Page 1

INSTALLATION &

OPERATION MANUAL

GHF SERIES HEAVY DUTY

RANGE MATCHING GAS FRYERS

MODELS

GHF91 ML-135503

GHF90 ML-135504

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

GHF91

P.O. BOX 696, LOUISVILLE, KY 40201-0696

TEL. (502) 778-2791

FORM 35609 Rev. A (03-05)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

© VULCAN-HART, 2005

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

– 2 –

Page 3

Installation, Operation and Care of

MODEL GHF91 GAS FRYERS

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

GENERAL

Your Vulcan-Hart Gas Fryer is produced with quality workmanship and material. Proper installation,

usage and maintenance will result in many years of satisfactory performance.

It is suggested that you thoroughly read this entire manual and carefully follow all of the instructions

provided.

OPTIONAL FIELD INSTALLABLE ACCESSORIES

Tank Brush 4' (1.21 m) Quick Disconnect Hose

Tank Cover (2) Twin Fry Baskets

(4) Casters Single Basket

INSTALLATION

Before installing the fryer, verify that the type of gas (natural or propane) agrees with the specifications

on the fryer data plate which is located on the inside of the door. Also be sure the fryer is built for the

installation elevation.

The fryer must be restrained with adequate ties to prevent tipping when installed in order to avoid the

splashing of hot liquid.

UNPACKING

This fryer was carefully inspected before leaving the factory. The transportation company assumes

full responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking the

fryer, check for possible shipping damage. If the fryer is found to be damaged, save the packaging

material and contact the carrier within 15 days of delivery.

Do not use the door or its handle to lift or move the fryer.

ITEMS PACKAGED WITH FRYER

Crumb Screen Basket Hanger Warranty and Service Pack

Drain Pipe (2) Twin Fry Baskets

(4) Legs Manual

– 3 –

Page 4

LOCATION

CAUTION: The equipment area must be kept free and clear of combustible substances.

Installation clearances:

COMBUSTIBLE NONCOMBUSTIBLE

CONSTRUCTION CONSTRUCTION

Back: 6" (152 mm) 0"

Right Side: 6" (152 mm) 0"

Left Side: 6" (152 mm) 0"

The installation location must allow adequate clearances for servicing and proper operation. A

minimum front clearance of 36" (914 mm) is required.

There must be at least 16" (406 mm) clearance between the fryer and any open top flame units.

Adequate clearances for servicing and proper operation must be allowed.

Install the fryer in an area with sufficient air supply for combustion of the gas at the fryer burners.

Provide adequate clearance for air openings into the combustion chamber. Do not obstruct the flow

of combustion and ventilation air.

Do not permit fans to blow directly at the fryer. Wherever possible, avoid open windows next to the

sides or back of the fryer. Avoid wall-type fans which create air cross currents within the room.

INSTALLATION CODES AND STANDARDS

Your Vulcan fryer must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1 (latest edition). Copies may be obtained from The American

Gas Association, Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from The

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CSA B149.1 Natural Gas and Propane Installation Code.

3. CSA C22.2 Canadian Electrical Code.

The above are available from the Canadian Standard Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

ASSEMBLY

Legs

Position fryer in an open space near the final installation area. Tilt fryer back, being careful to avoid

scratching the finish. Thread front legs clockwise into mounting plates provided on the bottom of the

fryer until seated. Tilt to front and thread back legs similarly. Carefully raise fryer to its normal position

and place it in the installing location.

– 4 –

Page 5

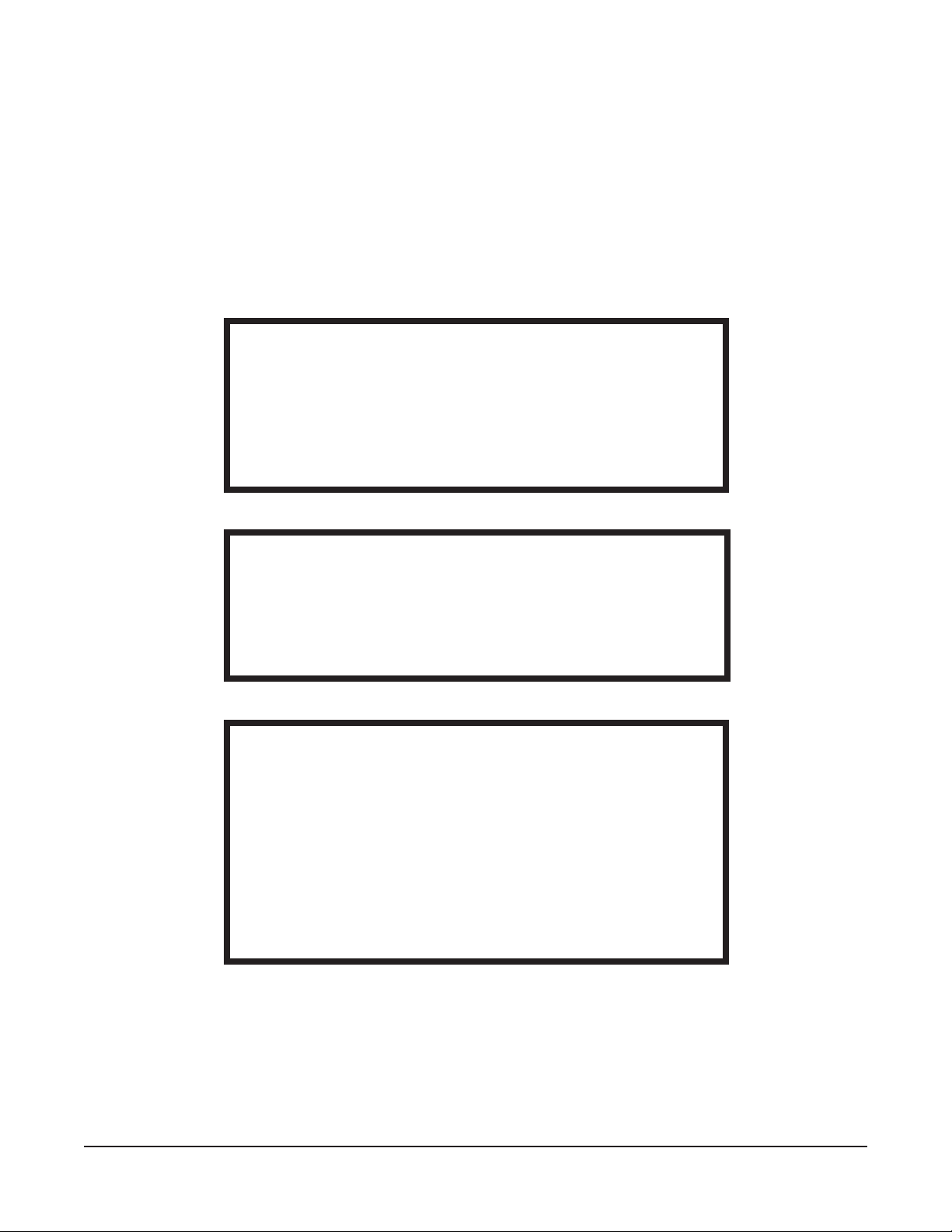

Fryers Mounted on Optional Casters

Fryers mounted on casters must use a flexible

connector (NOT SUPPLIED BY VULCAN) that

complies with the Standard for Connectors of

Movable Gas Appliances, ANSI-Z21.69 • CSA6.16

and a quick-disconnect device that complies with

the Standard for Quick-Disconnect Devices for

Use With Gas Fuel, ANSI-Z21 • CSA6.9.

In addition, adequate means must be provided to

limit the movement of the appliance without depending

on the connector and the quick-disconnect device

or its associated piping to limit the appliance

movement. Attach the restraining device to the rear

Fig. 1

of the fryer as shown in Fig. 1.

If it is necessary to disconnect the restraint, turn off the gas supply before disconnection. Reconnect

the restraint before turning the gas supply on and returning the fryer to its installation position.

Instructions for installing casters to the fryer are included with the casters.

LEVELING THE FRYER

Stand Alone Installations

Once gas connections have been made, place a spirit level on top of the fryer. Adjust the legs to ensure

that the fryer is level front-to-back and side-to-side in the final installed position.

Battery Installations

When the fryer is part of a battery lineup, line the fryer up front-to-back and side-to-side with adjacent

battery equipment. Equipment front tops and manifold pipes must be aligned with adjacent equipment.

Once the fryer is in its exact location in the battery lineup, place a spirit level on top of the fryer. Adjust

the legs to ensure that the fryer is level front-to-back and side-to-side in the final installed position.

GAS CONNECTIONS

CAUTION: All gas supply connections and any pipe joint compound used must be resistant

to the action of propane gases.

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR

LEAKS. USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

Rear Gas Connection for Stand Alone Installations

The gas inlet is located at the lower left rear.

Codes require that a gas shutoff valve be installed in the gas line ahead of the fryer.

The gas supply line must be at least the equivalent of

disconnect flex hose,

3

/4" (19 mm) iron pipe must be used unless 3/4" (19 mm) to 1/2" (12.7 mm) reducing

1

/2" (12.7 mm) iron pipe. If using the optional quick-

fittings are used. Make sure the pipes are clean and free of obstructions, dirt, and piping compound.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

– 5 –

Page 6

Front Gas Connection for Battery Installations

Codes require that a gas shutoff valve be installed in the gas line ahead of the fryer and battery of

equipment.

The gas manifold of a battery lineup of which the fryer is a part, must be installed using a regulator

design-certified by a nationally recognized testing lab to the applicable ANSI standard (regulators

available from Vulcan-Hart). The pressure regulator must have a maximum regulation capacity to

handle the total connected load and must have an adjustment range for manifold pressure marked on

the equipment rating plate(s). If the manifold pressure of the connected equipment is not the same, a

separate regulator must be supplied for all devices operating under different manifold pressure ratings.

Set all fryers in line with each other and adjacent ranges (16" [40 cm] clearance required between fryer

and open top flame units). Remove control panels for access to union connections or manifold pipes.

Screw each union finger-tight to adjoining connection. Do not overtighten. Tighten each union,

ensuring that the gas manifold is not pulled to the left or right by overtightening the unions. When all

fryers in the battery are connected finger-tight, then tighten with a pipe wrench. Always use pipe joint

compound that is resistant to the action of liquid petroleum gases on unions.

TESTING THE GAS SUPPLY SYSTEM

When test pressures exceed

1

/2 psig (3.45 kPa), the fryer and its individual shutoff valve must be

disconnected from the gas supply piping system.

1

When test pressures are

/2 psig (3.45 kPa) or less, the fryer must be isolated from the gas supply

system by closing its individual manual shutoff valve.

FLUE CONNECTIONS

DO NOT obstruct the flow of flue gases from the flue located at the rear of the fryer. It is recommended

that the flue gases be ventilated to the outside of the building through a ventilation system installed by

qualified personnel.

Adequate ventilation must be provided and must comply with NFPA Standard #96 (latest edition), and

with local codes.

Never make flue connections directly to the fryer.

The fryer must be located under a hood which has an adequate connection to an exhaust duct. The

hood must extend 6" (152.4 mm) beyond fryer sides.

Clearance above fryer should be adequate for products of combustion to be removed efficiently. An

18" (457 mm) minimum clearance should be maintained between the flue vent and the filters of the hood

venting system.

Information on the construction and installation of ventilating hoods may be obtained from the standard

for "Vapor Removal from Cooking Equipment," NFPA No. 96 (latest edition), available from the National

Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

Adequate air should be provided in the kitchen to replace air taken out by the ventilating system. This

will prevent fryer function from being affected by a reduced atmospheric pressure.

– 6 –

Page 7

OPERATION

WARNING: HOT OIL AND PARTS CAN CAUSE BURNS. USE CARE WHEN OPERATING,

CLEANING AND SERVICING THE FRYER.

WARNING: SPILLING HOT OIL CAN CAUSE SEVERE BURNS. DO NOT MOVE FRYER

WITHOUT DRAINING ALL OIL FROM THE TANK.

Tank warranty may be voided by improper operation. Turn gas valve off when draining or filling.

BEFORE FIRST USE

Cleaning

Using a non-corrosive, grease-dissolving commercial cleaner, clean the protective metal oils from all

surface parts and the fry tank interior. Follow the cleaner manufacturer's directions. Drain through the

valve in the bottom. Rinse thoroughly and drain. Be sure to remove all traces of cleaner; it can affect

the food taste. Wipe fry tank completely dry with a soft clean cloth.

Clean all fryer accessories. Rinse all parts thoroughly and wipe dry.

Seasoning

Light seasoning of the backsplash area is required to avoid possible surface corrosion. With a soft,

lint-free cloth, apply a thin layer of cooking oil over entire backsplash area. This should also be done

after every cleaning.

FILL FRY TANK WITH LIQUID SHORTENING

CAUTION: Before turning the burners on, the fry tank must be filled with liquid shortening.

If this is not done, the tank walls can be damaged. Warpage can cause leaks.

DO NOT melt solid shortening in the fry tank. The fry tank will be damaged and the shortening will

be scorched. Melt solid frying compound in a separate container, being careful to just melt and not

overheat it; then carefully pour into fry tank.

Keep shortening between the MIN and MAX lines in the fry tank. DO NOT add shortening beyond the

MAX line.

Shortening expands when heated. Adding shortening beyond the MAX line may cause an overflow of

hot shortening.

Add fresh liquid frying compound as needed.

– 7 –

Page 8

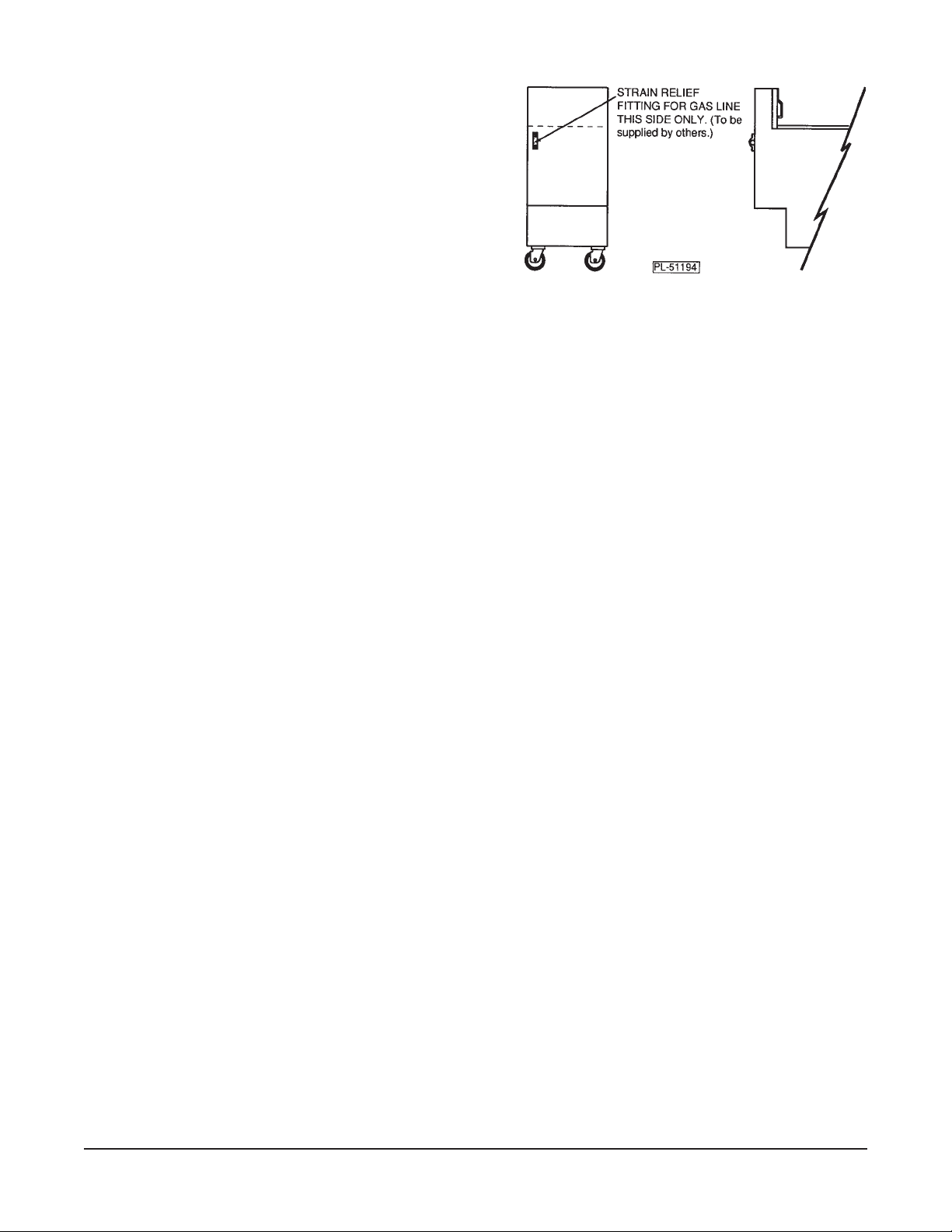

LIGHTING THE PILOT

1. Turn thermostat OFF. Thermostat is located behind the door

(Fig. 2).

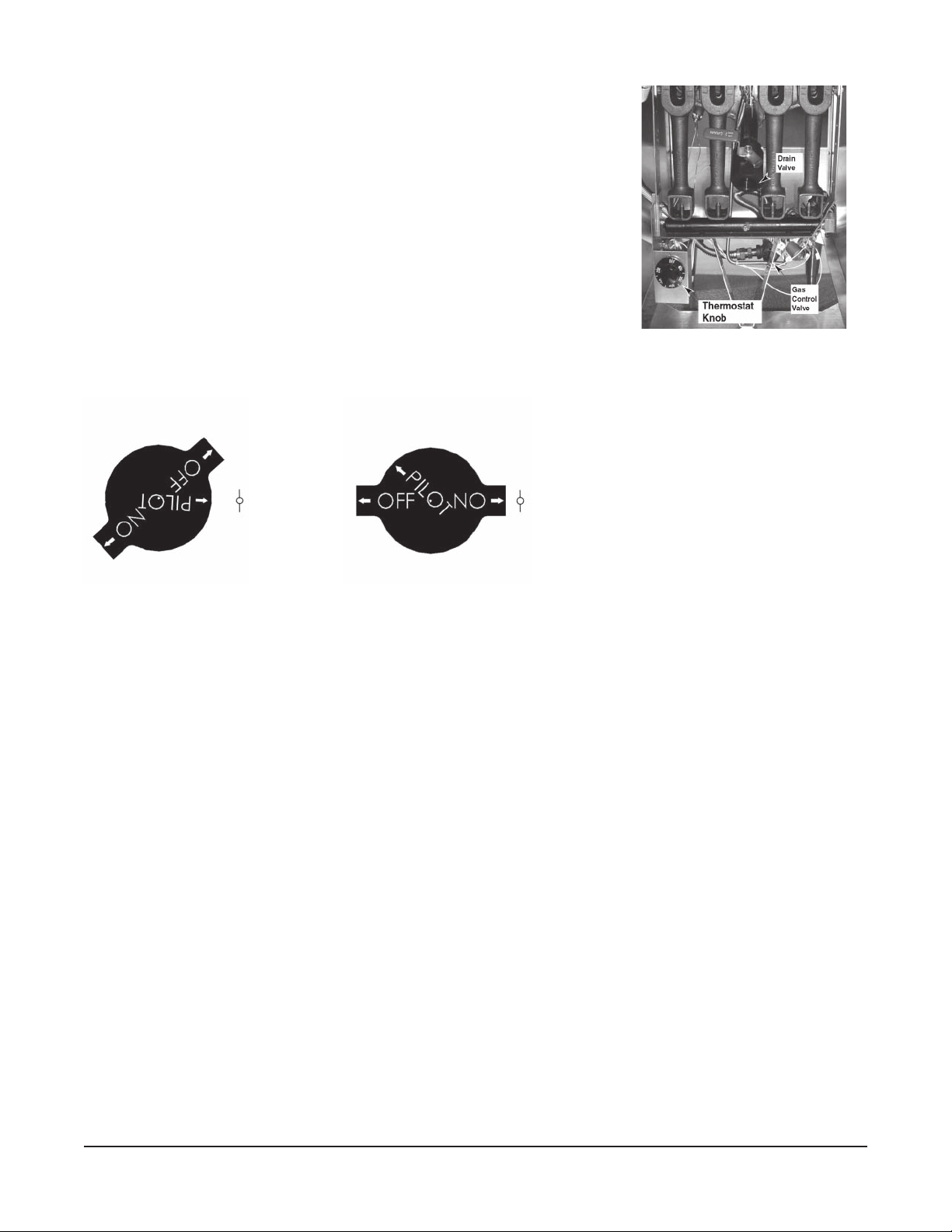

2. Turn gas control valve knob to OFF/PILOT (Fig. 3). Wait 5

minutes for unburned gas to vent.

3. Push gas control knob in (Fig. 3).

4. While still holding knob in, light the pilot with a lit taper. Continue

to depress knob for 30 seconds, then release the knob. Pilot

should remain lit when knob is released.

If pilot does not remain lit, repeat Steps 2, 3, and 4.

5. Turn gas control knob to ON (Fig. 4).

6. If gas supply is interrupted, repeat Steps 1-5.

Fig. 2

Fig. 3

Fig. 4

TURNING THE FRYER ON

To turn the fryer on, set the thermostat knob to the desired temperature. After the set temperature has

been reached, the gas control shuts off gas flow to the burners. The pilot remains lit. The burners will

cycle on and off, maintaining the set temperature.

TURNING THE FRYER OFF

1. Turn the thermostat OFF.

2. Turn the gas control valve knob to PILOT. In this position the pilot will remain lit.

3. To shut off all gas to the system, including the pilot, turn the gas control valve knob to OFF.

EXTENDED SHUTDOWN

1. Turn the manual gas shutoff valve OFF.

2. Turn the thermostat knob OFF.

3. Turn the gas control valve knob to OFF.

– 8 –

Page 9

HIGH LIMIT DEVICE

A high limit device will shut the fryer down if the oil overheats. DO NOT relight pilot until oil temperature

has lowered to at least 350°F (176°C). If the situation persists, contact your local Vulcan-Hart

authorized servicer.

DAILY FILTERING

Turn the gas valve off when draining or filling the fryer.

Allow frying compound to cool before draining or filling.

If you have used melted solid frying compound, always filter the frying compound when the cold zone

area under the tubes is hot and liquefied. A cold fryer heated up will not drain properly because the frying

compound under the cold zone tube area will remain solid. If necessary, the drain stick may be used

to carefully stir up solid frying compound to an area above the tubes where it will melt. After the cold

zone is liquefied, turn the fryer thermostat and gas valve OFF.

Open the filter bag and slip it over the end of the drain valve nipple. Tie it securely in place behind the

ring on the drain valve nipple so it won't slide off. Place receptacle under the bag and carefully open

the drain valve.

When the fry tank is empty, flush out scraps and sediment in the fry tank with a small amount of warm

oil. Allow fry tank to drain thoroughly.

Remove filter bag, dispose of crumbs, and wash filter bag.

If it is necessary to clean the fry tank more thoroughly, follow the procedures shown in CLEANING —

WEEKLY OR AS REQUIRED.

Close drain valve and pour filtered frying compound back into fry tank.

FRYING COMPOUND MAINTENANCE

Frying compound life may be extended by following these procedures:

• Do not salt foods over the fryer.

• Use good quality frying compound.

• Filter frying compound daily at a minimum.

• Replace frying compound if it becomes poorly flavored.

• Keep equipment and surroundings clean.

• Set thermostats correctly. Do not use excessively high temperatures.

• Remove excess moisture and particles from food products before placing in fryer.

• Dip out several cups of frying compound from the fry tank every day and add fresh frying compound

to replace it.

– 9 –

Page 10

CLEANING

CAUTION: Do not spray with hose or steam cleaner. Doing so will cause extensive damage (not

covered under warranty).

Daily

Clean your fryer regularly. If regular cleaning is neglected, grease will be burned on and discolorations

may form. These may be removed by washing with detergent or soap and water. Particularly stubborn

discolorations may be removed with a self-soaping scouring pad or a paste made of water and a mild

scouring powder applied with a plastic open pad or sponge. Do not use standard steel wool on stainless

steel finishes. Pieces of the steel wool will adhere to the stainless steel and cause rusting.

Always rub in the direction of the polish lines on the stainless steel front to preserve the original finish.

Keeping the fryer exterior clean and free of accumulated grease will prevent stubborn stains from

forming. Wash all exterior surfaces at least once daily. Use a cloth with warm water and a mild soap

or detergent. Follow with a clear rinse, then dry.

Weekly or as Required

1. Drain and strain frying compound into a clean container and refrigerate if necessary.

2. Close drain valve and fill tank with hot water. Add a good grade of non-corrosive, grease-

dissolving commercial cleaner.

3. Set thermostat to 300°F (148°C) and bring to a boil. Boil long enough to loosen all "varnish" and

"carbon" (15-20 minutes). If necessary, scrub inside of the tank with a long-handled pot brush. Do

not leave fryer unattended.

4. Drain cleaning solution from the fry tank slowly so you can clean side walls as exposed.

5. Open the drain valve completely and thoroughly rinse tank with clean water. Be sure to remove

all traces of cleaner.

6. Close drain valve and refill tank with clean hot (minimum 140°F [60°C]) water. Add 1 cup

(237 ml) of vinegar to neutralize alkaline left by the cleaner. Bring solution to a boil and allow it

to stand for a few minutes.

7. Drain tank and rinse thoroughly with clear hot water. All traces of cleaner must be removed; it can

affect the food taste. Thoroughly dry fry tank.

8. Close the drain valve.

9. Add liquid frying compound to the proper level.

Cleaning Stainless Steel

Stainless steel may be cleaned with ordinary soap or detergent and water. To prevent water spots and

streaks, rinse equipment thoroughly with warm water and wipe dry with a soft clean cloth. The addition

of a rinsing agent will also help prevent spotting.

– 10 –

Page 11

Fingerprints

Fingerprints are sometimes a problem on highly polished surfaces of stainless steel. They can be

minimized by applying a cleaner that will leave a thin, oily or waxy film. Wipe cleaner on and remove

excess with a soft dry cloth. After using, subsequent fingerprints will usually disappear when wiped

lightly with a soft cloth containing a little of the cleaner. If the surface is especially dirty to start with,

wash first with soap or detergent and water.

Burned On Foods and Grease

Soaking with hot soapy water will help greatly to remove burned on foods and grease. Stubborn

deposits can be removed with scouring powder mixed into a paste and applied with stainless steel wool

or sponges.

Precautions

When scraping off heavy deposits of grease or oil from stainless steel equipment, never use ordinary

steel scrapers or knives. Particles of ordinary steel may become embedded in, or lodge on, the surface

of the stainless steel. These will rust, causing unsightly stains. Where it is necessary to scrape, use

stainless steel, wood, plastic, or rubber tools, or stainless steel wool.

– 11 –

Page 12

MAINTENANCE

WARNING: HOT OIL AND PARTS CAN CAUSE BURNS. USE CARE WHEN OPERATING,

CLEANING AND SERVICING THE FRYER.

WARNING: SPILLING HOT OIL CAN CAUSE SEVERE BURNS. DO NOT MOVE FRYER

WITHOUT DRAINING ALL OIL FROM THE TANK.

VENT

Annually, when the fryer is cool, check the flue and clear any obstructions.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this model, contact the Vulcan-Hart Service

Agency in your area (refer to our website, www.vulcanhart.com for a complete listing of Authorized

Service and Parts depots).

When calling for service, the following information must be available: model number, serial number,

manufacture date (MD) and voltage.

FORM 35609 Rev. A (03-05) PRINTED IN U.S.A.

– 12 –

Page 13

– 12 –

F35609 Rév. A (03-05) IMPRIMÉ AUX É-U.

numéro de série, la date de fabrication, le type de gaz et d’alimentation électrique.

Lors d’une demande de service, fournir les renseignements suivants : le numéro de modèle, le

www.vulcanhart.com)

l’adresse :

nos succursales de service de l’entretien et de pièces autorisées, visiter notre site Web à

communiquer avec le service de l’entretien Vulcan-Hart le plus près (pour une liste complète de

Pour l’entretien de l’appareil ou pour obtenir des renseignements sur des pièces de rechange,

SERVICE DE L’ENTRETIEN ET PIÈCES DE RECHANGE

qu’il n’est pas obstrué.

Une fois par année, lorsque la friteuse est froide, vérifier le conduit d’évacuation pour s’assurer

CONDUIT D’ÉVACUATION

PRÉALABLE VIDANGER LE BAC À FRIRE.

GRAVES BRÛLURES. NE PAS DÉPLACER LA FRITEUSE SANS AVOIR AU

AVERTISSEMENT : LES RENVERSEMENTS D’HUILE CHAUDE PEUVENT CAUSER DE

PRUDENCE LORS DE L’EXPLOITATION ET DE L’ENTRETIEN DE LA FRITEUSE.

COMPOSANTS PEUVENT CAUSER DES BRÛLURES. EXERCER UNE EXTRÊME

AVERTISSEMENT : LORSQU’ILS SONT CHAUDS, L’HUILE CHAUDE ET LES

ENTRETIEN

Page 14

– 11 –

inoxydable, en bois, en plastique ou en caoutchouc ou encore un tampon en acier inoxydable.

non visibles à l’œil nu. S’il est absolument nécessaire de gratter, utiliser un instrument en acier

s’incruster ou de se loger dans la surface en acier inoxydable, provoquant la formation de taches

graisse ou d’huile sur une surface en acier inoxydable. Des particules d’acier risquent de

Ne jamais utiliser une racle en acier ordinaire ou un couteau pour enlever les dépôts tenaces de

Précautions

d’acier inoxydable ou d’une éponge.

dépôts rebelles à l’aide d’une pâte de poudre à récurer que l’on applique au moyen d’une laine

La graisse et les aliments brûlés s’enlèvent facilement à l’eau chaude savonneuse. Enlever les

Graisse et aliments brûlés

particulièrement sale au départ, la laver d’abord à l’eau savonneuse ou au détergent.

d’un chiffon doux ou d’un chiffon contenant une petite quantité du nettoyant. Si la surface est

et sec. Par la suite, les empreintes de doigts disparaîtront en les essuyant légèrement à l’aide

d’huile ou de cire. Étendre le produit sur la surface et enlever l’excédent à l’aide d’un chiffon doux

polies. Pour en minimiser la formation, appliquer un produit de nettoyage qui laissera un léger film

Les empreintes de doigts constituent parfois un problème sur les surfaces en acier inoxydable très

Empreintes de doigts

Page 15

– 10 –

s’avérer efficace.

chaude et l’essuyer à l’aide d’un chiffon doux et propre. L’ajout d’agent de rinçage peut également

inoxydable. Pour éviter la présence de taches d’eau et de rayures, rincer l’appareil à fond à l’eau

Utiliser du savon ordinaire ou du détergent et de l’eau pure pour le nettoyage de l’acier

Nettoyage de l’acier inoxydable

9. Ajouter de la graisse à frire liquide jusqu’à la marque de niveau d’huile.

8. Fermer le robinet de vidange.

qui risque d’altérer le goût des aliments. Bien essuyer.

7. Vidanger le bac et rincer à fond à l’eau chaude. Éliminer toute trace de produit de nettoyage

de nettoyage. Amener la solution à ébullition et laisser bouillir pendant quelques minutes.

Ajouter 237 ml (1 tasse) de vinaigre pour neutraliser la solution alcaline laissée par le produit

6. Fermer le robinet de vidange et remplir le bac à frire d’eau chaude (60 °C [140 °F] minimum).

Éliminer toute trace de produit de nettoyage.

5. Ouvrir complètement le robinet de vidange et rincer à fond le bac à frire à l’eau propre.

qu’elles sont exposées.

4. Évacuer lentement la solution nettoyante du bac en nettoyant les parois au fur et à mesure

friteuse sans surveillance.

du bac, au besoin, au moyen d’une brosse à long manche pour marmites. Ne pas laisser la

suffisamment pour faire décoller toutes les particules (de 15 à 20 minutes). Frotter l’intérieur

3. Régler le thermostat à 148 °C (300 °F) et amener la solution à ébullition. Laisser bouillir

dégraissage sans acide pour usage commercial de qualité.

2. Fermer le robinet de vidange et remplir le bac d’eau chaude et d’un produit de nettoyage et de

1. Vidanger la graisse à frire et la filtrer dans un contenant propre. Réfrigérer au besoin.

Nettoyage hebdomadaire ou au besoin

passé à l’eau tiède et au savon doux ou à l’aide d’un détergent. Rincer à l’eau claire et essuyer.

la formation de taches rebelles. Laver l’extérieur au moins une fois par jour à l’aide d’un chiffon

Maintenir propre l’extérieur de la friteuse et enlever toute accumulation de graisse pour empêcher

Toujours frotter dans le sens du «grain» de l’acier inoxydable pour en préserver le fini.

inoxydable. Des particules risquent d’adhérer à l’acier inoxydable et d’en provoquer la corrosion.

au moyen d’un tampon en plastique ou d’une éponge. Ne pas utiliser de laine d’acier sur l’acier

un tampon à récurer savonneux ou une pâte à base d’eau et de poudre à récurer douce appliquée

l’aide d’un détergent. Pour nettoyer les marques de décoloration particulièrement tenaces, utiliser

l’intérieur du bac à frire. En cas de décoloration, laver la partie atteinte à l’eau savonneuse ou à

Nettoyer la friteuse régulièrement, faute de quoi la graisse risque de brûler et de décolorer

Nettoyage quotidien

ce qui risque de causer de graves dommages (non couverts par la garantie).

ATTENTION : Ne pas nettoyer l’appareil à la vapeur ou au moyen d’un tuyau d’arrosage,

NETTOYAGE

Page 16

– 9 –

• Chaque jour, enlever plusieurs tasses de graisse du bac à frire et ajouter de la nouvelle graisse.

• Enlever l’excès d’humidité et les particules sur les aliments avant de les déposer dans la friteuse.

• Régler les thermostats correctement. Ne pas utiliser de températures trop élevées.

• Maintenir la cuisine et les appareils propres.

• Remplacer la graisse lorsque les aliments perdent leur saveur.

• Filtrer la graisse au moins une fois par jour.

• Utiliser de la graisse de qualité.

• Ne pas saler les aliments au-dessus de la friteuse.

Pour prolonger la durée de vie utile de la graisse à frire, suivre les indications suivantes :

ENTRETIEN DE LA GRAISSE À FRIRE

Fermer le robinet de vidange et transvider la graisse filtrée dans le bac à frire.

NETTOYAGE HEBDOMADAIRE OU AU BESOIN.

S’il s’avère nécessaire de nettoyer le bac à frire plus en profondeur, suivre les dIrectives à la section

Enlever le sac filtrant, jeter les résidus et laver le sac.

de graisse tiède. Vidanger complètement le bac et l’essuyer.

Lorsque le bac à frire est vide, rincer les résidus présents dans le bac au moyen d’une petite quantité

Placer un récipient en dessous du sac et ouvrir le robinet de vidange avec précaution.

solidement en place au moyen de la bague du mamelon de façon à ce qu’il ne puisse pas glisser.

Ouvrir le sac filtrant et le glisser sur l’extrémité ouverte du mamelon du robinet de vidange. Le fixer

thermostat et le robinet de gaz à OFF (arrêt).

solide au-dessus de la zone froide et la faire fondre. Une fois la graisse fondue, mettre le

chauffe depuis quelques minutes. Au besoin, utiliser la tige de nettoyage pour pousser la graisse

puisque la graisse qui se trouve sous le tube de la zone froide demeure solide même si la friteuse

Toujours filtrer la graisse lorsqu’elle est à l’état liquide. Une friteuse froide ne vidange pas efficacement

Laisser la graisse refroidir avant la vidange ou le remplissage.

Fermer le robinet de gaz pour la vidange et le remplissage du bac à frire.

FILTRAGE QUOTIDIEN

succursale Vulcan-Hart la plus près.

n’est pas inférieure à 176 °C (350 °F), autrement communiquer immédiatement avec la

dépasse la température sécuritaire. NE PAS rallumer la veilleuse tant que la température de l’huile

Un thermostat de sécurité assure l’arrêt de la friteuse et l’extinction de la veilleuse lorsque l’huile

THERMOSTAT DE SÉCURITÉ

Page 17

– 8 –

3. Mettre le bouton du robinet de gaz à OFF (arrêt).

2. Mettre le bouton du thermostat à OFF (arrêt).

1. Mettre le robinet d’arrêt de gaz manuel à OFF (arrêt).

ARRÊT PROLONGÉ

commande à OFF (arrêt).

3. Pour couper l’alimentation en gaz de tout le système, y compris la veilleuse, mettre le levier de

cette position.

2. Tourner le levier de commande du gaz à PILOT (veilleuse). La veilleuse demeure allumée à

1. Régler le thermostat à OFF (arrêt).

ARRÊT DE LA FRITEUSE

s’éteint. La friteuse s’allume et s’éteint par intermittence de manière à maintenir la température.

la température désirée est atteinte, l’alimentation en gaz des brûleurs est coupée et la flamme

Pour mettre la friteuse en marche, régler le bouton du thermostat à la température désirée. Lorsque

du gaz

commande

Levier de

Fig. 2

thermostat

Bouton du

MARCHE

Fig. 4

ARRÊT

VEILLEUSE

Fig. 3

VEILLEUSE

ARRÊT

ALLUMAGE DE LA FRITEUSE

MARCHE

6. Reprendre les étapes de 1 à 5 si l’alimentation en gaz est coupée.

5. Mettre le levier de commande de gaz à ON (marche) (Fig. 4).

pas allumée.

Reprendre les étapes 2, 3 et 4 tant que la veilleuse ne demeure

le levier est relâché.

puis le relâcher. La veilleuse devrait demeurer allumée lorsque

d’une bougie. Maintenir le levier enfoncé pendant 30 secondes

4. Toujours en appuyant sur le levier, allumer la veilleuse au moyen

vidange

Robinet de

3. Enfoncer le levier de commande du gaz (Fig. 3).

l’échappement des gaz non brûlés.

de la veilleuse) (Fig. 3). Attendre 5 minutes pour permettre

2. Tourner le levier de commande du gaz jusqu’à OFF/PILOT (arrêt

1. Régler le thermostat (placé derrière la porte) à OFF (arrêt) (Fig. 2).

ALLUMAGE DE LA VEILLEUSE

Page 18

– 7 –

Ajouter de la graisse fraîche au besoin.

de débordement de la graisse chaude.

L’huile prend de l’expansion lorsqu’elle est chauffée. Si elle dépasse la marque MAX, il y a risque

à frire passé la marque MAX.

Remplir le bac à frire jusqu’à la marque de niveau d’huile MIN. et MAX. NE PAS ajouter de graisse

façon à ne pas la faire surchauffer, puis verser dans le bac à frire avec précaution.

de faire brûler la graisse. Faire fondre la graisse dans un contenant séparé à faible température de

NE PAS faire fondre de graisse solide dans le bac à frire. Ceci risquerait d’endommager le bac et

des fuites.

faute de quoi les parois du bac risquent de s’endommager. Le gauchissement peut provoquer

ATTENTION : Avant d’allumer les brûleurs, remplir le bac à frire de graisse à frire liquide,

REMPLISSAGE DU BAC À FRIRE DE GRAISSE LIQUIDE

du dosseret. Répéter après chaque nettoyage.

d’un chiffon doux non pelucheux, appliquer une mince couche d’huile de cuisson sur toute la surface

Il est nécessaire de procéder à l’apprêtage du dosseret pour empêcher la formation de rouille. À l’aide

Apprêtage

Nettoyer tous les accessoires de la friteuse, les rincer et les essuyer.

des aliments. Essuyer le bac à frire avec un chiffon propre et doux.

au fond du bac. S’assurer qu’il ne reste aucune trace de nettoyant, car celui-ci peut altérer le goût

du fabricant. Rincer à fond tous les composants et vidanger les résidus par le robinet de vidange

et de dégraissage sans acide pour enlever toute trace du film protecteur d’huile. Suivre les indications

Nettoyer tous les composants de surface et l’intérieur du bac à frire au moyen d’un produit de nettoyage

Nettoyage

AVANT UNE PREMIÈRE UTILISATION

pour la vidange et le remplissage du bac.

Un usage incorrect peut entraîner l’annulation de la garantie du bac à frire. Fermer le robinet de gaz

VIDANGER LE BAC À FRIRE.

GRAVES BRÛLURES. NE PAS DÉPLACER LA FRITEUSE SANS AVOIR AU PRÉALABLE

AVERTISSEMENT: LES RENVERSEMENTS D’HUILE CHAUDE PEUVENT CAUSER DE

FONCTIONNEMENT

DE L’EXPLOITATION ET DE L’ENTRETIEN DE LA FRITEUSE.

PEUVENT CAUSER DES BRÛLURES. EXERCER UNE EXTRÊME PRUDENCE LORS

AVERTISSEMENT: LORSQU’ILS SONT CHAUDS, L’HUILE CHAUDE ET LES COMPOSANTS

Page 19

– 6 –

bon fonctionnement de la friteuse.

remplacé par de l’air frais, faute de quoi une pression atmosphérique insuffisante empêchera le

La cuisine doit être suffisamment aérée pour que l’air évacué par le système de ventilation soit

Quincy, MA 02269.

peut se procurer un exemplaire auprès de la National Fire Protection Association, Batterymarch Park,

vapeurs chargées de graisse et de la fumée provenant des appareils de cuisson commerciaux dont on

la norme NFPA n° 96 (dernière édition) relative à l’installation d’équipement pour la dispersion des

Les informations sur la construction et l’installation des hottes de ventilation sont comprises dans

filtres de la hotte.

brûlés. Observer un dégagement minimum de 457 mm (18 po) entre le conduit d’évacuation et les

Un dégagement approprié est requis au-dessus de l’appareil pour l’évacuation efficace des gaz

dépasser les côtés de la friteuse de 152,4 mm (6 po).

Placer la friteuse sous une hotte appropriée raccordée à un conduit d’évacuation. Celle-ci doit

Ne jamais raccorder un conduit d’évacuation directement à la friteuse.

des codes locaux.

S’assurer d’une ventilation suffisante conformément à la norme NFPA n° 96 (dernière édition) et

l’immeuble par un système de ventilation installé par un personnel qualifié.

l’appareil. Il est recommandé que les gaz de combustion soient ventilés à l’extérieur de

NE PAS obstruer le débit des gaz de combustion dans le conduit d’évacuation à l’arrière de

CONDUIT D’ÉVACUATION

canalisation de gaz en fermant son robinet manuel

Lorsque la pression d’essai est égale ou inférieure à 3,45 kPa (1/2 psi), isoler l’appareil de la

pression, débrancher la friteuse et son robinet d’arrêt de la conduite de gaz.

Si la pression de la canalisation de gaz est supérieure à 3,45 kPa (1/2 psi) lors d’essais de

ESSAIS DE LA CANALISATION DE GAZ

raccords-unions de pâte à joints de tuyaux résistant à l’action du gaz propane.

sont bien raccordés, serrer les raccords au moyen d’une clé à tuyau. Toujours enduire les

la droite suite au serrage exagéré des raccords-unions. Lorsque tous les appareils de la batterie

à tour de rôle en s’assurant que la tubulure d’alimentation en gaz n’avance pas vers la gauche ou

chaque raccord-union au raccordement adjacent. Ne pas trop serrer. Serrer les raccords-unions

raccordements des raccords-unions et des tubulures d’alimentation. Visser solidement à la main

tout appareil à flamme nue). Enlever les panneaux de commande pour accéder aux

Aligner toutes les friteuses et les cuisinières adjacentes (dégagement de 406 mm [16 po] requis de

différente, chacun d’eux doit être muni d’un régulateur distinct.

indications de la plaque signalétique. Si la pression d’alimentation de certains appareils est

de manière à supporter la puissance totale installée et sa marge de réglage doit correspondre aux

national, selon les normes ANSI en vigueur, (disponible auprès de Vulcan-Hart). Il doit être réglé

doit comporter un régulateur de pression approuvé par un laboratoire d’essais reconnu au niveau

La tubulure d’alimentation en gaz d’un alignement d’appareils en batterie dont la friteuse fait partie

amont de l’appareil et de l’équipement en batterie.

Conformément aux exigences des codes, installer un robinet d’arrêt dans la conduite de gaz, en

Branchement du gaz avant pour installations de friteuses en batterie

Page 20

– 5 –

Après avoir enrayé toute possibilité de fuite, purger la conduite de gaz pour évacuer tout l’air qu’elle contient.

corps étranger ni trace de saleté ou de pâte à joints.

(3/4 à 1/2 po) soient utilisés. S’assurer que les tuyaux sont propres et qu’ils ne comportent aucun

utiliser un tuyau en fonte de 19 mm (3/4 po) à moins que des raccords de réduction de 19 à 12,7 mm

cas d’une friteuse munie d’un tuyau flexible doté d’un raccord à débranchement rapide en option,

La canalisation de gaz doit être composée d’un tuyau de fonte d’au moins 12,7 mm (1/2 po). Dans le

amont de l’appareil.

Conformément aux exigences des codes, installer un robinet d’arrêt dans la conduite de gaz, en

L’entrée de gaz se trouve à l’arrière de l’appareil, dans le coin inférieur gauche.

Branchement du gaz arrière pour installations de friteuses autonomes

NE PRÉSENTENT AUCUNE FUITE. NE PAS SE SERVIR D’UNE FLAMME NUE.

DE LA CONDUITE DE GAZ À L’AIDE D’EAU SAVONNEUSE POUR S’ASSURER QU’ILS

AVERTISSEMENT: AVANT DE PROCÉDER À L’ALLUMAGE, VÉRIFIER TOUS LES JOINTS

de tuyaux doivent résister à l’action du gaz propane.

ATTENTION : Tous les raccords d’alimentation de la conduite de gaz et la pâte à joints

BRANCHEMENT DU GAZ

Fig. 1

est de niveau d’avant vers l’arrière, puis latéralement dans la position d’installation finale.

déposer un niveau à bulle sur le dessus de la friteuse. Régler les pieds pour s’assurer que l’appareil

aux appareils adjacents. Lorsque la friteuse est placée au bon endroit dans l’alignement en batterie,

avec l’équipement en batterie adjacent. Aligner les dessus avant et les tubulures d’alimentation

Si la friteuse fait partie d’un alignement en batterie, l’aligner d’avant vers l’arrière et latéralement

Installations de friteuses en batterie

latéralement dans la position d’installation finale.

friteuse. Régler les pieds pour s’assurer que l’appareil est de niveau d’avant vers l’arrière, puis

Une fois le branchement du gaz effectué, déposer un niveau à bulle d’air sur le dessus de la

Installations de friteuses autonomes

NIVELAGE DE LA FRITEUSE

Les roulettes s’accompagnent des directives d’installation séparées.

Le rattacher avant de rétablir l’alimentation en gaz et de remettre l’appareil en position d’exploitation.

S’il s’avère nécessaire de détacher le dispositif de retenue, couper l’alimentation en gaz de l’appareil.

de la friteuse tel qu’illustré (Fig. 1).

immobile. Fixer le dispositif de retenue à l’arrière

rapide, ni même sur la tuyauterie pour le garder

sur le connecteur ou le raccord à débranchement

le mouvement de l’appareil sans devoir compter

En plus, prendre les moyens nécessaires pour limiter

(en sous-traitance)

CÔTÉ ILLUSTRÉ SEULEMENT

D’ALIMENTATION EN GAZ DU

RETENUE POUR LA CONDUITE

FIXER LE DISPOSITIF DE

conforme aux normes ANSI-Z21 ou CSA 6.9.

mobile et d’un raccord à débranchement rapide

CSA6.16 sur les connecteurs des appareils au gaz

VULCAN) conforme aux normes ANSI-Z21.69 ou

munir d’un connecteur flexible (NON FOURNI PAR

Si l’appareil doit être installé sur des roulettes, se

Friteuses montées sur roulettes en option

Page 21

– 4 –

arrière en même temps. Ramener avec soin la friteuse à sa position normale et la placer à l’endroit prévu.

fixation sous l’appareil dans le sens des aiguilles d’une montre. L’incliner vers l’avant et visser les pieds

prenant soin de ne pas égratigner le revêtement. Visser solidement les pieds avant dans les trous de

Placer la friteuse dans un espace libre à proximité de l’emplacement prévu. L’incliner vers l’arrière en

Pieds

ASSEMBLAGE

normalisation, 5060 Spectrum Way, Bureau 100, Mississauga, Ontario, Canada L4W 5N6.

On peut se procurer un exemplaire des normes ci-dessus auprès de l’Association canadienne de

3. Norme CSA C22.2 du Code canadien de l’électricité.

2. Norme CSA B149.1 du Code d’installation des appareils fonctionnant au gaz naturel et propane.

1. Codes locaux.

Au Canada :

exemplaire auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

3. Norme ANSI-NFPA n° 70 (dernière édition) du National Electrical dont on peut se procurer un

exemplaire auprès de l’American Gas Association Inc., 1515 Wilson Blvd., Arlington, VA 22209.

2. Norme ANSI/Z223.1 (dernière édition) du National Fuel Gas Code dont on peut se procurer un

1. Codes locaux

Aux États-Unis :

L’installation de votre friteuse Vulcan doit se faire selon les codes suivants :

CODES D’INSTALLATION ET NORMES

produisent des courants d’air.

ne pas ouvrir les fenêtres à proximité de l’appareil ni utiliser des ventilateurs muraux qui

Veiller à ce que les ventilateurs ne soufflent pas directement sur la friteuse. Lorsque c’est possible,

combustion et à la ventilation.

combustion. Installer la friteuse de manière à ne pas obstruer la circulation de l’air nécessaire à la

dégagement approprié est requis pour les ouvertures d’approvisionnement d’air de la chambre de

S’assurer d’une ventilation suffisante dans le local pour permettre la combustion des gaz brûlés. Un

Installer la friteuse dans un endroit suffisamment espacé pour en faciliter l’utilisation et l’entretien.

Observer un dégagement d’au moins 406 mm (16 po) entre la friteuse et tout appareil à flamme nue.

Observer un dégagement d’au moins 914 mm (36 po) à l’avant de la friteuse.

Installer la friteuse dans un endroit suffisamment espacé pour en faciliter l’utilisation et l’entretien.

Côté gauche : 152 mm (6 po) 0"

Côté droit : 152 mm (6 po) 0"

Arrière : 152 mm (6 po) 0"

COMBUSTIBLE INCOMBUSTIBLE

CONSTRUCTION CONSTRUCTION

Dégagement requis lors de l’installation :

ATTENTION : Aucune substance combustible ne doit se trouver à proximité de l’appareil.

EMPLACEMENT

Page 22

– 3 –

Quatre pieds Manuel

Tuyau de vidange Deux paniers jumelés

Grille ramasse-miettes Support de panier Carte de garantie

ACCESSOIRES EXPÉDIÉS AVEC LA FRITEUSE

Ne pas soulever ou déplacer la friteuse par la porte ou la poignée.

matériel d’emballage et aviser le transporteur dans les 15 jours suivant la date de réception.

l’appareil, vérifier s’il n’a pas été endommagé lors du transport. En cas de dommages, conserver le

transporteur en assume l’entière responsabilité jusqu’à la livraison. Immédiatement après avoir déballé

Cette friteuse a été inspectée avant de quitter l’usine. En acceptant de livrer cette marchandise, le

DÉBALLAGE

éclaboussures de composé à friture chaud.

Stabiliser la friteuse à l’aide d’attaches appropriées pour l’empêcher de basculer et éviter ainsi les

que l’appareil a été conçu en fonction de l’altitude de l’endroit où il sera installé.

aux spécifications de la plaque signalétique se trouvant sur l’intérieur de la porte. S’assurer aussi

Avant d’installer la friteuse, s’assurer que le type de gaz (naturel ou propane) de l’immeuble correspond

INSTALLATION

Quatre roulettes Panier simple

Couvercle de bac Deux paniers à friture jumelés

Brosse à bac Tuyau à débranchement rapide de 1,21 m (4 pi)

ACCESSOIRES POUR INSTALLATION SUR PLACE EN OPTION

Il est recommandé de lire ce manuel au complet et de suivre attentivement toutes les instructions.

pendant de nombreuses années.

matériaux. Leur installation et entretien appropriés permettront d’en obtenir un rendement optimal

Les friteuses au gaz Vulcan-Hart sont fabriquées avec le plus grand soin et à partir des meilleurs

GÉNÉRALITÉS

DOCUMENT À CONSERVER EN CAS DE BESOIN.

FRITEUSE AU GAZ MODÈLE GHF91

INSTALLATION, ENTRETIEN ET FONCTIONNEMENT

Page 23

– 2 –

© COMPAGNIE VULCAN-HART, 2005

FONCTIONNER CET APPAREIL.

EN CAS DE PANNE DE COURANT, NE PAS FAIRE

INSTALLATION OU TOUT ENTRETIEN.

ET D’ENTRETIEN AVANT DE PROCÉDER À TOUTE

INSTRUCTIONS D’INSTALLATION, DE FONCTIONNEMENT

DES BLESSURES ET MÊME LA MORT. LIRE LES

PEUVENT CAUSER DES DOMMAGES MATÉRIELS,

ET L’ENTRETIEN INCORRECTS DE CET APPAREIL

L’INSTALLATION, LE RÉGLAGE, LA MODIFICATION

AVERTISSEMENT

APPAREIL.

PROXIMITÉ DE CET APPAREIL OU DE TOUT AUTRE

AUTRE LIQUIDE OU VAPEUR INFLAMMABLE À

NE PAS RANGER NI UTILISER DE L’ESSENCE NI TOUT

MESURE DE SÉCURITÉ

L’ENTRETIEN.

AVEC LE FOURNISSEUR DE GAZ ATTITRÉ POUR

AVEC LA COMPAGNIE DE GAZ LA PLUS PRÈS OU

LE ROBINET D’ARRÊT PRINCIPAL ET COMMUNIQUER

EN CAS D’ODEURS DE GAZ, ÉTEINDRE L’APPAREIL PAR

IMPORTANT

PROCURER CES INFORMATIONS CHEZ LE FOURNISSEUR DE GAZ LE PLUS PRÈS.

PERSONNE AYANT RESPIRÉ LES GAZ QUE CET APPAREIL DÉGAGE. ON PEUT SE

AFFICHER À UN ENDROIT VISIBLE LES PREMIERS SOINS À ADMINISTRER À TOUTE

CONCERNÉS DANS CE MANUEL.

DÉMARRAGE INITIAL CHEZ LE CLIENT DE MÊME QUE LE RÉGLAGE DES APPAREILS

À INSTALLER DES APPAREILS FONCTIONNANT AU GAZ ET À EFFECTUER LE

CE MANUEL A ÉTÉ PRÉPARÉ À L’INTENTION D’UN PERSONNEL QUALIFIÉ ET AUTORISÉ

MESURES DE SÉCURITÉ IMPORTANTES

Page 24

GHF91

WWW.VULCANHART.COM F35609 Rév. A (03-05)

UNE DIVISION DE GROUPE ITW ÉQUIPEMENT ALIMENTAIRE, LLC TÉL. (502) 778-2791

VULCAN-HART P.O. BOX 696, LOUISVILLE, KY 40201-0696

pièces et de service autorisé le plus près, visiter notre site Web à : www.vulcanhart.com

Pour de plus amples détails concernant Vulcan-Hart ou pour repérer le détaillant de

GHF90 ML-135504

GHF91 ML-135503

MODÈLES

DE LA SÉRIE GHF

AUX CUISINIÈRES À SERVICE INTENSE

FRITEUSE AU GAZ POUR AGENCEMENT

MODE D’EMPLOI

MODE D’INSTALLATION ET

Loading...

Loading...