Page 1

INSTALLATION, SERVICE

& PARTS MANUAL FOR

SNORKEL GAS CONVECTION OVEN MODELS:

SG-22, SG-2SM, SG-1010, SG-10SM

ELECTRONIC IGNITION MODELS:

SG-22E, SG-2SME, SG-1010E, & SG-10SME

VULCAN-HART CORPORATION, 3600 NORTH POINT BOULEVARD, BALTIMORE, MARYLAND 21222

Page 2

IMPORTANT

OPERATING, INSTALLING AND SERVICE PERSONNEL

Operating information for this equipment has been prepared for use by qualified and/authorized

operating personnel.

All installation and service on this equipment is to be performed by qualified, certified, licensed and/

authorized installation or service personnel, with the exception of any part marked with a + in front of

the part number.

Service may be obtained by contacting the Factory Service Department, Factory Representative or

Local Service Agency.

DEFINITIONS

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified or authorized operating personnel are those who have carefully read the information in this

manual and are familiar with the equipment's functions or have had previous experience with the

operation of the equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, a firm, corporation or company which either in

person or through a representative are engaged in, and are responsible for:

1. The installation of gas piping from the outlet side of the gas meter, or the service regulator when

the meter is not provided, and the connection and installation of the gas appliance. Qualified

installation personnel must be experienced in such work, be familiar with all precautions required,

and have complied with all requirements of state or local authorities having jurisdiction.

Reference in the United States of America - National Fuel Gas Code ANSI Z223.1 (Latest

Edition). In Canada - Canadian Standard CAN/CGA-B149.1 NAT. GAS (Latest Edition) or

CAN/CGA-B149.2 PROPANE GAS (Latest Edition).

2. The installation of electrical wiring from the electric meter, main control box or service outlet to

the electric appliance. Qualified installation personnel must be experienced in such work, be

familiar with all precautions required, and have complied with all requirements of state or local

authorities having jurisdiction. Reference: In the United States of America - National Electrical

Code ANSI NFPA No. 70 (Latest Edition). In Canada - Canadian Electric Code Part 1 CSAC22.1 (Latest Edition).

3. The installation of steam piping from the source of supply to the service inlet of the appliance.

Qualified installation personnel must be experienced in such work, be familiar with all precautions

required, and have complied with all requirements of state or local authorities having jurisdiction.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Vulcan equipment who have been

endorsed by the Vulcan-Hart Corporation. All authorized service personnel are required to be

equipped with a complete set of service and parts manuals and stock a minimum amount of parts

for Vulcan equipment.

Page 3

IMPORTANT NOTES FOR ALL VULCAN APPLIANCES

1. These units are produced with the best possible workmanship and material. Proper installation is vital if best

performance and appearance are to be achieved. Installer must follow the installation instructions carefully.

2. Information on the construction and installation of ventilating hoods may be obtained from the "Standard for the

installation of equipment for the removal of smoke and grease laden vapors from commercial cooking equipment,"

NFPA No. 96 (latest edition) available from the National Fire Protection Association, Battery March Park, Quincy

MA 02269.

3. For an appliance equipped with a flexible electric supply cord, the cord is equipped with a three prong (grounding)

plug. This grounding plug is for your protection against shock hazard and should be plugged directly into a properly

grounded three prong receptacle. Do not cut or remove the grounding prong from this plug. If the appliance is not

equipped with a grounding plug, and electric supply is needed, ground the appliance by using the ground lug

provided (refer to the wiring diagram).

(FOR GAS APPLIANCES ONLY)

4. Do not obstruct the air flow into and around the appliance. This air flow is necessary for proper combustion of

gases and for ventilation of the appliance. Provisions for ventilation of incoming air supply for the equipment in the

room must be in accordance with National Fuel Gas Code ANSI Z223.1 (latest edition).

5. Do not obstruct the flow of flue gases from the flue duct (when so equipped) located on the rear (or sides) of the

appliance. It is recommended that the flue gases be ventilated to the outside of the building through a ventilation

system installed by qualified personnel.

6. For an appliance equipped with casters, (1) the installation shall be made with a connector that complies with the

Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 (latest edition), and Addenda, Z21.69a (latest

edition), and a quick-disconnect device that complies with the Standard for Quick-Disconnect Devices for Use With

Gas Fuel, ANSI Z21.41 (latest edition), and Addenda, Z21.41 a (latest edition) and Z21.41 b (latest edition), and (2)

adequate means must be provided to limit the movement of the appliance without depending on the connector and

the quick-disconnect device or its associated piping to limit the appliance movement. If disconnection of the

restraint is necessary, reconnect this restraint after the appliance has been returned to its originally installed

position.

7. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 psig (3.45 k Pa).

8. The appliance must be isolated from the gas supply system by closing its individual manual shutoff valve during

any pressure testing of the gas supply system at test pressures equal to or less than 1/2 psig (3.45 k Pa).

CAUTIONS

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS EQUIPMENT OR ANY OTHER

APPLIANCE.

1. KEEP THE APPLIANCE FREE AND CLEAR FROM ALL COMBUSTIBLE SUBSTANCES.

2. IN THE EVENT A GAS ODOR IS DETECTED, SHUT UNIT(S) DOWN AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER

FOR SERVICE.

3. POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION MAY BE OBTAINED FROM A

LOCAL GAS SUPPLIER.

Page 4

CAUTIONS (Continued)

CLEARANCES: FROM THE TERMINATION OF THE

APPLIANCE FLUE VENT TO THE FILTERS OF THE

HOOD VENTING SYSTEM, AN 18 INCH MINIMUM

CLEARANCE MUST BE MAINTAINED.

REFERENCE: ANSI/NFPA 96-1984 4-1.2.2.2. OF THE

NATIONAL FIRE PROTECTION ASSOCIATION, INC.,

BATTERYMARCH PARK, QUINCY, MA 02269. AND

NATIONAL BUILDING CODE 1976 SEC. 1015.7b (2)

OF THE AMERICAN INSURANCE ASSOCIATION

ENGINEERING AND SAFETY SERVICE, 85 JOHN

STREET, NEW YORK, N.Y. 10038.

LOADING: BEFORE LOADING THE OVEN SET THE

LOAD CONTROL DIAL TO THE PROPER SETTING

FOR THE PRODUCT AND THE COOKING LOAD

(SEE SEPARATE COOKING CHART).

OPENING OVEN DOORS: BEFORE OPENING THE

OVEN DOORS, PUSH THE AUXILIARY FAN SWITCH

TO THE "OFF" POSITION.

OPENING OVEN DOORS WILL AUTOMATICALLY

CUT "OFF" THE FAN AND THE HEATING

ELEMENTS, BUT IF THE FAN SWITCH IS NOT

PUSHED TO THE "OFF" POSITION, HOT AIR

GATHERED WITHIN THE OVEN CAVITY MAY BE

PUSHED OUT WHEN THE DOORS ARE OPENED.

CAUTION: DO NOT STAND DIRECTLY IN

FRONT OF THE OVEN WHILE

OPENING DOORS

WHEN OPENING THE DOORS, THE OPERATOR

SHOULD PULL DOOR HANDLES OPEN WHILE

SIMULTANEOUSLY STEPPING BACK AWAY FROM

THE FRONT OF THE UNIT.

LOAD THE OVEN AS QUICKLY AS POSSIBLE TO

CONSERVE HEAT. CENTER PANS ON THE RACKS.

HI LIMIT: IS A PROTECTIVE DEVICE WHICH

SENSES THE TEMPERATURE OF THE UNIT TO

PREVENT APPLIANCE OVERHEATING.

THE HI LIMIT OPERATES INDEPENDENTLY AND

WILL AUTOMATICALLY CAUSE UNIT SHUTDOWN

SHOULD THE PRIMARY CONTROL FAIL.

IF THIS SITUATION OCCURS, DO NOT ATTEMPT

TO BYPASS THE HI LIMIT. SHUT UNIT DOWN AND

CONTACT A SERVICE AGENCY.

4

Page 5

VULCAN SNORKEL™ GAS CONVECTION OVEN

INSTALLATION, SERVICE and PARTS MANUAL INDEX

Vulcan Snorkel™ is produced with the best possible

workmanship and material. Proper usage and

maintenance will result in many years of satisfactory

performance.

DESCRIPTION PAGE

DEFINITIONS OF PERSONNEL (Operating, Installation and Service)

and SHIPPING DAMAGE CLAIM PROCEDURES

CAUTIONS 114594-1 & 2

INDEX 114594-3

GENERAL THEORY OF OPERATION 114594-4

INSTALLATION INSTRUCTIONS 114594-5

SG-2SMT & SG-10SMT ADD-A-SECTION INSTRUCTIONS 114594-5 thru 11

INSTALLATION INSTRUCTIONS (Continued) 114594-12 thru 14

FLUE CONNECTIONS 114594-15

The manufacturer suggests that you thoroughly read this

entire manual and carefully follow all of the instructions

provided.

(Inside Front Cover)

TROUBLE SHOOTING SERVICE 114594-15 & 16

PARTS DESCRIPTION & REPLACEMENT 114594-17 thru 19

POWER PANEL - PARTS REPLACEMENT

PRESSURE REG. - PILOT ADJ. - ORIFICE DATA 114594-2

COOKING CHART 114594-22 & 23

REPLACEMENT PARTS LIST 114594-24 thru 44

REVISION PAGE (Inside Back Cover)

The rating plate stating the model number, serial

number, gas type, voltage and amperage is located

inside the lower front cover of the unit on the right hand

side.

Motors in Vulcan convection ovens are permanently

lubricated and require no additional maintenance.

The vent of this appliance should be checked every 6

months for restrictions.

A complete set of wiring diagrams are packed

separately in the unit.

A wiring decal is located inside the control panel

compartment.

114594-20

WARNING: Back and sides of unit must be installed 6"

from combustible construction.

5

Page 6

GENERAL THEORY OF OPERATION

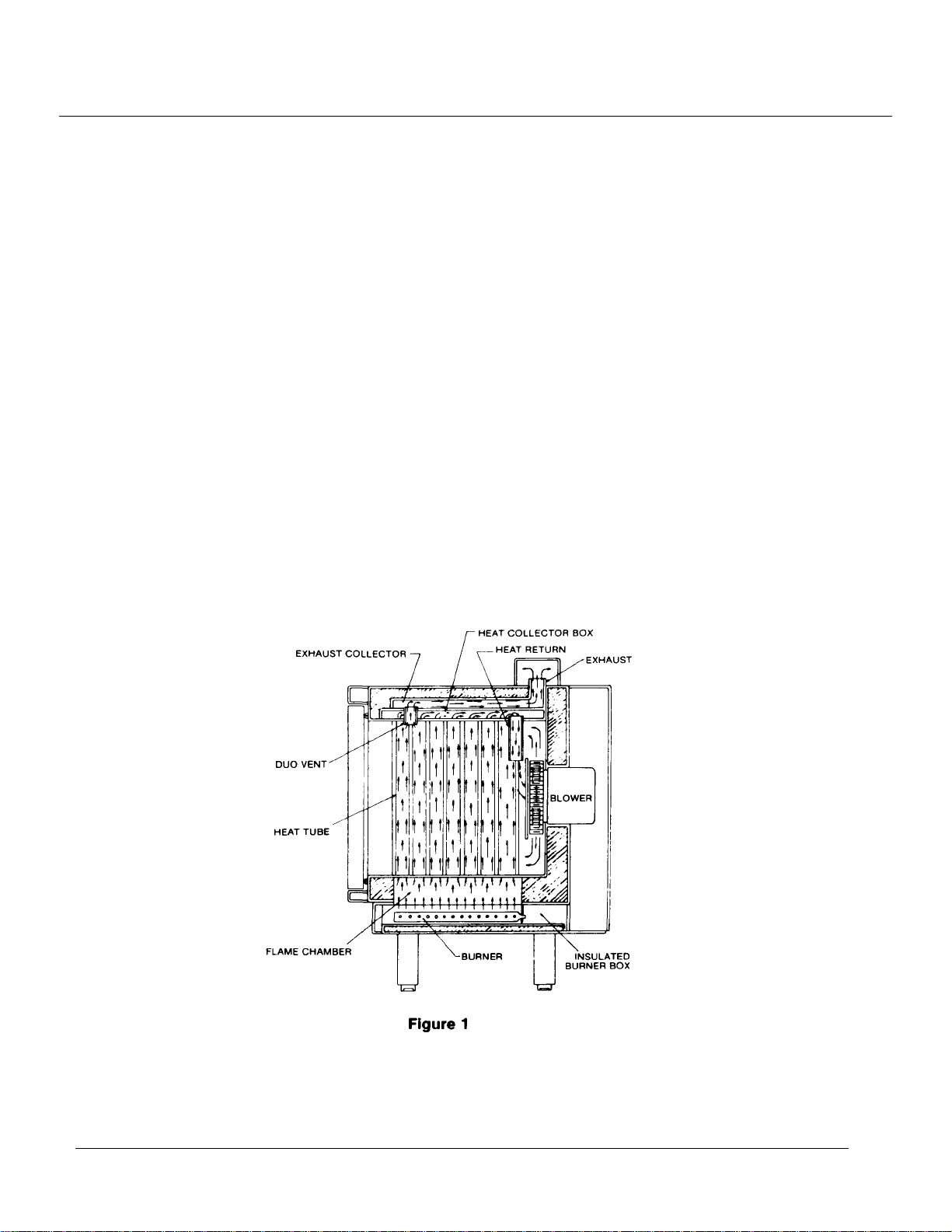

Figure 1 shows the air distribution and the path of the

flue products in the Vulcan Snorkel™ oven. There are

two tubular sheet metal burners which operate in an

insulated combustion chamber with minimum air

requirements. The flame chamber collects the heat

generated by the burners and directs it through the heat

exchanger tubes which are within the cooking

compartment. The heated flue products are collected in

a box above the oven compartment and directed to the

blower inlet through the Snorkel tube. The oven

compartment is heated indirectly via the heat exchanger

tubes and directly with the flue products drawn into the

oven by the Snorkel tube. A circulating fan also

distributes heat throughout the oven evenly. The two

vents in the top of the oven compartment evacuate

moisture and also vent the oven flue products.

The blower and solenoid operate independently of each

other. The blower operates as long as the doors and

closed or the auxiliary fan switch is actuated. The

solenoid is controlled by the thermostat and the Load

Control. The thermostat must be On and the thermostat

and the load control set to an operating position for the

solenoid to come On and supply heat the oven. Either

the thermostat or load control switch in the "Off" position

will shut off the solenoid.

In order to provide protection against a pilot outage

hazzard, a valve controls the main flow of gas to the

burner. As long as a pilot flame is present, the valve will

remain open. In the absence of pilot heat, the valve

closes, eliminating gas to the burner. Each burner has its

own valve which allows them to operate independently

of each other.

A snap acting door switch, mechanically linked with the

right hand door, shuts off both the heat and the blower

when the door is opened and will automatically reset

when the door is closed.

In ovens equipped with optional auxiliary fan switch, the

door inter-lock can be over-ridden by depressing the

"Auxiliary Fan Switch." The oven over-ride affects the

blower only (not the heat) and is intended for rapid

cooling of the oven interior.

Under "Component Description and Replacement"

section the detailed function of each component is

explained.

6

Page 7

INSTALLATION INSTRUCTIONS

This appliance when installed must be electrically

grounded in accordance with National Electrical Code

ANSI C1-1981.

Vulcan ovens are produced with the best possible

workmanship and material. Proper installation is vital

if best performance is to be achieved. Please follow

these instructions carefully.

3. SG-22 & SG-1010 units are shipped in two

sections with a 7” leg stand mounted on the

bottom unit. Position bottom unit as near to the

final location as possible.

4. Pipe joint compounds used when connecting appliances to gas should be resistant to the action of

propane gas.

1. Remove crating with care. Remove all wood

blocking, packing material and accessories.

2. Each unit is factory equipped and electrically connected for use with type of gas and electric supply

indicated on rating plate behind the lower panelCheck the type of gas and electric supply

available.

5. Pipe joints should be tested for leaks with a soap

and water solution before operating the unit.

6. Mount the upper section on top of the lower section from the front of units. Allow the upper section

to overhang the lower unit at the front by approximately 8 inches. Refer to Detail A.

SG-2SMT AND SG-10SMT ADD-A-SECTION INSTRUCTIONS

PART A

PREPARING THE SG-2SMT UNIT FOR

STACKING.

(T in SMT indicates Top oven in double deck convection oven. B in SMB indicates Bottom oven in

double deck convection oven)

TOOLS REQUIRED FOR THIS PROCEDURE:

6" adjustable wrench, 1/4" socket drive, 7/16" hex

head socket, 6" long 1/4" driver extension, 5/16" hex

head socket and flat head screwdriver.

1. Disconnect the unit from the gas and the power

supply and remove two rear lower aluminized access panels. Remove panels using a 5/16" hex

head socket. Also remove S/S lower front cover. To

remove the front cover, slip a flat edged screwdriver

behind the panel and pop the panel off.

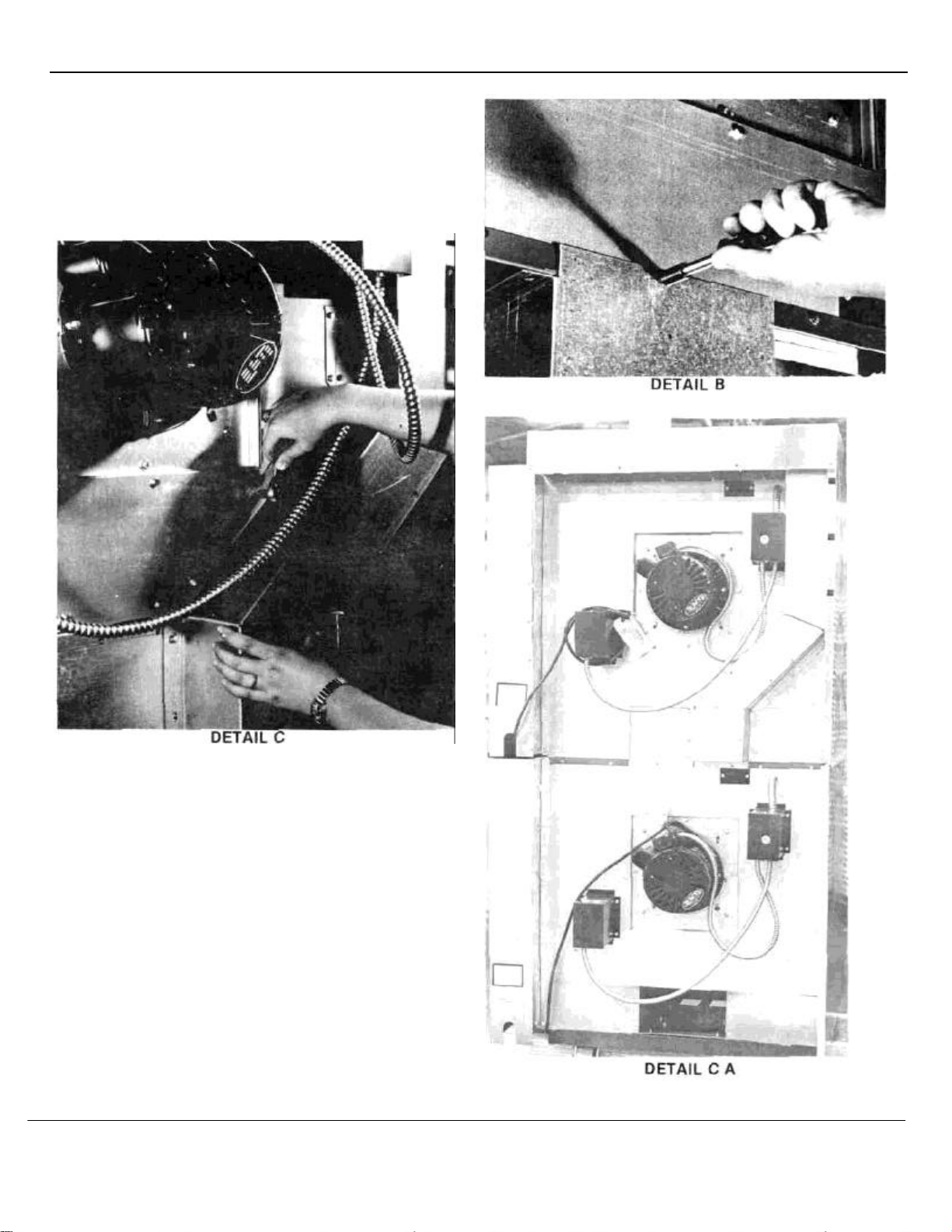

3. Using a 5/16" socket, remove the four bottom baffles

(2 front, 2 rear). (See Details B and C)

2. Using a 6" adjustable wrench and a 7/16" socket,

remove four screws (2 rear, 2 front) attaching the

leg stand to two burner insulation pans. Remove

and discard pans. (See Detail A)

7

Page 8

SG-2SMT & SG-10SMT ADD-A-SECTION INST. (Continued)

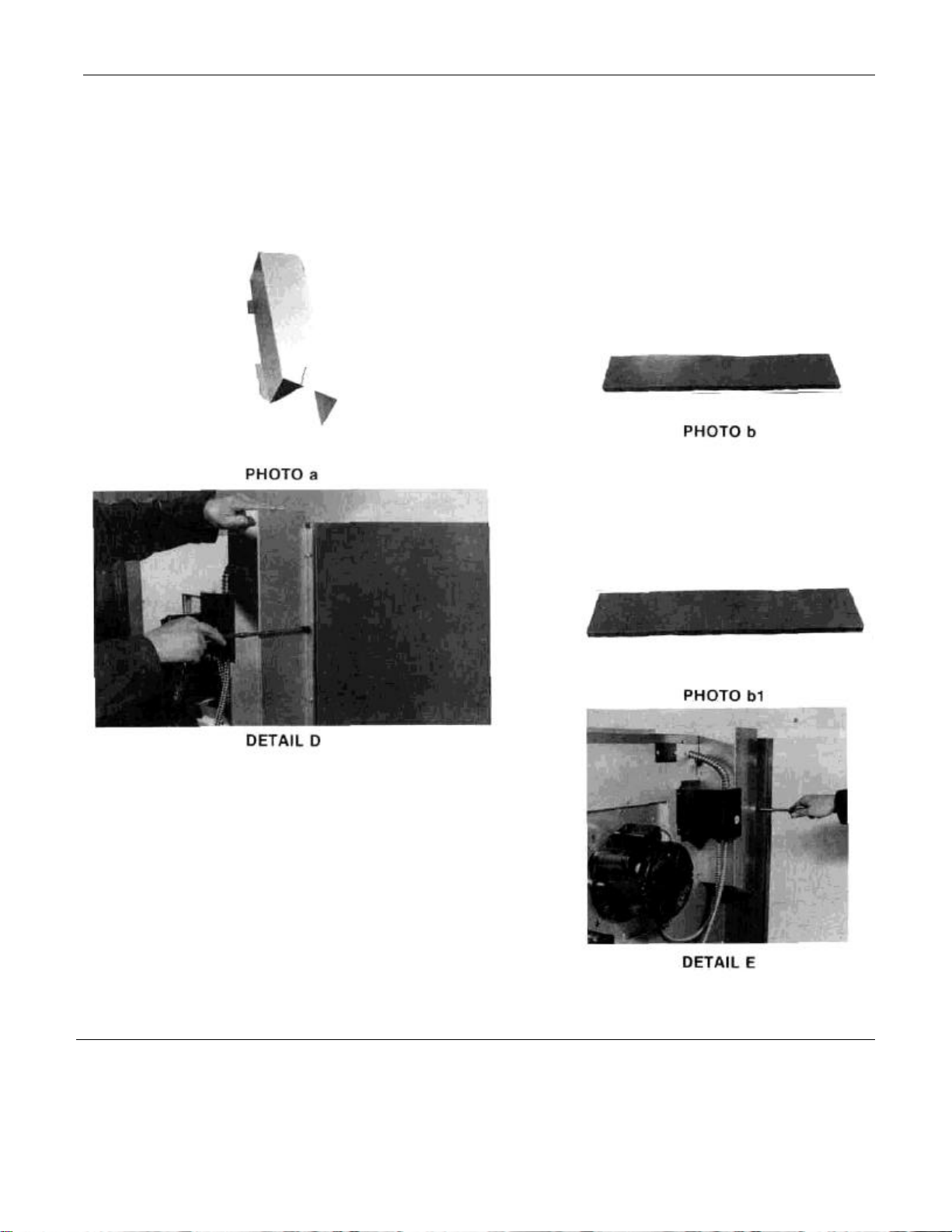

4. Using a 5/16" socket, remove three 5/16" hex head

screws from the upper right hand back of the unit.

Install flue extension piece (a) to body back using

six 5/16" hex head screws. Do not fully tighten the

three screws on the right hand side of the flue

extension. Loosen the two 5/16" screws located on

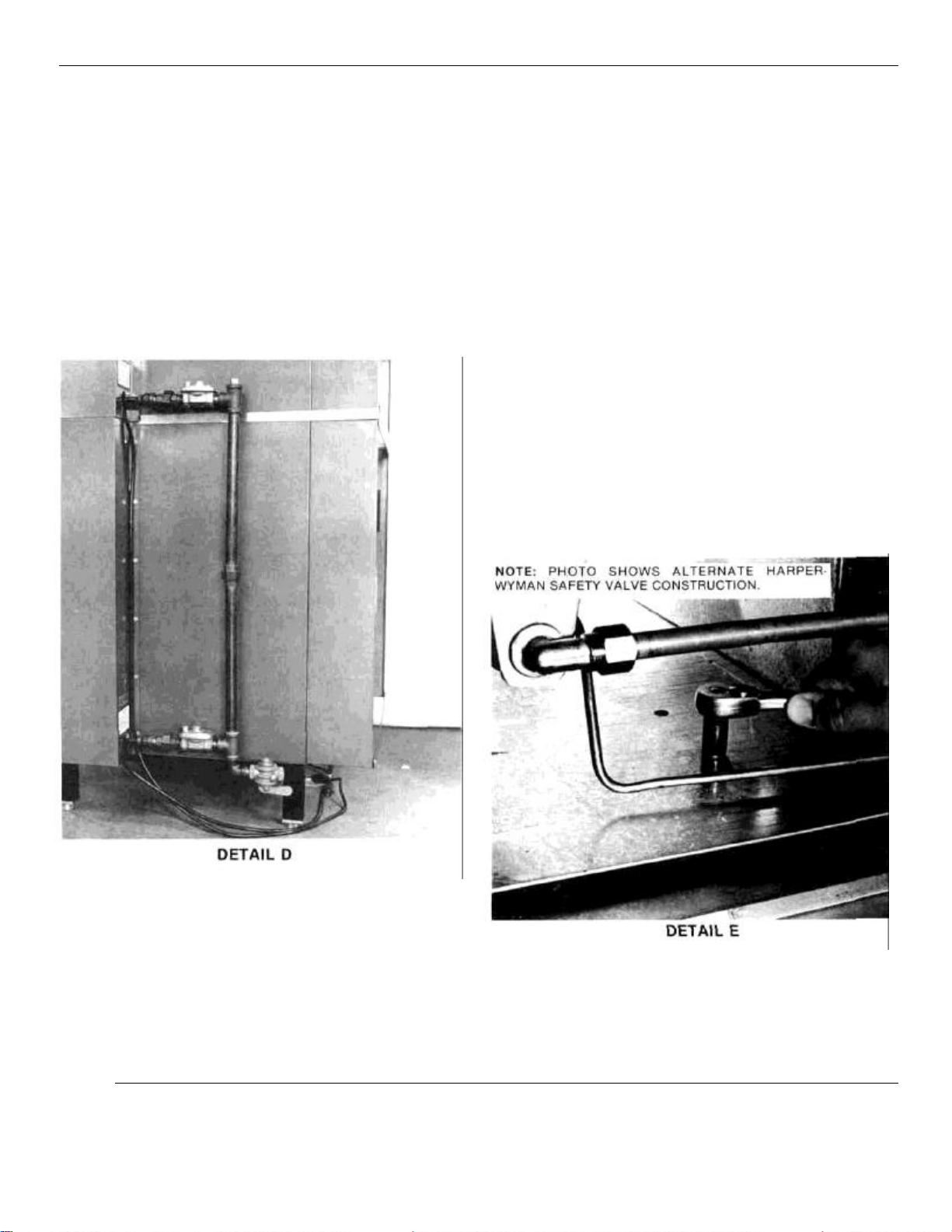

the lower right hand back of the unit. (See Detail D)

5. Locate the back right hand side extensions piece

(b). Assemble by sliding the slotted right hand

side extensions between the body back and body

side. Tighten body back using the 5/16" screws

shown in Detail E. Assemble the left hand

extension piece (b1) in the same manner.

8

Page 9

SG-2SMT & SG-10SMT ADD-A-SECTION INST. (Continued)

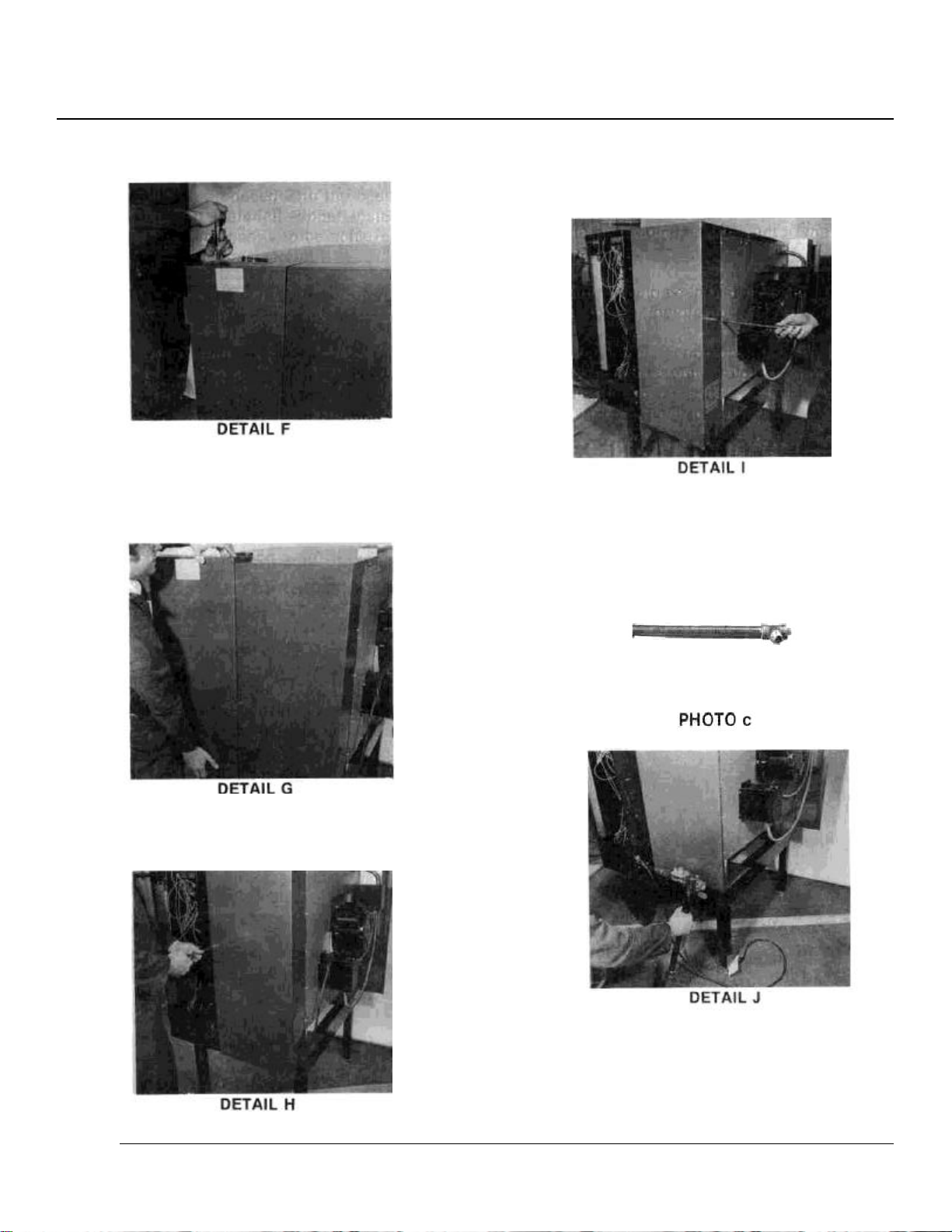

6. Return and face the front of unit. Remove four 5/16"

hex screws holding the front right hand body side

cover. (See Detail F)

9. Return to the back of the unit and face it. Loosen four

5/16" left hand body back hex head screws and (See

Detail I) remove the right hand body side cover (Now

to your left) to expose unit's manifold piping and

electrical connection.

7. Remove front right hand side body cover by holding

the cover at the top and bottom while lifting upward,

then pull straight out, away from oven. (See Detail

G)

8. While still facing the front of unit, remove six 5/16"

screws from the back right hand body side cover.

(See Detail H)

10. Remove the shut-off valve from the manifold pipe

assembly and connect tee and union manifold

assembly (c) to the unit regulator. (See Detail J)

9

Page 10

SG-2SMT & SG-10SMT ADD-A-SECTION INST. (Continued)

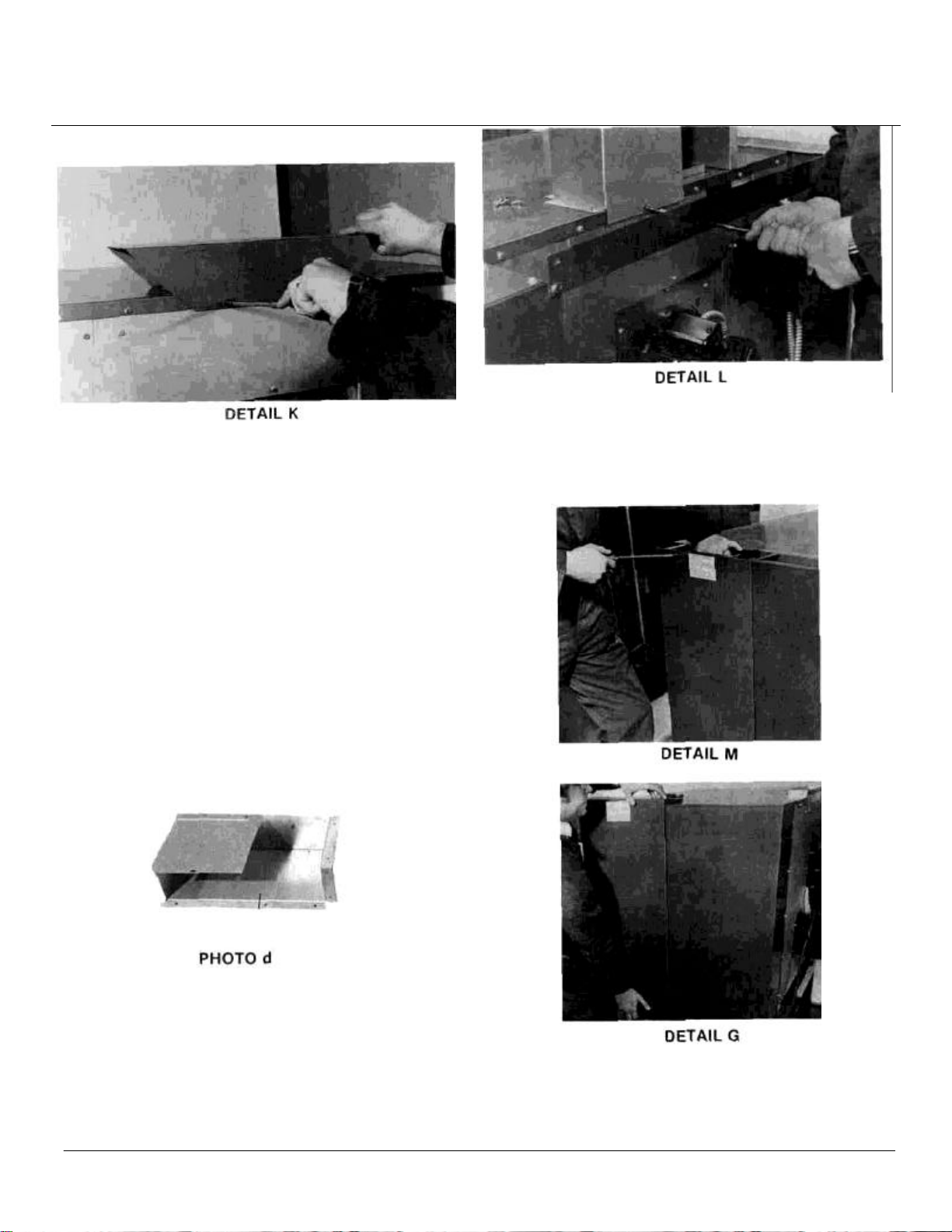

11. Using a 5/16" socket, remove the side flue deflector

from the top of the unit. (See Detail K)

12. Remove the two remaining 7/16" bolts from the bottom

of the leg stand. Allow the unit to rest unbolted on the

stand until stacking is required.

PART B.

PREPARING THE SMB UNIT FOR STACKING.

TOOLS REQUIRED FOR THIS PROCEDURE:

5/16" hex head socket, 1/4" socket driver and 6" x 1/4"

socket drive extension.

1. Assemble aluminized flue housing (d) to SMB body top

using (8) 5/16" hex head screws. (See Detail L)

2. While facing the front of the unit disassemble three

5/16" hex head screws from the front right hand body

side cover. Remove body side cover by placing hands

at the top and bottom of cover while lifting upward, and

then pull and straighten out away from oven. (See

Detail M and Detail G)

10

Page 11

SG-2SMT & SG-10SMT ADD-A-SECTION INST. (Continued)

3. While still facing the front of the unit. Remove six

5/16" hex head screws from the back right hand body

side cover.

4. Facing the back of the unit, remove four 5/16" hex

head bolts and the right hand body side cover (now

on your left) to expose the manifold and electrical

connection.

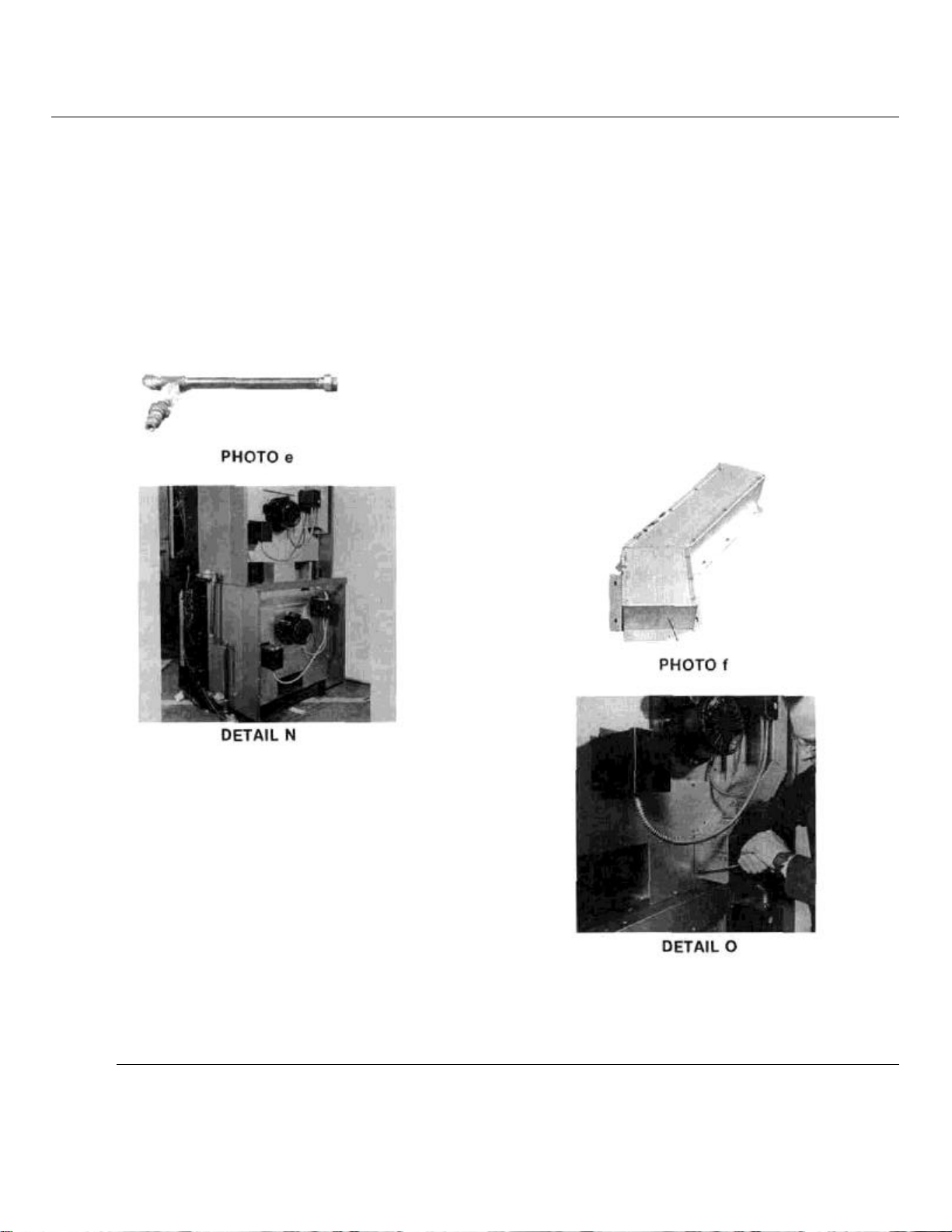

5. Assemble second half of manifold assembly (e) to

SMB section as shown in Detail N.

7. Place new full width flue deflector on rear top of

stacked units as shown in Detail N.

8. Assemble angled aluminized flue duct (f) to the back

right hand side of unit using five 5/16" hex head bolts.

DO NOT ASSEMBLE BOLTS TO THE FAR RIGHT

HAND SIDE OF FLUE DUCT YET. (See Detail 0)

6. Remove the SMT unit from the stand and carefully

stack onto the SMB UNIT. (This operation will require

the assistance of three other people.) Be sure to line

up parts properly.

11

Page 12

SG-2SMT & SG-10SMT ADD-A-SECTION INST. (Continued)

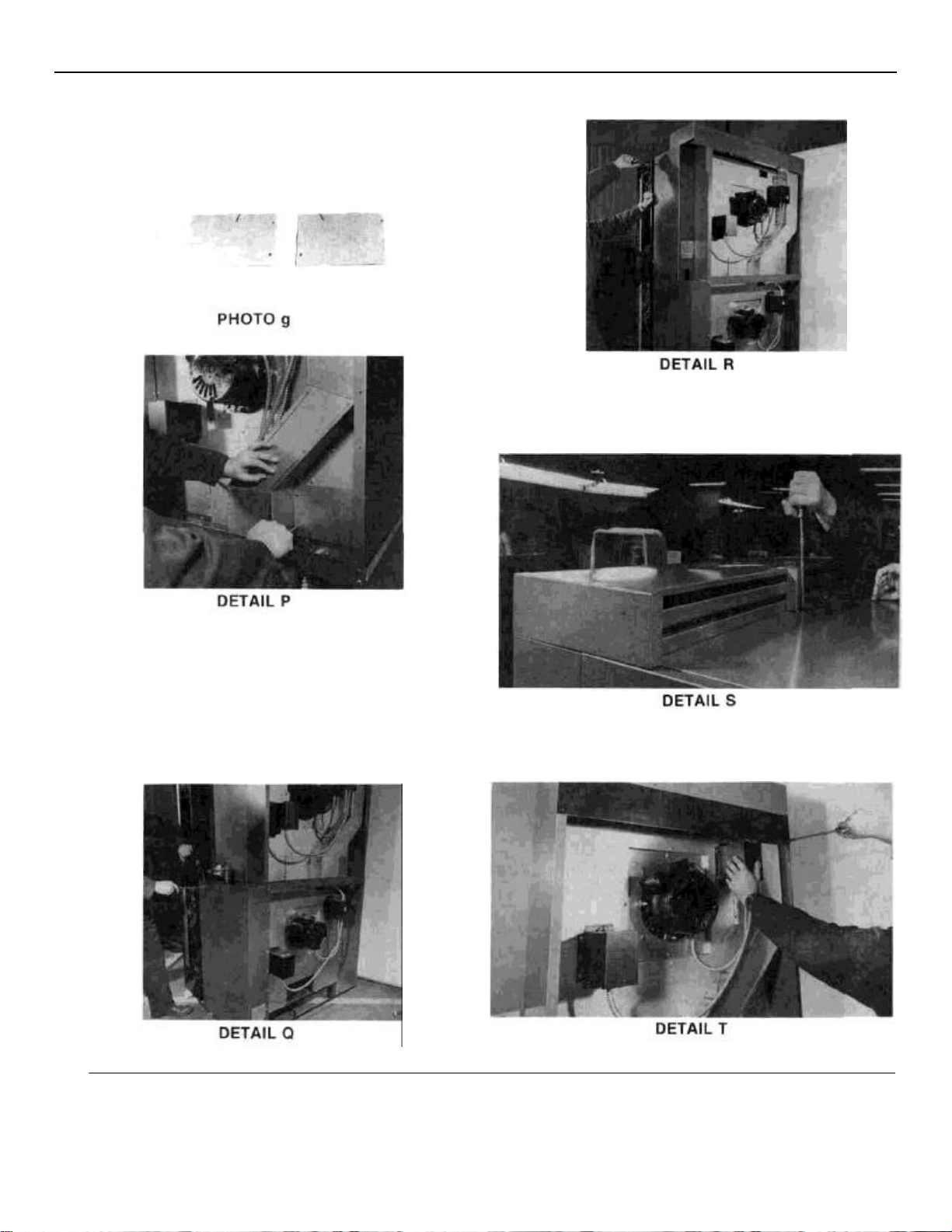

9. Bolt two closure panels (g) to upper back of unit

using four 5/16" hex head bolts and finish

attaching angled flue duct as shown in Detail P.

11. Reinstall the SMT manifold cover using six 5/16" hex

head bolts (See Detail R)

12. Tighten down all but the two back 5/16" hex head

screws of the new flue deflector resting on top of the

SMT unit (See Detail S).

10. While facing back of unit, remove two 51/6" hex

head bolts holding two stacking braces to the SMB

unit. See Detail N. Reinstall the bottom side

manifold cover using fourteen 5/16" hex head

bolts (See Detail Q) and reassemble stacking

straps to the SMB and SMT sections.

13. Assemble black hood stacking strip to back of SMT

unit using four 5/16" hex head screws. (See Detail T)

12

Page 13

SG-2SMT & SG-10SMT ADD-A-SECTION INST. (Continued)

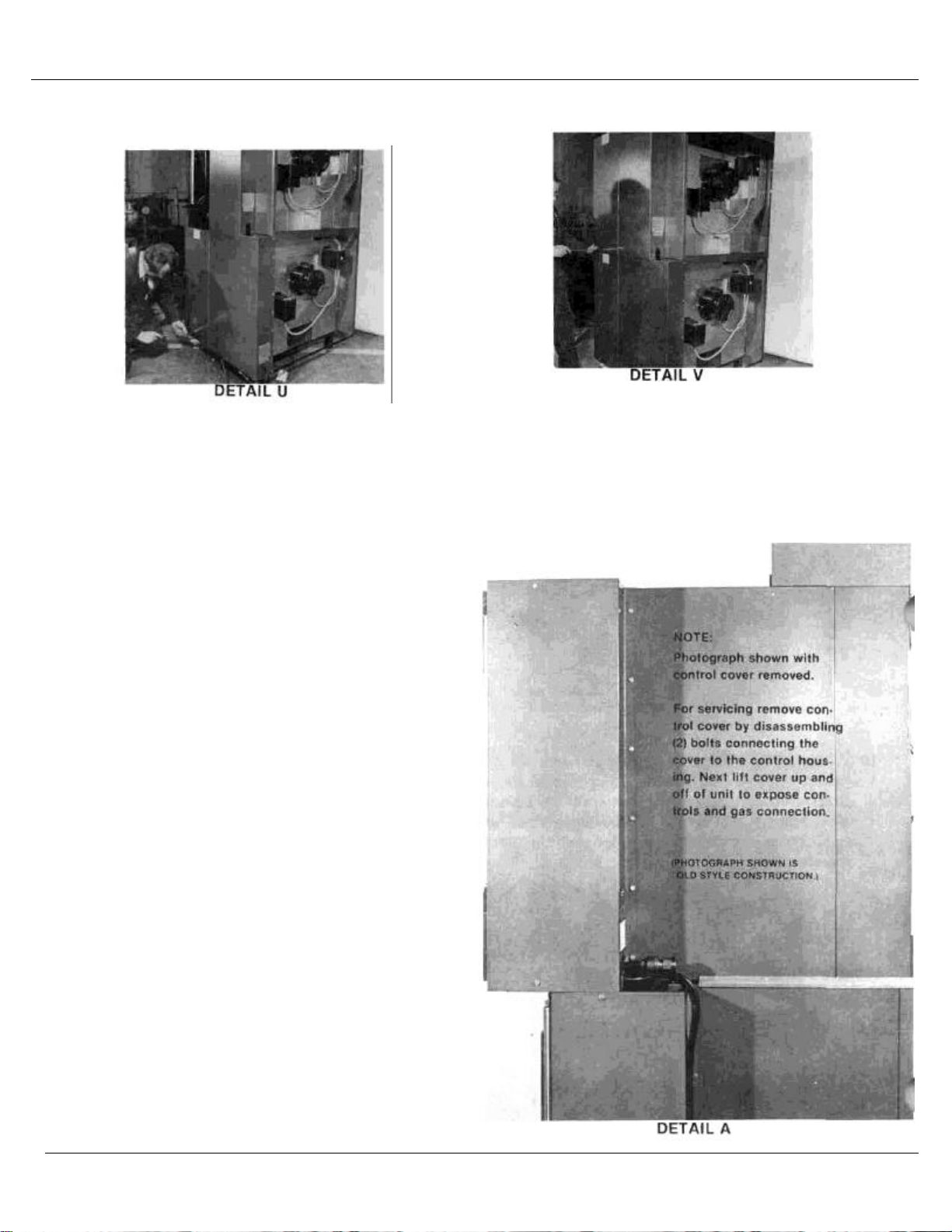

14. Reassemble the top and bottom right front side

control covers using seven 5/16" hex head screws.

(See Detail U and Detail V)

NOTE: All convection oven sections built before

October, 1983 will require the use of a 3.7"

regulator. Any convection oven section built

after October, 1983 will require the use of a 6"

regulator. For orifice size differences, refer to

chart on page 21 of this manual.

a. To determine if your unit was built prior to October,

1983, refer to the rating plate serial number. The first

two digits of this number indicates the year, the

second two numbers indicates the month, i.e. YEAR

83 MONTH 10, SERIAL NUMBER 8310.

If your unit was built prior to October, 1983 proceed

to Step b.

b. New units are provided with a 6" pressure regulator

preassembled to the interconnecting manifold pipe.

15. Unit is now ready to be placed into operation.

f. Reconnect the unit to the gas supply and test for

leaks. Reinstall the side panel and continue with the

installation and operating manuals.

c. Turn off the gas supply and remove the 3.7 inch

pressure regulator from the existing unit.

d. Assemble the 3.7" regulator, removed in Step c, to

the interconnecting manifold as shown in Detail A.

e. Connect the manifold assembly to the unit making

sure that the 6 inch pressure regulator is connected

to the lower unit as indicated in Detail A.

13

Page 14

INSTALLATION INSTRUCTIONS (Continued from Page 7)

7. Attach flue cover to the lower section with sheet metal

screws provided. Detail B.

8. Position upper section in line with lower section. Install

flue closure assembly, connecting upper and lower

sections with sheet metal screws provided. Detail C &

CA.

9. Install connection pipe with unions per Detail D.

10. Connect upper and lower units together at the front per

11. Be sure supply cords are accessible or connections

Detail E.

have been made to the junction box.

14

Page 15

INSTALLATION INSTRUCTIONS (Continued)

12. Connect oven to gas supply through the shut-off

valve and gas pressure regulator provided. Locate the

shut-off valve in an accessible location.

Units for use on natural gas are equipped with a

pressure regulator with a preset outlet pressure of 6"

W.C. Units for use on propane gas have a regulator

with a preset outlet pressure of 10.0" W.C. Regulator

must be mounted horizontally to provide the preset

outlet pressure. If regulator is mounted in any other

position, the outlet pressure must be reset.

Note: Do not obstruct the leak limiter on pressure

regulator. A leak limiter is supplied with every regulator

to allow excess gas pressure to escape. Do not obstruct

leak limiter on gas pressure regulator as obstruction

may cause regulator to malfunction.

13. Connect the oven to the electric supply. 120 volt

ovens single phase units are equipped with a 7 ft. 3 in.

wire (including ground) supply cord. 120 volt appliances

are equipped with a three prong (grounding) plug for

your protection against shock hazard and should be

plugged directly into a properly grounded three prong

receptacle. Do not cut or remove the grounding prong

from its plug. 208/240 volts units with a single or three

phase motor are provided with a terminal block.

208/240 volt units must be electrically grounded at the

time of installation.

14. Either a draft diverter or a low profile deflector is

shipped with every oven. A low profile deflector is intended for use when the oven is installed under canopy

type hoods. When the oven is directly connected to a

vent system, a down draft diverter must be used.

15. Using a carpenter's level placed on a rack, adjust

the feet on the bottom of each leg, so that oven is level

from the front to back and side to side.

(Note: Level the oven when in its permanent position

only).

15

Page 16

INSTALLATION INSTRUCTIONS (Continued)

16. Turn on the gas. Purge the gas line to remove air.

Check for leaks.

LIGHTING INSTRUCTIONS

(ELECTRONIC IGNITION)

CAUTION: Use a soap solution or similar means (do

not check with open flame).

17. PILOT LIGHTING INSTRUCTIONS:

Units with Standing Pilots (Ref. to Detail F).

1. If the pilot light is out, turn the master switch off,

open the doors, then wait 5 minutes before

relighting.

2. Light the pilot with a taper.

3. Turn the Master Switch to the "On" position.

4. Set the thermostat control knob to the desired

temperature. (See Cooking Chart for reference)

5. Set the load control to the proper setting. (See

Cooking Chart for reference.

6. For daily shutdown, turn the master switch, the

thermostat knob, and the load control knob to the

"Off" position.

7. For seasonal shutdown, extinguish the pilot,

turn master switch, thermostat knob and load

control knob to "Off" position.

NOTE: Pilot burner flames are preset at the factory

before shipping, approximately 1/2" high. The flame

should impinge on the sensing bulb located directly

below each pilot burner. If pilot does not light, turn the

gas off, wait 5 minutes and repeat steps 1 through 5 of

17. It is not necessary to repeat pilot lighting everyday.

For units with electronic ignition, pilot lighting is not

necessary. The main burners are spark ignited when

the thermostat is turned on.

1. Start Up Procedure:

Open The Doors, Turn The Thermostat And Load

Control To The "Off" Positions.

2. Turn The Master Switch To The "On" Position. A

Clicking Sound Will Be Heard. Pilots Have Ignited

When Clicking Stops.

3. Close Doors - Turn The Thermostat And The Load

Control To The Desired Setting. (See Cooking

Chart For Reference.)

4. For Daily Or Seasonal Shutdown:

Turn The Master Switch, The Thermostat And The

Load Control To The "Off" Position. (Turn the ShutOff Valve To the "Off" Position, Seasonal Only.)

NOTE: Photo Shows Alternate Harpe-Wyman

Protective Valve Construction.

CAUTION: Fan must rotate clockwise when viewed

through the oven door. On three phase motor units, fan

rotation can be reversed by interchanging any two

power supply leads. On single phase units with

incorrect fan rotation, contact factory.

16

Page 17

FLUE CONNECTIONS

22.

Good ventilation, which includes flue connections and

room drafts, is just as important for correct oven

operation as adequate gas supply.

Generally speaking, ovens should never be directly

flue connected, if a direct flue system can be avoided.

The ideal method of ventilating an oven is the use of a

properly designed hood. Hood should extend about

6" beyond all sides of the appliance. The hood should

be connected to an adequate exhaust duct or system.

When ovens are installed in locations with low ceilings, care must be taken to insure proper clearance

for the flue products. Lack of this clearance above

outlet of rear flue piping will interfere with heat circulation in the oven and could create a fire hazard

condition. Refer to NFPA #96.

TROUBLE-SHOOTING – SERVICE

The following is intended to provide a guide for trouble

shooting procedure and covers some of the more

common problems with the equipment. The servicing

personnel, as with any other equipment, need to

become familiar enough with the circuit and the

components in order to be able to follow a logical

sequence of trouble shooting, and repair malfunctions

not mentioned in the following paragraphs.

The instruments necessary for trouble shooting would

be:

A. A.C. Voltmeter to measure line voltages up to 480

volts.

B. A.C. Amp-meter to measure line currents.

C. Accurate Thermometer to measure oven

temperature

up to 500°F.

Do not permit fans to blow directly at the oven and

wherever possible, avoid open windows next to the oven

sides or back, avoid wall type fans which create air cross

currents within the room.

It is also necessary that sufficient room air should be

allowed to enter the room to compensate for the amount

of air removed by any ventilating system. Otherwise, a

subnormal atmosphere pressure will occur, affecting oven

operation adversely and causing undesirable working

conditions.

A properly designed and installed hood will act as the

heart of the ventilating system for the room or area in

which the oven is installed, and will leave the oven

independent of changing draft conditions.

With the main power and oven circuit breakers "ON",

the master switch turned to the "ON" position and the

oven door closed:

Problem: 1. No blower, no heat

Procedure: Depress the Oven Light switch or turn

timer knob to "0" position. If the lights come On and

the Buzzer sounds, follow step B. If not, follow step A.

STEP A—Measure the voltage between leads 93 and

94 (The supply side) of the Master Switch.

If no voltage, check connection to Power Supply cord

and verify power at wall socket.

If 120 volts, measure the voltage across 21 and

If no voltage, the Master Switch is defective.

In the following paragraphs, the voltmeter is used to

measure the voltage between 2 phases on 208, 240,

480 volt and between one phase and neutral on

220/380 and 240/415 volt supplies. Do not measure

the voltage with respect to the chassis ground. For the

sake of simplicity, the measured voltage is referred to

120 volt, assuming that the supply is 120 volt. When

supply is 240 or 220, the measured voltage should

also be 240 or 220—it is also assumed that the voltage

rating of the oven matches exactly (within the

allowable supply tolerance) that of the field supply.

Refer to the appropriate wiring diagram which has

been packaged separately with this unit in an 11 x 14

clear plastic envelope.

17

If 120 volts, check for bad connection from the switch

terminal to the Thermostat and motor connections.

STEP B—Only the door switch can disable the blower

and heat at the same time. While opening and closing

the right hand door listen for a click near the top of

the right hand door. If no click, the door switch

requires adjustment. If the switch does click but no

heat or blower, the switch may be defective.

Page 18

TROUBLE-SHOOTING - SERVICE (Continued)

Problem: 2. The blower is "ON" (with auxiliary

fan switch de-energized) but no heat.

Procedure: Turn the thermostat knob to about the

400°F. position. If the oven signal light is turned "ON",

follow step A; if not, follow step B.

STEP A — Oven indicator light is "ON". This is an indication that the door switch, and the thermostat are

functioning properly. The problem can then be related

to the load control switch or the solenoid.

Problem: 3. The oven heats up properly when

empty, but as soon as the food is put in it, the

temperature drops and the oven never

recovers.

Procedure: Meals containing excessive moisture can

cause the temperature to drop. Also, a cause of

temperature drop is excess load.

Problem: 4. The oven temperature keeps

increasing beyond the setting of the

thermostat.

Turn the load control knob to "HI" position.

Check the voltage between terminals L 1 & L 2 of the

load control switch.

If no voltage, check for bad connection or faulty lead

to the switch.

If 120 volts, check the voltage across H 1 & H 2 ter-

minals of the switch.

If no voltage, the switch is defective.

If 120 volts, check for defective solenoid or faulty

connection between the load control and the solenoid.

STEP B — Oven indicator light does not come "On".

This is an indication that the door switch, load control

or thermostat could be defective. (Check for a bad

connection between the master switch and the

thermostat, defective thermostat or bad connection

between the normally open contact of the door switches and leads going to the solenoids.

Procedure: If the thermostat indicator light cycles on

and off, check for defective solenoid. If the thermostat

light remains "On" check for defective thermostat

contacts.

Problem: 5 The motor turns off and

automatically comes back "ON" after a few

minutes.

Procedure: The internal thermal protector of the motor

is sensing a high temperature which is caused by:

A—High current. Check for clockwise rotation of the

shaft, for any binding on the shaft or the blower wheel

(the wheel should be rotated freely by a hand touch). If

none of the above, the motor may be defective.

B—High ambient. Check for hot air leakage from inside

the oven to the back through the light or motor

housings. Check to see if hot air is being blown on the

motor from the adjacent equipment.

Check for proper ventilation in the area.

208-240 volt units note: Sometimes the over current

affects the circuit breaker (15 amp breaker) before it

does the thermal protector; and the circuit breaker

keeps tripping to the "OFF" position.

18

Page 19

PARTS, ORDERING-REPLACEMENT-ADJUSTMENTS

REPLACEMENT PARTS ORDERING

The following information must accompany a replacement

parts order or it cannot be filled.

A. Model and Style or Serial Number

B. Gas Type

C. Voltage and Phase

D. Appliance finish, Permafinish, Stainless Steel, etc.

(If applicable to part to be replaced). This information can

be found on the rating plate on the unit. Parts may be

ordered from your dealer, service agency, or parts

distributor.

WARNING: Turn the main gas valve and power

disconnect switch to "OFF" before servicing the

equipment. Reconnect the leads of the replacing

components exactly to the original position and reverse

procedure for adding the new component.

1. SWITCH PANEL

Remove two screws from the rear flange of the Switch

Panel louvered cover. Push cover back exposing switch

panel components.

B. Replacing the Thermostat

Remove rear body top.

Remove the thermostat bulb from it's two retaining

clips located in the right rear corner of oven cavity.

Push bulb and capillary tube through the grommet in the

cavity top.

Push bulb and capillary through the hole in switch

panel compartment.

Remove silicone tubing from capillary and save for

reinstallation.

Disconnect wires from thermostat. Remove control knobs

and mounting screws. Pull thermostat off back of panel.

When reinstalling thermostat, reverse procedure listed

above. Do not kink capillary or place sharp bend in bulb.

Thermostat Calibration Check

Use a calibrated potentiometer with a thermocouple

located in the center of the fan guard assembly.

Set the thermostat knob to a mid range temperature.

Allow adequate time for the temperature to stabilize.

Thermostat Calibration

A. Replacing Rocker Switches And Indicator

Lights

Remove all wire connections to a component. Make a

note of the terminal positions.

Compress spring clips on the top and bottom of the

component while forcing it out the front of the switch

panel.

Replace the component in the original position by pushing

through the front face of the switch panel until the spring

clips lock into place.

Reconnect wires to proper terminals.

Remove knob from dial shaft B.

Turn screw "A" clockwise to decrease temperature and

counterclockwise to increase temperature.

Note: 1/4 turn of screw "A" represents a temperature shift

of 35 degrees F.

19

Page 20

PARTS, REPLACEMENT (Continued)

C. Load Control A.D.P.S.T.

This Cycling Switch varies, according to its setting,

the percent on-time of the output as shown below:

Dial Setting Percent On-Time

Hi 100

Hi— 83

Med+ 72

Med 60

Med— 48

LO+ 37

Lo 27

Off 0

INFINITE LOAD CONTROL SWITCH

The Load Control, as shown schematically, is connected in series with the thermostat, thus providing a

variable rate of temperature rise to reach the thermostat setting, as well as maintaining the temperature

at the final set temperature. Therefore, with the load

control set at Lo, it will take much longer to reach a

desired temperature than with a setting of Hi. The

cooking chart shows the necessary dial setting for

different food products.

the buzzer. The buzzer will continue to sound until the

knob is manually turned to "Hold" position where all

contacts are opened, (timer motor and buzzer turned

off).

To replace, remove the knob and the lock-nut—

reinstall same as item C.

2. BLOWER MOTOR

The blower motor has internal thermal protection, and

its sealed bearings do not require any lubrication. The

mounting of the blower assembly allows servicing from

inside the oven as follows:

Remove the fan cover.

Loosen the set screw on the centrifugal fan with

allen wrench.

Pull the centrifugal fan forward off of the motor

shaft with a wheel puller.

Remove the four nuts holding the motor mounting

plate. Pull the motor assembly forward and rest it on

the cavity bottom.

Remove the junction box cover and supply leads.

Rest the motor on its back. Remove four flat head

screws, lockwashers, nuts and spacers used to

fasten the motor mounting plate to the motor.

CAUTION: The motor is suitable for connection to two

different voltage supplies. Check the connection

instruction inside the motor junction box cover to

assure the proper connection for the available voltage

supply.

To replace this switch remove the knob and the lock

nut. To reinstall, make sure the dimples on the face of

the switch fall in the slot of the switch panel in order to

prevent it from rotating.

The direction of rotation is clockwise as viewed from

inside the oven. The 1-phase motors are internally

designed for C.W. rotation. On 3-phase motors, interchange any two supply leads to convert C.C.W. to

C.W. rotation.

D. Timer (one or five-hour models).

The normally open and common contacts of the

electric timer are connected together, energizing the

timer motor when the knob is set to the desired position. Once the timer completes its set interval (at the

zero mark) the common terminal disconnects from

timer motor (shuts the motor off) and connects with

20

Page 21

PART REPLACEMENT (Continued)

3. OVEN LIGHTS

The two 50 watt, 120 volt bulbs are connected in series

in the electric ovens and in parallel in the gas

convection ovens.

To replace lamps, remove the four mounting bolts

holding the lamp window assembly. Both the lamp, as

well as the socket can now be serviced. Make sure the

replacement lamp is the high temperature type and is

not larger than 50 watts.

4. DOOR SWITCH

With the oven door closed, the normally open contact of

the door switch is closed providing power to the heat

and motor controls. When the door opens,

the normally open contact is de-energized, and the

solenoid and the blower are turned off.

To adjust or replace the door switch (refer to Detail G),

remove the two mounting screws on the underside of

the top finishing piece. Depress the door catches up

inside the top channel and pull the top finishing piece

off.

The door switch is controlled by a cam type device

mounted to the top of the right hinge pin. The cam must

actuate the door switch when the door is approximately

3 inches from being closed.

To replace the door switch, remove the mounting

screws on the door switch support bracket and remove

the defective switch from the bracket.

21

Page 22

POWER PANEL-PART REPLACEMENT

A. CONTACTOR The 3-pole motor contactor is used

on units equipped with 3-phase motors. It is energized

when the power is on and the door is closed but also

when the door is open but the auxiliary fan switch is

depressed to the "ON" position.

To replace, remove the two mounting screws and

disconnect the leads.

B. RELAY The S.P.S.T. relay provides power to the

blower motor, on units equipped with auxiliary fan

switch, in order to over-ride the door interlock.

To replace, follow item A procedure.

C. BUZZER Signaled by the timer, the buzzer sounds

when the pre-set time is completed.

To replace, cut both wires approximately 3" from the

buzzer and strip the ends. Remove the bracket holding

the defective buzzer. Install the new buzzer equipped

with mounting bracket and lead, and connect the wires

with wire nuts.

D. CIRCUIT BREAKER The circuit breakers in 208,

240, 480 volt models provide protection for the control

circuits and the lights. The circuit breakers are

constructed with internal time delay. They detect short

circuit or overload conditions in the equipment and trip

to "OFF" position.

E. TRANSFORMER The control transformer is used

to step down the available supply voltage from 480 to

240 volt on the electric models and from either 480 or

240 to 120 volt on the gas models for the use of the

control and oven light circuits. The jumper straps (or

wires) are used to change the input and output

voltages to the required ratio. Below is the schematic

showing the 3 connections used in different models. In

replacing the old transformers with new ones care must

be taken to follow the required connections accurately.

SHUT-OFF VALVE SERVICE

The gas shut-off valve is located at the rear of the unit

and should be used to shut the unit down when service is

required to gas components. This valve should also be

used to turn all gas off to the unit when the unit is being

shut down for an extended period of time.

If the shut-off valve requires service this may be accomplished only by turning off the gas supply upstream

of the valve.

22

Page 23

PRESSURE REG.-PILOT ADJ.-AIR ADJ.-ORIFICE DATA

FOR ALL UNITS MANUFA

CTURED AFTER OCTOBER

1, 1983

BURNER ORIFICE DATA

MAXIMUM INPUT

PRESSURE REG.

ORIFICE DRILL

MAXIMUM INPUT

PRESSURE REG.

ORIFICE DRILL

PRESSURE REGULATOR SERVICE

NOTE: The unit and its individual shut-off valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 PISG (3.45 K Pa.).

The appliance must also be- isolated from the gas

supply piping system by closing it's individual manual

shut-off valves during any pressure testing of the gas

supply piping system at test pressures equal to or less

than 1/2 PSIG (3.45L Pa.) as stated by the American

National Standards Z83.11-1984. Copies of this

Standard are available from the American Gas

Association, 1515 Wilson Blvd., Arlington, VA 22209.

The pressure regulator is located at the rear of the unit

downstream of the shut-off valve. If the pressure

regulator requires service, this may be accomplished

by turning off the gas supply upstream of the shut-off

valve and pressure regulator and then removing both

of these parts.

Blockage of the pressure regulator leak limiter will

result in eratic burner operation and pilot outage.

BURNER ORIFICE DATA

NOTE: Prior to replacing a pressure regulator, in an

effort to correct problems traced to this component,

remove and clean the leak limiter.

PILOT BURNER ADJUSTMENT

Remove lower panel assembly (spring clip mounted)

and light both pilot burners.

Adjust pilot flame heights to approximately 1/2"

Flame should impinge on the sensing bulbs located

directly below the pilot burner flames. See Detail A for

location of the pilot. Both pilot valves are located in the

front center of the burner compartment.

AIR ADJUSTMENT

Although the burner air supply is adjusted before

shipment, it should be checked at the time of installation. Excessive air will cause flames to lift off a

burner when cold or may cause flash-back during

normal cycling of unit, particularly when propane gas is

used.

Insufficient air will cause flames to burn with a yellow

tip and result in carbon accumulation in the flame

chamber and heat exchange tubes.

INCLUDING "E" UNITS

NOTE: DATA ALSO APPLIES TO E-UNIT CONSTRUCTION

MODEL

PER BURNER

SG-2SM, SG-22, SG-2 30,000 6" W.C. #38 NAT.

SG-2SM, SG-22, SG-2 30,000 10.0" W.C. #1/16 PROPANE

SG-10SM, SG-1010, SG-10 35,000 6' W.C. #35 NAT.

SG-10SM, SG-1010, SG-10 35,000 10.0" W.C. #53 PROPANE

FOR ALL UNITS MANUFACTURED BEFORE OCTOBER 1, 1983

INCLUDING "E" UNITS BURNER ORIFICE DATA

MODEL

PER BURNER

SG-2SM, SG-22 30,000 3.7" W.C. #36 NAT.

SG-2SM, SG-22 30,000 10,00" W.C. #1/16 PROPANE

SG-10SM, SG-1010 35,000 3.7 " W.C. #33 NAT.

SG-10, SG-1010 35,000 10.0" W.C. #53 PROPANE

SETTING

SETTING

SIZE

SIZE

GAS

GAS

REPLACEMENT OF REGULATOR, OR SHUTOFF VALVE

INCLUDING "E" UNITS

• Turn off gas supply upstream of unit.

• Break gas connection at shut-off valve.

• Break compression fittings at front manifold.

• Remove (4) bolts (inside center chamber) to rear

manifold support.

• Disconnect wires to solenoid at wire nuts.

• Pull manifold out back of unit.

• Remount manifold by reversing procedure listed

above.

23

Page 24

COOKING CHART

SETTING

IMPORTANT

Recommended temperatures, times, number of racks and load

control settings are intended as a guide only. Adjustments must be

made to compensate for variations in recipes, ingredients, installation

and personal preference in product appearance.

RECOMMENDED TEMPERATURES, TIMES

AND LOADS FOR ROASTING

Meat roasting is most satisfactory at temperatures of 225° to 325°F.

for Beef, Lamb, Poultry and Ham; 325° for fresh Pork as

recommended by USDA and American Meat Institute.

ROASTING TEMPERATURE CHART

PRODUCT TEMPERATURE

Standing Rib Roasts — Oven Ready 250°F Hi 3 to 4 Hrs. — Rare

4 to 4 1/2 Hrs. — Med.

Rolled Rib Roasts — 20 to 22 Ibs. 275°F Hi 4 Hrs. — Med.

Veal Roast — 15 Ibs. 300°F Hi 3 Hrs. — Med. Well

Turkeys — 15 to 20 Ibs. 300°F Hi 3 Hrs.

Meat Load — 8 to 10 Ibs. 350°F Hi 45 to 60 Minutes

A pan, approximately 12" x 20" x 1", full of water may be placed in the

oven bottom. This water supplies humidity to reduce shrinkage. Water

should be added if necessary during roasting.

Roasting pans should be no deeper than necessary to hold drippings,

usually 2" to 2 1/2 ".

Cooking time and shrinkage may vary with roasting temperature, cut

and grade of meat and degree of doneness. Smaller cuts will generally

show greater time savings than larger cuts at a given temperature.

LOAD

CONTROL

APPROXIMATE TIMES

SETTING

RECOMMENDED TEMPERATURES, FOR BAKING (ALL SNORKEL MODELS)

PRODUCT TEMPERATURE

Cakes

Sheet Cakes 18 x 26 x 1" Pan

Scaled 4 1/2 to 6 Ibs. Per Pan 325° to 360°F 20 to 23 4 Med to Med—

Scaled 6 to 7 1/2 Ibs. Per Pan 335° to 350°F 22 to 25 4 Med to Med—

Sheet Cakes 18 x 26 x 2" Pan 300° to 325°F 25 to 35 3 Med—

Equals 2-12 x 18 x 2" Pans

Scaled 10 to 12 Ibs. Per 18 x 26 x 2" Pan

or 5 to 6 Ibs. Per 12 x 18 x 2" Pan

Angel or Sponge Cakes

Sheet Pans 18 x 26 x 1" 300° to 325°F 15 to 20 4 Lo+

Scaled 5 to 6 Lbs. Per Pan

Loaf or Tube Pans 315° to 340°F 20 to 30 3-4 Med— to Lo

Cup Cakes 350° to 400°F 6 to 12 4 Med to Med—

Frozen Fruit Pies 350° to 375°F 30 to 45 4 Med to Med—

Pumpkin or Custard Pies 300° to 350°F 30 to 45 4 Med to Med—

Cobblers

12 x 18 x 2" or 12 x 20 x 2 1/2 350° to 400°F 30 to 45 4 Med

Meringue Pies 350° to 425°F 6 to 10 4 Med to Med—

Fruit Turnovers 350° to 375°F 15 to 25 5 Med to Med—

18 x 26 x 1" Pans

Cookies

Rolled or Pressed 350° to 400°F 6 to 12 5 Med to Lo+

Drop 350° to 400°F 6 to 15 5 Med to Med—

Brownies 350°F 12 to 20 5 Med to Med—

Rolls—1 oz. 350° to 400°F 5 to 10 4 Med to Med—

Rolls—1 1/2 to 2 1/2 ozs. 350° to 400°F 8 to 15 4 Med to Med—

Loaf Bread—1 Ib. 325° to 375°F 20 to 40 3 (30 Pans) Med—

TIME IN

MINUTES

NO. of

RACKS

5 Med + to Med

3 Med—

3 Med— to Lo+

3 Med—

3 Med to Med—

2 Med to Med—

4 Med to Med—

3 Med— to Lo+

4 Med— to Lo+

3 Lo+

4 Med— to Lo+

3 Lo+

4 Med— to Lo

3 Med—

3 Med— to Lo+

2 (20 Pans) Lo +

NOTE: Pies and Cobblers; Fruit, Custard and Pumpkin Pies in tins, should be placed on 18 x 26 x 1" pans for baking.

NOTE: This chart is for models: SG-2SM, SG-22, SG-10SM & SG-1010. and E-Units. (E—Electric Ignition Option)

LOAD

CONTROL

114594-24

Page 25

COOKING CHART (Continued)

RECOMMENDED TEMPERATURES, TIMES AND LOADS FOR BAKING (ALL SNORKEL MODELS)

TIME IN NO. OF LOAD

PRODUCT TEMPERATURE MINUTES RACKS CONTROL

Yeast Breads

Note: Yeast Breads should be fully proofed for best results.

Sweet Rolls & Danish Pastries 325° to 375°F 5 to 15 4 Med to Med—

3 Med— to Lo+

Quick Breads

Biscuits 350° to 400°F 5 to 15 4 Med to Med—

Rolled 1/2" Thick 3 Med-to Lo +

Muffins 325° to 375°F 6 to 18 4 Med—

3 Med— to Lo+

Corn Bread

5 to 7 Ibs. Per Pan 335° to 400°F 10 to 20 4 Med to Med—

Per 18 x 26 x 1" Pan

8 to 20 Ibs. Per 18 x 26 x 2" Pan 335° to 400°F 15 to 25 4 Med to Med—

3 Med— to Lo +

Corn Muffins 335° to 385°F 10 to 20 4 Med to Med—

3 Med to Lo+

OVEN "BROILING" OR "FRYING"

Hamburger Patties

8 Per Ib. 400° to 450°F 5 to 6 4 to 6 Hi- to Med+

Med. to Well Done

6 Per Ib. 400° to 450°F 7 to 10 4 to 6 Hi to Hi—

2 & 3 Hi— to Med+

4 Per Ib. 375° to 450°F 8 to 12 4 to 6 Hi

2 & 3 Hi— to Med+

Fish Sticks & Portions—Frozen Breaded

1 oz. 350° to 400°F 6 to 10 4 Hi— to Med

2 1/2 to 3 ozs 350° to 375°F 8 to 15 4 Med + to Med

2 & 3 Med to Med—

Chicken Pieces—"Broiled" or Oven "Fried"

2 to 2 1/2 Ib. Bird 375° to 425°F 8 to 15 4 to 5 Hi— to Med

2 & 3 Med+ to Med—

2 1/2 to 3 Ib. Bird 350° to 400°F 15 to 25 4 Med + to Med

2 & 3 Med to Med—

Lobsters—1 to 1 1/2" Ib. 400° to 450°F 8 to 14 2 to 4 Hi to Med

Lobster Tails—Frozen

1/2 to 3/4 Ib. 350° to 400°F 10 to 15 2 to 4 Hi—to Med

REHEATING PREPARED FOODS

Frozen French Fries 400° to 450°F 6 to 8 4 Hi— to Med

2 to 3 Med + to Med—

Frozen Lunches ("TV" Dinners) 350° to 400°F 10 to 12 4 to 5 Hi to Med

2 to 3 Med+ to Med—

Frozen Entrees (3/4" to 1" Thick) 300° to 350°F 10 to 20 2 to 5 Hi to Med

Frozen Meals (8 oz.) Foil Pkg. 350° to 400°F 20 to 30 2 to 5 Hi

CASSEROLES

Food Service Pans

2" to 3" Deep 325° to 375°F 15 to 25

3" to 4 " Deep 325° to 375°F 20 to 35 2 to 4 Med + to Med—

Ramikins or Foil Pans 350° to 400°F 5 to 6 4 to 5 Hi to Med+

Up to 1 1/2" Deep 2 to 4 Med+ to Med

*(Frozen 10 to 15 Minutes)

RECOMMENDED TEMPERATURES, TIMES AND LOADS, MISCELLANEOUS PRODUCTS

Baked Potatoes

120 Count Per 50 Ibs. 400° to 450°F 20 to 25 2 to 5 Hi— to Med

100 Count Per 50 Ibs. 400° to 450°F 25 to 40 2 to 5 Hi— to Med

80 Count Per 50 Ibs. 400° to 425°F 30 to 50 2 to 5 Med + to Med—

Pizzas — Frozen or with Prebaked Crust 425° to 475°F 5 to 10 4 Hi— to Med

2 & 3 Med to Med—

Melted Cheese Sandwiches 400° to 425°F 8 to 10 4 Hi— to Med

2 & 3 Med + to Med—

NOTES ON SPECIAL PROCEDURES FOR BAKING

Yeast Bread: Cooking starts immediately in the convection oven. Yeast Breads do not usually rise as much in a convection oven as in a conventional

oven. It is, therefore, usually necessary to allow fuller proof, 2 1/2 to 3 times increase in volume for the best results.

Pies: When baking pies in your convection oven, 3 or 4 pies should be put on an 18 x 26" sheet or bun pan. This procedure helps the bottom crust to

bake, makes handling easier and reduces the possibility of boll over spoiling the appearance of the pies on the lower racks.

NOTE: This chart is for models: SG-2SM, SG-22, SG-10SM & SG-1010, & E-Units. (E—Electric Ignition Option)

114594-25

2 & 3 Med+ to Med

2 & 3 Med + to Med—

Page 26

REPLACEMENT PARTS LIST AND PHOTOGRAPHS

SG-22, SG-1010, SG-2SM, SG-10SM, SG-22E, SG-1010E. SG-2SME, & SG-10SME

WARNING ALL SERVICE PERSONNEL

WHEN SERVICING THIS EQUIPMENT, USE ONLY CERTIFIED (U.L. OR A.G.A.)

CONTROLS, DUPLICATING THOSE ORGINALLY SUPPLIED ON THIS

EQUIPMENT BY VULCAN-HART CORP. DO NOT SUBSTITUTE COMPONENTS

WITH DIFFERENT MODEL NUMBERS.

DO NOT SUBSTITUTE COMPONENTS WITH DIFFERENT MANUFACTURING

NAMES.

DO NOT SUBSTITUTE COMPONENTS WITH REBUILT CONTROLS. ANY

UNAUTHORIZED SUBSTITUTION OF CONTROLS AS STATED ABOVE MAY BE A

SAFETY HAZARD AND WILL AUTOMATICALLY VOID THE WARRANTY AND THE

CERTIFICATION ASSOCIATED WITH THIS EQUIPMENT.

Replacement Part Orders:

The following information must accompany a replacement parts order or it cannot be filled.

A. Model and serial number

B. Type of gas

C. Unit voltage, amperage and motor phase

D. Appliance finish black, gray, stainless steel etc.

This information may be found on the unit rating plate located inside the lower front panel.

Parts may be ordered from your dealer, service agency, or parts distributor.

114594-26

Page 27

PARTS-REAR EXTERIOR

QTY.

22B

ITEM

DESCRIPTION

NO.

40 LAMP BOX ASSEMBLY 111395-G1 2 111395-G1 111395-G1 2 111395-G1 2

66 MOTOR 120V 111205-5 1 111205-5 1 111205-5 1 111205-5 1

66A MOTOR 480V (NS) 111205-8 1 111205-8 1 111205-8 1 111205-8 1

100 CONDUIT 114540-B35 2 114540-B35 2 114540-B35 2 114540-B35 2

99 UPPER CONTROL

PANEL EXT. ASSY. (NS) 114629-G2 1

99A UPPER CONTROL PANEL

EXT.ASSY. 114629-G4 1

99 B COVER LOWER EXT.

ASSY. 114649-G2 1 111492-G5 1 114649-G2 1

101 FLUE DEFLECTOR ASSY. 111457-G1 1

102 FLUE CLOSURE ASSY. 111457-G1 1 111456-2 1

103 FLUE STACK

ITEM

DESCRIPTION

NO.

40 LAMP BOX ASSEMBLY 111395-G1 2 111395-G1 111395-G1 2 111395-G1 2

66 MOTOR 120V 111205-5 1 111205-5 1 111205-5 1 111205-5 1

66A MOTOR 480V (NS) 111205-8 1 111205-8 1 111205-8 1 111205-8 1

100 CONDUIT 114540-B35 2 114540-B35 2 114540-B35 2 114540-B35 2

99 UPPER CONTROL

PANEL EXT. ASSY. (NS) 114629-G2 1

99A UPPER CONTROL PANEL

EXT. ASSY 114629-G3 1

99B COVER LOWER EXT.

ASSY. 114649-G1 1 111492-G5 1

101 FLUE DEFLECTOR ASSY. 111457-G1 1

102 FLUE CLOSURE ASSY. 111457-G1 111456-2 1

103 FLUE STACK

T-TOP OVEN IN DOUBLE OVEN B-BOTTOM OVEN IN DOUBLE OVEN E-ELECTRONIC IGNITION

PART NO.

SG-10, SMT

& E-UNITS

PART NO.

SG-2SMT

& E-UNITS

QTY.

SG-10, SMT

& E-UNITS

QTY.

SG-2, SMT

& E-UNITS

PART NO.

SG-10, SMB &

E-UNITS

PART NO.

SG-2SMB

& E-UNITS

QTY.

SG-10 MB

& E-UNITS

QTY.

SG-2 SMB

& E-UNITS

PART NO.

SG-1010T

& E-UNITS

PART NO.

SG-22T

& E-UNITS

QTY.

1010T&

E-UNITS

QTY.

SG22T

& E-UNITS

PART NO.

SG-22B &

E-UNITS

PART NO.

SG-22B

& E-UNITS

QTY.

SG-22B

& E-UNITS

SG-

& E-UNITS

114594-27

Page 28

PARTS-BREAKER HOUSING

DESCRIPTION

PART NO.

ITEM

NUMBER

10 RELAY 111497-A2 3 111497-A2 3

11 BUZZER 111499-1 1 111499-1 1

14 PORCELAIN BLOCK 114881-1 1 114881-1 1

16 TRANSFORMER 111500-6 1 111500-6 1

17 TERMINAL BLOCK (3-POLE) 110472-8 1 110472-8 1

67 GROUND LUG 3.1500/06089 1 3.1500/06089 1

68 BREAKER 111501-5 1 111501-5 1

(240 VOLT, 1 PHASE)

(SG-2SMT, 10 SMT)

T-TOP OVEN IN DOUBLE OVEN E—ELECTRONIC IGNITION

PART NO.

SG2SM, SG-22

& E-UNITS

QUANTITY

SG2SM, SG-22

& E-UNITS

SG-10SM

SG-1010

& E-UNITS

QUANTITY

SG-10SM

SG-1010

& E-UNITS

114594-28

Page 29

PARTS-BREAKER HOUSING (Continued)

PART NO.

2SM

2SM

PART NO.

0SM

ITEM

NUMBER

10 RELAY 111497-A2 1 111497-A2 3

11 BUZZER (NS) 111499-1 1 111499-1 1

14 PORCELAIN BLOCK 114881-1 1 114881-1 1

16 TRANSFORMER 111500-6 1 111500-6 1

17 TERMIMAL BLOCK

67 GROND LUG 3.1500/06089 1 3.1500/06089 1

68 BREAKER 111501-5 2 111501-5 2

69 CONTACTOR (FOR

12 BREAKER MOUNTING BRKT. 114648-1 1 (2)-22 114648-1 1 (2)1010

DESCRIPTION

208, 240 VOLT

(SG-2SM, 10SM, 22 & 1010)

(3-POLE) 110472-8 1 110472-8 1

(OPTIONAL 3-PHASE MOTOR) 111497-C2 1 111497-C2 1

NS—NOT SHOWN ON PHOTOGRAPH E—ELECTRONIC IGNITION

SG-

SG-22

& E-UNITS

QUANTITY

SG-

SG-22

& E-UNITS

SG-1

SG-1010

& E-UNITS

QUANTITY

SG-10SM

SG-1010

& E-UNITS

114594-29

Page 30

PARTS-BREAKER HOUSING (Continued)

2SM,

PART NO.

2SM &

&

QUANTITY

2SM &

&

PART NO.

&

&

QUANTITY

1010 &

ITEM

NUMBER

10 RELAY 111497-A1 1 111497-A1 1

11 BUZZER 111499-2 1 111499-2 1

14 PORCELAIN BLOCK 114881-1 2 114881-1 2

16 TRANSFORMER 111500-7 1 111500-7 1

17 TERMINAL BLOCK 110472-8 1 110472-8 1

18 FUSE HOLDER (NS) 113053-1 1 113053-1 1

25 FUSE 3A. GLASS (NS) 3.1105-19 1 3.1105.19 1

67 GROUND LUG 3.1500/06089 1 3.1500/0689 1

69

DESCRIPTION

(480 VOLT SG-

10SM, 22 & 1010)

CONTACTOR 3-POLE,

NS—NOT SHOWN ON PHOTOGRAPH E—ELECTRONIC IGNITION

SG-

SG-22

E-UNITS

111497-C1 1 114971-C1 1

SG-

SG-22

E-UNITS

SG-10SM

SG-1010

E-UNITS

SG-10SM &

SG-

E-UNITS

114594-30

Page 31

PARTS-BREAKER HOUSING (Continued)

PART NO.

QUANTITY

&

ITEM

NUMBER

10 RELAY 111497-A1 3 111497-A1 3

11 BUZZER 111499-2 1 111499-2 1

67 GROUND LUG 3.1500 1 3.1500 1

14 PORCELAIN BLOCK 114881-1 1 114881-1 1

(120 VOLT SG-2SMT, 10SMT)

E—ELECTRONIC IGNITION T-TOP OVEN IN DOUBLE OVEN

DESCRIPTION

SG2SMT &

E-UNITS

SG2SMT &

E-UNITS

PART NO.

SG-10SMT

E-UNITS

QUANTITY

SG-10SMT &

E-UNITS

114594-31

Page 32

PARTS-BREAKER HOUSING

DESCRIPTION

PART NO.

SG2SM,

&

SG2SM,

&

PART NO.

10SM

&

10SM

&

ITEM

NUMBER

10 RELAY 111497-A1 1 111497-A1 1

11 BUZZER 111499-2 1 111499-2 1

14 PORCELAIN BLOCK 114881-1 2 114881-1 2

67 GROUND LUG 3.1500/06089 1 3.1500/06089 1

(120 VOLT, SG-2SM,

10SM, 22 & 1010)

QUANTITY

SG-22

E-UNITS

E—ELECTRONIC IGNITION

SG-22

E-UNITS

SG-

SG-1010

E-UNITS

QUANTITY

SG-

SG-1010

E-UNITS

114594-32

Page 33

PARTS-CONTROL PANEL

PART NO.

2SM

QUANTITY

2SM

PART NO.

10SM

&

10SM

&

ITEM

NUMBER

DESCRIPTION

208/240V, 120V, 480V

1 ROCKER SWITCH 111496-B1 3 111496-B1 3

2 SIGNAL LIGHT 111496-E4 2 111496-E4 2

3 THERMOSTAT 111506-3 1 111506-3 1

4 CONTROL KNOB 111242-1 3 111242-1 3

5 INFINITE SWITCH 111503-1 1 111503-1 1

6 TIMER 60 MIN. 120V 111690-1 1 111690-1 1

TIMER 60 MIN. 240V 111690-2 1 111690-2 1

7 TIMER 5 HR. (OPTIONAL 120V) (NS) 111690-3 1 111690-3 1

TIMER 5 HR. (OPTIONAL 240V) (NS) 111690-4 1 111690-4 1

8 DECAL FOR 5 HR. TIMER (NS)

9 MYLAR CONTROL PLATE 112450-1 1 112450-1 1

NS—NOT SHOWN ON PHOTOGRAPH

SGSG-22 &

E-UNITS

111693-1 1 111693-1 1

SGSG-22 &

E-UNITS

SG-

SG-1010

E-UNITS

ELECTRONIC IGNITION

QUANTITY

SG-

SG-1010

E-UNITS

33

Page 34

CONTROL PANEL (Continued)

DESCRIPTION

PART NO.

2SM &

&

QUANTITY

2SM &

&

PART NO.

&

&

TY

&

1010 &

ITEM

NUMBER

1 ROCKER SWITCH 111496-B1 4 111496-B1 3

2 SIGNAL LIGHT 111496-E4 2 111496-E4 2

3 THERMOSTAT 111506-3 1 111506-3 1

4 CONTROL KNOB 111242-1 4 111242-1 4

5 INFINITE SWITCH (NS) 111503-1 1 111503-1 1

6 TIMER, 60 MINUTE, 120V 111690-1 1 111690-1 1

6A TIMER, 60 MINUTE, 240V 111690-2 1 111690-2 1

7 TIMER, 5 HOUR (OPTIONAL 120 V) 111690-3 1 111690-3 1

7A TIMER, 5 HOUR (OPTIONAL 240 V) 111690-4 1 111690-4 1

9 MYLAR CONTROL PLATE 113931-1 1 113931-1 1

NS—NOT SHOWN ON PHOTOGRAPH E—ELECTRONIC IGNITION

120, 208/240V

(SG-2SM, -22,-10SM,-1010)

SG-

SG-22

E-UNITS

SG-

SG-22

E-UNITS

SG-10SM

SG-1010

E-UNITS

QUANTI

SG-10SM

SG-

E-UNITS

1114594-34

Page 35

PARTS-SOLENOID HOUSING (NS) NOT SHOWN BY PHOTO

SG2SM,

&

SG2SM,

22 &

PART NO.

10SM,

&

QUANTITY

10SM

&

PART NO.

ITEM

NUMBER

42 SOLENOID VALVE 111497-F1 2 111497-F1 2

44 ELBOW 90° COMP. FITTING

71 SOLENOID HOUSING

72 INLET PIPE ASSEMBLY 112380-G1 1 112380-G1 1

74 90° ELBOW FITTING 3/8NPT

75 FITTING 90° ELBOW

76 PILOT TUBE SOLENOID TO

78A (NS) PILOT FEED TUBE (STANDARD) 114643-1 1 114643-1 1

78 PILOT FEED TUBE (ELECTRONIC 112485-1 1 112485-1 1

NOTE: PHOTO SHOWS ELECTRONIC IGNITION CONSTRUCTION E—ELECTRONIC IGNITION

DESCRIPTION

1/8 MPT X 1/4 CC 114678-2 1 114678-2 1

ASSEMBLY 114653-G1 1 114653-G1 1

TO 7/16 CC ST. 114800-4 1 114800-4 1

1/4 CC x 1/4 CC 103638-1 1 103638-1 1

ADJ. VALVE 114634-1 1 114634-1 1

IGNITION)

SG-22

E-UNITS

QUANTITY

SGE-UNITS

SG-

SG-1010

E-UNITS

SG-

SG-1010

E-UNITS

114594-35

Page 36

PARTS--ELECTRONIC IGNITION (FOR SUFFIX "E" UNITS)

QUANTITY

2SME

NOTE: FOR UNITS EQUIPPED WITH ROBERTSHAW

ELECTRONIC IGNITION SYSTEM.

ITEM

NUMBER

100 SM-2 SPARK MODULE 114806-1 2 4

101 LT. HD. 58" WIRE WITH ELECTRODE 114805-1 1 2

102 RT. HD. 30" WIRE WITH ELECTRODE 114805-2 1 2

103 43-U4 PILOT 114658-1 2 4

104 BRACKET 114671-2 1 2

105 INSULATION COVER 114672-1 1 2

106 BREAKER MOUNTING BRACKET 114648-1 1 2

107 INSULATION (NS) 4" x 5" x 1" 114616-6 1 2

108 FAN-115V (NS) 115207-1 1 2

DESCRIPTION

NS—NOT SHOWN IN PHOTOGRAPH

PART

NUMBER

SG-

SG-10SME

QUANTITY

SG-22E,

SG-1010E

114594-36

Page 37

PARTS-OVEN LAMP ASSEMBLY

PART NO.

2SM

&

QUANTITY

2SM

&

PART NO.

10SM

&

QUANTITY

10SM

1010 &

ITEM

NUMBER

36 LAMP SOCKET 21201-20 2 21201-20 2

37 LIGHT BULB 155V 50W (FROSTED) 107793-2 2 107793-2 2

38 LAMP BOX HOUSING ASSEM. 111395-G1 2 111395-G1 2

39 LAMP BOX GASKET (NS) 111206-1 2 111206-1 2

40 LAMP BOX ASSEMBLY 111394-G1 2 111394-G1 2

41 LAMP WINDOW ASSEMBLY 111175-G1 2 111175-G1 2

79 REAR CLOSURE 112827-1 2 112827-1 2

DESCRIPTION

NS—NOT SHOWN ON PHOTOGRAPH E-ELECTRONIC IGNITION

SGSG-22

E-UNITS

SGSG-22

E-UNITS

SG-

SG-1010

E-UNITS

SG-

SG-

E-UNITS

114594-37

Page 38

PARTS-FLAME CHAMBER

PART NO.

SG2SM,

&

SG2SM,

22 &

PART NO.

10SM,

&

QUANTITY

10SM,

1010 &

ITEM

NUMBER

43 DOUBLE PILOT VALVE 109557-4 1 109557-4 1

46 BURNER NOZZLE 90° 104079-F 2 104079-F 2

57 RIGHT PILOT TUBE 3/16" 114633-2 1 114633-2 1

58 LEFT PILOT TUBE 3/16" 114633-1 1 114633-1 1

59 LEFT & RIGHT NOZZLE

60 BURNER SPUD (NAT.) (NS) 10901-36 2 10901-33 2

60A BURNER SPUD

61 BURNER ASSEMBLY 112709-G1 2 112709-G2 2

80 MAIN GAS SUPPLY TUBE 114620-1 1 114620-1 1

45 OVEN PILOT PROTECTION 114613-1 2 114613-F 2

47 FITTING ELBOW

52 7/16" CC TEE 114614-1 1 114614-1 1

97 7/16" CC ELBOW 103638-3 1 103638-3 1

DESCRIPTION

TUBE 114619-1 2 114619-1 1

(PROPANE) (NS) 10901-52 2 10901-53 2

1/8FM X 1/4CC (NS) 114678-2 1 114678-2 1

NS—NOT SHOWN IN PHOTOGRAPH E—ELECTRONIC IGNITION

QUANTITY

SG-

SG-22

E-UNITS

SGE-UNITS

SG-1010

E-UNITS

SG-

SG-

E-UNITS

114594-38

NOTE: PHOTO SHOWS ALTERNATE

HARPER-WYMAN AUTOMATIC VALVE CONSTRUCTION.

Page 39

PARTS-MOTOR

2SM,

&

QUANTITY

2SM,

&

10SM

QUANTITY

10SM

ITEM

NUMBER

62 MOTOR MOUNT 112629-1 1 112629-1 1

63 MOUNTING BOLT 102085-20 4 102085-20 4

64 MOTOR SPACER 112630-1 4 112630-1 4

65 LOCK NUT 104084-9 4 104084-9 4

66 MOTOR 120V OR 208/240 1 PH 111205-5 1 111205-5 1

78 LOCKWASHER (NS) 3.0201/102524 4 3.0201/102524 4

DESCRIPTION

Motor 480V 3 PH OR

208/240 3 PH OPTION 111205-8 1 111205-8 1

NS—NOT SHOWN ON PHOTOGRAPH E—ELECTRONIC IGNITION

SGSG-22

E-UNITS

SG-

SG-22

E-UNITS

SG-

SG-1010 &

E-UNITS

SG-

SG-1010 &

E-UNITS

114594-39

Page 40

PARTS-FLAME CHAMBER

PART NO.

2SM,

&

22 &

PART NO.

10SM,

QUANTITY

ITEM

NUMBER

42 SOLENOID VALVE (ND) 111497-F1 2 111497-F1 2

43 DOUBLE PILOT VALVE (NS) 104079-F 2 104079-F 2

44 ELBOW 1/8M TO 1/4 CC (NS) 13178 1 13178 1

45 OVEN PILOT PROTECTION (NS) 114613-F 2 114613-F 2

46 BURNER NOZZLE 90° (NS) 104079-F 2 104079-F 2

47 FITTING ELBOW

48 3/4 CLOSE NIPPLE (NS) 113500-E11 1 113500-E11 1

49 SHUT-OFF VALVE (NS) 111420-1 1 111420-1 1

50 REGULATOR 6" RV43A

50A REGULATOR 10RV-43

52 TEE FITTING (NS) 114614-1 1 114614-1 1

53 COUPLING 3/4 x 3/8 (NS) 114782-3 1 114782-3 1

54 3/8 CLOSE NIPPLE (NS) 113500-C6 1 113500-C6 1

55 MAIN GAS SUPPLY

57 RIGHT PILOT TUBE 3/16 (NS) 114633-2 1 114633-2 1

58 LEFT PILOT TUBE 3/16 (NS) 114633-1 1 114633-1 1

59 LT. & RT. NOZZLE TO VALVE

60 BURNER SPUD (NAT.) (NS) 10901-36 2 10901-33 2

60A BURNER SPUD (PROPANE) (NS) 10901-1/6 2 10901-53 2

61 BURNER ASSEMBLY (NS) 112709-G1 2 112709-G2 2

DESCRIPTION

1/8 FM X 1/4 CC (NS) 114678-2 1 114678-2 1

(NAT. GAS) (NS) 108279-9 1 108279-1 1

(PROPANE GAS) (NS) 108279-3 1 108279-3 1

7/16 TUBE (NS) 114620-1 1 114620-1 1

TUBES 7/16 (NS) 114619-1 2 114619-1 2

NS— NOT SHOWN IN PHOTOGRAPH E—ELECTRONIC IGNITION

SG-

SG-22

E-UNITS

SG2SM,

G-

E-UNITS

SG-

SG-1010 &

E-UNITS

QUANTITY

SG-10SM

SG-1010&

E-UNITS

114594-40

Page 41

PARTS-PILOT PROTECTION SYSTEM

PART NO.

2SM,

&

QUANTITY

2SM,

22 &

PART NO.

10SM,

&

QUANTITY

10SM

&

ITEM

NUMBER

100 OVEN PILOT PROTECTION 114644-1 2 114644-1 2

101 LEFT & RIGHT SUPPLY TUBING

55 MAIN GAS SUPPLY TUBING 114620-1 1 114620-1 1

52 TEE 7/16 CC 114614-1 1 114614-1 1

97 ELBOW 7/16 CC 103638-3 1 103638-3 1

NOTE: FOR USE WITH THE ROBERTSHAW PILOT PROTECTION SYSTEM E—ELECTRONIC IGNITION

DESCRIPTION

SG-

SG-22

E-UNITS

114635-1

SG-

SG-&

E-UNITS

2

SG-

SG-1010

E-UNITS

114635-1

SG-

SG-1010

E-UN ITS

2

41

Page 42

PARTS-USING THE PILOT PROTECTION SYSTEM

QUANTITY

2SM

&,

PART NO.

10SM

1010,

QUANTITY

1010,

ITEM

NUMBER

102 BURNER 114646-1 2 114646-2 2

103 OVEN PILOT 114645-1 2 114645-1 2

104 LEFT HAND PILOT TUBE 114658-1 1 114658-1 1

105 RIGHT HAND PILOT TUBE 114658-2 1 114658-2 1

NOTE: FOR USE WITH THE ROBERTSHAW PROTECTION SYSTEM E—ELECTRONIC IGNITION

DESCRIPTION

PART NO.

SG-2SM, SG-22

& E-UNITS

SGSG-22

E-UNITS

SGSG-

E-UNITS

SG-10SM

SGE-UNITS

-42

Page 43

PARTS-USING THE PILOT PROTECTION SYSTEM (Continued)

PART NO.

2SM

&

QUANTITY

2SM

PART NO.

10SM

&

QUANTITY

10SM

&

ITEM

NUMBER

102 BURNER 114646-1 2 114646-2 2

103 OVEN PILOT 114645-1 2 114645-1 2

DESCRIPTION

SGSG-22

E-UNITS

SGSG-22 &

E-UNITS

SG-

SG-1010

E-UNITS

SG-

SG-1010

E-UNITS

NOTE; FOR USE WITH THE ROBERTSHAW PROTECTION SYSTEM E—ELECTRONIC IGNITION

114594-43

Page 44

PARTS-DOOR ASSEMBLY & MECHANISM

PART NO.

2SM,

&

QUANTITY

2SM

&

10SM

&

QUANTITY

&

ITEM

NUMBER

81 DOOR STRIKE 111170-1 2 111170-1 2

82 DOOR CATCH PLATE 111934-1 1 111923-1 1

83 COMPRESSION SPRING 20707-23 2 20707-23 2

84 MICRO SWITCH 111496-F1 1 111496-F1 1

85 MICRO SWITCH SUPPORT 110619-1 1 110619-1 1

86 MICRO SWITCH INSULATION

87 DOOR ADJ. BRACKET 111139-1 4 111939-1 4

88 HINGE PIN BEARING 104629-2 4 104629-2 4

89 COLLAR HINGE PIN 1/2" 3.0209-2 1 3.0209-2 1

90 DOOR HANDLE ASSEMBLY 113030-G1 2 113030-G1 2

91 DOOR PANEL ASSEMBLY 112606-G2 2 112606-G2 2

93 DOOR WINDOW 111294-2 2 111294-2 2

94 PLUG BUTTON (NS) 3.0317-8 4 3.0317-8 4

96 DOOR CATCH 111794-1 2 111794-1 2

NS—NOT SHOWN ON PHOTOGRAPH E—ELECTRONIC IGNITION

DESCRIPTION

(3" LONG) (NS) 111365-1 2 111365-1 2

SG-

SG-22

E-UNITS

SGSG-22

E-UNITS

PART NO.

SG-

SG-1010

E-UNITS

SG-10SM

SG-1010

E-UNITS

114594-44

Page 45

PARTS-OVEN CAVITY

2SM

&

QUANTITY

2SM

22 &

10SM

1010&

QUANTITY

10SM

&

ITEM

NUMBER

19 FAN COVER ASSEMBLY 111136-G2 1 111136-G2 1

19A FAN COVER ASSEMBLY (SS) 111136-G4 1 111136-G4 1

21 OVEN RACK 111265-15 6 111265-1 6

22 RIGHT HAND RACK SUPPORT 111430-2 1 111430-3 1

23 LEFT HAND RACK SUPPORT 111430-1 1 111430-4 1

24 DRIP TRAY GUIDE (NS) 112845-1 2 112845-2 2

26 DRIP TRAY (NS) 111429-1 1 111429-3 1

26A DRIP TRAY (SS) (NS) 111429-2 1 111429-4 1

27 RIGHT HAND SIDE LINING 112697-1 1 112697-5 1

28 LEFT HAND SIDE LINING 112697-2 1 112697-6 1

29 RIGHT HAND SIDE LINING (SS) 112697-3 1 112697-1 1

30 LEFT HAND SIDE LINING (SS) 112697-4 1 112697-8 1

31 DOOR GASKET 111688-1 1 111688-1 1

32 TOP & BOTTOM DOOR GASKET

33 SIDE DOOR GASKET SHIM (NS) 111339-2 2 111339-2 2

34 AIROTOR 10" 3.1300-3 1 3.1300-3 1

35 SNORKELTUBE ASSEMBLY 114296-G1 1 113627-G1 1

DESCRIPTION

SHIM (NS) 111339-1 2 111339-1 2

SGSG-22

E-UNITS

SGSG-

E-UNITS

SG-

SG-

E-UNITS

SG-

SG-1010

E-UNITS

NS—NOT SHOWN ON PHOTOGRAPH SS—STAINLESS STEEL E-ELECTRONIC IGNITION

114594-45

Page 46

PARTS-CONTROL COVER PANEL ASSEMBLY

PART NO.

2SM,

&

QUANTITY

2SM,

&

PART NO.

&

QUANTITY

10SM

&

ITEM

NUMBER

97 CONTROL COVER 114630-1 1 114630-1 1

98 CONTROL COVER 114642-1 1 114642-1 1

99 PANEL-UPPER EXT.

99A PANEL-UPPER EXT.

99 B PANEL-LOWER

DESCRIPTION

ASSEMBLY (SMT UNITS) 114629-G1 1 114629-G1 1

ASSEMBLY (T UNITS) 114629-G3 1 114629-G3 1

EXT. ASSEMBLY

(SMB. & B UNITS) (NS) 114649-G1 1 114629-G2 1

SGSG-22

E-UNITS

SG-

SG-22

E-UNITS

SG-10SM

SG-1010

E-UNITS

SG-

SG-1010

E-UNITS

NS—NOT SHOWN ON PHOTOGRAPH E—ELECTRONIC IGNITION

T—Top Oven In Double Oven B—Bottom Oven In Bottom Oven

114594-46

Page 47

MANUAL ASSEMBLY 114594-G1

SHEET PART NUMBER

I.S.P. MANUAL FOR SG-22, 22E, 2SM, 2SME, SG-1010, 1010E, 10SM, & 10SME CONVECTION OVEN

SIGN

MANUAL 114594-G1

SUB NO.

AFFECTED

DATE

DML 5 114594-1 thru 114594-46 12-27-84

114594-47

Loading...

Loading...