Page 1

INSTALLATION &

OPERATION MANUAL

GH SERIES

HEAVY DUTY GAS RANGES

MODELS

GH30 ML-52141

GH30C ML-53146

GH30S ML-52156

GH45 ML-52142

GH45C ML-52147

GH45S ML-52157

GH6 ML-126402

GH6C ML-126403

GH6S ML-126405

GH60 ML-52144

GH60C ML-52149

GH60S ML-52159

GH60T ML-52171

GH60TC ML-52190

GH60TS ML-52168

GH72 ML-52145

GH72C ML-52150

GH72S ML-52160

GH72/45 ML-52176

GH72/45C ML-52185

GH72/45S ML-52167

GH60/45 ML-52174

GH60/45C ML-52184

GH60/45S ML-52165

GH60T45 ML-52186

GH60T45C ML-52191

GH60T45S ML-52169

GHX45 ML-52217

GHX60 ML-52218

GHX60T ML-52223

GHX72 ML-52219

MODEL GH6C

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

P.O. BOX 696, LOUISVILLE, KY 40201-0696

TEL. (502) 778-2791

FORM 35634 (2-05)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN SHUTOFF VALVE AND CONTACT THE LOCAL

GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

– 2 –

Page 3

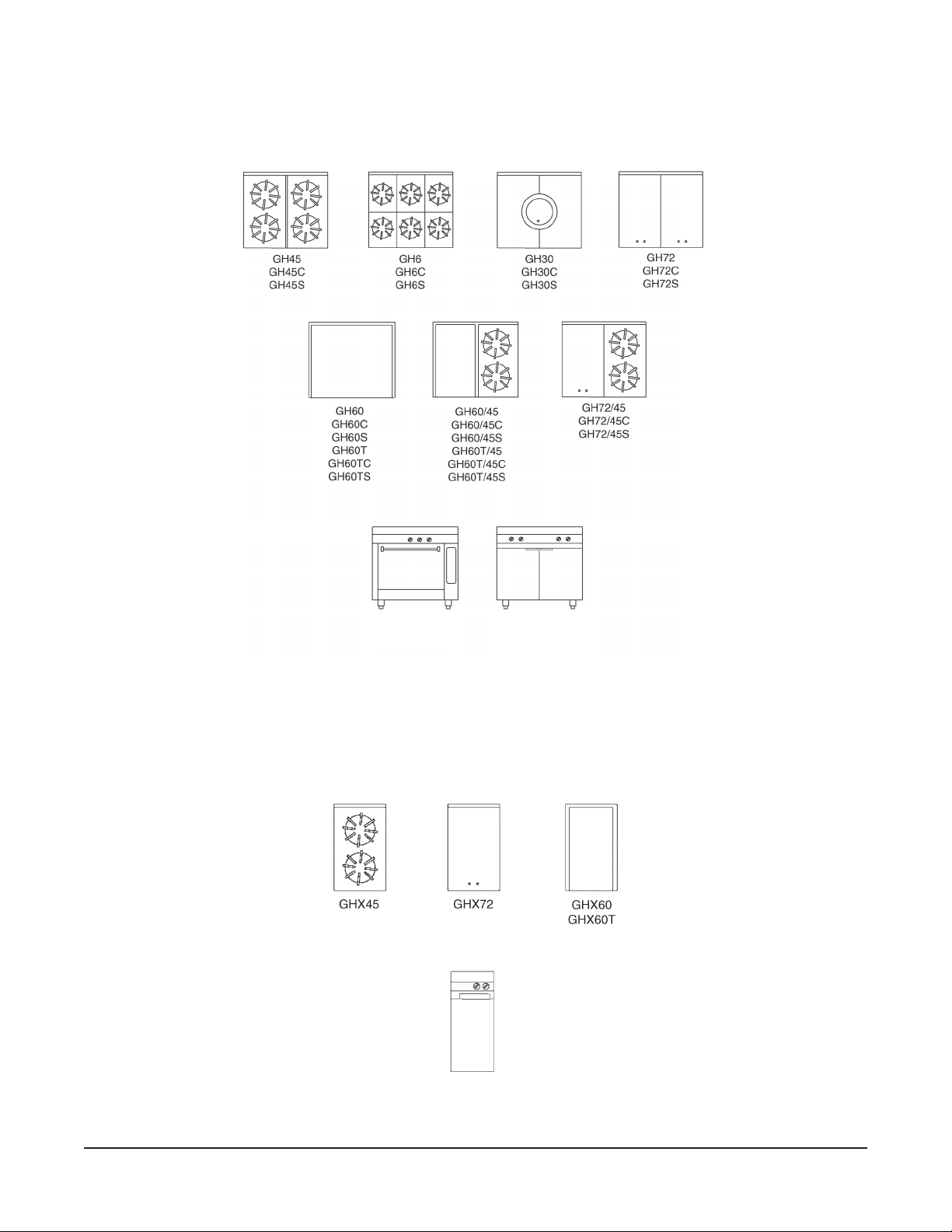

CONFIGURATIONS OF GH SERIES HEAVY-DUTY RANGES WITH

STANDARD OVENS, CONVECTION OVENS AND STORAGE BASES

FULL BODY

34" (864) WIDE

OVEN BASE

FULL BODY

34" (864) WIDE

STORAGE BASE

CONFIGURATIONS OF GH SERIES HEAVY-DUTY EXPANDO RANGES

WITH STORAGE BASE

FULL BODY

18" (457) WIDE

STORAGE BASE

– 3 –

Page 4

Installation, Operation and Care Of

MODEL GH SERIES HEAVY-DUTY GAS RANGES

SAVE THESE INSTRUCTIONS

GENERAL

Vulcan ranges and ovens are produced with quality workmanship and material. Proper installation,

usage and maintenance of your range will result in many years of satisfactory performance.

The manufacturer suggests that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

INSTALLATION

UNPACKING

This range was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the range is found to be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

Carefully unpack range(s) and place in the approximate installation position, whether as a battery or

single stand-alone range. Remove all shipping wire and wood blocking. Remove parts (packed in a

cardboard box) from oven cavity, or cabinet body or on top of modular range(s).

Before installing, check the electrical service (Convection Oven Models only) and type of gas supply

(natural or propane) to make sure they agree with the specifications on the rating plate located on the

lower left-hand corner of the front frame behind the bellcrank. If the supply and equipment

requirements do not agree, do not proceed with the installation. Contact your dealer or Vulcan-Hart

immediately.

LOCATION

CAUTION: The equipment area must be kept free and clear of combustible substances.

The following ranges, when installed, must have a minimum clearance from combustible construction

of 6" (152 mm) at the sides and 6" (152 mm) at the rear. Clearance from noncombustible construction

can be 0" (0 mm) at the sides and rear:

GH30

GH30C

GH30S

GH45

GH45C

GH45S

GH6

GH6C

GH6S

GH60

GH60C

GH60S

GH60T

GH60TC

GH60TS

GH72

GH72C

GH72S

GH72/45

GH72/45C

GH72/45S

GH60/45

GH60/45C

GH60/45S

GH60T45

GH60T45C

GH60T45S

GHX45

GHX60

GHX60T

GHX72

– 4 –

Page 5

Snorkel® Ranges must not be included in back-to-back setups.

The installation location must allow adequate clearances for servicing and proper operation. A minimum

front clearance of 35" (889 mm) is required.

The range(s) must be installed so that the flow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber(s) must be provided. Make sure

there is an adequate supply of air in the room to allow for combustion of the gas at the burners.

INSTALLATION CODES AND STANDARDS

Your Vulcan range(s) must be installed in accordance with:

In the United States:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1 (latest edition), Copies may be obtained from the American

Gas Association, Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. National Electrical Code ANSI/NFPA-70 (latest edition). Copies available from the National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CSA B149.1 Natural Gas and Propane Installation Code.

3. CSA C22.1 Canadian Electrical Code.

The above are available from the Canadian Standard Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

ASSEMBLY

Ranges Mounted on Casters

Ranges mounted on casters must use a flexible connector (not supplied

by Vulcan) that complies with the Standard for Connectors for Movable

Gas Appliances, ANSI Z21.69 • CSA 6.16 and a quick-disconnect

device that complies with the Standard for Quick-Disconnect Devices

for Use With Gas Fuel, ANSI-Z21.41 • CSA 6.9. In addition, adequate

means must be provided to limit movement of the appliance without

depending on the connector and the quick-disconnect device or its

associated piping to limit appliance movement. Attach the restraining

device at the rear of the range as shown in Fig. 1.

Fig. 1

If disconnection of the restraint is necessary, turn off the gas supply before disconnection. Reconnect

this restraint prior to turning the gas supply on and returning the range to its installation position.

Separate instructions for installing casters to the range are included with the casters.

– 5 –

Page 6

Bumper Bars

CAUTION: Failure to install bumper bars may cause

motor damage and will void the warranty.

Remove existing #10 screws. Position bumper bars as

shown in Fig. 2. Replace #10 screws and secure

bumper bars.

Fig. 2

Battery Installation

If you are installing a new battery range to an existing field appliance manufactured before January

1998, the union on the existing field appliance must be checked against the union being used on the

new range. The union manufacturer's name around the face surface of the union nut must match. If the

new range has been shipped using a Ward union and the old appliance has something different — i.e.,

Stockham — it must be replaced with a Ward union (Fig. 3). Failure to replace this union could result

in a gas leak.

If a Ward union is needed for installation, it must be ordered through the Vulcan-Hart Parts Depot (Part

No. FP-088-89).

Fig. 3

Questions or concerns regarding the above installation procedures may be addressed by calling a

Vulcan-Hart Service Agency. (refer to our website, www.vulcanhart.com for a complete listing of

Authorized Service and Parts depots).

Proceed with the battery installation as follows:

1. Move next range into position and level as explained in LEVELING. Engage union nut on

manifold pipe with male fitting on next range and draw up union nut hand-tight. Be sure

ranges butt both front and rear. If manifolds do not line up, then ranges are not level. Do not

adjust manifold brackets to make manifolds line up, except in extreme cases, because this

will cause gas valves not to line up perfectly with manifold cover holes. Bolt top frames

1

together, using 10-24 x

/2 " (12.7 mm) bolts (packed in plastic bag in range oven).

– 6 –

Page 7

2. Continue leveling, connecting manifold pipe and

bolting top frames of ranges together until all ranges

in the battery are connected, and then tighten

manifold unions gas-tight. Use wrench to keep

section of union assembled to pipe from rotating.

Failure to do this may result in misalignment of valve

stems.

3. Unpack high shelves or backguards and remove

backsplashes.

4. Place high shelf or backguard in position (see

ASSEMBLY — RISER, BACKGUARD AND HIGH

SHELF in this manual).

5. Replace back tops and backsplashes.

6. If front plates do not line up perfectly, adjust by

means of bolts under front plate. Similar front

adjustment is provided for the one-piece cast-iron

griddle (Model GH60) (Fig. 4).

Fig. 4

Riser, Backguard and High Shelf

Remove the shipping brackets on the corner of the range where a high shelf support casting is to be

bolted. It is not necessary to remove either shipping bracket on ranges equipped with a backguard as

the brackets will be used for support when remounting the rear top plate and backguard backsplash.

1. Carefully unpack riser, backguard or high shelf with the back down, on floor in front of range.

Remove backsplash panel from riser, backguard or high shelf.

2. Remove top castings, back top and shipping brackets from the range. Identify top casting(s) so

they are replaced in the same positions on the same range as when received from the factory.

When assembling a riser, backguard or high shelf to batteried equipment, remove only the extreme right

and left shipping brackets of setup section requiring mounting (Fig. 5).

Fig. 5

– 7 –

Page 8

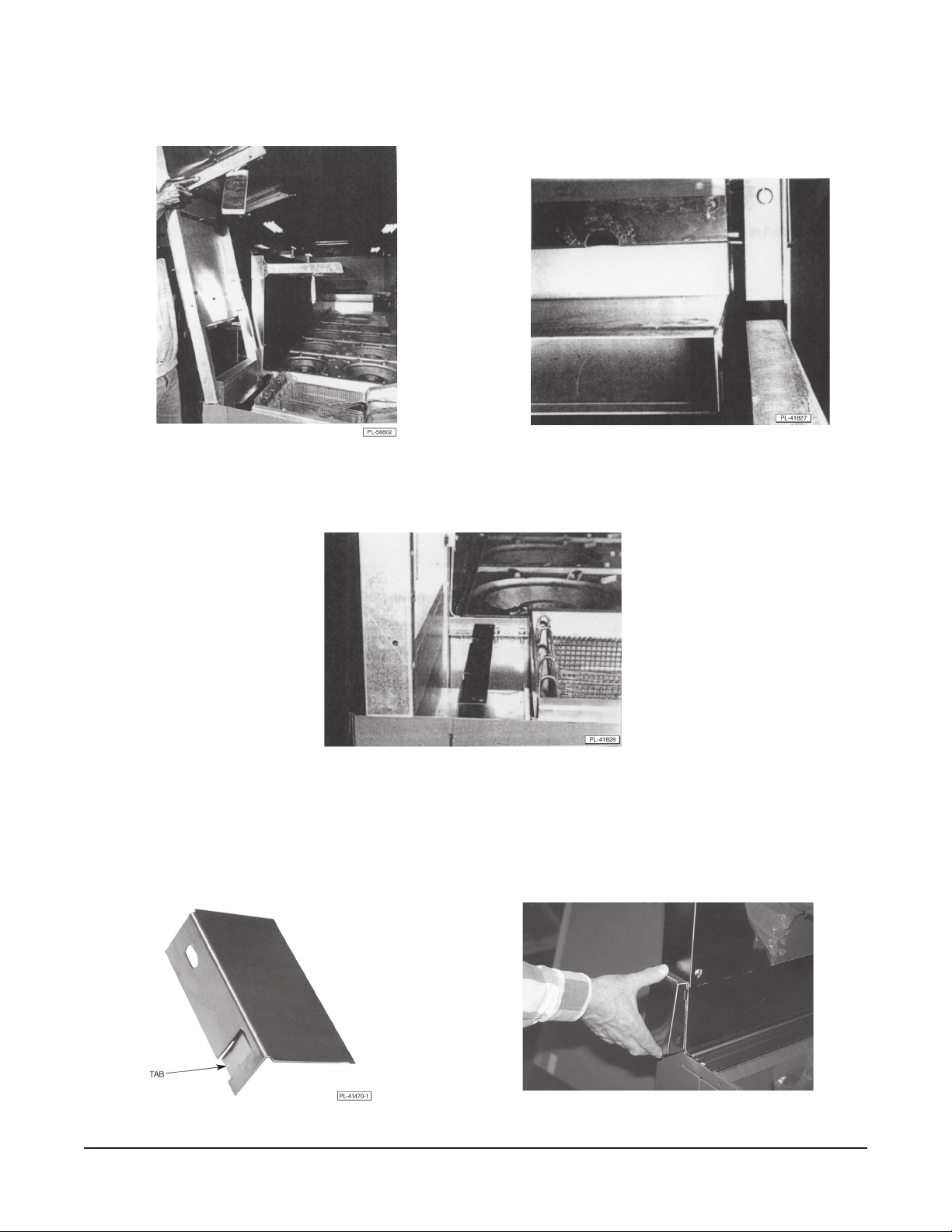

3. Carefully lift riser, backguard or high shelf over range (Fig. 6).

4. Carefully guide support channels into the two openings provided at the rear of the range (Fig. 7).

Fig. 6

Fig. 7

While lowering support channels into openings, be sure that the lower angle flange of the riser,

backguard or high shelf is positioned outside the flue back (Fig. 8).

Fig. 8

Once the backguard is setting in place on the range, install the left and right end caps. End caps simply

slide on, in between the splasher and the backguard. There is a tab on the cap that can be pulled out

or pushed in (with a screwdriver) to adjust cap for tightness. Two caps are packaged with each

backguard in a separate plastic bag. Be sure to look for caps in the backguard box. See Figs. 9, 10,

11 and 12.

Fig. 9

Fig. 10

– 8 –

Page 9

Fig. 11

Fig. 12

5.

Replace back tops and top castings onto range (Fig. 12). Shipping brackets removed in Step 2

are no longer required and may be discarded.

6. Replace riser, backguard or high shelf backsplash panel. Mounting is now complete.

Thermostatically Controlled Griddle Installation

Set metal brick supports and bricks in place.

1. Center Support (1) — Place in center with smooth surface down (Fig. 13).

Fig. 13

2. Narrow Supports (2) — Place one on each side with smooth surface down and oval holes to

outside (Fig. 14).

Fig. 14

– 9 –

Page 10

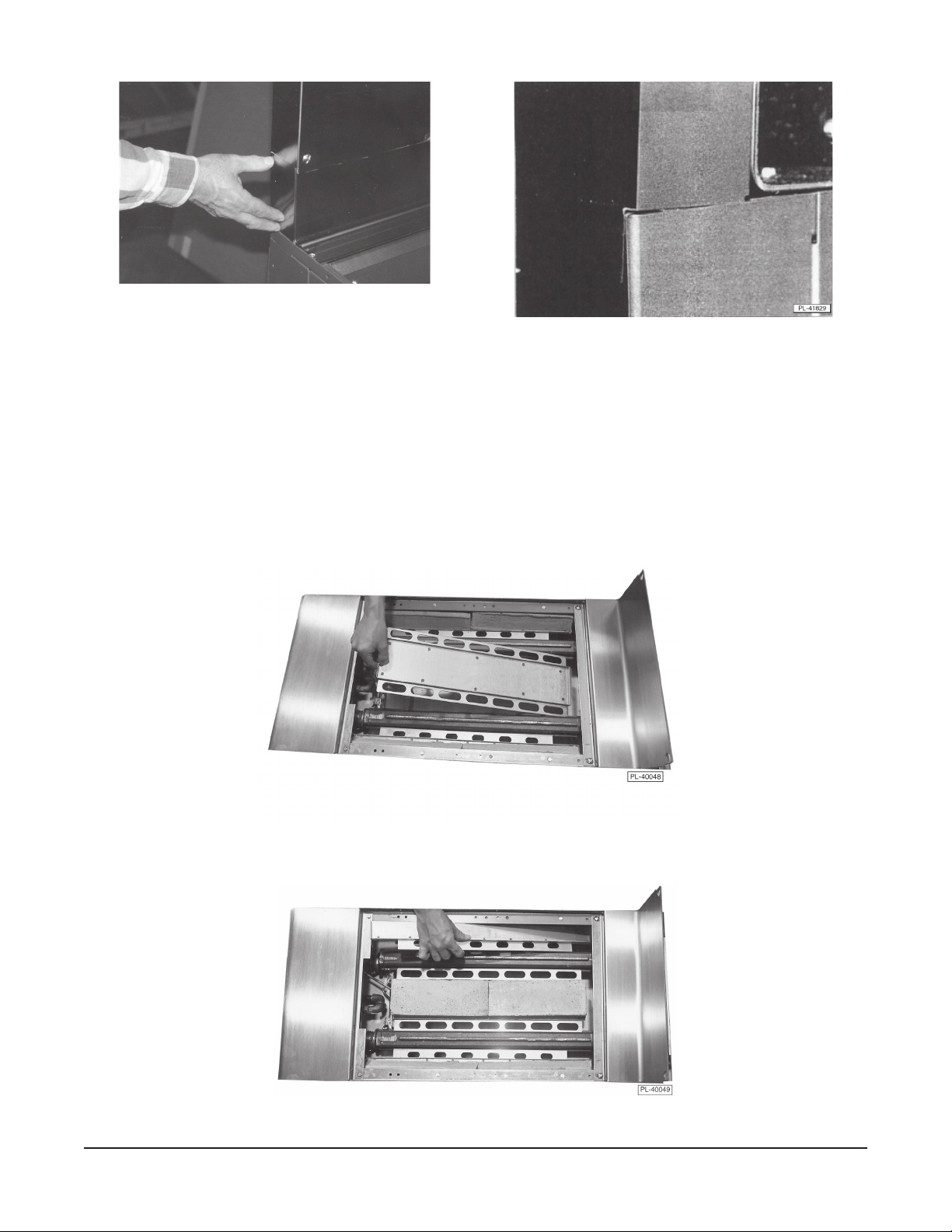

3. Triangle-shaped Bricks (4) — Place two each side (Fig. 15).

Fig. 15

4. Large Bricks (2) — Set in center support as shown in Figs. 14 and 15.

5. The griddle plate is packaged separately from the range. On the top burner box front area of the

range, locate the coiled thermostat bulb and capillary assembly. Gently uncoil the capillary line.

Lift the griddle plate onto the range top, being careful not to crush the thermostat bulb or capillary.

Wedge a 2 x 4 under the front part of the griddle to hold up the plate. This will be necessary to install

the thermostat bulb into the V-slot bracket, located on the under side of the griddle plate.

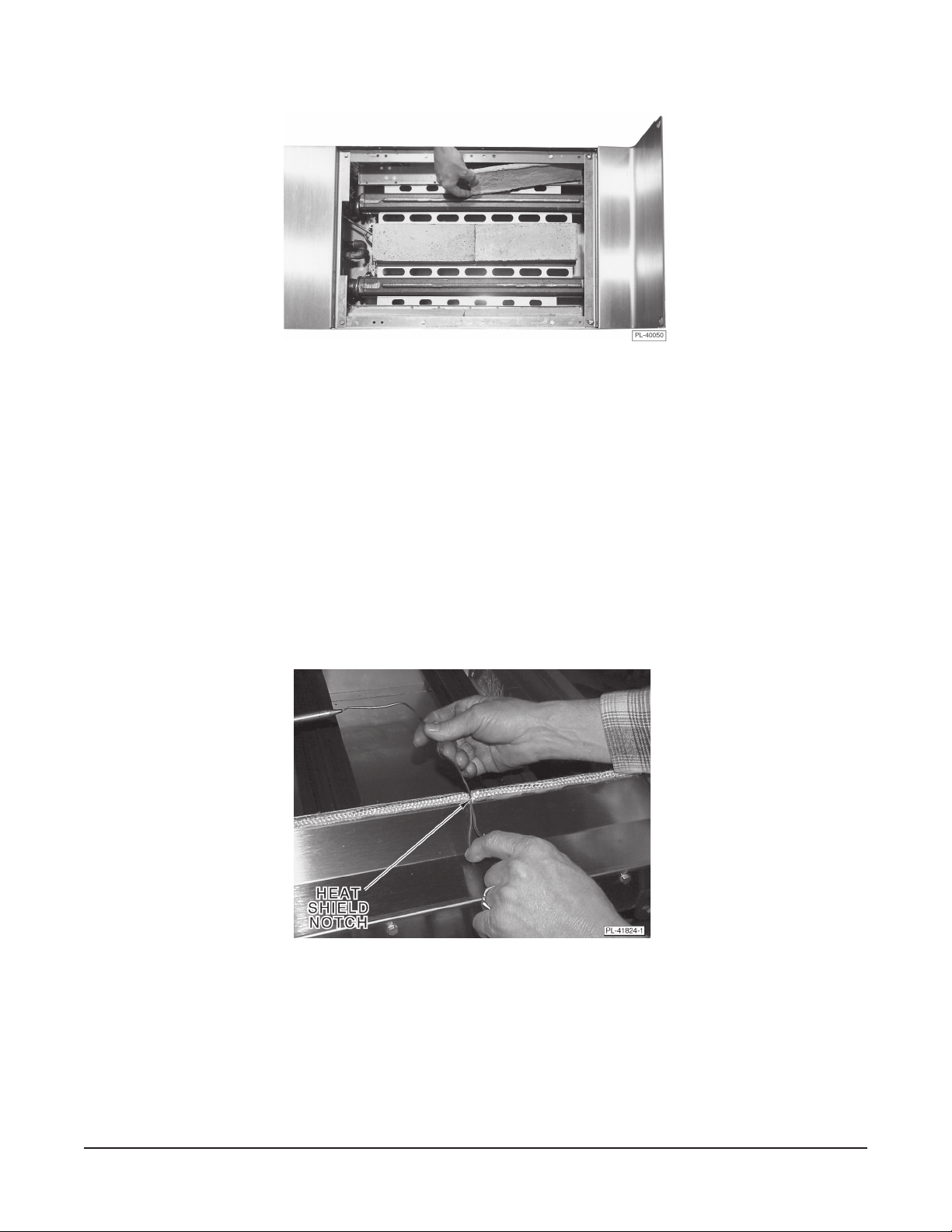

6. Feed the thermostat bulb and capillary up over the heat shield and through the notched area

supplied in the shield (Fig. 16).

Fig. 16

– 10 –

Page 11

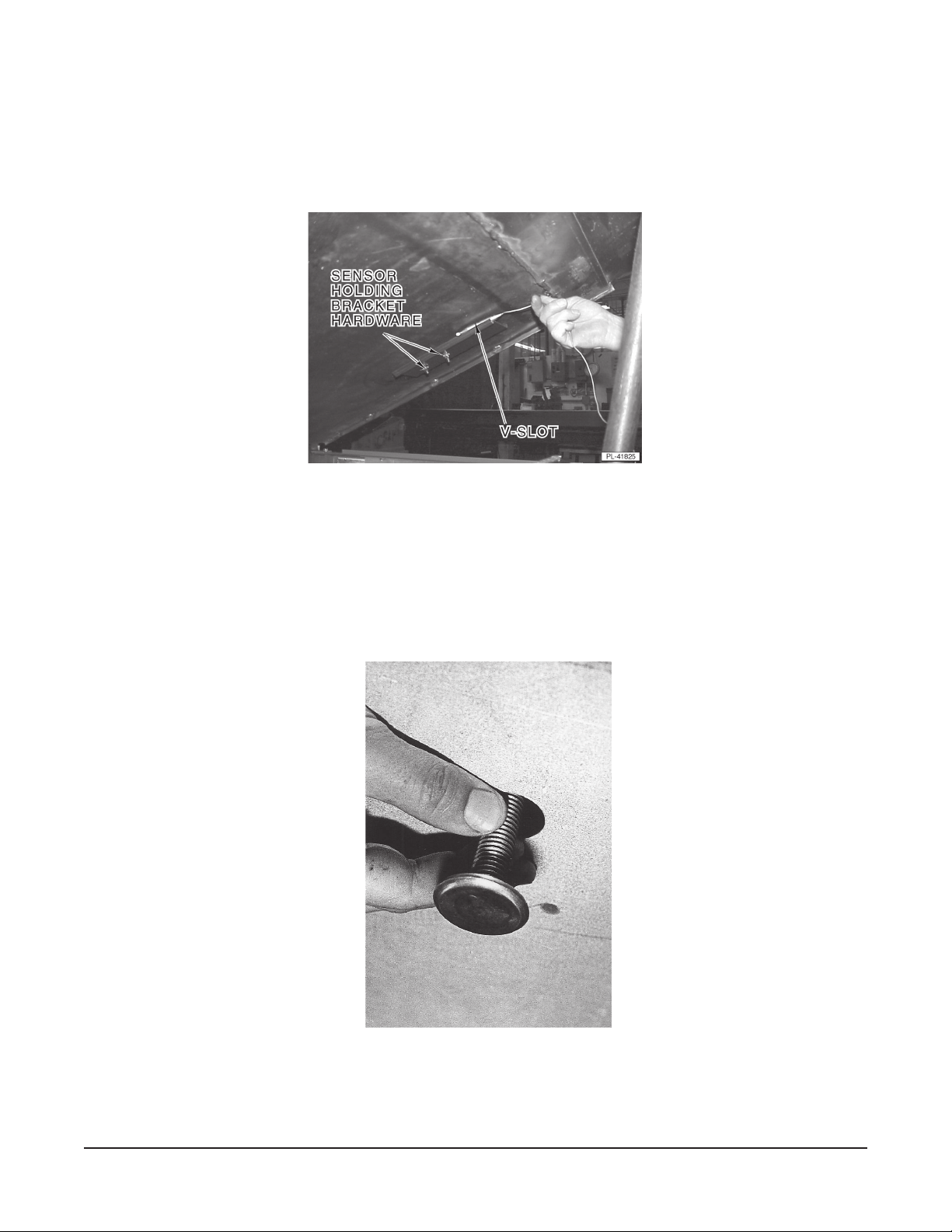

7. Slide the thermostat bulb through the V-slot bracket (Fig. 17). Neatly coil the excess capillary line

without kinking and lay resting in front of the heat shield. Do not pinch the line when reinstalling

the control cover.

NOTE: The bulb should not be exposed and should be completely encased inside the V-slot

bracket. Also take care to insure that the capillary line is not exposed in any way to the burner

flame.

Fig. 17

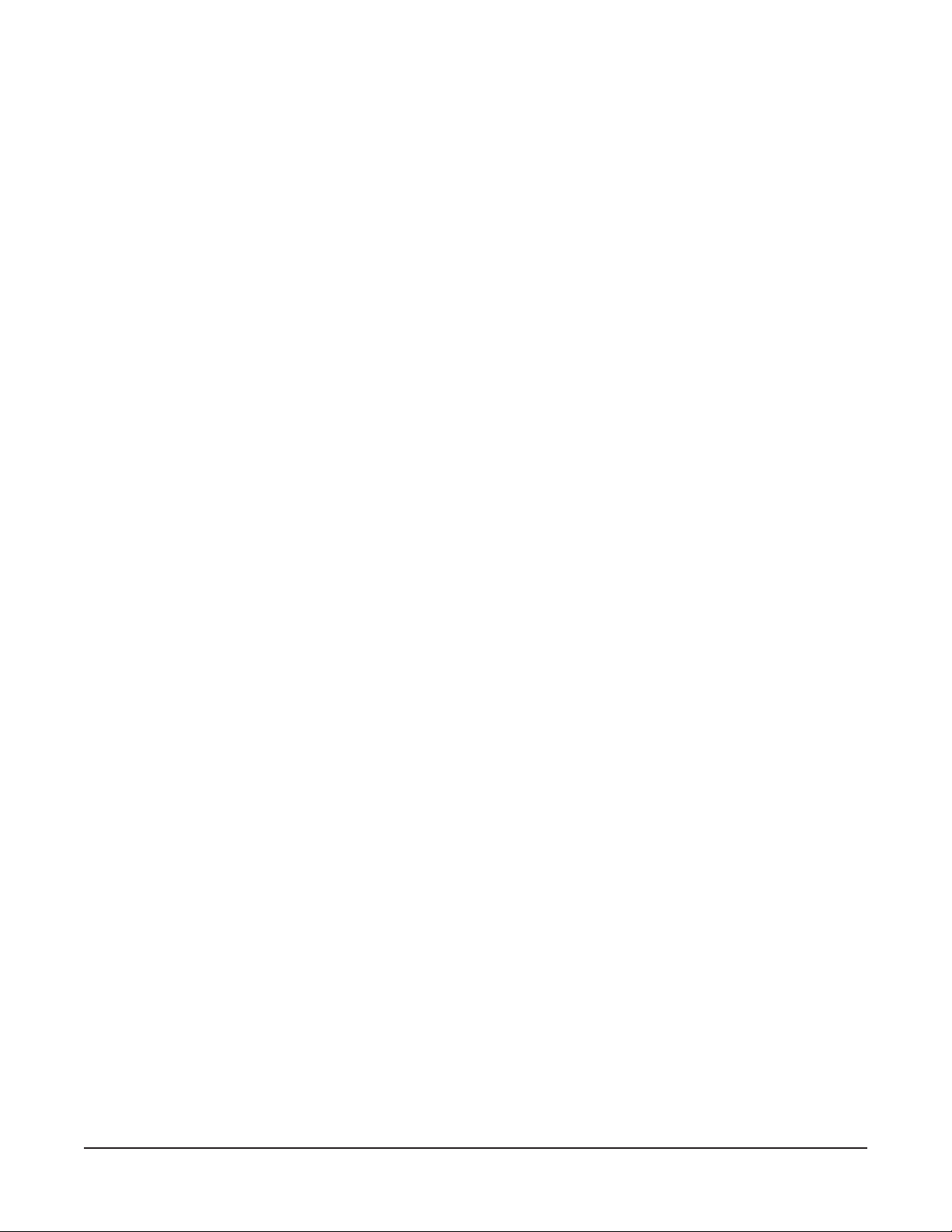

LEVELING

Unlevel range(s) will create battery installation problems in lining up the manifolding system, and result

in uneven cooked product. Using a carpenter's level, level the range(s) from front to rear and side to

side. With range in its exact location or battery position, adjust leg heights. If installing a battery of

equipment, begin with first unit in battery lineup. Adjust legs by turning feet until all legs are resting on

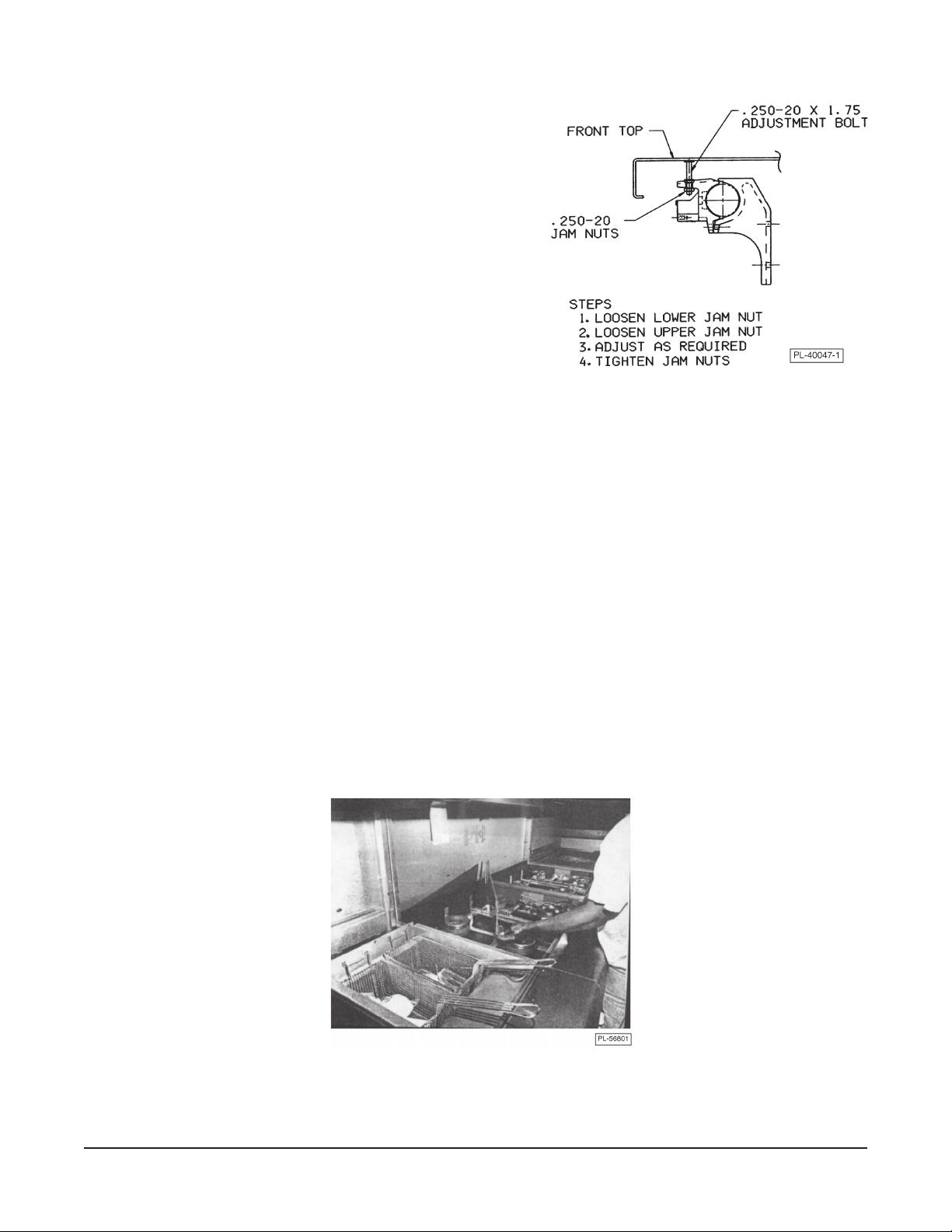

the floor. If "less legs base" or "toe base" is used, screw the leveling bolt until floor contact is made (Fig. 18).

Fig. 18

The casters provided for the ranges are the nonleveling type; therefore, the floor must be reasonably

level or baked products will be uneven and performance will be inconsistent.

– 11 –

Page 12

GAS CONNECTIONS

CAUTION: All gas supply connections and any pipe joint compound used must be resistant to

the action of propane gases.

Remove oven bottom(s) and baffles.

Remove upper manifold panel(s).

Connect gas supply to the range(s). Make sure the pipes are clean and free of obstructions, dirt and

piping compound.

Codes require that a gas shutoff valve be installed in the gas line ahead of the range(s).

Ranges manufactured for use with propane gas are equipped with fixed orifices.

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR

LEAKS. USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

Single Range Installations

All single stand-alone ranges require installation using a regulator (design-certified by a nationally

recognized testing lab to the applicable ANSI standard) for an outlet (manifold) pressure of 6" (1.49 kPa)

Water Column for natural gas supply, and outlet (manifold) pressure of 10" (2.49 kPa) Water Column

for propane gas supply (available from Vulcan-Hart). The regulator must be adjusted to agree with the

pressures indicated on the rating plate. When installing the regulator, follow instructions supplied by the

regulator manufacturer.

Manifold pressure for the incoming store line must be at least 7" (1.74 kPa) Water Column for natural

gas and 11" (2.74 kPa) Water Column for propane gas.

If a pressure regulator is not installed, the warranty on related parts, as well as performance-related

problems, will not be covered.

Battery Installations

The gas manifold of this range, or the battery of which it is a part, must be installed using a regulator

design-certified by a nationally recognized testing lab to the applicable ANSI standard (regulators

available from Vulcan-Hart). The pressure regulator must have a maximum regulation capacity to

handle the total connected load and must have an adjustment range for manifold pressure marked on

the range rating plate. If the manifold pressure of the connected ranges is not the same, a separate

regulator must be supplied for all ranges operating under different manifold pressure ratings.

If a pressure regulator is not installed, the warranty on related parts, as well as performance-related

problems, will not be covered.

TESTING THE GAS SUPPLY SYSTEM

1

When test pressures exceed

/2 psig (3.45 kPa), the range and its individual shutoff valve must be

disconnected from the gas supply piping system.

When test pressures are

1

/2 psig (3.45 kPa) or less, the range must be isolated from the gas supply

system by closing its individual manual shutoff valve.

– 12 –

Page 13

FLUE CONNECTIONS

DO NOT obstruct the flow of flue gases from the flue duct located on the rear of the range. It is

recommended that the flue gases be ventilated to the outside of the building through a ventilation

system installed by qualified personnel.

A minimum of 18" (45 cm) must be maintained between the grease removal device and the cooking

surface.

Information on the construction and installation of ventilating hoods may be obtained from the standard

for "Vapor Removal from Cooking Equipment," NFPA No. 96 (latest edition), available from the National

Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE

PROVIDED WITH A THREE-PRONG GROUNDING PLUG. IT IS IMPERATIVE THAT THIS

PLUG BE CONNECTED INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF

THE RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN.

DO NOT REMOVE THE GROUNDING PRONG FROM THIS PLUG.

If your range is not equipped with a grounding plug and electric supply is needed, ground the range by

using the ground lug provided (refer to the wiring diagram which is packaged in a clear plastic ziplock

bag located within the oven cavity on the oven rack).

Do not connect the range to electrical supply until after gas connections have been made.

– 13 –

Page 14

OPERATION

WARNING: THE RANGE AND ITS PARTS ARE HOT. BE CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE RANGE.

BEFORE FIRST USE

Seasoning of Cast-Iron Hot Tops and Even-Heat Tops

These tops are made of cast iron and should be seasoned prior to use. To season, pour a small amount

of cooking oil (about 1 ounce [28 grams] per square foot [.09 square meters] of surface) over the top.

With a cloth, spread the oil over the entire surface to create a thin film. Wipe off any excess oil with a

cloth. Turn burners on very low and allow to heat up gradually for about 2 hours. Repeat this procedure

a second time before regular use. This will resist cracking of the cast iron and ensure longer life.

Cleaning Griddle Plate at Start-Up

The griddle plate is shipped covered with a protective coating of grease. Remove this film only when

the griddle plate is being cleaned prior to its first cooking use. Remove film by scraping the griddle

surface with the straight edge of a large piece of stiff cardboard. For cleaning procedures, see

CLEANING - GRIDDLE TOP in this manual.

Seasoning of Griddle Plate

CAUTION: This griddle plate is steel, but the surface is relatively soft and can be scored or

dented by carelessly using a spatula. Be careful not to dent, scratch or gouge the plate surface.

Do not try to knock off loose food that may be on the spatula by tapping the corner edge of the

spatula on the griddle surface.

A new griddle surface must be seasoned to do a good cooking job. The metal surface of the griddle is

porous. Food tends to get trapped in these pores and stick; therefore, it is important to "season" or "fill

up" these pores with cooking oil before cooking. Seasoning gives the surface a slick, hard finish from

which the food will release easily.

To season, heat the griddle to a low temperature 300 to 350°F (148 to 176°C) (use a surface

temperature gauge) and pour on a small amount of cooking oil (about 1 ounce [28 grams] per square

foot [.09 square meters] of surface). With a cloth, spread the oil over the entire griddle surface to create

a thin film. Wipe off any excess oil with a cloth.

Repeat this procedure two to three times until the griddle has a slick, mirrorlike surface.

– 14 –

Page 15

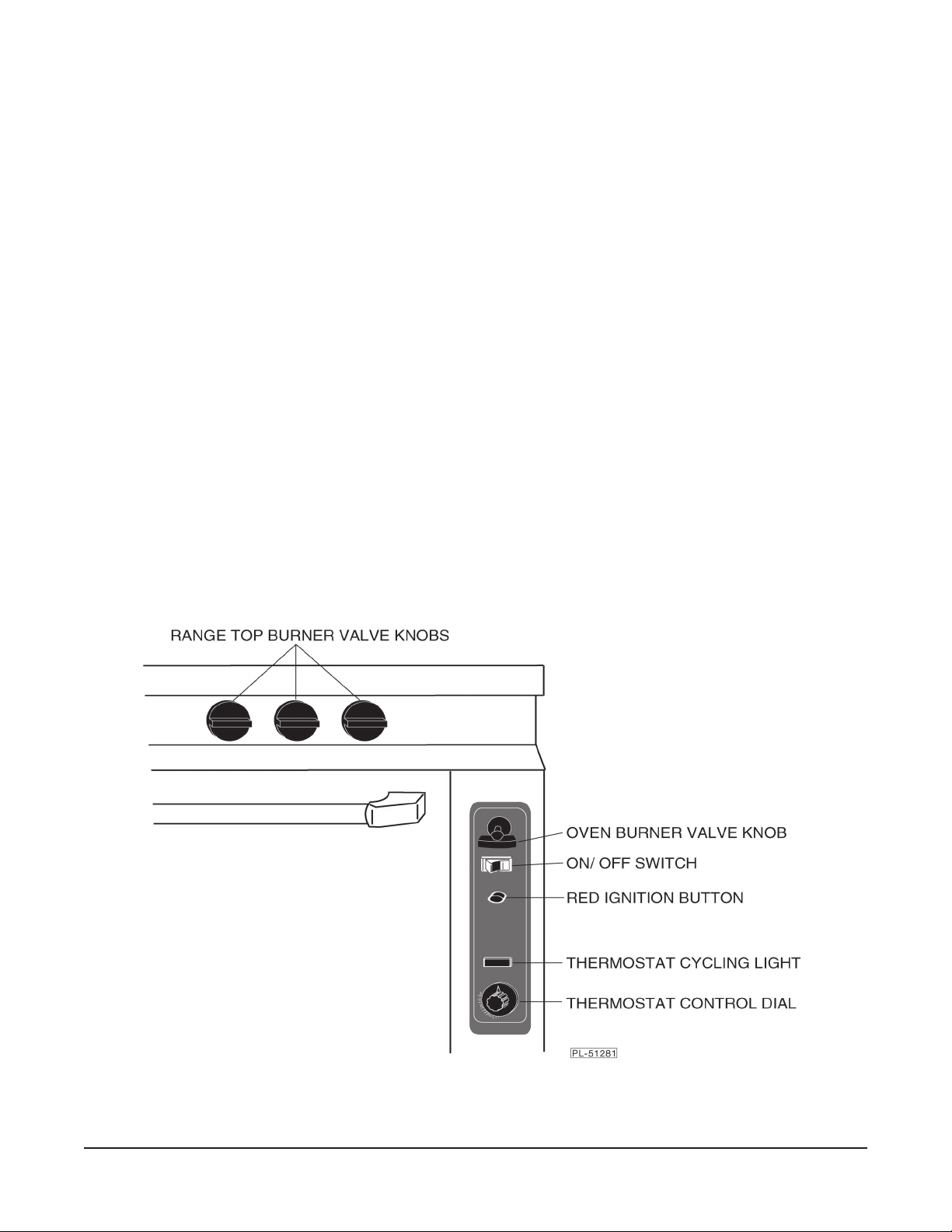

CONTROLS (Fig. 19)

RANGE TOP BURNER When opened, allows gas to flow to the range section. To

VALVE KNOB open valve, turn knob counterclockwise. To close valve, turn

knob clockwise.

OVEN BURNER VALVE KNOB When opened, allows gas to flow to the oven burner. To open

valve, turn knob counterclockwise. To close valve, turn knob

clockwise.

RED IGNITION BUTTON Used to ignite the oven pilot. To operate, push button in and

follow pilot lighting instructions.

THERMOSTAT CONTROL DIAL Used to regulate the amount of heat needed to cook a

product. The thermostat dial’s temperature range is from

150°F to 500°F (65° C to 260°C). Turn dial counterclockwise

to increase temperature and clockwise to decrease

temperature.

ON-OFF SWITCH To turn power on, push switch to the ON position. When switch

(CONVECTION OVENS ONLY) light illuminates, power is being transmitted to the unit.

THERMOSTAT CYCLING LIGHT When lit, indicates that the thermostat is calling for

(CONVECTION OVENS ONLY) heat. When thermostat reaches the dial set

temperature, the light will automatically shut off.

Fig. 19

– 15 –

Page 16

LIGHTING AND SHUTTING DOWN PILOTS

Open Top, Griddle Top and Hot Top Burner Pilots

1. Turn main gas supply ON.

2. Turn all top burner valve knobs ON to purge gas line of air.

3. Turn top burner valve knobs OFF.

4. Wait 30 seconds.

5. Using a taper, light the pilot(s).

6. If pilot fails to light, wait 5 minutes and repeat Steps 1 through 5.

7. Turn one top burner valve ON to make sure that all gas lines are completely purged of air. Turn

burner OFF when gas begins to flow.

Nightly Shutdown: Turn burner valve OFF; pilot will remain lit.

Complete Shutdown: Turn burner valve OFF; pilot will remain lit. Turn main gas valve OFF.

Standard Oven Pilot

Before lighting oven, be sure that range top sections have been lit.

1. Open oven door and locate square pilot lighter cutout.

2. Using a taper, light oven pilot by depressing red ignition button (Fig. 20) located on the side control

panel above the thermostat knob. Light the pilot and continue to hold the ignition button in for 30

seconds. If pilot fails to light, turn main gas valve OFF and wait 5 minutes before repeating Steps

1 and 2.

3. Set oven thermostat to desired temperature.

Fig. 20

Nightly Shutdown: Turn oven burner valve OFF.

Complete Shutdown: Turn oven burner valve OFF. Turn main gas supply OFF.

– 16 –

Page 17

Convection Oven Pilot

Before lighting oven, be sure that range top sections have been lit.

1. Connect range to the main electrical supply line. Open oven door panel and locate square pilot

lighter cutout.

2. Turn red gas valve (located behind the control panel) ON, purging the gas line of all air. Turn gas

valve and power switch OFF. Close oven door.

3. Light oven pilot by depressing the red ignition button (Fig. 20), and using a taper, ignite the pilot.

Hold ignition button in for 30 seconds, or until pilot remains lit. Turn gas valve back ON.

4. If pilot fails to light, turn main gas valve OFF. Wait 5 minutes and repeat Steps 2 and 3.

5. After pilot is lit, push the power switch ON and turn the temperature dial to the desired setting.

Nightly Shutdown: Turn power switch OFF and the temperature dial to 0 degrees.

Complete Shutdown:

1. Push power switch OFF.

2. Turn red gas valve (located behind the control panel) OFF.

3. Turn main gas supply OFF.

4. Disconnect electrical supply cord.

ADJUSTMENTS

All adjustment procedures associated with pilot lighting should be performed by an authorized VulcanHart installation or service person. The bypass (minimum burner) flame adjustment must be made

at the time the range is installed.

After adjustments are complete, replace oven control panel(s). Check identification so that each panel

is returned to its respective range. Replace oven baffles and oven bottom(s).

Replace upper manifold panel(s). Position brick in ranges where necessary (Fig. 21). Replace top

casting(s). Check identification so that each may be returned to its respective original range as

received from the factory.

Fig. 21

– 17 –

Page 18

INSERTING AND REMOVING STANDARD CONVECTION OVEN RACKS

Convection oven sections use different-style racks and rack guides.

On ovens provided with oven rack stops, it is necessary to place the rack, including the support hook,

along the top of the side liner runners and slide the rack completely to the rear of the oven compartment

until the rack drops into place (Fig. 22).

Fig. 22

To remove the racks, reverse this procedure by raising the rear of the oven rack support hooks above

the runner and pulling the racks forward (Fig. 23).

Fig. 23

USING THE RANGE

Open Burners

Since both burners are lit from constantly burning pilots, turn the control knobs to HI to put each burner

into operation. Then adjust to a lower flame for better cooking results and to minimize gas usage.

The left-hand control knob is for the rear burner; the right-hand control knob is for the front burner.

Oven Burners

Turn red burner valve handle to the vertical position, then turn thermostat dial to desired temperature.

On Convection Oven Models, also turn the power switch to ON.

– 18 –

Page 19

LOADING AND UNLOADING THE OVEN

Open the door and load as quickly as practical to conserve heat. Take care to avoid spilling liquids while

loading. Close the door and refer to recipe for cooking time.

Provide adequate space for product unloading. Rapid unloading will conserve heat and ensure proper

preheating conditions for the next load, if applicable.

OPERATING SUGGESTIONS

Center-Fired Hot Top Range

Turn all burners fully on to heat top quickly. When operating temperature is reached, turn some of the

rings down or off and you will save as much as 80% of the gas. Keeping all rings turned fully on not only

wastes gas but also increases wear on the equipment. During an idling period, the pilot burners in the

center will keep the top warm.

Heat is concentrated in the center, use this area to bring food to a boil, then move pots away from the

center to maintain a rolling boil or simmer.

Open-Top Ranges

Open-top ranges are quickly lighted and require no preheating time. Light only as many burners as

needed.

Griddle Top and Even-Heat Top Ranges

Heat top thoroughly before using. The top can be kept hot with burners turned partially down. During

off periods, turn the burners down or heat only half the top.

Range Ovens

Allow time to preheat ovens before using (25 min. to 400°F [204°C]). If properly used, the automatic

temperature control will cut gas and food costs. Do not turn on maximum heat all the time. Turn

thermostat down to 250°F (121°C) when oven is idling, or turn oven off when not in use.

This oven gives you double capacity because you can do pan work on both shelves. If you are cooking

high roasts, the entire height of the oven can be utilized by removing a shelf or racks and placing roast

pan directly on the insulated oven bottom.

Moderate oven temperatures will produce better food, reduce shrinkage and keep maintenance costs

down. Using a low temperature for roasting (about 325°F [162°C] or even lower) will reduce meat costs

by reducing shrinkage.

A pan of water (approximately 12" x 20" x 1" [305 mm x 508 mm x 25.4 mm]) may be placed in the oven

bottom. This water supplies humidity to reduce shrinkage. If necessary, add water during roasting.

Standard Oven Cooking

If you have a standard oven, use your normal recipe times and temperatures.

– 19 –

Page 20

Convection Oven Cooking

If you have a convection oven, reduce your normal recipe temperature by 25°F (-3°C). Cooking time

in a convection oven will vary slightly from your normal recipe time.

Cooking starts immediately in the convection oven. Yeast breads do not usually rise as much in the

convection oven. It is, therefore, usually necessary to allow fuller proof, two-and-a-half to three times

increase in volume for the best results.

When baking pies in your convection oven, put three or four pies on an 18" x 26" (457 mm x 660 mm)

sheet or bun pan. This procedure helps the bottom crust to bake, makes handling easier and reduces

the possibility of boilover, which would spoil the appearance of the pies on the lower racks.

Pies and cobblers, fruit, custard and pumpkin pies in tins should be placed on 18" x 26" x 1"

(457 mm x 660 mm x 25.4 mm) pans for baking.

CLEANING

WARNING: (CONVECTION OVEN MODELS ONLY) DISCONNECT ELECTRICAL POWER

SUPPLY BEFORE CLEANING.

Suggestions for Care and Cleaning

Vulcan equipment is strongly constructed and is designed to give you long, satisfactory service at low

cost, provided you give it proper care. Frequent cleaning and occasional adjusting should reward you

with low operating and maintenance costs and faster, better service.

After cleaning cast-iron tops, any even-heat tops and griddle plates, reseason following the seasoning

procedures described in BEFORE FIRST USE. If your range(s) will be shut down for an extended

period, put a heavy coat of grease on the surface(s).

Open-Top Burners

Daily

Remove grates and clean under and around open burners.

Weekly

1. Clean each burner thoroughly. Clean stainless steel or chromed surfaces with a damp cloth and

polish with a soft dry cloth. A detergent may be used for cleaning. To remove discolorations, use

a nonabrasive cleaner, always rubbing with the grain of the metal.

2. Clean bottom drip pan. To remove drip pan, reach under and lift rear of pan about 1" (25.4 mm),

1

slide pan to the rear about

/2" (12.7 mm) and drop front end of pan free. Slide pan forward between

the front legs. To replace pan, reverse this procedure.

3. Burner air shutter openings must be kept clean.

4. Main burner ports must be kept clean. To clean burners, boil them in a strong solution of lye water

for 15-20 minutes, then brush with a wire brush. A coat hanger may be used to clean out particles

in burner ports.

5. Open burner pilot flash tubes and burner ignition port must be clear for burners to ignite properly

from the pilot.

– 20 –

Page 21

Griddle Top

Empty grease daily. Clean griddle top regularly.

KEEP GRIDDLE PLATE SURFACE CLEAN. To produce evenly cooked, perfectly browned griddle

products, keep griddle free of carbonized grease. Carbonized grease on the surface hinders the

transfer of heat from the griddle surface to food. This results in spotty browning and loss of cooking

efficiency; and worst of all, carbonized grease tends to cling to the griddled foods, giving them a highly

unsatisfactory and unappetizing appearance. To keep the griddle clean and operating at peak

efficiency, follow these simple instructions:

After Each Use

Clean griddle with a wire brush or flexible spatula.

Daily

1. Thoroughly clean backsplash, sides and front. Remove grease drawer, empty it and wash it out

in the same manner as any ordinary cooking utensil.

2. Clean griddle surface thoroughly. Use a griddle stone, wire brush or stainless steel wool on the

surface. Rub with the grain of the metal while the griddle is still warm. A detergent may be used

on the plate surface to help clean it, but you must make sure the detergent is thoroughly removed.

After removal of the detergent, the surface of the plate should then be reseasoned (see BEFORE

FIRST USE).

If the griddle is to be shut down for an extended period, put a heavy coat of grease over the griddle

plate.

3. Clean stainless surfaces with a damp cloth and polish with a soft dry cloth. To remove

discolorations, use a nonabrasive cleaner.

Exterior

Daily

Clean exterior finish of equipment with a mild solution of soap or similar grease-dissolving material.

– 21 –

Page 22

Range Tops

Daily

1. Wipe top while still warm with a soft cloth or other grease-absorbing material to remove spillovers,

grease, etc., before they burn in. A crust on top of the range looks unsightly and slows down speed

of cooking because it reduces the flow of heat to the utensil. Scrape the top if necessary.

2. Clean drip pan under burners.

Weekly

Boil open-top grates and burners in a solution of washing soda and water.

Range Ovens

Daily

Clean oven and door daily, especially if fruit pies or tomato sauces were baked, meats were roasted

or spillovers occurred.

CAUTION: Do not use scouring powder on finishes. Scouring powder is extremely difficult to

remove completely. It can build up accumulations that will damage the oven or remove

corrosion-resistant finishes.

Stainless Steel

Here are a few simple cleaning procedures that have been found effective for keeping stainless steel

equipment clean, sparkling and bright.

General Cleaning

Use ordinary soap or detergent and water for routine cleaning of stainless steel. To prevent water spots

and streaks, rinse equipment thoroughly with warm water and wipe dry with a soft clean cloth. The

addition of a rinsing agent will also help prevent spotting.

Stubborn spots or stains that resist soap and water usually can be removed with a paste made of water

and a mild scouring powder. When applying these powders, be sure to rub in the direction of the polish

lines on the steel to preserve the original finish.

Fingerprints

Fingerprints are sometimes a problem on highly polished surfaces of stainless steel. They can be

minimized by applying a cleaner that will leave a thin oily or waxy film.

To use these cleaners, simply wipe on and remove excess with a soft dry cloth. After using, subsequent

fingerprints will usually disappear when wiped lightly with a soft cloth or with a cloth containing a little

of the cleaner. If the surface is especially dirty to start, wash first with soap or detergent and water.

Burned-On Foods and Grease

Soaking with hot soapy water will help greatly to remove burned-on foods and grease. Stubborn

deposits can be removed with scouring powder mixed into a paste and applied with nylon pad or

sponges, rubbing with the grain of the metal. Do not use ordinary steel wool because particles can

become embedded and eventually rust, causing unsightly spots and stains.

– 22 –

Page 23

Heat Tint

Straw-colored or slightly darkened areas may appear on stainless steel in and around ovens and

ranges where temperatures reach 500°F (260°C) or more. This "heat tint" is caused by a slight oxidation

of the stainless steel and is not harmful.

To control or minimize this condition, never use more heat than is absolutely necessary.

Heat tint can be removed by scouring vigorously with stainless steel wool and a paste made of scouring

powder. Remember to rub in the direction of the polish lines.

Commercial heat tint remover products may also be used.

Precautions

When scraping off heavy deposits of grease or oil from stainless steel equipment, never use ordinary

steel scrapers and knives. Particles of ordinary steel may become embedded in, or lodge on, the

surface of the stainless steel. These will rust, causing unsightly stains and possible contamination of

food. Where it is necessary to scrape, use stainless steel, wood, plastic or rubber tools.

MAINTENANCE

WARNING: (CONVECTION OVEN MODELS ONLY) DISCONNECT THE ELECTRICAL

POWER TO THE MACHINE AND FOLLOW LOCKOUT/TAGOUT PROCEDURES.

LUBRICATION

Motors in Vulcan convection ovens are permanently lubricated and require no additional maintenance.

If the gas valve is hard to turn or leaking, contact your local service agency.

FLUE

Annually check the flue when it is cool to be sure it is free of obstructions.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this model, contact the Vulcan-Hart Service

Agency in your area (refer to our website, www.vulcanhart.com for a complete listing of Authorized

Service and Parts depots).

When calling for service, the following information must be available: model number, serial number,

manufacture date (MD) and voltage.

– 23 –

Page 24

TROUBLESHOOTING

OVEN

PROBLEM PROBABLE CAUSES

Too Much Bottom Heat Insufficient heat input. (Call for Service)

Overactive flue. (Call for Service)

Uneven Bake Too low temperature.

Improper operation.

Side Burning Improper bypass setting. (Call for Service)

Fluctuating gas pressure. (Call for Service)

Too Much Top Heat Too high temperature.

Faulty ventilation. (Call for Service)

Excessive heat input. (Call for Service)

Thermostat needs calibration. (Call for Service)

Uneven Bake - Side to Side Range not level side to side.

Oven burner, bottom or baffles improperly installed.

Pulling to Edge of Pan Warped pans.

Oven not level.

Uneven Bake - Front to Rear Overactive flue. (Call for Service)

Range not level front to back.

Door not closing properly. (Call for Service)

Dried-Out Products Too low temperature.

Too long baking time.

Thermostat calibration. (Call for Service)

Pilot Outage Gas supply not sufficient. (Call for Service)

Pilot flame too low. (Call for Service)

Restriction in pilot orifice. (Call for Service)

Malfunctioning check valve. (Call for Service)

CONVECTION OVEN MODELS ONLY:

Cavity leaking. (Call for Service)

Gasket problems. (Call for Service)

Snorkel tube blocked.

Blower running backward. (Call for Service)

Excessive Meat Shrinkage Roasting temperature too high.

TOP BURNER OPERATION

PROBLEM PROBABLE CAUSES

Improper Burner Combustion Improper use, allowing improper ventilation.

Excessive Valve Handle Temperatures Poor door fit. (Call for Service)

Sticking Top Burner Valves Oven door left open.

Poor Ignition Insufficient gas input. (Call for Service)

Poor air-to-gas adjustment. (Call for Service)

Restriction in pilot orifice. (Call for Service)

Restriction in main burner ignition port. (Call for Service)

Restriction in control valve. (Call for Service)

Restriction in gas orifice. (Call for Service)

FORM 35634 (2-05) PRINTED IN U.S.A.

– 24 –

Page 25

– 24 –

F35634 (2-05) IMPRIMÉ AUX É.-U.

Injecteur de gaz obstrué. (Placer un appel de service)

Robinet de commande obstrué. (Placer un appel de service)

Tête d’allumage principale du brûleur obstruée. (Placer un appel de service)

Injecteur de la veilleuse obstrué. (Placer un appel de service)

Rapport air-gaz mal réglé. (Placer un appel de service)

Mauvais allumage Entrée de gaz insuffisante. (Placer un appel de service)

figés

Robinets de la surface de cuisson Porte du four laissée ouverte.

chaude

Poignée de robinet excessivement Porte mal réglée. (Placer un appel de service)

Mauvaise combustion du brûleur Mauvaise utilisation causant une mauvaise ventilation.

PROBLÈME CAUSES POSSIBLES

BRÛLEURS DE LA SURFACE DE CUISSON

Flétrissement excessif de la viande Rôtissage à une température trop élevée.

Ventilateur fonctionnant en sens inverse. (Placer un appel de service)

Tube Snorkel obstrué.

Joints d’étanchéité défectueux. (Placer un appel de service)

Fuite dans l’enceinte de cuisson. (Placer un appel de service)

MODÈLES SUR FOUR À AIR PULSÉ SEULEMENT :

Soupape de sûreté défectueuse. (Placer un appel de service)

Injecteur de la veilleuse obstrué. (Placer un appel de service)

Flamme de la veilleuse trop faible. (Placer un appel de service)

Extinction de la veilleuse Alimentation en gaz insuffisante. (Placer un appel de service)

Thermostat mal étalonné. (Placer un appel de service)

Cuisson trop longue.

Produit déshydraté Température trop basse.

Porte ne fermant pas bien. (Placer un appel de service)

Cuisinière mal nivelée d’avant vers l’arrière.

Cuisson inégale d’avant vers l’arrière Conduit d’évacuation trop actif. (Placer un appel de service)

de la tôle Four mal nivelé.

Le produit gravite vers un côté Tôles gauchies.

Déflecteurs, sole ou brûleur du four mal installés.

Cuisson inégale d’un côté à l’autre Cuisinière mal nivelée d’un côté à l’autre.

Thermostat mal étalonné. (Placer un appel de service)

Entrée de chaleur excessive. (Placer un appel de service)

Ventilation défectueuse. (Placer un appel de service)

Dessus du produit trop chauffé Température trop élevée.

Pression de gaz instable. (Placer un appel de service)

Côtés brûlés Conduit de dérivation mal réglé. (Placer un appel de service)

Mauvais fonctionnement.

Cuisson inégale Température trop basse.

Conduit d’évacuation trop actif. (Placer un appel de service)

Fond du produit trop chauffé Entrée de chaleur insuffisante. (Placer un appel de service)

PROBLÈME CAUSES POSSIBLES

FOUR

DÉPANNAGE

Page 26

– 23 –

de fabrication (MD) et les caractéristiques électriques de l’appareil.

Lors d’un appel de service, s’assurer d’avoir en main le numéro de modèle, le numéro de série, la date

ENTRETIEN

www.vulcan-hart.com).

l’adresse

avec le service de l’entretien Vulcan le plus près (consulter la liste complète des points de service à

Pour obtenir des renseignements sur l’entretien ou les pièces de rechange de cet appareil, communiquer

SERVICE DE L’ENTRETIEN ET DES PIÈCES DE RECHANGE

obstrué.

Une fois par année, quand l'appareil est refroidi, s’assurer que le conduit d’évacuation n’est pas

CONDUIT D’ÉVACUATION

de service le plus près.

entretien. En cas de fuite au robinet de gaz ou si celui-ci est difficile à ouvrir, communiquer avec le point

Les moteurs des fours à air pulsé Vulcan sont lubrifiés en permanence et ne requièrent aucun

LUBRIFICATION

ET D'ÉTIQUETAGE.

DE PROCÉDER À TOUT ENTRETIEN ET SUIVRE LES DIRECTIVES DE VERROUILLAGE

AVERTISSEMENT : (FOUR À AIR PULSÉ SEULEMENT) DÉBRANCHER L’APPAREIL AVANT

instrument en acier inoxydable, en bois, en plastique ou en caoutchouc.

possiblement la contamination des aliments. S’il est absolument nécessaire de gratter, utiliser un

ou de se loger dans la surface en acier inoxydable, provoquant une légère formation de rouille et

ou d’huile sur une surface en acier inoxydable. Des particules d’acier ordinaire risquent de s’incruster

Ne jamais utiliser une racle en acier ordinaire ou un couteau pour enlever les dépôts tenaces de graisse

Précautions

On peut également utiliser un dissolvant de colorations de recuit commercial.

des lignes du poli.

inoxydable et de pâte fabriquée à partir de poudre à récurer. Prendre bien soin de frotter dans le sens

Les colorations de recuit s’enlèvent en récurant la surface vigoureusement à l’aide d’une laine d’acier

nécessaire.

Pour empêcher ou minimiser ce phénomène, ne jamais chauffer l’appareil plus qu’il n’est vraiment

par une légère oxydation de l’acier inoxydable et ne sont pas nocives.

est soumis à des températures de 260 °C (500 °F) ou plus. Ces «colorations de recuit» sont causées

Il peut se former des taches de couleur paille ou légèrement plus foncées lorsque l’acier inoxydable

Colorations de recuit

Page 27

– 22 –

former des taches non visibles à l’œil nu et faire rouiller la surface.

d’acier ordinaire puisqu’elle pourrait laisser des particules qui risquent de s’incruster. Elles pourraient

tampon à récurer en nylon ou d’une éponge en frottant dans le sens du grain. Ne pas utiliser de la laine

rebelles à l’aide d’une pâte fabriquée à partir de poudre à récurer que l’on applique au moyen d’un

La graisse et les aliments brûlés s’enlèvent facilement à l’eau chaude savonneuse. Enlever les dépôts

Graisse et aliments brûlés

au départ, la laver d’abord à l’eau savonneuse ou avec un détergent.

doux ou d’un chiffon contenant une petite quantité du nettoyant. Si la surface est particulièrement sale

sec. Par la suite, les empreintes de doigts disparaîtront en les essuyant légèrement à l’aide d’un chiffon

Étendre ce type de nettoyant sur la surface et enlever l’excédent d’huile à l’aide d’un chiffon doux et

d’huile ou de cire.

polies. Il est possible de minimiser leur formation au moyen d’un nettoyant qui laissera un léger film

Les empreintes de doigts constituent parfois un problème sur les surfaces en acier inoxydable très

Empreintes de doigts

bien soin de frotter dans le sens des lignes du poli de l’acier pour lui préserver son apparence originale.

pâte fabriquée à partir d’eau et de poudre à récurer douce. Lors de l’application de ce mélange, prendre

Normalement, les taches rebelles et résistantes à l’eau savonneuse peuvent s’enlever au moyen d’une

efficace.

l’essuyer à l’aide d’un chiffon sec, doux et propre. L’ajout d’agent de rinçage peut également s’avérer

Pour éviter la présence de taches d’eau et de rayures, rincer l’appareil à fond à l’eau chaude et

Utiliser du savon ordinaire ou du détergent et de l’eau pour le nettoyage quotidien de l’acier inoxydable.

Nettoyage général

brillant et étincelant.

Suivre les indications qui suivent pour le nettoyage de l’acier inoxydable pour qu’il demeure propre,

Acier inoxydable

anti-corrosif.

difficilement et peut s’accumuler, ce qui risque d’endommager le four et d’enlever le revêtement

ATTENTION : Ne pas utiliser de poudre à récurer sur aucun revêtement. Celle-ci s’enlève très

sauces aux tomates ou de viande ou après un débordement.

Nettoyer quotidiennement le four et la porte, spécialement après la cuisson de tartes aux fruits, de

Nettoyage quotidien

Fours

de sodium.

Faire bouillir les grilles de même que les brûleurs découverts dans une solution d’eau et de carbonate

Nettoyage hebdomadaire

2. Nettoyer la lèchefrite se trouvant sous les brûleurs.

chaleur vers les chaudrons. Gratter la surface si nécessaire.

belle apparence à l’appareil et réduit la vitesse de cuisson puisqu’elle nuit au transfert de la

résidus avant qu’ils ne s’incrustent. Une croûte sur la surface de la cuisinière ne donne pas une

cuisson pendant qu’elle est encore chaude pour enlever les débordements, la graisse ou autres

1. À l’aide d’un chiffon doux ou d’un autre matériel absorbant la graisse, essuyer la surface de

Nettoyage quotidien

Surfaces de cuisson

Page 28

– 21 –

produit similaire pour dissoudre la graisse.

Nettoyer le revêtement extérieur de l’appareil à l’aide d’une solution savonneuse douce ou d’un autre

Nettoyage quotidien

Revêtement extérieur

d’un chiffon doux et sec. Enlever les taches de décoloration à l’aide d’un nettoyant non abrasif.

3. Nettoyer les surfaces en acier inoxydable à l’aide d’un chiffon humide et les polir ensuite à l’aide

surface.

Dans le cas d’un arrêt prolongé, enduire la plaque d’une bonne couche de graisse sur toute la

À FRIRE).

apprêter la surface de cuisson de nouveau (se reporter à la section APPRÊTAGE DE LA PLAQUE

qu’aucune trace de détergent ne demeure sur la surface. Après avoir enlevé tout le détergent,

est encore chaude. Pour faciliter la tâche, utiliser un détergent. Toutefois, il est important

inoxydable, nettoyer à fond la surface de la plaque. Frotter dans le sens du grain pendant qu’elle

2. À l’aide d’une pierre pour plaques à frire, d’une brosse métallique ou d’une laine d’acier

tiroir de propreté et le laver de la même manière qu’un ustensile de cuisson ordinaire.

1. Nettoyer à fond le panneau anti-éclaboussures, les côtés et le devant de la cuisinière. Vider le

Nettoyage quotidien

Nettoyer la plaque à frire à l’aide d’une brosse métallique ou d’une spatule flexible.

Après chaque usage

propres et pour ne pas affecter leur fonctionnement, suivre les directives suivantes :

cuits sur la plaque, leur donnant une apparence peu appétissante. Pour que les plaques demeurent

réduisant la qualité de cuisson. Pire encore, la graisse carbonisée a tendance à adhérer aux aliments

transfert de la chaleur de la plaque à la surface des aliments, ne les brunissant que partiellement et

des produits parfaitement dorés, ne jamais laisser de graisse carbonisée sur une plaque. Elle nuit au

MAINTENIR LA SURFACE DES PLAQUES À FRIRE PROPRE. Pour obtenir une cuisson uniforme et

Vider le tiroir de propreté quotidiennement et nettoyer l’appareil régulièrement.

Plaque à frire

Page 29

– 20 –

doivent d’être propres pour bien s’allumer à partir de la veilleuse.

5. Les tubes de retour de flammes des veilleuses des brûleurs découverts et leurs têtes d’allumage

Utiliser un cintre pour enlever les particules se trouvant dans les têtes de brûleurs.

d’eau savonneuse pendant environ 15 à 20 minutes, puis les brosser à l’aide d’une brosse métallique.

4. Garder les têtes de brûleurs propres. Pour nettoyer les brûleurs, les faire bouillir dans une solution

3. Garder les ouvertures d’obturateur d’air des brûleurs propres.

Pour la remettre en place, procéder selon l’ordre inverse.

l’arrière et finalement la laisser tomber par en avant de manière qu’elle glisse entre les pattes.

ensuite la tôle d’environ 25 mm (1 po) par l’arrière pour la glisser d’environ 13 mm (1/2 po) vers

2. Nettoyer la lèchefrite. Pour l’enlever, passer la main par en dessous de la cuisinière, soulever

en frottant dans le sens du grain du métal.

un détergent. Pour enlever les taches de décoloration, utiliser un nettoyant non abrasif toujours

d’un chiffon humide pour les polir ensuite à l’aide d’un chiffon doux et sec. On peut aussi utiliser

1. Nettoyer chaque brûleur à fond. Nettoyer les surfaces en acier inoxydable ou chromées à l’aide

Nettoyage hebdomadaire

Enlever les grilles, puis nettoyer autour et sous les brûleurs.

Nettoyage quotidien

Brûleurs découverts

Dans le cas d’un arrêt prolongé, enduire les surfaces de ces appareils d’une bonne couche de graisse.

reprendre le processus d’apprêtage expliqué à la section AVANT UNE PREMIÈRE UTILISATION.

Une fois les surfaces de cuisson en fonte, les plaques à bouillir et les plaques à frire nettoyées,

d’obtenir une cuisson plus rapide et un rendement supérieur.

occasionnels permettront de maintenir les coûts d’exploitation et d’entretien à un faible niveau et

offrent un rendement à long terme satisfaisant et à faible coût. Les nettoyages fréquents et les réglages

Les appareils Vulcan sont construits très solidement et, pour autant qu’ils soient bien entretenus, ils

Suggestions d’entretien et de nettoyage

DE LE NETTOYER.

AVERTISSEMENT: (FOURS À AIR PULSÉ SEULEMENT) DÉBRANCHER L’APPAREIL AVANT

NETTOYAGE

déposer ces produits sur une tôle de 457 x 660 x 25 mm (18 x 26 x 1 po).

Pour la cuisson de tartes, de tourtes aux fruits et de tartes à la crème ou à la citrouille dans des moules,

sont éliminés et les produits conservent leur apparence savoureuse.

les tartes sont plus faciles à manipuler, les risques de débordements sur les tartes de la grille inférieure

tôle de 457 x 660 mm (18 x 26 po) ou dans un moule à brioches. Ainsi, les fonds de tarte cuisent mieux,

Pour la cuisson de tartes dans un four à air pulsé, les mettre par groupe de trois ou quatre dans une

volume pour de meilleurs résultats.

lève pas autant que dans un four conventionnel. Il faut donc laisser la pâte atteindre 2 1/2 à 3 fois son

Dans un four à air pulsé, la cuisson commence immédiatement. Habituellement, le pain au levain ne

de cuisson varie légèrement du temps de cuisson dans un four normal.

Pour la cuisson dans un four à air pulsé, réduire la température de cuisson de 4 °C (25 °F). Le temps

Cuisson dans un four à air pulsé

Page 30

– 19 –

Pour la cuisson dans un four conventionnel, utiliser les temps et les températures de cuisson normaux.

Cuisson dans un four conventionnel

dégagée réduit le flétrissement. En ajouter au besoin pendant le rôtissage.

Placer un plat rempli d’eau (environ 305 x 508 x 25 mm [12 x 20 x 1 po]) dans le four. L’humidité

des aliments.

température (environ 163 °C [325 °F]) réduit le flétrissement des produits et, par conséquent, le coût

de diminuer le flétrissement des produits et de réduire les coûts d’entretien. La cuisson de rôtis à basse

L’exploitation du four à une température modérée permet d’obtenir une meilleure qualité de cuisson,

sole.

toute sa hauteur en enlevant une tablette ou les grilles pour déposer la casserole directement sur la

simultanément. Pour la cuisson d’un rôti de forme élevée, il est également possible d’utiliser le four sur

Ce four permet de doubler la production puisqu’il est possible d’y cuire les aliments sur deux grilles

période de temps mort ou éteindre le four lorsqu’il ne sert pas.

maintenir les brûleurs allumés au maximum en tout temps. Régler le thermostat à 121 °C (250 °F) en

thermostat automatique permettra de réduire la consommation de gaz et le coût des aliments. Ne pas

Préchauffer le four avant d’y faire cuire des aliments (25 min à 204 °C [400°F]). S’il est bien utilisé, le

Fours

baisse ou ne chauffer que la moitié de la surface de cuisson.

maintenant les brûleurs partiellement allumés. Lors des périodes d’inactivité, régler les brûleurs à la

Chauffer toute la surface de cuisson avant de l’utiliser. Il est possible de la garder chaude en

Cuisinières à plaques à frire et plaques à bouillir

N’allumer que le nombre de brûleurs nécessaires.

Les cuisinières à brûleurs découverts s’allument rapidement et ne nécessitent aucun préchauffage.

Cuisinières à brûleurs découverts

ébullition pour ensuite les déplacer en périphérie pour continuer à faire bouillir ou pour faire mijoter.

Puisque la chaleur est concentrée au centre, se servir de cette région pour amener les produits à

de temps mort, les veilleuses au centre de la plaque maintiennent la surface de cuisson chaude.

gaspillage de gaz, mais contribue également à réduire la durée de vie utile de l’équipement. En période

gaz allant jusqu’à 80 %. Garder tous les ronds ouverts au maximum non seulement constitue un

température requise est atteinte, abaisser ou éteindre certains ronds pour obtenir une économie de

Ouvrir tous les brûleurs au maximum pour chauffer la surface de cuisson rapidement. Lorsque la

Cuisinière à plaque chauffée par le centre

TYPES D’EXPLOITATION SUGGÉRÉS

prochaine fournée, s’il y a lieu.

de lui conserver sa chaleur et d’assurer des conditions appropriées pour le préchauffage de la

Prévoir suffisamment d’espace pour le déchargement du four. Le déchargement rapide du four permet

et consulter la recette pour le temps de cuisson requis.

l’enceinte de cuisson. Éviter les débordements de liquide au moment du chargement. Fermer la porte

Ouvrir la porte et charger le four le plus rapidement possible afin de conserver la chaleur dans

CHARGEMENT ET DÉCHARGEMENT DU FOUR

Page 31

GRILLE

BUTÉES

– 18 –

Fig. 23

ENCEINTE DE CUISSON

GLISSIÈRES

désirée. Pour les fours à air pulsé, mettre aussi l’appareil sous tension avec l’interrupteur général.

Tourner le robinet rouge en position verticale, puis régler le bouton du thermostat à la température

Brûleurs du four

Le robinet de gauche sert à allumer le brûleur arrière et celui de droite, le brûleur avant.

baisse pour obtenir de meilleurs résultats de cuisson et réduire la consommation de gaz.

d’ouvrir les robinets de chaque brûleur à MAX (HI) pour les allumer. Régler ensuite leur flamme à la

Puisque l’allumage des deux brûleurs est produit par des veilleuses qui brûlent constamment, il suffit

Brûleurs découverts

UTILISATION DE LA CUISINIÈRE

CROCHET DE LA GRILLE

GRILLE

GRILLE

GRILLE

AVANT

BUTÉES

AVANT

PAROI LATÉRALE DU FOUR

Fig. 22

ENCEINTE DE CUISSON

GLISSIÈRES

PAROI LATÉRALE DU FOUR

ARRIÈRE

le crochet se retrouve sur la glissière puis en tirant la grille vers l’avant (Fig. 23).

Pour enlever une grille, procéder selon l’ordre inverse, soit en soulevant la grille par l’arrière pour que

CROCHET DE LA GRILLE

ARRIÈRE

ce qu’elle soit bien en place (Fig. 22).

de même que son crochet, sur chaque glissière et de la glisser au fond de l’enceinte de cuisson jusqu’à

Pour les fours dont les glissières latérales sont munies de butées, il est nécessaire de placer la grille,

Les grilles et les crémaillères des fours à air pulsé sont différentes de celles des fours conventionnels.

POSE ET ENLÈVEMENT DES GRILLES DE FOURS À AIR PULSÉ OU CONVENTIONNELS

Page 32

Fig. 21

– 17 –

identifier.

retourner sur le même appareil qu’à leur arrivée de l’usine au moyen des marques permettant de les

appropriés (Fig. 21). Remettre les moulures de la surface de cuisson en place tout en s’assurant de les

Remettre la main courante par-dessus la tubulure d’alimentation. Mettre les briques aux endroits

four respectif.

en vérifiant les marques permettant de les identifier. Remettre les déflecteurs et les soles dans leur

Une fois les réglages terminés, remettre les panneaux de commande du four à leur place respective

être réglée au moment de l’installation de l’appareil.

ayant trait à l’allumage des veilleuses. La flamme du brûleur de déviation (plus petite flamme) doit

Seul un technicien autorisé à l’installation ou à l’entretien Vulcan-Hart doit procéder aux réglages

RÉGLAGES

4. Débrancher le cordon d’alimentation.

3. Fermer le robinet de gaz principal.

2. Fermer le robinet de gaz rouge (situé derrière le panneau de commande).

1. Mettre hors tension avec l’interrupteur général.

Arrêt complet :

Arrêt nocturne : Mettre l’interrupteur général à la position ARRÊT et le bouton du thermostat à 0.

général et régler le bouton du thermostat à la température désirée.

5. Une fois la veilleuse allumée, mettre l’appareil sous tension en appuyant sur l’interrupteur

de reprendre les étapes 2 et 3.

4. Si la veilleuse refuse de s’allumer, fermer le robinet de gaz principal et attendre 5 minutes avant

30 secondes ou jusqu’à ce que la veilleuse s’allume. Rouvrir le robinet de gaz.

rouge (Fig. 20). Mettre la veilleuse à feu et maintenir le bouton d’allumage enfoncé pendant

3. À l’aide d’une bougie, allumer la veilleuse du four en appuyant sur le bouton d’allumage

général. Fermer la porte du four.

trouvant dans la conduite de gaz. Fermer le robinet et éteindre l’appareil avec l’interrupteur

2. Ouvrir le robinet de gaz rouge (situé derrière le panneau de commande) pour évacuer l’air se

carrée du bouton d’allumage de la veilleuse.

1. Brancher le four à la prise de courant principale. Ouvrir la porte du four et repérer la découpe

Avant d’allumer le four, s’assurer que les sections de la surface de cuisson sont allumées.

Veilleuse de four à air pulsé

Page 33

– 16 –

Fig. 20

Arrêt complet : Fermer le robinet de chaque brûleur. Fermer le robinet de gaz principal.

Arrêt nocturne : Fermer le robinet du brûleur du four.

3. Régler le thermostat à la température désirée.

s’allumer, fermer le robinet de gaz principal et attendre 5 minutes avant de reprendre les étapes 1 et 2.

veilleuse à feu et maintenir le bouton d’allumage enfoncé pendant 30 secondes. Si la veilleuse refuse de

(Fig. 20) situé sur le panneau de commande latéral, au-dessus du bouton du thermostat. Mettre la

2. À l’aide d’une bougie, allumer la veilleuse du four en appuyant sur le bouton d’allumage rouge

1. Ouvrir la porte du four et repérer la découpe carrée du bouton d’allumage de la veilleuse.

Avant d’allumer le four, s’assurer que les sections de la surface de cuisson sont allumées.

Veilleuse de four standard

robinet de gaz principal.

Arrêt complet : Fermer le robinet de chaque brûleur; les veilleuses demeurent allumées. Fermer le

Arrêt nocturne : Fermer le robinet de chaque brûleur; la veilleuse demeure allumée.

autres conduites de l’appareil. Fermer ensuite le brûleur dès que le gaz commence à circuler.

7. Ouvrir le robinet d’un des brûleurs de la surface de cuisson pour évacuer l’air contenu dans les

6. Si la veilleuse refuse de s’allumer, attendre cinq minutes et reprendre les étapes 1 à 5.

5. Allumer la veilleuse de chaque brûleur de la surface de cuisson à l’aide d’une bougie.

4. Attendre 30 secondes.

3. Fermer le robinet de tous les brûleurs de la surface de cuisson.

conduite de gaz.

2. Ouvrir le robinet de tous les brûleurs de la surface de cuisson pour évacuer l’air de la

1. Ouvrir le robinet de gaz principal.

Veilleuses de brûleurs découverts, plaque à frire et plaque à bouillir

ALLUMAGE ET EXTINCTION DES VEILLEUSES

Page 34

– 15 –

Fig. 19

BOUTON DU THERMOSTAT

VOYANT DU THERMOSTAT

BUTTON D’ALLUMAGE ROUGE

INTERRUPTEUR MARCHE-ARRÊT

ROBINET DU FOUR

ROBINETS DES BRÛLEURS DE LA SURFACE DE CUISSON

automatiquement.

la température commandée, le voyant s’éteint

(FOURS À AIR PULSÉ SEULEMENT) commande l’arrivée de chaleur. Lorsque le four a atteint

VOYANT DU THERMOSTAT Lorsqu’il est allumé, ce voyant indique que le thermostat

allumé, indique que le courant est transmis à l’appareil.

(FOURS À AIR PULSÉ SEULEMENT) (position MARCHE). Le voyant témoin, lorsqu’il est

INTERRUPTEUR MARCHE-ARRÊT Bouton-poussoir servant à mettre l’appareil sous tension

inverse pour la diminuer.

sens contraire des aiguilles d’une montre et dans le sens

augmenter la température, tourner le bouton dans le

le thermostat entre 66 et 260 °C (150 et 500 °F). Pour

pour la cuisson d’un produit. Ce cadran permet de régler

BOUTON DU THERMOSTAT Dispositif servant à régler la quantité de chaleur requise

veilleuse.

sur le bouton et suivre les directives d’allumage de la

BOUTON D’ALLUMAGE ROUGE Bouton servant à allumer la veilleuse du four. Appuyer

sens inverse pour le fermer.

le sens contraire des aiguilles d’une montre et dans le

le brûleur du four. Pour l’ouvrir, tourner le bouton dans

ROBINET DU FOUR Lorsque ce robinet est ouvert, le gaz est acheminé vers

d’une montre et dans le sens inverse pour les fermer.

tourner les boutons dans le sens contraire des aiguilles

vers la surface de cuisson de l’appareil. Pour les ouvrir,

DE CUISSON

ROBINETS DE LA SURFFFACE Lorsque ces robinets sont ouverts, le gaz est acheminé

COMMANDES (Fig. 19)

Page 35

– 14 –

Reprendre la manœuvre deux ou trois fois, jusqu’à ce que la surface soit lisse et miroitante.

de la plaque de manière à obtenir un mince film, puis essuyer le surplus.

par mètre carré [une once par pied carré]). À l’aide d’un chiffon propre, l’étendre sur toute la surface

un indicateur de température de surface et verser une petite quantité d’huile de cuisson (environ 30 ml

Pour l’apprêter, chauffer la plaque à frire à basse température (149 à 177 °C [300 à 350 °F]) en utilisant

qu’elle devienne lisse et dure, ce qui facilite l’enlèvement des aliments.

C’est pourquoi il est important d’apprêter la surface ou de «remplir» les pores d’huile de cuisson pour

surface de métal est poreuse et les aliments ont tendance à s’incruster dans les pores et à y adhérer.

Il est nécessaire d’apprêter une plaque à frire neuve pour obtenir une bonne qualité de cuisson. Sa

plaque à frire pour tenter de déloger des aliments qui pourraient s’y trouver.

bosseler, l’égratigner ou la rayer. Ne pas cogner les coins ou les rebords d’une spatule sur la

rayer ou bosseler suite à l’utilisation négligente d’une spatule. Prendre soin de ne pas la

ATTENTION : Cette plaque à frire est en acier, mais sa surface est relativement tendre et peut

Apprêtage de la plaque à frire

NETTOYAGE - PLAQUE À FRIRE.

au moyen d’un gros morceau de carton rigide dont le bord est droit. Se reporter à la section

substance qu’au moment de la nettoyer avant une première cuisson. Pour ce faire, racler la surface

La plaque à frire est couverte d’une couche de graisse protectrice pour la livraison. N’enlever cette

Nettoyage de la plaque à frire avant une première utilisation

formation de fissures et à prolonger sa durée de vie utile.

avant une première utilisation de manière à obtenir une meilleure protection de la fonte contre la

deux heures que la plaque se réchauffe graduellement. Reprendre ce processus une deuxième fois

un mince film, puis essuyer le surplus. Allumer les brûleurs à la puissance minimale et attendre environ

par pied carré]). À l’aide d’un chiffon propre, étendre l’huile sur toute la surface de manière à obtenir

verser une petite quantité d’huile de cuisson sur la plaque (environ 30 ml par mètre carré [une once

Ces plaques sont en fonte et doivent être apprêtées avant une première utilisation. Pour ce faire,

Apprêtage des plaques à frire et plaques à bouillir en fonte

AVANT UNE PREMIÈRE UTILISATION

FONCTIONNEMENT

EXTRÊME PRUDENCE LORS DE SON UTILISATION, NETTOYAGE OU ENTRETIEN.

AVERTISSEMENT : LA CUISINIÈRE ET SES COMPOSANTS SONT CHAUDS. EXERCER UNE

Page 36

– 13 –

Ne pas établir l’alimentation électrique tant que tous les raccordements du gaz n’auront pas été faits.

le sac de plastique sur une grille de l’enceinte du four).

le mettre à la terre à l’aide de la cosse fournie à cette fin (voir le schéma de câblage se trouvant dans

Si l’appareil requiert une source de courant électrique sans être muni d’une fiche de mise à la terre,

UN ÉLECTRICIEN. NE PAS ENLEVER LA BROCHE DE MISE À LA TERRE DE LA FICHE.

DOIT ÊTRE CORRECTEMENT MISE À LA TERRE. SI ELLE NE L’EST PAS, COMMUNIQUER AVEC

BROCHES DONT UNE MISE À LA TERRE. LA PRISE DANS LAQUELLE ELLE EST BRANCHÉE

AVERTISSEMENT : LE CORDON D’ALIMENTATION EST POURVU D’UNE FICHE À TROIS

PROCÉDURE D’ÉTIQUETAGE ET DE VERROUILLAGE.

AVERTISSEMENT : COUPER L’ALIMENTATION ÉLECTRIQUE DE L’APPAREIL ET SUIVRE LA

AUTRE CODE D’ÉLECTRICITÉ EN VIGUEUR.

CONFORMES AUX NORMES CONCERNÉES DU CODE CANADIEN DE L’ÉLECTRICITÉ OU DE TOUT

AVERTISSEMENT : LE RACCORDEMENT ÉLECTRIQUE ET LA MISE À LA TERRE DOIVENT ÊTRE

RACCORDEMENT ÉLECTRIQUE

Park, Quincy, MA 02269.

on peut se procurer un exemplaire auprès de la National Fire Protection Association, Batterymarch

vapeurs chargées de graisse et de la fumée provenant des appareils de cuisson commerciaux dont

dans la norme NFPA n° 96 (dernière édition) sur l’installation d’équipement pour la dispersion des

Des renseignements à propos de la construction et de l’installation de hottes de ventilation sont inclus

et la surface de cuisson.

Maintenir un dégagement minimum de 457 mm (18 po) entre le dispositif d’évacuation de la graisse

ventilation installé par un personnel qualifié.

recommandé que les gaz brûlés soient évacués à l’extérieur de l’immeuble par un système de

NE PAS obstruer le débit des gaz brûlés dans le conduit d’évacuation à l’arrière de l’appareil. Il est

CONDUIT D’ÉVACUATION

Page 37

– 12 –

canalisation de gaz en fermant son robinet d’arrêt manuel.

Lorsque la pression d’essai est égale ou inférieure à 3,45 kPa (1/2 psig), isoler l’appareil de la

débrancher la cuisinière et son robinet d’arrêt de la conduite de gaz.

Si la pression de la canalisation de gaz est supérieure à 3,45 kPa (1/2 psig) lors d’essais de pression,

ESSAIS DE LA CANALISATION DE GAZ

dépendent ni les problèmes de rendement causés par son absence.

Si l’appareil n’est pas muni d’un régulateur de pression, la garantie ne couvre pas les pièces qui en

chacun d’eux doit être muni d’un régulateur distinct.

indications de la plaque signalétique. Si la pression d’admission de certains appareils est différente,

de manière à supporter la puissance totale installée. Sa marge de réglage doit correspondre aux

ANSI applicables (disponible auprès de Vulcan-Hart). Le régulateur de pression doit pouvoir être réglé

régulateur de pression homologué par un laboratoire d’essais reconnu en conformité avec les normes

La tubulure d’alimentation de cet appareil, ou de la batterie dont il fait partie, doit comporter un

Installation en batterie

dépendent ni les problèmes de rendement causés par son absence.

Si l’appareil n’est pas muni d’un régulateur de pression, la garantie ne couvre pas les pièces qui en

pour le gaz naturel et de 2,74 kPa (11 po de colonne d’eau) pour le gaz propane.

La pression d’admission requise pour la conduite d’arrivée est de 1,74 kPa (7 po de colonne d’eau)

Pour son installation, suivre les instructions du fabricant.

pression doit être réglé en fonction de la pression indiquée sur la plaque signalétique de l’appareil.

(10 po de colonne d’eau) pour le gaz propane (disponible auprès de Vulcan-Hart). Le régulateur de

dans la conduite de sortie est de 1,49 kPa (6 po de colonne d’eau) pour le gaz naturel et de 2,49 kPa

un laboratoire d’essais reconnu en conformité avec les normes ANSI applicables) et dont la pression

Toutes les cuisinières autonomes de la série GH requièrent un régulateur de pression (homologué par

Installation d’une cuisinière autonome

pourrait s’y trouver.

Une fois la recherche de fuites terminée, purger toutes les conduites de gaz pour évacuer l’air qui

QU’ILS NE PRÉSENTENT AUCUNE FUITE. NE PAS SE SERVIR D’UNE FLAMME NUE.

SAVONNEUSE DANS TOUS LES JOINTS DE LA CONDUITE DE GAZ POUR S’ASSURER

AVERTISSEMENT : AVANT DE PROCÉDER À L’ALLUMAGE, FAIRE CIRCULER DE L’EAU

Les appareils conçus pour le gaz propane sont munis d’injecteurs fixes.

de la cuisinière.

Conformément aux exigences des codes, installer un robinet d’arrêt dans la conduite de gaz, en amont

comportent aucun corps étranger ni trace de pâte à joints.

Raccorder la conduite de gaz à chaque appareil. S’assurer que les tuyaux sont propres et qu’ils ne

Enlever la main courante couvrant la tubulure d’alimentation.

Enlever la sole et les déflecteurs de chaque four.

doivent résister à l’action du gaz propane.

ATTENTION : Tous les raccords d’alimentation de la conduite de gaz et la pâte à joints de tuyaux

BRANCHEMENT DU GAZ

Page 38

– 11 –

Fig. 18

des produits ne sera pas uniforme et le rendement des appareils sera irrégulier.

Les roulettes de ces appareils ne se nivellent pas. Le plancher doit être de niveau sans quoi la cuisson

Fig. 17

SUPPORT EN V

le sol (Fig. 18).

sans pattes ou sur pieds évasés, visser le boulon de nivelage jusqu’au contact de la cuisinière avec

du groupe. Régler les pieds jusqu’à ce que toutes les pattes reposent sur le sol. Dans le cas d’appareils

prévu, puis régler la hauteur des pattes. Dans le cas d’une batterie, commencer par le premier appareil

est bien nivelé d’avant vers l’arrière et latéralement. Installer la cuisinière ou la batterie à l’emplacement

affectant l’uniformité de la cuisson. À l’aide d’un niveau de menuisier, s’assurer que chaque appareil

Le mauvais nivelage des cuisinières peut causer le désalignement de la tubulure d’alimentation,

NIVELAGE

CAPTEUR

RETENUE DE

FIXATION DE

V. S’assurer également que le tube capillaire n’est exposé d’aucune manière à la flamme du brûleur.

NOTA : Le bulbe ne doit pas être à découvert et doit être complètement recouvert par le support en

moment de remettre en place le couvercle des commandes.

excédent sans faire de pli et le déposer devant le bouclier thermique. Ne pas écraser le fil au

7. Glisser le bulbe du thermostat dans le support en V (Fig. 17). Bien enrouler le tube capillaire

Page 39

– 10 –

Fig. 16

THERMIQUE

BOUCLIER

ENCOCHE DU

Fig. 15

thermique en le passant dans l’encoche du bouclier prévue à cette fin (Fig. 16).

6. Acheminer le fil d’alimentation du bulbe du thermostat et du tube capillaire jusqu’au bouclier

plaque à frire.

soulevée, installer le bulbe du thermostat dans le support en V fixé sur la face inférieure de la

soulevée, caler un bout de 2 X 4 sous la partie avant de la plaque à frire. Une fois la plaque

soin de ne pas écraser le bulbe du thermostat et le tube capillaire. Pour la maintenir ainsi

délicatement le tube capillaire. Soulever la plaque à frire du dessus de la cuisinière en prenant

à l’avant de la cuisinière, repérer le bulbe du thermostat et le tube capillaire assemblé. Dérouler

5. La plaque à frire et la cuisinière sont emballées séparément. Sur le boîtier du brûleur supérieur

4. Briques larges (2) – Les installer au centre comme l’illustrent les figures 14 et 15.

3. Briques triangulaires (4) – En installer deux de chaque côté (Fig. 15).

Page 40

– 9 –

Fig. 14

Fig. 13

vers l’extérieur (Fig. 14).

2. Supports étroits (2) – Déposer de chaque côté, la surface uniforme vers le bas et les trous ovales

Fig. 12

1. Support du centre (1) – Déposer au centre, la surface uniforme vers le bas (Fig. 13).

Mettre les supports métalliques de briques en place puis y déposer les briques.

Installation d’une plaque à frire à commande thermostatique

surélevée en place. L’assemblage est maintenant terminé.

6. Remettre le panneau anti-éclaboussures du conduit d’évacuation, du dosseret ou de la tablette

Les supports d’expédition enlevés à l’étape 2 ne sont plus requis et peuvent être mis de côté.

5. Remettre les moulures de la surface de cuisson et l’écran anti-éclaboussures en place (Fig. 12).

Fig. 11

Page 41

– 8 –

Fig. 10

Fig. 9

capuchons se trouvent dans la boîte du dosseret. Voir les figures 9, 10, 11 et 12.

accompagné de deux capuchons, emballés dans un sac de plastique séparé. S’assurer que les

à une languette pouvant être enfoncée ou relevée (à l’aide d’un tournevis). Chaque dosseret est

droite et gauche, entre le panneau anti-éclaboussures et le dosseret. Chaque capuchon s’ajuste grâce

Une fois le dosseret installé sur la cuisinière, ajouter les capuchons faciles à insérer aux extrémités

Fig. 8

Fig. 7

d’évacuation, du dosseret ou de la tablette surélevée se trouve à l’extérieur, derrière le carneau (Fig. 8).

Au moment d’abaisser les profilés dans les ouvertures, s’assurer que la bordure bridée du conduit

Fig. 6

4. Guider avec soin les profilés dans les deux ouvertures prévues à l’arrière de l’appareil (Fig. 7).

3. Lever avec soin le conduit d’évacuation, le dosseret ou la tablette surélevée (Fig. 6).

Page 42

– 7 –

Fig. 5

qui nécessitent des fixations (Fig. 5).

de cuisinières, n’enlever que les supports d’expédition des sections aux extrémités droite et gauche

Lors de l’assemblage de conduits d’évacuation, de dosserets ou de tablettes surélevées à une batterie

et sur la même cuisinière.

d’expédition de la cuisinière. Identifier chaque moulure de manière à les remettre au même endroit

2. Enlever les moulures de la surface de cuisson, l’écran anti-éclaboussures et les supports