STEAM

Model CEM10U

SPECIFICATIONS

Electric heated combination oven convection steamer, VulcanHart Model No. CEM10U. Stainless steel interior and exterior.

Cooking compartment is fully welded stainless steel with fully

coved and large radius corners and interior light. Removable

10 position pan rack assembly with 1 wire rack. Door is

welded stainless steel for strength with sealed door hinges.

Single pane glass mounted in door with hinged oating inner

reective glass panel with full perimeter silicone gasket. Door

is cool to the touch and includes a mounted drip tray. Deluxe

manual control with seven position master control (convection

cooking, steam cooking, thermostat controlled steam cooking,

combination cooking, warming-rethermalization, cool down

and off), vent control. Temperature selection range: 68° to 518°F

in convection cooking, 212° to 518°F combination cooking,

or 68° to 212°F in ther mo stat controlled steam cookin. Two

position humidity control and two speed convection fan.

Automatic shut-down at elapsed time with audible buzzer

which continues until manually shut off. 4" stainless steel legs

with counter feet.

Exterior Dimensions:

37"w x 401⁄2"d x 42"h on 4" legs.

37"w x 401⁄2"d x 70"h on oven support.

UL listed. UL listed to Canadian safety standards. Classied by

UL to NSF Std. #4.

Item # C.S.I. Section 11420

CEM10U

ELECTRIC COMBI OVEN

CEM10U 10 level, half size

STANDARD FEATURES

Stainless steel interior and exterior. ■

Cooking compartment is fully welded stainless steel with ■

fully coved and large radius corners and interior light.

Removable 10 position pan rack assembly with 1 wire ■

rack.

Door is welded stainless steel for strength with sealed ■

door hinges. Single pane glass mounted in door with

hinged oating inner reective glass panel with full

perimeter silicone gasket. Door is cool to the touch and

includes a mounted drip tray.

Deluxe manual control with seven position master ■

control (convection cooking, steam cooking, thermostat

controlled steam cooking, combination cooking,

warming-rethermalization, cool down and off).

Temperature selection range: 68° to 518°F in convection ■

cooking, 212° to 518°F combination cooking, or 68° to

212°F in ther mo stat controlled steam cooking

Two position humidity control and two speed convection ■

fan.

Automatic shut-down at elapsed time with audible buzzer ■

which continues until manually shut off.

4" stainless steel legs with counter feet. ■

Requires 208 or 240 volts, 60 Hz, 3 phase power supply. ■

One year limited parts and labor warranty. ■

OPTIONS

Correction facility package:

a. Security type tamper resistant fasteners with tack

welds.

b. Control cover with hasp (lock by others).

c. No internal product probe.

480 volts, 60 Hz, 3 phase.

Second year extended limited parts and labor warranty.

ACCESSORIES (Packaged & Sold Separately)

Stainless steel oven support.

Product probe kit (eld installed).

Core probe for vacuum package 2MM.

Flexible water connection with (3⁄4" NSHT) - 2 required.

External oven spray with retractable hose.

Wire racks. Qty.______.

12 x 20 Wire basket. Qty.______.

Chicken rack. Qty.______.

Water treatment system.

a divisi on of IT W Food Equ ipmen t Group LLC

P.O. Box 696 ■ Louisville, KY 40201 ■ Toll-free: 1-800-814-2028 ■ Local: 502-778-2791 ■ Quote & Order Fax: 1-800-444-0602

F-37464 (09/10)

STEAM

CEM10U

ELECTRIC COMBI OVEN

WATER QUALITY STATEMENT

The fact that a water supply is potable is no guarantee that it is

suitable for steam generation. Your water supply must be within these

general guidelines:

SUPPLY PRESSURE 20 - 60 psig

HARDNESS* less than 3 grains

SILICA less than 13 ppm

TOTAL CHLORIDE less than 4.0 ppm

CHLORINE & CHLORAMINES 0 ppm

pH RANGE 7-8

UN-DISSOLVED SOLIDS less than 5 microns

* 17.1 ppm = 1 grain of hardness

Other factors affecting steam generation are iron content, amount

of chlorination and dissolved gases. Water supplies vary from state

to state and from locations within a state. Therefore it is necessary

that the local water treatment specialist be consulted before the

installation of any steam generating equipment.

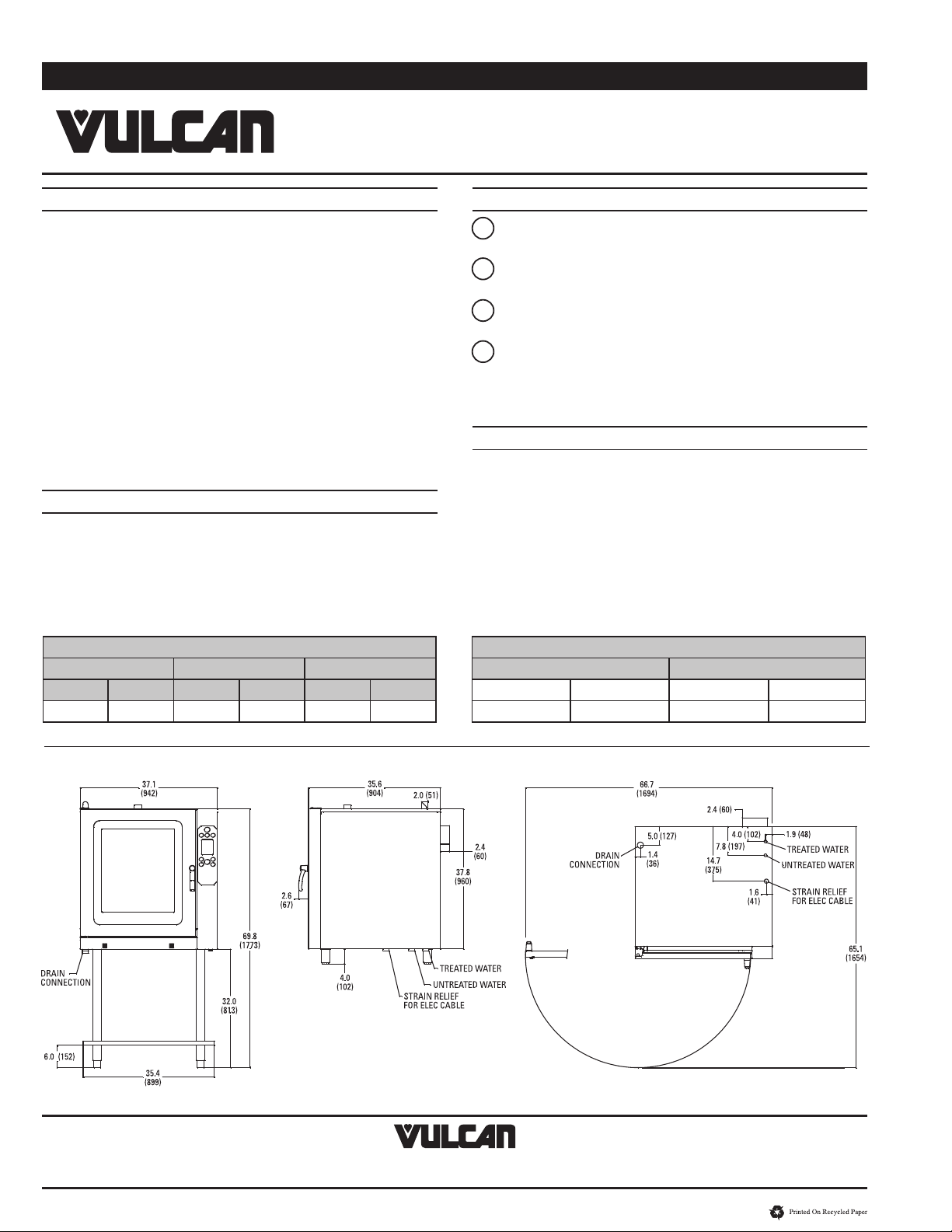

CLEARANCES

Rear - 6", Left Side - 2", Right Side - 6"

Allow for sufcient distance if a “high heat source” (i.e. Broiler) is •

located next to the unit.

Allow for sufcient clearance on right side for service access •

(contact the factory service department for recommendations).

Installation must comply with all local re and health codes.•

ELECTRICAL RATING

208V/60/3 240V/60/3 480V/60/3

KW AMP KW AMP KW AMP

15 43 17 40 16 19

SERVICE CON NECTIONS

E Electric connection: Single point supply 2" (51 mm) dia.

(3⁄4" - 19 mm strain relief).

C1 Cold water connection: 3⁄4" NSHT for generator feed. Inlet

water pressure between 20 and 60 psi (138-414 kPa).

C2 Cold water connection: 3⁄4" NSHT for cold water condenser.

Inlet water pressure between 20 and 60 psi (138-414 kPa).

D Drain: Condensate box, compartment and boiler 11/2" NPT.

(Provide an open air type drain within 12" of condensate box

and for best results at a distance so that steam vapors will not

enter the steamer from underneath the control area. Do not

connect solidly to any drain connection.)

NOTE

Dimensions which locate the above connections have a tolerance •

of + or -3" (+ or -75 mm).

Installation of backow preventers, vacuum breakers and other •

specic code requirements is the responsibility of the owner

and installer. It is the responsibility of the owner and installer to

comply with local codes.

Do not use plastic drains. •

This appliance is manufactured for commercial installation only •

and is not intended for home use.

PAN CAPACITY

STEAM TABLE PANS BAKE PANS

12" x 20" x 21⁄2" 12" x 20" x 4" 18" x 13" 18" x 26"

10 5 10 N/A

a divisi on of IT W Food Equ ipmen t Group LLC

P.O. Box 696 ■ Louisville, KY 40201 ■ Toll-free: 1-800-814-2028 ■ Local: 502-778-2791 ■ Quote & Order Fax: 1-800-444-0602

F-37464 (09/10)

NOTE: In line w ith its p olicy to continually imp rove its products, Vulcan rese rves the right to change materi als and s pecicatio ns without noti ce.

Loading...

Loading...