Vulcan Fitness vfb12 Service Manual

SERVICE MANUAL

VFB12

Flash

Bake

®

OVEN

ML-114905 W/O CORD

ML-114908 W/CORD

- NOTICE This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qu alif ied. If yo u have attend ed a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this manual.

Thi s manu al i s no t i nten ded to be al l en comp assi ng . I f you have

not attende d a Vulcan S ervic e School for this produ ct , you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e n ecessary too ls, in strument s and skills should be

performed b y a trained Vu lcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan-Hart , is prohibited.

A Product of VULCAN-HART LOUISVILLE , KY. 40201-0696

Form 24586 ( 4/97)

FlashBake OVEN

TABLE OF CONTENTS

GENERAL............................................................................. 3

Introduction .................................................................. 3

Specifications ................................................................ 3

Tools....................................................................... 5

Lubrication .................................................................. 5

REMOVAL AND REPLACEMENT OF PARTS ................................................. 6

Covers And Panels ............................................................ 6

Ov en Cavity Panels ............................................................ 7

Door ....................................................................... 8

Door Gasket ................................................................. 8

Lamp Shields ................................................................ 9

Pulley Plate Assembly.......................................................... 9

High Limit Thermostat......................................................... 10

Door Springs ................................................................ 10

Exhaust Bl ower .............................................................. 11

Display .................................................................... 12

Keypad .................................................................... 12

Rack Drive Motor And Bushing .................................................. 12

Upper Lamp Shi eld Switch ..................................................... 13

Fuse ...................................................................... 13

Door Lock Solenoid ........................................................... 14

Thermistor (Front & Rear) ...................................................... 14

Photo Detector (Bottom & Top) .................................................. 14

Lamps..................................................................... 15

Lamp Socket ................................................................ 16

Relay Board ................................................................ 16

Control Board ............................................................... 17

Control Board Proms.......................................................... 17

SERVICE PROCEDURES AND ADJUSTMENTS .............................................. 18

Photo Detector Test........................................................... 18

Control Board Test Leds ....................................................... 18

Control Board Bypass ......................................................... 18

Lamp Test.................................................................. 18

Control Board Test ........................................................... 19

Voltage Test ................................................................ 20

Manual Voltage Det ect ion Over-ride .............................................. 20

Clearing Memory............................................................. 21

Alarm s And Diagnostics ........................................................ 22

ELECTRICAL OPERATION .............................................................. 23

Component Func tion .......................................................... 23

Component Locat ion .......................................................... 24

Sequence of O per ation ........................................................ 25

Wiring Diagram .............................................................. 27

TROUBLESHOOTING .................................................................. 28

© Vulcan 1997

2

FlashBake OVEN - GENERAL

GENERAL

INTRODUCTION

General

®

The Flash

employs a revolutionary high quality, high speed

cooking technology. The baking process is so fast that

food retai ns i ts natural j ui ces. B r ead products brown

and become cri sp while vegetabl es retai n t heir c ol or

and textur e. The t exture, appear ance and quality of

food cooked i n thi s o ve n i s superior to t hat provided

by any other method of cook ing.

In conventional ovens, the cooking process occurs by

transferr ing heat energy from t he ai r i nside t he ov e n

into the food. Hot surfaces inside the oven also

transfer heat di re ct ly i nto the f ood by conduc tion. In

convection ovens, the air-to-food heat transfer is

enhanced by the uniform circulation of the heated air

around the food. Forced air ovens blow the heated air

directly onto the food, providing marginal increases in

cooking speeds.

Flash

to cook by radiative heat transfer. The infrared energy

browns the surface of the f ood, while the visible li ght

energy penetrates and heats i t i nternally. Using the

proper combination of visible and infrared light

energy, the Flash

speed baking and high-quality food.

Bake

oven is a versatile oven that

Bake

ovens use visible and infrared light energy

Bake

oven provides efficient, high-

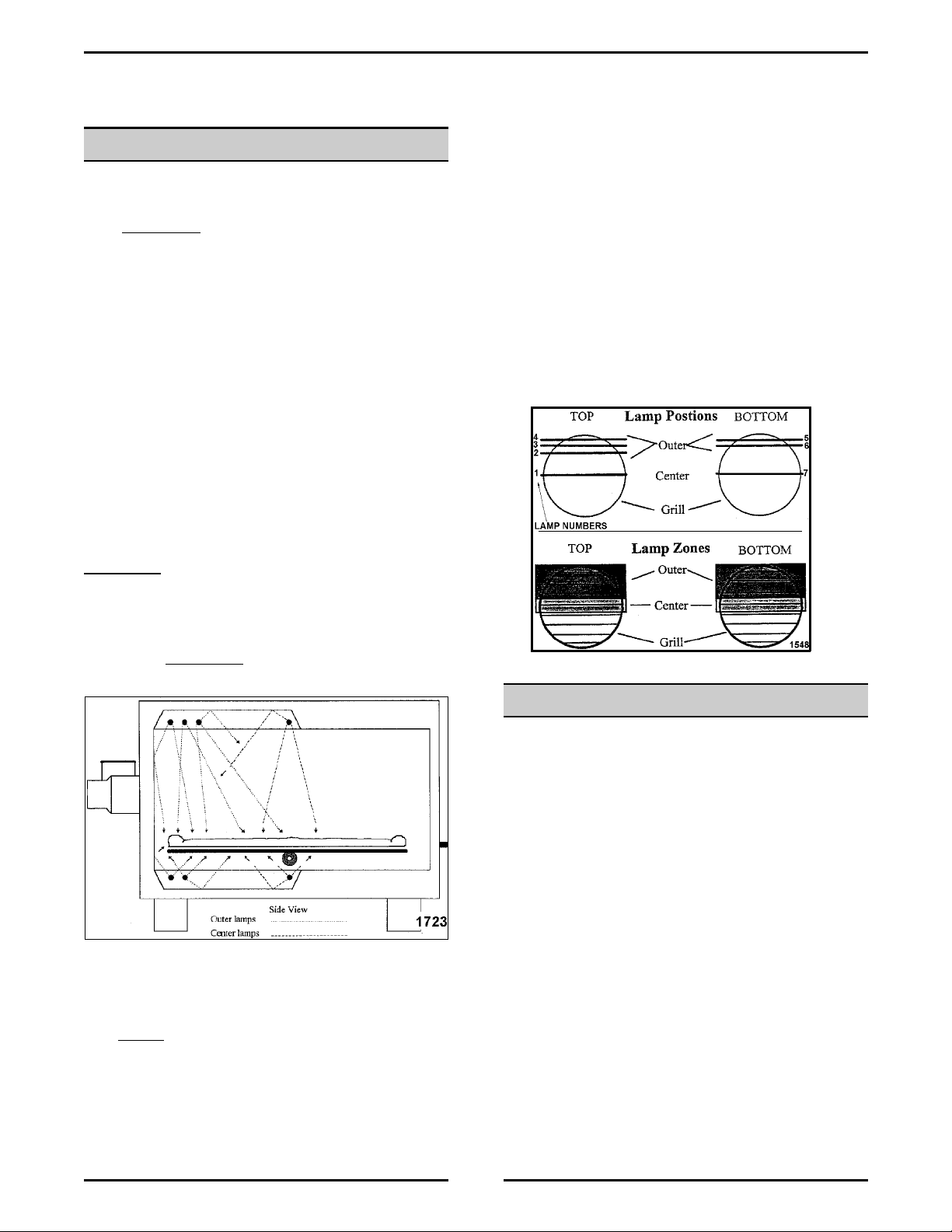

Zone Power Levels

The lamps are positioned so tha t th e center lamps are

above and below the center of the grill. The outer

lamps are l ocat ed abov e and below the rear of t he

grill. There is only one top center lamp and one

bottom c enter lamp. The top outer has three lam ps

and the bottom outer has two lamps.

Changing the top outer and bottom outer power levels

will have a greater effect on cooking times and

browning than changing the center power levels. This

is because outer intensities contain 70% of the

cooking energy while the center intensities only

contain 30% of the cooki ng ener gy .

• Use metal pans (thin wall pans will warp),

Corning Vision War e

• Do not

use paper (it will burn), Pyrex® dishes or

plastic.

®

or foil.

SPECIFICATIONS

General

• If the inlet air is obstruc te d or heated the ov en

will not operate properly.

• Install the HFB12 oven on a level counter top or

other stable surface of sufficient strength to

safely support the oven.

• Position the oven at an appropriate height to

allow safe handl ing o f h ot food and c onv enient

access to the oven controls.

• Position the oven so t hat the open door does not

extend i nto areas that may resul t in acc idental

contact wit h hot oven parts.

• The oven can be ordered with a 6' power cord for

receptacle i nstal l ati on. If t hi s i s the case assure

that t he unit cor d can be pl ugged int o the out l et

without strai n on the cord or plug.

3

FlashBake OVEN - GENERAL

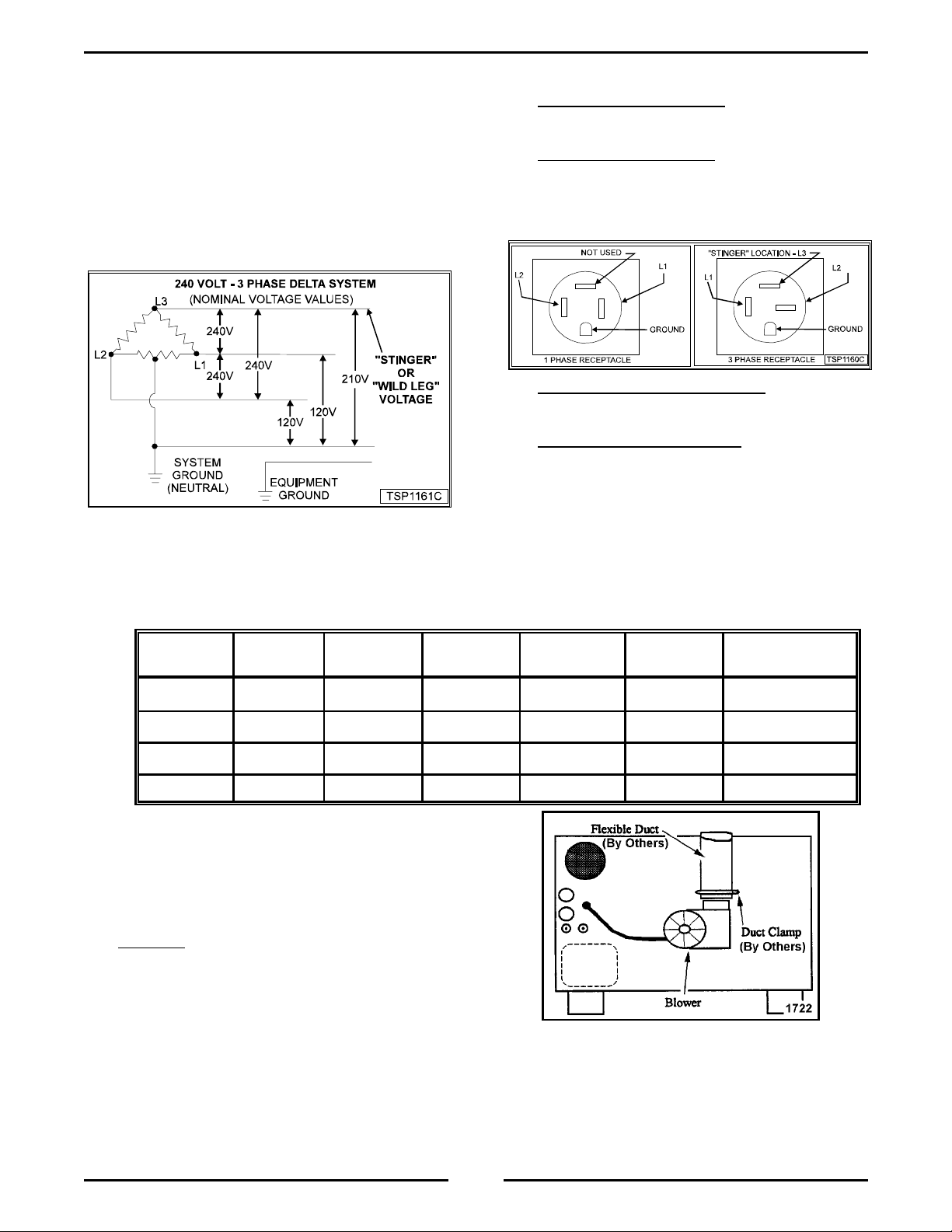

Electrical

NOTE:

Throughout this manual the term “STINGER”

(sometimes called “Wild Leg ”) will be use d to identify

the leg of a three phase system that shows more than

approxim ately 120 vol ts to system ground ( neutral).

The “Stinger” leg of a 240 volt 3 phase system can be

easily identified using a voltmeter. The line-to-ground

vol tage of t he “Stinger” will read approxi mately 210

volts. The line-to-ground voltage of the other two legs

will read approximately 120 volts.

• For cord connected Ovens:

Plug the oven into a

dedicated circuit outlet of the appropriate NEMA

style and rating.

• For hard-wired Ovens:

Have a qualified

electri cian wire the Ov en into a p roperly rated

dedicated circuit, connecting to the pigt ails in the

juncti on box on t he rear of the Ove n, using t he

appropriate c onduit, wire and connectors.

• This HFB12 oven automatically adapts to either

208 volt or 240 volt operation. For 3 phase

operation, the oven automatically senses and

adapts to the existing phase rotation.

VOLTAGE MAX.

POWER

MAX.

CURRENT

208/60/1 11.9 kW 56 amp 9 kW 43 amp 60 amp 14-60R

240/60/1 11.9 kW 52 amp 9 kW 40 amp 60 amp 14-60R

208/60/3 11.9 kW 35 amp 9 kW 27 amp 40 amp 15-50R

240/60/3 11.9 kW 32 amp 9 kW 25 amp 40 amp 15-50R

Exhaust Duct

TYPICAL

POWER

• For a single phase 240 volt Oven:

Both “hot legs”

must read 120 volts to gr ound. The “stinger” leg

must not be attached to a single phase oven.

• For a 3 phase 240 volt Oven:

a 3 phase

supply circ uit

vol t oven, the “stinger” leg of the

240

be connected as follows:

MUST

When c onnecti ng

• For a hard-wired oven, connect the stinger to

the blue pigtail. The blue wire is mar k ed with

a label i ndicating the stinger connection.

• For a cord connected ov en, the stinger m ust

be wired t o the receptac le at the pin location

opposite the ground lug.

TYPICAL

CURRENT

BREAKER

SIZE

NEMA

RECEPTACLE

• A length of flexible exhaust duct may be attached

to the ov en to vent hot air out of the cooking

area. Attach the duct to the blower assembly with

a clamp.

• If needed

, a length of 4" flex ible e xhaust duct

(made of metal suitable for high temperature) not

exceeding 6 feet may be attached to the HFB12

oven to vent hot air out of the cooking area.

Attach the duct to the blower asse mbly as show n

below.

that will restrict air flow.

Be sure there are no bends in the duct

Depending on the

length of the duct required, it may be necessary

to have a supplementary exhaust system to

ensure adequate air flow.

• The other end of the duct c an be vented into an

existing hood, or to the outside in a manner

consistent with local building codes.

4

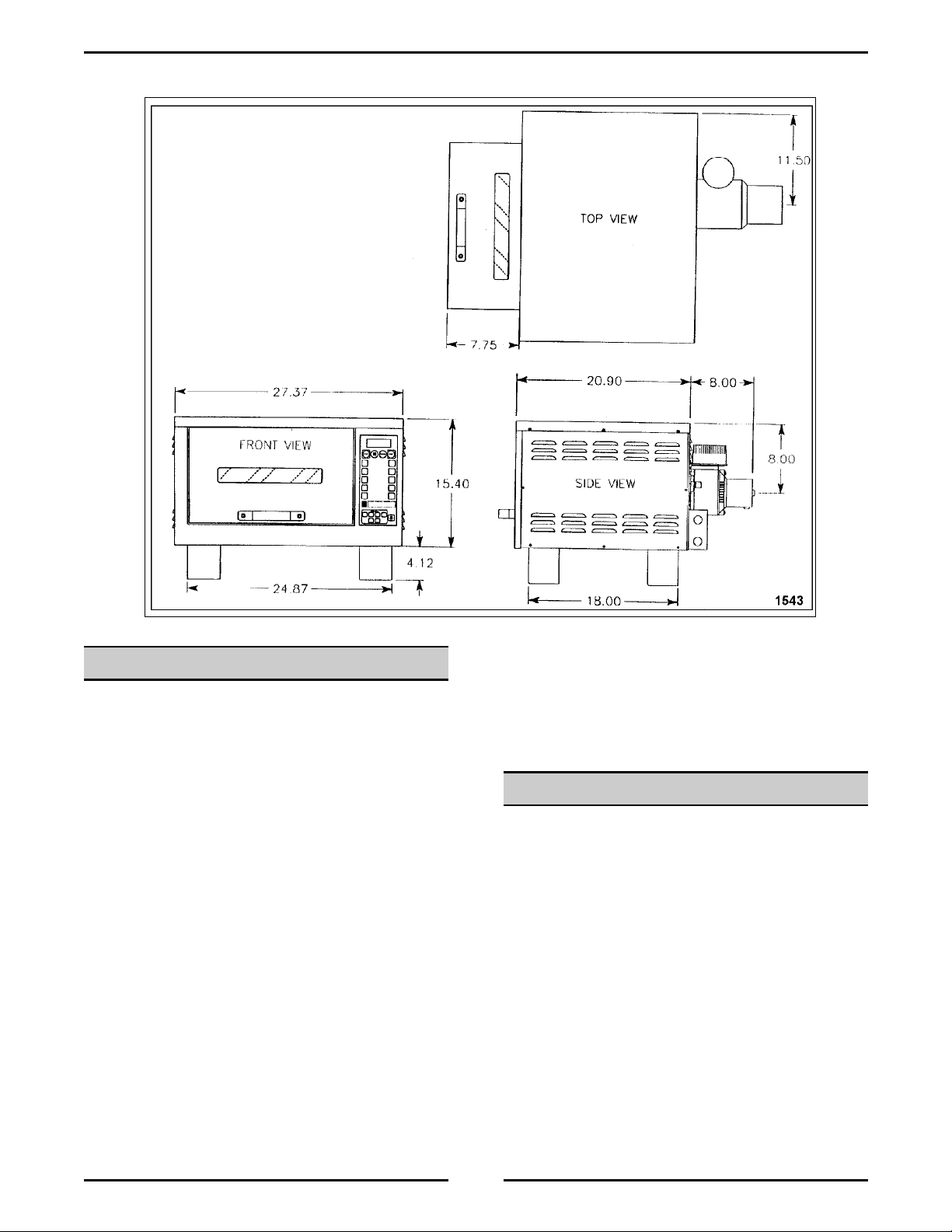

Dimensions

FlashBake OVEN - GENERAL

TOOLS

Standard

• Standard set of hand tools

• VOM with AC current tester (Any VOM with a

sensitivity of at least 20,000 ohms per volt)

Special

• Elect rogrease - 424 031-1 used on relay board

high voltage connections.

• Heat sink compound - 519504 used on high limit

thermostat and thermistor.

• Hi-Tem p Lock-Ti te (green) - 424 028-1 used on

pulley plates.

• Hi-Temp grease - 424023-1 used on pulley driv e

shaft.

• General P urpose Silicone - 424030-1 - used on

gasket.

• Grounding K it - 84919.

• Torque Wrench (in•lb)

LUBRICATION

• Hy-Temp Grease - 424023-1 - Pulley drive

shaft

5

FlashBake OVEN - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

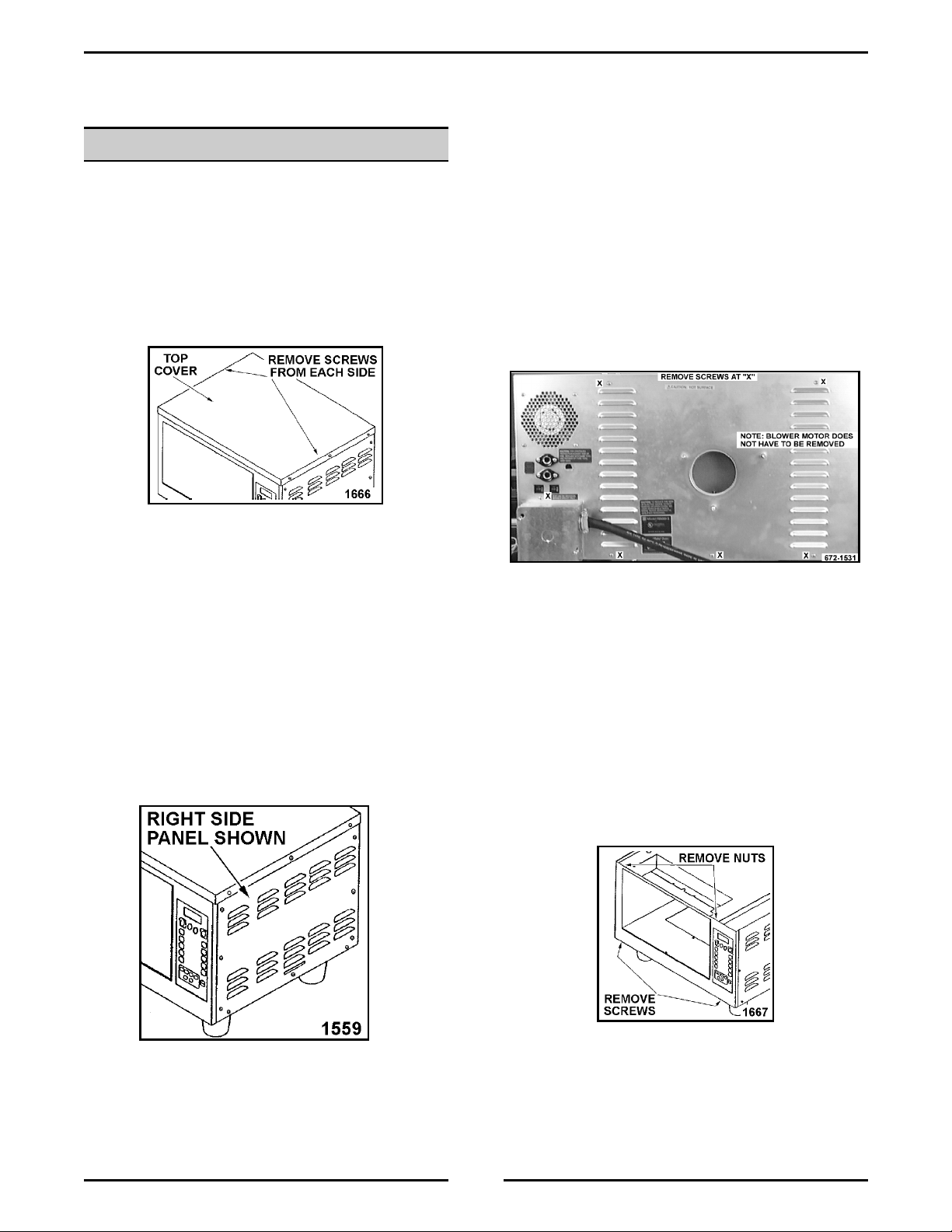

COVERS AND PANELS

WARNING:

POWER TO THE MACHINE AT THE MAIN CIRCUIT

BOX. PLACE A TAG ON THE CIRCUIT BOX

INDICATI NG THE CIRCUIT IS BEING SERV ICED.

Top Cover

1. Remove the screws from both sides of the cover.

2. Lift strai ght up on the cover and rem ove it f rom

the ov en.

NOTE:

back panel screws.

3. Reverse proc edur e to install .

Right or Left Side Panels

DISCONNECT THE ELECTRICAL

The bac k has a cut-out to al low for the

Back Panel

1. Remove the top cover as outlined under

“COVERS AND PANELS”.

2. Disconnect the lead wires from the fuses, circuit

breakers, control cooling fan and exhaust fan.

3. Remove the screws that secure the back panel to

the ov en.

4. Lift up to clear the junction box on the lower right

corner of the oven on units that are hard wired.

5. Reverse proc edur e to install .

Front Panel

1. Remove the top cover as outlined under

“COVERS AND PANELS”.

1. Remov e the screws from the t op cover on the

side you are wanting to r emov e.

2. Remove the screws that secure the side panel to

the ov en fram e.

NOTE:

openings down.

3. Reverse proc edur e to install .

Position t he side panels with the l ouv er

2. Remove the three screws from the front edge of

the left side panel.

3. Remov e the right side panel as outlined under

“COVERS AND PANELS” and disconnect the

lead wires to the control panel.

4. Remove the screws that secure the front panel to

the bottom of the oven.

5. Remove the nuts from the studs on the top o f the

front panel and remove the front panel.

6. Reverse proc edur e to install .

6

FlashBake OVEN - REMOVAL AND REPLACEMENT OF PARTS

Top Plate Panel

1. Remove the top cover as outlined under

“COVERS AND PANELS”.

2. Disconnect the lead wires to the high limit

thermostat .

3. Remove the thermistor and wire ties attached to

the top plat e.

4. Remove the screws that secure the top plate.

5. Remove the nuts f r om the f r ont studs.

6. Pull top plat e toward back of ov en until the front

edge has cleared the door lock.

NOTE:

have t o rem ove the rack dri v e p u l ley as outli ne

under “RACK DRIVE P ULLE Y ”.

3. Reverse proc edur e to install .

Back Panel

1. Remove the side panels as outlined under

“OVEN CAVITY PANELS”.

2. Remove the screws that secure the panel to t he

oven cavi ty outer wall.

3. Pull the panel to the front of the oven to remove.

4. Reverse proc edur e to install .

Upper Panel

1. Remove the side panels as outlined under

“OVEN CAVITY PANELS”.

2. Remove the screws that secure the panel to t he

oven cavi ty wall.

When removing the right panel, you may

7. Reverse proc edur e to install .

OVEN CAVITY PANELS

WARNING:

POWER TO THE MACHINE AT THE MAIN CIRCUIT

BOX. PLACE A TAG ON THE CIRCUIT BOX

INDICATI NG THE CIRCUIT IS BEING SERV ICED.

CAUTION: Do not scratch or d ull the surface of

the reflective oven cavity panels. This could affect

the operation of the oven.

Side Panels

1. Remove the screws that secure the panel to t he

oven cavi ty outer wall.

2. Pull the panel to the fro n t of the oven to remove.

If the right side panel is difficult to remove, check

the top edge where it m eets the upper panel . It

may be caught on the edge.

DISCONNECT THE ELECTRICAL

3. Pull the panel to the front of the oven to r e move.

4. Reverse proc edur e to install .

7

FlashBake OVEN - REMOVAL AND REPLACEMENT OF PARTS

DOOR

WARNING:

POWER TO THE MACHINE AT THE MAIN CIRCUIT

BOX. PLACE A TAG ON THE CIRCUIT BOX

INDICATI NG THE CIRCUIT IS BEING SERV ICED.

Removal

1. Open the door to expose the screws on the side

of the door.

2. Remove the screw that is closest to the top of the

door from each side.

DISCONNECT THE ELECTRICAL

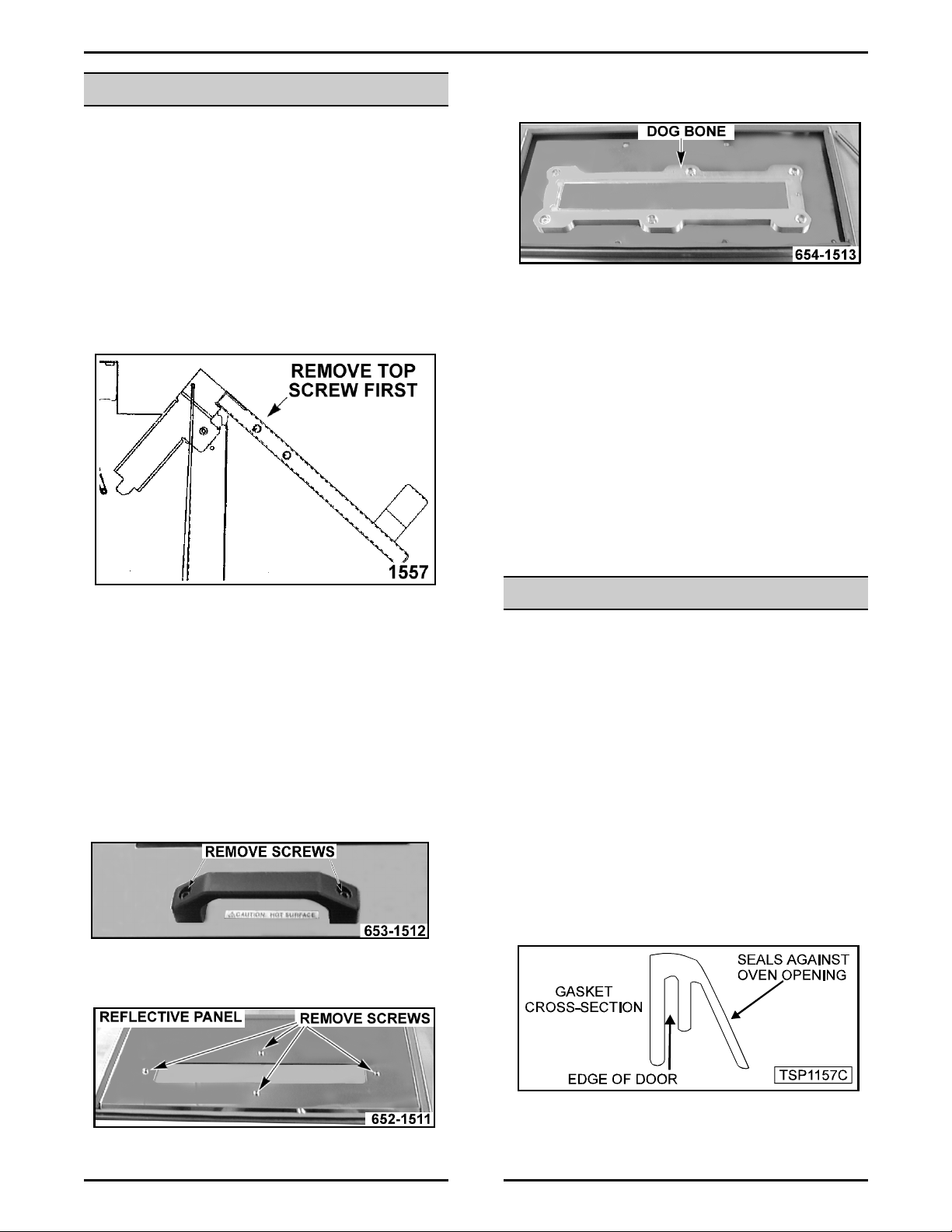

4. Remove the nuts that secure the dog bone to the

outer door panel and r emov e the dog bone.

NOTE:

temp l ock-tite on t he stud threads. Tighte n the

nuts to

will cause the outer door panel to become

deformed.

NOTE:

pattern allows for installation one way. The

reflective glass should be positioned to the

interior of the oven cavity and the welder’s glass

to the customer side. There will be a “W”

stamped in t he dog bone indicating t he welder’s

glass.

When instal li ng the dog bone, use hi gh

8 in•lb

. Do not over tighten the nuts. This

When i nstalli ng the dog bone, the hole

3. Allow the door to move to the open position and

remove the remaining screws.

4. Pull t he door from the hinges.

5. Reverse proc edur e to install .

Disassembly

1. Remove the door as outlined under “DOOR”.

2. Remove the door handle from the door.

3. Remove the inside reflective panel for t he door .

5. Reverse proc edur e to install .

DOOR GASKET

WARNING:

POWER TO THE MACHINE AT THE MAIN CIRCUIT

BOX. PLACE A TAG ON THE CIRCUIT BOX

INDICATI NG THE CIRCUIT IS BEING SERV ICED.

1. Remove the door as outlined under “DOOR”.

2. Disassembly the door to expose the gasket.

3. Remov e t he gasket f r om the i nside edge of the

door.

4. Remove any silicone from the opening.

5. Apply general purpose silicone in t h e groove of

the gasket that is att ached to the edge of the

door.

DISCONNECT THE ELECTRICAL

8

FlashBake OVEN - REMOVAL AND REPLACEMENT OF PARTS

6. Install t he repl acem ent gasket ont o t h e edge of

the opening and allow to set for a minimum of

before cooking.

hours

Lower Lamp Shield

8

1. Open the door and remove the rack.

2. Remov e the screws fro m the f ram e of t he lower

lamp shield.

3. Push the shield assembl y to the lef t side of the

oven.

4. Lift the fr ont edge of the frame up.

5. Pull the lower lamp shield from the oven. You may

have t o maneuver it around t he pulleys.

6. Reverse proc edur e to install .

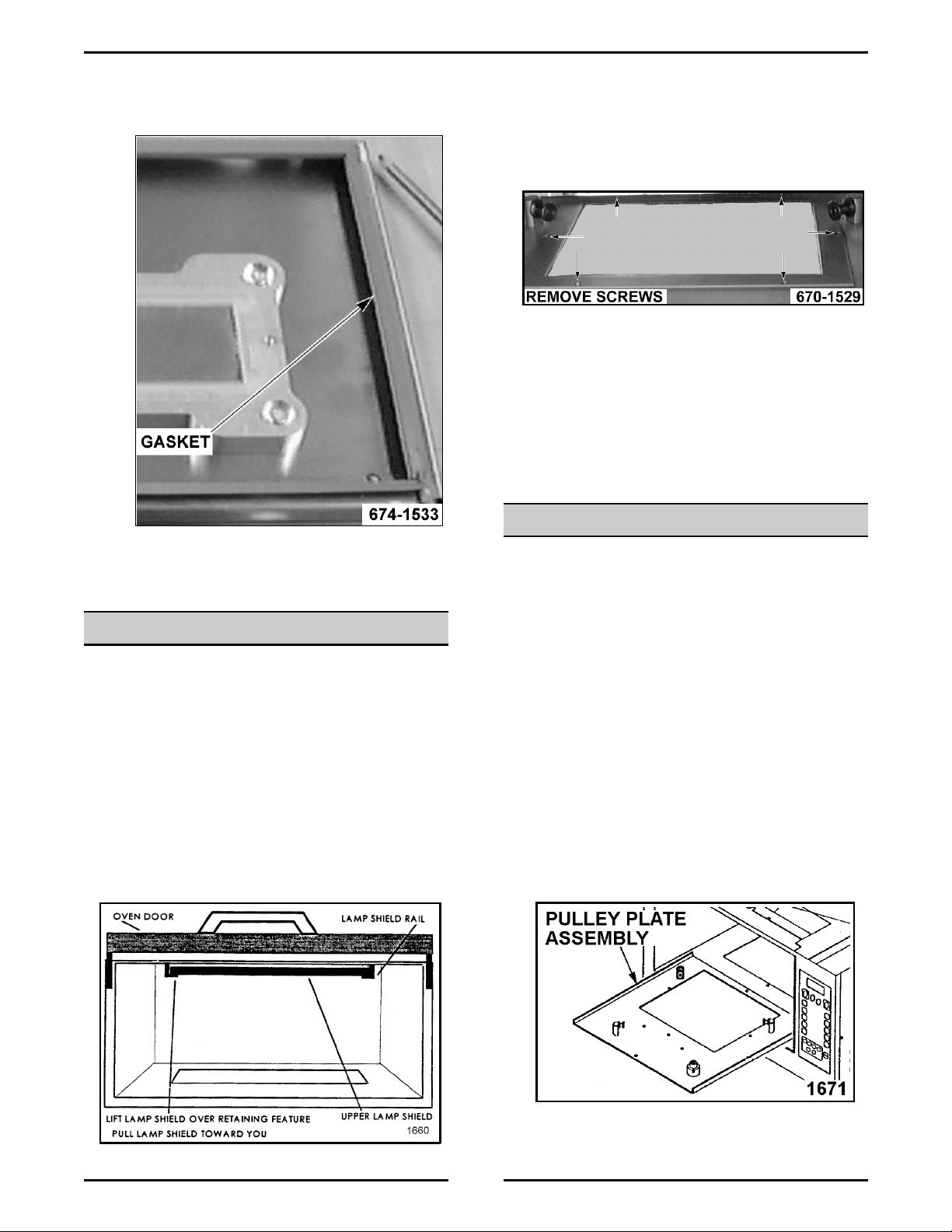

PULLEY PLATE ASSEMBLY

7. Re-assemble the door and install the door on the

oven.

LAMP SHIELDS

WARNING:

POWER TO THE MACHINE AT THE MAIN CIRCUIT

BOX. PLACE A TAG ON THE CIRCUIT BOX

INDICATI NG THE CIRCUIT IS BEING SERV ICED.

Top Lamp Shield

1. Open the door.

2. Lift the front edge of the shield over the retaining

feature.

3. Pull the shield toward you and remove it from the

oven.

DISCONNECT THE ELECTRICAL

WARNING:

POWER TO THE M A CHINE AT THE MA IN CIRCUIT

BOX. PLACE A TAG ON THE CIRCUIT BOX

INDICATI NG THE CIRCUIT IS BEING SERV ICED.

NOTE:

right front corner with the screw faci ng the front.

NOTE:

is shorter than the two roller supports on the left side.

Removal

1. Remov e t he lower l am p shiel d as outl ined under

“LAMP SHIELDS”.

2. Remove the screw from the front edge of the

roller plate.

3. Pull t he roller plate out of the oven cavi ty.

DISCONNECT THE ELECTRICAL

The horizontal roller support is positioned in the

The vertical roller support in the left rear corner

4. Reverse proc edur e to install .

9

Loading...

Loading...