Page 1

C24EO SERIES

STEAMER

MODEL ML

C24EO3 ML-136006

INSTALLATION &

OPERATION MANUAL

C24EO5 ML-136007

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanequipment.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANEQUIPMENT.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

FORM F-37496 (03-14 )

Page 2

C24EO SERIES STEAMER

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL THIS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY

THIS MANUAL.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE INSTALLA TION,

OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

© VULCAN-HART, 2014

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

— 2 —

Page 3

C24EO SERIES STEAMER

TABLE OF CONTENTS

INSTALLATION, OPERATION AND CARE OF MODEL C24EO SERIES STEAMERS ....................5

GENERAL ....................................................................................................................................5

INSTALLATION ............................................................................................................................5

UNPACKING................................................................................................................................5

INSTALLATION CODES AND STANDARDS ..............................................................................5

LOCATION...................................................................................................................................5

LEVELING FEET .........................................................................................................................6

LEVELING ...................................................................................................................................6

ANCHORING STEAMER ............................................................................................................6

STACKING STAND ......................................................................................................................6

ELECTRICAL CONNECTIONS ...................................................................................................7

ELECTRICAL DATA .....................................................................................................................8

SERVICE CONNECTIONS .........................................................................................................8

Water Connections ................................................................................................................8

Water Treatment ....................................................................................................................8

Water Requirements ..............................................................................................................8

Drain Connection ...................................................................................................................8

VENT HOOD ...............................................................................................................................9

INSTALLATION STARTUP PROCEDURE ..................................................................................9

Calibration Procedure ..........................................................................................................10

OPERATION ....................................................................................................................................12

CONTROLS ...............................................................................................................................12

OPERATING THE STEAMER ...................................................................................................12

LOW WATER ............................................................................................................................12

SHUTDOWN .............................................................................................................................13

EXTENDED SHUTDOWN .........................................................................................................13

CLEANING ......................................................................................................................................14

COOKING COMPARTMENT DRAIN .........................................................................................14

COMPARTMENT .......................................................................................................................14

DOOR GASKET ........................................................................................................................14

LEAVE COMPARTMENT DOOR OPEN....................................................................................14

STAINLESS STEEL EQUIPMENT CARE AND CLEANING ......................................................15

MAINTENANCE ..............................................................................................................................17

REMOVAL OF LIME SCALE DEPOSITS ..................................................................................17

DOOR GASKET ........................................................................................................................17

COOKING HINTS ............................................................................................................................18

ACCEPTABLE PAN SIZES ........................................................................................................18

— 3 —

Page 4

C24EO SERIES STEAMER

COOKING GUIDELINES ...........................................................................................................18

Preparation ..........................................................................................................................18

Frozen Food Items ...............................................................................................................18

PRODUCTS TO BE COOKED IN SOLID PANS .......................................................................19

PRODUCTS TO BE COOKED IN PERFORATED PANS ..........................................................20

TROUBLESHOOTING ....................................................................................................................22

SERVICE AND PARTS INFORMATION ..........................................................................................23

— 4 —

Page 5

C24EO SERIES STEAMER

INSTALLATION, OPERATION AND CARE OF

MODEL C24EO SERIES STEAMERS

PLEASE KEEP THIS MANUAL FOR FUTURE USE

GENERAL

Vulcan convection steamers are produced

with quality workmanship and material. Proper

installation, usage and maintenance will result

in many years of satisfactory performance. It is

suggested that you thoroughly read this entire

manual and carefully follow all of the instructions

provided.

The C24EO3 Steamer is rated at 8.0 kW and

the C24EO5 Steamer is rated at 12.0 kW.

Model C24EO3 can accommodate three 2

deep (6.4 cm) steam pans. Model C24EO5

can accommodate fi ve 2

steam pans. The C24EO3 and C24EO5

electric convection steamers are designed for

cooking vegetables, eggs, and other foods,

in commercial kitchens. The steamer has a

0 to 60 minute timer. The steamers are designed

for installation on countertops or on optional

stands.

1

/2" deep (6.4 cm)

1

/2"

INSTALLATION

Before installing, verify that the electrical supply

agrees with the specifi cations on the data plate

located on the front of the steamer in the lower

right hand corner. If the supply and equipment

requirements do not agree, do not proceed with

the installation. Contact your dealer or VulcanHart immediately.

The C24EO3 is shipped pre-wired for 208

V, 50 to 60 Hz, 3-phase. 240 V and single

phase operation require changes to the heater

connection 240 V, 50 to 60 Hz, 3-phase / 240

V, 50 to 60 Hz, 1-phase and 208 V, 50 to 60

Hz, 1-phase.

UNPACKING

This steamer was inspected before leaving the

factory. The transportation company assumes full

responsibility for safe delivery upon acceptance

of the shipment. Immediately after unpacking,

check for possible shipping damage. If the

steamer is found to be damaged, save the

packaging material and contact the carrier within

15 days of delivery.

INSTALLATION CODES

AND STANDARDS

The steamer must be installed in accordance

with:

In the United States of America:

1. State and local codes.

2. National Electrical Code, ANSI/NFPA-70

(latest edition). Copies may be obtained from

The National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269.

3. Vapor Removal from Cooking Equipment,

(NFPA-96, latest edition) available from

NFPA.

In Canada:

1. Local codes.

2. Canadian Electric Code, CSA C22.2 (latest

edition). Copies may be obtained from

The Canadian Standard Association, 5060

Spectrum Way, Suite 100, Mississauga,

Ontario, Canada L4W 5N6.

LOCATION

The C24EO5 is voltage specifi c. It is available

at 208 V, 50 to 60 Hz, 3-phase / 240 V, 50 to 60

Hz, 3-phase or 480 V, 50 to 60 Hz, 3-phase. It

can be fi eld converted to single phase.

The installation location must allow adequate

clearances for servicing and proper operation.

Minimum clearance for proper air circulation is

2" (5.1 cm) on the sides and 6" (15.2 cm) on

the back.

— 5 —

Page 6

C24EO SERIES STEAMER

LEVELING FEET

This steamer is shipped with four 2" leveling

feet. Optional 4" leveling feet are available.

The 2" feet can be removed and the optional 4"

feet can be threaded into holes on the bottom

of the unit.

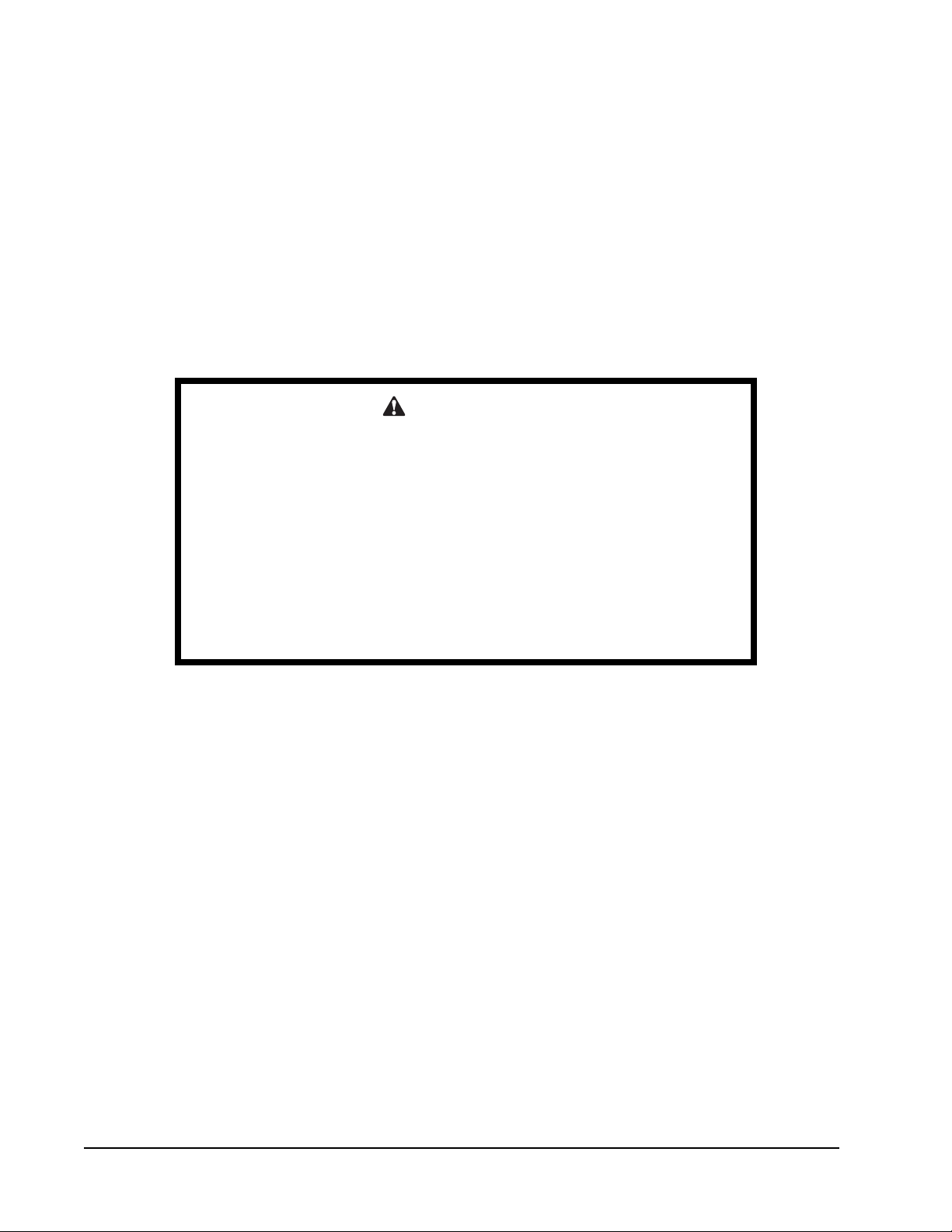

LEVELING

Position and level the unit using leveling feet.

Front of unit should be

the rear as indicated in Figure 1. Unit should be

level side to side.

Level the steamer front to back and side to side

by turning the adjustable feet.

1

/16" to 1/8" higher than

ANCHORING STEAMER

1. Place steamer in the desired location on

the countertop and mark four corners.

Remove the steamer and drill

indicated in Figure 2.

2. Apply a bead of RTV or other NSF approved

sealant around the bottom edge of the

steamer. If anchoring the steamer, this

bottom seal is necessary to meet NSF

requirements.

3. Set steamer on countertop and bolt down

securely with

3

/8" by 16" bolts (not supplied).

Screw length should be tabletop thickness

1

plus

/2" for proper thread engagement.

1

/2" holes as

Figure 1: Leveling Steamer

Figure 2: Anchoring Steamer

OPTIONAL ACCESSORIES

Optional accessories such as stands and

stacking kit will include directions for

assembly.

— 6 —

Page 7

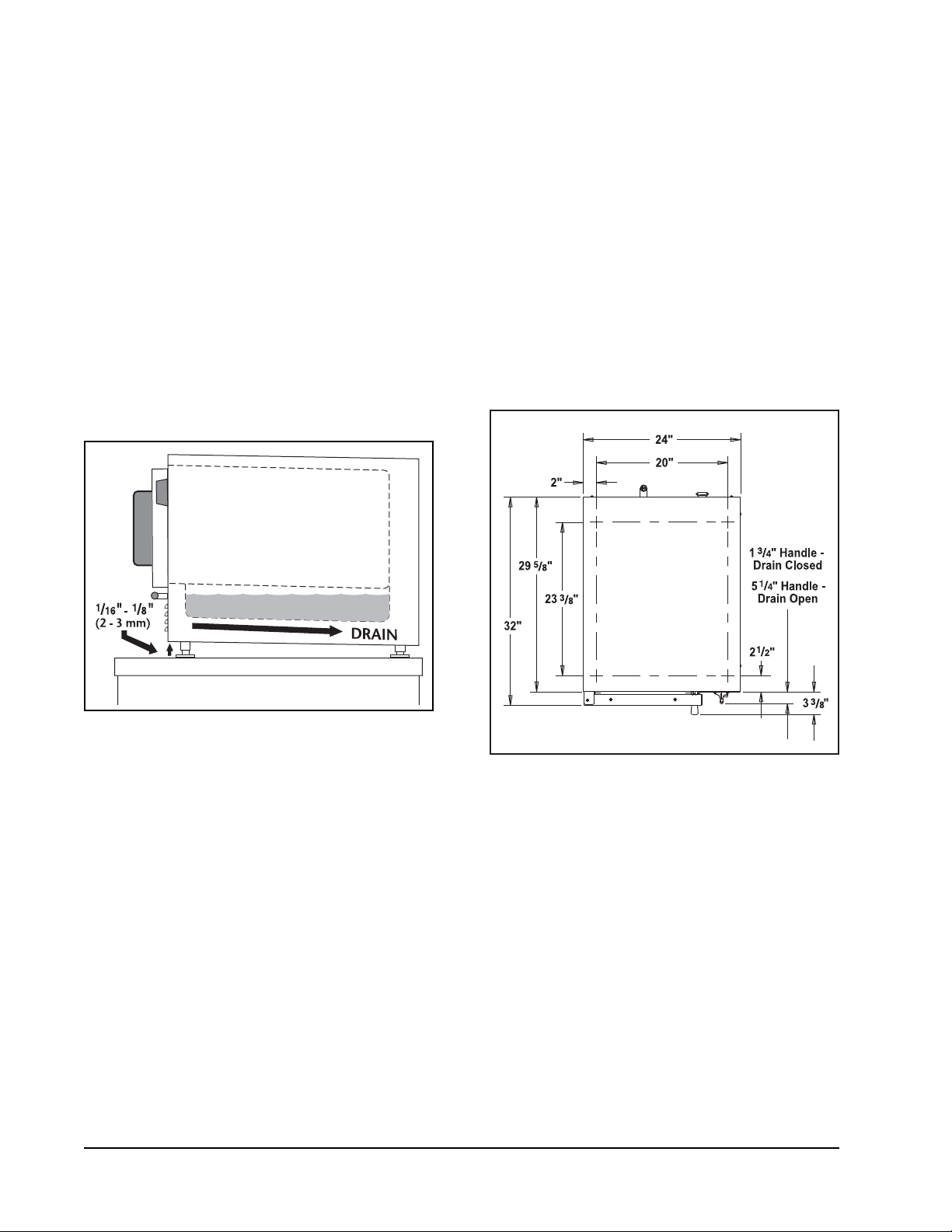

ELECTRICAL CONNECTIONS

To Control

Transformer

To Control

Transformer

3-S, 20

3-S, 20

1-S, 20

1-S, 20

21

2

21

22

23

2

2

2

22

2

23

2

rimary taps of Control Transformer must be connected

according to the appliance data plate voltage marking and

actual connected supply.

To Control

Transformer

3-S, 30

3-S, 1

3-S, 0

1C 1 T1

2C T2 2

1C 2 T2

2C T3 3

2C T1 1

1C 3 - T 3

21

22

23

rimary taps of Control Transformer must be connected

according to the appliance data plate voltage marking and

actual connected supply.

To Control

Transformer

To Control

Transformer

3-S, 2020

1-S, 2020

21

2

21

22

23

2

2

2

22

2

23

2

rimary taps of Control Transformer must be connected

according to the appliance data plate voltage marking and

actual connected supply.

For operation from a 20 supply, all elements are to

be connected as shown. For 20 supply, disconnect and

insulate element leads with range, reen and ed markers.

ot used for

20 operation

: Electrical and

grounding connections must comply

with the applicable portions of the

National Electrical Code and/or other

local electrical codes.

When making electrical connections, use copper

wire suitable for at least 200°F (90°C). The

steamer must be grounded. The wiring diagram

is located on the inside of the right panel.

Steamers are wired for 3-phase and can be

converted to 1-phase by relocating the jumper

wires on the terminal block as shown on the

wiring diagram.

C24EO SERIES STEAMER

— 7 —

Page 8

C24EO SERIES STEAMER

ELECTRICAL DATA

Model Volts KW Amp @

1PH

C24EO3 208 8 38.5 22.2

240 8 33.3 19.2

C24EO5 208 12 57.7 33.3

240 12 50.0 28.9

480 12 N/A 14.4

Amp @

3 PH

SERVICE CONNECTIONS

Water Connections

No water supply connections are required, as

the steamer is fi lled manually.

Water Treatment

A local water treatment specialist should be

consulted before installation of steam generating

equipment.

equipment life. Water conditions vary from one

location to another. Ask your municipal water

supplier for details about your local water supply

prior to installation. Presence of sediment, silica,

excess chlorides or other dissolved solids may

lead to a recommendation for alternate form(s)

of water treatment. Test the water with the test

strip included with the steamer. Other factors

affecting steam generation are iron content,

amount of chloridation and dissolved gases.

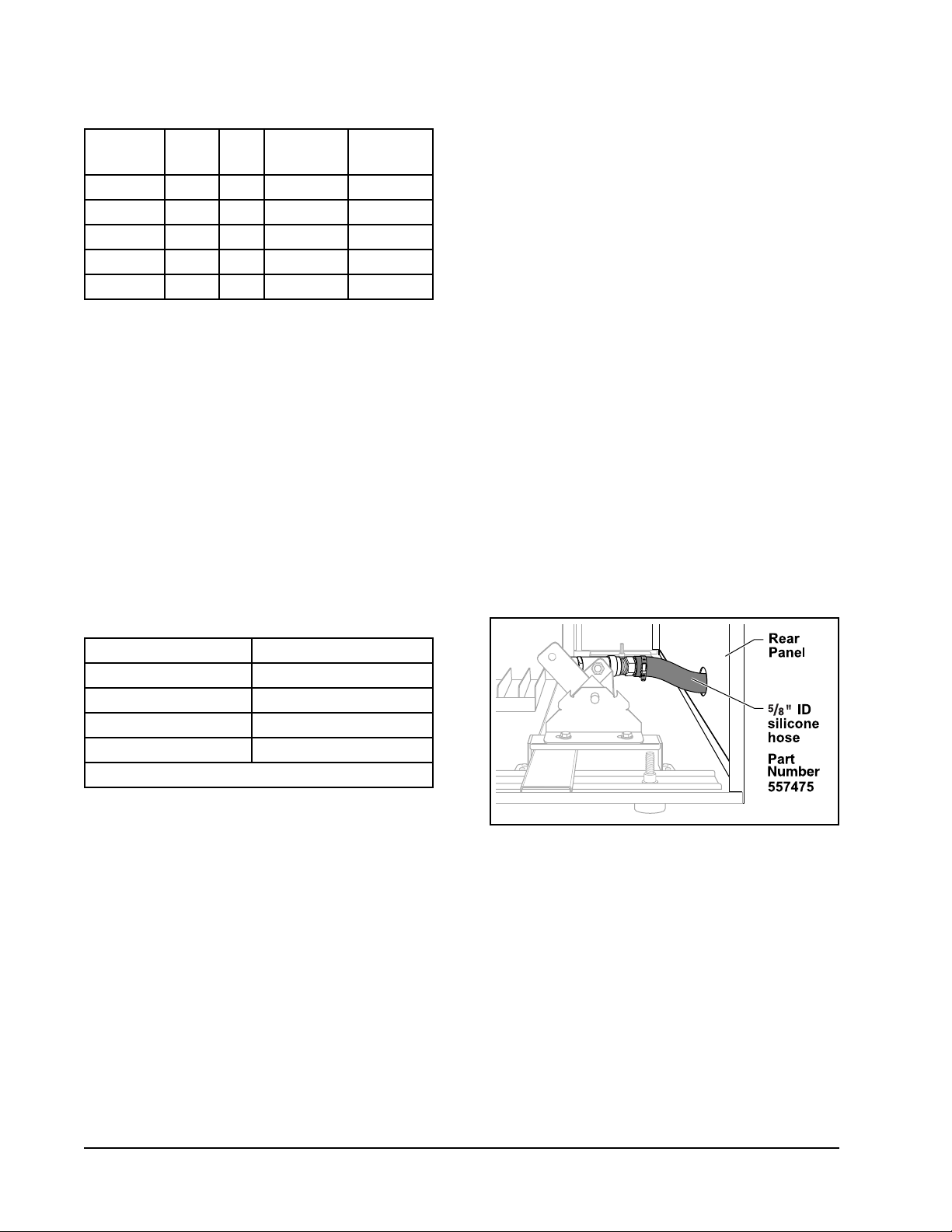

Drain Connection

The C24EO can be confi gured to drain through

either the rear panel or through the bottom base

plate.

The unit is confi gured to be drained through the

rear panel from the factory. The unit is supplied

5

with a 12" length of

/8" ID hose. If this length is

insuffi cient, remove the hose and install a new

hose ordered to the desired length. The factory

5

/8" ID silicone hose part number is 557475. Hose

is sold by the foot.

See Figure 3.

Hardness* No more than 3 grains

Silica less than 13 ppm

Total Chlorine less than 4.0 ppm

PH range 6.5 to 8

Undissolved Solids less than 5 microns

*17.1 ppm = 1 grain of hardness

If the water supply fails to meet these standards,

it will be necessary to install a water conditioner.

The use of strainers or fi lters will not remove

minerals from the water.

Water Requirements

Proper water quality can improve the taste

of the food prepared in the steamer, reduce

liming in the steam generator and extend

Figure 3: Rear Panel Drain Connection

(Viewed with right side panel removed)

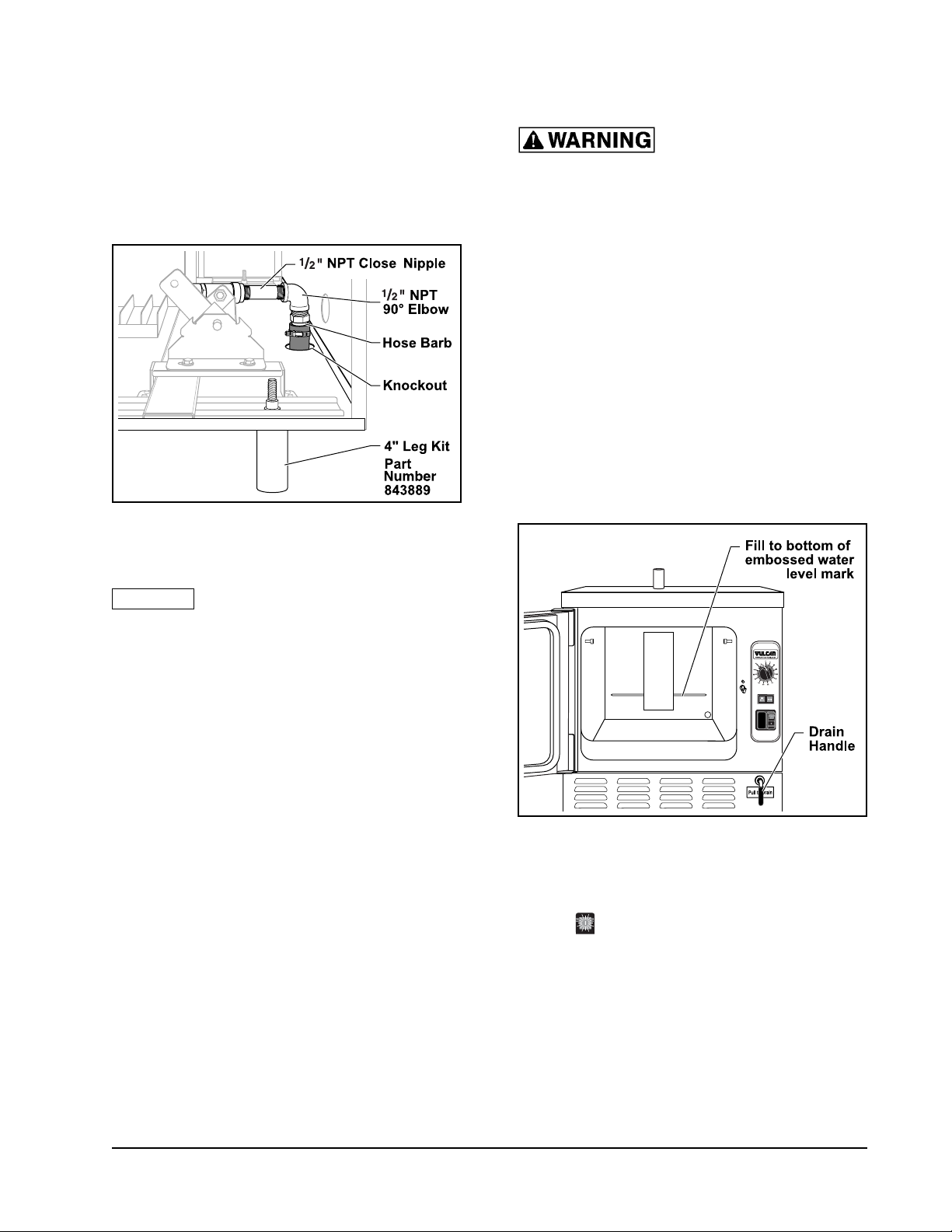

To fi eld confi gure the drain through the bottom

base plate, the 4" leg kit (part number 843889) is

required. Also required are a

nipple (1

1

/8" long) and a 1/2" NPT 90° elbow, which

1

/2" NPT close pipe

are available through local home improvement

or plumbing supply houses.

1. Remove right side panel.

2. Remove hose barb from drain.

— 8 —

3. Remove knockout from base plate.

Page 9

C24EO SERIES STEAMER

4. Install the 1/2" NPT close nipple (11/8" long)

into drain.

1

5. Install

/2" NPT 90° elbow onto pipe nipple.

6. Re-use hose barb.

7. Install hose barb into elbow with clamp, cut

to desired length or route to drain.

Figure 4: Bottom Panel Drain Connection

(Viewed with right side panel removed)

INSTALLATION ST ARTUP PROCEDURE

: The steamer and its

parts are hot. Use care when operating,

cleaning or servicing the steamer. The

cooking compartment contains live steam

and hot water. Stay clear when opening

the door.

Once the steamer is installed, thoroughly test

the steamer before operation.

1. Check that the proper electrical connections

have been made.

2. Close the drain valve by pushing the Drain

Handle in, located in the lower right hand

corner. Open the door and pour water into

the cooking compartment up to the water

level mark (the water level mark is visible

on the back wall of the steamer). Do not

overfi ll.

NOTICE Do not connect steamer drain solidly

to any drain piping. The steamer drain must

vent to the atmosphere to avoid creating a back

pressure and possible back siphoning into the

compartment.

VENT HOOD

Local codes may require the steamer to be

located under an exhaust hood. Information on

the construction and installation of ventilating

hoods may be obtained from Vapor Removal

from Cooking Equipment, NFPA Standard No.

96 (latest edition).

BEFORE FIRST USE

Thoroughly clean the steamer before using for

the fi rst time. See the CLEANING section in

this manual.

Figure 5: Water Level Mark

3. Rotate the Timer to CONTINUOUS position.

Fully depress the Power Switch to the

ON

position. The Power Switch will turn

amber, indicating the unit is turned on.

4. With the door open, press in on the door

switch (small rod), located above the door

latch. The COOK light will come on. Release

the door switch and the COOK light will turn

off.

— 9 —

Page 10

C24EO SERIES STEAMER

5. Close the compartment door and wait

approximately 10 minutes for unit to preheat.

6. Rotate the Timer to 5 minutes. The Timer

will not start counting down until the cavity

has reached preheat temperature.

7. When the timer returns to 0, a buzzer will

sound signaling the end of the cooking cycle.

To silence the buzzer, turn the Timer dial to

the OFF position.

8. To turn the steamer off:

a. Depress the Power Switch to

position.

the OFF

b. Allow the steamer

to cool.

c. Open the drain valve and drain the water

from the steamer.

d. Open the compartment door to allow the

inside to dry out.

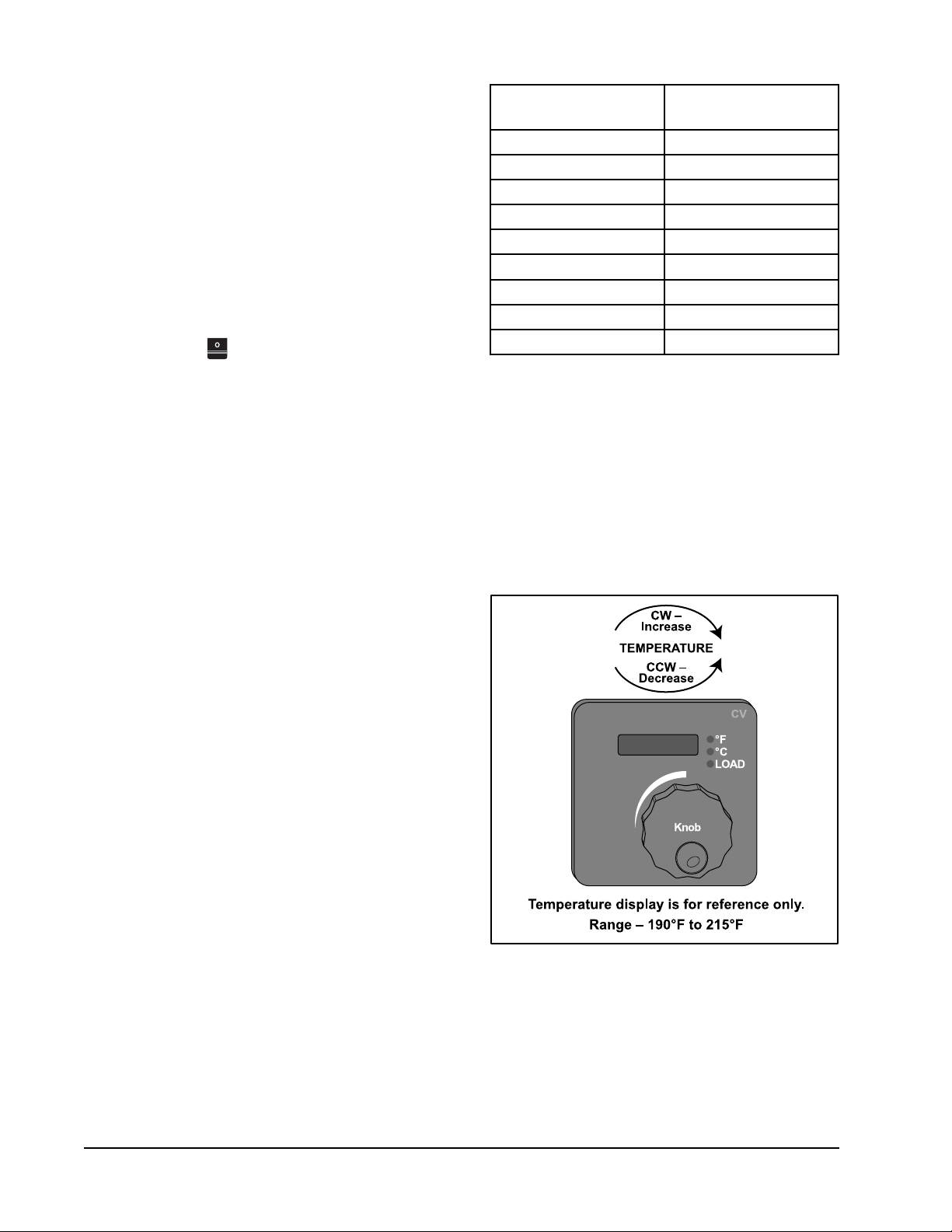

CALIBRATION PROCEDURE

The right hand side panel must be removed

to access the temperature controller. To

achieve optimum steamer operation, rotate the

Temperature Control to the temperature that

corresponds to the elevation that it is located at.

ELEVATION (FT) DIGITAL THER-

MOMETER - °F (C)

Sea Level 210 (99)

1,000 208 (98)

2,000 206 (97)

3,000 204 (96)

4,000 202 (94)

6,000 198 (93)

7,000 196 (91)

8,000 195 (90)

9,000 or above 194 (90)

1. Remove right side panel.

2. Place a temperature probe approximately

one inch down in the center of steam vent

pipe.

3. Turn steamer on by selecting CONTINUOUS

mode.

4. Using the table above, fi nd the corresponding

temperature for the elevation and set the

Temperature Control.

NOTE: The steamer is preset at the factory to

sea level.

A handheld digital thermometer and thermocouple

are required.

NOTE: If temperature setting is too high, the

boiling action will be excessive and

cause water droplets to exit the steam

vent pipe resulting in high water usage.

Figure 6: Temperature Control

— 10 —

Page 11

C24EO SERIES STEAMER

NOTE: Temperature Control is configured

by vendor to Fahrenheit and cannot

be changed to Celsius. The display

indicates set point temperature only.

a. Wait 3 seconds after releasing the knob

for the selection to be saved in memory.

Display will blink momentarily to indicate

temperature is saved.

b. Allow temperature to stabilize by

completing two heating cycles with door

closed.

NOTE: Temperature display on control is for

reference only. When calibrating, use

the recorded temperature from meter.

5. Record temperature reading from meter when

load light goes out.

6. Compare recorded temperature to the

temperature from table.

a. If recorded temperature is correct, no

adjustment is necessary.

b. If recorded temperature is not correct,

adjust temperature setting and re-check

the temperature reading with meter.

NOTE: If unit cannot be calibrated call your

Authorized Vulcan Servicer.

7. If correct temperature reading is not attained

after 3 attempts, call your Authorized Vulcan

Servicer.

— 11 —

Page 12

C24EO SERIES STEAMER

OPERATION

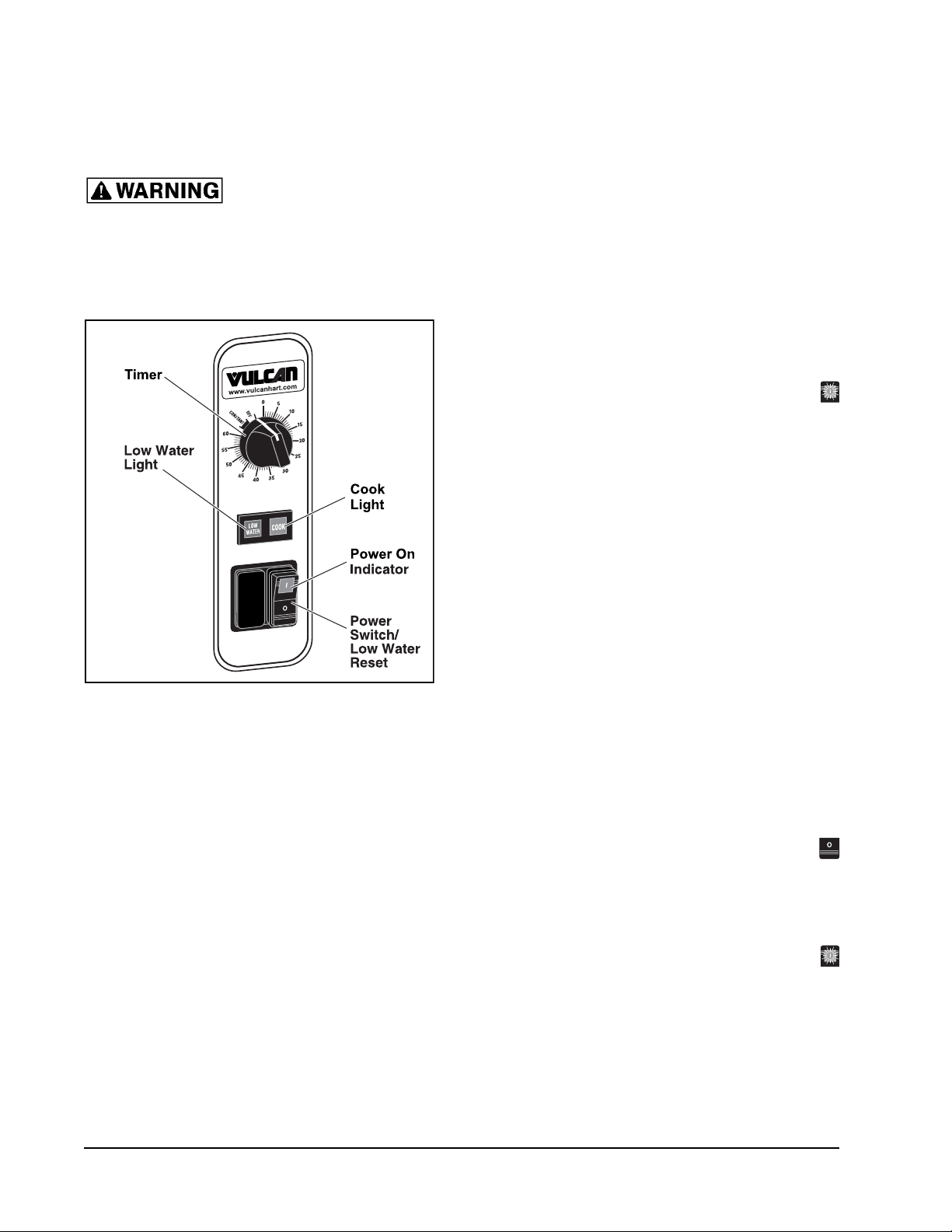

CONTROLS

: The steamer and its

parts are hot. Use care when operating,

cleaning or servicing the steamer. The

cooking compartment contains live steam

and hot water. Stay clear when opening

the door.

OPERATING THE STEAMER

1. Push the the drain lever in to close the drain

valve.

2. Open the door and pour water into the

cooking compartment up to the water level

mark. The water level mark is visible on the

back wall of the steamer. Unit capacity is 3

gallons. Do not overfi ll.

3. Close door.

4. Verify Timer is in the OFF position.

5. Fully depress Power Switch to ON

position. Power light in switch will illuminate

amber.

6. Set timer to 5 minutes. In approximately 15

minutes unit will be preheated and ready to

cook.

7. Set timer to desired time (0 to 60 minutes)

or to CONTINUOUS position.

8. At the end of the timed cycle an audible

alarm will sound.

Figure 7: Controls

Power Switch/Low Water Reset: Turns

unit OFF/ON/RESETS LOW WATER LIGHT/

ALARM.

Low Water Light: When lit, indicates additional

water is required.

Timer: Selects the desired cooking time or the

CONTINUOUS position.

COOK Light: When lit, indicates the timer is

set and door is closed.

9. The unit returns to the idle temperature.

NOTE: Timer will not function until preheat has

been completed.

LOW WATER

1. When the Low Water light is illuminated

the unit needs to be refi lled with water. An

audible alarm will sound.

2. Fully depress Power Switch to OFF

position.

4. Refi ll unit with water.

5. Close door.

6. Fully depress Power Switch to ON

position to cancel Low Water alarm.

7. Timer will resume when steamer reaches

cooking temperature.

NOTE: Refi ll the unit when not in use or during

slow times to avoid running out of water.

Running out of water during a cooking

cycle will lengthen cook time.

— 12 —

Page 13

C24EO SERIES STEAMER

SHUTDOWN

1. Rotate Timer to OFF position.

2. Fully depress Power Switch to OFF

position.

3. Allow steamer to cool.

4. Open the drain valve and drain the water

from steamer.

5. Open the compartment door to allow the

inside to dry.

6. Follow cleaning instructions in this manual.

EXTENDED SHUTDOWN

1. Fully depress Power Switch to OFF

position.

2. Clean the interior and exterior of unit.

3. Leave door open.

4. Disconnect power.

— 13 —

Page 14

C24EO SERIES STEAMER

CLEANING

COOKING COMPARTMENT DRAIN

Remove any particles or debris that may be

blocking the drain. Make a solution of warm

water with non-chloride detergent and pour

1

/2 gallon (1.9 liters) of it down the compartment

drain. Rinse by pouring

hot water down the compartment drain.

1

/2 gallon (1.9 liters) of

Thoroughly clean the exposed surfaces (sides,

front, door and top) with a damp cloth and polish

with a clean cloth daily. To remove discolorations,

use a nonabrasive cleaner.

DOOR GASKET

Clean the gasket sealing surface of the

compartment door daily to remove food acids for

maximum gasket life. Do not use any solvents or

sharp instruments. Wash with a cloth moistened

in a solution of mild detergent and warm water.

Rinse with a fresh cloth moistened with warm

water to remove all traces of detergent.

Wipe dry with a clean cloth. Never apply food

oils or petroleum lubricants directly to the door

gasket. Petroleum-based solvents and lubricants

will reduce gasket life.

LEAVE COMPARTMENT DOOR OPEN

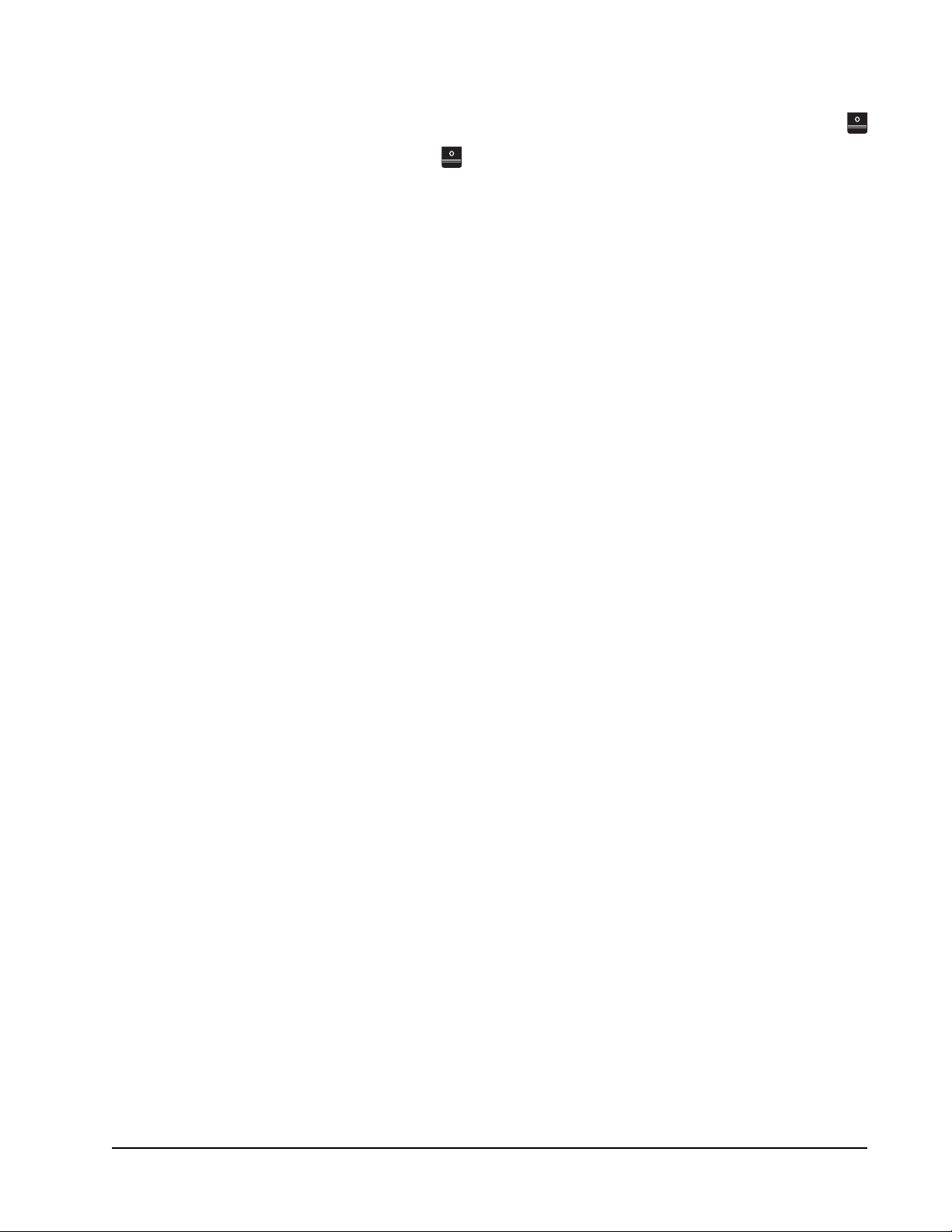

Figure 8: Oven Cavity

COMPARTMENT

The compartment, pan guides, and baffl e should

be cleaned daily. The exterior should be cleaned

daily.

Remove the pan guides by lifting up and out.

Wash with a solution of warm water with nonchloride detergent. Rinse with warm water.

Remove the baffl e from the compartment by

lifting up and out. Wash with a solution of warm

water with non-chloride detergent. Rinse with

warm water.

NOTE: Failure to reinstall baffl e after cleaning

will affect cooking performance.

Wash the inside of the compartment with

a solution of warm water with non-chloride

detergent. Rinse with warm water.

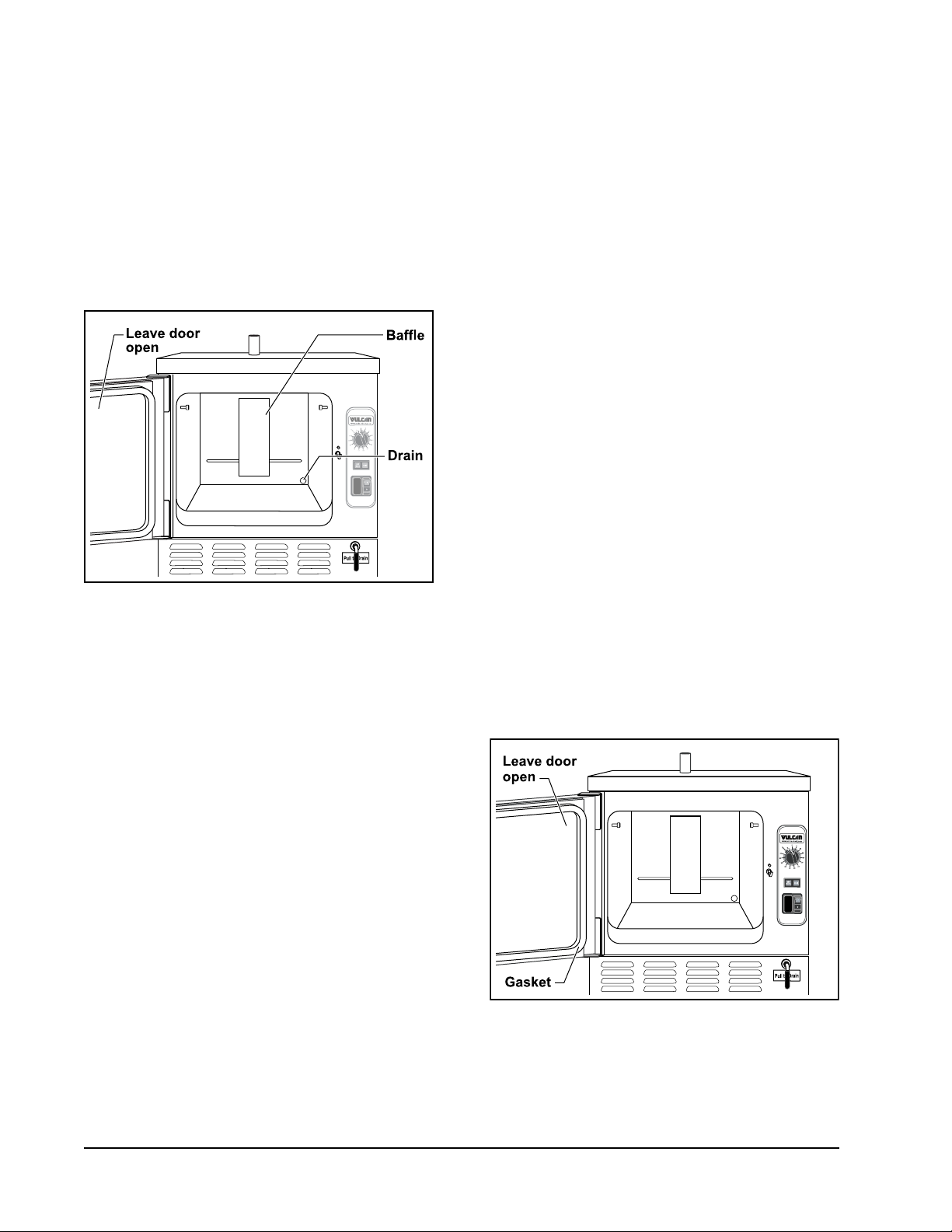

Leave the compartment door slightly open when

the steamer is not in use. When the compartment

is idle, never latch the door and apply pressure

to the door gasket. Leaving the gasket under

pressure can cause permanent deformation

and reduce gasket life.

Figure 9: Leave Door Open

— 14 —

Page 15

C24EO SERIES STEAMER

STAINLESS STEEL EQUIPMENT CARE

AND CLEANING

Contrary to popular belief, stainless steels

ARE susceptible to rusting.

Corrosion on metals is everywhere. It is

recognized quickly on iron and steel as unsightly

yellow/orange rust. Such metals are called

“active” because they actively corrode in a

natural environment when their atoms combine

with oxygen to form rust.

Stainless steels are passive metals because

they contain other metals, like chromium,

nickel and manganese, that stabilize the atoms.

400 series stainless steels are called ferritic,

contain chromium, and are magnetic; 300 series

stainless steels are called austenitic, containing

chromium and nickel; and 200 series stainless,

also austenitic, contains manganese, nitrogen

and carbon. Austenitic types of stainless are

not magnetic, and generally provide greater

resistance to corrosion than ferritic types.

With 12 to 30% chromium, an invisible passive

fi lm covers the steel’s surface acting as a shield

against corrosion. As long as the fi lm is intact

and not broken or contaminated, the metal is

passive and stainless. If the passive fi lm of

stainless steel has been broken, equipment

starts to corrode and starts to rust.

Enemies of Stainless Steel

There are three basic things which can break

down stainless steel’s passivity layer and allow

corrosion to occur.

1. Mechanical abrasion.

Water comes out of the faucet in varying degrees

of hardness. Depending on what part of the

country you live in, you may have hard or soft

water. Hard water may leave spots, and when

heated leaves deposits behind that if left to sit, will

break down the passive layer and rust stainless

steel. Other deposits from food preparation and

service must be properly removed.

Chlorides are found nearly everywhere. They

are in water, food and table salt. One of the worst

chloride perpetrators can come from household

and industrial cleaners.

So what does all this mean?

Don’t despair!

Here are a few steps that can help prevent

stainless steel rust.

1. Use the proper tools.

When cleaning stainless steel products, use

non-abrasive tools. Soft cloths and plastic

scouring pads will not harm steel’s passive

layer. Stainless steel pads also can be used

but the scrubbing motion must be in the

direction of the manufacturers’ polishing

marks.

2. Clean with the polish lines.

Some stainless steel comes with visible

polishing lines or grain. When visible lines

are present, always scrub in a motion parallel

to the lines. When the grain cannot be seen,

play it safe and use a soft cloth or plastic

scouring pad.

3. Use alkaline, alkaline chlorinated or nonchloride containing cleaners.

2. Deposits and water.

3. Chlorides.

Mechanical abrasion means those things that

will scratch a steel surface. Steel pads, wire

brushes and scrapers are prime examples.

While many traditional cleaners are loaded

with chlorides, the industry is providing

an ever-increasing choice of non-chloride

cleaners. If you are not sure of chloride

content in the cleaner used, contact your

cleaning supplier. If your present cleaner

contains chlorides, ask your supplier if

they have an alternative. Avoid cleaners

containing quaternary salts; it also can attack

stainless steel and cause pitting and rusting.

— 15 —

Page 16

C24EO SERIES STEAMER

4. Treat your water.

Though this is not always practical,

softening hard water can do much to reduce

deposits. There are certain fi lters that can be

installed to remove distasteful and corrosive

elements. To insure proper water treatment,

call a treatment specialist.

5. Keep your food equipment clean.

Use alkaline, alkaline chlorinated or non-

chloride cleaners at recommended strength.

Clean frequently to avoid build-up of hard

stubborn stains. If you boil water in stainless

steel equipment, remember the single

most likely cause of damage is chlorides

in the water. Heating cleaners that contain

chlorides have a similar effect.

6. Rinse, rinse, rinse.

If chlorinated cleaners are used, rinse

and wipe equipment and supplies dry

immediately. The sooner you wipe off

standing water, especially when it contains

cleaning agents, the better. After wiping

equipment down, allow it to air dry; oxygen

helps maintain the stainless steel’s passivity

fi lm.

7. Never use hydrochloric acid (muriatic

acid) on stainless steel.

8. Regularly restore/passivate stainless

steel.

Recommended cleaners for specifi c

situations

Job

Routine

cleaning

Fingerprints &

smears

Stubborn

stains &

discoloration

Grease & fatty

acids, blood,

burnt-onfoods

Grease & oil Any good

Restoration/

Passivation

Cleaning

Agent

Soap,

ammonia,

detergent,

Medallion

Arcal 20,

Lac-O-Nu

Ecoshine

Cameo, Talc,

Zud, First

Impression

Easy-off,

De-Grease It

Oven Aid

commercial

detergent

Benefi t, Super

Sheen

Comments

Apply with

cloth or

sponge

Provides

barrier fi lm

Rub in

direction of

polish lines

Excellent

removal on all

fi nishes

Apply with

sponge or

cloth

Review

1. Stainless steels rust when passivity (fi lm-shield) breaks down as a result of scrapes, scratches,

deposits and chlorides.

2. Stainless steel rust starts with pits and cracks.

3. Use the proper tools. Do not use steel pads, wire brushes or scrapers to clean stainless steel.

4. Use non-chlorinated cleaners at recommended concentrations. Use only chloride-free cleaners.

5. Soften your water. Use fi lters and softeners whenever possible.

6. Wipe off cleaning agent(s) and standing water as soon as possible. Prolonged contact causes

eventual problems.

To learn more about chloride-stress corrosion and how to prevent it, contact the equipment manufacturer

or cleaning material supplier.

Developed by Packer Engineering, Naperville, Ill., an independent testing laboratory.

— 16 —

Page 17

MAINTENANCE

C24EO SERIES STEAMER

: The steamer and its

parts are hot. Use care when operating,

cleaning or servicing the steamer. The

cooking compartment contains live steam

and hot water. Stay clear when opening

the door.

Steamer must be cleaned daily. See CLEANING

section.

REMOVAL OF LIME SCALE DEPOSITS

: Read and follow the

instructions on the deliming material

package. Avoid contact with skin and eyes.

Wear plastic or rubber gloves and safety

goggles when handling. Wash thoroughly

after handling. If deliming solution comes

in contact with the skin or eyes, rinse

thoroughly with clean water.

: The steamer and its

parts are hot. Use care when operating,

cleaning or servicing the steamer. The

cooking compartment contains live steam

and hot water. Stay clear when opening

the door.

The steamer should be delimed when scale

is present in the cavity well. Deliming may be

required frequently depending on water quality

and scale build up. This is in accordance with

the minimum preventive maintenance schedule

required by warranty.

2. Plastic or rubber gloves.

3. Safety goggles or face shield.

4. Spray bottle.

5. 1-gallon container for mixing the deliming

solution.

NOTE: Deliming solution may cause the surface

of aluminum measuring tools to tarnish

or etch.

Procedure:

1. Turn steamer off. Drain the steamer.

2. One bag will treat a C24EO3 or C24EO5

steamer.

• 1 bag to 2 gallons warm water

3. Spray cavity walls with solution. Pour solution

into cavity well.

• Maximum steamer capacity 3 gallons

position

position.

4. Fully depress Power Switch to ON

and set Timer for 5 min. After timer sounds,

rotate Timer dial to OFF position and fully

depress Power Switch to OFF

5. Let delime solution soak for a minimum of

30 minutes, maximum 60 minutes. If scale

is still present, repeat steps 1 through 5.

6. Drain the steamer and rinse thoroughly with

warm clean water.

7. Dry with a clean dry cloth.

8. Leave steamer door open when not in use.

Items required (not provided):

1. Deliming Solution – Scale Release™

Part Number 854893-13 (qty. 1).

• Contact the local Authorized Vulcan

Servicer or refer to website www.

vulcanequipment.com

DOOR GASKET

If the door gasket is leaking due to a nick or

cut, it must be replaced. Damage to the gasket

sealing surface will cause steam leakage.

— 17 —

Page 18

C24EO SERIES STEAMER

COOKING HINTS

The steamer effi ciently cooks vegetables and

other foods for immediate serving. Steam

cooking should be carefully time controlled.

Keep hot food holding-time to a minimum to

produce the most appetizing results. Prepare

small batches. Cook only enough to start serving,

then cook additional amounts to meet demand.

ACCEPTABLE PAN SIZES

The steamer accommodates combinations of full,

half and one-third size pans, solid or perforated.

Model Number of Pans Accommodated

Depth of Pan

1" 21/2"4" 6"

C24EO3 6321

C24EO5 10 5 3 2

COOKING GUIDELINES

PREPARATION

Prepare vegetables, fruits, meats, seafood and

poultry normally by cleaning, separating, cutting,

removing stems, etc. Cook root vegetables in

a perforated pan. Other vegetables may be

cooked in a perforated pan unless juices are

being saved. Liquids can be collected in a solid

12" x 20" pan placed under a perforated pan.

Perforated pans are used for frankfurters,

wieners and similar items when juices do not

need to be preserved. Solid pans are good

for cooking puddings, rice, and hot breakfast

cereals. Vegetables and fruits are cooked in

solid pans in their own juice. Meats and poultry

are cooked in solid pans to preserve their juice

or retain broth.

Canned foods can be heated in their opened

cans (cans placed in 12" x 20" solid pans) or

the contents may be poured into solid pans.

DO NOT place unopened cans in the steamer.

The steamer cooks vegetables, frankfurters,

eggs in their shells, and certain other meats or

food items at atmospheric pressure.

These cooking guidelines are suggestions only.

You should experiment with your food products

to determine the cooking times that will give you

the best results. Variables which affect cooking

time include size, weight, thickness of foods,

temperature, density, previous condition of the

foods (fresh, pre-blanched or frozen) and degree

of doneness desired.

Frozen Food Items

Separate frozen foods into smaller pieces to

allow more effi cient cooking.

Use a pan cover for precooked frozen dishes

that cannot be cooked in the covered containers

in which they are packed if they require more

than 15 minutes of cooking time. When a cover is

used, approximately one-third additional cooking

time is necessary.

Cooking time for frozen foods depends on the

amount of defrosting required. If time permits,

allow frozen foods to partially thaw overnight in

a refrigerator. This will reduce their cooking time.

— 18 —

Page 19

C24EO SERIES STEAMER

PRODUCTS TO BE COOKED IN SOLID PANS

PRODUCT TIME (MINUTES) WEIGHT PER PAN

Eggs, Scrambled 9 to 12 8 doz.

Rice, Long Grain (Cover with 4 cups water/lb.) 23 to 25 2 lbs.

Pasta (Place perforated pan inside solid pan,

cover with cold water)

Spaghetti – Regular/Vermicelli 10 to 15

Macaroni - Shells/Elbows 13 to 18

Noodles - 1/2" Wide 10 to 15

Lasagna Noodles 13 to 18

Frozen Casseroles, Lasagna 33 to 35 Full Pan

Meat Loaf, 3-5 Lb. Each 38 to 40 15 lbs.

Beef

Ground Chuck 19 to 25 10 lbs.

Sliced as Purchased 33 to 40 10 lbs.

Shrimp, Frozen, 10 Shrimp per Lb. 4 to 5 4 lbs.

Beans

Baked 8 to 9 10 lb. Can

Refried 8 to 9 10 lb. Can

Canned Vegetables 5 to 6 10 lb. Can

Prunes, Dried 11 to 15

— 19 —

Page 20

C24EO SERIES STEAMER

PRODUCTS TO BE COOKED IN PERFORATED PANS

PRODUCT TIME (MINUTES) WEIGHT PER PAN

SEAFOOD

Clams

Frozen 9 to 12 3 doz.

Fresh, Cherrystone 4 to 6 3 doz.

King Crab, Frozen

Claws 3 to 4 2

Legs 3 to 6 4

Lobster Tail, Frozen 5 to 6 10 lbs.

Lobster, Live, 10" - 12" 4 to 5 4 Per Pan

Salmon Fillets, Frozen, 8 ounce each 4 to 5 7

Scallops, Fresh 3 to 4 3 lbs.

Scrod Fillets, Fresh 3 to 5 4 lbs.

EGGS

1

/2 lbs.

1

/2 lbs.

1

/2 lbs.

Hard Cooked 14 to 15 4 doz.

Soft Cooked 8 to 10 4 doz.

Soft Yoke for Caesar Salad 5 to 8 4 doz.

MEATS

Chicken — Breasts, Legs, Thighs 19 to 20 15 lbs.

Turkey, Frozen

Breasts (2) 86 to 90 6 to 7 lbs. Each

Cut Lengthwise 53 to 55 20 to 25 lbs.

Corned Beef 40 to 75 6 to 8 lbs.

Hot Dogs and Wieners 2 to 3 80 to 100 Count

VEGETABLES

Asparagus Spears

Frozen 10 to 12 3 lbs.

Fresh 4 to 5 5 lbs.

Beans

Green 2" Cut, Frozen/Fresh 5 to 6 5 lbs.

Lima, Frozen 7 to 8 5 lbs.

Baby Lima, Frozen 4 to 5 5 lbs.

Brussel Sprouts, Frozen 5 to 6 5 lbs.

— 20 —

Page 21

C24EO SERIES STEAMER

PRODUCT TIME (MINUTES) WEIGHT PER PAN

VEGETABLES (Cont’d.)

Broccoli

Spears, Frozen 6 to 8 4 lbs.

Spears, Fresh 4 to 6 5 lbs.

Flowerettes, Frozen 4 to 6 5 lbs.

Cabbage, Fresh, 1/6 Cut 6 to 8 5 lbs.

Carrots

Baby Whole, Frozen 6 to 8 7 lbs.

Crinkle Cut, Frozen 7 to 8 4 lbs.

Sliced, Fresh 9 to 11 9 lbs.

Caulifl ower, Flowerettes

Frozen 4 to 6 4 lbs.

Fresh 7 to 8 5 lbs.

Celery, 1" Diagonal Cut 5 to 7 5 lbs.

Corn

Yellow Whole Kernel, Frozen 3 to 5 5 lbs.

Cobbettes, Frozen 6 to 8 27 Ears

Corn-On-Cob, Fresh 16 to 18 80 Ears

16 to 18 54 Ears

10 to 12 18 Ears

Peas, Green 4 to 6 5 lbs.

Potatoes, Whole Russet 50 to 55 40 lbs.

Spinach

Chopped, Frozen 15 to 17 6 lbs.

Defrosted 4 to 5 6 lbs.

Fresh Cut 2 to 3 2 lbs.

Squash, Acorn Halves 22 to 25 10 Halves

Zucchini, Slices 6 to 8 10 lbs.

Frozen Mixed Vegetables 6 to 7 5 lbs.

FRUIT

Fruit, Blanch for Peeling

Grapefruit, Oranges 2 to 3

Pineapple, Whole for Cutting 2 to 4

— 21 —

Page 22

C24EO SERIES STEAMER

TROUBLESHOOTING

SYMPTOMS POSSIBLE CAUSES REMEDY

Steamer not steaming No main power source. Check the power source.

Door is open. Close door.

Power switch in OFF position. Set power switch to ON.

Timer is off. Set Timer.

Needs water. Add water.

Steamer not steaming

properly

Door leaks Damaged door gasket. Check door gasket for

Water does not drain

properly

Excessive scale buildup in the

cavity well.

Not connected to correct

voltage.

Damage to gasket sealing

surface.

Blocked or obstructed steam

vent.

Unit not level. See leveling instructions in

Drain clogged. Unclog drain.

Descale the steamer (see

REMOVAL OF LIME SCALE

DEPOSITS).

If voltage is not correct,

contact your Authorized Vulcan

Servicer.

damage.

If adjustment is needed,

contact your Authorized Vulcan

Servicer.

Clear steam vent.

the installation section of this

manual.

Water foaming Cooking seafood without catch

pan.

— 22 —

Use a catch pan. Drain and

replace water.

Page 23

C24EO SERIES STEAMER

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this model, contact the Authorized Vulcan Servicer

in your area. Refer to our website, www.vulcanequipment.com for a complete listing of Authorized

Service and Parts depots.

When calling for service, the following information (located on your machine data plate) must be available:

Model Number

Serial Number

Manufacture Date (MD)

Voltage

— 23 —

Page 24

C24EO SERIES STEAMER

(03-14)

— 24 —

PRINTED IN U.S.A.

Page 25

IMPRIMÉ AUX ÉTA TS-UNIS.

— 24 —

(03-14)

CUISEUR À VAPEUR DE SÉRIE C24EO

Page 26

— 23 —

CUISEUR À VAPEUR DE SÉRIE C24EO

Tension

Date de fabrication (MD)

Numéro de série

Numéro de modèle

signalétique de votre machine) doivent être disponibles :

Lorsque vous appelez pour un service, les renseignements suivants (qui se trouvent sur la plaque

vulcanequipment.com pour obtenir une liste complète des services autorisés et des dépôts de pièces.

avec le préposé à l'entretien Vulcan agréé de votre région. Reportez-vous à notre site Web, www.

Pour obtenir des renseignements sur l'entretien et les pièces relatifs à ce modèle, communiquez

RENSEIGNEMENTS SUR L'ENTRETIEN ET LES PIÈCES

Page 27

— 22 —

et remplacez l'eau.

Utilisez une cuvette. Vidangez

du présent manuel.

section relative à l'installation

de mise à niveau dans la

Nettoyez l'évent à vapeur.

à l'entretien Vulcan agréé.

communiquez avec le préposé

Si un réglage est nécessaire,

dommages éventuels.

de la porte pour détecter des

Vérifi ez le joint d'étanchéité

l'entretien Vulcan agréé.

avec votre préposé à

appropriée, communiquez

Si la tension n'est pas

cuvette.

Vidange bouchée. Débouchez la vidange.

L'unité n'est pas de niveau. Reportez-vous aux instructions

obstrué.

Évent à vapeur bouché ou

d'étanchéité du joint.

Dommages à la surface

endommagé.

Joint d'étanchéité de la porte

appropriée.

Pas branché à la tension

Mousse sur l'eau Cuisson de fruits de mer sans

correctement

L'eau ne s'écoule pas

porte

Fuites au niveau de la

CALCAIRES).

RETRAIT DES DÉPÔTS

(reportez-vous à la section

Détartrez le cuiseur à vapeur

(MARCHE).

d'alimentation à la position ON

Réglez le commutateur

d'alimentation.

Vérifi ez la source

DÉPANNAGE

cavité.

tartre dans la paroi de la

Accumulation excessive de

Besoin d'eau. Ajoutez de l'eau.

La minuterie est désactivée. Réglez la minuterie.

la position OFF (ARRÊT).

Commutateur d'alimentation à

La porte est ouverte. Fermez la porte.

principale.

Aucune source d'alimentation

la vapeur

cuit pas correctement à

Le cuiseur à vapeur ne

cuit pas à la vapeur

Le cuiseur à vapeur ne

SYMPTÔMES CAUSES POSSIBLES ACTIONS CORRECTIVES

CUISEUR À VAPEUR DE SÉRIE C24EO

Page 28

— 21 —

Ananas, entier pour découper 2 à 4

Pamplemousses, oranges 2 à 3

Fruits, blanchir pour éplucher

FRUITS

Légumes mélangés congelés 6 à 7 5 lb.

Courgette Zucchini en tranches 6 à 8 10 lb.

Demi-courges, demi-glands 22 à 25 10 moitiés

Frais coupés 2 à 3 2 lb.

Décongelés 4 à 5 6 lb.

Hachés, congelés 15 à 17 6 lb.

Épinards

Pommes de terre, reinette entière 50 à 55 40 lb.

Pois verts 4 à 6 5 lb.

10 à 12 18 épis

16 à 18 54 épis

Maïs en épis frais 16 à 18 80 épis

Morceaux d'épis congelés 6 à 8 27 épis

Graine entière jaune congelée 3 à 5 5 lb.

Maïs

Céleri, coupe diagonale de 1 po 5 à 7 5 lb.

Frais 7 à 8 5 lb.

congelés 4 à 6 4 lb.

Choux-fl eurs, bouquets

Tranchées, fraîches 9 à 11 9 lb.

Coupe ondulée congelée 7 à 8 4 lb.

Mini-carottes entières congelées 6 à 8 7 lb.

Carottes

Chou frais, coupe de 1/6 6 à 8 5 lb.

Bouquets congelés 4 à 6 5 lb.

Turions frais 4 à 6 5 lb.

PLATEAU

Turions congelés 6 à 8 4 lb.

Brocoli

LÉGUMES (suite.)

ALIMENT TEMPS (MINUTES) POIDS PAR

CUISEUR À VAPEUR DE SÉRIE C24EO

Page 29

— 20 —

Choux de Bruxelles congelés 5 à 6 5 lb.

Mini-Lima congelé 4 à 5 5 lb.

Lima congelé 7 à 8 5 lb.

verts, coupe de 2 po, congelés/frais 5 à 6 5 lb.

Haricots

Frais 4 à 5 5 lb.

congelés 10 à 12 3 lb.

Turion d'asperge

LÉGUMES

Hot-dogs et saucisses 2 à 3 80 à 100 moules

Bœuf salé 40 à 75 6 à 8 lb.

coupe en longueur 53 à 55 20 à 25 lb.

Poitrines (2) 86 à 90 6 à 7 lb. Chaque

/2 lb.

/2 lb.

/2 lb.

Dinde congelée

Poulet – poitrines, jambes, cuisses 19 à 20 15 lb.

VIANDES

Texture souple pour salade César 5 à 8 4 douzaines.

Œuf à la coque 8 à 10 4 douzaines.

Œuf dur 14 à 15 4 douzaines.

ŒUFS

Filets d'églefi n frais 3 à 5 4 lb.

Pétoncles frais 3 à 4 3 lb.

1

Filets de saumon congelés, 8 onces chacun 4 à 5 7

Homard vivant de 10 po à 12 po 4 à 5 4 par plateau

Queue de homard congelée 5 à 6 10 lb.

1

1

Pattes 3 à 6 4

Pinces 3 à 4 2

Crabe royal congelé

Palourde américaine fraîche 4 à 6 3 douzaines.

congelées 9 à 12 3 douzaines.

PLATEAU

Praires

FRUITS DE MER

ALIMENT TEMPS (MINUTES) POIDS PAR

ALIMENTS À CUIRE DANS DES PLATEAUX PERFORÉS

CUISEUR À VAPEUR DE SÉRIE C24EO

Page 30

de 10 lb

de 10 lb

— 19 —

Pruneaux séchés 11 à 15

Conserves de légumes 5 à 6 Boîte de conserve

Haricots frits 8 à 9 Boîte de conserve

de 10 lb

Cuit au four 8 à 9 Boîte de conserve

Haricots

Crevettes congelées, 10 crevettes par lb. 4 à 5 4 lb.

En tranches telles qu'achetées 33 à 40 10 lb.

Viande de bœuf hachée 19 à 25 10 lb.

Viande de bœuf

Pain de viande, 3-5 lb chaque 38 à 40 15 lb.

Cocottes gelées, lasagnes 33 à 35 Plateau entier

Nouilles Lasagnes 13 à 18

Nouilles – 1/2 po de large 10 à 15

Macaroni – Shells/Elbows 13 à 18

Spaghetti – Regular/Vermicelli 10 à 15

couvrez avec de l'eau froide)

l'intérieur du plateau solide,

Pâtes alimentaires (placez le plateau perforé à

PLATEAU

Riz long grain (couvrez avec 4 tasses d'eau/lb.) 23 à 25 2 lb.

Œufs brouillés 9 à 12 8 douzaines.

(MINUTES)

POIDS PAR

ALIMENT TEMPS

ALIMENTS À CUIRE DANS DES PLATEAUX SOLIDES

CUISEUR À VAPEUR DE SÉRIE C24EO

Page 31

— 18 —

leur temps de cuisson.

dans un réfrigérateur. Cela permet de réduire

congelés se dégivrer partiellement toute la nuit

Si le temps le permet, laissez les aliments

dépend de la quantité de dégivrage nécessaire.

Le temps de cuisson des aliments congelés

de cuisson supplémentaire est nécessaire.

couvercle est utilisé, environ un tiers de temps

15 minutes de temps de cuisson. Lorsqu'un

ils sont emballés, s'ils nécessitent plus de

dans les contenants couverts dans lesquels

surgelés précuits qui ne peuvent pas être cuits

Utilisez un couvercle du plateau pour les plats

voulu.

préblanchis ou congelés) et le degré de cuisson

la densité, l'état antérieur des aliments (frais,

poids, l'épaisseur des aliments, la température,

de cuisson sont notamment les dimensions, le

résultats. Les variables qui affectent le temps

temps de cuisson qui vous donnera les meilleurs

vos produits alimentaires afi n de déterminer le

sont que des suggestions. Vous devez tester

Ces lignes directrices relatives à la cuisson ne

morceaux pour obtenir une cuisson plus effi cace.

Séparez les aliments congelés en plus petits

Aliments congelés

LA CUISSON

dans le cuiseur à vapeur.

solides. NE placez PAS des boîtes fermées

le contenu peut être versé dans les plateaux

dans les plateaux solides de 12 po x 20 po) ou

dans leurs boîtes ouvertes (boîtes placées

Les aliments en conserve peuvent être chauffés

préserver leur jus ou pour recueillir le bouillon.

volailles cuisent dans des plateaux solides pour

solides, dans leur propre jus. Les viandes et les

légumes et les fruits cuisent dans des plateaux

des céréales chaudes pour le petit-déjeuner. Les

appropriés pour la cuisson des puddings, du riz et

d'être préservé. Les plateaux solides sont

aliments similaires, lorsque le jus n'a pas besoin

saucisses de Francfort, les saucisses et les

Les plateaux perforés sont utilisés pour les

charge

1 po 21/2 po 4 po 6 po

Profondeur de plateaux

alimentaires à la pression atmosphérique.

coquilles et certaines autres viandes ou produits

saucisses de Francfort, des œufs dans leurs

Le cuiseur à vapeur cuit des légumes, des

LIGNES DIRECTRICES RELATIVES À

C24EO5 10 5 3 2

C24EO3 6321

Modèle Nombre de plateaux pris en

perforés.

plateaux et de tiers de plateaux, solides ou

combinaisons de plateaux entiers, de demiLe cuiseur à vapeur prend en charge les

TAILLES DE PLATEAU ACCEPTABLES

perforé.

solide de 12 po x 20 po, placé sous un plateau

liquides peuvent être collectés dans un plateau

perforé si vous voulez en récupérer le jus. Les

faire cuire d'autres légumes dans un plateau

racines dans un plateau perforé. Vous pouvez

retirant les tiges, etc. Préparez les légumesen nettoyant, en séparant, en découpant et en

les viandes, les fruits de mer et les volailles

Préparez normalement les légumes, les fruits,

PRÉPARATION

à la demande.

des quantités supplémentaires pour répondre

assez pour commencer à servir, puis préparez

Préparez par petites quantités. Préparez juste

pour obtenir des résultats les plus appétissants.

maintien de la chaleur des aliments au minimum,

scrupuleusement contrôlée. Gardez le temps de

La durée de la cuisson à vapeur doit être

et autres aliments à servir immédiatement.

Le cuiseur à vapeur cuit effi cacement les légumes

SUGGESTIONS RELATIVES À LA CUISSON

CUISEUR À VAPEUR DE SÉRIE C24EO

Page 32

— 17 —

.

et réglez

vapeur.

d'étanchéité du joint causent des fuites de

être remplacé. Les dommages à la surface

une fuite due à une entaille ou coupure, il doit

Si le joint d'étanchéité de la porte présente

JOINT D'ÉTANCHÉITÉ DE LA PORTE

lorsque vous ne l'utilisez pas.

8. Laissez la porte du cuiseur à vapeur ouverte

7. Essuyez avec un chiffon propre.

soigneusement à l'eau tiède.

6. Vidangez le cuiseur à vapeur et rincez

toujours présent, répétez les étapes 1 à 5.

maximum de 60 minutes. Si le tartre est

pendant un minimum de 30 minutes et un

5. Laissez la solution de détartrage tremper

fond à la position OFF (ARRÊT)

appuyez le commutateur d'alimentation à

de minuterie à la position OFF (ARRÊT) et

la minuterie, tournez le cadran de réglage

la minuterie sur 5 min. Après la sonnerie de

fond à la position ON (MARCHE)

4. Appuyez le commutateur d'alimentation à

3 gallons

• Capacité maximale du cuiseur à vapeur :

la cavité.

cavité. Versez la solution dans la paroi de

3. Pulvérisez la solution sur les parois de la

• 1 sac dans 2 gallons d'eau tiède

ou C24EO5.

2. Un sac peut traiter un cuiseur à vapeur C24EO3

cuiseur à vapeur.

1. Arrêtez le cuiseur à vapeur. Vidangez le

site Web www.vulcanequipment.com

Vulcan agréé ou reportez-vous sur le

• Communiquez le préposé à l'entretien

(quantité 1).

Release™, numéro de pièce 854893-13

1. Solution de déchaulage – Scale

Éléments requis (non fournis) :

par la garantie.

programme d'entretien préventif minimal requis

du tartre. Cette opération est conforme au

selon la qualité de l'eau et l'accumulation

Le déchaulage peut être requis fréquemment

le tartre est présent dans la paroi de la cavité.

Le cuiseur à vapeur doit être déchaulé lorsque

vous lorsque vous ouvrez la porte.

vapeur vive et de l'eau chaude. Éloignezcompartiment de cuisson contient de la

ou entretenez le cuiseur à vapeur. Le

attention lorsque vous utilisez, nettoyez

et ses pièces sont chauds. Faites

: Le cuiseur à vapeur

de l'eau propre.

ou les yeux, rincez-les abondamment avec

déchaulage entre en contact avec la peau

après la manipulation. Si la solution de

Lavez-vous soigneusement les mains

de protection lors de la manipulation.

plastique ou en caoutchouc et des lunettes

la peau et les yeux. Portez des gants en

de déchaulage. Évitez tout contact avec

instructions sur l'emballage du matériel

: Lisez et suivez les

CUISEUR À VAPEUR DE SÉRIE C24EO

Procédure :

aluminium.

de la surface des outils de mesure en

entraîner le ternissement ou la corrosion

REMARQUE : La solution de déchaulage peut

solution de déchaulage.

5. Récipient d'un gallon pour mélanger la

4. Flacon pulvérisateur.

3. Lunettes de sécurité ou masque protecteur .

2. Gants en plastique ou en caoutchouc.

ENTRETIEN

RETRAIT DES DÉPÔTS CALCAIRES

NETTOYAGE.

quotidiennement. Reportez-vous à la section

Le cuiseur à vapeur doit être nettoyé

vous lorsque vous ouvrez la porte.

vapeur vive et de l'eau chaude. Éloignezcompartiment de cuisson contient de la

ou entretenez le cuiseur à vapeur. Le

attention lorsque vous utilisez, nettoyez

et ses pièces sont chauds. Faites

: Le cuiseur à vapeur

Page 33

— 16 —

Ill., un laboratoire d'essai indépendant.

Développé par Packer Engineering, Naperville,

matériel de nettoyage.

le fabricant de l'équipement ou le fournisseur du

façon d'éviter ce problème, communiquez avec

corrosion sous contrainte due aux chlorures et la

Pour obtenir plus de renseignements sur la

prolongé peut causer des problèmes.

stagnante dès que possible. Un contact

6. Essuyez les agents nettoyants et l'eau

situations spécifi ques

Agents nettoyants recommandés pour des

l'acier inoxydable.

8. Restaurer ou passiver régulièrement

chiffon

éponge ou d'un

l'aide d'une

Appliquez à

fi nitions

sur toutes les

des souillures

élimination

Excellente

de polissage

sens des lignes

Frottez dans le

barrière

Fournit un fi lm

éponge

chiffon ou d'une

l'aide d'un

Appliquez à

Commentaires

Agent de

Super Sheen

Benefi t,

commercial

détergent

Tout bon

Oven Aid

De-Grease It

Easy-off,

Impression

Zud, First

Cameo, Talc,

Ecoshine

Lac-O-Nu

Arcal 20,

médaillon

détergent,

ammoniac,

Savon,

nettoyage

des adoucisseurs chaque fois que possible.

5. Adoucissez votre eau. Utilisez des fi ltres et

chlorures.

seulement des agents nettoyants sans

aux concentrations recommandées. Utilisez

4. Utilisez des agents nettoyants non chlorés

l'acier inoxydable.

métalliques ou de racloirs pour nettoyer

pas de plaquettes en acier, de brosses

3. Utilisez des outils appropriés. N'utilisez

par des piqûres et des fi ssures.

2. La rouille de l'acier inoxydable commence

et de présence de chlorures.

à la suite d'érafl ures, de rayures, de dépôts

passivité (fi lm de protection) se décompose

1. Les aciers inoxydables rouillent lorsque la

Révision

Passivation

Restauration/

huile

Graisse et

brûlés

aliments

gras, sang,

et acides

Graisse

décoloration

tenaces et

Taches

traînées

digitales et

Empreintes

routine

Nettoyage de

Travail

(acide muriatique) sur l'acier inoxydable.

7. Ne jamais utiliser l'acide chlorhydrique

l'acier inoxydable.

contribue à maintenir le fi lm de passivité de

l'équipement, laissez-le sécher à l'air; l'oxygène

de nettoyage, mieux ça vaut. Après avoir essuyé

stagnante, surtout lorsqu'elle contient des agents

et les fournitures. Plus tôt vous essuyez l'eau

rincez et essuyez immédiatement l'équipement

Si des agents nettoyants chlorés sont utilisés,

6. Rincer, rincer, rincer.

des chlorures donne un effet similaire.

chauffage d'agents nettoyants qui contiennent

est la présence de chlorures dans l'eau. Le

seule cause la plus probable de dommages

en acier inoxydable, n'oubliez pas que la

Si vous faites bouillir de l'eau dans un équipement

éviter l'accumulation de taches tenaces fermes.

recommandée. Nettoyez fréquemment pour

alcalins chlorés ou sans chlorures à la quantité

Utilisez des agents nettoyants alcalins,

dans un état propre.

5. Conserver votre équipement alimentaire

avec un spécialiste du traitement.

assurer un bon traitement de l'eau, communiquez

les éléments déplaisants et corrosifs. Pour

Certains fi ltres peuvent être installés pour retirer

de façon signifi cative à réduire les dépôts.

l'adoucissement d'une eau dure peut contribuer

Même si ce n'est pas toujours pratique,

4. Traiter votre eau.

et de la corrosion.

inoxydable et entraîner l'apparition des piqûres

quaternaires; ils peuvent aussi attaquer l'acier

Évitez les agents nettoyants contenant des sels

votre fournisseur s'il a un produit alternatif.

actuel contient des chlorures, demandez à

CUISEUR À VAPEUR DE SÉRIE C24EO

Page 34

— 15 —

d'agent nettoyant. Si votre agent nettoyant

utilisé, communiquez avec votre fournisseur

du contenu en chlorures de l'agent nettoyant

nettoyants sans chlorure. Si vous n'êtes pas sûr

l'industrie fournit un choix grandissant d'agents

traditionnels sont chargés de chlorures,

Alors que de nombreux agents nettoyants

alcalins chlorés ou sans chlorures.

3. Utiliser des agents nettoyants alcalins,

ou un tampon à récurer en plastique.

privilégiez la sécurité et utilisez un chiffon doux

lignes. Lorsque les grains ne sont pas visibles,

toujours dans un mouvement parallèle aux

Lorsque les lignes visibles sont présentes, frottez

des lignes ou des grains de polissage visibles.

Certains aciers inoxydables sont livrés avec

polissage.

2. Nettoyer conformément aux lignes de

sens des marques de polissage des fabricants.

mouvement de récurage doit se produire dans le

peuvent également être utilisées, mais le

de l'acier. Les plaquettes en acier inoxydable

plastique ne nuisent pas à la couche passive

Les chiffons doux et les tampons à récurer en

inoxydable, utilisez des outils non abrasifs.

Lorsque vous nettoyez des produits en acier

1. Utiliser des outils appropriés.

empêcher la rouille de l'acier inoxydable.

Voici quelques conseils qui peuvent aider à

désespérez pas!

Alors, que signifi e tout cela? Ne

des agents nettoyants domestiques et industriels.

sources de chlorure le plus dangereux provient

nourriture et dans le sel de table. L'une des

dans le monde. Ils sont dans l'eau, dans la

Les chlorures sont présents presque partout

correctement éliminés.

de la nourriture et de l'entretien doivent être

D'autres dépôts qui résultent de la préparation

l'acier inoxydable, s'ils ne sont pas éliminés.

qui peuvent briser la couche passive et rouiller

lorsqu'elles sont chauffées, laissent des dépôts

douce. L'eau dure peut laisser des taches et

vous pouvez avoir de l'eau dure ou de l'eau

dureté. Selon la région du pays où vous vivez,

L'eau sort du robinet avec divers degrés de

racloirs sont des exemples parfaits.

Plaquettes en acier, brosses métalliques et

choses qui peuvent rayer la surface de l'acier.

L'abrasion mécanique fait allusion à toutes ces

3. Chlorures.

2. Dépôts et eau.

1. Abrasion mécanique.

et faciliter la corrosion.

briser la couche passive de l'acier inoxydable

Il y a trois choses fondamentales qui peuvent

Ennemis de l'acier inoxydable

commence à se corroder et à rouiller.

de l'acier inoxydable a été cassé, l'équipement

métal est passif et inoxydable. Si le fi lm passif

est intact et n'est pas cassé ou contaminé, le

que bouclier contre la corrosion. T ant que le fi lm

recouvre la surface de l'acier agissant en tant

Avec 12 à 30 % de chrome, un fi lm passif invisible

ceux de type ferritique.

une plus grande résistance à la corrosion que

pas magnétiques et fournissent généralement

aciers inoxydables de type austénitique ne sont

du manganèse, de l'azote et du carbone. Les

sont également austénitiques et contiennent

nickel et les aciers inoxydables de série 200

austénitiques et contiennent du chrome et du

inoxydables de série 300 sont appelés

du chrome et sont magnétiques; les aciers

série 400 sont appelés ferritiques, contiennent

stabilisent les atomes. Les aciers inoxydables de

tels que le chrome, le nickel et le manganèse, qui

« passifs », car ils contiennent d'autres métaux

Les aciers inoxydables sont des métaux

combinent avec l'oxygène pour former la rouille.

environnement naturel, lorsque leurs atomes

parce qu'ils se corrodent activement dans un

ou orange. De tels métaux sont dits « actifs »

forme de taches de rouille disgracieuses jaune

reconnait rapidement sur le fer et l'acier sous

La corrosion des métaux est répandue. Elle se

aciers inoxydables SONT sujets à la rouille.

Contrairement à la croyance populaire, les

INOXYDABLE

DE L'ÉQUIPEMENT EN ACIER

ENTRETIEN ET NETTOYAGE

CUISEUR À VAPEUR DE SÉRIE C24EO

Page 35

— 14 —

Figure 9 : Laisser la porte ouverte

Joint

ouverte.

Laissez la porte

de vie du joint.

déformation permanente et de réduire la durée

sous pression, vous risquez de provoquer une

d'étanchéité de la porte. Si vous laissez le joint

et n'appliquez jamais une pression sur le joint

n'est pas utilisé, ne verrouillez jamais la porte

en cours d'utilisation. Lorsque le compartiment

ouverte lorsque le cuiseur à vapeur n'est pas

Laissez la porte du compartiment légèrement

(les côtés, la partie avant, la porte et la partie

Nettoyez soigneusement les surfaces exposées

chlorure. Rincez avec de l'eau chaude.

solution d'eau tiède avec du détergent sans

Lavez l'intérieur du compartiment à l'aide d'une

réduites.

les performances de cuisson seront

place le défl ecteur après le nettoyage,

REMARQUE : Si vous oubliez de remettre en

chlorure. Rincez avec de l'eau chaude.

solution d'eau tiède avec du détergent sans

soulevant et en le sortant. Lavez à l'aide d'une

Retirez le défl ecteur du compartiment en le

de l'eau chaude.

avec du détergent sans chlorure. Rincez avec

sortant. Lavez à l'aide d'une solution d'eau tiède

Retirez les plateaux en les soulevant et en les

doit être nettoyé tous les jours.

doivent être nettoyés tous les jours. L'extérieur

Le compartiment, les plateaux et le défl ecteur

COMPARTIMENT

COMPARTIMENT OUVERT

LAISSER LA PORTE DU

de vie du joint d'étanchéité.

lubrifi ants à base de pétrole réduisent la durée

d'étanchéité de la porte. Les solvants et les

à base de pétrole directement sur le joint

jamais les huiles alimentaires ou les lubrifi ants

Essuyez avec un chiffon propre. N'appliquez

enlever toutes les traces de détergent.

d'un chiffon propre imbibé d'eau tiède pour

détergent doux et d'eau tiède. Rincez à l'aide

à l'aide d'un chiffon imbibé d'une solution de

aucun solvant ou instrument tranchant. Lavez

de vie maximale du joint d'étanchéité. N'utilisez

les acides alimentaires afi n d'obtenir une durée

du joint de la porte du compartiment pour retirer

Nettoyez quotidiennement la surface d'étanchéité

JOINT D'ÉTANCHÉITÉ DE LA PORTE

nettoyant non abrasif.

Pour retirer une décoloration, utilisez un agent

polissez chaque jour avec un chiffon propre.

supérieure) à l'aide d'un chiffon humide et

Vidange

Déflecteur

Figure 8 : Cavité du four

ouverte.

Laissez la porte

le compartiment de vidange.

/2 gallon) d'eau chaude dans

1

versant 1,9 litre (

dans le compartiment de vidange. Rincez en

/2 gallon) de cette solution

1

et versez 1,9 litre (

d'eau tiède avec du détergent sans chlorure

bloquer la vidange. Préparez une solution

Retirez les particules ou les débris qui peuvent

CUISSON

VIDANGE DU COMPARTIMENT DE

NETTOYAGE

CUISEUR À VAPEUR DE SÉRIE C24EO

Page 36

— 13 —

présent manuel.

6. Suivez les instructions de nettoyage du

permettre à l'intérieur de sécher.

5. Ouvrez la porte du compartiment pour

l'eau du cuiseur à vapeur.

4. Ouvrez le robinet de vidange et vidangez

3. Laissez le cuiseur à vapeur refroidir.

.

pour

fond à la position OFF (ARRÊT)

2. Appuyez le commutateur d'alimentation à

1. Tournez la position OFF (ARRÊT).

ARRÊT

temps de cuisson.

pendant un cycle de cuisson allonge le

manquer d'eau. Le manque d'eau

les périodes creuses pour éviter de

pas en cours d'utilisation ou pendant

REMARQUE : Remplissez l'unité lorsqu'il n'est

de cuisson.

le cuiseur à vapeur atteint la température

7. La minuterie reprend le décompte lorsque

annuler l'alarme de niveau d'eau bas.

fond à la position ON (MARCHE)

6. Enfoncez le commutateur d'alimentation à

5. Fermez la porte.

4. Débranchez le cordon d'alimentation.

3. Laissez la porte ouverte.

.

2. Nettoyez l'intérieur et l'extérieur de l'unité.

.

fond à la position OFF (ARRÊT)

1. Appuyez le commutateur d'alimentation à

ARRÊT PROLONGÉ

CUISEUR À VAPEUR DE SÉRIE C24EO

NIVEAU D'EAU BAS

4. Remplissez l'unité avec de l'eau.

fond à la position ON (MARCHE)

2. Appuyez le commutateur d'alimentation à

alarme sonore retentit.

s'allume, l'unité doit être remplie d'eau. Une

1. Lorsque le voyant de niveau d'eau bas

Page 37

— 12 —

terminé.

jusqu'à ce que le préchauffage soit

REMARQUE : La minuterie ne fonctionne pas

9. L'unité revient à la température de ralenti.

sonore retentit.

8. À la fi n du cycle temporisé, une alarme

(CONTINUE).

60 minutes) ou à la position CONTINUOUS

7. Réglez la minuterie sur le temps voulu (0 à

porte est fermée.

il indique que la minuterie est réglée et que la

Voyant COOK (CUISSON) : Lorsqu'il est allumé,

(CONTINUE).

cuisson voulu ou la position CONTINUOUS

Timer (Minuterie) : Sélectionne le temps de

d'eau est requis.

Lorsqu'il est allumé, il indique que l'appoint

Voyant Low Water (Niveau d'eau bas) :

NIVEAU D'EAU BAS.

RÉINITIALISE LE VOY ANT OU L'ALARME DE

bas) : Met l'unité en MARCHE et à l'ARRÊT/

d'alimentation/Réinitialisation à niveau d'eau

Power Switch/Low Water Reset (Commutateur

Figure 7 : Commandes

et prête à cuire.

environ 15 minutes, l'unité sera préchauffée

6. Réglez la minuterie sur 5 minutes. Dans

s'allume en orange.

Le voyant d'alimentation du commutateur

.

à fond à la position ON (MARCHE)

5. Appuyez le commutateur d'alimentation

OFF (ARRÊT).

à niveau d'eau bas)

d'alimentation/Réinitialisation

(Commutateur

Water Reset

Power Switch/Low

d’alimentation

Voyant

(Cuisson)

Voyant Cook

(Niveau d'eau bas)

Voyant Low Water

4. Vérifi ez que la minuterie est à la positon

3. Fermez la porte.

Minuterie

remplissez pas excessivement.

La capacité de l'unité est de 3 gallons. Ne

visible sur la paroi arrière du cuiseur à vapeur.

niveau d'eau. Le repère de niveau d'eau est

compartiment de cuisson jusqu'au repère de

2. Ouvrez la porte et versez de l'eau dans le

vous lorsque vous ouvrez la porte.

vapeur vive et de l'eau chaude. Éloignezcompartiment de cuisson contient de la

ou entretenez le cuiseur à vapeur. Le

attention lorsque vous utilisez, nettoyez

robinet de vidange.

1. Poussez le levier de vidange pour fermer le

: Le cuiseur à vapeur

et ses pièces sont chauds. Faites

VAPEUR

FONCTIONNEMENT DU CUISEUR À

COMMANDES

FONCTIONNEMENT

CUISEUR À VAPEUR DE SÉRIE C24EO

Page 38

— 11 —

CUISEUR À VAPEUR DE SÉRIE C24EO

préposé à l'entretien Vulcan agréé.

pas atteinte après 3 tentatives, appelez votre

7. Si la lecture de température appropriée n'est

Vulcan agréé.

appelez votre préposé à l'entretien

REMARQUE : Si l'unité ne peut être étalonnée,

température à l'aide du thermomètre.

température et revérifi ez la lecture de

pas correcte, ajustez le réglage de

b. Si la température enregistrée n'est

correcte, aucun réglage n'est nécessaire.

a. Si la température enregistrée est

du tableau.

6. Comparez la température enregistrée à celle

lorsque le voyant de charge s'éteint.

5. Enregistrez la température dans le thermomètre

thermomètre.

la température enregistrée dans le

seulement. Lors de l'étalonnage, utilisez

commande est à titre de référence

REMARQUE : La température affi chée sur la

la porte fermée.

achevant deux cycles de chauffage avec

b. Laissez la température se stabiliser en

que la température est enregistrée.

clignote momentanément pour indiquer

enregistrée dans la mémoire. L'affi chage

du bouton pour que la sélection soit

a. Attendez 3 secondes après le relâchement

la température du point de consigne.

Celsius. L'affi chage indique seulement

Fahrenheit et ne peut être changée en

est confi gurée par le fournisseur en

REMARQUE : La commande de température

Page 39

— 10 —

Diminution

CCW –

TEMPÉRATURE

Augmentation

CW –

Figure 6 : Commande de température

Plage – 190 °F à 215 °F

La température affichée est à titre de référence seulement.

réglez la commande de température.

température correspondante à l'altitude et

4. À l'aide du tableau ci-dessus, trouvez la

(CONTINU).

en sélectionnant le mode CONTINUOUS

3. Mettez en marche le cuiseur à vapeur

d'évent à vapeur.

un pouce vers le bas, au centre du tuyau

2. Placez une sonde de température à environ

1. Retirez le panneau latéral droit.

forte consommation d'eau.

du cuiseur à vapeur, entraînant une

s'échapperont du tuyau de ventilation

et des gouttelettes d'eau chaude

trop élevé, l'ébullition sera excessive

REMARQUE : Si le réglage de température est

portatifs sont requis.

Un thermomètre et un thermocouple numériques

à l'usine au niveau de la mer.

REMARQUE : Le cuiseur à vapeur est préréglé

laquelle se trouve le cuiseur à vapeur.

à la température qui correspond à l'altitude à

vapeur, tournez la commande de température

obtenir un fonctionnement optimal du cuiseur à

d'accéder au contrôleur de température. Pour

Le panneau latéral droit doit être retiré afi n

PROCÉDURE D'ÉTALONNAGE

permettre à l'intérieur de sécher.

d. Ouvrez la porte du compartiment pour

l'eau du cuiseur à vapeur.

c. Ouvrez le robinet de vidange et vidangez

refroidir.

.

b. Laissez le cuiseur à vapeur

à la position OFF (ARRÊT)

a. Appuyez le commutateur d'alimentation

(°F)

8 000 90 (195)

7 000 91 (196)

6 000 93 (198)

4 000 94 (202)

3 000 96 (204)

2 000 97 (206)

1 000 98 (208)

NUMÉRIQUE – °C

9 000 ou plus 90 (194)

8. Pour arrêter le cuiseur à vapeur :

à la position OFF (ARRÊT).

tournez le cadran de réglage de minuterie

de cuisson. Pour interrompre la sonnerie,

sonnerie retentit pour signaler la fi n du cycle

7. Lorsque la minuterie retourne sur 0, une

température de préchauffage.

jusqu'à ce que la cavité atteigne la

minuterie ne commence pas à décompter

Niveau de la mer 99 (210)

6. Tournez la minuterie sur 5 minutes. La

préchauffe.

environ 10 minutes pour que l'unité se

ALTITUDE (PI) THERMOMÈTRE

5. Fermez la porte du compartiment et attendez

CUISEUR À VAPEUR DE SÉRIE C24EO

Page 40

— 9 —

. Le commutateur

de vidange

Poignée

(CUISSON) s'éteint.

commutateur de la porte et le voyant COOK

COOK (CUISSON) s'allume. Relâchez le

au-dessus du loquet de la porte. Le voyant

commutateur de la porte (petite tige), situé

4. Lorsque la porte est ouverte, appuyez sur le

l'unité est en marche.

d'alimentation devient orange, indiquant que

position ON (MARCHE)

le commutateur d'alimentation à fond à la

CONTINUOUS (CONTINUE). Appuyez

3. Tournez la minuterie à la position

Figure 5 : Repère de niveau d'eau

BUÉES

manuel.

vous à la section NETTOYAGE du présent