Page 1

MCDONALD'S ELECTRIC FRYERS

INSTALLATION, SERVICE

AND PARTS

MANUAL FOR MODELS

REF-1M and REF-2SM

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

Page 2

OPERATING, INSTALLATION AND SERVICE PERSONNEL

Operating information for this equipment has been prepared for use by qualified and/or authorized operating

personnel.

All installation and service on this equipment is to be performed by qualified, certified, licensed and/or

authorized installation or service personnel, with the exception of any marked with a c in front of the part

number.

Service may be obtained by contacting the Factory Service Department, Factory Representative or Local

Service Agency.

DEFINITIONS

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified or authorized operating personnel are those who have carefully read the information in this manual

and are familiar with the equipment's functions or have had previous experience with the operation of the

equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, a firm, corporation or company which either in person or

through a representative are engaged in, and are responsible for:

1. The installation of gas piping from the outlet side of the gas meter, or the service regulator when the meter

is not provided, and the connection and installation of the gas appliance. Qualified installation personnel

must be experienced in such work, be familiar with all precautions required, and have complied with all

requirements of state or local authorities having jurisdiction. Reference in the United States of America National Fuel Gas code ANSI Z223.1 (Latest Edition). In Canada-Canadian Standard CAN1-B149.1 NAT.

GAS (Latest Edition) or CAN1-B149.2 PROPANE (Latest Edition).

2. The installation of electrical wiring from the electric meter, main control box or service outlet to the electric

appliance. Qualified installation personnel must be experienced in such work, be familiar with all

precautions required, and have complied with all requirements of state or local authorities having

jurisdiction. Reference: In the United States of America-National Electrical Code ANSI NFPA No. 70

(Latest Edition). In Canada-Canadian Electrical Code Part 1 CSA -C22.1 (Latest Edition).

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Vulcan equipment who have been endorsed by

the Vulcan-Hart Corporation. All authorized service personnel are required to be equipped with a complete set

of service parts manuals and stock a minimum amount of parts for Vulcan equipment.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected and packed by

skilled personnel before leaving the factory. The transportation company assumes full responsibility for safe

delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE — Be certain this is noted on freight bill or express receipt and signed by

person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY — Regardless of extent of damage.

3. CONCEALED LOSS OR DAMAGE — If damage is unnoticed until merchandise is unpacked, notify

transportation company or carrier immediately, and file "concealed damage" claim with them. This should

be done within (15) days of date of delivery is made to you. Be sure to retain container for inspection.

We cannot assume responsibility for damage or loss incurred in transit. We will, however, be glad to furnish

you with necessary documents to support your claim.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

Page 3

IMPORTANT NOTES FOR ALL VULCAN APPLIANCES

1. These units are produced with the best possible workmanship and material. Proper installation is vital if best performance and

appearance are to be achieved. Installer must follow the installation instructions carefully.

2. Information on the construction and installation of ventilating hoods may be obtained from the "Standard for the installation of

equipment for the removal of smoke and grease laden vapors from commercial cooking equipment," NFPA No. 96 (latest

edition) available from the National Fire Protection Association, Battery March Park, Quincy MA 02269.

3. For an appliance equipped with a flexible electric supply cord, the cord is equipped with a three prong (grounding) plug. This

grounding plug is for your protection against shock hazard and should be plugged directly into a properly grounded three prong

recepticle. Do not cut or remove the grounding prong from this plug. If the appliance is not equipped with a grounding plug, and

electric supply is needed, ground the appliance by using the ground lug provided (refer to the wiring diagram).

(FOR GAS APPLIANCES ONLY)

4. Do not obstruct the air flow into and around the appliance. This air flow is necessary for proper combustion of gases and for

ventilation of the appliance. Provisions for ventilation of incoming air supply for the equipment in the room must be in accordance

with National Fuel Gas Code ANSI Z223.1 (latest edition).

5. Do not obstruct the flow of flue gases from the flue duct (when so equipped) located on the rear (or sides) of the appliance. It is

recommended that the flue gases be ventilated to the outside of the building through a ventilation system installed by qualified

personnel.

6. For an appliance equipped with casters, (1) the installation shall be made with a connector that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21.69 (latest edition), and Addenda, Z21.69a (latest edition), and a quickdisconnect device that complies with the Standard for Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z21.41 (latest

edition), and Addenda, Z21.41 a (latest edition) and Z21.41 b (latest edition), and (2) adequate means must be provided to limit

the movement of the appliance without depending on the connector and the quick-disconnect device or its associated piping to

limit the appliance movement. If disconnection of the restraint is necessary, reconnect this restraint after the appliance has been

returned to its originally installed position.

7. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/ 2 psig (3.45 k Pa).

8. The appliance must be isolated from the gas supply system by closing its individual manual shutoff valve during any pressure

testing of the gas supply system at test pressures equal to or less than 1/ 2 psig (3.45 k Pa).

CAUTIONS

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS EQUIPMENT OR ANY OTHER APPLIANCE.

1. KEEP THE APPLIANCE FREE AND CLEAR FROM ALL COMBUSTIBLE SUBSTANCES.

2. IN THE EVENT A GAS ODOR IS DETECTED, SHUT UNIT(S) DOWN AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER

FOR SERVICE.

3. POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION MAY BE OBTAINED FROM A

LOCAL GAS SUPPLIER.

Page 4

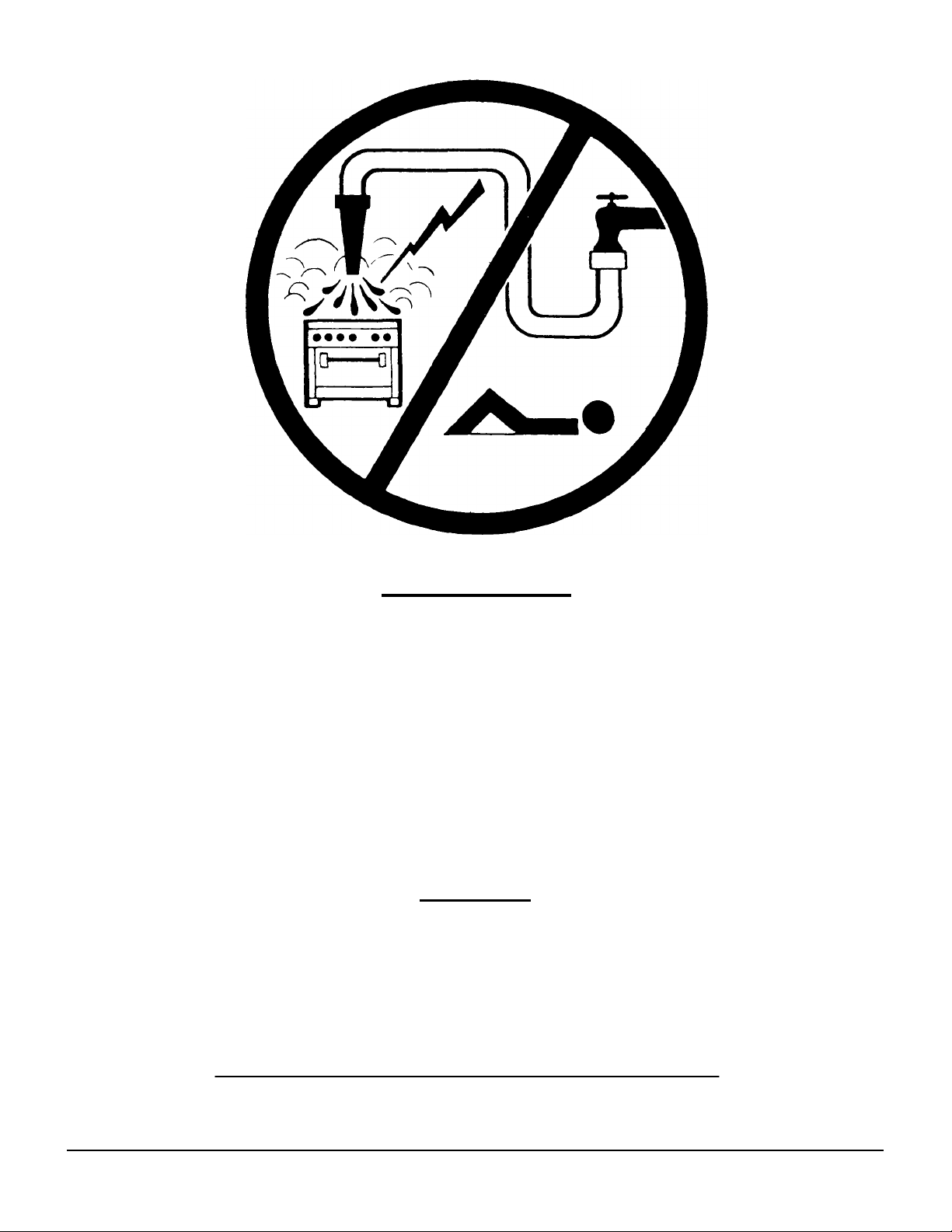

WARNING:

DO NOT SPRAY LIQUIDS OR VAPORS ON OR

NEAR EQUIPMENT UTILIZING ELECTRICITY

CAUTION

FROM THE TERMINATION OF THE APPLIANCE FLUE VENT TO THE FILTERS OF THE HOOD VENTING SYSTEM, AN 18

INCH MINIMUM CLEARANCE MUST BE MAINTAINED.

REFERENCE: ANSI/NFPA 96-1984 4-1.2.2.2. OF THE NATIONAL FIRE PROTECTION ASSOCIATION INC.,

BATTERYMARCH PARK, QUINCY, MASS. 02269, AND NATIONAL BUILDING CODE 1976 SEC. 1015.7b OF THE

AMERICAN INSURANCE ASSOCIATION ENGINEERING AND SAFETY SERVICE, 85 JOHN STREET, NEW YORK, N.Y.

10038.

IMPORTANT

THIS EQUIPMENT IS DESIGN CERTIFIED BY A NATIONALLY

RECOGNIZED TESTING LABORATORY TO THE

APPROPRIATE NATIONAL STANDARDS AS INDICATED ON

THE EQUIPMENT RATING PLATE. ANY MODIFICATION

WITHOUT WRITTEN PERMISSION OF VULCAN-HART

CORPORATION VOIDS THE CERTI FICATION AND WARRANTY

OF THIS UNIT.

115591-4

Page 5

REF FRYER INSTALLATION, SERVICE &

PARTS MANUAL INDEX

Your Vulcan fryer is produced with the best possible workmanship and material. Proper usage and maintenance will

result in many years of satisfactory performance.

DESCRIPTION PAGE

DEFINITION OF PERSONNEL (Inside front cover) 115591-2

CAUTIONS, WARNINGS & IMPORTANT NOTATIONS 115591-2 THRU -5

SECTION 1 - INSTALLATION INSTRUCTIONS 115591-6

SECTION 11 - SERVICE 115591-7 THRU -13

SECTION III - TROUBLE SHOOTING 115591-14 THRU -15

SECTION IV - PARTS LIST & PHOTOS 115591-16 THRU -33

REVISION PAGE (Inside back cover) 115591-34

A RATING PLATE IS LOCATED ON THE INSIDE FRYER DOOR PANEL STATING THE MODEL NUMBER, SERIAL NUMBER,

VOLTAGE AND AMPERAGE. FRYER MUST BE INSTALLED AT LEAST 16 INCHES AWAY FROM OPEN TOP FLAME UNITS.

The manufacturer suggests that you thoroughly read this entire

manual and carefully follow all of the instructions provided.

A complete set of wiring diagrams are packaged separately and placed in the fryer tank for shipment. A wiring decal may also be

found mounted behind the contactor cover door of the unit.

115591-5

Page 6

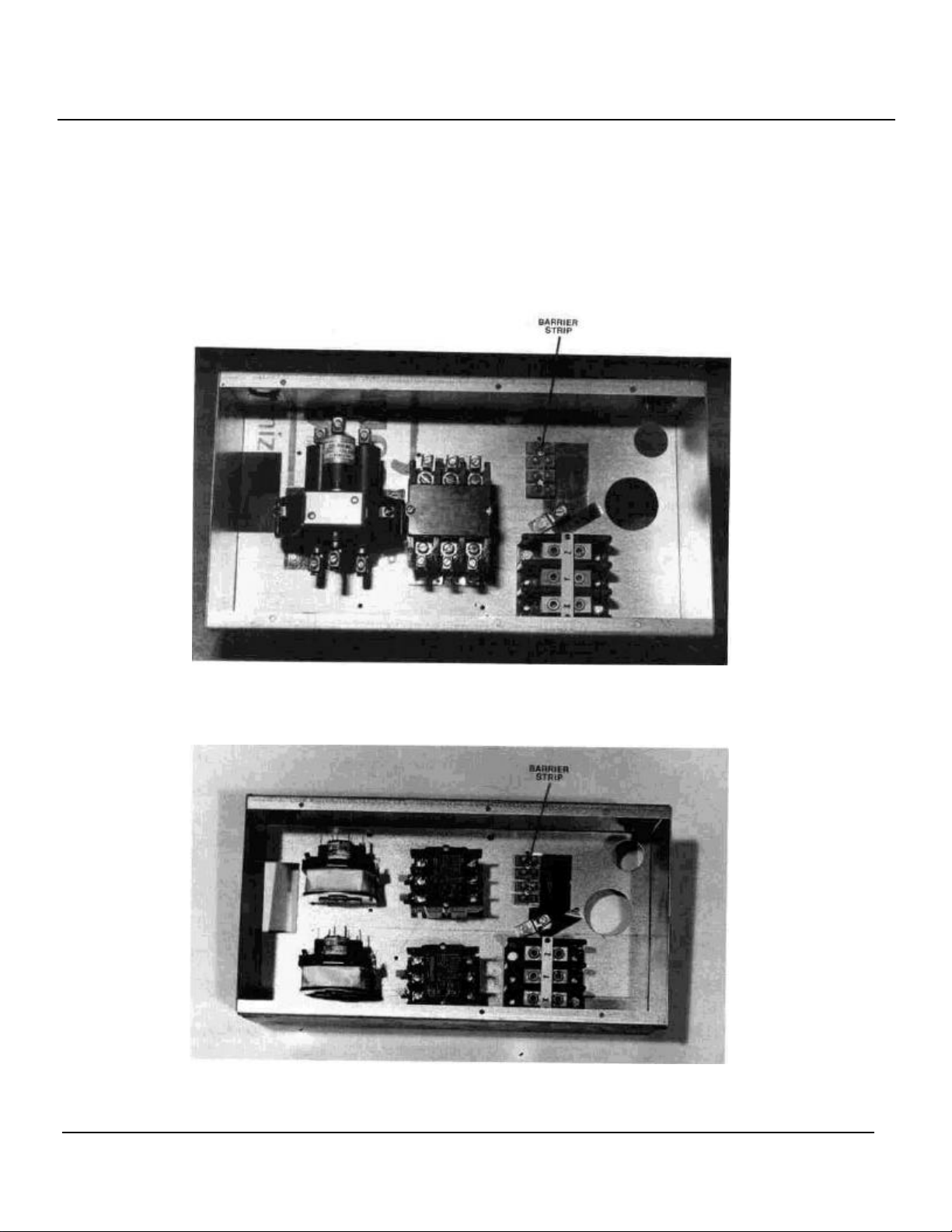

SECTION I INSTALLATION

DETAIL A

DETAIL B

115591

-

6

Place fryer as near to its' final position as possible. Connect 120V 60 Hertz electric supply to fryer barrier strip.

Barrier strip may be connected from rear of unit. To reach

barrier, remove electric cover plate from unit. After connecting 120V 60 Hertz electric supply to fryer barrier

strip, verify with a voltmeter that the following condition

exists. (See Details A & B).

1. Black to white 120V 60 Hertz.

2. Black to ground 120V 60 Hertz.

3. White to ground 0.00V 60 Hertz.

For each 15 1/2" section a high voltage line capable of

handling 16 KW at the unit's rated voltage (208, 240,

480) is required. If a fan interlock is needed, it should be

connected to 1 and 2 on the barrier strip. 1 and 2 go to a

set of dry contacts on the power switch.

Page 7

SECTION II SERVICE___________________________________________

SWITCH PANEL OPERATION

DETAIL A1

1. MASTER SWITCH - Controls electric supply to unit. (Optional - ventilator interlock.)

2. POWER "ON" LIGHT - Light Indicates when electrical supply is on.

3. TEMPERATURE CONTROL - Maintains frying temperature by controlling power supply.

4. HEATING LIGHT

5. HIGH LIMIT TEST SWITCH - Bypasses temperature control for testing of high limit thermostats.

6. FIRST HIGH LIMIT LIGHT - When "On", indicates first high limit thermostat has shut down.

7. SECOND HIGH LIMIT LIGHT

8. TROUBLE LIGHT - Indicates unit has been shut down by second high limit thermostat.

- When "On", indicates temperature control is calling for power to

elements.

- When "On", indicates second high limit thermostat has shut down

unit. (reset required)

115591-7

Page 8

SECTION II SERVICE (Continued)

CLEANING HEATING ELEMENTS & THERMOSTAT BULB

1. The kettle must be at operating temperature.

2. Turn master switch off.

3. Raise elements out of hot shortening with a lift rod and

allow shortening to drip off for five minutes.

CAUTION

4. Place cover(s) over kettle(s). To prevent fire and

preserve clean shortening.

5. Turn operating thermostat to 300°F. (148.8°C).

6. Turn master switch on. Do not leave the fryer

unattended. The second high limit will trip out

terminating the bum off cycle

7. Turn master switch off at termination of burn off cycle.

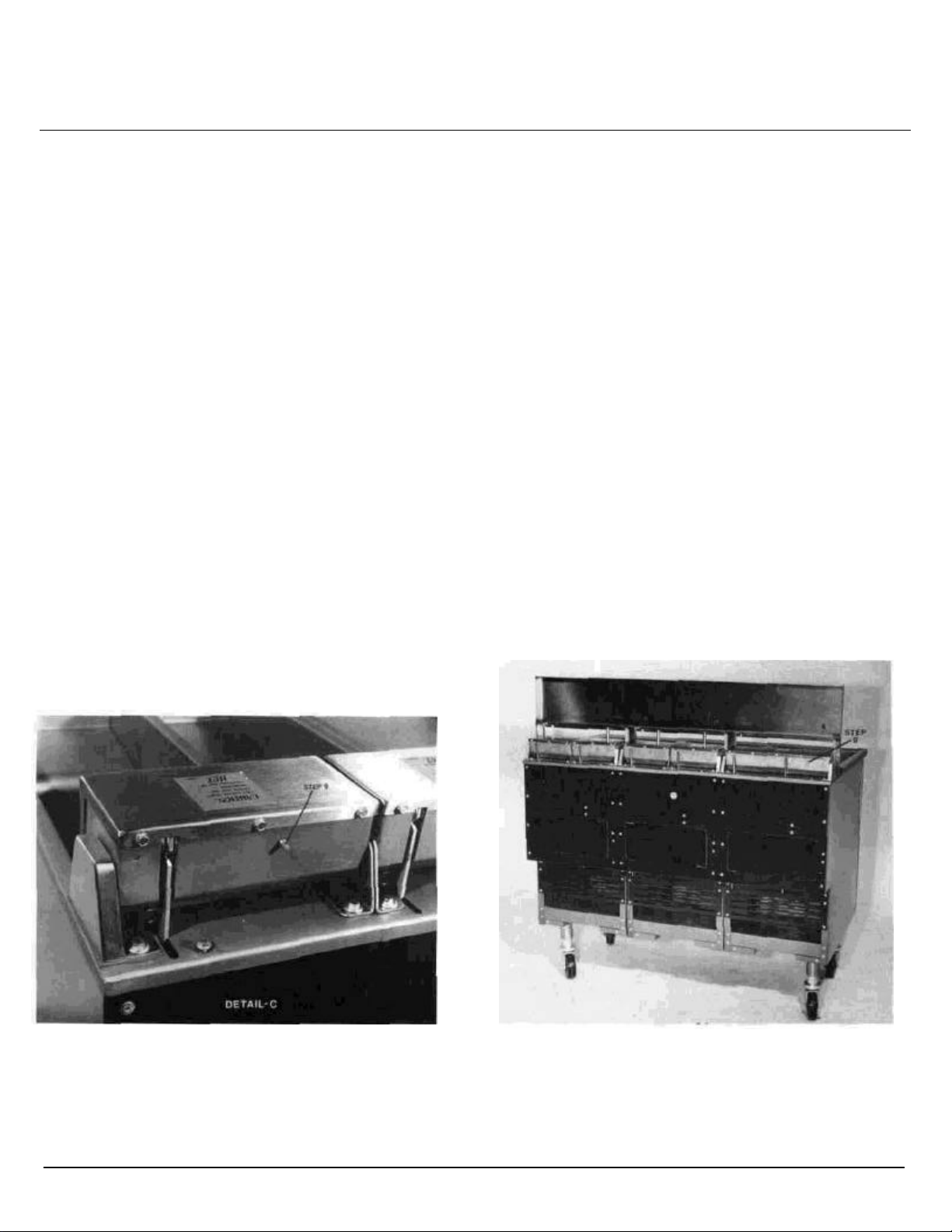

DETAIL C DETAIL C1

15591-8

8. Heating elements will heat up in excess of 600°F

(315.5°C) glowing red. If any do not glow, call service

agency. Some smoking, cracking sound and flames will

occur. This is normal. If excessive flaming occurs,

extinguish immediately to prevent damage to elements

and thermostat bulbs.

9. Allow elements to cool and press reset button on rear

of element head (See Detail C & C1).

10. Brush residue from elements and thermostat bulbs with

a stiff nylon brush. Care should be taken not to bend or

displace temperature controller bulbs.

11. Remove cover(s) from kettle(s) and lower elements into

shortening.

12. Proceed with filtering procedures.

Page 9

SECTION II SERVICE (Continued)

THERMOSTAT CALIBRATION PROCEDURES

1. Thermostat calibration is factory set before unit shipment. Thermostat calibration should not be performed

unless unit temperature is registered within 5°F (15°C) plus or minus the thermostat setting.

Check thermostat calibration as follows:

NOTE: The following tools will be required: Digital pyrome-

ter and holder, 1/8" flatblade, screwdriver, maple

paddle.

1. The shortening must be at the proper level as indicated

by the indicator line on the vat wall.

2. Inset a digital pyrometer, alnor pyrometer or a deep fat

thermometer at the rear of the fryer exactly where the

computer probe would go.

3. Set the thermostat knob at the correct cooking temperature and turn on unit.

4. Allow the shortening temperature to stabilize by letting

the fryer cycle on and off after reaching the desired

temperature at least three times.

5. Agitate the shortening using maple paddle until step

6 is completed

6. After the stabilizing period, the instant the burner acates (as noted by the burners "On" light turning on),

the shortening temperature should be plus of minus

5°F (-15°C) of the thermostat setting.

7. If it is within ± 5°F (-15°C) you are finished

calibrating. If not follow steps 8 thru 11 for

recalibration.

8. Loosen the set screw in the temperature control

knob. Rotate knob without moving shaft and set the

knob to match the pyrometer reading.

9. Retighten the set screw. CAUTION: Do not

overtighten.

10. Turn the dial to the desired temperature.

11. Repeat steps 4,5 and 6.

NOTE: Do not calibrate using new shortening unless

you agitate the shortening as indicated in

step 5.

115591-9

Page 10

SECTION II SERVICE (Continued)

DETAI

L

C2 115591

-

10

SERVICING MULTI-FUNCTION BOARD

NOTE: The multi-function board incorporates the follow

ing features utilizing a thermosistor probe to

sense fat melt cycle, fat melt temperature trip,

oil temperature and the first high limit tempera

ture trip.

A. Melt Cycle & Temperature

1. Set the temperature control knob to the frying

temperature and turn on the master switch.

2. After an initial off period of approximately 45

seconds, the elements will cycle on for 2 seconds

and off for 28 seconds until the shortening melts

and a temperature of 135°F (57°C) is obtained,

after which the operating thermostat will take over

and bring the unit to the set temperature. If the fat

melt cycle responds, but comes out of fat melt at

more than ± 10° of 135° F. (57°C) see fat melt

calibration procedures in item no. 3. If the fat melt

cycle fails to respond, see item 4 below.

3. Fat Melt Calibration

NOTE: This procedure should be performed by an

authorized service person only. If the unit is

coming out of the fat melt cycle at ± 10°F (-12°C),

try the following calibration procedure before

replacing the multi-function board.

A. Insert pyrometer in place of the computer

probe.

B. Turn unit "off" and allow unit to cool to below

135°F (57°C) or begin calibration from cold

start.

C. Remove (2) screws from upper corners

of control panel, drop control panel down, dis-

connect the electric harness and remove panel.

D. Locate defective multi-function board on

back wall of the control area.

E. Locate fat melt adjustment screw resting in the

bottom center of the board to the right of pin #12.

F. Remove the adjustment screw sealant by

gently chipping with screwdriver

G. Turn fat melt adjustment screw full clockwise.

H. Connect a DC voltmeter between pins 13 and 15.

I. Reconnect control panel wire harness while

holding panel assembly in hand. Turn power switch

"On" and set the potentiometer knob to frying

temperature.

J. Check DC voltmeter for a reading of 5 volts

K. When pyrometer reaches 135°F (57°C) and while

observing the voltmeter gently rotate fat melt

adjustment screw counterclockwise until DC

voltmeter reads 0 volts.

NOTE: It is advisable to secure adjustment screw

by placing a small drop of enameled paint or

fingernail polish in center of screw. Calibration is

now complete, remove voltmeter and replace

control panel.

4. If the fat melt cycle is inoperative, the multi-funcion

control board must be replaced.

NOTE: Field repair of the multi-function board is

not practical, therefore, when the board

malfunctions, it must be completely replaced. Ref.

to Detail C2

Page 11

SECTION II SERVICE (Continued)

SERVICING MULTI -FUNCTION BOARD (Continued)

To replace multi-function board, disconnect unit

power and remove (2) screws in the upper comers

of the control panel. Fold down control panel as sembly. Disconnect electrical harness and remove

panel. The multi-function boards are located on

the back wall of the control box area. Ref. to

Detail C.

NOTE: Split vat units utilize (2) boards, (1) to the

right and (1) to the left upper wall. Single vat units

utilize (1) board mounted to the upper left wall.

Remove (4) screws securing defective board. Disconnect multi pinned plug. Remove the 11 wire

connections one at a time transfering each connector from the old board onto the new board.

Reconnect multi pinned plug and remount new

multi-function board. Reconnect wire harness and

close up control panel assembly. Reinstall (2)

screws to secure panel mounting.

SERVICE NOTE:

Harness connectors, in split vat fryers, which

serve the same purpose for left side or right sides,

have been identified by a "red" dot for "left" and a

"green" dot for "right". When reconnecting

harness insure that red dots connect to left hand

components and green dots to right hand

components.

6. Stop agitating and allow fryer to cycle On and Off

automatically three (3) times.

7. After the stabilizing period, the instant the element

actuates (as noted by the fryer "On" light turning

on), the shortening temperature should be plus

or minus 5°F. (-15°C) of the thermostat setting.

8. If it is within ± 5°F. (-15°C) you are finished

calibrating.

9. If not, loosen the set screw in the temperature

control knob. Rotate knob without moving shaft

and set the knob, to match the pyrometer

reading.

10. Retighten the set screw.

DO NOT OVERTIGHTEN.

11. Turn the dial to the desired temperature.

12. Repeat steps 6,7 and 8

13. If, after repeating steps 6 thru 7 oil temperature

calibration is not achieved, replacement of the

multi-function board will be required.

B. OIL TEMPERATURE

The fryer oil temperature is controlled by the multi

function board, monitored by the thermistor probe and

set by the potentiometer.

The following calibration check will help determine the

operational status of the temperature controller in the

multi function board.

NOTE: Best results can be obtained by not using new

shortening.

1. The shortening must be at the proper level as indicated by the indicator line on the vat wall.

2. Insert pyrometer, at the rear of the fryer exactly

where the computer probe would go.

3. Set the thermostat knob to the correct cooking

temperature and turn on unit.

4. Allow the shortening temperature to cycle off

after reaching the desired temperature.

5. Agitate the shortening using a maple paddle to

eliminate the cold zone in the bottom of the kettle.

115591-11

14. Replacement of the multi-function board is to be

performed only by a certified Vulcan service

agency. Service personnel should disconnect

unit power and follow board replacement

procedure outlined in item 3 of melt cycle and

temperature in Section II Service.

HIGH LIMIT CONTROL

The function of the high limit control is to shut the unit

down in the event of a thermostat failure which would

allow the cooking oil to be overheated. The operating

temperature of the high limit control is 35° or 60° higher

than the highest temperature allowed by the thermostat

when the thermostat is functioning properly.

In the event of a high limit 'Shut -Down" the entire control

system will be put out of operation.

DO NOT attempt to restart the fryer until the temperature

of the cooking oil has lowered to approximately 350°.

CAUTION

IF THIS SITUATION CONTINUALLY OCCURS, DO

NOTATTEMPT TO BYPASS THE HIGH LIMIT. SHUT

UNIT DOWN AND CONTACT A SERVICE AGENCY.

Page 12

SECTION II SERVICE (Continued)

HIGH LIMIT TEST PROCEDURE

This test is to be made in order to determine if the protec tion devices are properly functioning. (See steps 1 thru

9). Tools required to complete this procedure are: A

pyrometer, maple paddle.

1. Check fryer oil level. Unit oil level must reach vat full

line.

2. Remove computer probe from probe holder.

3. Insert properly calibrated shortening pyrometer probe

into holder.

4. Turn fryer power switch "On", set temperature control

knob at 375°F (190.6°C) and let oil stabilize for at

least 15 minutes.

5. Push and hold top half of red test switch while continuously stirring oil.

6. Record temperature at which first high limit indicator

light turns "On". Indicator should turn "On" between

400° to 420°F (204.4° to 215.6°C). When light

appears, release switch.

NOTE: If first high limit test is failed, contact service

agency. Fryer operation may continue if second high

limit test is passed.

7. To check second high limit, push and hold bottom half

of red test switch, while continuously stirring the the oil

8. Record temperature at which second high limit

indicator light turns "On" indicator should turn on

between 420° to 450°F (215.6° to 232.2°C) when light

appears, release switch.

NOTE: If second high limit test is failed, shut fryer

down immediately and contact service agency.

9. Once unit cools down, reset by turning main power

switch off and then on, normal frying operation will

then automatically be resumed.

The following procedure is to be performed by authorized

service personnel only!

If the high limit test is consistently failed within a range of

±25°F (-3.8°C) high limit calibration of the multi-function

board may correct the problem.

To calibrate the first high limit control of the multi-function

board, complete the procedures below.

1. After failing high limit test, allow fryer to cool until the

high limit light closes, this is marked by the

deillumination of the first high limit light.

2. Remove (2) screws in upper corner of the control

panel, drop control assembly down and hold it in

palm of your hand.

3. Locate the high limit adjustment screw resting next to

wire pin #8 on the lower left hand side of the multifunction board.

4. Using a screwdriver gently chip of the protective

adjustment screw board.

5. Rotate the high limit adjustment screw full clockwise.

6. Depress first high limit test switch using the

pyrometer monitor temperature rise.

7. As the oil temperature approaches 410°F (210°C) be

prepared to rotate adjustment screw counterclockwise. When the oil temperature reaches

410°F (210°C). Gently rotate adjustment screw counterclockwise until the first high limit light illuminates.

Calibration is now complete.

8. Reassemble fryer for normal cooking operation.

DETAIL D DETAIL E

115591-12

Page 13

SECTION II SERVICE (Continued)

DETAIL F

115591

-

13

Replacement Of Mini Fan

The mini fan is located behind the control panel mounted

to the center bottom flange of the control area. The mini

fan is utilized to draw hot air outside of the control area.

Should this fan malfunction, it must be immediately replaced as follows:

1. Disconnect unit power or turn breakers off at main

power source.

2. Remover (1) screw from each of the upper control

panel corners.

3. Drop control panel down and disconnect electrical

harness plug to remove panel assembly from the

control area.

4. Locate mini fan centered in bottom control area

flange.

5. Remove the (4) screws securing fan.

6. Disconnect the (2) fan wires and remove bad fan from

the control area.

7. Install new fan, close up control area. Return unit

power.

Page 14

SECTION III TROUBLESHOOTING GUIDE__________________________

5V power

scheduled maintenance section of equipment

scheduled maintenance section of equipment

A. Set temperature control to normal cooking

equipment

scheduled maintenance section of equipment

WARNING: Inspection, testing and repair of electrical equipment should be performed only by qualified service

personnel. The unit should be unplugged when servicing, except when electrical tests are required.

DANGER: Use extreme care during electrical circuit tests. Live circuits may be exposed.

PROBLEM CAUSE CORRECTIVE ACTION

A. On-Off switch not "On". A. Turn On/Off switch "On" FRYER DOES NOT HEAT.

B. 115V store circuit breaker "Off". B Reset store circuit breaker.

C. Control voltage plug not plugged in wall. C. Plug in all power supply cords & insure

twist locks are engaged.

D. Control circuit not connected to power

inside fryer.

E. On-Off switch defective. E. Replace switch. (Refer to non-scheduled

D. Remove rear panel& check for 11

connection.

maintenance section of equipment manual.)

POWER SWITCH "ON".

POWER LIGHT ON.

OFF.

"ON", NO HEAT LIGHT CONTACTOR

CAN BE HEARD CYCLING EVERY 30

SECONDS.

POWER SWITCH "ON,

POWER LIGHT -ON", NO HEATING LIGHT.

POWER SWITCH "ON", POWER LIGHT

"ON", AND NO HEATING LIGHT,

TROUBLE LIGHT & SECOND LIMIT "ON".

A. Ventilator circuit breaker tripped. A. Reset vent circuit breaker.

B. Open wiring in interlock system. B. Call service agency.

C. Defective power switch. C. Replace power switch. (Refer to non-

manual.)

A. High voltage store circuit breaker

tripped, (one for each 15 1/2" fryer section.)

B. Heating light defective. (Oil temperature

increasing without heating light.)

A. Temperature control set too low

B. Fat melt timer is inoperative.

C. Multi-function temperature control

board is inoperative.

A. Shortening temperature above 435°F

(224°C) second high limit inoperative.

B. Second high limit inoperative (will not

reset).

A. Reset vent circuit breaker POWER SWITCH "ON", POWER LIGHT

B. Replace heating light. (Refer to nonmanual.)

temperature.

B. & C. Replace multi-function temperature

& board. (Refer to non-

scheduled maintenance section of

manual.

A. Allow shortening to cool to 390° (199°C)

and push second high limit reset button.

B. Replace second high limit. (Refer to non manual.)

115591-14

Page 15

SECTION III TROUBLESHOOTING GUIDE

B. Solid fat not properly located on heating

&

scheduled maintenance section of equipment

element.

connection.

scheduled maintenance section of equipment

PROBLEM CAUSE CORRECTIVE ACTION

MELT CYCLE DOES NOT FUNCTION

(UNIT GOES TO FULL HEAT WHEN

TURNED "On").

A. Thermistor sensor is still hot from a

previous change of hot shortening.

A. Allow kettle to cool. To force cool, pack solid

shortening around probe (between elements at

rear).

UNIT GOES TO FULL POWER BEFORE

SHORTENING AROUND ELEMENTS IS

DISSOLVED.

SHORTENING WILL NOT MELT

WITHIN 45 MINUTES.

B. Melt function defective. B. Replace multi-function temperature control

board. (Refer to non-scheduled maintenance

section of equipment manual.

A. Wire rack not removed prior to adding

solid shortening.

element.

C. Fat melt function defective. C. Replace multi-function temperature control

A. Melt cycle thermostat out of calibration. A. Adjust fat melt thermostat function. (Refer to

B. Melt cycle timer incorrect. Should be 2

seconds "On", 28 seconds "Off".

C. Defective heating element. C. Call service agency to replace heating

D. Heating element power/supply problem. D. Check breakers X -Y-Z block for bad

A. Remove rack, allow system to cook & initiate

fat melt.

B. Be sure block is centered over element coils

push full to back of fryer.

board. (Refer to non-scheduled maintenance

section of equipment manual.)

nonmanual.)

B. Replace multi-function temperature control

board. (Refer to non-scheduled maintenance

section of equipment manual.)

UNIT WILL NOT COME OUT OF FAT

MELT.

FRYER COMES "ON", NO FAT MELT

CYCLE. FRYER HEATS UNTIL SECOND

HIGH LIMIT TRIPS. (RUN-AWAY)

FRYER GOES THROUGH FAT MELT,

THE FULL HEAT RUNS UNIT

1st OR 2nd HIGH LIMIT TRIPS.

(RUN-AWAY)

LIMIT TEMPERATURE BELOW

375°F. (190. 5)°C).

115591-15

A. Defective multi-function temperature

control board.

A. Stuck mercury relay in temperature

control system.

A. Defective temperature control board. A. Replace temperature control board. (Refer to

A. Fryer out of calibration. A. Recalibrate, see calibration FRYER SHUTS DOWN WITH HIGH

B. Improper first high limit calibration. B. Calibration of first high limit required. Contact

A. Replace multi-function temperature control

board. (Refer to non-scheduled maintenance

section of this manual.)

A. Turn unit "Off" and tag fryer for non-use until

service agency has repaired.

non-

manual.)

service agency.

Page 16

SECTION IV PARTS LIST________________________________________

REF FRYER

REPLACEMENT PARTS LIST

&

PHOTOS

REPLACEMENT PARTS ORDERING

THE FOLLOWING INFORMATION MUST ACCOMPANY A REPLACEMENT PARTS ORDER OR IT CANNOT BE FILLED.

A. MODEL AND STYLE OR SERIAL NUMBER

B. VOLTAGE AND PHASE.

C. APPLIANCE FINISH, PERMAFINISH, STAINLESS STEEL ETC. (IF APPLICABLE TO PART TO BE REPLACED.)

THIS INF ORMATION CAN BE FOUND ON THE RATING PLATE LOCATED INSIDE THE FRYER DOOR PANEL.

PARTS MAY BE ORDERED FROM YOUR DEALER, SERVICE AGENCY, PARTS DISTRIBUTOR.

FOR FURTHER INFORMATION CONCERNING PARTS, ORDERING LOCATION, CONTACT V ULCAN-HART CORPORATION, 3600

NORTH POINT BLVD., BALTIMORE, MD. 21222 OR IN CANADA, VULCAN-HART CANADA INC., 79 WEST STREET, SOUTH,

ORILLIA, ONTARIO, L3V K5.

USE RATING PLATE AND WARNING PLATES LOCATED INSIDE LEFT HAND DOOR PANEL TO HELP YOU OBTAIN THE

INFORMATION LISTED ABOVE. THESE PLATES WILL PROVIDE ALL NECESSARY INFORMATION REQUIRED BY THE SERVICE

AGENCY.

WARNING ALL SERVICE PERSONNEL

WHEN SERVICING THIS EQUIPMENT, USE ONLY CERTIFIED

CONTROLS, DUPLICATING THOSE ORIGINALLY SUPPLIED ON THIS EQUIPMENT BY

VULCAN-HART CORP., DO NOT SUBSTITUTE COMPONENTS WITH DIFFERENT MODEL NUMBERS

DO NOT SUBSTITUTE COMPONENTS WITH DIFFERENT MANUFACTURING NAMES

DO NOT SUBSTITUTE COMPONENTS WITH REBUILT CONTROLS WITHOUT

AUTHORIZATION FROM VULCAN-HART CORP. ANY UNAUTHORIZED SUBSTITUTION OF

CONTROLS AS STATED ABOVE MAY BE A SAFETY HAZARD AND WILL AUTOMATICALLY VOID

THIS WARRANTY AND THE CERTIFICATION ASSOCIATED WITH THIS EQUIPMENT

DETAIL G

115591-16

Page 17

PARTS LIST (Continued)

4SF

*1 114339

-

G1 Main top assembly

1 1

Protects unit from shortening

1

1 1

1

1

5 114159

-

1 Probe tube

1 2 3 2 4 6 3 5 2 4

Holds temperature probe in

place during unit operation.

ITEM PART

No. No. DESCRIPTION 1M 2M 3M 2SM 4SM 6SM 12SM 14SM 2FM

REF REF REF REF REF REF REF REF REF REF

PARTS IDENTIFICATION/FUNCTION/PHOTOS

QUANTITY

FUNCTION

2 114184-G1 Main top assembly

•3 114192-G1 Main top assembly

4 114206-1 Basket hanger 1 2 3 1 2 3 2 3 2 2 Holds probe tubes and fryer

6 114194-8 (Single) control 1 2 3

7 114043-9 (Split) control panel

8 114123-G1

9 111686-2 Hanger button 2 4 6 2 4 6 4 6 4 4 Allow basket hanger to rest on

10 114210-1 Caster with brakes 2 2 2 2 2 2 2 2 2 2

(single unit)

(double unit)

(triple unit)

panel Mylar

Mylar

Door panel

assembly

1 1 1 Protects unit from shortening

1 1 2

1 2 3 1 2

1 2 3 1 2 3 2 3 3 3

10A 114210-2 Caster without

brakes

•11 114244-1

Blank control panel

Mylar

1 1

drippings and supports basket

hanger.

Protects unit from shortening

drippings and supports basket

hanger.

drippings and supports basket

hanger.

baskets.

Protects metal control panel and

describes operators controls.

2 Protects metal control panel and

describes operators controls.

Closes off fryer front and

protects control area.

m ain top.

Adjustable wheel assembly

which allows unit to be rolled in

and out from under hood for

cleaning or relocation.

Used to cover operators control

area on frymate units.

12 114211 Door pull 1 2 3 1 2 3 2 3 3 3 Allows door assembly to be

13 114224-G2 Tank assembly 1 2 3

*Items not shown by photograph

115591-17

(single)

1 1 2

Photo shown on next page.

opened and closed.

Holds shortening and product

while unit is frying.

Page 18

PARTS LIST (Continued)

115591

-18

Page 19

PARTS LIST (Continued)

No.

1

1

1 1 1

1

1 1

Encloses fryer back and protects

Encloses fryer back and protects

ITEM

PART No.

14 114088-G2 Tank assembly

DESCRIPTION

(split)

REF

1M

PARTS IDENTIFICATION/FUNCTION/PHOTOS

QUANTITY

REF

REF

REF

REF

REF

2M

3M

2SM

4SM

1 2 3 1 2

6SM

REF

12SM

REF

14SM

REF

2FM

REF

4SFM

2 Holds shortening and product

while unit is frying.

FUNCTION

l15 114225-1 Fryer back 1

l16 114163-1 Fryer back

17 114199-1 Fryer back

18 114345-1 Rear door 1 2 3 1 2 3 2 3 2 2

19 114146-2 Reset button (high

limit)

20 114344-1 Rear closure 1 2 3 1 2 3 2 3 2 2 Encloses lower portion of fryer

lItems not shown by photograph

1 2 3 2 4 6 3 5 2 4 Used to reset second high limit.

controls from dust etc.

1

the fat melt and high limit

thermostat.

back

115591-19

Page 20

PARTS LIST (Continued)

No.

Control panel cover

ITEM

PART No.

6 114194-8

DESCRIPTION

Mylar control panel

(single)

REF

REF

1M

2M

1 2 3

PARTS IDENTIFICATION/FUNCTION/PHOTOS

QUANTITY

REF

REF

REF

REF

REF

3M

2SM

4SM

6SM

12SM

REF

14SM

1 1 2

REF

2FM

REF

FUNCTION

4SFM

Protects metal control panel and

describes operators control.

7 114043-9

21 115563-1

21A 115563-G1 Wire harness (split)

22 115431-G1

23 114042-G1

23A 114042-G2 Control panel (split)

Mylar Control panel

(split)

Wire Harness

electric (single)

assembly

Control panel

(single)

1 2 3 1 2

1 2 3

1 1 2

1 2 3 1 1 2

1 2 3 1 2 3 2 3 2

1 2 3

1 1 2

1 2 3 1 2

24 111496-E4 Signal light (Red) 3 6 9 6 12 18

25 111496-B1 "On-Off" switch 1 2 3 2 4 6 3 5 2

26 111496-E6 Trouble light 1 2 3 2 4 6 3 5 2

27 111496-E3

28 114254-1

28A 115638-G1 Potentiometer

29 111496-B3 Test switch (red) 1 2 3 2 4 6 3 5 2

Heating light

(amber)

Potentiometer knob

assembly

1 2 3 2 4 6 3 5 2

1 2 3 2 4 6 3 5 2

1 2 3 2 4 6 3 5 2

9 15 6 12 1 st or 2nd high limit light, when

2 Protects metal control panel and

describes operators controls.

Wiring assembly that feeds

supply to fryer control circuit

2

2 Protects the connecting points

of the control panel

1 Supports operators controls,

switches, etc.

2

"On": Indicates that 1 st or 2nd

high limit thermostat has shut

down unit. Power light on

indicates electric supply is "On".

4 Controls electric supply to unit

4 Indicates solid state ignition

device has "locked out".

4 When on indicates temperature

control is calling for gas to

4 Sets shortening temperature

4 Sets shortening temperature

4 Bypasses temperature control

for testing of high limit

thermostats.

115591-20

Page 21

PARTS LIST (Continued)

ITEM

maintop.

olds temperature probe in place

racks (single)

tank

bottom

in proper place.

33 114176

-1

Element clamp

2 4 6 2 4 4

PART No. DESCRIPTION

No.

13 114224-G2 Frytank assembly

(single)

REF

REF

1M

2M

1 2 3

PARTS IDENTIFICATION/FUNCTION/PHOTOS

QUANTITY

REF

REF

REF

REF

REF

REF

REF

REF

3M

2SM

4SM

6SM

12SM

14SM

2FM

4SFM

1 1 2

FUNCTION

Holds shortening and product

while unit is operating.

14 114088-G2 Frytank assembly

(split)

9 111686-2 Hanger buttons 2 4 6 2 4 6 4 6 4 4 Allows basket hanger to rest on

5 114159-1 Probe tube 1 2 3 2 4 6 3 5 2 4 H

4 114206-1 Basket hanger 1 2 3 1 2 3 2 3 2 2 Holds probe tubes and fryer

30 114309-G1 Element head

assembly (single)

30A 114306-G1 Element head

assembly (split)

31 114214-2 Basket support

31A 114214-1 Basket support

racks (split)

32 114177-1 Element clamp

32A 114177-2 Element clamp top 4 8 12 4 8 12 8 12 8 8

34 114137-1 Double element

clamp angle.

35 111830-1 High limit bulb

clamp

1 2 3 1 2

1 2 3

1 2 3

2 4 6 2 4 6 4 10 4 4 Secures and positions elements

1 2 3

4 8 12 8 16 24 12 16 8 16 Secures and positions high limit

1 1 2 Supports fryer elements while

2 4 6 2 4

1 1 2 Supports fryer baskets while in

2 4 6 2 4

1 1 2

2

during unit operation

baskets in place.

allowing elements to be raised

and lowered inside the tank.

4

4

bulb to element assembly.

115591-21

Page 22

PARTS LIST (Continued)

2M

Secures and positions probe

degree of shortening heat for

ITEM

PART No. DESCRIPTION

No.

36 106666-42 Probe clamp 4 8 12 8 16 24 12 24 8 16

37 114142-1 Thermistor probe 1 2 3 2 4 6 3 6 2 4 A device which senses the

38 114027-1 Heating element

38A 114027-2 Heating element

38B 114027-3 Heating element

39 111830-2 Tube clamp-

*42 114146-2 Second high limit 1 2 3 2 4 6 3 5 2 4 A device which protects the

* = NOT SHOWN BY PHOTO

208V

240V

480V

capillary.

PARTS IDENTIFICATION/FUNCTION/PHOTOS

QUANTITY

REF

REF

REF

REF

REF

1M

6 12 18 6 12 18 12 18 12 12 Device which heats

4 8 12 4 8 12 8 12 8 8 Secures high limit capillary

3M

2SM

4SM

REF

6SM

REF

12SM

REF

14SM

REF

2FM

FUNCTION

REF

4SFM

to fryer element assembly.

the temperature control

shortening.

into

fryer in case the first high

limit should fail or the

solenoid becomes stuck in

the open position.

115591-22

Page 23

PARTS LIST (Continued)

115591-23

Page 24

PARTS LIST (Continued)

115591-24

Page 25

PARTS LIST (Continued)

5 114159

-1

Probe tube

1 2 3 2 4 6 2 5 2 4

Holds temperature probe

in place during unit operation.

*11

114244

-1

Blank mylar

1 1 Used to cover operators

QUANTITY

ITEM PART

No. No. DESCRIPTION 1M 2M 3M 2SM 4SM 6SM 12SM 14SM 2FM 4SFM FUNCTION

31 114214-2 Basket rack

(single)

31A 114214-1 Basket rack

(split

*Not shown by photo

REF REF REF REF REF REF REF REF REF REF

support

cover

PARTS IDENTIFICATION/FUNCTION/PHOTOS

1 1 1

1 1 2

2 4 6 2 4

Supports fryer basket while

in fryer tank.

4

area on frymate units. Blank

battery used as a work station .

115591-25

Page 26

PARTS LIST (Continued)

PART No. DESCRIPTION

No.

40 114197-01 Fry tank cover

40A 114541-G1 Fry tank cover

41 107023-1 Tank cover handle 1 2 3 1 2 3 2 3 2 2 Device used to lift cover "ON"

REF

1M

1 2 3

assembly (single)

assembly (split)

PARTS IDENTIFICATION/FUNCTION/PHOTOS

QUANTITY ITEM

REF

REF

REF

REF

REF

2M

3M

2SM

4SM

2 4 6 2 4

6SM

REF

12SM

REF

REF

2FM

14SM

1 1 2

FUNCTION

REF

4SFM

Covers vat while fryer is not in

use

4

and "OFF".

REF - FRYER TANK COVER-SINGLE AND SPLIT

115591-26

Page 27

PARTS LIST (Continued)

No.

(single)

component locations.

1

1

PARTS IDENTIFICATION/FUNCTION/PHOTOS

REF

2SM

QUANTITY

REF

REF

4SM

6SM

1 1 1 1

REF

12SM

REF

14SM

1 1 1

ITEM

PART No.

8 114123-G1

43 113810-4

44 115523-D Important decal 1 1 1 1 1 1 1 1 1

45 114245-1

45A 114246-1 Drain pipe hook

46 114098-2 Drain pipe 1 1 1 1 1 1 1 1 1

47 115529-D

47A 115530-D Wiring decal (split)

DESCRIPTION

Fryer door panel

assembly

Electric rating plate

Drain pipe hook

(bottom)

Wiring decal

REF

REF

2M

REF

3M

1M

1 2 3 1 2 3 2 3 2

1 2 3 1 2 3 2 3 2

1 1 1 1 1 1 1 1 1

1 1 1

REF

2FM

REF

FUNCTION

4SFM

2 Closes off fryer front and

protects control area.

1 Plate which describes model

number, serial number and unit

voltage.

1 Informs installation, service and

operation personnel of proper

procedures.

1 Supports drain pipe.

1 Used to draw shortening from

frytank.

Describe wiring and electrical

115591-27

Page 28

PARTS LIST (Continued)

PARTS IDENTIFICATION/FUNCTION/PHOTOS

PART No.

No.

48 114164-1

49 114165-1 Contactor cover 1 2 3 1 2 3 2 3 2

50 114166-1

51 108834-1 Door magnet 1 2 3 1 2 3 2 3 2

*52

112779-1

52A

112779-2

53 113797-1

54 106715-1

55 114212-1 1" ball valve, left 1 2 3 1 2 3 2 3 2

55A 114212-2

*46 114098)2 Drain pipe 1 1 1 1 1 1 1 1 1

+*56 115502-1

+*56A 115502-2

115591-28

DESCRIPTION

REF

REF

2M

REF

3M

1M

Power supply cab.

Terminal block

Door hinge

(bottom) Door

hinge (top)

Disconnect caution

decal

Turn disconnect

decal

1" ball valve, right

closure, top front 1 2 3

Closure, top front

1 2 3 1 2 3 2 3 2

1 2 3 1 2 3 2 3 2

1 2 3 1 2 3 2 3 2

1 2 3 1 2 3 2 3 2

1 2 3 1 2 3 2 3 2

QUANTITY ITEM

REF

REF

REF

2SM

4SM

1 2 3 1 2

1 2 3 1 2

6SM

REF

12SM

1 1 2

REF

14SM

REF

2FM

FUNCTION

REF

4SFM

2 Houses fryer cabinet power

supply

2 Encloses contactor area.

2 Encloses terminal block area.

2 A magnetic catch which holds

the door in the closed position.

2 Supports and allows door rod to

swing open and closed freely

2 A caution signal for service

personnel.

2 A caution signal for service

personnel.

2 Adjustable flow valves used to

drain shortening from fry tank.

2

1 Used to drain shortening from

fryer tank.

Encloses top front section of

2

Page 29

PARTS LIST (Continued)

+*57A

PARTS IDENTIFICATION/FUNCTION/PHOTOS

ITEM

PART No.

No.

+*57 115505-1 Closure bottom left 1 2 3

115508-1

+*57B

115506-1

+*57C

115507-1

*= Not shown by photograph

+= Note photos show old style closures

DESCRIPTION

Closure bottom Rt.

Closure bottom Lt.

Closure bottom Rt.

REF

REF

REF

1M

2M

3M

1 2 3

REF

2SM

1

1

QUANTITY

REF

4SM

2

2

REF

6SM

3

3

REF

REF

REF

12SM

14SM

1 1 2

1

1

1

1

2

2

2FM

2

2

FUNCTION

REF

4SF

Enclosed lower section

2

M - UNITS SM - UNITS

115591-29

Page 30

PARTS LIST (Continued)

ITEM PART

No. No. DESCRIPTION 1M 2M 3M 2SM 4SM 6SM 12SM 14SM 2FM 4SFM FUNCTION

58 110472-8 Terminal block 1 2 3 1 2 3 2 3 2 2 Wire connection heater power 3 Ph.

*58A 110472-9 Terminal block 1 1 1 1 1 1 1 1 1 1 Neutral connection

59 114208-1 Barrier strip 1 2 3 1 2 3 2 3 2 2 Wire connection - control power 1 Ph.

60 111497-C1 Cont. 3-pole, 30A

60A 111497-C6 Cont. 3-pole, 50A 1 2 3

*60B 111497-C2 Cont. 3-pole, 30A

*60C 111497-C7 Cont. 3-pole, 50A 1 2 3

61 3.1500 Ground lug 1 2 3 1 2 3 2 3 2 3 A device used to ground electrical

62 110711-1 Ground label 1 2 3 1 2 3 2 3 2 3 Identifying label for ground lug.

*63 114166-1 Terminal block cover 1 2 3 1 2 3 2 3 2 2 Metal plate used to cover terminal

*64 114470-1 Decal for wiring plans 1 2 3 1 2 3 2 3 2 2 Describes wiring details.

115591-30

208/240, 220/380 &

240/415 volt

220/380, 240/415V

208/240 & 480 volt

220/380,240/415 volt

220/380,240/415 volt

located behind

terminal block cover.

PARTS IDENTIFICATION/FUNCTION/PHOTOS

QUANTITY

REF REF REF REF REF REF REF REF REF REF

2 4 6 2 4

1 1 2

2 4 6 2 4

1 1 2

4 An electronically controlled switch

4

which turns the fryer "ON" and "OFF".

wiring.

block area.

Page 31

PARTS LIST (Continued)

4

4

ITEM PART

No. No. DESCRIPTION 1M 2M 3M 2SM 4SM 6SM 12SM 14SM 2FM 4SFM FUNCTION

*65 114165-1 Contactor cover 1 2 3 1 2 3 2 3 2 2 Protects contactors.

66 111497-R1 Mercury relay 1 2 3

66A 111497-R3 Mercury relay

*66B 111497-R2 Mercury relay 1 2 3

*66C 111497-R4 Mercury relay

*74 113799-2 Fuse 2 4 6 2 4 6 4 6 4 4 Circuit protection for

*75 113807-1 Fuse holder 2 4 6 2 4 6 4 6 4 4 Device used to mount fuse

* =Not shown by photograph

208/240 & 480V

(single)

208/240 & 480V

(split)

220/380V, 240/415V

(single)

220/380V, 240/415V

(split)

PARTS IDENTIFICATION/FUNCTION/PHOTOS

QUANTITY

REF REF REF REF REF REP REF REF REF REF

1 1 2

2 4 6 2 4

1 1 2

2 4 6 2 4

control circuit

and fan.

to fryer.

M-Units SM-Units

115591-31

Page 32

PARTS LIST (Continued)

ITEM

PART No. DESCRIPTION

No.

13 114224-G2

Tank assembly

(single)

REF

REF

2M

1M

1 2 3

PARTS IDENTIFICATION/FUNCTION/PHOTOS

QUANTITY

REF

REF

REF

REF

REF

REF

REF

3M

2SM

4SM

6SM

12SM

14SM

1 1 2

2FM

REF

4SFM

FUNCTION

Holds shortening and product

while unit is operating

14 114088-G2

67 106363-1

68 102570-3 Eye bolt 2 4 6 2 4 6 4 6 4 4 Secures spring in place

*69 114195-1 Wire channel 1 2 3 1 2 3 2 3 2 2 Protects wiring from abrasions.

Tank asssembly

(split)

Element head

springs

2 4 6 2 4 6 4 6 4 4

1 2 3 1 2

2 Holds shortening and product

Controls tension placed on

element heads as elements are

raised and lowered from frytank.

* = Not shown by photograph

M-Units SM-Units

115591-32

Page 33

PARTS LIST (Continued)

Controls: Fat melt timing

temperature

package.

ITEM

No.

PART No. DESCRIPTION

REF

1M

PARTS IDENTIFICATION/FUNCTION/PHOTOS

QUANTITY

REF

REF

REF

REF

REF

REF

2M

3M

2SM

4SM

6SM

12SM

REF

14SM

REF

2FM

REF

4SF

FUNCTION

70 415144-12 Control closure 1 2 3 1 2 3 2 3 2 2

71

72 115207-1 Mini-fan 1 2 3 1 2 3 2 3 2 2

21

*21 A

73 113840-2

115562-G1

115562-G1

* = Not shown

Multi-function

temperature control

board.

Wire harness

assembly (single)

Wire harness

assembly (split)

Thermostat snap

disc

1 2 3 2 4 6 3 4 2 4

1

2

3

1

2

1

2

3

1

1 2 3 1 2 3 2 3 2 2

2

Encloses control area and

houses the temp. control board.

Fat melt temperature

First high limit trip

cooking

in fry vat.

Provides cooling air for control

2

Wiring assembly that feeds

electrical supply to fryer control

circuits.

2

Turns on cooling fan when

compartment temperature

exceeds 100°F.

M -Unit shown

115591-33

Page 34

MANUAL ASSEMBLY 115591-G1

I.S.P. MANUAL FOR REF SERIES FRYERS

SIGN MANUAL 115591-G1 SUB NO. SHEET PART NO. AFFECTED DATE

D.M.L. 0 115591-1 THRU-34 10/2/85

D.M.L. 1 115591-33 7/13/92

Loading...

Loading...