Page 1

INSTALLATION & OPERATION MANUAL FOR

Cheesemelters

MODELS

VCM24

VCM34

VCM36

VCM48

VCM60

VCM72

www.vulcanhart.com

MLS

ML-135124

ML-135123

ML-135126

ML-135127

ML-135128

ML-135129

MODELS

CMJ24

CMJ34

CMJ36

CMJ48

CMJ60

CMJ72

www.wolfrange.com

MLS

ML-135124

ML-135123

ML-135126

ML-135127

ML-135128

ML-135129

ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

CMJ36

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-36954 (04-07)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE

INSTALLING OR SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

-

2 -

Page 3

INSTALLATION, OPERATION AND CARE OF

CHEESEMELTERS

GENERAL

Cheesemelters are produced with quality workmanship and material. Proper installation,

usage and maintenance of your Cheesemelter will result in many years of satisfactory

performance.

Model # of Burners BTU/hr Input Rating

VCM24 / CMJ24 1 18,000

VCM34 / CMJ34 1 24,000

VCM36 / CMJ36 1 24,000

VCM48 / CMJ48 2 36,000 (2 @ 18,000)

VCM60 / CMJ60 2 42,000 (1 @ 18,000 + 1 @ 24,000)

VCM72 / CMJ72 2 48,000 (2 @ 24,000)

INSTALLATION

Before installing, verify that the type of gas supply (natural or propane) agrees with the

specifications on the rating plate located underneath the grease drip pan. If the supply

and equipment requirements do not agree, do not proceed with the installation. Contact

your dealer immediately.

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the cheesemelter is

found to be damaged, save the packaging material and contact the carrier within 15 days

of delivery.

Before installing, verify that the type of gas (natural or propane) and the clearance

dimensions (see page 4) agree with the specifications on the rating plate which is located

under the crumb tray on the right side.

LOCATION

The equipment area must be kept free and clear of combustible substanc es.

Minimum Clearances

Combustible Construction Non-Combustible Construction

Back 2" 0"

Sides 20" 0

Bottom 10" 4"

-

3 -

Page 4

The installation location must allow adequate clearances for servicing and proper

operation. While another gas-fired cheesemelter can be placed adjacent to this

Cheesemelter, there must be no obstructio n to the front of the Cheesemelter. A minimum

front clearance of 36" (91 c m) is required.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance for air

openings into the combustion chamber must be provided. Make sure there is an adequate

supply of air in the room to repl ace air taken out by the ventila ting system.

Do not permit fans to blow directly at the Cheesemelter. Avoid wall-type fans which

create air cross currents within the room. Avoid open windows next to the Cheesemelter.

Maintain an 18" (46 cm) clearance from the top of the flue vent to the filters of the hood

venting system.

INSTALLATION CODES AND STANDARDS

The Charbroiler must be installed in ac cordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall incl ude but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

NOTE: In the Commonwealth of Massachusetts

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, availabl e

from the National Fire Protection Associa tion, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd. , Etobicoke, Ontario, Canada M9W 1R3

ASSEMBLY

Cheesemelters Mounted on a Co unter (Fig. 1)

Cheesemelters mounted on a counter must be equipped with 4" (10 cm) legs. The

countertop must be of noncombustible construction. Place Cheesemelter in position, then

level. Unscrew the front legs from the chassis about 1/4" (6 mm) and remove the lower

control panel for servicing.

Cheesemelters Mounted on a Wall (Fig. 2)

Secure brackets to the wall by means of lag screws or bolts. Make sure Cheesemelter is

level and lag screws or bolts engage wall studs.

Cheesemelter Mounted on Special Hi-She lf (Fig. 3)

-

4 -

Page 5

If the Cheesemelter is to be mounted over a Gas Range, a reinforced hi-shelf and special

mounting brackets are required. These are furnished when ordered as an elevated

Cheesemelter.

Fig. 1 Fig. 2 Fig. 3

1. Remove existing rear shelf and install the reinforce d high shelf.

2. Install mounting brackets on both top corners of rein forced shelf, using the four bolts

provided.

3. Place and align Cheesemelter on top of brackets; place the back of the unit flush

with the rear of the shelf.

4. Using a #19 drill bit, drill from below through the four holes provided on the mounting

bracket into the base of the unit.

5. Drive four #10-24 self-tappin g screws (provided) into the drille d holes.

6. Attach both Cheesemelter and high shelf to the common rear panel with self-tapping

screws.

GAS CONNECTIONS

CAUTION: Gas supply connections and any pipe joint compound must be resistant

to the action of propane gases.

Location of the gas inlet is at the top right rear corner of the top panel. Codes require that

a gas shutoff valve must be installed in the gas line ahead of the Cheesemelter.

Connect gas supply (1/2“pipe minimum recommended size). Make sure the pipes are

clean and free of obstructions.

Maximum line pressure for natural and propane gas is 14" W.C. Mini mum line pressure is

7" W.C. for natural gas and 11" W.C. for propane gas.

-

5 -

Page 6

GAS PRESSURE REGULATOR INSTALLATION

Gas regulator pressure is preset at 6” Water Column (W.C.) for natural gas, and 10” W.C.

for propane gas. Minor ad justments may be required bas ed on site specific gas pressure .

Install the regulator as close to the cheesemelter on the gas supply line as possible.

Make sure that the arrow on the underside of the regulator is oriented in the direction of

gas flow to the cheesemelter (Fig. 2) and the regulator is positioned with the vent plug

and adjustment screw upright (Fig. 3).

Fig. 2

Fig. 3

The minimum supply pressure (upstream of the regulator) should be 7-9” W.C. for natural

gas and 11-12” W.C. for propane gas. At no time should the hotplate be connected to

supply pressure greater than ½ psig (3.45 kPa ) or 14” W.C.

TESTING THE GAS SUPPLY SYSTEM

When gas supply pressure exceeds ½ psig (3.45 kPa), the Cheesemelter and its

individual shutoff valve must be disconnected from the gas supply piping system.

When gas supply pressure is ½ psig (3.45 kPa) or less, the Cheesemelter should be

isolated from the gas suppl y system by closing its individual ma nual shutoff valve.

FLUE CONNECTIONS

DO NOT obstruct flow of flue gases f rom the flue located on the rear of the Cheesemelter.

It is recommended that the flue gases be ventilated to the outside of the building through

a ventilation system installed by qualified pers onnel.

Information on the construction and installation of ventilating hoods may be obtained from

the standard for "Vapor Removal from Cooking Equipmen t," NFPA No. 96 (latest edition),

available from The National Fire Protection Association, Batterymarch Park, Quincy, MA

02269.

-

6 -

Page 7

OPERATION

WARNING: THE CHEESEMELTER AND ITS PARTS ARE HOT. BE CAREFUL WHEN

OPERATING, CLEANING OR SERVICING THE CHEESEMELTER.

CONTROLS

Burner Valve — the burner valve regulates the flow of gas throughout the

Cheesemelter. Gas flow is increased by turning the valve

counterclockwise. After preheating, the maximum output is not

required. Turn the valve clockwise until the desired

performance is achieved.

Sliding Shelves (Rack) — there are three rack positions. Place the shelf on the

rack needed for Cheesemelting. For deeper, longer heat, use

lower positions. For thinner foods, or faster cooking, use top

shelves.

Grease Pan (Drip Tray) — the grease pan collects grease and waste. Do not allow

the grease pan to overflow. Empty the grease pan when threequarters full to reduce the possibility of spillage.

Pilot Adjustment Valve — regulates th e flow of gas to the pilot burn er.

LIGHTING, RELIGHTING AND SHUTDOWN INSTRUCTIONS

1. Turn gas shutoff valve and burner valve to the OFF position and wait 5 minutes.

2. Turn gas shutoff valve ON. Light the pilot adjacent to the main burner. Adjust the pilot

valve screw until the pilot fla me has a slight yellow tip.

3. After the pilot has been established, turn the burner valve to the ON position. The

burner flames may be adjusted, using the air shutters located behind the louvered

panel in the front of the broiler below the burner valve.

4. If the burners fail to light, turn off all valves, wa it 5 minutes and repeat steps 1-3.

5. To shut down, turn the burner valves to the OFF position.

PREHEATING

Place the rack in its highest position. Turn the burner valve knob completely

counterclockwise and preheat for 15 minutes.

RECIPE AND RACK ADJUSTMENT

Positioning the Cheesemelter rack is an important factor in the desired product end

results. Position the rack farther away from the burners for thick casseroles and for

melting cheese or butter to avoid drying the product. Position the rack closer to the

burners for bacon, toast and quick heating, but watch carefu lly to avoid burning.

-

7 -

Page 8

LOADING AND UNLOADING

Place the rack in the desired position. Pull the rack out for loading. Load as quickly as

possible and avoid spillage. Push the rack into place and cook for the appropriate time.

Lower and pull the rack out for unloading.

CLEANING

Interior

When the Cheesemelter is cool, remove rack. Clean the rack and drip tray daily by

soaking in warm detergent water. Scrub with a stiff-bristled brush. Do not use harsh

abrasives.

After scrubbing, wash with soapy water, rinse and dry. Soap and water will normally do

the job. Heavy spattering or spillovers may require cleaning with mild cleaner or soapy

wet pads.

Exterior

When the Cheesemelter is cool, knobs and stainless steel surfaces may be cleaned with

mild soap and water applied with a damp cloth. Rinse the surface with clean water and

dry with a soft clean cloth. Do not use abrasive cleaners or strong liquid cleaners on

stainless steel surfaces as they may damage the finish.

Spray-On Cleaners

Be careful when using spray-on cleaners. Some cleaners may contain caustics. Please

follow cleaner manufacturer's instructio ns.

MAINTENANCE

WARNING: THE CHEESEMELTER AND ITS PARTS ARE HOT. BE CAREFUL WHEN

OPERATING, CLEANING OR SERVICING THE CHEESEMELTER.

LUBRICATION

All moving parts must be checked for wear and lubric ated if necessary. Contact your local

Service Agency.

All valves and controls should be lubricated with a high-temperature grease by your local

Service Agency.

VENT

Annually, when the Cheesemelter is cool, check the flue and clear any obstructions.

SERVICE AND PARTS INFORMATION

Contact the Service Agency in your area to obtain service and parts information.

-

8 -

Page 9

TROUBLESHOOTING

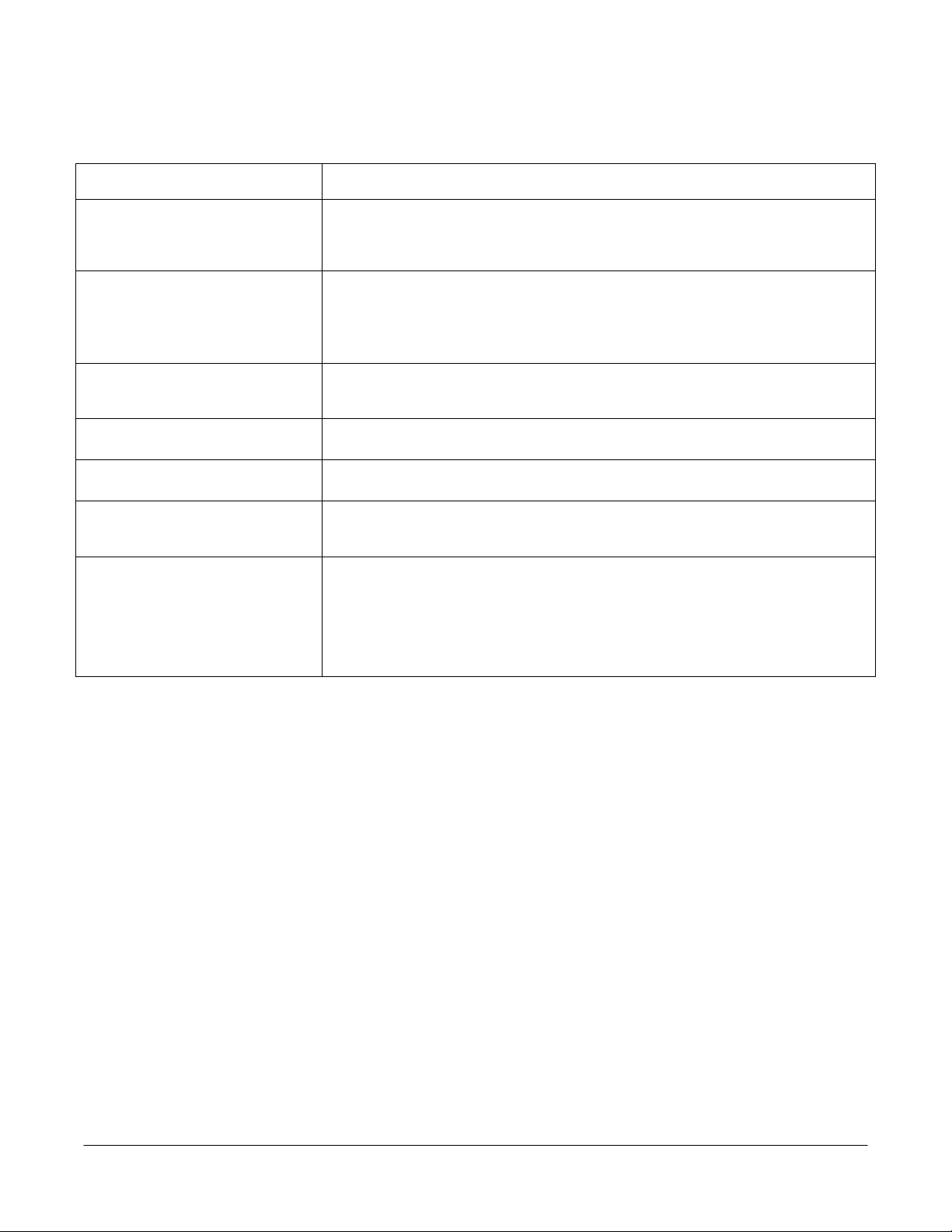

PROBLEM POSSIBLE CAUSES

Uneven heating

Side burning

Too much top heat

Uneven heat, side to

side

Uneven heat, front to

back

Dried-out products

Pilot outage

Poor ignition

1. Temperature too low

2. Improper operation of Cheesemelter

3. Fluctuating gas pressure

1. Temperature too hig h

2. Improper ventilation

3. Excessive heat input

4. Pressure too high, or orifice(s) too large

1. Chees emelter not level, side to side

2. Cheesemelter burner improperly installed

Cheesemelter not level, front to ba ck

1. Melting time too long, or product too close to burners

2. Pressure too high, or orifice(s) too large

1. Pilot flame too low

2. Restriction in pilot orifice

1. Insufficient gas input

2. Poor air-to-gas adjustment

3. Restriction in pilot orifice

4. Restriction in main bu rner ignition port

5. Pilot ad justment is incorrect

-

9 -

Loading...

Loading...