Page 1

INSTALLATION, SERVICE &

PARTS MANUAL FOR FRYCAT™

CATALYTIC GAS FRYERS

MODEL: CCFD-2C-KFC

VULCAN-HART CORPORATION, 3600 NORTH POINT BOULEVARD, BALTIMORE, MARYLAND 21222, TEL. (301) 284-0660

Page 2

OPERATING, INSTALLATION AND SERVICE PERSONNEL

Operating information for this equipment has been prepared for use by qualified and/or authorized operating

personnel.

All installation and service on this equipment is to be performed by qualified, certified, licensed and/or

authorized installation or service personnel, with the exception of any marked with a , in front of the part

number.

Service may be obtained by contacting the Factory Service Department, Factory Representative or Local

Service Agency.

DEFINITIONS

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified or authorized operating personnel are those who have carefully read the information in this manual

and are familiar with the equipment's functions or have had previous experience with the operation of the

equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, a firm, corporation or company which either in person or

through a representative are engaged in, and are responsible for:

1. The installation of gas piping from the outlet side of the gas meter, or the service regulator when the meter

is not provided, and the connection and installation of the gas appliance. Qualified installation personnel

must be experienced in such work, be familiar with all precautions required, and have complied with all

requirements of state or local authorities having jurisdiction. Reference in the United States of America National Fuel Gas code ANSI Z223 1 (Latest Edition) In Canada-Canadian Standard CAN1-B149 1 NAT

GAS (Latest Edition) or CAN1-B149 2 PROPANE (Latest Edition).

2. The installation of electrical wiring from the electric meter, main control box or service outlet to the electric

appliance. Qualified installation personnel must be experienced in such work, be familiar with all

precautions required, and have complied with all requirements of state or local authorities having

jurisdiction. Reference In the United States of America-National Electrical Code ANSI NFPA No 70 (Latest

Edition) In Canada-Canadian Electrical Code Part 1 CSA-C22 1 (Latest Edition).

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Vulcan equipment who have been endorsed by

the Vulcan-Hart Corporation. All authorized service personnel are required to be equipped with a complete

set of service parts manuals and stock a minimum amount of parts for Vulcan equipment.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected and packed by

skilled personnel before leaving the factory. The transportation company assumes full responsibility for safe

delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE — Be certain this is noted on freight bill or express receipt and signed by

person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY — Regardless of extent of damage.

3. CONCEALED LOSS OR DAMAGE — If damage is unnoticed until merchandise is unpacked, notify

transportation company or carrier immediately, and file 'concealed damage" claim with them. This should

be done within (15) days of date of delivery is made to you. Be sure to retain container for inspection.

We cannot assume responsibility for damage or loss incurred in transit. We will, however, be glad to

furnish you with necessary documents to support your claim.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

Page 3

IMPORTANT NOTES FOR ALL VULCAN APPLIANCES

1. These units are produced with the best possible workmanship and material. Proper installation is vital if best performance and

appearance are to be achieved. Installer must follow the installation instructions carefully.

2. Information on the construction and installation of ventilating hoods may be obtained from the "Standard for the installation of

equipment for the removal of smoke and grease laden vapors from commercial cooking equipment,” NFPA No 96 (latest edition)

available from the National Fire Protection Association, Battery March Park, Quincy MA 02269.

3. For an appliance equipped with a flexible electric supply cord, the cord is equipped with a three-prong (grounding) plug. This

grounding plug is for your protection against shock hazard and should be plugged directly into a properly grounded three prong

receptacle. Do not cut or remove the grounding prong from this plug If the appliance is not equipped with a grounding plug, and

electric supply is needed, ground the appliance by using the ground lug provided (refer to the wiring diagram).

(FOR GAS APPLIANCES ONLY)

4. Do not obstruct the air flow into and around the appliance. This air flow is necessary for proper combustion of gases and for

ventilation of the appliance. Provisions for ventilation of incoming air supply for the equipment in the room must be in accordance

with National Fuel Gas Code ANSI Z223.1 (latest edition).

5. Do not obstruct the flow of flue gases from the flue duct (when so equipped) located on the rear (or sides) of the appliance. It is

recommended that the flue gases be ventilated to the outside of the building through a ventilation system installed by qualified

personnel.

6. For an appliance equipped with casters, (1) the installation shall be made with a connector that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21.69 (latest edition), and Addenda, Z21. 69a (latest edition), and a quickdisconnect device that complies with the Standard for Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z21.41 (latest

edition), and Addenda, Z21.41 a (latest edition) and Z21.41 b (latest edition), and (2) adequate means must be provided to limit

the movement of the appliance without depending on the connector and the quick-disconnect device or its associated piping to

limit the appliance movement.

If disconnection of the restraint is necessary, reconnect this restraint after the appliance has been returned to its originally

installed position.

7. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing

of that system at test pressures in excess of 1/2 psig (3.45 k Pa).

8. The appliance must be isolated from the gas supply system by closing its individual manual shutoff valve during any pressure

testing of the gas supply system at test pressures equal to or less than 1/2 psig (3.45 k Pa).

CAUTIONS

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS EQUIPMENT OR ANY OTHER APPLIANCE.

1. KEEP THE APPLIANCE FREE AND CLEAR FROM ALL COMBUSTIBLE SUBSTANCES.

2. IN THE EVENT A GAS ODOR IS DETECTED, SHUT UNIT(S) DOWN AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

3. POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION MAY BE OBTAINED FROM A

LOCAL GAS SUPPLIER.

Page 4

WARNINGS . . .

FROM THE TERMINATION OF THE

REFERENCE: ANSI/NFPA

96-1984 4

-

1.2.2.2.

OF THE NATIONAL FIRE

DO NOT SPRAY LIQUIDS OR VAPORS ON OR NEAR

WARNING:

EQUIPMENT UTILIZING ELECTRICITY

APPLIANCE FLUE VENT TO THE

FILTERS OF THE HOOD VENTING

SYSTEM, AN 18 INCH MINIMUM

CLEARANCE MUST BE MAINTAINED.

PROTECTION ASSOCIATION, INC., BATTERYMARCH PARK, QUINCY, MA

02269, AND NATIONAL BUILDING CODE 1976 SEC. 1015.7b (2) OF THE

AMERICAN INSURANCE ASSOCIATION. ENGINEERING AND SAFETY

SERVICE, 85 JOHN STREET, NEW YORK, NY 10038

116696-5

Page 5

IMPORTANT NOTES

1. Vulcan units are produced with the best possible workmanship and material. Proper installation is vital if best

performance and appearance is to be achieved. Installer must follow the installation instructions carefully.

2. Keep the appliance area free and clear from all combustible substances,

3. For an appliance equipped with a flexible electric supply cord, the cord is equipped with a three prong (grounding)

plug. This grounding plug is for your protection against shock hazard and should be plugged directly into a three

prong receptacle. Do not cut or remove the grounding prong from this plug. If the appliance is not equipped with a

grounding plug, and electric supply is needed, ground the appliance by using the ground lug provided (refer to the

wiring diagram).

4. Retain this manual for future reference.

IMPORTANT

THIS EQUIPMENT IS DESIGN CERTIFIED BY A NATIONALLY

RECOGNIZED TESTING LABORATORY TO THE

APPROPRIATE NATIONAL STANDARDS AS INDICATED ON

THE EQUIPMENT RATING PLATE. ANY MODIFICATION

WITHOUT WRITTEN PERMISSION OF VULCAN-HART

CORPORATION VOIDS CERTIFICATION AND WARRANTY OF

THIS UNIT.

5. CAUTION: Post in a prominent location, instructions to be followed in the event the smell of gas is detected. This

information may be obtained from a local gas supplier.

6. Do not obstruct the air flow into and around the appliance. This air flow is necessary for proper combustion of gases

and for ventilation of the appliance. Provisions for ventilation and incoming air supply for the equipment in the room

must be in accordance with National Fuel Gas Code ANSI-Z223.1-1984.

7. Do not obstruct the flow of flue gases from the flue duct (when so equipped) located on the rear, sides or top of the

appliance. It is recommended that the flue gases be ventilated to the outside of the building through a ventilation

system installed by qualified personnel.

8. All CCFD-2C-KFC fryers are to be installed with a 6" clearance at the sides and rear adjacent to combustible

construction.

NOTE: An 18" minimum clearance must be maintained when placing a fryer next to adjacent to or behind an open top

flame unit.

9. The unit wiring diagram is packed in a clear plastic Ziploc bag placed within the fryer tank and also printed on the last

page of the CCFD-2C-KFC fryer installation, service and parts manual. A wiring diagram decal may be found

mounted on the inside left hand body side, just beyond the door area.

116696-6

Page 6

INSTALLATION, SERVICE & PARTS MANUAL

FRYCAT™ GAS FRYER MODEL CCFD-2C-KFC INDEX

Your Vulcan fryer is produced with the best possible workmanship Proper usage and maintenance will result in many

years of satisfactory performance.

DESCRIPTION PAGE

The manufacturer suggests that you thoroughly read this entire

manual and carefully follow all of the instructions provided.

DEFINITIONS OF PERSONNEL (Operating, Installation & Service) and

SHIPPING DAMAGE CLAIM PROCEDURES

Warranty Information 116696-3

Cautions 116696-4 thru -5

Important Notes 116696-6

Installation for Units on Casters 116696-8

Uncrating Instructions 116696-9

Electrical Connection 116696-9

Gas Supply Connection 116696-9

Installation Procedures to Verify Fryer Operation 116696-10

Computer Mounting Installation Procedures 116696-10 thru -11

Switch Panel Controls 116696-11

Adding Shortening 116696-11

Initial Operation Instructions 116696-12

Cleaning 116696-12

Blower Motor 116696-12

Door Switch 116696-12

Blower Air Adjustment 116696-13

Foam Pre-Filter Cleaning 116696-13

Ignitor Modules 116696-14

Ignitor Module Reset 116696-14

Setting Ignitor Location 116696-14

High Limit Control 116696-14

Suggestions for Care and Cleaning 116696-14

Removal of Control Box Housing 116696-15 thru -16

Troubleshooting Guides 116696-17 thru -21

Replacements Parts List & Photographs 116696-22 thru -32

Replacements Parts List & Exploded View 116696-33 thru 35

Wiring Diagram 116696-36

Revision Page (Inside Back Cover)

(Inside Front Cover)

SERVICE NOTE:

DO NOT ATTEMPT TO REMOVE SPARK IGNITORS OR BURNERS WITHOUT

CONSULTING VULCAN-HART SERVICE DEPARTMENT.

TELEPHONE: 1-800-638-2474

CAUTION: ELECTRICIAN

CONTINUITY OF ELECTRICAL GROUND TO WHICH THIS APPLIANCE WILL BE

CONNECTED MUST BE CONFIRMED. SEVERE DAMAGE TO ELECTRONIC

COMPONENTS CAN OCCUR AS A RESULT OF INADEQUATE GROUNDING.

116696-7

Page 7

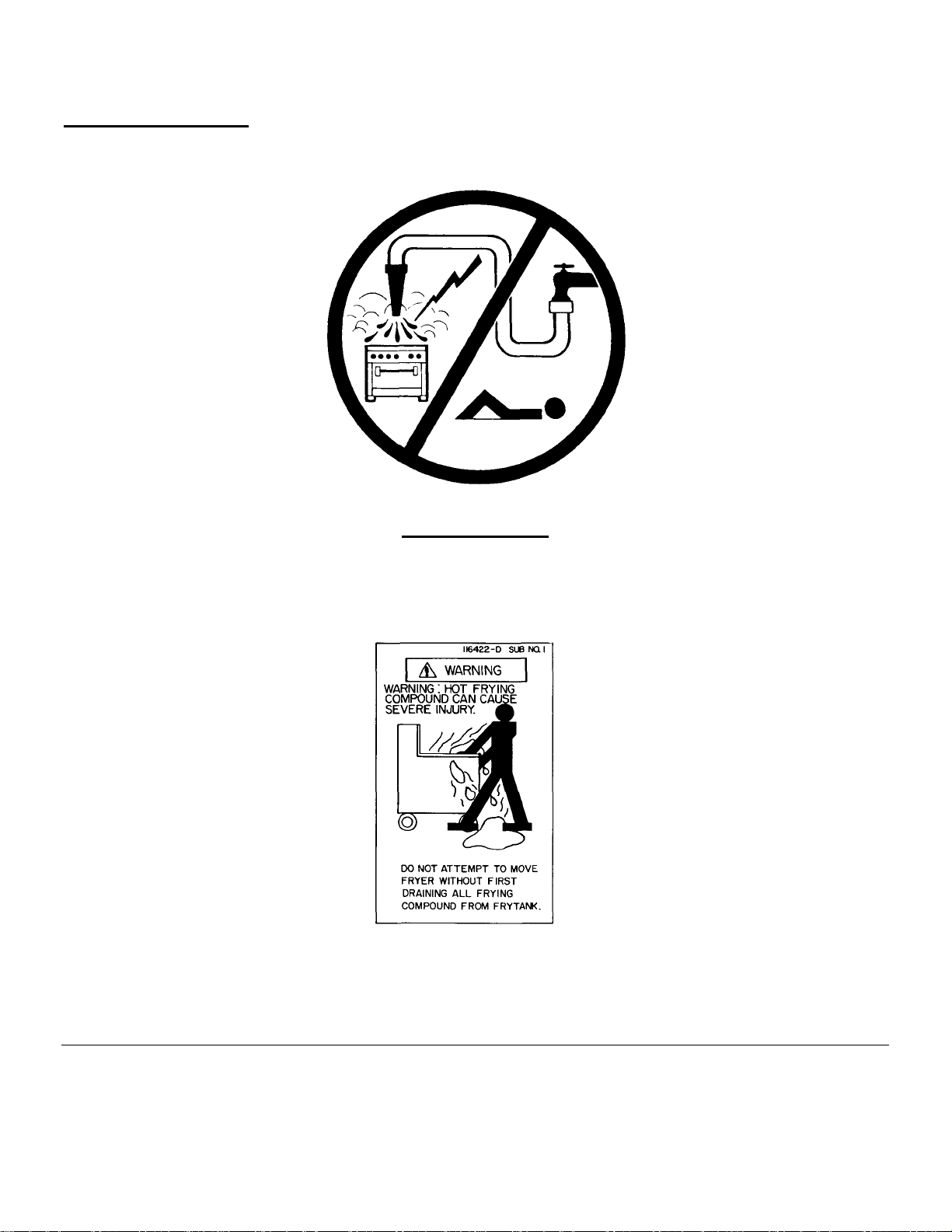

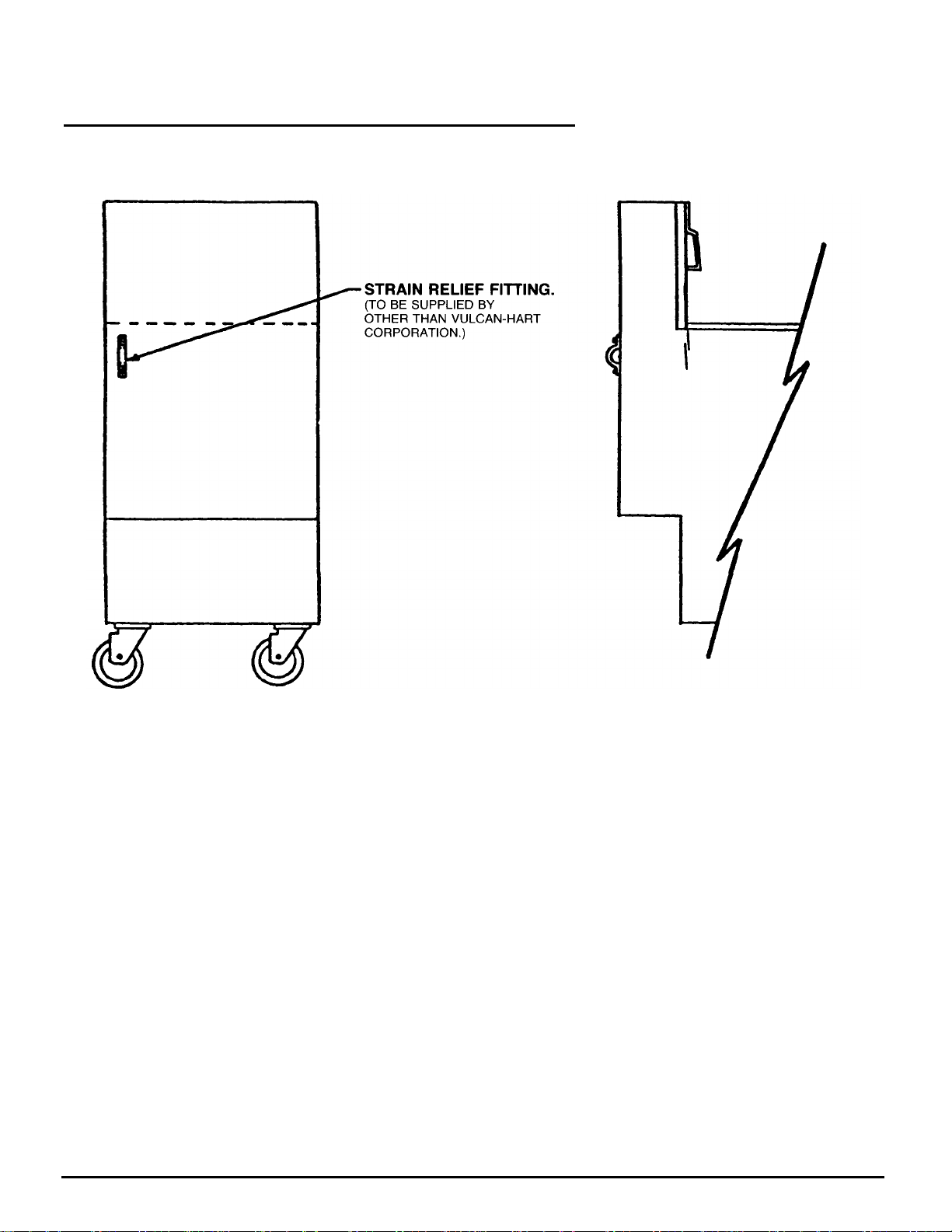

INSTALLATION FOR UNITS ON CASTERS

NOTE: All units on casters must be installed with a gas connector that complies with the American

National Standard ANSI Z21.69-1979 for movable gas appliances.

UNITS MOUNTED ON CASTERS UTILIZING A FLEX HOSE AND QUICK DISCONNECT GAS

CONNECTION MUST BE INSTALLED WITH RESTRAINING DEVICE AT ALL TIMES. THE

RESTRAINING DEVICE IS TO BE SUPPLIED BY OTHER THAN VULCAN-HART

CORPORATION.

If necessary, appliance strain relief may be disconnected when moving unit for cleaning. However,

caution must be taken that the gas supply has been turned off and disconnected. Reconnect

harness prior to the reconnecting of the gas supply and restoring unit to position and operation.

116696-8

Page 8

UNCRATING INSTRUCTIONS

DETAIL A

116696

-

9

The following procedure should be followed when uncrating all CCF fryers.

NOTE: Personnel required to perform uncrating proce-

dure (2).

1. Place crated unit in open area near to final installation

locality.

2. Using band cutters, carefully remove (2) outer crating

straps.

3. Unfold cardboard crate top and remove (4) cardboard

cover protector sleeves.

4. Lift cardboard crate shell from unit.

5. Using band cutters, carefully remove (2) inner crating

straps.

6. Remove (2) cardboard protector sleeves from top right

and left hand tank sides.

7. Remove clear plastic protective cover from unit.

ELECTRICAL CONNECTION

Improper grounding and/or polarity will result in lock out

of unit and eventual damage to the ignition systems. The

unit is supplied with a 10 foot long 3 wire supply cord.

This appliance is equipped with a 3 prong (grounding)

8. Carefully lift unit styrofoam support block and wood

crating platform, then gently rest unit onto the floor.

9. Check unit packaging in areas indicated for the

following items:

FRYER TANK

A. Instruction Manual Packet (1).

B. Wiring Diagram Packet (1).

C. Clean-Out Rod (1).

D. Basket Supports (2).

E. Drain Pipe (1).

Items missing from the above packing list may be

obtained by contacting the local area Vulcan parts

depot or the Vulcan-Hart Corporation, Baltimore,

Maryland - Division Parts Department.

10. Discard crating materials.

11. Gently lift unit front and carefully wheel fryer to final

installation location.

plug for your protection against shock hazard and should

be plugged directly into a properly grounded three prong

receptacle. DO NOT cut or remove the grounding prong

from this plug. (DETAIL A)

GAS SUPPLY CONNECTION

For proper functioning of the CCF catalytic fryers, a gas

main feed inlet pressure of at least 5.0" W.C. (Water Column) but not more than 8.75" W.C. must be maintained

for natural gas while the unit is in operation. A gas main

feed inlet pressure of at least 12.0" W.C. but not more

than 13.0"W.C. must be maintained for propane gas

while the unit is in operation.

The pressure regulator setting of the CCFD-2C-KFC fryer

is 3.0"W.C. for natural gas and 9.0" W.C. for propane

gas.

When connecting unit to gas supply, installation

personnel must install this equipment in accordance with

all state and local authorities having jurisdiction. Refer to

inside front cover of manual under qualified personnel,

ITEM NO. 1.

All gas supply connections and any pipe joint compound

used must be resistant to the action of propane gases.

Pipe joints should be tested for leaks with a soap and

water solution before operating unit. (DETAIL A)

Page 9

INSTALLATION PROCEDURES TO VERIFY

FRYER OPERATION

After making all electrical and gas connections, verify

fryer operation before installing computer as follows:

NOTE: An independent gas shut-off valve is supplied

within the fryer unit location to the rear of the gas

manifold system connecting to the 1/2" inlet gas pipe. This

shut-off valve must be in open position for proper unit

functioning.

1. Clean fryer tank as stated within the K.F.C. C.O.M.

and fill melted shortening to 1/2" below the vat full

mark.

2. Packing fryer vat with solid shortening

A. Remove basket rack supports.

B. Place solid cube of shortening to the rear of the

fryer tank. On split vat models be sure to push

cube down over the center divider in equal

sections.

C. Chop shortening cube up and pack shortening

well all around the heat exchanger tubes and

thermistor probe(s).

D. Replace basket rack supports in correct position

on top of the packed solid shortening.

E. Turn unit on and place unit into fat melt operation.

HAZARD NOTE: Failure to pack solid shortening as

described above may result in vat fire. Caution

should be taken and fryer should not be left

unattended.

3. Close fryer doors.

4. Check left side vat operation first by pushing left side

power switch to "ON" position. Verify fryer operation

and turn left vat side "OFF".

5. Check right side vat operation by pushing right side

power switch to "ON". Verify right side fryer operation.

6. Push left side power switch back "ON" and verify

simultaneous operation of both vats.

7. Allow fryer to operate for two to three minutes.

8. Shut fryer "OFF" and unplug electric supply. This completes fryer operation check out. NOTE: If fryer fails to

operate during any of the above procedures, verify

gas supply, electrical connections and refer to VulcanHart troubleshooting instructions.

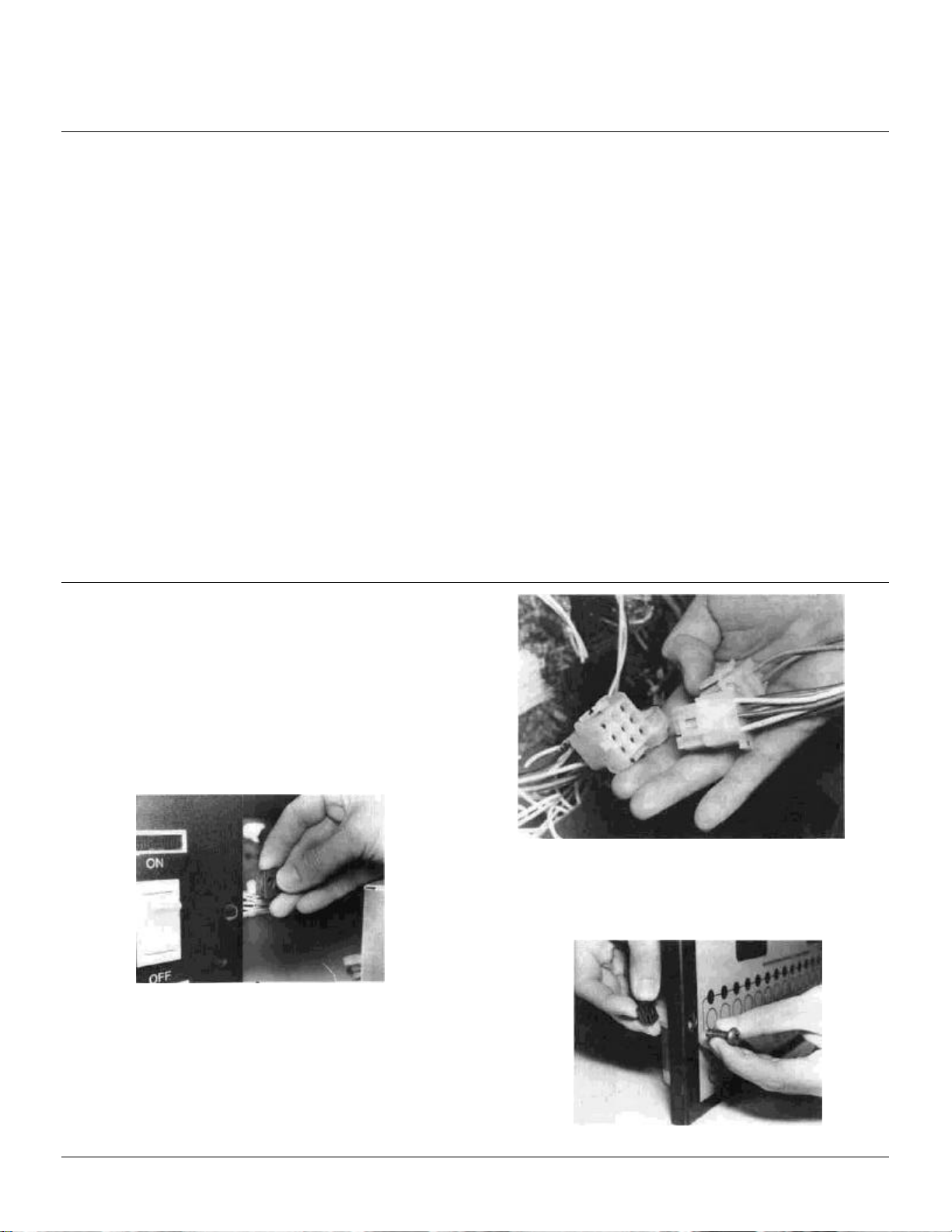

COMPUTER MOUNTING INSTALLATION PROCEDURES

After verifying fryer operation, mount the computer panel

separately supplied by Stratford Control Systems, Inc. to

the CCFD-2C-KFC fryer following the instructions below:

1. Remove computer from shipment package.

2. Remove (2) black screws and (2) tinnerman nuts from

the right (RT.) and left (LT.) hand sides of the

computer panel.

3. Place clip section of tinnerman nuts (1 ea.) onto the

RT. & LT. hand fryer control housing frame. (See

Detail B).

DETAIL C

6. Align tinnerman nuts and computer mounting holes.

7. Reinstall black screws to the RT. and LT. hand sides

of the computer panel. Be sure screws are tightly secured. (See Detail D).

DETAIL B

4. Connect (2) sets of wiring harness cables (1 set for

LT. vat and 1 set for RT. vat.) supplied with the fryer

to the plugs provided on the rear of the computer

panel. (See Detail C).

5. Insert computer panel into the rectangular spacing

provided in the control housing frame.

116696-10

DETAIL D

Page 10

COMPUTER MOUNTING INSTALLATION PROCEDURES

116696

-

11

NOTE: Check (FAST) operating instructions to verify cor-

rect computer installation and operation procedures.

8. Verify computer operation as follows:

A. Close fryer doors and plug in fryer electrical supply

cord.

B. Push right and left vat power switches to "ON".

C. Allow unit to heat up to frying temperature.

NOTE: If computer display reads LO-R or LO-L, the fryer

is in the automatic melt mode and the burner may not

come on immediately. When unit reaches programmed

frying temperature, computer display will indicate cooking

mode as described in the (FAST) computer operation instructions.

D. This completes the computer check-out procedure.

NOTE: If computer does not operate properly, refer

to (FAST) troubleshooting instructions.

SWITCH PANEL CONTROLS CCFD-2C-KFC

1. Power Switch "ON-OFF" - Controls electric supply to

unit.

2. Panel "ON" Light - Light "ON" indicates that electric

supply is functioning.

3. Microprocessor Controlled Cooking Computer -

Preprogramming device which, when activated, controls unit frying modes. (Computer supplied by other

than Vulcan-Hart Corp.) (See Detail E).

4. Heating Light - When "ON" indicates that the temperature controller is calling for gas to the burner.

5. Trouble Light - When "ON" indicates that ignition device has locked out (reset required). NOTE: To reset,

turn power switch "OFF" then "ON".

DETAIL E

ADDING SHORTENING

REFER TO CONFIDENTIAL OPERATION MANUAL.

See also pg. 10 of this manual (Packing fryer vat with solid shortening).

Page 11

INITIAL OPERATION INSTRUCTIONS

DETAIL F

116696

-12

1. Push power supply rocker switch to "ON" position.

NOTE: Gas line service valve must be in "OPEN"

position and all power supply cords and harness cables

must be connected to the unit power source for

operational functioning. The independent gas shut-off

valve supplied within the unit located to the rear of the

unit manifold system connecting to the 1/2" inlet pipe

must be in the open position for proper unit operation.

NOTE: If the shortening temperature is less than 185°F

the fryer is in the automatic melt mode and the burner

During the first few "ON" pulses, the trouble indicator

light may come on indicating no ignition due to air in the

gas line. If this happens, turn the rocker switch off and

then back on and try again.

For service or extended shutdown, turn service valve to

"CLOSED" position, push unit power supply rocker

switch to "OFF" position and disconnect power supply

cord from main power source.

The above information may also be found on the inside

fryer door panel.

may not come on immediately. In this mode, the burner

pulses "ON" 4 seconds and "OFF" 26 seconds.

CLEANING__________________________________________________

New fryer tanks must be cleaned before filling with shortening.

REFER TO KFC CONFIDENTIAL OPERATION MANUAL.

BLOWER MOTOR

CCFD-2C-KFC series fryers are equipped with a factory

installed blower motor. Proper operation of the blower

motor is vital to the fryer performance. The blower motor

is the main source of air flow servicing the burner ignition

system.

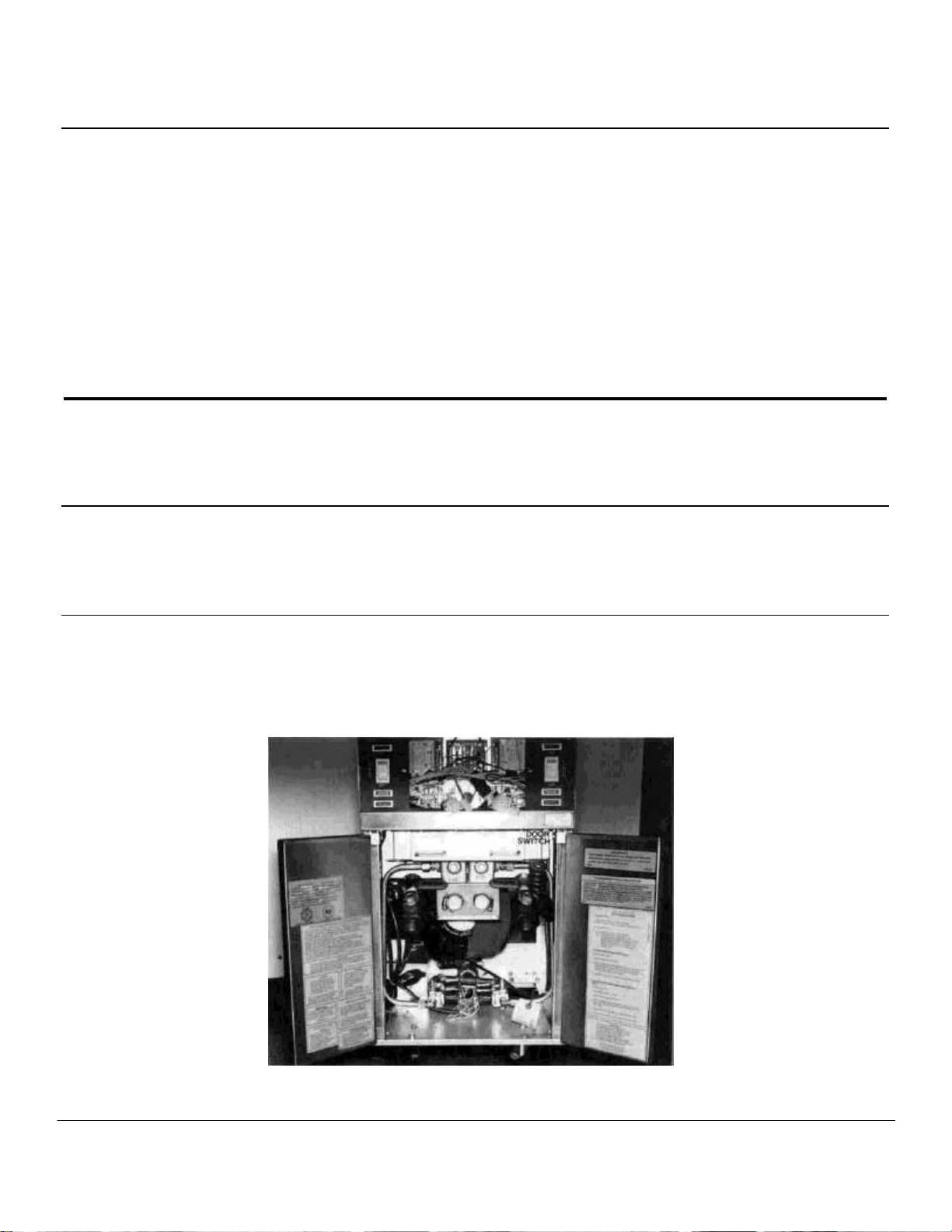

DOOR SWTICH

Each CCFD-2C-KFC fryer is equipped with a door safety

switch that will automatically shut the unit down when the

fryer door is opened. However, operating and service

personnel should NOT rely on door switch to shut unit

down while working inside the door panel control area.

WARNING: Do not rely on door switch to shut unit power

down. Push fryer power switch to "OFF" before entering

the inside door panel control area for filtering or servicing.

By-passing the fryer door switch should be done by

service personnel only. (See Detail F).

Page 12

BLOWER AIR ADJUSTMENT

NOTE: The critical air adjustment for each burner has

been factory tested and set. Further adjustment should

not be required unless the fryer is being installed above

2,000 ft. elevation or burner or fan replacement has been

made. If air adjustment is necessary, contact local

service agency. (Refer to color trend guide chart.)

NOTE: All CCFD-2C-KFC series fryers are equipped with

an air filter. This filter must be in place at all times during

unit operation. Failure to use air filter will result in unit

breakdown and will automatically void all warranties

associated with the unit.

The air filter is a critical part of the unit functioning and

should be checked frequently. Clean foam pre-filter when

soiling becomes apparent.

FOAM PRE-FILTER CLEANING

To clean CCF series pre-filters, follow steps 1 thru 7 from

air filter replacement of windjammer or swirlwind blower

systems below. After removing filter element assembly,

detach the gray foam pre-filter from the filter element.

Wash foam piece out in lukewarm water using a mild

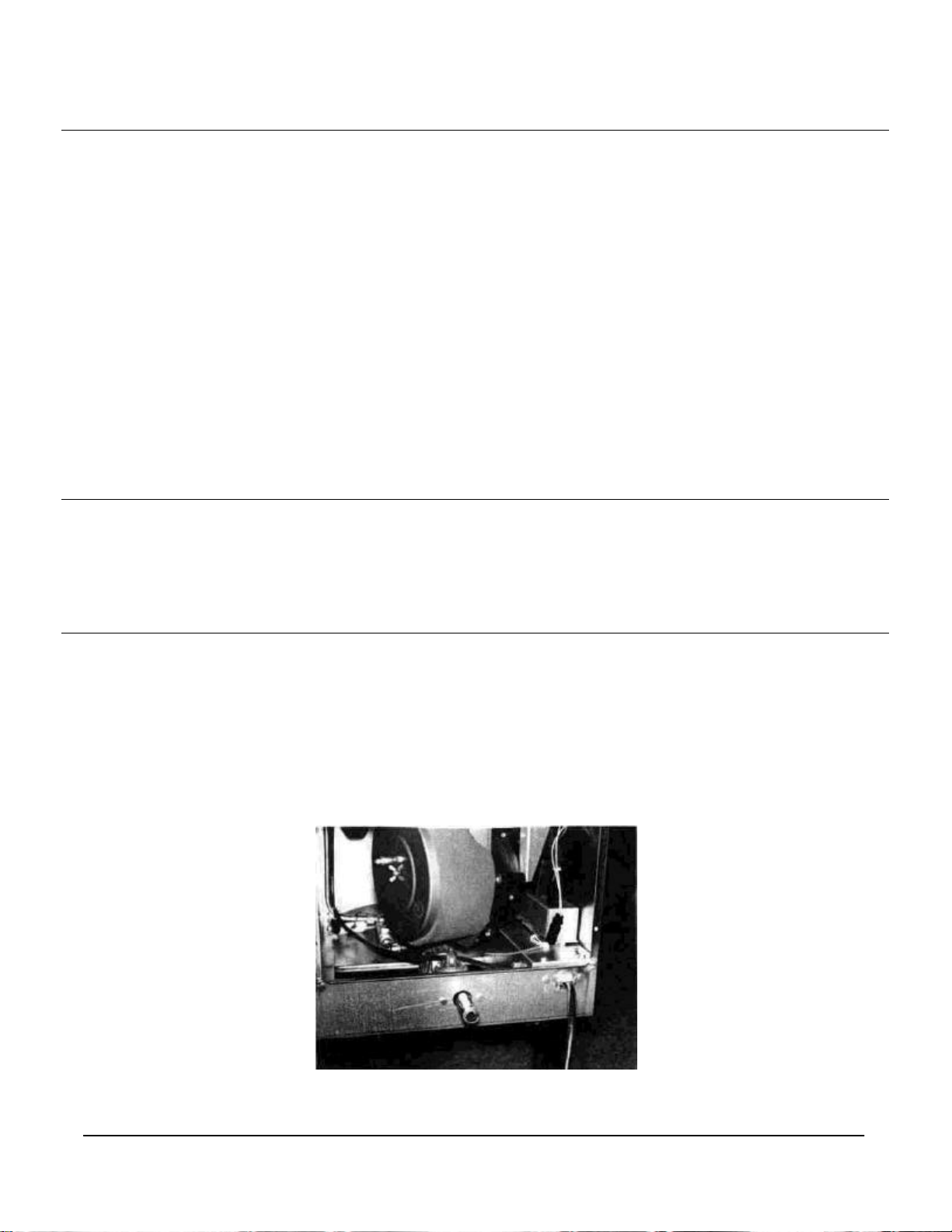

CYLINDRICAL (SOLBERG) AIR FILTER REPLACEMENT FOR USE

WITH WINDJAMMER OR SWIRLWIND BLOWER SYSTEMS

CONSTRUCTED AFTER 2-9-87

NOTE: Blower air filter is serviceable from rear of unit only. (Refer to Detail G. - Refer also to blower air adjustment

notation above and page 13 of KFC Manual 116697-G1).

To replace blower air filter, follow the steps below:

1. Push power switch to "OFF".

2. Disconnect filter receptacle.

3. Disconnect power supply cord.

4. Disconnect gas supply, if necessary to make unit accessible from rear.

5. Remove wing nut from blower mounting bracket.

6. Remove filter cover cap from blower mounting bracket.

7. Remove filter from blower mounting bracket.

8. Check replacement filter element. Be sure gray pre-filter covers entire surface of filter element.

9. Install filter onto blower mounting bracket. (Turn until very tight.)

10. Install filter cover cap securely with flanged side against filter assembly. NOTE: Cap must be tightly fitted

against filter assembly to insure proper filtration of dust particles.

11. Reinstall wing nut to blower mounting bracket.

12. Reconnect gas supply and power supply line.

13. Reposition fryer and connect filter receptacle.

14. Push power switch to "ON" position and continue with normal unit operating procedures.

soap solution. Rinse with cool water and ring dry. Evenly

reinstall the gray foam pre-filter over the entire filter element. To reinstall filter element assembly onto the unit,

follow steps 8 thru 14 from air filter replacement of

windjammer or swirlwind blower systems below.

DETAIL G

116696-13

Page 13

CCFD-2C-KFC UNIT IGNITOR MODULES

INTERFACE BOARDS, IGNITORS, BURNER, HIGH LIMIT

AND TANK PROBE FUNCTIONS

1. Igniter Modules: An electrode module (2 required per

unit) which accepts electric signals from the interface

board to energize the spark igniters.

2. Igniters: An electronic device which passes an ignition spark to ignite the fryer burners (2 required per

unit).

3. Burners: Fibermatrix heat exchanging device which

provides the main source of infrared type heat for fryer

operation.

4. High Limit Control: An electronic device that will shut

the unit down in the event of thermostat failure. The

operating temperature of the high limit control is 435°F

or 60°F (223.8°C or 15.5°C) higher than the highest

temperature allowed by the thermostat. In the event of

a high limit "shut-down", the entire control system will

be put out of operation. DO NOT attempt to restart the

IGNITOR MODULE RESET

The igniter module reset system protects the igniter modules from overloads.

If trouble light illuminates immediately after the power

fryer until the shortening temperature has lowered to

approximately 350°F (176.6°C). CAUTION: If this

situation continually occurs, DO NOT attempt to

bypass the high limit. Shut unit down and contact an

authorized factory service agency.

5. High Limit Probe: An electronically actuated device

mounted through the right side of the front tank wall

which senses the shortening temperature to allow the

high limit monitoring of unit over heating conditions.

6. Thermistor Probe: An electronically actuated device

mounted through the tank front wall which senses

shortening temperature allowing the temperature

control board to monitor unit heating.

7. Interface Board: A back-up temperature controlling

circuit board that will allow fryer to operate in the event

the computer controller were to fail.

switch is activated, turn fryer power switch "OFF", and back

"ON". If after second attempt, fryer continues to malfunction,

turn fryer "OFF" and contact service agency.

SETTING IGNITOR LOCATION

This setting will provide optimum ignition reliability and

prevent igniter module lockout. The igniter location is factory set and should not require adjustment unless the

igniter has been replaced or has been knocked out of

adjustment.

Should adjustment become necessary, contact local service agency.

HIGH LIMIT CONTROL

The function of high limit control is to shut the unit down

in the event of a thermostat failure which would allow the

cooking oil to be overheated. The operating temperature

of the high limit control is 435°F or 60°F (223.8°C or

15.5°C) higher than the highest temperature allowed by

the thermostat.

In the event of a high limit "shutdown", the entire control

system will be put out of operation.

DO NOT attempt to restart the fryer until the temperature

of the cooking oil has lowered to approximately 350°F

(176.6°C).

If the situation continually occurs, do not attempt to

bypass the high limit. Shut unit down and contact a

service agency.

SUGGESTIONS FOR CARE AND CLEANING

REFER TO KFC CONFIDENTIAL OPERATION MANUAL.

116696-14

Page 14

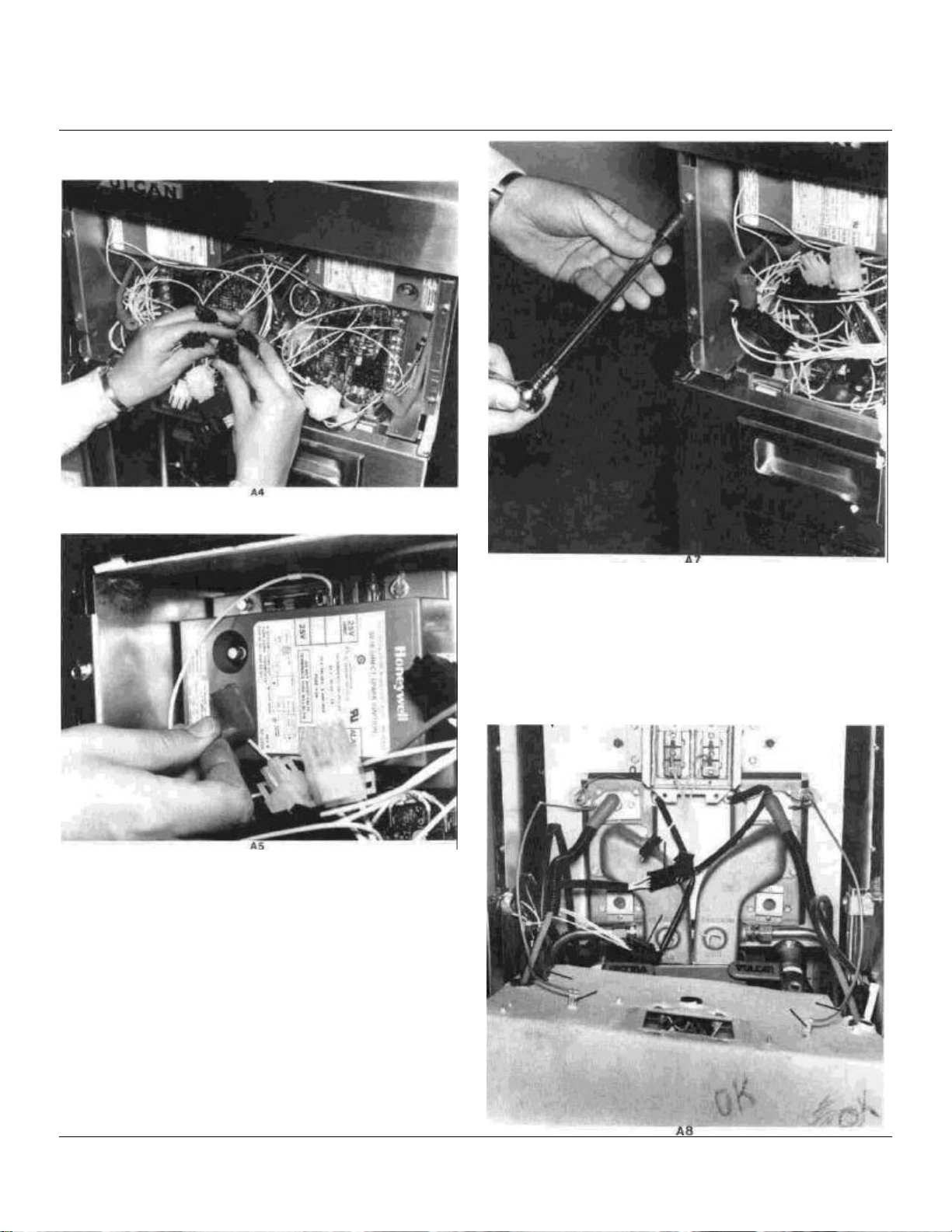

REMOVAL OF CONTROL BOX HOUSING

15

For servicing of computer panel, igniter module, interface

boards; follow steps A1 thru A3.

For removal of igniters, high limit, burners or probes, follow

steps A1 thru A9.

NOTE: During servicing before installing any new probe,

A1. Remove (2) screws from the top left (LT.) and right

(RT.) hand (HD.) corners of the control panel front.

(Photo A1).

wrap probe threaded end with Teflon tape to prevent tank

leakage.

To remove computer panel or gain access to reset button,

igniter modules and interface boards:

A3. Detach the computer panel assembly from the fryer

body. If complete removal is desired, disconnect (2 sets

for LT. SD. vat and (1) set for RT. SD. vat) wiring

harness plugs. Panel may now be completely removed to

access computer or igniter modules and interface

boards. (Photo A3)

A2. Open fryer doors and remove (2) screws located beneath the lower front channel RT. and LT. HD. sides.

(Photo A2)

To service igniter burners, assemblies, high limit and

tank probes, remove control housing following steps A4

thru A9 on page 16.

116696-

Page 15

REMOVAL OF CONTROL BOX HOUSING (Cont.)

A4. Disconnect all remaining wire leads and igniter wires

from the control area. (Photos A4 & A5)

A5. Disengage (4) screws positioned along the RT. and

LT. hand control housing box front side flanges. (Photo

A7)

A6. Disengage (4) screws securing housing to high limit

bracket.

A7. Disconnect high limit wire connector plug.

A8. Remove housing box assembly from fryer frame. Dis-

connect main power wire harness plug and (2) green ignitor module ground wires (photo A8). Now housing may

be completely removed from unit. This will allow complete

servicing access to the burners, ignitors, high limit and

unit tank probes.

116696-16

Page 16

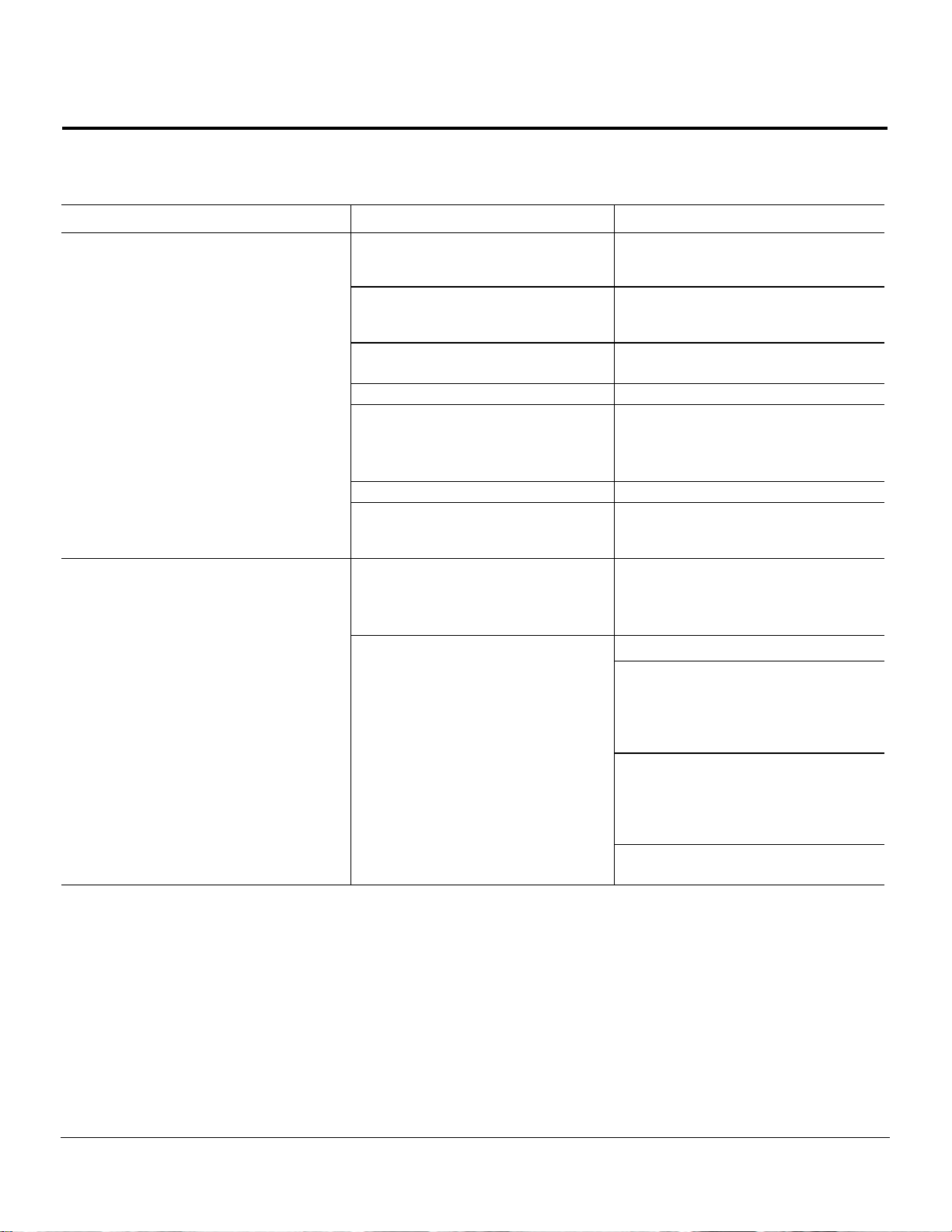

TROUBLESHOOTING GUIDE

CAUTIONS

• Be sure air filters are properly in place at all times.

• When reinstalling control box, be sure not to pinch wiring between control box and burner tubes. Be sure

ignitor ground (green) wires are connected to the (2) 1/4" tabs on the back of the box.

• When connecting interface harness to P.C. boards, do not exert excessive force, board damage may result.

• When removing or installing ignitors, do not allow ignitor to brush against burner. Permanent burner damage

may result.

• Refer to wiring diagram C116597-2.

• WARNING: Blower relay turns on 120 volt A.C. to blower. Be sure fryer is "unplugged" when working with

blower and blower relay wiring.

WHEN TROUBLESHOOTING, THE FOLLOWING QUICK CHECK SHOULD BE DONE FIRST TO DETERMINE IF

PROBLEM IS DUE TO COMPUTER MALFUNCTION OR FRYER MALFUNCTION.

1. Push unit power switch to "OFF" on both left and right side of control panel.

2. Disconnect unit electric supply.

3. Remove (2) screws securing computer panel.

4. Disconnect both sets of computer wire harnesses. (1) set

for left side vat and (1) set for right side vat.

5. Reconnect unit electrical supply.

6. Verify fryer operation using steps 1 thru 7 described in the installation procedures section of this manual.

NOTE: Upon completion of the above check, if fryer operation seems normal then problem area has been

isolated to a computer malfunction.

If fryer is not operating properly, refer to the following pages for possible troubleshooting solutions.

IMPORTANT TO READ FIRST

116696-17

Page 17

TROUBLESHOOTING GUIDE (Cont.)____________________________

Before servicing this equipment, read through the applicable sections in their entirety and read all "CAUTIONS"

at the beginning of this guide.

PROBLEM CAUSE REMEDY

LOUD IGNITION

NO HEAT

Improper gas pressure (Nat. gas) Manifold regulator pressure should be set

at 3.0" W.C. main feed pressure should

not drop below 5.0" W.C.

(Propane gas) Main manifold pressure should be set at

9.0" W.C. and main feed pressure should

not drop below 11.0" W.C.

Air Adjustment Adjust air so that burner is at full intensity

within 3 seconds.

Defective high voltage ignitor wire Replace high voltage lead.

Defective ignitor Allowing spark leakage or intermittent

spark. Replace ignitor. (Sparking can be

clearly heard when listening at front of unit

with door open.)

Improper spark gap Check and set gap to. 160".

Obstructed ignitor Remove ignitor, check ignitor gap for

burner particles or carbon, clean off

particles and reinstall ignition.

Door switch malfunction Be sure door switches are activating when

doors are closed. (When doors are open,

pull out door switch posts to activate and

observe operation.)

No electrical power

Check for 110V supply to fryer.

Check for 24V grounded ignition system

power. Check for 24V AC to ground at

wire #1 of both power switches. If no

voltage, then check for AC voltage

input/output at rear most transformer.

Check for 24 VAC isolated "computer"

power between wires # 16 & # 17 on both

interface boards. If no voltage, check for

AC voltage input/output of forward most

transformer.

Make sure all wiring harness connectors

are engaged and locked in place.

116696-18

Page 18

TROUBLESHOOTING GUIDE (Cont.)

PROBLEM CAUSE REMEDY

NO HEAT (Cont.) Malfunctioning sensors Check thermistor probe terminations

on "back-up" interface P.C. boards. Be

sure terminations are not touching or

shorted. Probe terminations are

labeled on P.C. boards as "PRB-1" and

"PRB-2" (two terminals each) remove

one or both PRB-1 wires. Measure

OHMS resistance through the wires. If

fryer is cold, resistance is about 100-K

OHMS. If reading is infinity-probe is

defective-replace probe. If reading is

zero-check wires for a direct short,

replace probe if necessary. Repeat

this procedure and check PRB-2 wires.

NOTE: PRB-2 is probe connection

for computer.

PRB-1 is probe connection

for back-up interface control.

Computer & back-up interface If computer is displaying "PROB" or

system has no display, check interface

harness (from computer to interface

P.C. boards) to be sure all connectors

are properly engaged and check

connectors to be sure all pins are

securely in place. If harness seems

to be in proper condition, but computer

still displays "PROB", refer to

"Malfunctioning sensors". Disconnect

computer wiring harness from P.C.

boards. Fryer should operate on

back-up temperature control. This

would indicate a defective computer or

computer interface. Replace as

required. If unit still fails to operatecheck for 24V supply across terminal

#5 and #6 of back-up interface

board. If power supply is confirmedreplace P.C. board.

TROUBLE LIGHT "FLASHES" Normal operation

THEN "HEATING" LIGHT COMES ON

TROUBLE LIGHT COMES ON Indicates power to ignitor module Check 3A fuse on ignitor module. If

AND STAYS ON input, but no power out. bad, look for short circuit or ground

on ignitor board output (overload)

before replacing fuse.

Defective ignitor module. Replace.

116696-19

Page 19

TROUBLESHOOTING GUIDE (Cont.)_____________________________

section.

PROBLEM CAUSE REMEDY

TROUBLE LIGHT "ON"

No gas

No air supply

Improper air supply If air adjustment is way off, either too

Improper or no burner flame If burner is lighting, but a blue flame is

Check "in-house" plumbing for shut-off

valves and fire protection valves to be

sure they are open.

Be sure flexible hose is connected to fryer.

Be sure shut-off valve in fryer is open.

Be sure solenoid wires are securely

connected, and supplying 24V when fryer

calls for heat.

Check for blower operation - voltage

supply, harness connections, jammed

wheel blower or defective motor. Replace

if necessary.

Check blower relay for normal operation.

Blower relay energizes when either left or

right power switch is turned on. Replace if

defective (24 VAC coil).

much or too little, burners may not ignite -

adjust air as required.

present, check air filter-replace if

necessary. If problem still exists, take the

following steps:

• Check blower for proper operation.

• Check gas pressure and air adjustments

as described in the "Loud Lighting"

Second high limit open

Loss of flame sense Make sure green ground wires of ignitor

• If burner won't brighten, replace burner.

Make sure 2nd hi-limit plugs are locked in

place.

Make sure hi-limit switches are closed (If

oil temp. is below 435°F.)

boards are seated to their terminals on

ignitor boards. Check for proper electrode

grounding. (See troubleshooting guide

"Cautions").

116696-20

Page 20

TROUBLESHOOTING GUIDE (Cont.)____________________________

116696

-21

PROBLEM CAUSE REMEDY

UNIT HAS NO FAT MELT CYCLE Computer is inoperative and unit is

operating on "back-up" interface board

Make sure computer harnesses are

attached.

Refer to "Malfunctioning Sensor" section.

NOTE: If above checks OK, then replace

computer.

COMPUTER (INTERMITTENT)

Bad computer connections Faulty

harness.

General wiring problems related to

interface wire harness.

Check for pins not seated in connections. FRYER OPERATING WITHOUT

Check for connectors to be mated and

locked in position.

Page 21

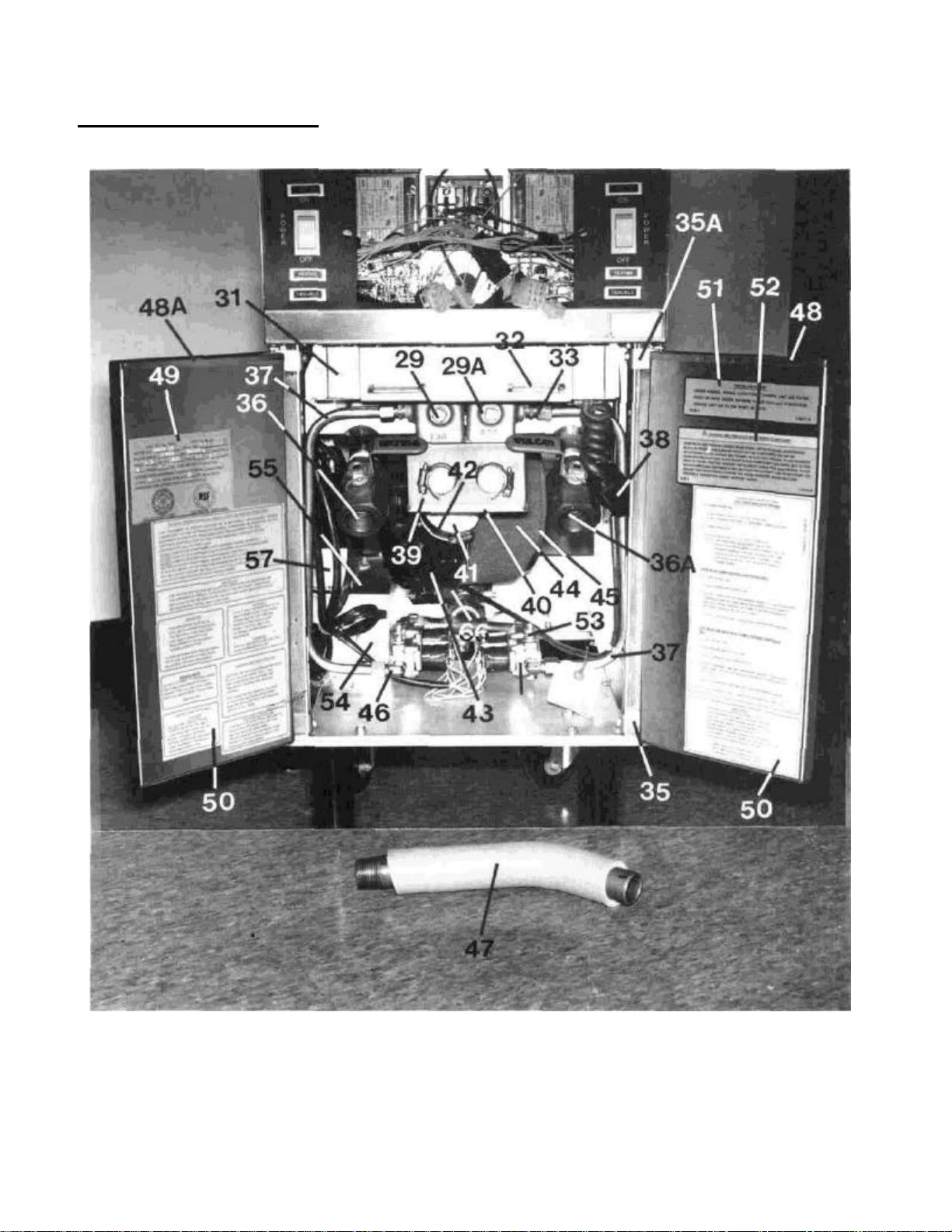

REPLACEMENT PARTS LIST & PHOTOGRAPHS

REPLACEMENT PARTS LIST AND PHOTOGRAPHS

FOR CCFD-2C-KFC SERIES FRYERS

WARNING ALL SERVICE PERSONNEL

WHEN SERVICING THIS EQUIPMENT, USE ONLY CERTIFIED (U.L. OR A.G.A.)

CONTROLS, DUPLICATING THOSE ORIGINALLY SUPPLIED ON THIS EQUIPMENT BY

VULCAN-HART CORPORATION

DO NOT SUBSTITUTE COMPONENTS WITH DIFFERENT MODEL NUMBER

DO NOT SUBSTITUTE COMPONENTS WITH DIFFERENT MANUFACTURING NAMES

DO NOT SUBSTITUTE COMPONENTS WITH REBUILT CONTROLS WITHOUT AUTHORIZATION FROM VULCAN-HART CORP.

ANY UNAUTHORIZED SUBSTITUTION OF CONTROLS AS STATED ABOVE MAY BE A SAFETY HAZARD AND WILL

AUTOMATICALLY VOID THE WARRANTY AND THE CERTIFICATION ASSOCIATED WITH THIS EQUIPMENT.

REPLACEMENT PARTS ORDERS:

The following information must accompany a replacement parts order or it cannot be filled:

A. Model and Serial Number.

B. Type of Gas.

C. Unit Voltage, Amperage and Motor Phase.

D. Appliance Finish Black, Grey, Stainless steel, etc.

This information may be found on the unit rating plate located inside the fryer door panel.

Parts may be ordered from your dealer, service agency or parts distributor. For information concerning parts ordering location

contact:

VULCAN-HART CORPORATION

VULCAN-HART CANADA 3600 NORTH POINT BLVD. OR

79 WEST STREET, SOUTH BALTIMORE, MD 21222 ORILLILA, ONTARIO L3V 6K5

SERVICE NOTE:

DO NOT ATTEMPT TO REMOVE SPARK IGNITORS OR BURNERS WITHOUT CONSULTING VULCAN-HART SERVICE

DEPARTMENT: TELEPHONE: 1-800-638-2474

CAUTION: ELECTRICIAN

CONTINUITY OF ELECTRICAL GROUND TO WHICH THIS APPLIANCE WILL BE CONNECTED MUST BE CONFIRMED.

SEVERE DAMAGE TO ELECTRONIC COMPONENTS CAN OCCUR AS A RESULT OF INADEQUATE GROUNDING.

116696-22

Page 22

PARTS LIST (Cont.)__________________________________________

ITEM NO. PART NO. DESCRIPTION QUANTITY

1 115801-G3 Fryer Tank 1

2 116675-G1 LT. Body Side 1

2A 116675-G2 RT. Body Side (NS) 1

3 116493-G1 Front Top Assembly 1

4 116480-G9 Frame Control Panel Assembly 1

5 116527-D1 Control Panel Mylar 1

6 114123-G5 Panel Assembly Door Front (RT. HD.) 1

6A 114123-G4 Panel Assembly Door Front (LT. HD.) 1

7 115843-G2 Leg Assembly 4

8 110118-22 Caster 2

9 113112-5 Leg 9" 2

73 114211-1 Door Handle 2

116696-23

Page 23

PARTS LIST (Cont.)

ITEM NO. PART NO. DESCRIPTION QUANTITY

4 116480-G9 Frame Control Panel Assembly 1

5 116527-D1 Decal Control Panel 1

10 111496-E13 Light-28V Heating 2

11 111496-E10 Light-28V Trouble 2

12 111496-E8 Light-Single Red 2

13 111496-B1 Power Switch 2

116696-24

Page 24

PARTS LIST (Cont.)__________________________________________

ITEM NO. PART NO. DESCRIPTION QUANTITY

14 116475-G1 Modular Control Box 1

15 116011-1 Ignitor Module 24V 2

16 116012-1 Board Interface 2

17 114151-4 Relay 24V VAC (NS) 1

17A 116535-1 Relay 24V DC 2

18 114145-2 Second High Limit 2

19 06089 Ground Lug 1

20 114149-8 Ignitor Cable 2

21 115207-1 Mini Cooling Fan 1

22 See Note Below Fuse Ignitor Module 2

23 113840-2 Mini Cooling Fan Thermal Disc (NS) 1

24 115977-2 Mini Fan Cover 1

NOTE: Ignitor module fuse is a standard 250 volt 3 amp fuse obtainable through any good local hardware store or

service agency.

116696-25

Page 25

PARTS LIST (Cont.)__________________________________________

ITEM NO. PART NO. DESCRIPTION QUANTITY

18 114145-2 Second High Limit 2

20 114149-8 Ignitor Cable 2

25 116724-1 Tube Flex (Ignitor Cable) 2

26 114141-3 Thermistor Probe 2

27 116616-1 Sight Glass Cover 2

28 115517-1 Sight Glass 2

29 116446-2 Air Mixing Chamber (LT. HD.) 1

29A 116446-1 Air Mixing Chamber (RT. HD.) 1

30 114715-018-A1 Ignitor Wire to Module (Ground Lead) 2

33 114700-4 Male Straight CC Fitting 3/8" x 1/2" 2

116696-26

Page 26

PARTS LIST (Cont.)___________________________________________

ITEM NO. PART NO. DESCRIPTION

17 114151-4 Relay 24 VAC (NS)

29 116446-2 Air Mixing Chamber (LT. HD.)

29A 116446-1 Air Mixing Chamber (RT. HD.)

31 111496-F2 Door Switch

32 115887-1 Magnet

33 114700-4

34 109290-29 Orifice Spud #29 (Natural) (NS) SELECT AS 2

34A 109290-47 Orifice Spud #47 (Propane) (NS) REQUIRED 2

35 112780-5 Door Hinge (Bottom)

35A 112780-6 Door Hinge (Top)

36 114212-3 Drain Valve (LT. HD.)

36A 114212-4 Drain Valve (RT.HD.)

37 115734-1

38 115998-3 Cord Receptacle

39 115735-G2 Box Assembly Air Adjustor

40 115787-2 Cover, Air Adjustor

41 116640-1 Hose, Primary Air

42 115481-3 Clamp Hose

43 116673-1 Blower Swirlwind

43A 116673-3 Blower Windjammer (SELECT) 1

44 116660-3 Filter Solberg

45 116637-2 Cap, Filter

46 114800-2

47 116656-1 Drain Pipe

48 114123-G5 Door Panel Assembly (RT. HD.)

48A 114123-G4 Door Panel Assembly (LT. HD.)

49 115606-1 Rating Plate

50 116504-D Important Door Decal

51 116516-D1 Fryer Air Filter Decal

52 116576-D Solid Shortening Compound

53 104738-2 Pressure Tap

54 116525-G1 Transformer Base Assembly

55 116526-1 Transformer Cover

56 111500-12 Transformer 40 VA (NS)

57 116478-1 Housing Relay

65 3.0127-3 Filter Cap Wing Nut

66 116642-G1 Blower Filter Bracket

Male Straight CC Fitting 3/8" x 1/2"

Burner Tube 1/2"

Elbow 1/2"- 90°

QUANTITY

1

1

1

2

2

2

2

2

1

1

2

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

116696-27

Page 27

PARTS LIST (Cont.)

116696-28

Page 28

PARTS LIST (Cont.)

ITEM NO. PART NO. DESCRIPTION

46 114800-2 Elbow 1/2" x 3/8" -90°

58 111497-F8 Valve Automatic

59 113500-C6 Pipe Nipple 3/8" x 3/4" long

53 104738-2 Pressure Tap

60 12901 Nozzle

61 114678-1 3/8" Elbow Compression

62 113500-C16 Nipple 3/8 NPT, 2" long

63 114789-7 Tee

64 113500-D7 Close Nipple 1/2" x 1 1/8" long

67 116653-1 Pipe 1/2 NPT

68

68A

69 108604-3 Valve, Shut-Off 1/2 NPT

70 116653-G1 Pipe Inlet Gas 3/4" NPT Assembly

108279-1

108279-3

Regulator (Natural)

Regulator (Propane) (NS)

3/8 x 3/8 x 1/2 NPT

(SELECT)

QUANTITY

2

4

2

3

2

2

2

1

1

1

1

1

1

1

116696-29

Page 29

PARTS LIST (Cont.)

ITEM NO. PART NO. DESCRIPTION QUANTITY

1 115801-G3 Frytank Assembly 1

18 114145-2 Second High Limit 2

26 114141-3 Thermistor Probe 2

116696-30

Page 30

PARTS LIST (Cont.)___________________________________________

ITEM NO. PART NO. DESCRIPTION QUANTITY

8 110118-22 Casters (NS)

43 116673-1 Blower Swirlwind

44 116660-3 Filter Solberg

55 116526-1 Transformer Cover

57 116478-1 Housing Relay

68

68A

69 108604-3 Valve, Shut-Off 1/2 NPT

70 116653-G1 Pipe Inlet Gas 1/2" NPT Assembly

71 116293-D Warning Heat Shield - Decal

45 116637-2 Cap Filter

65 3.0127-3 Filter Wing Nut

73 105016-1 115 Volt Elec. Supply Cord

74 114109-2 Body Back

108279-1

108279-3

Regulator (Natural)

Regulator (Propane)

(SELECT)

1

1

1

1

1

1

1

1

1

2

1

1

1

1

116696-31

Page 31

PARTS LIST (Cont)

ITEM NO. PART NO. DESCRIPTION QUANTITY

18 114145-2 Second High Limit 2

20 114149-8 Ignitor Cable 2

72 114608-G1 Clean-Out Rod Assembly 1

116696-32

Page 32

PARTS LIST (Cont.)___________________________________________

ITEM NO. PART NO. DESCRIPTION QUANTITY

1 116654-1 Body Bottom, Front

2 116655-1 Body Bottom, Rear

3 116675-G1 Body Side Assembly, Left Hand

4 116675-G2 Body Side Assembly, Right Hand

5 114123-G5 Panel Assembly Door, Right Hand

6 114123-G4 Panel Assembly Door, Left Hand

7 112780-6 Hinge Door, Top

8 112780-5 Hinge Door, Bottom

9 115887-1 Magnet Door

10 116525-G1 Base Assembly Transformer

11 111500-12 Transformer 40VA

12 116526-1 Cover Transformer

13 114151-4 Relay 24 Volt (AC)

14 116478-1 Housing Relay

15 113112-5 Leg,9"

16 115843-G2 Leg Assembly

17 110118-22 Caster, 3"

18 105016-1 Supply Cord 115V

19 30314-3 Cord Grip

20 115452-G7 Manifold Assembly

21 114232-G5 Sub-Manifold Assembly

22 108604-3

23 108279-14 Regulator (Nat) Select 1

24 111497-F8 Solenoid Valve 24 Volt

25 115734-1 Burner Tubing

26 114800-2 CC Fitting 90° Elbow

27 114700-4 CC Fitting Straight

28 109290-29 Fitting Orifice (Nat) Select 2

29 116446-1 Tube Air Mixer, Rt Hd

30 116446-2 Tube Air Mixer, Lt Hd

30A 115784-1 Gasket, Air Mixer Tube (NS)

30B 115785-1 Gasket, End Cap (NS)

31 114799-3

32 115735-2 Box Assembly Air Adjuster

32A 115541-2 Gasket Foam 3M Tape (NS)

33 115787-2 Cover Air Adjuster

34 114706-2 Sleeve Air Adjuster

35 114703-3 Plunger Air Adjustor

36 116110-1 Plate Mounting Burner, Lt Hd

37 116110-2 Plate Mounting Burner, Rt Hd

38 115941-1 Insulation Burner Mounting (NS)

39 116616-1 Cover Sight Glass

40 115518-1 Sight Glass

41 115519-1 Insulation Sight Glass (NS)

42 116214-2 Ignitor

42A 115815-2 Gasket Ignitor

43 116155-2 Wedge, Ignitor

116696-33

108279-15 Regulator (LP)

109290-47 Fitting Orifice (LP)

Shut Off Valve, 1/2" NPT

Pipe Plug 3/8"

1

1

1

1

1

1

2

2

2

1

2

1

1

1

2

2

2

1

2

1

1

1

1

4

2

2

2

2

1

1

2

2

2

1

1

1

2

2

1

1

2

2

2

2

2

4

2

Page 33

PARTS LIST (Cont.)___________________________________________

ITEM NO. PART NO. DESCRIPTION

44 116751-G3 Burner Assembly, Lt Hd

45 116751-G4 Burner Assembly, Rt Hd

46 115783-G1 Burner

47 115801-G3 Tank Assembly

47A 116774-1 Insulation, Tank Front (NS)

47B 114616-C16 Insulation, Tank Bottom 1" (NS)

47C 116314-1 Insulation, Tank Rear 1/2" (NS)

48 114212-3 Valve Drain, Lt Hd

49 114212-4 Valve Drain, Rt Hd

50 116490-1 Housing High Limit

51 116491-1 Bracket Guides, High Limit Housing

52 114145-2 Second High Limit Control

53 116510-1 Insulation, High Limit (NS)

54 115226-3

55 114141-3 Prope Dual Thermistor

56 116650-G1 Flue Box Assembly

56A 1166775-1 Insulation Flue Box (NS)

57 114152-5 Bottom Flue

58 114109-2 Back Upper Body

59 115885-G2 Flue Cap Assembly

60 116673-3 Blower (Fasco) Select 1

60A 116727-1 Gasket (Fasco) (NS) Select 1

61 116725-1 Tube PVC Blower (NS)

62 116640-1 Hose, Primary Air

63 115481-3 Clamp, Hose

64 116642-G3 Blower Support Assembly

65 116660-3 Filter Solberg

66 116818-1 Pre-Filter

67 116637-2 Cap Filter

68 30127-3 Nut-Wing

69 104738-2 Tap Pressure

70 116475-G1 Control Box Modular

71 116509-1 Insulation, Control Box (NS)

72 115207-1 Fan Cooling

73 116732-1 Bracket Fan

74 115977-2 Cover Fan

75 113840-2 Disc Thermal (NS)

76 115998-3 Cord Receptacle

77 116011-1 Board Ignitor

78 116012-1 Board Interface

79 114149-8 Cable Ignitor (HV)

80 116724-1 Tube Flex (HV)

81 06089 Lug Ground

82 116484-4 Control Box "Fascia"

83 111496-F2 Switch Interlock

84 116493-G1 Front Top Assembly

85 116527-D1 Decal Control Panel

116696-34

116673-1 Blower (Ametex)

116753-1 Gasket (Ametex) (NS)

Fitting 1/4 NPT x 3/16 CC (Swagelock)

QUANTITY

1

1

2

1

1

1

1

1

1

1

2

2

1

4

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

4

1

1

1

1

1

1

1

2

2

2

2

2

1

2

1

1

Page 34

PARTS LIST (Cont.)

ITEM NO. PART NO. DESCRIPTION QUANTITY

86 111496-B1 Rocker Switch 2

87 111496-E10 Light Trouble "Red" 2

88 111496-E13 Lighting Heater "Amber" 2

89 111496-E8 Light Signal "Red" 2

90 116480-G9 Control Panel 1

91 116813-1 Pressure Tap Plug 1

116696-35

Page 35

WIRING DIAGRAM

Loading...

Loading...