Page 1

ITW Food Equipment Group, LLC

10405 Westlake Dr.

Charlotte, NC 28273

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-47200 (10-13)

INSTALLATION & OPERATION MANUAL FOR

MODELS

36RB

36IRB

www.vulcanequipment.com

MODELS

C36RB

C36IRB

www.wolfequipment.com

36RB/36IRB

Salamander Broilers

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE

INSTALLING OR SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

- 2 -

Page 3

INSTALLATION, OPERATION AND CARE OF

Radiant Altitude Kits

Accessory Number

Description

ALTISR-N01

KIT, RB ALTITUDE NG SEA-1999FT

ALTISR-P02

KIT, RB ALTITUDE LP SEA-1999FT

ALTISR-N03

KIT, RB ALTITUDE NG 2000-3999FT

ALTISR-P04

KIT, RB ALTITUDE LP 2000-3999FT

ALTISR-N05

KIT, RB ALTITUDE NG 4000-6999FT

ALTISR-P06

KIT, RB ALTITUDE LP 4000-6999FT

ALTISR-N07

KIT, RB ALTITUDE NG 7000-8999FT

ALTISR-P08

KIT, RB ALTITUDE LP 7000-8999FT

ALTISR-N09

KIT, RB ALTITUDE NG 9000-10000FT

ALTISR-P10

KIT, RB ALTITUDE LP 9000-10000FT

Common Accessories

Accessory Number

Description

WALLMNT-CHRBKR

SST WALL MOUNT BRACKETS

COUNTER-ADJLEG

SET OF (4) 6” ADJUSTABLE LEGS

CONNECT-CHALL

KIT, SALAMANDER INTERPLUMBING

SALAMANDER BROILERS

GENERAL

Salamander Broilers are produced with quality workmanship and material. Proper

installation, usage, and maintenance of your broiler will result in many years of

satisfactory performance.

It is suggested that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

Accessories are sold separately for the Salamander Broiler:

- 3 -

Page 4

Infrared Altitude Kits

Accessory Number

Description

ALTISI-N01

KIT, RB ALTITUDE NG SEA-1999FT

ALTISI-P02

KIT, RB ALTITUDE LP SEA-1999FT

ALTISI-N03

KIT, RB ALTITUDE NG 2000-3999FT

ALTISI-P04

KIT, RB ALTITUDE LP 2000-3999FT

ALTISI-N05

KIT, RB ALTITUDE NG 4000-6999FT

ALTISI-P06

KIT, RB ALTITUDE LP 4000-6999FT

ALTISI-N07

KIT, RB ALTITUDE NG 7000-8999FT

ALTISI-P08

KIT, RB ALTITUDE LP 7000-8999FT

ALTISI-N09

KIT, RB ALTITUDE NG 9000-10000FT

ALTISI-P10

KIT, RB ALTITUDE LP 9000-10000FT

Minimum Clearance

Combustible Construction

Non-Combustible Construction

Rear

0”

0”

Sides (Infrared) 36IRB & C36IRB

2”

0”

Sides (Radiant) 36RB & C36RB

6”

0”

Bottom

4” with legs

0”

INSTALLATION

Before installing, verify that the type of gas supply (natural or propane) agrees with the

specifications on the rating plate located underneath the broiler rack drip tray. If the

supply and equipment requirements do not agree, do not proceed with the installation.

Contact your dealer immediately.

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the broiler is found

to be damaged, save the packaging material and contact the carrier within 15 days of

delivery.

Before installing, verify that the type of gas (natural or propane) and the clearance

dimensions (see below) agree with the specifications on the rating plate which is located

under the crumb tray on the right side.

LOCATION

The equipment area must be kept free and clear of combustible substances.

- 4 -

Page 5

The installation location must allow adequate clearances for servicing and proper

operation. A minimum front clearance of 24" is required.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance for air

openings into the combustion chamber must be provided. Make sure there is an adequate

supply of air in the room to replace air taken out by the ventilating system. Do not permit

fans to blow directly at the broiler. Avoid wall-type fans which create air cross currents

within the room. Avoid open windows next to the broiler. Maintain an 18" (46 cm)

clearance from the top of the broiler flue vent to the filters of the hood venting system.

INSTALLATION CODES AND STANDARDS

The broiler must be installed in accordance with:

In the United States of America:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall include but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

NOTE: In the Commonwealth of Massachusetts

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3

GAS CONNECTIONS

CAUTION: All gas supply connections and any pipe joint compound used must be

resistant to the action of propane gases.

Codes require that a gas shutoff valve be installed in the gas line ahead of the broiler.

NATURAL GAS: Standard orifices are set at 5" W.C. (Water Column). A pressure

regulator is supplied and must be installed when the broiler is connected to the gas

supply.

PROPANE GAS: Standard orifices are set at 10" W.C. (Water Column). A pressure

regulator is supplied and must be installed when the broiler is connected to the gas

supply.

- 5 -

Page 6

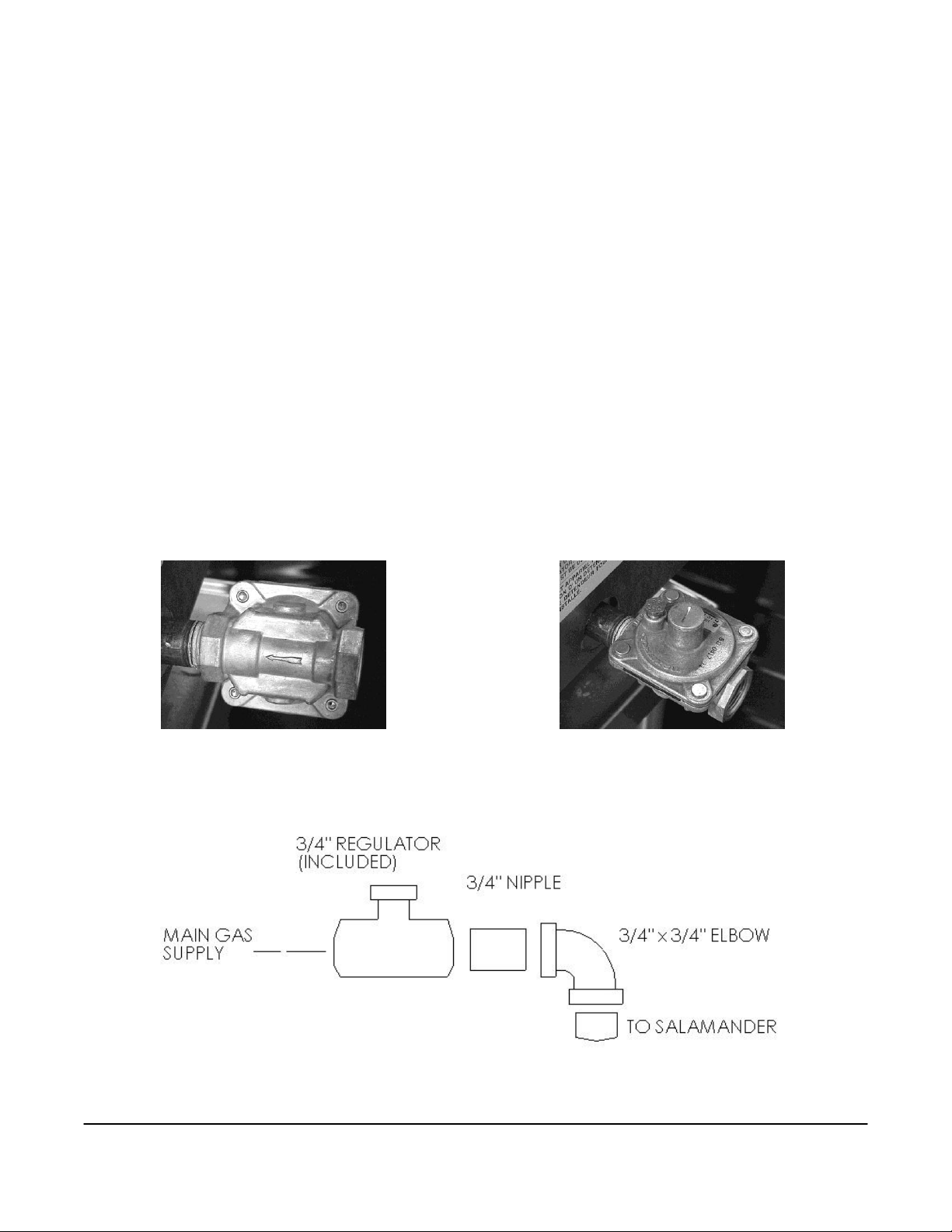

The gas supply line must be ¾” or larger. If flexible or semi-rigid connections are used,

Fig. 1

Fig. 2

the inside diameter must be the equivalent of ¾” iron pipe or larger. All connections of

the flexible and semi-rigid type must comply with all local and national requirements.

Make sure gas piping is clean and free of dirt, piping compound, and obstructions.

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR

LEAKS. USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

After piping has been checked for leaks, all piping receiving gas should be fully purged to

remove air.

GAS PRESSURE REGULATOR INSTALLATION

Gas regulator pressure is p r e set at 5” W at er Col umn (W .C.) for natural g as , and 10” W.C.

for propane gas. Minor adjustments may be required based on site specific gas pressure.

Install the regulator as close to the broiler on the gas supply line as possible. Make sure

that the arrow on the underside of the regulator is oriented in the direction of gas flow to

the broiler (Fig. 1) and the regulator is positioned with the vent plug and adjustment

screw upright (Fig. 2). A recommended plumbing schematic is listed below only for

Salamander units as guide to the installer and ITW Cooking Equipment or Hobart is in no

way liable for plumbing installation (Fig. 3).

Fig. 3

- 6 -

Page 7

The minimum supply pressure (upstream of the regulator) should be 7-9 ” W.C. f or natural

gas and 11-1 2 ” W.C. for propane gas. At n o time should the regulator be connected to

sup p l y pressure greater than ½ psig (3.45 kPa) or 14” W.C.

FLUE CONNECTIONS

DO NOT obstruct the flow of flue gases from the flue located on the rear of the broiler. It

is recommended that the flue gases be ventilated to the outside of the building through a

ventilation system installed by qualified personnel.

Information on the construction and installation of ventilating hoods may be obtained from

the standard for "Vapor Removal from Cooking Equipment," NFPA No. 96 (latest edition),

available from the National Fire Protection Association, Batterymarch Park, Quincy, MA

02269.

ASSEMBLY

Salamander Broiler Mounted on a Wall (Fig. 4).

The separate wall mounting bracket accessory (WALLMNT-CHRBKR) will be needed to

wall mount the unit.

1. Follow the combustible/noncombustible clearance guidelines that are listed in the

“Installat i on” section in this manual .

2. Make sure brackets are level and properly spaced so that bracket holes will align

with the threaded holes on the bottom of the unit to be mounted. The short leg of the

bracket with the holes that are nearest the elbow bend is to be placed against the

wall. (Fig. 5)

3. Secure brackets to wall by means of lag screws or bolts. (Fig. 5)

4. Mount the brackets only in the upside-do wn “L” position as shown. (Fig. 5)

5. Make sure the lag bolts or screws engage wall studs. Ensure that the wall

construction is of the type that will support the salamander weight.

6. Pl ac e the s alamand er into position on t he b r a ck e t s , making sure that the unit’s

bottom threaded attachment points are aligned with the holes in the brackets.(Fig. 6)

7. Se c ure uni t into position with 3/8” bolts at th e bot tom of the unit.

Thread the bolts through the holes in the brackets and into the threaded attachment

points on the bottom of the unit. (Fig. 6)

- 7 -

Page 8

Radiant & Infrared Salamander shown on WALLMNT-CHRBKR Accessory

Fig. 4

Fig. 5 Fig. 6

- 8 -

Page 9

Assembly over a Gas Range (Fig. 7)

If the broiler is to be mounted over a gas range, a reinforced shelf and special mounting

brackets are required.

1. Use Instructions from RSHELF Accessory kit to install reinforced shelf over a range.

2. Using the four bolts provided, install mounting brackets on both top corners of

reinforced shelf.

3. Place and align broiler on top of brackets with the back of the unit flush with the rear

of the shelf.

4. Install 3/8-16 Bolts through underside of the RSHELF.

Radiant & Infrared Salamander shown on RSHELF Accessory

Fig. 7

OPERATION

WARNING: THE BROILER AND ITS PARTS ARE HOT. BE CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE BROILER.

- 9 -

Page 10

CONTROLS

Dual Zone Controls — Controls cooking areas in the left and right hand side of the cavity

allowing for flexibility and premium cooking performance.

Angled Handle — elevates or lowers the broiling grid to different positions. Grasp the

handle and pull towards broiler cavity. This releases the mechanism

and allows the lifting handle to move into the desired position.

Burner Valve — regulates the flow of gas to the burners. Gas flow is increased by

turning the valve counterclockwise.

Drip Tray — Collects grease and waste which is diverted by the tilt of the drip shield.

DO NOT allow the drip tray to overflow. Empty the drip tray when threequarters full to reduce the possibility of spillage.

Rack Handle — glides the grid forward for easy loading and unloading. To operate, pull

straight out.

LIGHTING, RELIGHTING AND SHUTDOWN INSTRUCTIONS

1. Turn burner valve to the OFF position and wait 5 minutes.

2. Light the pilot adjacent to the main burner. Adjust the pilot valve screw until the pilot

flame has a slight yellow tip. There are two pilots to light, on each end of the cooking

chamber.

3. After the pilot has been established, turn the burner valve to the ON position. The

burner flames may be adjusted, using the air shutters located behind the manifold

cover in the front of the range. There are no shutters on the IRB models.

4. If the burners fail to light, turn off all valves, wait 5 minutes and repeat steps 1-3.

5. To shut down, turn the burner valves to the OFF position.

RACK POSITION AND GAS SETTING

Each operator will find the optimum rack position and gas setting for various products;

however, it is recommended that gas input be reduced first when lower rack temperatures

are desired. Further reduction in rack temperatures, if necessary, can then be obtained

by lowering rack position. Infrared Models must use the full gas setting. Max and

minimum temperatures can be achieved at the following settings:

2 Burners On, rack at highest position, valves set to High – 800°F

1 Burner On, rack at lowest position, valves set to Low – 250°F

CLEANING

1. Allow broiler to cool.

2. To remove broiler rack for cleaning, adjust broiler rack to center position.

- 10 -

Page 11

3. Position left and right hands simultaneously on edges of broiler rack and raise both

rack stops.

4. Slide broiler rack and drip tray forward past rack stops, (which must be pivoted out

of the way) holding tray up against racks.

5. Remove broiler rack and drip tray from broiler.

6. Let back of tray drop down to vertical to allow front hooks to disengage.

7. Remove drip pan from broiler rack and clean as you would any normal utensil, using

care not to damage the front hooks

8. To replace, hook the drip tray to the broiler rack while tray is in a vertical position.

9. Replace broiler rack and drip tray in side channels while holding tray up close to

rack.

10. Clean bottom pan. Slide pan out and wash with soap and water. Rinse thoroughly

and wipe dry with a soft clean cloth.

11. Clean stainless steel surfaces with a mild detergent and water, using a damp cloth,

or with a commercial stainless steel cleaner. Rinse thoroughly and wipe dry with a

soft clean cloth.

12. Burner ports and throats should be thoroughly cleaned. Venturi must be free from

grease and lint. DO NOT insert pick in burner port holes.

MAINTENANCE

WARNING: THE BROILER AND ITS PARTS ARE HOT. BE CAREFUL WHEN

OPERATING, CLEANING OR SERVICING THE BROILER.

LUBRICATION

Burner valve stems must be lubricated. Upon sticking, a burner valve stem should receive

maintenance from your local authorized servicer.

PILOT LIGHTS

Pilot lights are to be kept clean and adjusted at the proper flame height.

VENT

Annually, when the broiler is cool, check the flue and clear any obstructions.

SERVICE AND PARTS INFORMATION

Contact your local Service Agency to obtain service and parts information.

- 11 -

Page 12

NOTES

FORM F-47200 (10-13) PRINTED IN THE U.S.A.

- 12 -

Page 13

- 12 -

FORM F-47200 (10-13) PRINTED IN THE U.S.A.

NOTES

Page 14

- 11 -

3. Positionner la main droite et la main gauche simultanément sur les bords de la grille

du grilloir et soulever les deux butées de grille.

4. Glisser la grille du grilloir et le plateau d’égouttement en avant des butées de grille,

(qui doivent pivoter vers l’extérieur) en gardant le plateau en haut contre les grilles.

5. Enlever la grille et le plateau d’égouttement du grilloir.

6. Laisser aller l’arrière du plateau vers le bas à la verticale pour faire dégager les

crochets avant.

7. Enlever le plateau d’égouttement de la grille du grilloir et nettoyer comme tout autre

ustensile normal, en prenant soin de ne pas endommager les crochets avant.

8. Pour replacer, accrocher le plateau d’égouttement à la grille du grilloir lorsque le

plateau est à la verticale.

9. Remettre la grille du grilloir et le plateau d’égouttement dans les canaux de côté en

tenant le plateau vers le haut, près de la grille.

10. Nettoyer le plateau du bas. Glisser le plateau vers l’extérieur et laver avec de l’eau

savonneuse. Rincer à fond et essuyer avec un chiffon doux et propre.

11. Nettoyer les surfaces en acier inoxydable avec un détergent doux et de l’eau,

utilisant un chiffon humide ou un nettoyant commercial pour l’acier inoxydable.

Rincer à fond et essuyer avec un chiffon doux propre.

12. Nettoyer à fond les orifices et gueulards du brûleur. Enlever la graisse et la charpie

du venturi. NE PAS insérer de piques dans les orifices du brûleur.

ENTRETIEN

AVERTISSEMENT : LE GRILLOIR ET SES COMPOSANTS SONT CHAUDS. EXERCER UNE

EXTRÊME PRUDENCE LORS DE SON UTILISATION, NETTOYAGE OU ENTRETIEN.

LUBRIFICATION :

Les tiges du robinet du brûleur doivent être lubrifiées. Lorsqu’une tige colle,

communiquer avec le service de l’entretien autorisé le plus près.

ALLUMAGE DES VEILLEUSES

Les voyants de la veilleuse doivent être propres. Régler l’éclairage des veilleuses selon

la hauteur de la flamme.

CONDUIT D’ÉVACUATION

Une fois par année, lorsque le grilloir est froid, s’assurer que le conduit d’évacuation

n’est pas obstrué.

SERVICE DE L’ENTRETIEN ET PIÈCES DE RECHANGE

Pour tout entretien ou renseignement sur les pièces mentionnées dans ce manuel, communiquer avec

le service de l’entretien le plus près.

Page 15

- 10 -

COMMANDES

Commandes à — Commande les zones de cuisson du côté gauche et droit de l'enceinte

deux zones permettant une flexibilité et une performance de cuisson excellente.

Poignée à angle — Permet d'élever ou d'abaisser la grille de grilloir et de la mettre à

différentes positions. Saisir la poignée et tirer en direction de l’enceinte

du grilloir. Ceci relâche le mécanisme et la poignée de levée peut être

placée à la position désirée.

Robinet du brûleur — Sert à régler le débit de gaz vers les brûleurs. Tourner le robinet dans le

sens contraire des aiguilles d’une montre pour augmenter le débit de gaz.

Plateau — Sert à recueillir la graisse et les déchets qui sont déviés par

d'égouttement l'inclinaison de l'écran d'égouttement. NE PAS laisser déborder le

plateau d'égouttement. Vider le plateau d'égouttement lorsqu'il est

plein au trois-quarts pour réduire la possibilité de débordement.

Poignée de grille — Permet de glisser la grille vers l'avant pour chargement et

déchargement faciles. Pour faire fonctionner, tirer tout droit.

DIRECTIVES D'ALLUMAGE, DE RÉALLUMAGE ET D'EXTINCTION

1. Mettre le robinet de gaz du brûleur à OFF (arrêt) et attendre 5 minutes.

2. Allumer la veilleuse adjacente au brûleur principal. Régler la vis du robinet de la

veilleuse jusqu’à ce que la pointe de la flamme soit jaune. Il y a deux veilleuses à

allumer, à chaque bout de l’enceinte de cuisson.

3. Lorsque la veilleuse est rétablie, mettre le robinet du brûleur à la position ON

(marche). Régler les flammes du brûleur en utilisant les obturateurs d’air placés

derrière le couvercle du collecteur en avant de la cuisinière. Il n’y a pas d’obturateurs

sur les modèles IRB.

4. Si les veilleuses refusent de s’allumer, fermer tous les robinets, attendre 5 minutes et

reprendre les étapes 1 à 3.

5. Pour fermer, mettre les robinets du brûleur à la position OFF (arrêt).

POSITIONNEMENT DE LA GRILLE ET RÉGLAGE DU GAZ

Chaque utilisateur va trouver la position idéale pour la grille et le réglage du gaz pour

différents produits; cependant, il est conseillé de réduire l’entrée de gaz en premier

lorsque des températures de grilles plus basses sont désirées. Si c’est nécessaire, on

peut obtenir une réduction des températures de grille en abaissant la position de la grille.

Les modèles à infrarouge doivent utiliser le réglage du gaz à fond. Les températures

maximales et minimales peuvent être atteintes en utilisant les réglages suivants :

2 brûleurs à On (marche), la grille à la position la plus haute, les robinets réglés à

une température élevée de 427 °C ( 800 °F )

1 brûleur à On (marche), la grille à la position la plus basse, les robinets réglés à

une basse température de 121 °C ( 250 °F )

ENTRETIEN

1. Laisser refroidir le grilloir.

2. Pour enlever la grille du grilloir pour le nettoyage, mettre la grille au centre.

Page 16

- 9 -

Assemblage au-dessus d'une cuisinière au gaz (Fig. 7)

Si le grilloir est monté au-dessus d'une cuisinière au gaz, une tablette renforcée et des

supports de montage spéciaux sont requis.

1. Utiliser les instructions de la trousse d'accessoire RSHELF pour installer une

tablette renforcée au-dessus d'une cuisinière.

2. Utiliser les quatre boulons fournis et installer les supports de montage sur les deux

coins supérieurs de la tablette renforcée.

3. Placer et aligner le grilloir sur le dessus des supports, le dos de l’appareil égal avec

l'arrière de la tablette.

4. Installer les boulons 3/8-16 sur le dessous de l’accessoire RSHELF.

Salamandre à radiant et infrarouge illustrée sur l'accessoire RSHELF

Fig. 7

FONCTIONNEMENT

AVERTISSEMENT : LE GRILLOIR ET SES COMPOSANTS SONT CHAUDS. EXERCER UNE

EXTRÊME PRUDENCE LORS DE SON UTILISATION, NETTOYAGE OU ENTRETIEN.

Page 17

- 8 -

Salamandre à radiant et infrarouge illustrée dans l'accessoire WSALLMNT-CHRBKR

Fig. 4

Fig. 5 Fig. 6

Page 18

- 7 -

La pression de canalisation minimale de gaz (en amont du régulateur) doit être réglée

à 1,74 - 2,24 kPa (7 - 9 po de colonne d’eau) pour le gaz naturel et à 2,74 – 2,99 kPa

(11 – 12 po de colonne d’eau) pour le gaz propane. Le régulateur ne doit jamais être

connecté à une pression de canalisation supérieure à 1/2 psig (3,45 kPa) ou 3,48 kPa

(14 po de colonne d’eau).

CONDUIT D’ÉVACUATION

NE PAS obstruer le débit des gaz de combustion dans le conduit d’évacuation à l’arrière

de l’appareil. Il est recommandé que les gaz de combustion soient ventilés à l’extérieur

de l’immeuble par un système de ventilation installé par un personnel qualifié.

Les informations sur la construction et l’installation des hottes de ventilation sont comprises

dans la norme NFPA n° 96 (dernière édition) relative à l’installation de matériel pour

l’évacuation de la fumée des appareils de cuisson dont on peut se procurer un exemplaire

auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

ASSEMBLAGE

Salamandre-grilloir montée sur un mur (Fig. 4).

L'accessoire de support de montage du mur séparé (WALLMNT-CHRBKR) sera requis

pour monter l'appareil au mur.

1. Suivre les directives de dégagement de construction combustible et incombustible

qui sont à la section "Installation" de ce manuel.

2. S'assurer que les supports sont de niveau et bien espacés pour que les trous du

support s'alignent avec les trous filetés dans le bas de l'appareil qui doit être monté.

Le pied court du support avec trous qui sont le plus près de la courbure du coude

doit être placé contre le mur. (Fig. 5)

3. Fixer les supports au mur à l'aide de tire-fonds ou écrous. (Fig. 5)

4. Monter les supports seulement dans la position "L" de haut en bas tel qu'illustré.

(Fig. 5)

5. S'assurer que les tire-fonds ou vis s'engagent dans les poteaux de cloison.

S'assurer que la construction du mur supportera le poids de la salamandre.

6. P lacer la salamandre dans la position des supports, en s'assurant que les points

d'attachement filetés du bas de l'appareil sont alignés avec les trous des supports

(Fig. 6)

7. Fixer l'appareil à sa position à l'aide de boulons de 10 mm (3/8 po) au bas de

l'appareil. Tarauder les boulons à travers les trous dans les supports et dans les

points d'attachement filetés dans le bas de l'appareil. (Fig. 6)

Page 19

- 6 -

La conduite de gaz doit être composée d’un tuyau de 19 mm (3/4 po) ou supérieur. Si des

raccords flexibles ou semi-rigides sont utilisés, le diamètre intérieur doit être l’équivalent d’un

tuyau de 19 mm (3/4 po) ou supérieur. Tous les raccords de type flexible et semi-rigide

doivent être conformes aux codes locaux et nationaux. S’assurer que les tuyaux sont propres

et qu’ils ne comportent aucun corps étranger ni saleté ou de pâte à joints.

AVERTISSEMENT : AVANT DE PROCÉDER À L'ALLUMAGE, FAIRE CIRCULER DE L'EAU

SAVONNEUSE DANS TOUS LES JOINTS DE LA CONDUITE DE GAZ POUR S'ASSURER

QU'ILS NE PRÉSENTENT AUCUNE FUITE. NE PAS SE SERVIR D'UNE FLAMME NUE.

Après avoir enrayé toute possibilité de fuite, purger la conduite de gaz pour évacuer tout

l'air qu'elle contient.

INSTALLATION D'UN RÉGULATEUR DE PRESSION DE GAZ

Le régulateur de pression de gaz est préréglé en usine à une pression de 1,25 kPa (5 po)

de colonne d’eau pour le gaz naturel et de 2,49 ka (10 po) de colonne d’eau pour le gaz

propane. Des réglages mineurs peuvent être requis selon la pression de gaz spécifique

de l’emplacement.

Installer le régulateur de pression de gaz aussi près que possible du grilloir, sur la

conduite d’alimentation en gaz. S’assurer que la flèche sous le régulateur est orientée

dans la direction de l’écoulement du gaz vers le grilloir (Fig. 1) et que le régulateur est

positionné de façon à ce que le bouchon d’aération et la vis de réglage soient à la

verticale (Fig. 2). Vous trouverez un schéma de plomberie recommandé ci-dessous,

seulement pour les salamandres et comme guide pour l’installateur. Équipement de

cuisson ITW ou la Compagnie Hobart ne sont en aucune façon responsable de

l’installation de la plomberie (Fig. 3).

Fig. 1 Fig. 2

Fig. 3

Page 20

- 5 -

Dans le bas

102 mm (4 po) avec pieds

Aucun

Installer celui-ci dans un endroit suffisamment espacé pour en faciliter l’entretien et en assurer le bon

fonctionnement. Un dégagement minimal de 610 mm (24 po) est requis devant l’appareil.

Ne pas obstruer le débit de combustion et la ventilation d'air. Prévoir un dégagement

suffisant pour les ouvertures d’air dans la chambre de combustion. S’assurer qu’il y a

une aération suffisante dans la pièce pour remplacer l’air évacué par le système de

ventilation. Veiller à ce que les ventilateurs ne soufflent pas directement sur l’appareil.

Dans la mesure du possible, ne pas ouvrir les fenêtres à proximité de l’appareil, ce qui

pourrait produire des courants d’air. Prévoir un dégagement de 457 mm (18 po) du

dessus de la sortie d’air du conduit de fumée vers le système de ventilation de la hotte.

CODES D’INSTALLATION ET NORMES

L’installation de la salamandre-grilloir doit se faire selon les codes suivants :

Aux États-Unis :

1. Codes locaux.

2. Norme ANSI/Z223.1 /NFPA N° 54 (dernière édition) du National Fuel Gas Code. Ceci devra

inclure mais ne pas se limiter à la norme NFPA N° 54 pour la ventilation, section 10.3.5.2,

dont on peut se procurer un exemplaire auprès de l’American Gas Association Inc., Comité

de normalisation reconnu Z223, 400 N. Capital St. NW, Washington, DC 20001, ou le

Secrétaire du Comité de normalisation, NFPA, 1 Batterymarch Park, Quincy, MA 02169-7471

NOTA : Dans le Commonwealth ou l’État du Massachusetts

Tous les appareils au gaz ventilés par une hotte de ventilation ou un système

d’évacuation muni d’un registre ou de moyens d’évacuation à puissance doivent être

conformes à la règlementation 248 CMR.

3. Norme NFPA N° 96 pour l’évacuation de la fumée des appareils de cuisson (dernière

édition) dont on peut se procurer un exemplaire auprès de la National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

Au Canada :

1. Codes locaux.

2. Code d’installation des appareils et équipements fonctionnant au gaz naturel,

CAN/CSA-B149.1 (dernière édition)

3. Code d’installation des appareils et équipements fonctionnant au gaz propane, CAN/CSA-B149.2

(dernière édition) dont on peut se procurer un exemplaire auprès de l’Association canadienne de

gaz, 178 Rexdale Blvd, Etobicoke, Ontario, Canada M9W 1R3

BRANCHEMENT DU GAZ

ATTENTION : Tous les raccords d'alimentation de la conduite de gaz et la pâte à

joints de tuyau doivent résister à l'action du gaz propane.

Conformément aux exigences des codes, installer un robinet d'arrêt dans la conduite de

gaz en amont du grilloir.

GAZ NATUREL : Les orifices standard sont réglés à une pression de 1,24 kPa (5 po de

colonne d'eau). Un régulateur de pression est fourni et doit être installé lorsque le grilloir

est raccordé à l'alimentation en gaz.

GAZ PROPANE : Les orifices standard sont réglés à une pression de 2,49 kPa (10 po de

colonne d'eau) Un régulateur de pression est fourni et doit être installé lorsque le grilloir

est raccordé à l'alimentation en gaz.

Page 21

- 4 -

Trousses d’altitude à Radiant

Numéro

d'accessoire

Description

ALTISI-N01

JEU D’ALTITUDE RB GN 1 999 PI (6 093 MM) (DU NIVEAU DE LA MER)

ALTISI-P02

JEU D’ALTITUDE RB GPL 1 999 PI (6 093 MM) (DU NIVEAU DE LA MER)

ALTISI-N03

JEU D’ALTITUDE RB GN 2 000 – 3 999 PI (6 097 – 12 189 MM) (DU NIVEAU DE LA MER)

ALTISI-P04

JEU D’ALTITUDE RB GPL 2 000 – 3 999 PI (6 097 – 12 189 MM) (DU NIVEAU DE LA MER)

ALTISI-N05

JEU D’ALTITUDE RB GN 4 000 – 6 999 PI (12 192 – 21 333 MM) (DU NIVEAU DE LA MER)

ALTISI-P06

JEU D’ALTITUDE RB GPL 4 000 – 6 999 PI (12 192 – 21 333 MM) (DU NIVEAU DE LA MER)

ALTISI-N07

JEU D’ALTITUDE RB GN 7 000 – 8 999 PI (21 336 – 27 429 MM) (DU NIVEAU DE LA MER)

ALTISI-P08

JEU D’ALTITUDE RB GPL 7 000 – 8 999 PI (21 336 – 27 429 MM) (DU NIVEAU DE LA MER)

ALTISI-N09

JEU D’ALTITUDE RB GN 9 000 – 10 000 PI (27 432 – 30 480 MM) (DU NIVEAU DE LA MER)

ALTISI-P10

JEU D’ALTITUDE RB GPL 9 000 – 10 000 PI (27 432 – 30 480 MM) (DU NIVEAU DE LA MER)

INSTALLATION

Avant de procéder à l’installation, s’assurer que le type de gaz (naturel ou propane) de

l’immeuble correspond aux spécifications de la plaque signalétique placée sous le

plateau d'égouttement de la grille du grilloir. Si ce n’est pas le cas, ne pas procéder à

l’installation. Communiquer avec votre dépositaire immédiatement.

DÉBALLAGE

Immédiatement après avoir déballé l’appareil, vérifier s’il n’a pas été endommagé lors du

transport. En cas de dommages, conserver le matériel d’emballage et aviser le

transporteur dans les 15 jours suivant la date de réception.

Avant de procéder à l'installation, s'assurer que le type de gaz (naturel ou propane) de

l'immeuble correspond aux spécifications de la plaque signalétique placée sous le tiroir

de propreté du côté droit de l'appareil.

EMPLACEMENT

Aucune substance combustible ne doit se trouver à proximité de l’appareil.

Dégagement minimal

Construction combustible

Construction incombustible

Arrière

Aucun

Aucun

Côtés (Infrarouge) 36IRB & C36IRB

51 mm (2 po)

Aucun

Côtés (Radiant) 36RB & C36RB

152 mm (6 po)

Aucun

Page 22

- 3 -

INSTALLATION, FONCTIONNEMENT ET ENTRETIEN

SALAMANDRES-GRILLOIRS

GÉNÉRALITÉS

Les salamandres-grilloirs sont fabriquées avec le plus grand soin et à partir des meilleurs

matériaux. Leur installation, utilisation et entretien appropriés permettront d’en obtenir

un rendement optimal pendant de nombreuses années.

Il est recommandé de lire ce manuel au complet et de suivre attentivement toutes les

instructions.

Les accessoires sont vendus séparément:

Jeux d’altitude à radiants

Numéro

d'accessoire

Description

ALTISR-N01

JEU D’ALTITUDE RB GN 1 999 PI (6 093 MM) (DU NIVEAU DE LA MER)

ALTISR-P02

JEU D’ALTITUDE RB GPL 1 999 PI (6 093 MM) (DU NIVEAU DE LA MER)

ALTISR-N03

JEU D’ALTITUDE RB GN 2 000 – 3 999 PI (6 097 – 12 189 MM) (DU NIVEAU DE LA MER)

ALTISR-P04

JEU D’ALTITUDE RB GPL 2 000 – 3 999 PI (6 097 – 12 189 MM) (DU NIVEAU DE LA MER)

ALTISR-N05

JEU D’ALTITUDE RB GN 4 000 – 6 999 PI (12 192 – 21 333 MM) (DU NIVEAU DE LA MER)

ALTISR-P06

JEU D’ALTITUDE RB GPL 4 000 – 6 999 PI (12 192 – 21333 MM) (DU NIVEAU DE LA MER)

ALTISR-N07

JEU D’ALTITUDE RB GG 7 000 – 8 999 PI (21 336 – 27 429 MM) (DU NIVEAU DE LA MER)

ALTISR-P08

JEU D’ALTITUDE RB GPL 7 000 – 8 999 PI (21 336 – 27 429 MM) (DU NIVEAU DE LA MER)

ALTISR-N09

JEU D’ALTITUDE RB GN 9 000 – 10 000 PI (27 432 – 30 480 MM) (DU NIVEAU DE LA MER)

ALTISR-P10

JEU D’ALTITUDE RB GPL 9 000 – 10 000 PI (27 432 – 30 480 MM) (DU NIVEAU DE LA MER)

Accessoires communs

Numéro d'accessoire

Description

WALLMNT-CHRBKR

SUPPORTS DE MONTAGE MURAL EN NOX

COUNTER-ADJLEG

SUPPORTS DE 4 PATTES RÉGLABLES DE 152 MM (6 PO)

CONNECT-CHALL

SUPPORTS DE PLOMBERIE INTERNE POUR SALAMANDRE

Page 23

- 2 -

MESURES DE SÉCURITÉ IMPORTANTES

CE MANUEL A ÉTÉ PRÉPARÉ À L’INTENTION D’UN PERSONNEL QUALIFIÉ ET

AUTORISÉ À INSTALLER DES APPAREILS FONCTIONNANT AU GAZ ET À

EFFECTUER LE DÉMARRAGE INITIAL CHEZ LE CLIENT DE MÊME QUE LE

RÉGLAGE DES APPAREILS CONCERNÉS DANS CE MANUEL.

AFFICHER À UN ENDROIT VISIBLE LES PREMIERS SOINS À ADMINISTRER À

TOUTE PERSONNE AYANT RESPIRÉ LES GAZ QUE CET APPAREIL DÉGAGE.

ON PEUT SE PROCURER CES INFORMATIONS CHEZ LE FOURNISSEUR DE

GAZ LE PLUS PRÈS.

IMPORTANT

EN CAS D’ODEURS DE GAZ, ÉTEINDRE L’APPAREIL

PAR LE ROBINET D’ARRÊT PRINCIPAL ET

COMMUNIQUER AVEC LA COMPAGNIE DE GAZ LA

PLUS PRÈS OU AVEC LE FOURNISSEUR DE

GAZ ATTITRÉ POUR L’ENTRETIEN.

MESURE DE SÉCURITÉ

NE PAS RANGER NI UTILISER DE L’ESSENCE NI

TOUT AUTRE LIQUIDE OU VAPEUR INFLAMMABLE

À PROXIMITÉ DE CET APPAREIL OU DE TOUT

AUTRE APPAREIL.

L’INSTALLATION, LE RÉGLAGE, LA MODIFICATION

ET L’ENTRETIEN INCORRECTS DE CET APPAREIL

PEUVENT CAUSER DES DOMMAGES MATÉRIELS,

DES BLESSURES ET MÊME LA MORT. LIRE LES

INSTRUCTIONS D’INSTALLATION, DE

FONCTIONNEMENT ET D’ENTRETIEN AVANT DE

PROCÉDER À TOUTE INSTALLATION OU TOUT

ENTRETIEN.

EN CAS DE PANNE DE COURANT, NE PAS FAIRE

FONCTIONNER CET APPAREIL.

Page 24

Une division de Groupe ITW Équipement alimentaire, SRL

10405 Westlake Dr.

Charlotte, NC 28273

DOCUMENT À CONSERVER EN CAS DE BESOIN

F-47200 (10-13)

MODE D’INSTALLATION

ET MODE D’EMPLOI

Salamandres-grilloirs

MODÈLES

36RB

36IRB

www.vulcanequipment.com

MODÈLES

C36RB

C36IRB

www.wolfequipment.com

36RB/36IRB

Loading...

Loading...