Page 1

948RX

SERVICE MANUAL

Heavy Duty Gas Griddles

924RX

936RX

948RX

960RX

972RX

MSA24

MSA36

MSA48

MSA60

MSA72

ASA24

ASA36

ASA48

ASA60

ASA72

- NOTICE -

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Vulcan-Hart 3600 North Point Blvd Baltimore, MD 21222

F25383 (0219)

Page 2

Heavy Duty Gas Griddles

TABLE OF CONTENTS

SERVICES UPDATES ...................................................................................... 3

SERVICE UPDATES ................................................................................... 3

TIS DOCUMENT LIST - 900RX SERIES ................................................................ 3

GENERAL .................................................................................................. 4

INTRODUCTION ....................................................................................... 4

INSTALLATION ........................................................................................ 4

OPERATION ........................................................................................... 4

CLEANING ............................................................................................. 4

SPECIFICATIONS ...................................................................................... 4

TOOLS ................................................................................................. 5

COMPONENT LOCATION .............................................................................. 5

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 6

COVERS AND PANELS ................................................................................ 6

MOMENTARY POWER SWITCH (900RX) .............................................................. 6

ELECTRIC IGNITER (900RX) ........................................................................... 7

BASO SAFETY VALVE ................................................................................. 7

THERMOSTAT VALVE ASSEMBLY .................................................................... 7

BURNER ............................................................................................... 9

PILOT, THERMOCOUPLE ASSEMBLY ................................................................. 9

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 11

CALIBRATION ........................................................................................ 11

PILOT ADJUSTMENT ................................................................................. 12

GAS PRESSURE MEASUREMENT .................................................................... 12

GAS PRESSURE REGULATOR ADJUSTMENT ....................................................... 13

BURNER ADJUSTMENT .............................................................................. 14

THERMOCOUPLE TEST .............................................................................. 14

ELECTRICAL OPERATION ................................................................................ 16

ELECTRICAL DIAGRAM .............................................................................. 16

TROUBLESHOOTING ..................................................................................... 18

TROUBLESHOOTING ................................................................................. 18

© VULCAN 2019

F25383 (0219) Page 2 of 19

Page 3

Heavy Duty Gas Griddles - SERVICES UPDATES

SERVICES UPDATES

SERVICE UPDATES

February 2019

• Updated PILOT, THERMOCOUPLE

ASSEMBLY.

November, 2018

• Added TIS Document List.

TIS DOCUMENT LIST - 900RX SERIES

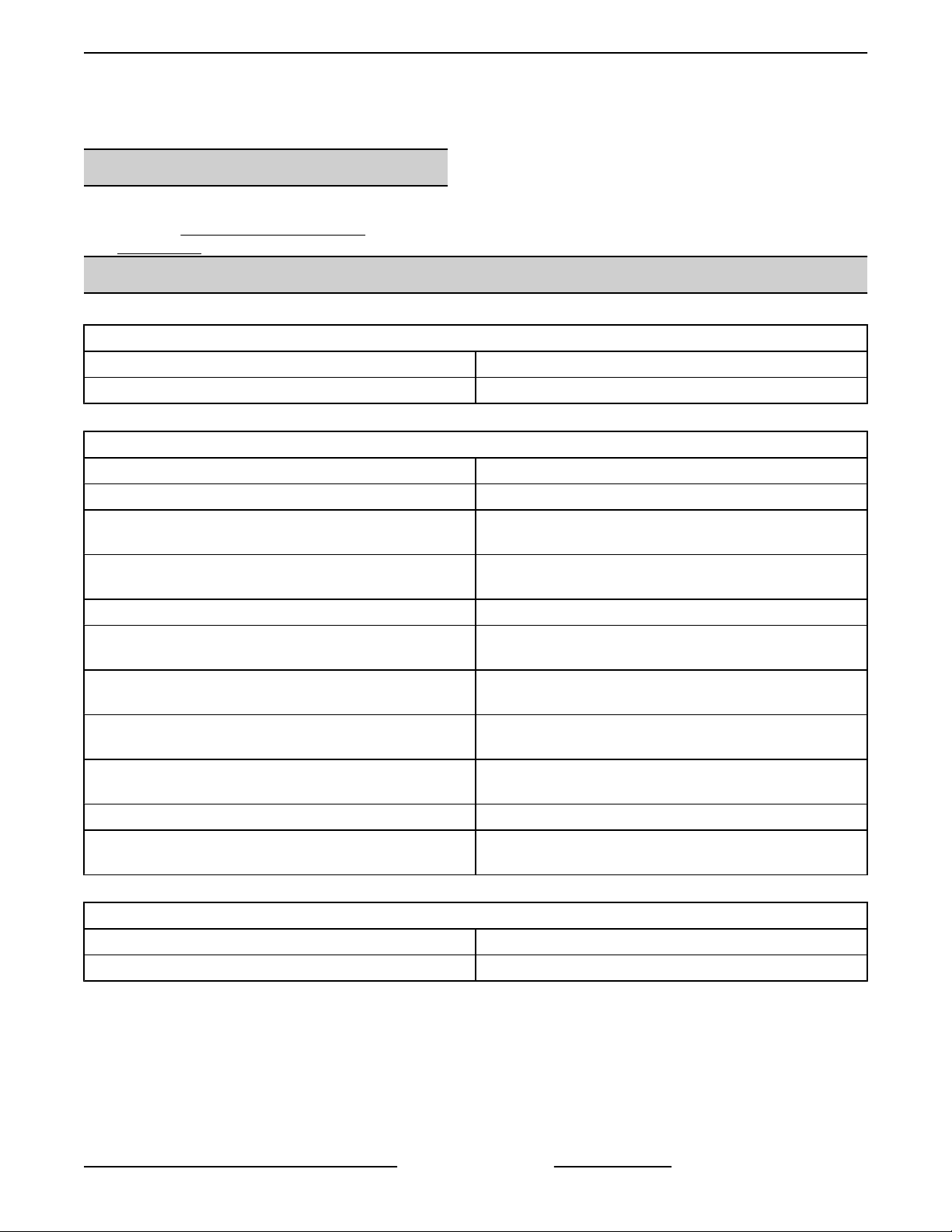

SERVICE TAB

Document Title Document Type

900RX Series Heavy Duty Gas Griddles Service Manual Service Manual

SERVICE TAB (Multimedia)

Document Title Document Type

Repairing Flood-Damaged Food Equipment Misc

900RX Series Heavy Duty Gas Operation & Installation

Manual

AGE, AGM, 900RE, 900RX, and ASA Series Gas Griddle

Grease Chute P/N 498234-A Installation Instructions

Fundamentals of Gas Service Instructions

Rating Plate Locations on Current Vulcan-Hart/Wolf

Range Equipment

TSB 0842 4 Position/3 Heat Switch - Ranges, Ovens,

Broilers

TSB 1037A Hobart to Vulcan "Common" Model Cross

Reference List

TSB 1301 Onwatch Quicklook 72 for Gas Cooking

Equipment

TSB 682 Griddle Lead Wire Upgrading Technical Service Bulletin (TSB)

RobertShaw FS Flame Switch Recall Vulcan & Wolf

Equipment Effected - PN 713933

Operator

Service Instructions

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Temporary Service Instructions (TSI)

PARTS TAB

Document Title Document Type

900RX and MSA Heavy Duty Gas Griddles Parts Catalog Parts Catalog

Page 3 of 19 F25383 (0219)

Page 4

Heavy Duty Gas Griddles - GENERAL

GENERAL

The griddle and its parts are hot. Use care when operating, cleaning or servicing the griddle.

INTRODUCTION

This Service Manual covers specific service

information related to the models listed on the front

cover and built after March 2010.

Procedures in this manual will apply to all 900RX

models unless specified. No procedure in this manual

will require the removal or raising of the griddle plate.

Pictures and illustrations can be of any model unless

the picture or illustration needs to be model specific.

MSA griddles have a standing pilot that must be lit

manually. One pilot services two burners via a flame

tube between the burners. The 900RX utilizes a spark

ignition system that has a 'momentarily on' switch that means the switch must be held down for sparking

to take place, and it ceases sparking when released.

The MSA and 900RX have BASO® pilot safety valves

that must be pressed to allow gas to feed the pilot

burner. For the 900RX, the pilot buttons must be

pressed at the same time the power switch is pressed

in order to light the pilot.

INSTALLATION

position until the gas supply to the unit is cut off or the

griddle gas shut-off valve is turned to the OFF position.

The pilots are monitored by thermocouples and pilot

safety valves. If the pilot goes out, the safety valve will

shut-off the gas supply to the pilot and main burners.

In the event of a failure of the electronic ignition

system, it is possible to ignite the pilots with an outside

source (such as a lit taper). You will have to reach

under the front of the unit and through the pilot cutout

to ignite the pilots while again depressing the

corresponding red button.

CLEANING

Detailed cleaning procedures are included in the

Installation & Operation manual sent with each unit.

SPECIFICATIONS

Stainless steel front, sides and front top ledge. Fully

welded stainless and aluminized steel body frame. 11"

low profile cooking height on 4" legs. 1" thick polished

steel griddle plate with 12 gage, 4" stainless steel back

and tapered side splashes. Grease chute is fully

welded to stop grease migration.

Generally, installations are made by the dealer or

contracted by the dealer or owner. Detailed

installation instructions are included in the Installation

and Operation Manual that is sent with each unit.

However, it should be noted that an improperly

installed unit, especially an unlevel unit can lead to

premature electrical component failures. A unit that is

higher in the front will cause the flue gases to vent

improperly and gather in the front near the electrical

components. All models must be installed with an

externally mounted regulator.

OPERATION

Detailed operation instructions are included in the

Installation & Operation Manual sent with each unit

and are also available at WWW.VULCANHART.COM.

The 900RX models feature an electric ignition system

that is controlled by a momentary power switch. The

power switch turns the electric ignition system off and

on only and will only supply power to the igniters when

held down in the ON position. The burners and pilots

will continue to work with the power switch in the OFF

One 27,000 BTU/hr. “U” shaped aluminized steel

burner and mechanical snap action thermostat for

each 12" of griddle width. Chrome thermostat knob

guards. Temperature adjusts from 200° to 550° F.

One pilot safety for every two burners. Manual shutoff valve. 3½" wide stainless steel grease trough.

120V 50/60Hz 1 Amp single phase electric ignition

circuit. Plug type is NEMA 5-15 USA. ¾" rear gas

connection and gas pressure regulator.

A gas pressure regulator supplied with the unit must

be installed.

Check and set the gas pressure after the regulator is

installed.

Manifold pressure should be:

Natural Gas 4.0" W.C.

Propane Gas 10.0" W.C.

Incoming pressure should be 5-9" W.C. for

Natural Gas and 11.0" W.C. for Propane Gas.

Incoming pressure should not exceed 14.0" W.C.

F25383 (0219) Page 4 of 19

Page 5

Heavy Duty Gas Griddles - GENERAL

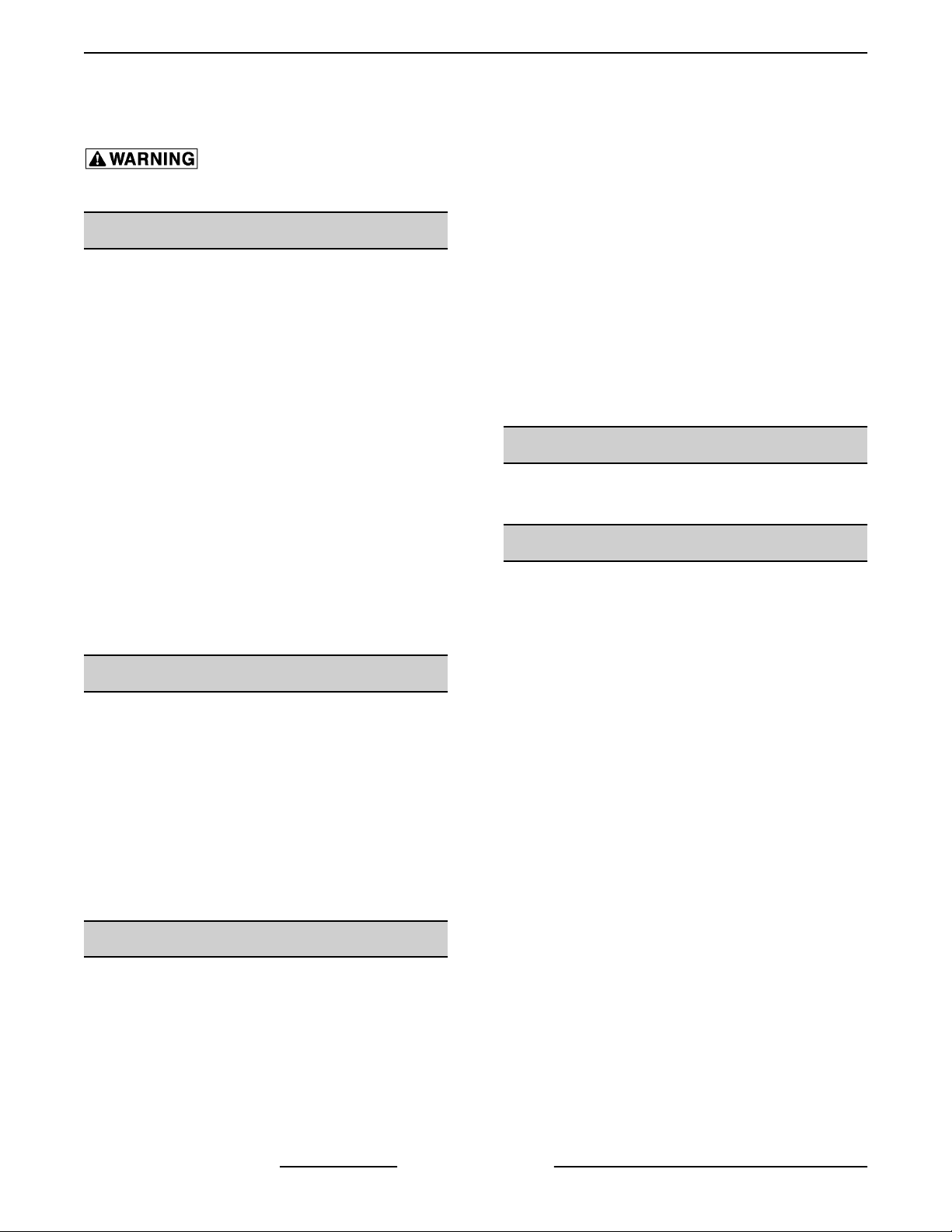

TOOLS

• Standard set of hand tools.

• VOM with A/C current tester (any quality VOM

with a sensitivity of at least 20,000 ohms per volt

can be used).

• Temperature tester (thermocouple type).

• U-Tube or Digital Manometer.

• Thread sealant suitable for use with natural or

propane gas.

• Aluminum Foil Tape - McMaster Carr Part No.

7631421 or equivalent.

• Adapter to test thermocouple, Johnstone Supply

Part No. H23-226 or equivalent.

6. Pilot flame adjustment

Top View 924RX

Fig. 3

1. Burner assembly

2. Electric igniter (RX only)

3. Thermostat

4. Orifice

5. Thermostat capillary tube

6. Pilot, igniter (RX only) and thermocouple

Fig. 1

COMPONENT LOCATION

Front View 924RX

Fig. 2

1. Pilot electric ignition system control switch (RX

only)

2. Power cord (RX only)

3. Thermostat

4. Gas shut off valve (RX only)

7. BASO® pilot safety valve

8. Pilot adjustment valve

5. BASO® pilot safety valve

Page 5 of 19 F25383 (0219)

Page 6

Heavy Duty Gas Griddles - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

COVERS AND PANELS

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

FRONT PANEL

1. Turn all thermostats to off position, loosen set

screw securing thermostat knobs and pull off

knobs.

NOT IN OFF POSITION FOR VIEW

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

All gas joints disturbed during servicing must be

checked for leaks. Check with a soap and water

solution (bubbles). Do not use an open flame.

NOTE: It will be necessary to remove the back panel

when changing a burner or to remove excessive

grease build up from flue area.

1. Disconnect gas supply at griddle.

Remove screws securing back panel to griddle.

Fig. 4

2. Remove screws securing front panel to griddle.

3. Pull front panel forward and lay aside. If servicing

a 900RX lay front panel face down in front of unit.

4. Install in reverse order.

NOTE: Before installing front panel, check that lineofsight through the front panel to see both pilot burners

and griddle burners. Move any flexible gas tubing, or

capillary tubing that may obstruct the sight holes.

Install in reverse order.

MOMENTARY POWER SWITCH

(900RX)

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

1. Remove FRONT PANEL.

2. Label and disconnect wires from power switch.

3. Squeeze switch retainers and slide switch out

through front of panel.

Fig. 5

BACK PANEL

4. Install in reverse order.

F25383 (0219) Page 6 of 19

Fig. 6

Page 7

Heavy Duty Gas Griddles - REMOVAL AND REPLACEMENT OF PARTS

ELECTRIC IGNITER (900RX)

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

1. Remove FRONT PANEL.

2. Push tab to release igniter from frame and pull

out of unit.

2. Measure distance between manifold pipe and

valve for reassembly later.

NOTE: Ignition wires must be routed in front of valves

as shown to prevent them from touching hot heat

shield.

Fig. 8

3. Disconnect all gas lines and thermocouple from

valve.

4. Remove valve from unit.

Fig. 7

3. Label and disconnect wires from electric igniter.

4. Install in reverse order.

BASO SAFETY VALVE

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

All gas joints disturbed during servicing must be

checked for leaks. Check with a soap and water

solution (bubbles). Do not use an open flame.

1. Remove FRONT PANEL.

5. Transfer fittings from old valve to new valve. Use

thread sealant on assembly.

6. Install new valve to same measurement as in

Step 2.

7. Continue to install in reverse order.

THERMOSTAT VALVE ASSEMBLY

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

All gas joints disturbed during servicing must be

checked for leaks. Check with a soap and water

solution (bubbles). Do not use an open flame.

1. Remove FRONT PANEL.

2. Disconnect gas line.

Page 7 of 19 F25383 (0219)

Page 8

Heavy Duty Gas Griddles - REMOVAL AND REPLACEMENT OF PARTS

3. Remove screws securing thermostat mounting

bracket to frame.

Fig. 9

4. Pull capillary tube out from underneath griddle

plate.

5. Transfer fittings from old thermostat to new

thermostat. Use thread sealant.

Fig. 11

11. Inlet to burner must be straight. Adjust thread on

orifice and/or extension to close gap between

orifice and burner to 1/16".

6. Transfer thermostat mounting bracket to new

thermostat.

7. Remove insulator sleeve from old capillary tube

and install on new thermostat.

8. Secure end of insulator sleeve to thick end of

capillary tube with metal tape as shown.

Fig. 10

9. Slide capillary tube all the way into slot

underneath griddle plate until it is fully seated.

10. Carefully insert orifice into burner and secure

thermostat mounting bracket to frame.

Fig. 12

12. Continue to install in reverse order.

F25383 (0219) Page 8 of 19

Page 9

Heavy Duty Gas Griddles - REMOVAL AND REPLACEMENT OF PARTS

BURNER

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

All gas joints disturbed during servicing must be

checked for leaks. Check with a soap and water

solution (bubbles). Do not use an open flame.

1. Remove FRONT PANEL and BACK PANEL.

2. Disconnect gas supply at griddle.

3. Remove screw securing burner to wall.

PILOT, THERMOCOUPLE

ASSEMBLY

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

1. Remove FRONT PANEL.

2. From underneath the front of the griddle, remove

screw securing pilot assembly bracket.

VIEW FROM REAR OF UNIT TO SEE PARTS

Fig. 13

4. At rear of unit, pull burner enough to disengage

burner pin from frame and pull burner out.

Fig. 14

5. Install in reverse order.

6. Adjust as outlined in BURNER ADJUSTMENT.

Fig. 15

3. Carefully lift to disengage bracket from slot and

work assembly down to access parts.

4. With pilot (1, Fig. 16) centered in flash tube

opening, center align ignition ports with both

sides of flash tube (2, Fig. 16). Verify 1/8” gap

between the end of flash tube and burner on both

sides.

Fig. 16

Page 9 of 19 F25383 (0219)

Page 10

Heavy Duty Gas Griddles - REMOVAL AND REPLACEMENT OF PARTS

5. Service assembly as required and assemble in

reverse order being sure bracket is seated in slot

for alignment.

F25383 (0219) Page 10 of 19

Page 11

Heavy Duty Gas Griddles - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

CALIBRATION

LEVEL

The griddle must be level (side-to-side and frontto-back) during operation to ensure proper

performance. Improper leveling can result in

uneven temperature distribution, cold spots, and

possibly damage electrical components.

1. Place a level on the griddle.

2. Adjust legs by turning the bullet feet at the bottom

of each leg. Using pliers or a crescent wrench,

turn the feet counter-clockwise to increase

height, and clockwise to decrease height until

leveling is achieved. Do not extend the legs more

than 1-¾”.

CALIBRATE

1. Each thermostat controls a 12” zone of the

griddle. Using a Surface Probe temperature

measurement device, observe the temperatures

at the center points of the cooking zones. These

points are located by starting 6” from the side

splash (left or right) and every 12” across the

width of the griddle, with all points located 12”

back from the front edge of the griddle plate.

NOTE: Use of infrared thermometers is not

recommended. These devices are highly sensitive to

surface color (clean or dirty), angle of reading and

distance from the unit.

Fig. 17

2. Set thermostats to 350°F and allow to stabilize.

3. Record the temperature tester readouts for each

zone for 3 cycles.

Temperature

Tester turn-off

deg F

Temperature

Tester turn-on

deg F

Turn-Off +

Turn-On

divide

by 2 = average

Total averages

divide by 3 ____

deg F

4. Calculate total average temperature for that

zone.

5. The temperature should be 350°F ±15°F. If not,

continue to next step.

Page 11 of 19 F25383 (0219)

Page 12

Heavy Duty Gas Griddles - SERVICE PROCEDURES AND ADJUSTMENTS

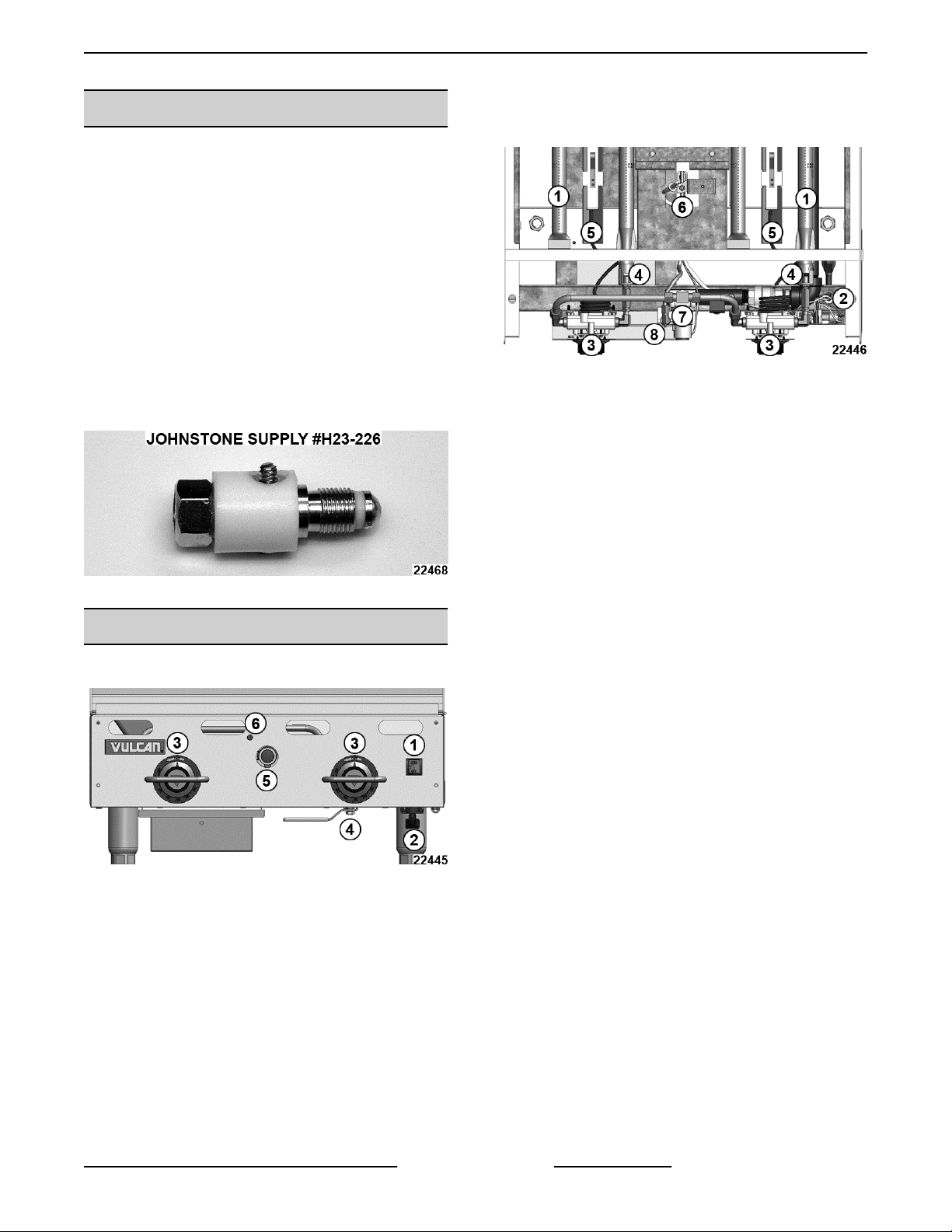

6. Carefully loosen the knob set screw. DO NOT

allow the knob to turn. Carefully remove the knob

from the thermostat shaft, exposing the

temperature dial.

Fig. 21

7. Loosen screws on the temperature dial and

adjust it so that the temperature indicated by the

knob arrow matches the griddle plate

temperature reading. Knob will have to be

carefully placed back on the shaft to verify

adjustment.

Fig. 23

9. Repeat Steps 3 thru 8 for each zone.

PILOT ADJUSTMENT

Using a flathead screwdriver, turn the slotted pilot

adjustment screw clockwise to decrease the flame,

and counterclockwise to increase the flame.

GAS PRESSURE MEASUREMENT

All gas joints disturbed during servicing must be

checked for leaks. Check with a soap and water

Fig. 22

Never adjust the screw in the center of the thermostat

shaft. This will ruin the factory calibration; the

thermostat will no longer operate properly and will

need to be replaced.

8. Once calibration is achieved, tighten the

temperature dial screws and knob set screws.

F25383 (0219) Page 12 of 19

solution (bubbles). Do not use an open flame.

1. Turn the gas supply off at a manual shutoff valve.

2. Remove the control panel.

3. Remove the pressure tap plug and attach

4. Turn gas back on.

5. Light pilot(s).

6. Turn all thermostats on to the maximum setting

7. Turn all the equipment on the same supply line

Fig. 24

manometer.

so that all burners are on.

on.

Page 13

Heavy Duty Gas Griddles - SERVICE PROCEDURES AND ADJUSTMENTS

8. Check gas pressure.

9. Gas pressure should read 4” W.C. for natural and

10” W.C. for propane gas. If not correct, refer to

GAS PRESSURE REGULATOR

ADJUSTMENT.

10. Turn gas supply off, disconnect manometer and

reinstall pressure tap plug.

924RX SHOWN

Fig. 25

GAS PRESSURE REGULATOR ADJUSTMENT

A gas pressure regulator is supplied with the griddle and must be installed as close to the griddle on the gas supply

line as possible. Make sure that the arrow on the underside of the regulator is oriented in the direction of gas flow

to the griddle and the regulator is positioned with the vent plug and adjustment screw upright. Check that vent plug

is not clogged by grease and debris.

Check and set the gas pressure after the regulator is installed. The pressure should be set for 4” water column

(W.C.) for natural gas and 10” W.C. for propane gas while all burners are on.

The supply pressure (upstream of the regulator) should be 7-9” W.C. for natural gas and 11-12” W.C. for propane

gas. At no time should the griddle be connected to supply pressure greater than ½ psig (3.45 kPa) or 14” W.C.

Graphic shows pressure plug location.

Page 13 of 19 F25383 (0219)

Page 14

Heavy Duty Gas Griddles - SERVICE PROCEDURES AND ADJUSTMENTS

Fig. 26

NOTE: MSA models are in same locations. There are no shut off valves.

BURNER ADJUSTMENT

For efficient burner operation, it is important that a

proper balance of gas volume and primary air supply

is maintained to give complete combustion.

Insufficient air supply results in a yellow streaming

flame. Primary air supply is controlled by the air

shutter on the front of the burner venturi. Loosen the

screw on the venturi and adjust the air shutter to just

eliminate yellow tips on the burner flames. Lock the air

shutter in place in place by tightening the screw.

Repeat this procedure as necessary with all burners.

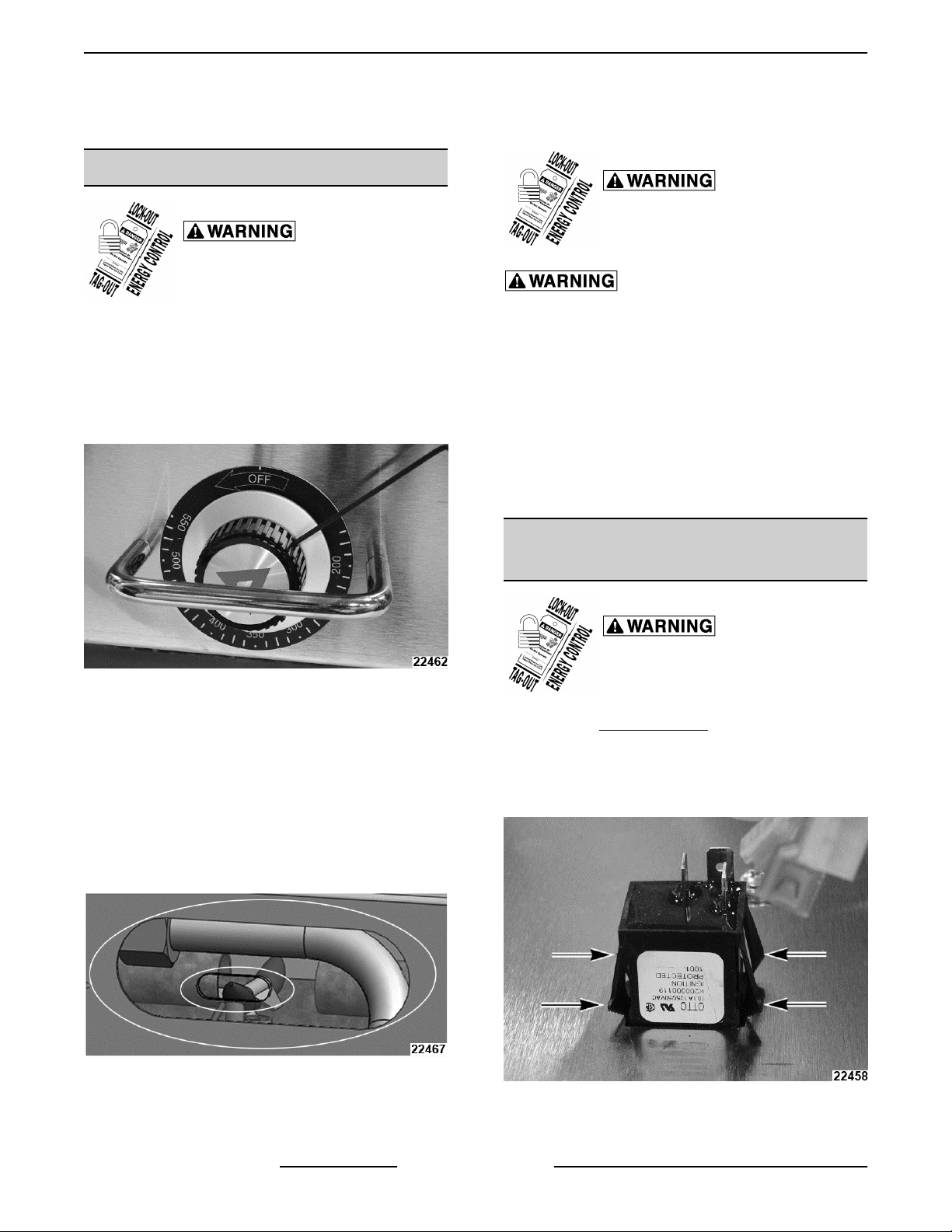

THERMOCOUPLE TEST

1. Unscrew thermocouple fitting from safety valve.

Fig. 27

F25383 (0219) Page 14 of 19

Page 15

Heavy Duty Gas Griddles - SERVICE PROCEDURES AND ADJUSTMENTS

Fig. 28

2. Install thermocouple test adapter finger tight plus

a quarter turn.

3. Install thermocouple into test adapter finger tight

plus a quarter turn.

B. If less than 17 millivolts is measured, install

a replacement thermocouple.

9. Remove test adapter.

NOTE: Over tightening can cause thermocouple tip

to short out.

4. Set VOM to DC millivolt scale and connect (+)

meter lead to pin on thermocouple adapter and

(-) meter lead to thermocouple.

Fig. 29

5. Light pilot flame.

6. Verify that thermocouple is sufficiently immersed

in flame. Adjust pilot valve to allow more gas flow

if necessary.

7. With thermostat off, allow pilot to burn for 3-4

minutes to stabilize voltage output from

thermocouple.

8. Verify thermocouple output voltage.

A. If 25 - 35 millivolts is measured, the

thermocouple is functioning properly.

Page 15 of 19 F25383 (0219)

Page 16

Heavy Duty Gas Griddles - ELECTRICAL OPERATION

ELECTRICAL OPERATION

ELECTRICAL DIAGRAM

Fig. 30

F25383 (0219) Page 16 of 19

Page 17

Heavy Duty Gas Griddles - ELECTRICAL OPERATION

Fig. 31

Page 17 of 19 F25383 (0219)

Page 18

Heavy Duty Gas Griddles - TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

SYMPTOMS POSSIBLE CAUSES

1. Power cord unplugged.

2. Igniter switch malfunction.

No spark to ignite pilot gas.

Sparks but gas does not ignite.

Gas pilot ignites but will not maintain flame.

3. Shorted electrode on ignitor.

4. Ignitor cable malfunction.

5. Interconnecting wiring malfunction.

6. Electric Igniter Module malfunction.

1. Service gas valve closed.

2. Gas supply not purged of air. Depress pilot safety button until

air is purged.

3. Gas supply off or insufficient gas pressure.

4. Adjust pilot valve to allow more gas flow.

5. Safety valve malfunction.

1. Air blowing pilot out. Prevent air flow from affecting unit.

2. Gas supply not purged of air. Depress pilot safety button until

air is purged.

3. Adjust pilot valve to allow more gas flow.

4. Thermocouple not sufficiently immersed in flame. Adjust

accordingly.

5. Thermocouple malfunction. Refer to THERMOCOUPLE

TEST.

6. Obstructed pilot orifice.

7. Insufficient gas pressure.

8. Safety valve malfunction.

1. Gas pressure incorrect or fluctuating.

2. Obstructed flue.

Gas burners ignite but will not maintain flame.

One or more burners have lower flame level

than the others.

F25383 (0219) Page 18 of 19

3. Gas orifice obstructed, improperly aligned / spaced, or

incorrect.

4. Burner malfunction.

1. Check gas pressure.

2. External air flow or vent hood problems may agitate affected

burners.

3. Gas orifice obstructed, improperly aligned / spaced, or

incorrect.

4. Adjust burner air shutter.

Page 19

Heavy Duty Gas Griddles - TROUBLESHOOTING

SYMPTOMS POSSIBLE CAUSES

1. Check gas pressure.

2. Check that burner is properly seated.

3. Check that burner ignition ports, pilot flash tube and pilot burner

One burner has a delayed ignition; a several

second lapse when the burner actually lights.

are all aligned.

4. Gas orifice obstructed, improperly aligned / spaced, or

incorrect.

5. Check burner shutter adjustment.

6. Check pilot flame adjustment.

1. Gas shut off valve not completely open.

2. Thermostats need calibrated. See CALIBRATION section.

3. Thermostat malfunction.

Excessive or low heat.

Heat does not come on when the thermostat

is turned on.

4. Gas pressure incorrect.

5. Unit's gas regulator not installed or malfunctioning.

6. Incorrect gas type.

7. Gas orifice obstructed or incorrect.

1. Pilot burner not lit.

2. Griddle shut-off valve not in ON position.

3. Low gas pressure.

4. Thermostat malfunction.

Page 19 of 19 F25383 (0219)

Loading...

Loading...