Page 1

OPERATION MANUAL

GCO2D & GCO2C

GAS CONVECTION OVENS

MODEL

INSTALLATION &

GCO2D ML-114569

GCO2C ML-114571

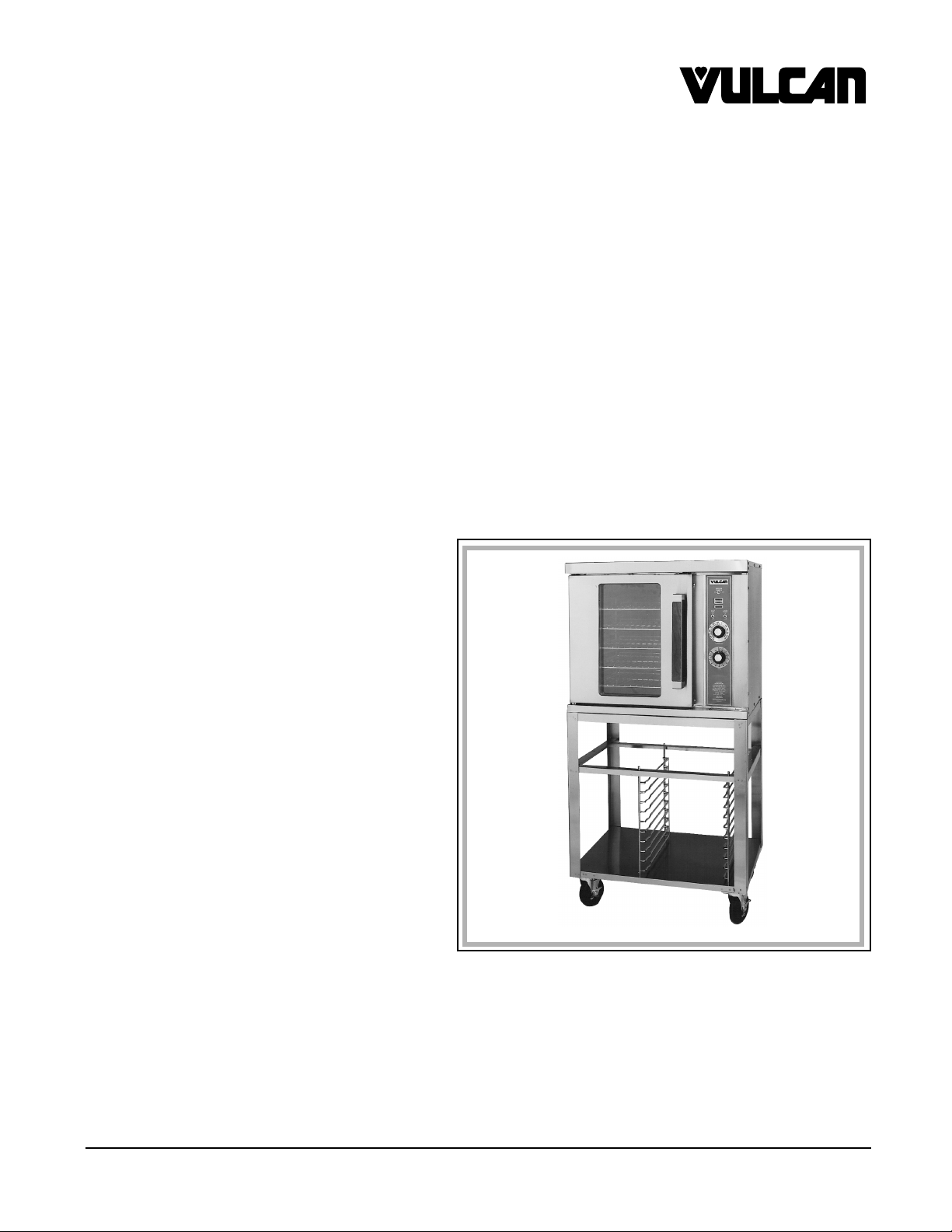

MODEL GCO2D

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 30975 Rev. C (Aug. 2000) www.vulcanhart.com

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN SHUTOFF VALVE AND CONTACT THE

LOCAL GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT

TO OPERATE THIS DEVICE.

© VULCAN-HART COMPANY, 1996

– 2 –

Page 3

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing Basic Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembling the Legs to the Single Oven. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembling the Chimney to the Single Oven . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembling the Oven to the Stand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembling Stacked Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gas Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Testing the Gas Supply System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Gas Pressures and Orifices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Burner Air Shutter Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Flue Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Controls — Model GCO2D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lighting the GCO2D Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Before First Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Using the GCO2D Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Controls — Model GCO2C Built before October 1999 . . . . . . . . . . . . . . . . . 10

Thermostat Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Timer Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Lighting the GCO2C Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Before First Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Using the GCO2C Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Error Messages — Model GCO2C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Controls — Model GCO2C Built after October 1999 . . . . . . . . . . . . . . . . . . 14

Manually Setting the Temperature and Cook Time . . . . . . . . . . . . . . . . . . . 15

To Program Menu Item and Rack # Cook Times . . . . . . . . . . . . . . . . . . . . . 15

Setting the Oven for Roast & Hold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Roast and Hold Operation — Model GCO2C . . . . . . . . . . . . . . . . . . . . . . . . 17

Proper Utensils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Conserving Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Suggested Cooking Guidelines — Models GCO2D and GCO2C . . . . . . . . 18

For Best Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Disconnecting the Gas Line Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Service and Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

– 3 –

Page 4

Installation, Operation, and Care of

GCO2D & GCO2C

GAS CONVECTION OVENS

KEEP THIS MANUAL FOR FUTURE USE

GENERAL

The GCO2D Gas Convection Oven is a single cavity oven and features a solid state thermostat, 1-hour

dial timer, and five racks as standard equipment. Additional oven racks are optional. Each oven is

equipped with a 25,000 Btu/hr burner and a

with painted grey exterior and porcelain interior; stainless steel interior and exterior are optional.

Stainless steel door with window (door hinging is field reversible) and stainless steel front are standard.

Model GCO2C has different controls than the GCO2D.

Two single ovens can be ordered with a stacking kit for mounting one oven on top of the other.

A single oven may be installed on an open stand with lower storage rack (optional).

Your Vulcan Gas Convection Oven is produced with quality workmanship and material. Proper

installation, usage and maintenance of your oven will result in many years of satisfactory performance.

1

⁄2 HP (0.37 kw) electric motor. The oven comes standard

Vulcan-Hart Company suggests that you thoroughly read this entire manual and carefully follow all of

the instructions provided.

LEDOMLEDOM

LEDOMLEDOMTATSOMREHTTATSOMREHT

LEDOM

D2OCGetatSdiloSlaiDruoH-1

9991rebotcOerofebC2OCGcinortcelEcinortcelEXX

9991rebotcOretfaC2OCGelbammargorPelbammargorPX X

TATSOMREHTTATSOMREHTREMITREMIT

TATSOMREHT

&TSAOR&TSAOR

REMITREMIT

REMIT

&TSAOR

DLOHDLOH

DLOHDLOH

DLOH

ELTNEGELTNEG

ELTNEGELTNEG

ELTNEG

EKABEKAB

EKABEKAB

EKAB

KOOC#KCARKOOC#KCAR

KOOC#KCARKOOC#KCAR

KOOC#KCAR

SEMITSEMIT

SEMITSEMIT

SEMIT

&TSAOR&TSAOR

INSTALLATION

UNPACKING

Immediately after unpacking the oven, check for possible shipping damage. If this oven is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, verify that the electrical supply and type of gas (natural or propane) agree with the

specifications on the oven data plate, located on the inside of the top front cover.

Do not use the door or its handle to lift the oven.

LOCATION

The equipment area must be kept free and clear of combustibles. Clearance from combustible or noncombustible construction of at least 3"

installation location must allow adequate clearance for servicing and proper operation.

(7.6 cm) on the sides and 3" (7.6 cm) at the back are required. The

The oven must be installed so that the flow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber must be provided. Make sure there

is an adequate supply of air in the room to allow for combustion of gas at the oven burners.

– 4 –

Page 5

INSTALLATION CODES AND STANDARDS

In the United States, Vulcan gas ovens must be installed in accordance with: 1) State and local codes;

2) National Fuel Gas Code, ANSI-Z223.1 (latest edition), available from American Gas Association,1515

Wilson Boulevard, Arlington, VA 22209; 3)ANSI/NFPA 96,

Vapor Removal from Cooking Equipment

(latest edition), available from National Fire Protection Association, Batterymarch Park, Quincy, MA

02269; and 4) National Electrical Code, NFPA-70 (latest edition).

In Canada, Vulcan gas ovens must be installed in accordance with: 1)Local codes; 2) CAN/CGAB149.1,

Natural Gas Installation Code

(latest edition) or CAN/CGA-B149.2,

Propane Installation Code

(latest edition), available from Canadian Standards Association, 178 Rexdale Boulevard, Etobicoke,

Ontario, Canada M9W 1R3; and 3) Canadian Electrical Code, CSA Standard C22.2 No. 3,

Features of Fuel Burning Equipment

(latest edition).

Electrical

INSTALLING BASIC OVEN

The basic oven must be installed on 4"

(10 cm) or 6" (15 cm) adjustable legs for counter installation or

be mounted on a modular stand. Installations on concrete bases or other supports restricting air

circulation underneath the oven are not advisable and may void the warranty.

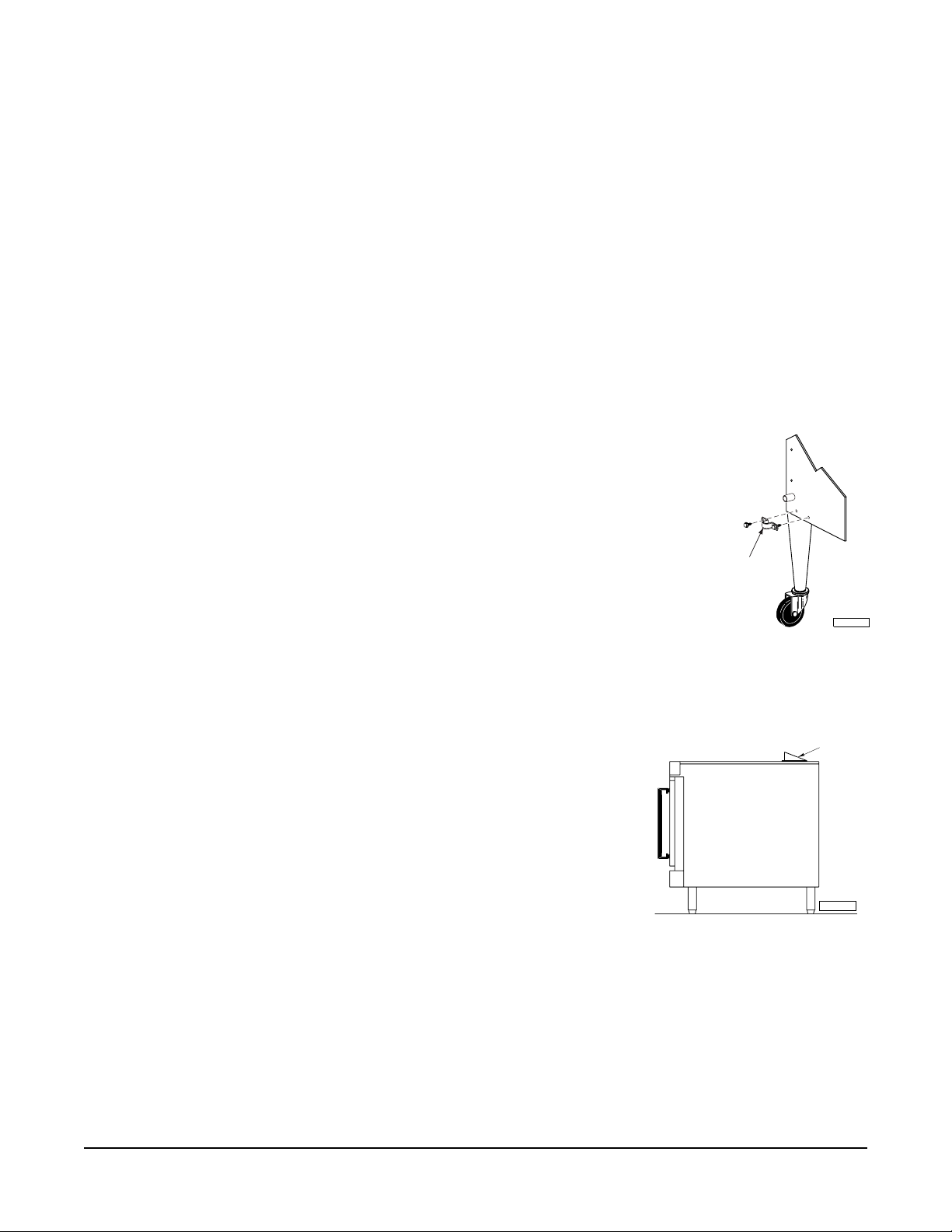

When the oven is mounted on casters, it must be installed with the

casters supplied, a connector (not supplied by Vulcan-Hart) complying

with either ANSI Z21.69 (latest edition) or CAN/CGA-6.16 (latest

edition), and a quick-disconnect device complying with either ANSI

Z21.41 (latest edition) or CAN1-6.9 (latest edition). It must also be

installed with a restraint device to prevent strain on the connector.

Remove two screws from the rear of the oven and install the tie down

strap shipped with the casters using these screws. Attach the gas line

strain relief to the tie down strap at the rear of the oven (Fig. 1).

Assembling the Legs to the Single Oven

The 4" (

10 cm) or 6" (15 cm) legs are packed inside the oven during shipment and must be installed on

CONNECT

GAS LINE

STRAIN RELIEF

HERE

Fig. 1

PL-53563

the bottom of the oven. Place the oven on its left side, being careful to avoid scratching the finish. The

gas pipe connection protrudes beyond the back; provide for this when oven is tipped back by resting

it on suitable spacers (2 x 4's etc.).

CHIMNEY

Thread each of the four leg assemblies into the holes provided on the

bottom corners of the oven. Carefully raise the oven to its normal upright

position.

Assembling the Chimney to the Single Oven

Remove the chimney from inside the oven cavity and use the screws

provided to fasten the chimney to the top rear of the oven (Fig. 2). The

flanges on the chimney are to be positioned over the top cover.

ASSEMBLING THE OVEN TO THE STAND

Fig. 2

PL-52240

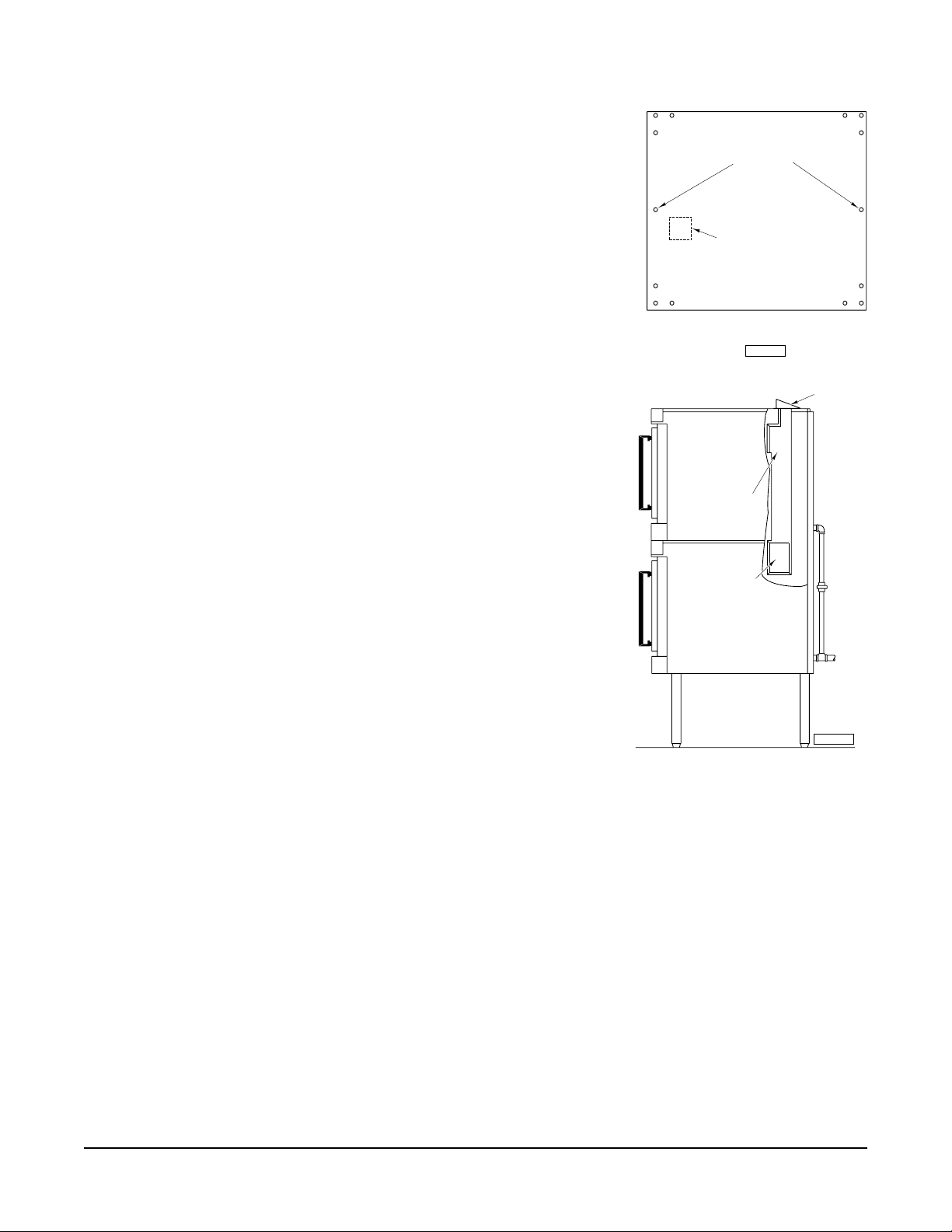

Position the oven on its back, taking care not to scratch or damage it. The gas pipe connection

protrudes beyond the back; provide for this when the oven is tipped back by resting it on suitable

spacers (2 x 4's). Install the two locating studs (included in the stand carton) into the screw plates on

the underside of the oven (Fig. 3).

Attach each of the four leg assemblies to the bottom of the stand with the 12 bolts and lockwashers

(3 per leg). If casters are used instead of legs, put fixed casters in rear and swivel casters in front using

12 bolts and lockwashers (3 per caster). Mount the oven on top of the stand.

– 5 –

Page 6

ASSEMBLING STACKED OVENS

FRONT OF TOP OVEN

Determine which oven will be on the bottom and place it on its left side,

3

being careful to avoid scratching the finish. Install the four 16

(42.5 cm) legs, using the 24 bolts and lockwashers provided (6 per leg).

Remove the two

7

/16" (1.1 cm) knockouts on each side of the top cover

⁄4"

and place oven in upright position at installation location. Turn the

adjustable feet in or out to level the oven front-to-back and side-toside (refer to LEVELING, page 6).

Remove right side panels from both ovens. Remove welded plate

from bottom of upper oven (Fig. 3). Install the two locating studs

(included in the leg stack set) into screw plates on underside of upper

oven (Fig. 3). Place upper oven on top of lower oven using the locating

studs.

Remove flue extension from upper oven. Install long flue extension

into existing right-angled flue extension in lower oven. Attach long flue

extension to wall of upper oven using screws provided. Secure

chimney to roof of upper oven (Fig. 4).

Install right side panels on both ovens. Connect the piping between

the top oven and bottom oven. Pipe joint compound must be resistant

to the action of propane gases.

The manual gas valve at the bottom of the control panel should remain

off until all electrical connections are made and the ovens are checked

or used.

LOCATING STUDS

BOTTOM

KNOCK OUT WELDED PLATE

FOR FLUE EXTENSION INSTALLATION

REAR OF TOP OVEN

PL-52992

Fig. 3

LONG FLUE

EXTENSION

RIGHT ANGLED

FLUE EXTENSION

CHIMNEY

LEVELING

Once the oven is in its permanent position, place a carpenter's level

on the oven rack. If the oven is installed on legs, turn the adjustable

feet in or out to level oven front-to-back and side-to-side. If the oven

is installed on casters, loosen set screws and turn casters in or out to

level oven front-to-back and side-to-side. Retighten set screws after

leveling.

Fig. 4

PL-52221

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE PROVIDED

WITH A THREE-PRONG GROUNDING PLUG. THIS PLUG MUST BE CONNECTED TO A PROPERLY

GROUNDED THREE-PRONG RECEPTACLE. IF THE RECEPTACLE IS NOT THE PROPER

GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT REMOVE THE GROUNDING PRONG

FROM THE PLUG.

The 120 volt models are equipped with a cord and plug.

Refer to electrical wiring diagram located inside the right side panel; remove control panel for access.

– 6 –

Page 7

Do not turn the power supply on until after the gas connections have been made and checked for leaks.

ATADLACIRTCELEATADLACIRTCELE

ATADLACIRTCELEATADLACIRTCELE

ATADLACIRTCELE

yticapmAtiucriCmuminiMyticapmAtiucriCmuminiM

yticapmAtiucriCmuminiMyticapmAtiucriCmuminiM

yticapmAtiucriCmuminiM

ledoMledoM

ledoMledoMstloVstloV

ledoM

D2OCG

C2OCG

stloVstloVztreHztreH

stloV

021061 51

042–002051 51

042–802061 51

021061 51

042–00206/051 51

ztreHztreHesahPesahP

ztreH

esahPesahP

esahP

.)noitidetsetal(07-APFN,edoClacirtcelElanoitaNehthtiwecnadroccanidelipmoC

eciveDevitcetorPmumixaMeciveDevitcetorPmumixaM

eciveDevitcetorPmumixaMeciveDevitcetorPmumixaM

eciveDevitcetorPmumixaM

SPMASPMA

SPMASPMA

SPMA

GAS CONNECTION

ATADSAGATADSAG

ATADSAGATADSAG

ATADSAG

RH/UTBTUPNIRH/UTBTUPNI

RH/UTBTUPNIRH/UTBTUPNIERUSSERPDLOFINAMERUSSERPDLOFINAM

ledoMledoM

ledoMledoM

ledoM

C2OCG,D2OCG000,52000,52)aPk8.0(.c.w"5.3)aPk5.2(.c.w"01

larutaNlarutaN

larutaNlarutaNenaporPenaporP

larutaN

RH/UTBTUPNI

enaporPenaporPlarutaNlarutaN

enaporP

larutaNlarutaNenaporPenaporP

larutaN

ERUSSERPDLOFINAMERUSSERPDLOFINAM

ERUSSERPDLOFINAM

enaporPenaporP

enaporP

For all gas supply connections, pipe joint compound must be resistant to the action of propane gases.

The oven is provided with a regulator integral to the gas solenoid valve, and requires no regulator

external to the device. A gas shutoff valve is supplied with each oven and is located at the bottom of

the control panel. No tools are required to access this valve.

Connect the oven(s) to the gas line after leveling. The gas supply line must be at least the equivalent

3

⁄4" (1.9 cm) iron pipe. Make sure the pipes are clean and free of obstructions, dirt and piping

of

compound.

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

TESTING THE GAS SUPPLY SYSTEM

The oven and its individual shutoff valve must be disconnected from the gas supply piping system

1

during any pressure testing of that system at test pressures greater than

/2 psig (3.45 kPa).

The oven must be isolated from the gas supply piping system by closing the manual shutoff valve during

1

pressure testing of the gas supply system at test pressures equal to or less than

/2 psig (3.45 kPa).

GAS PRESSURES AND ORIFICES

Natural Gas

The burner orifices are sized to deliver the nameplate input rating (25,000 Btu/hr) at a gas manifold

pressure of 3.5" w.c. (water column)

valve, and is factory set to supply 3.5" w.c.

(0.8 kPa). The gas pressure regulator is integral to the gas solenoid

(0.8 kPa) as required for natural gas.

Propane Gas

The burner orifices are sized to deliver the nameplate input rating (25,000 Btu/hr) at a gas manifold

pressure of 10.0" w.c. (water column)

valve, and is factory set to supply 10.0" w.c.

(2.5 kPa). The gas pressure regulator is integral to the gas solenoid

(2.5 kPa) as required for propane gas.

BURNER AIR SHUTTER ADJUSTMENTS

The burner has fixed, factory adjusted air openings and requires no field adjustment.

– 7 –

Page 8

FLUE CONNECTION

Ventilation requirements will vary with each installation and must comply with

Cooking Equipment

, NFPA Standard #96 (latest edition) and with local codes. Considerations to be

Vapor Removal from

kept in mind include:

• Flue connections should never be made directly to the oven.

• The oven should be located under a hood which has an adequate connection to an exhaust duct

and extends 6" (

15 cm) beyond the oven sides.

• Clearance above the oven flue should be adequate for the flue products to escape so that there

is no interference with heat circulation in the ovens.

OPERATION

WARNING: THE OVEN AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING, CLEANING,

OR PERFORMING ANY MAINTENANCE.

CONTROLS — MODEL GCO2D (Fig. 5)

MASTER SWITCH • Turns oven control circuits ON or OFF.

OVEN COOL SWITCH • Allows the fan motor to run with the

door ajar to speed oven cooling.

THERMOSTAT • Controls oven temperature during cooking

operation.

TIMER • Use to set cooking cycle time. The timer range is from

0 to 60 minutes. Alarm sounds continuously when

elapsed time counts down to 0; oven does not turn off.

Turn timer to OFF position to stop alarm. When oven is

not in use, keep timer at OFF position.

ON LIGHT (Amber) • Is lit when MASTER SWITCH is ON.

HEAT LIGHT (White) • Comes on and goes off when the burner

cycles on and off.

NO IGNITION LIGHT (Red) • Comes on if burner fails to ignite

after the third try. When lighting the oven, the NO

IGNITION LIGHT cycles ON during the 5 second purge

and OFF during the 7 second ignition trial.

ON

HEAT

IGNITION

OVEN

COOL

ON

OFF

T

500

475

450

425

400

350

THERMOSTAT

F

F

O

60

55

50

45

40

35

TIMER

TO SHUT

OVEN OFF

PLACE MASTER SWITCH IN

"OFF" POSTION TURN GAS

VALVE OFF

GAS VALVE

TO SHUT

OVEN OFF

PLACE MASTER SWITCH IN

"OFF" POSTION TURN GAS

VALVE OFF

ON LIGHT

HEAT LIGHT

NO IGNITION LIGHT

OVEN COOL SWITCH

MASTER

SWITCH

ON

OFF

M

E

P

F

150

225

250

300

300

0

5

10

15

20

25

30

ON

OFF

MASTER SWITCH

THERMOSTAT

TIMER

GAS VALVE

PL-52225

Fig. 5

GAS VALVE • When ON, allows gas to flow to the ignition

system.

– 8 –

Page 9

LIGHTING THE GCO2D OVEN

Open the manual valve. Turn the MASTER switch ON and turn the thermostat to its maximum setting.

Both the ON and HEAT lights should be lit. If the HEAT light is not on, make sure the door is closed.

After 5 seconds, the spark ignition system will initiate and the solenoid valve will open, allowing gas

flow to the burner for a period of 7 seconds. This 5 second purge and 7 second ignition trial will repeat

itself up to two more times if the burner does not light within the first 7 second ignition trial. During the

5 second prepurge, the red NO IGNITION light will be lit.

When the burner gas ignites, a slight roar will be audible. This roar is a normal condition of the power

burner, and will become almost undetectable in the normal operating mode after warm-up. The NO

IGNITION light will go off when ignition occurs.

If the burner fails to light after three trials, the red NO IGNITION light will be illuminated and remain

on. Turn the MASTER switch OFF for five minutes before repeating the operating sequence listed

above.

If burners do not light after five trials, turn off the manual valve and call a qualified servicer.

BEFORE FIRST USE

Before the oven is used for the first time, it must be "burned in" to release any odors that might result

from heating the new surfaces in the chamber.

Using a clean damp cloth, wipe the inside of the oven, including the racks.

Close the oven door, turn the MASTER switch ON, turn the thermostat to 300°F (

149°C) and allow the

oven to cycle for 6 to 8 hours before turning the switch OFF.

USING THE GCO2D OVEN

Preheating

1. Turn the MASTER switch ON. The amber ON light will glow, indicating that power to the oven

is on.

2. Set the THERMOSTAT as desired. Refer to SUGGESTED COOKING GUIDELINES — MODEL

GCO2D for temperatures and times for various products.

3. Prepare the product and place in suitable pans. When the white HEAT light goes off, the oven

has reached desired preheat temperature.

Cooking

1. Open the door and load the product into the oven. Place the pans in the center of racks. Close

the door.

2. Set the TIMER. After the preset time lapses, turn the timer OFF to stop the buzzer.

3. When the product is done, open the door and carefully remove the cooked product from the oven.

Wipe up any spills.

End of Day

1. Turn the THERMOSTAT OFF.

2. Turn the OVEN COOL switch ON.

3. Leave door ajar while the fan is on to cool the oven.

4. When oven has cooled sufficiently, turn OVEN COOL switch and MASTER switch OFF and clean

the oven.

– 9 –

Page 10

CONTROLS — MODEL GCO2C Built before October 1999 (Fig. 6)

HEAT LIGHT

TEMPERATURE KNOB

ROAST BUTTON

THERMOMETER BUTTON

TIME BUTTON

START/STOP BUTTON

GENTLE BAKE BUTTON

TEMPERATURE

HEAT

READY

ROAST

HOLD

TIME

TIME

START

STOP

GENTLE

BAKE

POWER

ON

OFF

COOL

DOWN

da;la;lasjfd;a

LIGHTING INSTRUCTIONS

ads;fjj;flPUSH MASTER SWITCH TO

"ON" POSTION. IF OVEN

FAILS TO LIGHT. PUSH

ON

GAS VALVE

sdifja;lldfjlfdal;

ds;fjalkdfja;sjdf;lfsdj;a;l

asdhflkajseflasdkjhflasklasj

shdjflkajh

OFF

THERMOSTAT

READY LIGHT

HOLD BUTTON

TIMER

TIMER KNOB

ON / OFF / OVEN COOL

SWITCH

GAS VALVE

PL-52224

Fig. 6

THERMOSTAT CONTROL

Temperature Display (When not timing product).

Displays set cook temperature while the light in the Roast Button is lit. Will be overridden to display

actual cavity temperature for 8 seconds when Thermometer Button is pushed.

1. The light in the Thermometer Button is lit while the actual temperature is being displayed.

2. The light in the Thermometer Button is not lit when the display returns to set temperature display.

Temperature Display (When product is being timed).

Displays set hold temperature while the light in the Hold Button is lit. Displays the roast temperature

when the Roast Button is lit. Will be overridden to display actual cavity temperature for 8 seconds when

the Thermometer Button is pushed.

1. The light in the Thermometer Button is lit while actual temperature is being displayed.

2. The light in the Thermometer Button is not lit when the display returns to set temperature display.

Temperature Knob (When not timing product).

1. Sets the roast temperature when the Roast Button light is lit. The Roast Button light can be

turned on by pressing the Roast Button.

2. Sets the hold temperature when the Hold Button light is lit. The Hold Button light can be turned

on by pressing the Hold Button.

Temperature Knob (When product is being timed).

1. Sets the roast temperature when the Roast Button light is lit. The Roast Button light cannot be

changed by pressing the Roast Button.

2. Sets the hold temperature when the Hold Button light is lit. The Hold Button light cannot be

changed by pressing the Hold Button.

– 10 –

Page 11

Roast Button Light (If On and not timing product, indicates the roast mode is selected).

• The displayed temperature settings will be for the roast temperature except when the Thermometer

Button is lit.

• Rotating the Thermostat Knob will change the roast set temperature.

• Cook time can be adjusted using the Timer Knob.

• The time displayed is the initial set cook time.

• It is possible to select the Hold mode using the Hold Button.

Roast Button Light (If On and product is being timed, indicates the roast mode is selected).

• The displayed temperature settings will be for the roast temperature except when the Thermometer

Button is lit.

• Rotating the Temperature Knob will change the roast set temperature.

• It is not possible to select the Hold mode using the Hold Button.

• The time displayed is the time counted down from the initial cook time setting.

Roast Button

1. Selects the Roast mode, indicated by the Roast Button Light described above.

2. Has no effect if timing in the Hold mode.

Thermometer Button — When pressed, displays the actual oven temperature for about 8 seconds,

then returns to the set temperature.

Heat Light — When lit, indicates that power is being supplied to the burner.

Ready Light — Is lit when the actual temperature is within 5°F (

3°C) of the set temperature for the

current mode, plus or minus.

TIMER CONTROL

Time Display (While not timing product).

— Displays the set cook time if the light in the Roast Button is lit.

Time Display (While product is being timed).

1. Displays the counted down cook time if the Roast Button light is lit in the Roast mode.

2. Displays the counted up hold time if the Hold Button is lit in the Hold mode. Count-up of hold time

does not begin until cavity temperature reaches the hold temperature.

Time Display Colon

1. Is flashing if product is timing.

2. Is not flashing if product is not being timed.

Time Button — Press to set cooking cycle time.

Time Button Light — Is lit when the Time Button is pressed.

Timer Knob — Sets the cook time when not already timing and the Cook Time indicator is lit.

– 11 –

Page 12

Gentle Bake Button

Selects the gentle bake time setting. A roast time must first be set. The gentle bake time can then be

set at the roast time value or less. The gentle bake time will be the portion of roast time to operate in

the gentle bake mode. Gentle bake mode will start first. When the gentle bake time has lapsed, the

remainder of the roast time will be in the non-gentle bake mode.

Use Gentle Bake when cooking delicate product, such as strudel, muffins, cupcakes, meringue pies,

etc., to keep product from forming waves on the top.

Use the Gentle Bake Button to switch between the selection of gentle bake mode and no gentle bake

mode time setting. A gentle bake mode time of zero means no gentle bake mode will occur.

The light in the Gentle Bake Button is lit during gentle bake mode.

Gentle Bake Mode

1. The fan cycles (45 seconds ON and 45 seconds OFF) throughout the gentle bake mode.

2. The fan stays on while the heat cycles in hold mode.

3. The fan stays on while heat cycles at 100% power when not timing.

4. Can be switched at any time.

Stop / Start Button

1. Starts timing a product in the mode selected if a cook time has been set.

2. Stops timing a product if a timing sequence is already in progress.

Hold Button — Selects Hold mode.

1. Allows selection of hold temperature.

2. Temperature indication of ---°F (---°C) indicates no hold mode.

Hold Button Light — Is lit when in the Hold mode.

1. When not timing, allows setting/enabling a hold mode setting of ---°F (---°C), meaning no hold

will take effect.

2. Any other temperature means that when the actual cook time has ended, the oven will enter the

Hold mode and use the hold temperature.

On / Off / Oven Cool Switch

1. ON turns oven control circuits on.

2. OFF turns oven control circuits off.

3. OVEN COOL allows the fan motor to run with the door ajar to speed oven cooling.

Gas Valve — When ON, allows gas to flow to the ignition system.

LIGHTING THE GCO2C OVEN

1. Turn manual gas valve ON.

2. Push ON / OFF / OVEN COOL switch to the ON position and set THERMOSTAT to its maximum

setting. The HEAT light should come on. If HEAT light is not on, make sure the door is closed.

3. If the oven fails to light, push the ON / OFF / OVEN COOL switch OFF. Wait 5 minutes before

trying to re-light the oven.

– 12 –

Page 13

BEFORE FIRST USE

Before using the oven for the first time, it must be "burned in" to release any odors that might result from

heating the new surfaces in the chamber.

1. Using a clean damp cloth, wipe the inside of the oven, including the racks.

2. Close the oven door, push the ON / OFF / OVEN COOL switch ON, turn the THERMOSTAT to

300°F (

149°C) and allow the oven to cycle for 6 to 8 hours before turning the ON / OFF / OVEN

COOL switch OFF.

USING THE GCO2C OVEN

Preheating

1. Close the oven door. Push ON / OFF / OVEN COOL switch ON. The HEAT light will come on,

indicating that power to the oven is on.

2. Set THERMOSTAT as desired. Refer to SUGGESTED COOKING GUIDELINES for temperatures

and times.

3. Prepare product and place in suitable pans. When READY light comes on, oven has reached

desired preheat temperature.

Cooking

1. Open the door and load the product into the oven. Place the pans in the center of racks. Close

the door.

2. Set ROAST temperature and time. Set HOLD temperature and GENTLE BAKE time, if desired.

GENTLE BAKE time cannot be more than ROAST time. GENTLE BAKE will cycle the fan during

the set time at the beginning of the cooking cycle.

3. Press the START/STOP button to start the cooking cycle.

4. At the end of the cooking cycle, the buzzer will sound continuously if the HOLD mode is OFF. If

the HOLD mode is ON, there will be a short beep at the beginning of Second Stage Cooking (oven

temperature will begin to decline to the HOLD temperature), and a long beep (20 seconds) at the

end of the cooking cycle. (Refer to ROAST AND HOLD OPERATION.)

5. When product is done, open the door and carefully remove cooked product from the oven. Wipe

up any spills.

End of Day

1. Push ON / OFF / OVEN COOL switch to OVEN COOL. Leave door ajar while the fan is on to cool

the oven.

2. When the oven has cooled sufficiently, turn the ON / OFF / OVEN COOL switch OFF and clean

the oven.

ERROR MESSAGES — Model GCO2C

E-01 High limit error. Contact Vulcan authorized service.

E-02 Low limit error. Contact Vulcan authorized service.

E-03 High ambient temperature, 215°F (

E-04 Low ambient temperature, 32°F (

102°C). Contact Vulcan authorized service.

0°C). Let control warm up after cold storage.

E-05 Ignition failure. After trying ignition three times, contact Vulcan authorized service.

E-06 Thermocouple probe open. Contact Vulcan authorized service.

When calling for service, please advise what error code was displayed.

– 13 –

Page 14

CONTROLS — MODEL GCO2C Built after October 1999

Always displays [HR:Min] when setting the time.

Displays [HR:Min] if the countdown Time is more than 1 Hour.

Displays [Min:Sec] if the countdown Time is less than 1 Hour.

Displays Temperature in °F.

R & H

MODE

OVEN

READY

MENU SELECT

PRIMARY

OVEN

HEATING

R & H

MODE

Indicates the oven is in the Roast and Hold Mode.

SECONDARY

1

SET

1

2

3

5

MENU RACK

NO IGNITION

ROAST

&

HOLD

4

START

STOP

6

ON

POWER

OFF

2

3

4

5

ON

OFF

OVEN

COOL

OVEN

READY

OVEN

HEATING

PRIMARY

SECONDARY

SET

ROAST

&

HOLD

START

STOP

Indicates the oven is preheated and ready for cooking.

Indicates the oven is preheating.

Primary indicates Menu Items 1, 3, or 5.

Secondary indicates Menu Items 2, 4, or 6.

Up arrow increases; Down arrow decreases — a displayed

Time or Temperature value (if arrow keys are lit).

TEMPERATURE: Use with SET to set the oven Temperature.

SET: Use with Time or Temperature.

TIME: Use with SET to manually set the cooking Time.

Changes to Roast and Hold mode.

Press once to start; press a second time to stop.

PL-53543

3/4

1/2

2 3 4

1

Select Menu Cook Times. Press once for Primary (1, 3, or 5).

5/6

Press a second time for Secondary (2, 4, or 6). See next page.

Rack Buttons select individual Menu / Rack # Cook

5

Times — once programmed.

– 14 –

Page 15

MANUALLY SETTING THE TEMPERATURE AND COOK TIME

To Set the Temperature

• Press the SET button. Press the TEMPERATURE button;

StPt

displays to indicate Setpoint.

• Use the Up and Down Arrow keys to increase or decrease the displayed Temperature value.

• Press the SET button again to save the Temperature setpoint in the computer.

To Set the Cook Time

• Press the SET button. Press the TIME button.

Tine

displays to indicate TIME.

• Use the Up and Down Arrow keys to increase or decrease the displayed Cook Time (HR:min).

• Press the SET button again to save the Time setting in the computer.

To Start Cooking

• Press the START / STOP button.

• The manual Cook Time counts down to 00:00. Displays [HR:Min] above 1 hour; [min: sec] below.

• The buzzer will sound. To silence the buzzer, press the START / STOP button again.

* The control retains the manual settings for Temperature and Time.

TO PROGRAM MENU ITEM and RACK # Cook Times

Factory Preset and Programmable Cook Times are shown in the table, below:

NOITCELESUNEM

yramirP2/11.nim01

yradnoceS2/12.nim51

yramirP4/33.nim02

yradnoceS4/34.nim52

yramirP6/55.nim03

yradnoceS6/56.nim53

UNEM

METIMETI

METIMETI

METI

TESERPYROTCAF

METIUNEMMETIUNEM

METIUNEMMETIUNEM

METIUNEM

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

METIUNEM

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

1KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

2KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

SEULAVELBAMMARGORP

3KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

4KCAR

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

5KCAR

The Primary indicator light with Menu 1 / 2 selects Menu Item 1 (Factory Preset Cook Time = 10

minutes). The Secondary indicator light with Menu 1 / 2 selects Menu Item 2 (Factory Preset Cook Time

= 15 minutes). Similarly, for Menu Buttons 3 / 4 or 5 / 6. Any Menu Item Cook Time can be changed

using the procedure below. Rack # Cook Times may be programmed if desired but are not required.

To Change the Time Setting for any Menu Item (1 – 6)

• To enter program mode, press and hold the Up and Down arrow buttons until PrOG displays.

✤ Select the Menu Item to be programmed (1 – 6).

Tine

displays to indicate TIME. Use the Up and

Down arrow buttons to increase or decrease the Menu Item's COOK TIME. Repeat this step for

any other Menu Items.

• Press the START / STOP button; LOC displays. Press the START / STOP button a second time

to save the Menu Item(s)' COOK TIME(s).

• Press the START / STOP button once to begin cooking (with the Menu Item's Cook Time). To

exit, press the START / STOP button a second time.

EMITKOOCEMITKOOC

EMITKOOCEMITKOOC

EMITKOOC

To Program Individual Rack # Cook Times for a Menu Item

• To enter program mode, press and hold the Up and Down arrow buttons until PrOG displays.

Tine

• Select the Menu Item to be programmed (1 – 6);

✤ Then select the Rack # (1 – 5). [

t 1

] indicates Rack #1; [

displays to indicate TIME.

t 2

] indicates Rack #2; ... [

t 5

] indicates

Rack #5. Use the Up and Down arrows to increase or decrease the COOK TIME for any Rack #.

LOC

• Press the START / STOP button;

displays. Press the START / STOP button a second time

to save the Menu / Rack #'s COOK TIME(s).

• To exit program mode, press START / STOP twice.

– 15 –

Page 16

Always Set the Temperature Before Setting the Time

StPt

• Press the SET button. Press the TEMPERATURE button;

displays. Use the Up and Down

Arrow keys to increase or decrease the Temperature. To save, press the SET button again.

At startup, the display will initially show a

GROWING BAR

. When the oven temperature reaches the Set

Point, the set temperature displays. The READY light is lit, the HEAT light goes out, and the oven is

ready for you to select the Cook Time, Menu Item Cook Time, or Menu / Rack # Cook Time.

Starting a Timed Cycle On All Racks

door

• Open the door,

will display.

• Place the desired product on any of the five racks.

• Close the door. The display should return to the set temperature or the

GROWING BAR

.

• Press the Menu Key once for Primary or twice for Secondary to select a Menu Item Cook Time.

• Press the START / STOP button *.

• The timer will count down the time remaining for the Menu Item Cook Time.

• When the time has counted down to 00:00, the buzzer will sound and all Rack Buttons will flash.

• To silence the buzzer, press the START / STOP button.

Pressing the START / STOP button after making a menu selection will time all racks for the

*

selected menu time.

Starting a Timed Cycle Using Programmed Individual Menu / Rack # Cook Time(s)

door

• After the set Temperature is reached, open the door;

• Close the door. The display returns to the set Temperature or the

displays. Place product(s) in oven.

GROWING BAR

.

• Select the Menu Item (once for Primary or twice for Secondary) and the Rack # to select the

Menu / Rack # Cook Time. If using simultaneous cook times, select the other Menu / Rack #'s.

• The timer selects the Rack # with the shortest Cook Time and counts down to 00:00.

• The buzzer sounds and the Rack # flashes. To silence the buzzer, press the flashing Rack #.

door

• Open the door;

displays; remove the finished product; close the door.

✣ The next shortest Cook Time displays, its Rack # flashes and the time counts down to 00:00.

• The buzzer sounds. Press the flashing Rack #. Open the door,

door

displays. Remove the

product, close the door. Repeat from ✣ until all Rack #'s are done.

To Display the Actual Oven Temperature

• Press and hold the Temperature button for 3 seconds to display Actual Oven Temp until released.

To End a Cooking Cycle

At the end of a cooking cycle, the alarm will sound. To silence the alarm and end a Menu Item cooking

cycle, press START / STOP. To silence the alarm and end a Rack # cooking cycle, press the Rack #.

To cancel a cooking cycle which might have been started in error, press and hold the Rack button to

be terminated and press START / STOP at the same time.

Door and Timing

Opening the door while loading additional product will interrupt all timing functions until the door is

closed and the timer resumes. For example, if a product time had diminished to 1 minute and the door

was opened for 30 seconds and then closed, the timer would still show 1 minute.

SETTING THE OVEN FOR ROAST & HOLD

• Press the Roast & Hold button to select Roast & Hold.

• Set the first stage Temperature and the Cook Time as described in: M

ANUALLY SETTING THE

TEMPERATURE AND COOK TIME. Press START / STOP to begin cooking.

The HOLD Temperature is preset by the computer control at 150°F

*

– 16 –

(66°C)

.

Page 17

ROAST AND HOLD OPERATION — GCO2C OVEN

Roast and Hold cooks the product in two stages. During First Stage Cooking, the oven temperature is

regulated by the Roast thermostat for the amount of time set on the Timer. After the lapsed time counts

down to 00:00, Second Stage Cooking begins. During Second Stage Cooking, the burners are off as

the temperature in the oven declines to the Hold Temperature. The door should remain closed during

Second Stage Cooking.

When the Hold temperature is reached, cooking is done. The Time Display counts up the Hold time and

flashes "Hold." Temperature in the oven will be maintained at the Hold temperature until the oven is

turned off.

ROAST AND HOLD DIAGRAM - Time vs. Temperature

400ºF

300ºF

200ºF

100ºF

TEMP.

TIME

PL-51607

OVEN TEMPERATURE

TIMER DISPLAY COUNTS DOWN,

COLON FLASHES.

COOKING FROM

STORED HEAT

LOAD PRODUCT

INTO OVEN

PRODUCT TEMPERATURE

PREHEAT FIRST STAGE COOKING SECOND STAGE

SHORT BEEP.

TIMER DISPLAY FLASHES 00:00.

ROAST THERMOSTAT OFF.

BURNERS OFF UNTIL HOLD

TEMPERATURE IS REACHED.

LONG BEEP (20 SEC.)

BURNERS MAINTAIN

HOLD TEMPERATURE.

TIMER DISPLAY COUNTS UP

HOLD TIME AND FLASHES

"HOLD."

COOKING

(DO NOT OPEN

DOORS)

HOLDING

PROPER UTENSILS

The use of proper utensils can enhance oven operation. Medium and light weight pans are recommended

since it is more economical to bake with lighter pans.

Meats should be roasted in shallow pans deep enough to hold all juices and allow free air circulation.

CONSERVING ENERGY

• Turn off unused equipment.

• Adjust menu patterns and cooking or baking schedules for optimum equipment use.

• Reduce thermostat settings in slack periods since gas equipment heats up and recovers quickly.

• Preheat only to the required cooking temperature for the specific food, not higher.

• Do not open the oven door unless absolutely necessary. Use the window to observe cooking

progress.

• Keep area around the oven door clean and free of food particles.

• Any obstruction that prevents the door from closing completely will adversely affect oven

efficiency.

OPERATING HINTS

When using the convection oven for the first time with a particular food, check the degree of doneness

periodically before the suggested time has lapsed to make sure the desired doneness is achieved.

Record your temperature and time settings for various products. The convection oven can provide

consistent, repeatable results.

– 17 –

Page 18

The convection oven is a bit faster than conventional deck-type ovens; temperature settings are lower

and cook times are shorter. Since recipes and foods are subject to many variations and tastes, the

guidelines regarding times and temperatures in this manual are SUGGESTIONS ONLY. Experiment

with your food products to determine the cooking temperatures and times that give you the best results.

CLEANING

WARNING:

DISCONNECT THE ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THAT YOU ARE WORKING ON THE OVEN BEFORE CLEANING.

Clean outside of the oven daily by wiping with a clean damp cloth.

Clean porcelain oven interior daily with soap or detergent and water. Rinse thoroughly and wipe dry

with a soft clean cloth.

Optional Stainless Steel Oven Interior

Soap or detergent and water usually handle routine cleaning. Rinse thoroughly and dry with a soft clean

cloth.

For burned-on foods and grease which resist simple soap and water cleaning, an abrasive cleanser

(scouring powder) mixed into a paste may be used. Apply with stainless steel wool or sponge, always

rubbing with the "grain."

This treatment is equally effective for "heat tint" (slightly darkened areas caused by oxidation). Again,

remember to rub in the direction of the polish lines. Rinse with clear water and dry with a soft cloth.

SUGGESTED COOKING GUIDELINES — MODELS GCO2D AND GCO2C

BAKED PRODUCTS

Product Temp. Time (min.) No. Shelves

°F(°C)

Sheet Cakes (5 lb. each) (2.3 kg) 300 (149) 30 5

Soda Biscuits 325 (163) 12 5

Yeast Rolls 325 (163) 15 – 20 5

Corn Bread 300 (149) 15 5

Gingerbread 300 (149) 18 3

Chocolate Cake 325 (163) 20 5

Chocolate Chip Cookies 325 (163) 10 5

Sugar Cookies 326 (163) 12 5

Yellow Cake 300 (149) 25 5

Angel Food Cake 275 (135) 25 5

Brownies 350 (177) 15 – 20 5

Apple Turnovers 350 (177) 20 – 25 5

Cream Puffs 300 (149) 25 – 30 5

Apple Pie (Fresh) 350 (177) 30 5

Pumpkin Pie 275 (135) 40 5

Berry Pies (Frozen) 325 (163) 40 5

Fruit Pie (Frozen) 325 (163) 45 5

Pizza (Individual, Frozen)

(Precooked Crust)

Bread (1 lb. loaf) (454 gr.) 340 (171) 30 3

Brown and Serve Rolls 350 (177) 15 5

Coffee Cake 300 (149) 45 3

Pineapple Upside Down Cake 325 (163) 30 5

Fruit Cobbler 375 (190) 25 5

Danish Pastry 325 (163) 12 – 15 5

Pie Shells 350 (177) 12 5

Cinnamon Buns 325 (163) 15 – 20 5

310 – 325 (154 – 163) 8 – 13 5

– 18 –

Page 19

MEAT & FISH PRODUCTS

Product Temp. Time (min.) No. Shelves

°F(°C)

Prime Rib (20 lb. rare) (9.1 kg) 250 (121) 23⁄4 Hr. 2

Rolled Roast Beef 275 (135) 21⁄2 Hr. 2

Veal Roast Boned (15 lb.) (6.8 kg) 275 (135) 21⁄2 Hr. 2

Stuffed Pork Chops 300 (149) 25 – 30 3

Lamb Chops 375 (190) 12 5

Steamship Round (80 lb.) (36.3 kg) 275 (135) 23⁄4 Hr. 1

Meatloaf 325 (163) 40 3

Hamburger Patties (4 oz.) (113 gr.) 400 (204) 8-10 5

Meat Pot Pies 350 (177) 40 5

Chicken Parts 300 – 325 (149 – 163) 30 – 40 5

Fish Sticks 350 (177) 18 5

MISCELLANEOUS PRODUCTS

Product Temp. Time (min.) No. Shelves

°F(°C)

Macaroni & Cheese 350 (177) 30 3

Cheese Sandwiches 375 (190) 10 5

Baked Potatoes (6 - 8 oz.) (170 - 227 gr.) 400 (204) 45 5

Baked Potatoes (10 oz.) (283 gr.) 400 (204) 55 5

Stuffed Peppers 350 (177) 20 5

Scalloped Potatoes 325 (163) 35 5

Lasagna 250 (121) 90 3

FOR BEST RESULTS

Product to be cooked should be centered on the oven rack, and the racks should be spaced evenly

inside the oven.

It is best not to rotate the product or open the door during the cooking cycle.

Preheat the oven to 50 F°

(28 C°) higher than desired cooking temperature. After the oven is loaded,

close the door and set thermostat to desired cooking temperature.

Make adjustments in the time and temperature settings until the desired results are obtained. Adjust

only one setting at a time. For example, if the product is too dark on the outside and not done on the

inside, the oven is too hot. Reduce the temperature by 25 F°

(14 C°).

These cooking charts will be helpful in arriving at time and temperature settings for products commonly

cooked in convection ovens, but it may be necessary to make adjustments in the settings until the

desired results are obtained.

When the desired results are obtained, make a note of the settings used for a particular recipe and

product load. For example, if four 18 x 26"

(45.7 x 66 cm) sheet cakes using 5 lb. (2.26 kg) of batter for

each cake, constitutes a typical product load and the size of the load is changed, the final results may

be affected. If either the weight of the cakes being baked or the number of cakes being baked at one

time changes, it may be necessary to make further adjustments in the time or temperature settings to

achieve the desired results.

– 19 –

Page 20

MAINTENANCE

WARNING: THE OVEN AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING, CLEANING,

OR PERFORMING ANY MAINTENANCE.

WARNING: DISCONNECT THE ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THAT YOU ARE WORKING ON THE OVEN BEFORE

PERFORMING ANY MAINTENANCE .

LUBRICATION

The fan motor comes with sealed bearings and requires no lubrication.

The door hinges and mechanism require occasional lubrication with mineral oil.

DISCONNECTING THE GAS LINE RESTRAINT

If this oven is placed on casters, it should be connected to the supply piping with the proper disconnect

device and restraint. If it is necessary to disconnect the restraint, first turn off the gas supply. Reconnect

the restraint before turning the gas supply on and returning the oven to its original installed position.

VENT

Annually check the flue, when cool, to be sure it is free of obstructions.

TROUBLESHOOTING

If the NO IGNITION LIGHT remains lit for more than 20 seconds after three trials (Model GCO2D), or

if E-05 displays after three trials (Model GCO2C):

• Turn oven off for 5 minutes before attempting to re-light.

• Check gas supply valves to be sure they are open.

• Check electrical power source and connections.

• Call your local Vulcan authorized service representative.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this oven, contact the Vulcan-Hart Service Agency

in your area (refer to listing supplied with the oven), or Vulcan-Hart Company Service Department at

the address or phone number shown on the front cover of this manual.

FORM 30975 Rev. C (Aug. 2000) PRINTED IN U.S.A.

– 20 –

Loading...

Loading...