Page 1

SERVICE MANUAL

C24EO SERIES ELECTRIC

COUNTERTOP STEAMERS

C24EO3 ML-136006

C24EO5 ML-136007

C24EO5

- NOTICE -

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Vulcan-Hart 3600 North Point Blvd Baltimore, MD 21222

F25386 (0415)

Page 2

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS

TABLE OF CONTENTS

GENERAL .................................................................................................. 3

INSTALLATION, OPERATION AND CLEANING ......................................................... 3

INTRODUCTION ....................................................................................... 3

FEATURES ........................................................................................ 3

STEAM COOKING ................................................................................. 3

MODEL DESIGNATIONS ........................................................................... 3

EXTERIOR DIMENSIONS .......................................................................... 3

SPECIFICATIONS ...................................................................................... 3

TOOLS ................................................................................................. 3

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 5

COVERS AND PANELS ................................................................................ 5

COMPONENT PANEL COMPONENTS ................................................................. 6

TIMER ................................................................................................. 6

HOLD THERMOSTAT .................................................................................. 6

HIGH LIMIT THERMOSTAT ............................................................................ 7

LOW WATER THERMOSTAT ........................................................................... 8

TEMPERATURE PROBE ............................................................................... 8

HEATING ELEMENT ASSEMBLY ....................................................................... 8

REMOVAL ......................................................................................... 8

INSTALLATION .................................................................................... 9

MANUAL DRAIN VALVE .............................................................................. 10

DOOR ................................................................................................ 10

DOOR GASKET ....................................................................................... 10

DOOR HANDLE ....................................................................................... 11

DOOR LATCH ASSEMBLY ............................................................................ 12

DOOR HINGE BEARINGS ............................................................................. 13

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 15

DOOR LATCH ADJUSTMENT ......................................................................... 15

OPENING A JAMMED DOOR ..................................................................... 15

ADJUSTMENT .................................................................................... 15

HEATING ELEMENT TEST ............................................................................ 16

TEMPERATURE CONTROL CALIBRATION ........................................................... 16

ELECTRICAL OPERATION ................................................................................ 18

COMPONENT FUNCTION ............................................................................ 18

COMPONENT LOCATION ............................................................................. 19

SEQUENCE OF OPERATION ......................................................................... 19

TIMED COOKING MODE .......................................................................... 19

CONSTANT COOKING MODE .................................................................... 20

SCHEMATIC DIAGRAM ............................................................................... 22

WIRING DIAGRAMS - HEATING ELEMENTS .......................................................... 23

C24EO3 - 208V/240V ............................................................................. 23

C24EO5 - 208V/240V ............................................................................. 23

C24EO5 - 480V ................................................................................... 24

TROUBLESHOOTING ..................................................................................... 26

TROUBLESHOOTING ................................................................................. 26

© VULCAN 2015

F25386 (0415) Page 2 of 27

Page 3

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - GENERAL

GENERAL

INSTALLATION, OPERATION AND

CLEANING

Refer to the Installation & Operation Manual for

specific instructions.

INTRODUCTION

Features

• Requires no water or drain line connections

(manual fill & manual drain).

• Cast aluminum element block for efficient heat

transfer and distribution.

• Field convertible to single phase or three phase

power depending on the supply available.

• 3.0 gallons maximum holding pan capacity.

Steam Cooking

The C24EO series steamer provides timed or

continuous mode cooking in a pressure-less

compartment. The small physical size of the steamer

offers an efficient way to produce many foods in small

batches. Pressure-less, convection steam cooking will

steam cook fresh foods or will steam defrost and cook

frozen foods providing the maximum color, flavor and

nutritional value with the least expenditure of energy

and labor. The pressureless cooking compartment

allows the operator to open and close the door,

anytime during a cooking cycle.

• Hardness - Less than 3 grains (17.1ppm = 1 grain

of hardness)

• Silica - Less than 13 ppm

• Total Chloride - Less than 4 ppm

• Ph range of - 7.0 to 8.0

• Un-dissolved Solids - less then 5 microns

ELECTRIC

AMPERAGE PER LINE

MODEL

C24EO3 8 22.2 19.2 - 38.5 33.3

C24E05 12 33.3 28.9 14.4 57.5 50.0

NOTES:

TOTAL

KW

1. Amperage values in the table are

nominal. Tolerance is +5/-10%.

2. HC24EO3 - Shipped for 208V 60-50

HZ 3 phase connection. Field

convertible to 240V three phase or

208/240V single phase. See wiring

diagram AI2853.

3. HC24EO5 - Shipped for 208V or

240V or 480V 60-50 HZ, 3 phase.

208V and 240V models are field

convertible to 1 phase. See wiring

diagram (LINK to AI2852).

3 PHASE 1 PHASE

208

240V 480V 208V 240V

V

Model Designations

• C24EO3 - 3 pan capacity

• C24EO5 - 5 pan capacity

NOTE: based on 2.5 inch pan depth

Exterior Dimensions

• C24EO3 - 24" w x 33" d x 19.5" h

• C24EO5 - 24" w x 33" d x 26" h

SPECIFICATIONS

A potable water supply does not guarantee that it's

suitable for steam generation. The water supply must

be within the following specifications or a local water

treatment specialist may need to be consulted. If a

water treatment system is installed, it must be properly

maintained.

WATER REQUIREMENTS

Page 3 of 27 F25386 (0415)

TOOLS

Standard

• Standard set of hand tools

• Clear silicone sealant

• VOM with an AC current tester (any quality VOM

with a sensitivity of at least 20,000 ohms per volt

can be used)

• Temperature meter & thermocouple

Special

• Thermal Transfer Compound, Dow Corning 340

Part No. 819643-2 (13.5 oz. tube) or equivalent

for heating element assembly

• Thermal Transfer Compound, Dow Corning 340

Part No. 519504 (2 oz. tube) or equivalent for

thermostats

• Torque wrench (in.-lb.)

Page 4

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - GENERAL

• Tile Trowel 3/16" x 5/32" V notch; Grainger

catalog stock number 5LG08 or equivalent for

coating heating element assembly with thermal

transfer compound

• Loctite® ODC-Free Cleaner and Degreaser

(McMaster-Carr Part No. 66415A21) or

equivalent fast drying, no residue cleaner.

• Loctite® 7471™ Primer N™ Part No. 544434-2

• Loctite® 271™ or equivalent

• Loctite® 242™ Part No. 520228 for threads of

door screws

• RTV 109 for securing gasket to door

• Lubriplate 630AA for door handle sliding bracket

F25386 (0415) Page 4 of 27

Page 5

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

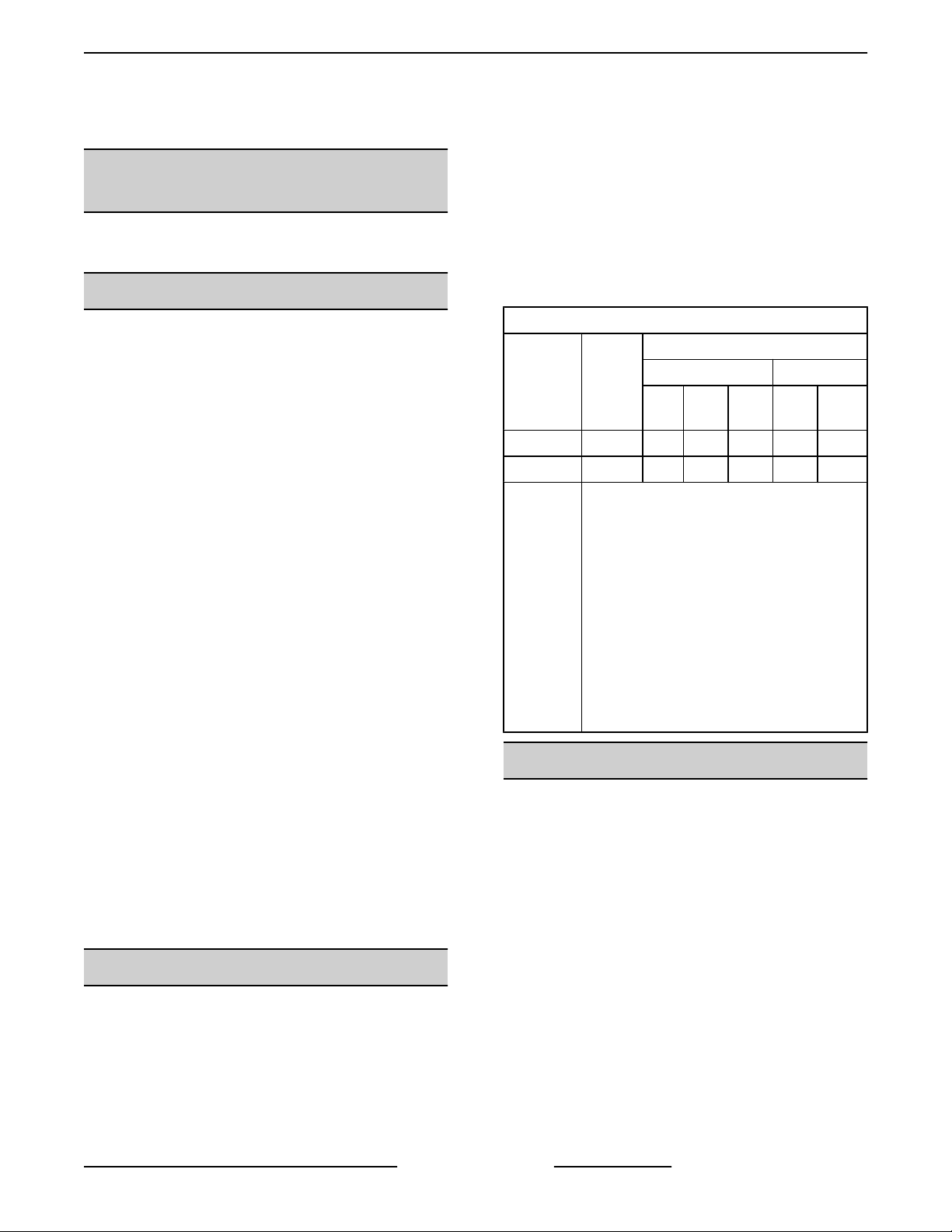

COVERS AND PANELS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

SIDE PANELS

1. Remove screws from bottom of panel.

Fig. 3

4. Lift top cover off machine.

5. Reverse procedure to install.

Fig. 1

2. Slide panel down to clear top cover.

3. Reverse procedure to install.

TOP COVER

1. Remove SIDE PANELS.

2. Remove screws securing rear of top cover.

REAR PANEL

1. Remove screws securing rear panel.

Fig. 4

2. Disconnect tube from steam vent pipe.

3. Remove rear panel.

4. Reverse procedure to install.

Fig. 2

3. Remove nuts securing front of top cover.

Page 5 of 27 F25386 (0415)

Page 6

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

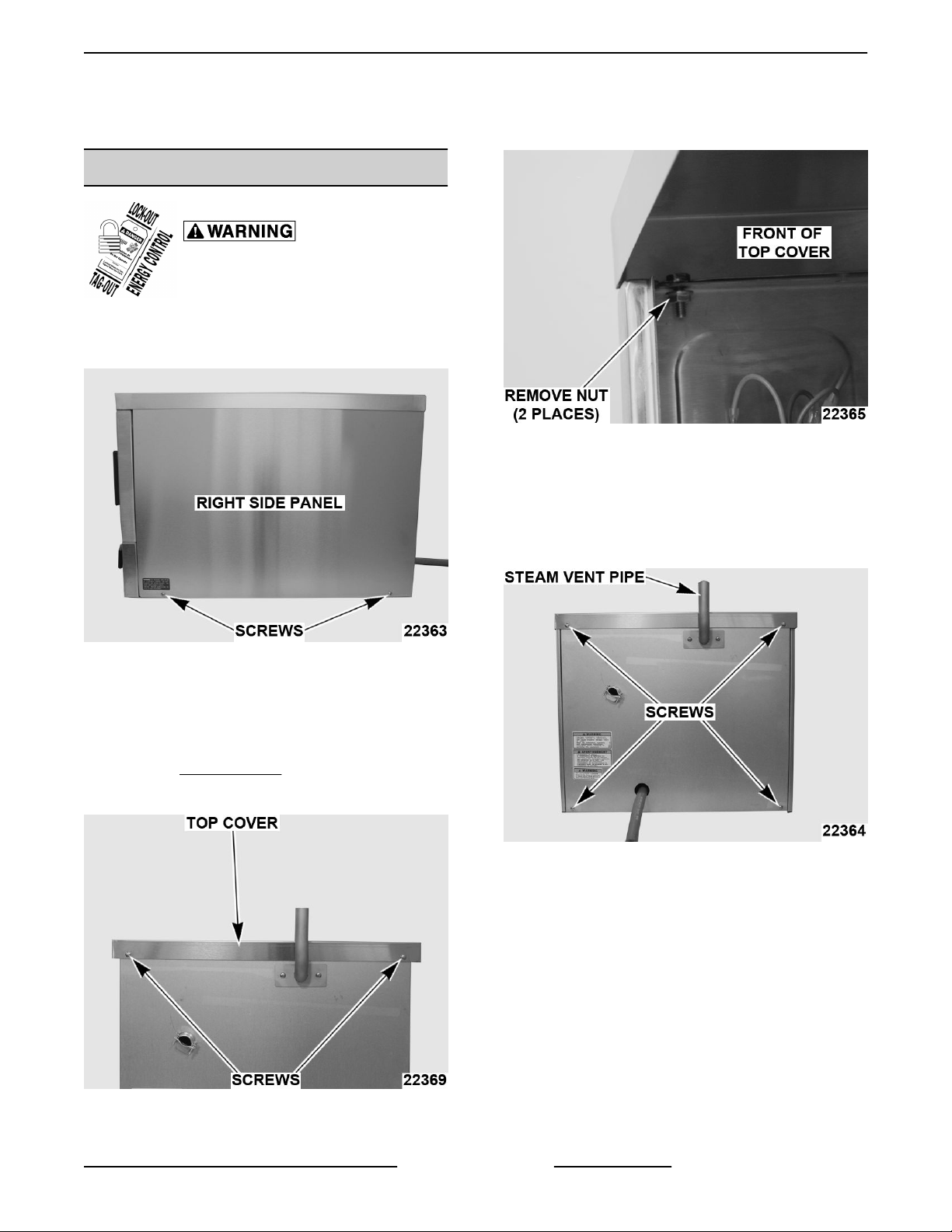

COMPONENT PANEL

COMPONENTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove right side panel as outlined under

COVERS AND PANELS.

2. Disconnect lead wires to component being

replaced.

Fig. 6

3. Remove timer knob.

4. Remove rotary shaft seal from timer shaft and

remove timer.

Fig. 5

3. Remove component.

4. Reverse procedure to install replacement

component and check steamer for proper

operation.

NOTE: If replacing temperature control, see in

SERVICE PROCEDURES AND ADJUSTMENTS.

TIMER

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove right

2. Disconnect lead wires to timer.

SIDE PANEL.

Fig. 7

5. Reverse procedure to install and check steamer

for proper operation.

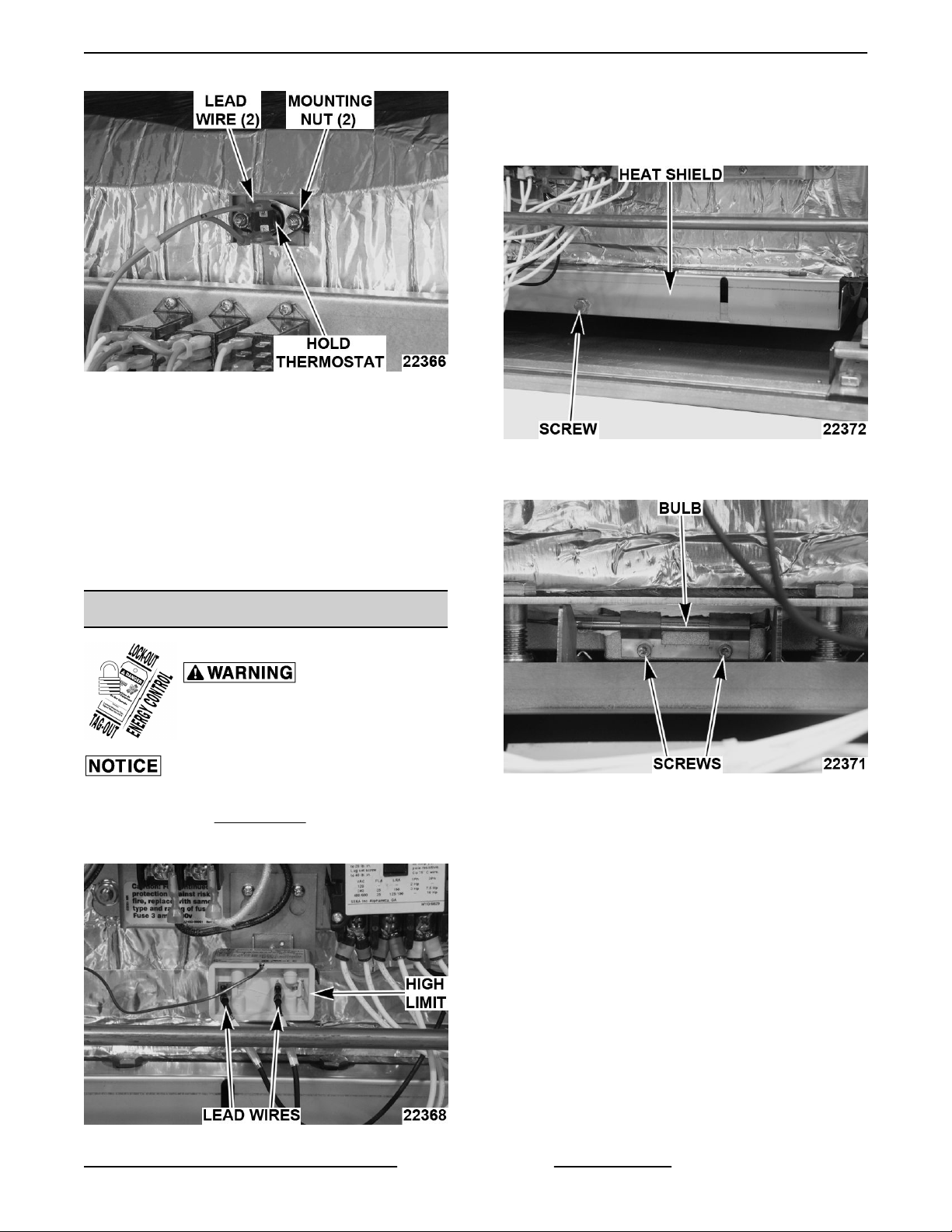

HOLD THERMOSTAT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove right

2. Remove lead wires and mounting nuts.

SIDE PANELS.

F25386 (0415) Page 6 of 27

Page 7

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

3. Remove thermostat from mounting bracket.

4. Remove screw and heat shield to access

capillary bulb.

Fig. 8

3. Remove hold thermostat.

4. Apply a small amount of thermal transfer

compound to the mating surface (disk side) of the

replacement thermostat.

A. Spread the compound completely and

evenly over the surface of the thermostat.

5. Reverse procedure to install and check steamer

for proper operation.

HIGH LIMIT THERMOSTAT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Do not sharply bend and kink, or clamp

down on the capillary tube or damage may occur.

1. Remove right SIDE PANEL.

2. Disconnect lead wires from high limit.

Fig. 10

5. Loosen screws securing capillary bulb.

Fig. 11

6. Remove high limit thermostat.

7. Reverse procedure to install and check steamer

for proper operation.

A. Apply a small amount of thermal transfer

compound between capillary bulb and

heating element assembly.

Fig. 9

NOTE: Do not clamp bulb with excessive force.

Page 7 of 27 F25386 (0415)

Page 8

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

LOW WATER THERMOSTAT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove right SIDE PANEL and REAR PANEL.

2. Disconnect lead wires.

Fig. 13

3. Remove temperature probe from steam vent

pipe.

4. Reverse procedure to install replacement probe

and check steamer for proper operation.

Fig. 12

3. Remove low water thermostat.

4. Reverse procedure to install and check steamer

for proper operation.

A. Apply small amount of thermal transfer

compound to tip of thermostat.

B. Apply Loctite 242 to threads of thermostat.

C. Install thermostat hand tight. Do not over

tighten.

TEMPERATURE PROBE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

5. Adjust temperature control as outlined under

TEMPERATURE CONTROL CALIBRATION in

SERVICE PROCEDURES AND

ADJUSTMENTS.

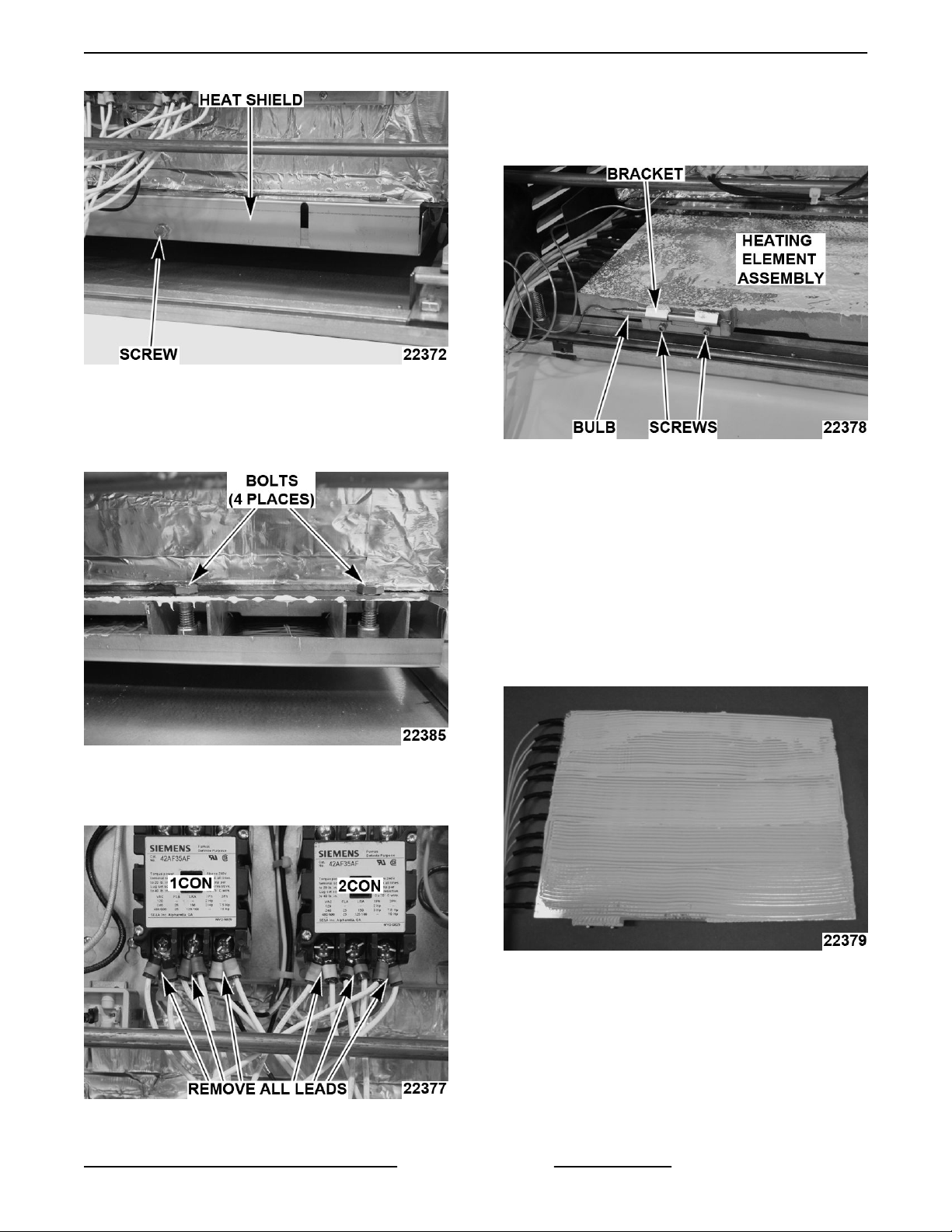

HEATING ELEMENT ASSEMBLY

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Removal

The heating element assembly contains elements

molded into a cast aluminum block. The block is

mounted on the underside of cooking compartment.

Heating element assembly sits on springs which

compress to hold assembly tight to bottom surface of

steam chamber but allow for thermal expansion and

contraction.

1. Remove right

2. Remove screw and heat shield.

SIDE PANEL.

1. Remove right SIDE PANEL and REAR PANEL.

2. Disconnect probe leads from the temperature

control.

F25386 (0415) Page 8 of 27

Page 9

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

5. Partially remove heating element assembly by

pulling assembly towards you.

6. Remove high limit thermostat bulb and bracket.

Fig. 14

3. Remove bolts.

NOTE: Support heating element assembly while

removing last bolt.

7. Remove heating element assembly.

Fig. 17

Fig. 15

4. Disconnect heating element leads from 1CON

and 2CON, noting their locations.

Installation

NOTE: When replacing element assembly for 3 pan

unit with 240V supply, disconnect and insulate

element leads with orange, green, and red markers

(three 664W elements not used).

1. Completely and evenly coat heating element

assembly with thermal transfer compound using

notched trowel. (Use one 13.5 oz. tube of thermal

transfer compound)

Fig. 16

Fig. 18

2. Partially install heating element assembly, then

mount high limit thermostat bulb and bracket to

assembly.

A. Apply thermal transfer compound between

high limit bulb and heating element

assembly.

3. Install heating element assembly. Push element

assembly towards front of machine.

Page 9 of 27 F25386 (0415)

Page 10

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

4. Connect lead wires to 1CON and 2CON in noted

positions.

5. Check steamer for proper operation.

MANUAL DRAIN VALVE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove right SIDE PANEL and REAR PANEL.

2. Remove pin and washer to disconnect the handle

linkage from linkage bracket.

6. Check steamer for leaks and proper operation.

DOOR

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Close door.

2. Remove left SIDE PANEL.

3. Remove nuts from upper hinge located inside

front panel.

Fig. 19

3. Remove nut and linkage bracket.

Fig. 20

4. Remove drain valve.

5. Reassemble parts removed in reverse order of

removal.

Fig. 21

4. Open door slightly, and while holding door, pull

upper hinge away from front panel.

5. Pull upper hinge out of upper door hinge bushing.

6. Lift door assembly up and off lower door hinge.

7. Reinstall parts removed in reverse order of

removal.

8. Check door for fit and proper sealing of gasket.

DOOR GASKET

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Open door.

2. Remove the shoulder screws and pan pusher

bracket from gasket plate.

A. Apply pipe thread sealant to plumbing

threads before assembly.

F25386 (0415) Page 10 of 27

Page 11

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 22

3. Remove gasket plate.

4. Remove gasket from inner door panel.

5. Remove RTV from bottom part of inner door

panel. Apply new RTV 109 to bottom of door

where shown when assembling gasket to door.

Fig. 23

6. Place a small amount of RTV109 into the inner

door panel gasket screw holes before assembly.

7. Position the new gasket on gasket plate and

reverse procedure to install.

DOOR HANDLE

Fig. 24

3. Pull outer door housing away from inner door

panel starting at the hinge side of door to

separate the door halves.

NOTE: The smaller radius of the step spacers fit into

the slots of the outer door housing and is used to

provide clearance for handle operation.

4. Remove lock nuts and stepped spacers from

threaded studs of door handle.

Fig. 25

INSTALLATION

1. Apply Lubriplate 630AA around slots of outer

door housing where step spacers contact

housing.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

REMOVAL

1. Open door.

2. Remove screws from top and bottom of door

assembly.

2. Install door handle into outer door housing such

that hinge side of door housing is to the left and

arrow on handle is pointed upward.

3. Install step spacer with smaller radius toward

handle and door housing. Smaller radius is a slip

fit with outer door housing slot.

Page 11 of 27 F25386 (0415)

Page 12

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

1. Separate outer door housing assembly from

inner door panel as outlined under DOOR

HANDLE.

2. Remove screws securing latch assembly to inner

door panel and remove latch mechanism.

Fig. 26

4. Install lock nuts and tighten until no gap exists

between handle, step spacer and lock nut. Do not

over-tighten lock nuts.

5. Close inner door panel so that latch mechanism

engages striker on front panel.

6. Install outer door housing onto inner door panel.

7. Align the top and bottom screw holes of outer

door housing with inner door panel.

Fig. 27

8. Apply Loctite 7471 Primer N and Loctite 242 to

threads of screws before assembling.

9. Install screws to secure door halves together.

10. Check opening and closing operation of door.

Fig. 28

3. Remove E-clip from latch assembly pins and pull

pins from latch mechanism.

Fig. 29

4. Remove retaining pin from spring pin.

5. Separate sliding bracket from stationary bracket.

DOOR LATCH ASSEMBLY

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

REMOVAL AND DISASSEMBLY

ASSEMBLY

F25386 (0415) Page 12 of 27

Fig. 30

Page 13

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

1. Apply Lubriplate 630AA to sides of sliding

bracket.

2. Insert spring pin into bottom of sliding bracket.

A. Place spring over spring pin.

3. Assemble sliding bracket into stationary bracket.

4. While holding head of spring pin against bottom

of sliding bracket, insert spring pin into keeper

hole in bottom of stationary bracket.

Fig. 31

2. Install outer door housing assembly as outlined

in DOOR HANDLE INSTALLATION.

3. Check opening and closing operation of door.

4. Check steamer for proper operation and leaks

around door seal.

DOOR HINGE BEARINGS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Close door.

2. Remove left side panel, see COVERS AND

PANELS.

3. Remove nuts from upper hinge located inside

front panel.

A. Secure spring pin in place with retaining pin.

NOTE: Install pins such that heads of pins will be

facing inward toward hinge side of inner door panel

when latch assembly is installed.

5. Install pins to assemble stationary and sliding

brackets together.

A. Secure pins into position with E-clip.

INSTALLATION

1. Install latch assembly onto inner door panel with

spring pin toward bottom of door panel.

A. Apply Loctite 271 to threads of screws

before assembly and secure latch assembly

to inner door panel.

Fig. 33

4. Open door slightly, and while holding door, pull

upper hinge away from front panel.

5. Pull upper hinge out of upper door hinge bearing.

6. Lift door assembly up and off lower door hinge.

7. Pry hinge bearing out from door assembly.

8. Remove outer door housing.

Do not drive bearing into place. The inner

door panel could be damaged. Press bearing into

position.

NOTE: When replacing door hinge bearings, replace

both hinge bearings.

Fig. 32

9. Position replacement hinge bearing over hinge

opening in door assembly.

Page 13 of 27 F25386 (0415)

Page 14

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 34

A. Press hinge bearing fully into door assembly

using a C-clamp or equivalent.

10. Reassemble parts removed in reverse order.

11. Check door for fit and proper door gasket sealing.

F25386 (0415) Page 14 of 27

Page 15

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

Certain procedures in this section require electrical test or measurements while power is applied

to the machine. Exercise extreme caution at all times. If test points are not easily accessible, disconnect power and

follow lockout / tagout procedures, attach test equipment and reapply power to the test.

DOOR LATCH ADJUSTMENT

Opening a Jammed Door

Should the steamer door jam and cannot

be opened, DO NOT FORCE OR PRY the door as

damage will occur.

1. Lift up on bottom of door at the handle end to

disengage latch.

A. If door does not open, remove right side

panel, see COVERS AND PANELS .

B. Locate the striker that catches on door latch

near steam chamber on front panel.

Fig. 35

C. Remove nut from striker and this should

release it from the panel.

Fig. 36

D. Open door.

2. Remove striker.

3. Remove any burrs on striker that may cause latch

to stick.

4. Apply Loctite 271 to threads of striker.

5. Reinstall striker with slotted side up. Snug striker

nut. Perform Adjustment, so door will not jam.

Adjustment

1. Reinstall striker with slot pointing upward and

hand tighten nut only.

2. Close door to center striker in front panel

mounting hole.

3. Open door and check striker slot for horizontal

alignment. The slot on striker must be kept

horizontal in order for door latch to catch properly

and latch.

4. Once proper slot alignment has been set, hold

striker close to its base then tighten the striker

nut. Be careful not to damage striker slot when

tightening or door may not latch properly.

NOTE: Do not over-tighten nut. If over-tightened,

striker may turn and change alignment.

NOTE: If door does not open easily, add shims

between striker and cabinet front. When adding shims

make certain that door gasket seals properly and

steamer does not leak. Remove shims as necessary

until leaking stops.

Page 15 of 27 F25386 (0415)

Page 16

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - SERVICE PROCEDURES AND ADJUSTMENTS

HEATING ELEMENT TEST

The heating element assembly contains elements

molded into a cast aluminum block. 3 pan units have

6 elements and 5 pan units have 3 elements. See

wiring diagrams.

1. Turn cooking mode switch to constant.

2. Measure voltage at heating element terminals on

contactors and verify it against data plate

voltage.

NOTE: For 480V units, element voltage is 277V.

A. If voltage is incorrect, find the source of the

problem.

B. If voltage is correct, check current draw

(amps) through the heating element lead

wires.

NOTE: This method is preferred over a resistance

check when a clamp on type amp meter is available.

MODEL VOLTS

208 2003 9.6 21.6

C24EO3

C24EO5

208 664 3.2 65.2

240 2667 11.1 21.6

208 4000 19.2 10.8

240 4000 16.7 14.4

480 4000 14.4 19.2

1. Values in the table are nominal. Tolerance is +5/-10%.

WATTS PER

ELEMENT

1) If current draw is correct then heating

element is functioning properly. See

table below for proper values.

2) If current draw is not correct, turn

cooking mode switch to OFF and

disconnect the electrical supply.

a. Replace heating element

assembly then proceed to step 3.

C. If unable to check current draw, a resistance

check may indicate a malfunctioning

element.

1) Turn the cooking mode switch to OFF

and disconnect the electrical supply.

2) Remove the lead wires from the

heating element and check resistance

(ohms). See table below for proper

values

3. Check for proper operation.

AMPS PER ELEMENT

LEAD

OHMS PER ELEMENT

2. 3 pan 208V units use three 2003W elements and three 664W elements.

NOTES:

TEMPERATURE CONTROL

CALIBRATION

To set the temperature control for optimum steamer

operation, the elevation above sea level for the service

location must first be determined. The steamer was

preset at the factory to sea level.

The elevation is used in conjunction with the elevation

table below, to determine the correct set point

temperature for the control.

NOTE: If the set point temperature is too high, the

excess boiling action will cause water droplets to exit

the steam vent pipe, and cause high water usage.

F25386 (0415) Page 16 of 27

3. 3 pan 208/240V units share the same element assembly block. 240V units use only the

three 2003W-marked elements (2667W actual).

4. Resistance values

1. Remove right side panel, see COVERS AND

2. Place a thermocouple approximately one inch

3. Turn steamer on by selecting constant mode.

4. Allow steamer temperature to stabilize by

5. Record the temperature reading when cook light

6. Using the elevation table, compare the recorded

PANELS .

down in the center of steam vent pipe.

completing two heating cycles.

goes out.

temperature to the temperature listed for the

specific elevation.

Page 17

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - SERVICE PROCEDURES AND ADJUSTMENTS

NOTE: Use temperature scale on control dial plate for

reference only. The scale represents dial turns in 1°F

increments, not the actual temperature. When

calibrating, use the recorded temperature taken from

thermocouple.

ELEVATION (FT) TEMPERATURE (°F)

Sea Level 210

1,000 208

2,000 206

3,000 204

4,000 202

5,000 200

6,000 198

7,000 196

8,000 195

9,000 or above 194

A. If the set point temperature of the control is

correct, no adjustment is necessary.

B. If the set point temperature of the control is

not correct, adjust the temperature control.

1) Turn the temperature control dial

clockwise to increase temperature or

counterclockwise to decrease

temperature.

NOTE: During temperature control adjustment,

display will blink on/off. When display reverts to a

steady image, that displayed temperature set point

has been "locked in" to memory.

Fig. 37

Page 17 of 27 F25386 (0415)

Page 18

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

Buzzer ................ Creates audible signal when timed cook cycle is complete and when a low water condition

exists.

Limiting Contactor

(1CON) ................

Regulating Contactor

(2CON) ................

Heating Element ...... Located below water reservoir. Heats water to produce steam.

Fuses (1FU & 2FU) .... Protect control circuitry from over-currents.

Low Water Light

(1LT) ..................

On Light (2LT) ........ Amber (AM) colored light. Lit when Power Switch (1S) is on.

Cook Light (3LT) ...... Red (RD) colored light. Lit when High Limit (1TAS) and Low Water (2TAS) thermostats

Relay (K1) ............ Controls Regulating Contactor (2CON) based on input from Hold Thermostat (3TAS) and

Relay (K2) ............ Latches Power Switch (1S) circuit. Turns on Low Water Light (1LT) and Buzzer when

Relay (K3) ............ Controlled by Power Switch (1S). Keeps Buzzer from sounding and Low Water Light

Power Switch (1S) .... Rocker switch that turns steamer OFF and ON (momentary on). Switch also resets Low

Supplies line voltage to heating element assembly. Energized whenever Power Switch

(1S) is on and High Limit Thermostat (1TAS) and Low Water Thermostat (2TAS) are

closed.

Supplies line voltage to heating element assembly. Energized whenever Hold

Thermostat (3TAS) is closed or the temperature controller calls for heat.

Amber (AM) colored light. Lit when Low Water Thermostat (2TAS) senses water level is

too low inside steamer.

are closed, door is closed and timer is set.

Temperature Controller. Does not allow Timer Motor to run while Hold Thermostat (3TAS)

is closed.

steamer is low on water.

(1LT) off when switch is in off position.

Water Light (1LT) and Buzzer.

Door Switch (1SW) ... Removes power from a portion of the steamer control circuit when door is opened.

High Limit Thermostat

(1TAS) ................

Low Water Thermostat

(2TAS) ................

Hold Thermostat

(3TAS) ................

Timer Motor .......... Counts cook time of product when time is dialed. Energizes buzzer and de-energizes

Temperature

Control ...............

Temperature Probe ... Senses cooking compartment temperature at steam vent and sends a corresponding DC

Transformer (1T) ..... Steps down line voltage to 120 VAC control circuit voltage.

F25386 (0415) Page 18 of 27

Protects steamer by removing control circuit power if the heating element assembly

temperature goes above 495°F.

Monitors presence of water inside steamer.

Controls temperature of cavity for pre-heat/hold mode (opens at 175°F). Disables timer

countdown if cavity temperature is too low.

temperature controller when time expires.

Monitors temperature probe and cycles power to regulating contactor (2 CON) for steam

generation.

voltage back to the temperature control (J-type thermocouple).

Page 19

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - ELECTRICAL OPERATION

COMPONENT LOCATION

Fig. 38

G. Door closed (door switch closed).

H. Timer off.

I. Cooking compartment filled to the water

level mark and below hold temperature of

175°F (+/- 5°F).

J. Drain valve is closed (drain lever pushed in).

2. Press momentary start switch (1S).

A. Limiting contactor (1CON) coil energized

thru high limit thermostat (1TAS).

1) Line voltage is supplied to one side of

heating elements.

B. Relay K2 coil energized thru low water

thermostat (2TAS).

1) K2-1 N.O. contacts close.

a. Power switch circuit is latched.

2) K2-2 N.C. contacts open.

a. Low water light (1LT) and buzzer

are de-energized.

C. ON indicator light (2LT, amber) comes on.

Fig. 39

SEQUENCE OF OPERATION

SCHEMATIC DIAGRAM AI2851 will be used to

explain the electrical sequence of operation.

Timed Cooking Mode

1. Conditions.

A. Steamer connected to correct voltage and is

properly grounded.

B. Power switch (1S) off.

1) Relay K3 energized. K3 N.C. contacts

open.

C. High limit thermostat closed.

D. Hold thermostat closed.

E. Low water thermostat closed.

F. Temperature control is setup properly and is

ready to use.

D. Relay K1 coil energized thru door switch

and hold thermostat (3TAS).

1) K1-3 N.O. contacts close and

regulating contactor (2CON) coil is

energized.

a. Line voltage is supplied to other

side of heating elements.

Elements heat.

2) K1-2 N.C. contacts open.

3) K1-1 N.C. contacts open (prevents

timer from being energized during

preheat).

3. Steamer reaches 175°F.

A. Hold thermostat opens and relay K1 coil is

de-energized.

1) K1-3 N.O. contacts close and remove

line voltage to heating element

assembly.

2) K1-1 and K1-2 N.C. contacts return to

close condition.

NOTE: Steamer will maintain hold temperature until

a cook time is dialed on timer, door is opened, or

power switch is turned off.

4. Set cook timer to desired time.

NOTE: Timer motor will not run when hold thermostat

(3TAS) is below 175°F.

Page 19 of 27 F25386 (0415)

Page 20

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - ELECTRICAL OPERATION

A. Timer contacts close, timer motor is

energized and timing down begins.

NOTE: Additional time can be set or the cook timer

can be turned off throughout the cooking cycle. If

turned to off, steamer reverts to hold temperature.

B. Cook light (3LT, red) comes on.

C. Temperature controller energized and

evaluates input from thermocouple.

1) If temperature is below set point,

temperature controller internal N.O.

contacts close and energize regulating

contactor (2CON) coil thru K1-2 N.C.

contacts.

a. Line voltage is supplied to other

side of heating elements.

Elements heat.

5. Temperature reaches set point and the

temperature control’s internal N.O. contacts

open.

A. Regulating contactor (2CON) coil

deenergized and power is removed from

heating elements.

Constant Cooking Mode

1. Conditions.

A. Steamer connected to correct voltage and is

properly grounded.

B. Power switch (1S) off.

1) Relay K3 energized. K3 N.C. contacts

open.

C. High limit thermostat closed.

D. Hold thermostat closed.

E. Low water thermostat closed.

Temperature control is setup properly and is

ready to use.

F. Door closed (door switch closed).

G. Timer off.

H. Cooking compartment filled to the water

level mark and below hold temperature of

175°F (+/- 5°F).

I. Drain valve is closed (drain lever pushed in).

2. Press momentary start switch (1S).

6. Steamer cycles on the temperature control until

cook time expires.

7. Time expires on cook timer.

A. Timer contacts 11 & 13 open, timer motor is

de-energized and timing stops.

B. Timer contacts 11 & 14 close.

1) Buzzer energized thru K2 N.O.

contacts and sounds.

NOTE: The buzzer continues to sound until timer dial

is set to off position or additional time is set.

C. Timer contacts 21 & 23 open, cook light

(3LT, red) goes out and temperature

controller is de-energized.

8. Turn cook timer off.

A. Timer contacts 11 & 14 open, buzzer is

deenergized.

B. Steamer reverts to hold temperature and

continues to cycle until a cook time is dialed

on timer, power switch is turned to off, or the

door is opened.

NOTE: If water level becomes low during cycling, low

water thermostat (2TAS) will open and low water light

(1LT, amber) will come on and buzzer will sound.

Timer and heating circuit will be de-energized until

water level is replenished and thermostat closes.

A. Limiting contactor (1CON) coil energized

thru high limit thermostat (1TAS).

1) Line voltage is supplied to one side of

heating elements.

B. Relay K2 coil energized thru low water

thermostat (2TAS).

1) K2 N.O. contacts close.

a. Power switch circuit is latched.

2) K2 N.C. contacts open.

a. Low water light (1LT) and buzzer

are de-energized.

C. ON indicator light (2LT, amber) comes on.

D. Relay K1 coil energized thru door switch

and hold thermostat (3TAS).

1) K1 N.O. contacts close and regulating

contactor (2CON) coil is energized.

a. Line voltage is supplied to other

side of heating elements.

Elements heat.

2) K1 N.C. contacts open.

3. Steamer reaches 175°F.

A. Hold thermostat opens and relay K1 coil is

de-energized.

F25386 (0415) Page 20 of 27

Page 21

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - ELECTRICAL OPERATION

B. K1 N.C. contacts close and N.O. contacts

open.

NOTE: Steamer will maintain hold temperature until

a cook time is dialed on timer, door is opened, or

power switch is turned off.

4. Set cook timer to constant.

A. Timer contacts 21 & 23 close, cook light

(3LT, red) comes on.

B. Temperature controller energized and

evaluates input from thermocouple.

1) If temperature is below set point,

temperature controller internal N.O.

contacts close and energize regulating

contactor (2CON) coil thru K1 N.C.

contacts.

a. Line voltage is supplied to other

side of heating elements.

Elements heat.

5. Temperature reaches set point and the

temperature control’s internal N.O. contacts

open.

A. Regulating contactor (2CON) coil

deenergized and power is removed from

heating elements.

6. Steamer cycles on the temperature control until

cook timer turned off.

7. Turn cook timer off.

A. Timer contacts 21 & 23 open, cook light

(3LT, red) goes out and temperature

controller is de-energized.

B. Steamer reverts to hold temperature and

continues to cycle until a cook time is dialed

on timer, power switch is turned to off, or the

door is opened.

NOTE: If water level becomes low during cycling, low

water thermostat (2TAS) will open and low water light

(1LT, amber) will come on and buzzer will sound.

Page 21 of 27 F25386 (0415)

Page 22

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - ELECTRICAL OPERATION

SCHEMATIC DIAGRAM

Fig. 40

F25386 (0415) Page 22 of 27

Page 23

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - ELECTRICAL OPERATION

WIRING DIAGRAMS - HEATING

ELEMENTS

C24EO3 - 208V/240V

C24EO5 - 208V/240V

C24EO3 - 208V/240V

Page 23 of 27 F25386 (0415)

Page 24

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - ELECTRICAL OPERATION

C24EO5 - 208V/240V

C24EO5 - 480V

F25386 (0415) Page 24 of 27

Page 25

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - ELECTRICAL OPERATION

C24EO5 - 480V

Page 25 of 27 F25386 (0415)

Page 26

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSES

Compartment leaks water around door.

1. Steamer not level.

2. Steamer overfilled.

1. Worn gasket.

Steam leaks around door.

Steamer will not heat (cook light off, low water light off).

Steamer will not heat (cook light on, low water light off).

2. Damaged gasket.

3. Steam vent pipe blocked.

4. Door not adjusted.

1. Line voltage incorrect or transformer malfunction.

2. Control circuit fuse(s) open.

3. High limit thermostat open.

4. Door open or door switch malfunction.

5. Power switch off or inoperative.

6. Relay K3 malfunction.

7. Timer malfunction or timer off (timed mode only).

1. Line voltage incorrect.

2. Heating element malfunction.

3. Regulating contactor malfunction.

4. Relay K1 malfunction.

5. Temperature probe malfunction.

6. Temperature controller malfunction.

1. Door open or door switch malfunction.

Timer motor does not run.

Door not closing properly.

Door won’t open. 1. Latch inoperative.

Buzzer not operating.

Water spraying out of steam vent pipe during a cook

cycle.

F25386 (0415) Page 26 of 27

2. High limit thermostat open.

3. Low water thermostat open.

4. Timer inoperative.

1. Door latch assembly.

2. Striker adjustment.

1. Timer malfunction.

2. Buzzer malfunction.

1. Temperature control set point too high.

2. Temperature probe malfunction.

3. Temperature control malfunction.

Page 27

C24EO SERIES ELECTRIC COUNTERTOP STEAMERS - TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSES

1. Temperature control set point too high.

High water usage.

Excessive or inconsistent cook times.

2. Temperature probe malfunction.

3. Temperature control malfunction.

4. Steamer operating in constant mode.

1. Door left open between loads.

2. Temperature control set point too low.

3. Heating element malfunction.

Page 27 of 27 F25386 (0415)

Loading...

Loading...