting attempts for

unburned gas to vent.

leave gas combination

before

3. Verify the inner cone of pilot burner flame is

Page 13 of 24

extending approximately 1/2" beyond the outer

edges of the pilot shield.

F25125 (March 2003)

Page 14

GR SERIES GAS FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

A. If adjustment is necessary, continue with

procedure.

4. Remove the adjustment screw cap from the

gas combination valve.

MILLIVOLT CONTROLS TEST

1. Verify millivolt control circuit wiring is correct

and connections are clean and secure.

2. Verify pilot burner flame is adjusted properly as

outlined under PILOT BURNER FLAME

ADJUSTMENT.

3. With control thermostat off and gas

combination valve knob/extension arm in the

pilot position, allow pilot to burn for 3-4 minutes

to stabilize voltage output from thermopile.

4. Verify thermopile output voltage.

A. Set VOM to DC millivolt scale and connect

meter leads to N.O. and COM terminals

on the high limit thermostat.

1) If 450 millivolts or greater is

measured, the thermopile is

functioning properly. Continue with

test.

2) If less than 450 millivolts is

measured, install a replacement

thermopile as outlined under

THERMOPILE in REMOVAL AND

REPLACEMENT OF PARTS.

NON FILTER READY SHOWN

A. To increase pilot flame, turn the screw

counterclockwise

turn the screw clockwise

5. With the pilot burner lit, turn gas combination

valve knob/extension arm to on and set the

control thermostat to call for heat.

A. If main burners do not light or pilot burner

goes out, proceed to MILLIVOLT

CONTROLS TEST.

. To decrease pilot flame,

.

5. Turn gas combination valve knob/extension

arm to on and set the control thermostat to call

for heat.

6. Verify main burners light and remain lit.

A. If main burners operate as described, the

millivolt controls are functioning properly.

B. If main burners do not light, continue with

test.

7. Verify control thermostat contacts are closing.

A. Connect meter leads to the TH terminal on

gas combination valve and COM terminal

on the high limit thermostat.

1) If 150 millivolts or greater is

measured, control thermostat is

functioning properly. Replace gas

combination valve as outlined under

GAS COMBINATION VALVE in

REMOVAL AND REPLACEMENT OF

PARTS.

F25125 (March 2003) Page 14 of 24

Page 15

GR SERIES GAS FRYERS - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

FRYER CONTROLS

Control Thermostat ........... Regulates shortening temperature at the selected set point. Temperature

range from off to 200

Thermopile .................. When heated by the pilot burner flame, generates DC millivolts to

energize pilot valve coil and main valve coil on the gas combination valve.

Gas Combination

Valve ....................... Allows gas flow to the pilot when pilot valve coil is energized; and gas flow

to the main burners when main valve coil is energized. Also, regulates the

gas manifold pressure.

High Limit Thermostat......... Prevents the shortening from reaching temperatures over 465°F (auto

reset).

/F thru 400/F.

KLEENSCREEN FILTER CONTROLS

Filter Power Switch ........... Supplies 120VAC to pump motor. Filter valve switch or discard valve

switch must be closed (valve handle extended).

Pump Motor ................. Operates pump to circulate shortening through filtering system.

Filter Valve Switch ............ Energizes pump motor to filter the shortening when the N.O. switch

contacts are closed (valve handle extended); and filter power switch is

turned on.

Discard Valve Switch .......... Energizes pump motor to discard the shortening from filter tank when the

N.O. switch contacts are closed (valve handle extended); and filter power

switch is turned on.

Page 15 of 24

F25125 (March 2003)

Page 16

GR SERIES GAS FRYERS - ELECTRICAL OPERATION

COMPONENT LOCATION

GR35 NON FILTER READY SHOWN

2GR45F KLEENSCREEN FRYER BATTERY SHOWN

GR45 FILTER READY SHOWN

F25125 (March 2003) Page 16 of 24

Page 17

GR SERIES GAS FRYERS - ELECTRICAL OPERATION

SEQUENCE OF OPERATION

Millivolt Controls

Refer to schematic diagram 7825.

1. Conditions.

A. Gas shutoff valve(s) on and gas

combination valve knob/extension arm in

the on position.

B. Shortening at proper level in fry tank and

below last set point temperature used.

C. Pilot lit.

1) Pilot valve coil is energized on gas

combination valve and pilot valve

opens for gas flow to pilot burner.

NOTE: Pilot flame must

generate 450 millivolts DC (minimum)

from thermopile.

D. Main valve coil on combination valve not

energized (valve closed).

E. Control thermostat off.

F. High limit thermostat closed.

2. Set control thermostat to call for heat.

A. Main valve coil on gas combination valve

is energized and main valve opens for gas

flow to main burners.

1) Main burners light.

NOTE: As long as the millivolts from

thermopile remain sufficient to keep the

pilot valve coil energized, and the control

thermostat is calling for heat, the main gas

valve stays open.

3. Shortening reaches set temperature and

control thermostat opens.

A. Main gas valve coil de-energized and

main valve closes.

1) Gas flow stops and main burners go

out.

4. Control thermostat cycles main burners until

thermostat is turned to off; gas valve

knob/extension arm is turned to pilot or off.

Kleenscreen Filtering System

be sufficient to

1. Conditions

A. Fryer connected to correct supply voltage

and is properly grounded.

B. Shortening between 300

NOTE: Oil should not be filtered outside of this

temperature range. At lower temperatures the

oil is thicker which may increase filtering time

and place a greater load on the pump. At

higher oil temperatures, oil seal life is

decreased.

C. Control thermostat off.

NOTE: Control thermostat must

during filtering.

D. Filter drawer assembly installed properly.

E. Filter power switch turned off.

F. Filter valve handle retracted.

1) Filter valve switch N.O. contacts

open.

G. Discard valve handle retracted.

1) Discard valve switch N.O. contacts

open.

2. Open the drain valve to the fryer section in

need of filtering and drain the shortening into

filter tank.

3. Turn filter power switch on.

A. Switch pilot light comes on.

4. Extend filter valve handle of the same fryer

section.

A. Filter valve switch N.O. contacts close.

1) Power supplied to pump motor.

B. Pump motor circulates oil through filter

until power is removed.

5. When the oil filtering process is completed,

close the manual drain valve to the fryer and

allow the fry tank to refill.

A. When all filtered oil is returned to the fryer,

retract the filter valve handle.

1) Power is removed from pump motor.

6. Turn filter power switch off.

/F and 350/F.

remain off

Refer to wiring diagram 7850. Refer to Installation &

Operation manual for specific instructions on

filtering.

NOTE: The filter valve handle and the discard valve

handle are connected to a mechanical valve and

switch assembly to route the flow of oil in the

filtering system and supply power to the pump

motor.

Page 17 of 24

F25125 (March 2003)

Page 18

SCHEMATIC DIAGRAM

Millivolt Controls

GR SERIES GAS FRYERS - ELECTRICAL OPERATION

F25125 (March 2003) Page 18 of 24

Page 19

WIRING DIAGRAMS

Millivolt Controls

GR SERIES GAS FRYERS - ELECTRICAL OPERATION

Page 19 of 24

F25125 (March 2003)

Page 20

GR SERIES GAS FRYERS - ELECTRICAL OPERATION

Junction Box, Kleenscreen Filtering System

F25125 (March 2003) Page 20 of 24

Page 21

Frymate (Dump Station)

GR SERIES GAS FRYERS - ELECTRICAL OPERATION

Page 21 of 24

F25125 (March 2003)

Page 22

GR SERIES GAS FRYERS - TROUBLESHOOTING

TROUBLESHOOTING

ALL MODELS

SYMPTOMS POSSIBLE CAUSES

Pilot burner will not light. 1. Gas supply off.

2. High limit thermostat open or malfunction.

3. Incorrect gas type.

4. Pilot burner flame adjustment too low.

5. Pilot burner orifice obstructed

6. Gas combination valve malfunction.

or incorrect.

Pilot burner lights but will not maintain flame. 1. Pilot burner

2. Pilot burner orifice obstructed or incorrect.

3. Thermopile malfunction.

4. Insufficient gas pressure.

5. High limit thermostat malfunction.

6. Gas combination valve malfunction.

Pilot burner adjusted properly but flame

fluctuates or goes out.

Main burner(s) light but will not maintain

flame.

Fryer does not heat, pilot burner lit. 1. Control thermostat off or malfunctioning.

Excessive or low heat. 1. Control thermostat calibration or malfunction.

1. Insufficient gas pressure due to other equipment

operating on same line.

2. Excessive drafts.

A. Vent hood not adjusted properly.

B. Fryer door open or removed.

1. Insufficient gas pressure.

2. Main burner(s) gas orifice obstructed or incorrect.

3. Thermopile malfunction

4. Main burner(s) malfunction.

5. Gas combination valve malfunction.

2. Gas combination valve malfunction.

3. Wiring connections loose or wiring malfunction.

2. Gas pressure incorrect.

3. Main burner(s) gas orifice

4. Flue obstructed.

5. Vent hood not adjusted properly.

6. Fryer load capacity exceeded.

flame adjustment too low.

obstructed or incorrect.

High limit thermostat shutting off main

burners.

Main burners light when control thermostat is

turned off.

F25125 (March 2003) Page 22 of 24

1. Shortening level below minimum fill line.

2. Control thermostat malfunction.

3. High limit thermostat malfunction.

1. Control thermostat malfunction.

2. Control thermostat terminals shorted or lead wire

grounded.

3. Gas combination valve malfunction.

Page 23

GR SERIES GAS FRYERS - TROUBLESHOOTING

FRYMATE (DUMP STATION)

WITH OPTIONAL HEATER

SYMPTOM POSSIBLE CAUSES

No heat. 1. Unplugged.

2. Power switch off or inoperative.

3. Main circuit breaker off or open.

4. Malfunctioning heat assembly.

KLEENSCREEN FILTERING

SYSTEM

SYMPTOM POSSIBLE CAUSES

Oil not filtering, pump motor is on. 1. Filter screen plugged.

2. Clog in filter system lines.

NOTE: When all filtered oil is returned to the fry tank and filter

power switch is off, open the filter drawer approximately 1".

Allow the remaining shortening in the line to drain into the filter

tank to prevent possible clogging after the shortening cools and

solidifies. Close the filter drawer when complete.

3. Shortening below 300

4. Filter valve switch malfunction.

5. Filter valve mechanical malfunction.

6. Pump is inoperative.

/F (too thick).

Shortening not discarding, pump motor

on.

Pump motor is not running. 1. Filter power switch inoperative.

1. Filter screen plugged.

2. Clog in filter system lines.

NOTE: When all filtered oil is returned to the fry tank and filter

power switch is off, open the filter drawer approximately 1".

Allow the remaining shortening in the line to drain into the filter

tank to prevent possible clogging after the shortening cools and

solidifies. Close the filter drawer when complete.

3. Shortening below 300

4. Discard valve switch malfunction.

5. Discard valve mechanical malfunction.

6. Discard hose connection not fully engaged.

7. Pump is inoperative.

2. Filter/discard handle not extended.

3. Filter/discard valve switch malfunction.

4. Filter relay malfunction.

5. Pump motor inoperative.

/F (too thick).

Page 23 of 24

F25125 (March 2003)

Page 24

GR SERIES GAS FRYERS - CONDENSED SPARE PARTS LIST

CONDENSED SPARE PARTS LIST

KLEENSCREEN FILTER

PART NUMBER DESCRIPTION NOTES

411496-B4 Lighted Rocker Switch, Filter

417792-1 Pump and Motor Assy, Filter (120VAC)

GR SERIES GAS FRYERS WITH MILLIVOLT CONTROL

PART NUMBER DESCRIPTION NOTES

419999-2 Thermostat, Reed Switch

419670-2 High Limit Thermostat (w/stuffing box)

410839-4 Thermopile, Millivolt (manual ign.)

410841-22 Gas Valve (NAT)

410841-23 Gas Valve (LP)

412212-7 Pilot (NAT)

412212-2 Pilot (LP)

F25125 (March 2003) Printed in U.S.A.

Loading...

Loading...