Page 1

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MA 21222

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-30832 (10-15)

MODELS

MG12 ML-52549

MG24 ML-52514

MG36 ML-52522

MG48 ML-52523

MG60 ML-52524

For additional information on Vulcan or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanequipment.com

INSTALLATION & OPERATION MANUAL

FOR MG SERIES GAS RESTAURANT

MODULAR RANGE

Page 2

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS AT MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury, or death.

Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO OPERATE THIS

DEVICE.

__________________________________________________________________________________

2

Page 3

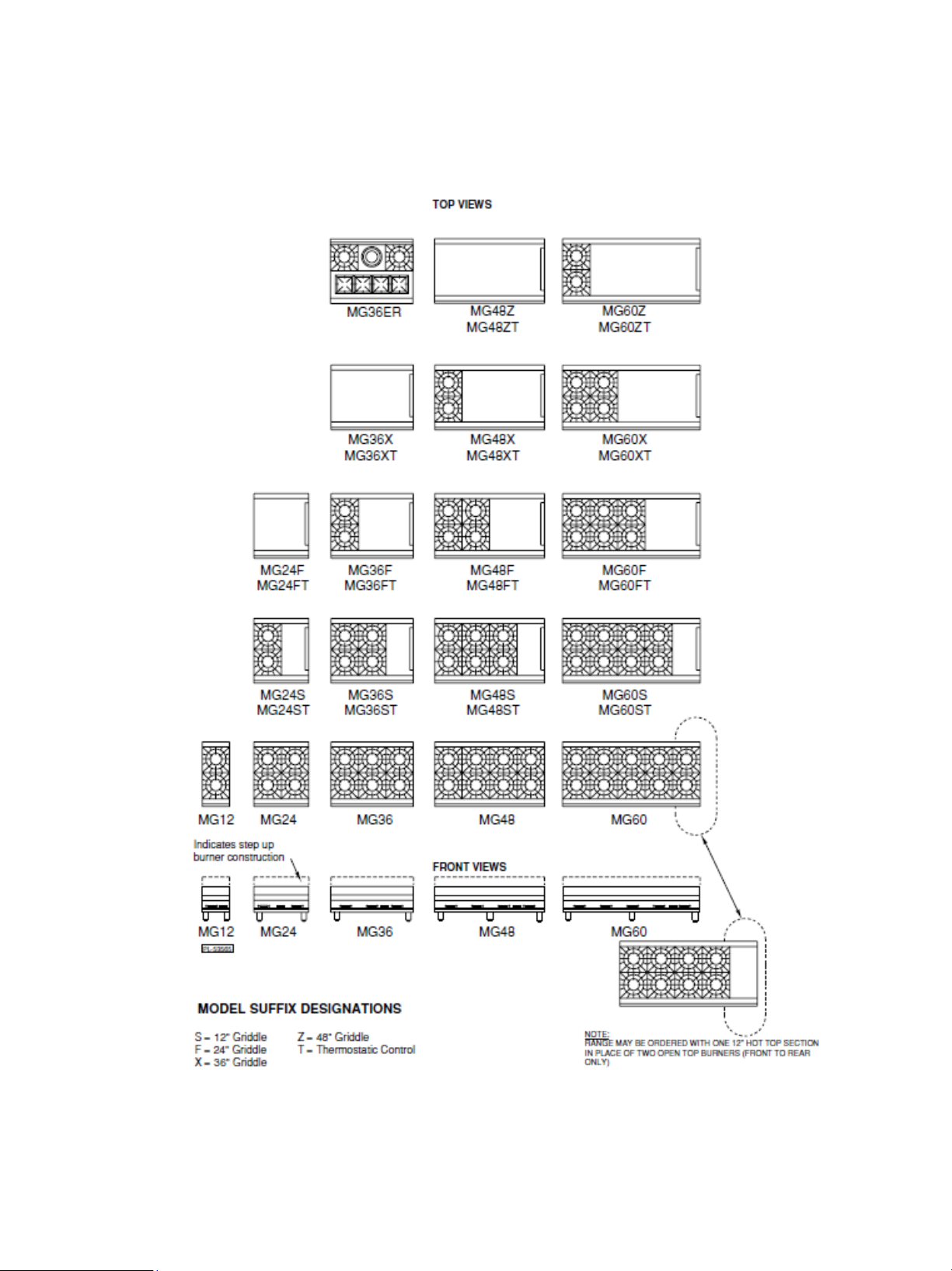

MG SERIES GAS RESTAURANT MODULAR RANGE

MODELS

__________________________________________________________________________________

3

Page 4

MG SERIES GAS RESTAURANT MODULAR RANGE MODELS……………………

3 INSTALLATION……………………………………………………………………………..

5 Uncrating…………………………………………………………………………....

5 Location……………………………………………………………………………..

6 Installation Codes And Standards……………………..…………………………

6 Assembly……………………………………………………………………………

6 Leveling……………………………………………………………………………...

11 Gas Connections…………………………………………………………………...

11 Testing The Gas Supply System…………………………………………………

12 Flue Connections…………………………………………………………………..

12 Lighting And Shutting Down The Pilots………………………………………….

12

OPERATION………………………………………………………………………………..

14 Controls……………………………………………………………………………...

14 Before First Use…………………………………………………………………….

14 Preheating……………………………………………………………………….….

14 Cleaning……………………………………………………………………….…….

15 MAINTENANCE…………………………………………………………………………….

16

TABLE OF CONTENTS

__________________________________________________________________________________

4

Page 5

Installation, Operation and Care of MG SERIES GAS RESTAURANT

MODULAR RANGE

KEEP THIS MANUAL FOR FUTURE REFERENCE

Vulcan ranges are produced with quality workmanship and material. Proper installation, usage and

maintenance of your range will result in many years of satisfactory performance.

The manufacturer suggests that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

INSTALLATION

UNCRATING

This range was inspected before leaving the factory. The carrier assumes full responsibility for the safe

delivery upon acceptance of the shipment. Check for possible shipping damage immediately after receipt.

If the range is found to be damaged, complete the following steps:

1. Carrier must be notified within 5 business days of receipt.

2. Carrier’s local terminal must be notified immediately upon discovery (note time, date, and

who was spoken to), and follow up and confirm with written or electronic communication.

3. All original packing materials must be kept for inspection purposes.

4. The range cannot have been moved, installed, or modified.

5. Notify Vulcan Customer Service immediately at 800-814-2028.

Carefully uncrate range and place in a work-accessible area as near to its final installed position as

possible. Remove all shipping wire and wood blocking.

Before installing, verify that the type of gas supply (natural or propane) agrees with the specifications on

the rating plate located under the left-hand cooking top, mounted to the side wall of the range.

If the supply and equipment requirements do not agree, do not proceed with the installation. Contact your

dealer or Vulcan-Hart Company immediately.

LOCATION

The equipment area must be kept free and clear of combustible

substances.

A standard 20,000 BTU burner input range must have a minimum clearance from combustible

construction of 6" (15 cm) at the sides and 6" (15 cm) at the rear.

A standard 26,000 BTU burner input range must have a minimum clearance from combustible

construction of 10" (25 cm) at the sides and 6" (15 cm) at the rear.

Step-up ranges using 20,000 or 26,000 BTU input burners must have a minimum clearance from

combustible construction of 10" (25 cm) at the sides and 6" (15 cm) at the rear.

The installation location must allow adequate clearances for servicing and proper operation.

__________________________________________________________________________________

5

Page 6

The range must be installed so that the flow of combustion and ventilation air will not be

obstructed. Adequate clearance for air openings into the combustion chamber must be

provided. Make sure there is an adequate supply of air in the room to allow for combustion of

the gas at the burners.

INSTALLATION CODES AND STANDARDS

For proper installation procedures in the United States of America, refer to:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1 (latest edition). Copies may be obtained from The

American Gas Assn., Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. National Electrical Code ANSI/NFPA-70 (latest edition). Copies may be obtained from The

National Fire Protection Assn., Batterymarch Park, Quincy, MA 02269.

In Canada, refer to:

1. Local codes.

2. CAN/CGA-B149.1 Installation for Natural Gas Burning Appliances and Equipment (latest

edition).

3. CAN/CGA-B149.2 Propane Installation Code (latest edition), available from The Canadian

Standards Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

ASSEMBLY

Installation of Standard Griddle Top Bricks

The griddle top section is extremely heavy. It will require three people to install the griddle and

griddle brick — two people to lift the griddle plate and one person to set the bricks and griddle

thermostat capillary bulb(s) in place.

The range griddle top section utilizes a two-fold baffle assembly to support the composite/mortar

fire bricks. There will always be only one small 61⁄2" (16 cm) wide baffle assembly with every

griddle top order. There will be at least one 97⁄8" (24 cm) wide baffle assembly per griddle,

possibly more, depending on the griddle width.

The 61⁄2" (16 cm) wide baffle will utilize two 10" x 4" (25 cm x 10 cm), and two 7" x 4" (17 cm x

10 cm) brick sets.

The 97⁄8" (25 cm) wide baffle assembly will utilize two 10" x 4" (25 cm x 10 cm), and two 7" x 4"

(17 cm x 10 cm) brick sets.

1. The griddle bricks are shipped in a rectangular cardboard box. Locate the box and carefully

inspect quantities as explained above.

If a brick has been broken into two pieces, it can still be used. Just place the pieces

into position as shown in Fig. 1. However, if a brick is broken into more than two pieces, it will

need to be replaced. Contact your local Vulcan servicer.

2. Clean anti-rust coating from top of griddle, following the procedures described in the

__________________________________________________________________________________

6

Page 7

CLEANING – GRIDDLE PLATE section of this manual.

3. Remove griddle plate. With one person at either side of the griddle, gently lift griddle straight

up. DO NOT pull griddle forward until the third person has checked to ensure that the

capillary bulb(s) (thermostatically controlled models only) are freed from the underside of the

of the griddle plate. If bulb(s) are still attached to the griddle, pull capillary bulb(s) wire gently

through the “V” shield(s) until the bulbs are free.

4. Rest the griddle plate in a secure place.

5. Thermostatically controlled griddles are shipped without the thermostat bulb in the “V” shield.

The bulb must be installed by the installer to prevent damage to the griddle and the

thermostat (not covered by the warranty). Exercise caution when placing brick in a

thermostatically controlled griddle section. DO NOT hit thermostat bulb while installing bricks.

The thermostat bulb is a sensitive device and may be easily knocked out of adjustment.

Into the 6-½" (16 cm) wide baffle, install:

a. Two 10" x 4" (25 cm x 10 cm) bricks, placing the miter edge, one to each side of the front

burner baffle area (Fig. 1).

b. Two 7" x 4" (17 cm x 10 cm) bricks, one to each side of the rear burner baffle area (Fig. 1).

Fig. 1

6. Into the 9-⅞" (24 cm) wide baffle, install:

a. Two 10" x 4" (25 cm x 10 cm) bricks, placing the miter edge, one to each side of the front

burner baffle area (see Fig. 1).

__________________________________________________________________________________

7

Page 8

b. Two 7" x 4" (17 cm x 10 cm) bricks, one to each side of the rear burner baffle area (see

Fig. 1).

7. If the burner has been strapped down, use wire cutters to remove the wire strapping device.

8. Check to ensure that all bricks and burners are secure.

9. Carefully replace the griddle top section. Be sure that the griddle capillary and bulb(s) are not

in a position to be damaged.

a. Gently pull the griddle capillary toward the front of the range and out from under the

griddle area.

b. While two people (one to each side of the griddle) are lowering the griddle into place,

the third person must gently feed the griddle thermostat bulb(s) through the “V”

shield(s) until completely covered. Ensure that the capillary is not positioned over the

burner flame pattern.

c. Continue to lower the plate into place until it is resting evenly on top of the range.

Installation of Hot Top Bricks

The range hot top sections utilize composite/mortar fire bricks for heat distribution to the burners.

Install these bricks before connecting the gas supply line or installing the back riser.

There should be one box of bricks per hot top section.

1. The composite/mortar bricks are shipped in a rectangular cardboard box. Locate the box and

carefully remove two 10" x 4" (25 cm x 10 cm), and two 7" x 4" (17 cm x 10 cm) bricks.

If a brick has been broken into two pieces, it can still be used. Just place the pieces into

position as shown in Fig. 1. However, if a brick is broken into more than two pieces, it will need to be

replaced. Contact your local Vulcan servicer.

2. Rest the hot top plate in a secure area.

3. Install two 10" x 4" (25 cm x 10 cm) composite/mortar bricks, placing the miter edge, one to

each side of the front burner baffle area (see Fig.1).

4. Install two 7" x 4" (17 cm x 10 cm) bricks, one to each side of the rear burner baffle area (see

Fig. 1).

5. If the burner has been strapped down, use wire cutters to remove the wire strapping device.

6. Check to ensure that all bricks and the burner are secure. Carefully replace the hot top

section on top of the range.

__________________________________________________________________________________

8

Page 9

MODELS

MG12

MG24

MG36

MG48

MG60

MG36ER

Std. 4" (10 cm)

High

Backsplash (1)

Std. 4" (10 cm)

High

Backsplash (1)

Std. 11" (27 cm)

High

Backsplash (1)

Std. 11" (27 cm)

High

Backsplash (1)

Std. 11" (27 cm)

High

Backsplash (1)

Std. 5" (12 cm)

High Backsplash

(1)

Backsplash

Channel (2)

Backsplash

Channel (2)

Backsplash

Channel (2)

Backsplash

Channel (2)

Backsplash

Channel (2)

Backsplash

Channel (2)

Heat Shield (1)

Heat Shield (1)

Heat Shield (1)

Heat Shield (1)

Heat Shield (1)

Heat Shield (1)

Backsplash

1 Remove the backsplash components from the crating materials.

2 Check the backsplash component parts against the list below to ensure that all the

required parts for the backsplash installation have been obtained.

• If any parts are missing, contact your dealer or closest parts depot immediately.

Fig. 2

3 Assemble the required components as shown in Fig. 2.

4 Lift the assembly up and slide the channels into the space provided at the rear of the

range – this may require two people.

__________________________________________________________________________________

9

Page 10

5 It may be necessary to pull the heat shield bottom out slightly in order to clear the flue

box. Be sure the backsplash is resting evenly and the channel holes are lining up with

the holes provided in the right- and left-hand body side (see Fig’s. 3 & 4).

Fig. 3 Fig. 4

Fig. 5

6. Install six #10 sheet metal screws (3 to each channel leg) (Fig. 5).

__________________________________________________________________________________

10

Page 11

LEVELING

Check the leveling of the range. Place a carpenter’s level across the range top plates. Level

front to back and side to side.

To adjust the leveling, tilt the range to one side and, using channel locks, unscrew the

adjustable leg insert as required. Repeat this procedure as necessary for each leg.

GAS CONNECTIONS

All gas supply connections and any pipe joint compound used must

be resistant to the action of propane gases.

Connect gas supply. Make sure the pipes are clean and free of obstructions. Codes require that

a gas shutoff valve be installed in the gas line ahead of the range. Standard ranges are

equipped with fixed burner orifices which coincide with installation elevation. Install the gas

pressure regulator. Before installing, ensure that regulator supplied agrees with rating plate gas

supply.

The gas pressure regulator is NOT factory installed. The

regulator for this gas type is packaged with the range. This

regulator must be field installed by a qualified installer.

Natural gas regulators are preset for 4.0" W.C. (Water

Column); propane gas regulators for 10.0" W.C.

1. Locate ¾" (1.9 cm) gas connection pipe extending

from rear of range.

2. Cover pipe threads with leak sealant.

3. Screw regulator hand-tight onto pipe with regulator

arrow pointing towards range body back (Fig. 6).

4. Using pipe wrench, tighten regulator securely in an

upright position (Fig. 6).

Fig. 6

The arrow on the regulator shows the direction of the gas flow (Fig. 6). The pressure regulator

must be mounted horizontally to ensure proper preset outlet pressure. If the regulator is

installed in any other position, the outlet pressure must be reset for proper operation.

A leak limiter is supplied with every regulator to allow excess gas pressure to escape. Do not

obstruct leak limiter on gas pressure regulator, because obstruction may cause regulator to

malfunction.

__________________________________________________________________________________

11

Page 12

Prior to lighting, check all joints in the gas supply line for leaks. Use

a soap and water solution. Do not use an open flame.

After piping has been checked for leaks, all piping receiving gas should be fully purged to

remove air.

TESTING THE GAS SUPPLY SYSTEM

When gas supply pressure exceeds 1⁄2 psig (3.45 kPa), the range and its individual shutoff valve

must be disconnected from the gas supply piping system.

When gas supply pressure exceeds 1⁄2 psig (3.45 kPa) or less, the range should be isolated from

the gas supply system by closing its individual manual shutoff valve until the range is ready for

start-up.

FLUE CONNECTIONS

DO NOT obstruct the flow of flue gases from the flue located on the rear of the range. It is

recommended that the flue gases be ventilated to the outside of the building through a

ventilation system installed by qualified personnel.

From the termination of the flue to the filters of the hood venting system, a minimum clearance

of 18" (45 cm) must be maintained.

Information on the construction and installation of ventilating hoods may be obtained from the

standard, “Vapor Removal from Cooking Equipment,” NFPA No. 96 (latest edition), available

from The National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

LIGHTING AND SHUTTING DOWN PILOTS

All adjustment procedures associated with initial start-up should be performed by an authorized

Vulcan installation or service person.

Hot Top and Griddle Top Burners

1 Turn main gas supply ON.

2 Turn all top burner valve knobs ON to purge gas line of air.

3 Turn top burner valve knobs OFF.

4 Wait 30 seconds.

5 Using a taper, light the hot top or griddle top pilot.

6 If pilot fails to light, wait 5 minutes and repeat Steps 1 through 5.

7 Turn one hot top or griddle top burner valve ON to ensure that all gas lines are

completely purged of air. Turn burner valve OFF when gas begins to flow.

__________________________________________________________________________________

12

Page 13

Nightly Shutdown

Turn burner valve OFF; pilot will remain lit.

Complete Shutdown

1 Turn burner valve OFF; pilot will remain lit.

2 Turn main gas supply OFF.

Open Top Burners

1 Turn main gas supply ON.

2 Turn all top burner valve knobs ON to purge gas line of air.

3 Turn top burner valve knobs OFF.

4 Wait 30 seconds.

5 Using a taper, light the open top pilot (Fig. 7).

Fig. 7

6 f pilot fails to light, wait 5 minutes and repeat Steps 1 thru 5.

7 Turn one open top burner valve ON to ensure that all gas lines are completely purged of

air. Turn burner OFF when gas begins to flow.

Nightly Shutdown

Turn burner valve OFF; pilot will remain lit.

Complete Shutdown

1 Turn burner valve OFF; pilot will remain lit.

2 Turn main gas supply OFF.

__________________________________________________________________________________

13

Page 14

OPERATION

The range and its parts are hot. Be very careful when operating,

cleaning or servicing the range.

CONTROLS

OPEN TOP BURNER KNOB — Regulates gas flow to top burners. To increase heat, turn knob

counterclockwise; to decrease, turn knob clockwise.

HOT TOP OR GRIDDLE TOP BURNER KNOB — Regulates gas flow to the hot top or griddle

top burner. To increase heat, turn knob counterclockwise; to decrease, turn knob clockwise.

BEFORE FIRST USE

Griddle Seasoning

This griddle plate is steel, but the surface is relatively soft and can be scored or

dented by the careless use of a spatula or scraper. Be careful not to dent, scratch, or gouge the

plate surface. Do not try to knock off loose food that may be on the spatula by tapping the

corner edge of the spatula on the griddle surface.

A new griddle surface must be seasoned to do a good cooking job. The metal surface of the

griddle is porous. Food tends to get trapped in these pores and stick; therefore, it is important to

“season” or “fill up” these pores with cooking oil before cooking. Seasoning gives the surface a

slick, hard finish from which the food will release easily.

To season, heat griddle top section at a low burner setting. Pour one ounce of cooking oil per

square foot of surface over the griddle top section. With an insulated cloth, spread the oil over

the entire griddle surface to create a thin film. Wipe off any excess oil with an insulated cloth.

Repeat this procedure 2 to 3 times until the griddle has a slick surface.

PREHEATING

Hot Top and Griddle Top Burners

Turn burner “ON” to highest heat to heat hot top section quickly. Hot top or griddle top will be

ready to cook on in about 10 minutes. After top section has reached operation temperature, turn

some of the burners down. You will save as much as 80% of gas consumption and notice very

little difference in cooking performance as long as you have allowed the entire hot top or griddle

top section to preheat properly.

Open Top Burners

Open top burners ignite quickly and do not require any preheating time. When food comes to a

rolling boil, cut back to slower boil to conserve energy, yet continue boiling. Turn burners ON

only when in use.

__________________________________________________________________________________

14

Page 15

CLEANING

Do not use Dawn® dish detergent to clean the exterior or interior components of the range.

Do not use scouring powder; it is extremely difficult to remove completely and can build up

accumulations that will damage the oven. Vulcan painted surfaces may be cleaned using a soft

cloth and mild detergent solution.

Ranges

Daily

While still warm, wipe top with a soft cloth or other grease absorbing material to remove

spillovers, grease, etc., before they burn in. A crust on top of the hot top range looks unsightly

and slows down cooking speed because it reduces the flow of heat to the utensil.

Empty the grease pan daily or as often as necessary. It is recommended that the grease pan be

emptied whenever it is ¾ filled. The drip shield, grids and grease pan should be washed with a

mild grease-dissolving solution.

Remove the grease pan slowly and be careful of liquid wave action.

Clean cast iron open top grates with a mild soap and water solution. Rinse thoroughly and dry

with a clean, water-absorbent towel. Immediately after drying (with grates still removed from the

range top), season grates lightly with liquid vegetable or Pam® spray-type cooking oil.

After seasoning, replace grates onto the range. Turn all open top sections ON LOW and allow

them to burn for at least 15 minutes before using pots or pans on the range top.

Season the open top grates after each cleaning. Failure to season grates will cause grates to

rust.

Weekly

Boil burners in a solution of washing soda. Rinse and dry parts thoroughly. Flash rusting may

occur. This is a normal condition and will not affect performance or the product.

When reinstalling the burner back onto the range, be sure the burner heads are properly

connected. Do not light the pilot or turn burner valve ON with the burner head removed.

Griddle Plate

Cleaning the griddle section will produce evenly cooked, perfectly browned griddle products and

will keep the cooking surface free from carbonized grease. Carbonized grease on the surface

hinders the transfer of heat to the food. This results in loss of cooking efficiency and spotty

browning which gives foods an unappetizing appearance. To keep the griddle clean and

operating at peak efficiency, follow these simple instructions:

After Each Use

Carefully clean griddle with wire brush or flexible spatula.

__________________________________________________________________________________

15

Page 16

Daily

Thoroughly clean backsplash, sides and front. Remove grease drip tray and pan, empty and

wash out in the same manner as any ordinary cooking utensil.

Clean griddle surface thoroughly. If necessary, use a griddle stone, wire brush or steel wool

over the surface. Rub with the grain of the metal while still warm. A detergent may be used on

the plate surface to help clean it, but the cleaner must be thoroughly removed. After removal of

detergent, the surface of the plate must be reseasoned with a thin film of oil to prevent rusting

and food sticking.

If the griddle is to be shut down for an extended period, put a heavy coat of grease over the

griddle plate.

MAINTENANCE

The range and its parts are hot. Be very careful when operating,

cleaning or servicing the range.

VENT

When cool, check the flue vent every six months for obstructions.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this modular range, contact the Vulcan

Service Contractor in your area. For a complete listing of service and parts depots refer to

www.vulcanequipment.com .

__________________________________________________________________________________

16

Page 17

16

__________________________________________________________________________________

www.vulcanequipment.com.

Pour obtenir une liste complète des dépôts de service et de pièces de rechange, visitez le site

concernant cette cuisinière modulaire, contactez l’agence de service Vulcan de votre région.

Pour trouver de l’information touchant le service technique et les pièces de rechange

INFORMATION SUR LE SERVICE TECHNIQUE ET LES PIÈCES DE RECHANGE

obstructions.

À tous les six mois, le conduit de cheminée doit être vérifié à froid pour y déceler des

VENTILATION

lors de l’emploi, du nettoyage ou de l’entretien de la cuisinière.

La cuisinière et ses composants sont chauds. Soyez très prudent

MAINTENANCE

sur la plaque lisse.

Si le gril doit être fermé pendant une période prolongée, posez une épaisse couche de graisse

aliments de coller.

être culottée de nouveau avec une mince couche d’huile pour prévenir la rouille et empêcher les

détergent doit être totalement retiré. Après avoir retiré le détergent, la surface de la plaque doit

encore chaud. Vous pouvez utiliser un détergent sur la surface pour aider au nettoyage, mais le

d’une brosse ou d’une laine d’acier sur la surface. Frottez dans le sens du métal quand il est

Nettoyez minutieusement la surface du gril lisse. Si nécessaire, servez-vous d’une pierre à gril,

graisse, videz-les et lavez-les de la même méthode que n’importe quel ustensile de cuisine.

Nettoyez soigneusement le dosseret, les côtés et le devant. Retirez le plateau et le bac à

Quotidiennement

Nettoyez soigneusement le gril lisse avec une brosse d’acier et une spatule flexible.

Après chaque utilisation

aux aliments une apparence peu appétissante.

pour résultat des pertes d’efficacité de cuisson et causeront un brunissement inégal qui donnera

carbonisées sur la surface empêchent le transfert de la chaleur vers les aliments. Elles auront

brunis, en plus de garder la surface de cuisson libre de toute graisse carbonisée. Les graisses

Le nettoyage d’une plaque lisse produira des aliments grillés uniformément et parfaitement

Gril lisse

Page 18

15

__________________________________________________________________________________

la tête a été enlevée.

accouplées correctement. N’allumez pas la veilleuse ou n’ouvrez pas le robinet d’un bruleur si

Quand vous remettez les brûleurs en place sur la cuisinière, assurez-vous que les têtes sont

conséquence normale et n’affectera pas le rendement du produit.

pièces minutieusement. Il se peut qu’il se produise une rouille de surface. Ceci est une

Faites bouillir les brûleurs dans une solution de bicarbonate de soude. Rincez et asséchez les

Sur une base hebdomadaire

rouilleront.

Huilez les grilles des surfaces à feu nu après chaque nettoyage. Si vous ne le faites pas, elles

ou des casseroles sur la cuisinière.

INTENSITÉ et laissez-les chauffer pendant au moins 15 minutes avant d’utiliser des chaudrons

Après les avoir huilées, replacez les grilles sur la cuisinière. Allumez tous les feux nus à BASSE

.

®

légère couche d’huile végétale ou d’un corps gras pulvérisé de type Pam

avoir asséché les grilles (encore séparées de la surface de la cuisinière), enduisez-les d’une

soigneusement et asséchez-les avec une serviette propre qui absorbe l’eau. Aussitôt après

Nettoyez les grilles en fonte des feux nus avec une solution de savon doux et d’eau. Rincez-les

vagues du liquide.

Déplacez le bac à graisse lentement et méfiez-vous de l’action de

le bac à graisse devraient être lavés dans une solution de dissolvant à graisses doux.

vider le bac à graisse aussitôt qu’il est au ¾ plein. La protection anti-égouttement, les grilles et

Videz le bac à graisse quotidiennement ou aussi souvent que nécessaire. Il est recommandé de

cuisine.

ralentissent la vitesse de cuisson car elles réduisent le transfert de la chaleur aux ustensiles de

Les croûtes qui se forment sur le dessus des plaques à bouillir sont disgracieuses et

matériau absorbant pour retirer les renversements, la graisse etc., avant qu’ils ne s’incrustent.

Pendant qu’elle est encore chaude, nettoyez la surface avec un linge propre ou un autre

Quotidiennement

Les cuisinières

Vulcan peuvent être nettoyés à l’aide d’un chiffon propre et d’une solution de savon doux.

peut aboutir à des accumulations qui vont endommager le four. Les revêtements peints de

N’employez pas de poudre à récurer; elle est extrêmement difficile à essuyer complètement et

de la cuisinière.

pour nettoyer les composants extérieurs et intérieurs

®

N’utilisez pas le savon à vaisselle Dawn

NETTOYAGE

continuant à bouillir. Allumez les brûleurs seulement si vous les utilisez.

Page 19

14

__________________________________________________________________________________

Lorsqu’un aliment parvient à grande ébullition, réduisez le feu pour économiser l’énergie tout en

Les brûleurs à feu nu s’allument rapidement et n’exigent pas de période de réchauffement.

Les brûleurs à feu nu

permis à la surface de plaque à bouillir ou au gril lisse de préchauffer de la bonne façon.

verrez très peu de différence dans les performances de cuisson en autant que vous ayez

certains brûleurs. Vous allez économiser jusqu’à 80% dans votre consommation de gaz et

Une fois que la surface sera montée à la température de fonctionnement, baissez le feu de

rapidement. Celle-ci, de même qu’un gril lisse, sera prête à la cuisson dans environ 10 minutes.

Allumez les brûleurs à l’intensité maximale pour chauffer une surface de plaque à bouillir

Brûleurs sur les plaques à bouillir et les grils lisses

RÉCHAUFFEMENT

Répétez cette procédure 2 ou 3 fois jusqu’à ce que le gril ait une surface luisante.

un chiffon isolé.

l’huile sur toute la surface du gril pour former une couche mince. Essuyez l’excès d’huile avec

). À l’aide d’un chiffon isolé, étendez

2

cuisson par pied carré de surface de grillage (30ml/dm

Pour le culottage, chauffez la surface du gril lisse à basse intensité. Versez une once d’huile à

aliments.

cuisson. Le culottage donne à la surface un fini luisant et dur d’où il sera facile de détacher les

conséquent important de « culotter » ou de « remplir » ces pores avec de l’huile avant la

du gril est poreuse. Les aliments ont tendance à se coincer dans ces pores et à coller; il est par

Pour qu’elle cuise bien, la surface d’un nouveau gril lisse doit être culottée. La surface de métal

partir des aliments collés sur une spatule en la frappant sur la surface du gril.

attention de ne pas bosseler, rayer ou creuser la surface de la plaque. N’essayez pas de faire

marquée ou bosselée par l’usage négligent d’une spatule ou d’un grattoir. Faites

La plaque de ce gril est en acier, mais sa surface est relativement molle et peut être

Culottage du gril lisse

AVANT LA PREMIÈRE UTILISATION

antihoraire.

chaleur, tournez le bouton dans le sens horaire; pour la réduire, tournez le bouton dans le sens

réguler l’écoulement du gaz vers un brûleur de plaque à bouillir ou gril lisse. Pour augmenter la

BOUTON DES BRÛLEURS DES PLAQUES À BOUILLIR OU DES GRILS LISSES – Sert à

tournez le bouton dans le sens antihoraire.

à feu nu. Pour augmenter la chaleur, tournez le bouton dans le sens horaire; pour la réduire,

BOUTON DES BRÛLEURS À FEUX NUS – Sert à réguler l’écoulement du gaz vers un brûleur

LES CONTRÔLES

lors de l’emploi, du nettoyage ou de l’entretien de la cuisinière.

La cuisinière et ses composants sont chauds. Soyez très prudent

MODE D’EMPLOI

Page 20

13

__________________________________________________________________________________

2 Fermez le robinet principal d’admission du gaz.

1 Mettez le robinet du brûleur à l’arrêt; la veilleuse restera allumée.

Fermeture totale

Mettez le robinet du brûleur à l’arrêt; la veilleuse restera allumée.

Fermeture de nuit

gaz commence à circuler.

des conduites d’admission du gaz a été expulsé totalement. Fermez le robinet lorsque le

7 Ouvrez le robinet d’un des brûleurs de la surface à feux nus pour vous assurer que l’air

6 Si la veilleuse ne s’allume pas, attendez 5 minutes et recommencez les étapes 1 à 5.

Fig. 7

5 À l’aide d’un briquet à long cou, allumez la veilleuse du feu nu (Fig. 7).

4 Patientez pendant 30 secondes.

3 Fermez les boutons des brûleurs de surface.

2 Ouvrez tous les boutons des brûleurs pour expulser l’air des conduites.

1 Ouvrez l’admission principale du gaz.

Brûleurs à feu nu

2 Fermez le robinet principal d’admission du gaz.

1 Mettez le robinet du brûleur à l’arrêt; la veilleuse restera allumée.

Fermeture totale

Mettez le robinet du brûleur à l’arrêt; la veilleuse restera allumée.

Fermeture de nuit

Page 21

12

__________________________________________________________________________________

robinet lorsque le gaz commence à couler.

assurer que l’air des conduites d’admission du gaz a été expulsé totalement. Fermez le

7 Ouvrez le robinet d’un des brûleurs de la plaque à bouillir ou du gril lisse pour vous

6 Si la veilleuse ne s’allume pas, attendez 5 minutes et recommencez les étapes 1 à 5.

lisse.

5 À l’aide d’un briquet à long cou, allumez la veilleuse de la plaque à bouillir ou du gril

4 Patientez pendant 30 secondes

3 Fermez les boutons des brûleurs.

2 Ouvrez tous les boutons des brûleurs pour expulser l’air des conduites.

1 Ouvrez l’admission principale du gaz.

Brûleurs des plaques à bouillir et des grils lisses

installateurs ou des techniciens de service autorisés par Vulcan.

Toutes les procédures de réglage reliées au démarrage initial devraient être effectuées par des

ALLUMAGE ET EXTINCTION DES VEILLEUSES

02269.

l’Association nationale de protection contre les incendies, Parc Batterymarch, Quincy, MA

cuisson», NFPA No 96 (édition la plus récente) que vous pouvez vous procurer auprès de

de ventilation en consultant la norme «Évacuation des vapeurs produites par l’équipement de

Vous pouvez obtenir de l’information sur la construction et l’installation des systèmes de hottes

prévoir un espace minimal de 18 po (45 cm).

À partir de l’extrémité du conduit de cheminée jusqu’aux filtres de la hotte de ventilation, il faut

bâtiment en passant par un système de ventilation installé par des professionnels qualifiés.

l’arrière de la cuisinière. Il est recommandé que les gaz brûlés soient évacués à l’extérieur du

NE BLOQUEZ PAS la circulation des gaz brûlés émanant du conduit de cheminée situé à

RACCORDEMENTS DU CONDUIT DE CHEMINÉE

que l’appareil soit prêt à démarrer.

isolée du système d’admission du gaz en fermant le robinet d’arrêt manuel individuel jusqu’à ce

Si la pression d’alimentation du gaz est de ½ psig (3,45 kPa) ou moins, la cuisinière devrait être

gaz.

sectionnement individuel doivent être déconnectés du système de conduites d’admission du

Si la pression d’alimentation du gaz dépasse ½ psig (3,45 kPa), la cuisinière et son robinet de

TESTAGE DU SYSTÈME D’ADMISSION DU GAZ

être totalement purgés pour en retirer l’air.

Après vous être assuré que la conduite ne fuit pas, tous les tuyaux acheminant le gaz devraient

solution d’eau et de savon. N’utilisez pas une flamme nue.

d’admission du gaz pour déceler les fuites. Servez-vous d’une

Avant l’allumage, vérifiez tous les joints dans la conduite

Page 22

11

__________________________________________________________________________________

toute obstruction peut l’empêcher de bien fonctionner.

surpression du gaz. Ne bouchez pas le limiteur de fuites du régulateur de pression du gaz car

Chaque régulateur est livré avec un limiteur de fuites pour permettre l’échappement de la

fonctionnement.

toute autre position, la pression de sortie doit être réglée de nouveau pour un bon

être monté horizontalement pour assurer la pression de sortie préréglée. S’il est installé dans

La flèche sur le régulateur indique la direction de la circulation du gaz (Fig. 6). Le régulateur doit

Fig. 6

solidement en position verticale (Fig. 6).

4. À l’aide d’une clé à tuyau, serrez le régulateur

flèche pointant vers l’arrière du châssis (Fig. 6).

3. Vissez le régulateur à la main sur la conduite, la

anti fuites.

2. Entourez les filets de la conduite avec un scellant

po (1,9 cm) sortant de l’arrière de la cuisinière.

1. Trouvez la conduite de raccordement du gaz de ¾

CE (Colonne d’eau); 10 po CE pour le gaz propane.

Les régulateurs pour le gaz naturel sont préréglés à 4 po

installateur qualifié.

livré avec celle-ci. Il doit être monté sur les lieux par un

usine. Le régulateur pour le type de gaz de la cuisinière est

Le régulateur de la pression du gaz n’est PAS installé en

signalétique.

l’installer, assurez-vous que le régulateur fourni correspond au débit du gaz de la plaque

sont appariés à l’altitude de l’installation. Installez un régulateur de pression de gaz. Avant de

avant la cuisinière. Les cuisinières de série sont équipées d’orifices de combustion fixes qui

exigent qu’un robinet de sectionnement du gaz soit installé dans la conduite d’alimentation

Raccordez le gaz. Assurez-vous que les conduites sont propres et sans obstructions. Les codes

joints utilisés doivent résister à l’action des gaz propane.

Tous les raccordements d’alimentation du gaz et toute pâte à

RACCORDEMENTS DU GAZ

dévissez les pieds réglables au besoin. Répétez cette procédure pour chaque pied au besoin.

Pour régler le niveau, penchez la cuisinière d’un côté et, à l’aide d’une pince multiprise,

la cuisinière. Mettez de niveau de l’avant vers l’arrière et d’un côté à l’autre.

Vérifiez le niveau de la cuisinière. Posez un niveau de menuisier sur les surfaces de cuisson de

MISE DE NIVEAU

Page 23

10

__________________________________________________________________________________

6. Vissez six vis à tôle #10 (3 par glissière) (Fig. 5).

Fig. 5

Fig. 3 Fig. 4

figures 3 & 4)

des glissières sont alignés avec les trous fournis des côtés gauche et droit du caisson (voir

conduit de cheminée. Assurez-vous que le dosseret est posé également et que les trous

5. Il peut s’avérer nécessaire de sortir légèrement le bouclier thermique pour dégager le

Page 24

MODÈLES

MG12

MG24

MG36

MG48

MG60

MG36ER

(1) Dosseret

standard,

hauteur de 4 po

(10 cm)

(1) Dosseret

standard,

hauteur de 4 po

(10 cm)

(1) Dosseret

standard,

hauteur de

11po (27 cm)

(1) Dosseret

standard,

hauteur de

11po (27 cm)

(1) Dosseret

standard,

hauteur de 11po

(27 cm)

(1) Dosseret

standard,

hauteur de 5 po

(12 cm)

(2) Glissières

pour dosseret

(2) Glissières

pour dosseret

(2) Glissières

pour dosseret

(2) Glissières

pour dosseret

(2) Glissières

pour dosseret

(2) Glissières

pour dosseret

(1) Bouclier

thermique

(1) Bouclier

thermique

(1) Bouclier

thermique

(1) Bouclier

thermique

(1) Bouclier

thermique

(1) Bouclier

thermique

9

__________________________________________________________________________________

cuisinière; il se pourrait que cela demande deux personnes.

4. Soulevez l’ensemble et passez les glissières dans l’espace préparé à l’arrière de la

3. Assemblez les composants requis tel qu’illustré à la figure 2.

Fig. 2

pièces de rechange le plus près de chez-vous.

• Si l’une des pièces est absente, contactez immédiatement votre détaillant ou le dépôt de

mains toutes les pièces requises pour l’installation.

2. Comparez les pièces du dosseret à la liste ci-dessous pour vous assurer que vous avez en

1. Retirez les composants du dosseret du matériel d’emballage.

Dosseret

Page 25

8

__________________________________________________________________________________

Replacez soigneusement la section de plaque à bouillir sur le dessus de la cuisinière.

6. Vérifiez et assurez-vous que toutes les briques et tous les brûleurs sont bien en place.

5. Si le brûleur a été attaché, utilisez un coupe-fil pour retirer le dispositif d’attache.

support (voir fig. 1).

4. Installez deux briques de 7 x 4 po (17 x 10 cm), une de chaque côté de la zone arrière du

coupé en angle de chaque côté avant de la zone du support (voir fig. 1).

3. Installez deux briques en composite/mortier de 10 x 4 po (25 x 10 cm) en plaçant le bout

2. Déposez la plaque à bouillir sur une surface sécuritaire.

Vulcan de votre localité.

brisée en plus de deux morceaux, elle devra être remplacée. Contactez l’agence de service

qu’à mettre les pièces en position tel qu’illustré à la figure 1. Si par contre, une brique s’est

Si une des briques s’est cassée en deux, elle peut quand même servir. Vous n’avez

et deux de 7 x 4 po (17 x 10 cm).

rectangulaire. Trouvez la boîte et retirez avec soin deux briques de 10 x 4 po (25 x 10 cm)

1. Les briques faites de composite et de mortier sont expédiées dans une boîte de carton

Il devrait y avoir une boîte de briques pour chaque section de plaque à bouillir.

raccorder la conduite d’alimentation du gaz ou d’installer le dosseret arrière.

composite et mortier pour distribuer la chaleur aux brûleurs. Installez ces briques avant de

Les cuisinières dotées de plaques à bouillir utilisent des briques réfractaires en matériau

Installation des briques sur les surfaces de plaques à bouillir

de la cuisinière.

c. Continuez à faire descendre la plaque jusqu’à ce qu’elle repose également sur le dessus

capillaire ne soit pas placé au-dessus du parcours de la flamme du brûleur.

bouclier en « V » jusqu’à ce qu’il soit complètement couvert. Assurez-vous que le

troisième personne doit faire passer délicatement le bulbe du thermostat dans le

b. Pendant que deux personnes (une de chaque côté) abaissent la plaque en place, la

dessous de la zone de la plaque lisse.

a. Tirez doucement le fil capillaire du gril vers l’avant de la cuisinière et en dehors du

bulbe ne se retrouve pas dans une position où il pourrait être endommagé.

9. Remettez la plaque lisse en place avec précaution. Veillez à ce que le fil capillaire et le

8. Vérifiez et assurez-vous que toutes les briques et tous les brûleurs sont bien en place.

Page 26

7

__________________________________________________________________________________

7. Si le brûleur a été attaché, utilisez un coupe-fil pour retirer le dispositif d’attache.

fig. 1).

b. Deux briques de 7 x 4 po (17 x 10 cm), une de chaque côté de la zone arrière des supports (voir

chaque côté de la zone des supports (Fig. 1).

a. Deux briques de 10 x 4 po (25 x 10 cm), en plaçant les côtés coupés en angle à l’avant de

6. Dans le support d’une largeur de 9-⅞ po (24 cm), déposez :

Fig. 1

b. Deux briques de 7 x 4 po (17 x 10 cm), une de chaque côté de la zone arrière des supports (Fig. 1).

côté de la zone des supports (Fig. 1).

a. Deux briques de 10 x 4 po (25 x 10 cm), en plaçant les côtés coupés en angle à l’avant de chaque

Dans le support d’une largeur de 6-½ po (16 cm), déposez:

facilement se dérégler en le cognant.

thermostat quand vous installez les briques. Le bulbe du thermostat est un dispositif sensible et peut

briques dans un plan de travail lisse à contrôles thermostatiques. NE FRAPPEZ PAS le bulbe du

plaque lisse et au thermostat (non couverts par la garantie). Soyez prudent lorsque vous placez les

bouclier en « V ». Le bulbe soit être mis en place par l’installateur pour prévenir des dommages à la

5. Les grils à contrôles thermostatiques sont livrés sans que le bulbe du thermostat soit attaché au

4. Posez la plaque lisse sur une surface sécuritaire.

bouclier (s) en « V » jusqu’à ce que les bulbes soient dégagés.

attaché (s) à la plaque, tirez doucement le (les) fil (s) du (des) bulbe (s) capillaire, au travers du (des)

s’est (se sont) dégagé (s) du dessous de la plaque du gril lisse. Si le (les) bulbe (s) est (sont) encore

personne ait vérifié si le (les) bulbe (s) capillaires (modèles à contrôles thermostatiques seulement)

plaque lisse directement par en haut. NE TIREZ PAS la plaque vers l’avant avant que la troisième

3. Retirez la plaque lisse. Une personne placée de chaque côté de l’appareil, soulevez doucement la

chapitre « NETTOYAGE – GRIL LISSE » de ce manuel.

2. Nettoyez la protection antirouille de la surface de travail du gril lisse en suivant les instructions du

Page 27

6

__________________________________________________________________________________

votre localité.

plus de deux morceaux, elle devra être remplacée. Contactez l’agence de service Vulcan de

mettre les pièces en position tel qu’illustré à la figure 1. Si par contre, une brique s’est brisée en

Si une des briques s’est cassée en deux, elle peut quand même servir. Vous n’avez qu’à

vérifiez les quantités tel que décrit ci-dessus.

1. Les briques du gril lisse sont expédiées dans une boîte de carton rectangulaire. Trouvez la boîte et

x 4 po (17 x 10 cm).

Le support de 9-⅞ po (25 cm) accepte deux jeux de briques de 10 x 4 po (25 x 10 cm), et deux jeux de 7

x 4 po (17 x 10 cm).

Le support de 6-½ po (16 cm) accepte deux jeux de briques de 10 x 4 po (25 x 10 cm), et deux jeux de 7

possiblement plus, selon la largeur du plan de travail.

chaque commande d’un gril lisse. Il y aura au moins un support de 9-⅞ po (24 cm) par gril lisse,

de composite et mortier. Il y aura toujours un seul petit support d’une largeur de 6-½ po (16 cm) livré avec

Le plan de travail à gril lisse utilise un support à deux côtés pour supporter les briques réfractaires faites

les briques et le (les) bulbe (s) capillaires en place.

l’installer avec ses briques – Deux personnes pour soulever la plaque lisse et une personne pour mettre

Le plan de travail à gril lisse est extrêmement lourd. Il exigera la présence de trois personnes pour

Installation des briques sur le gril lisse standard

ASSEMBLAGE

Ontario, Canada M9W 1R3.

on peut obtenir copie auprès de l’Association canadienne du gaz, 178 Chemin Rexdale, Etobicoke,

3. À CAN/CGA-B149, 2 «Code national des installations au gaz propane» (édition la plus récente) dont

2. À CAN/CGA-B149, 1 «Code national des installations au gaz naturel» (édition la plus récente).

1. Aux codes locaux.

Au Canada, référez-vous:

02269.

auprès de l’Association nationale de protection contre les incendies, Parc Batterymarch, Quincy, MA

3. Au Code national de l’électricité, ANSI/NFPA-70 (édition la plus récente). On peut en obtenir copie

copie auprès de l’Association américaine du gaz, Inc., 1515 Boulevard Wilson, Arlington, VA 22209.

2. Au Code national des gaz combustibles, ANSI-Z223, 1 (édition la plus récente). On peut en obtenir

1. Aux codes des états et aux codes locaux.

Pour les bonnes procédures d’installation aux États-Unis d’Amérique, référez-vous :

CODES ET STANDARDS D’INSTALLATION

combustion du gaz aux brûleurs.

chambre de combustion. Veillez à ce qu’il y ait un apport d’air suffisant dans la pièce pour permettre la

ventilation ne soit pas entravé. Vous devez assurer un dégagement adéquat pour les orifices d’air dans la

fonctionnement. La cuisinière doit être installée de sorte que le flux de l’air de combustion et de

L’emplacement de l’installation doit permettre des dégagements adéquats pour l’entretien et un bon

combustible à une distance minimale de 10 po (25 cm) dans les côtés et 6 po (15 cm) à l’arrière.

Les cuisinières à brûleurs étagés de 20 000 ou 26 000 BTU doivent être éloignées d’une construction

Page 28

5

__________________________________________________________________________________

une distance minimale de 10 po (25 cm) dans les côtés et 6 po (15 cm) à l’arrière.

Une cuisinière à brûleurs standards de 26 000 BTU doit être éloignée d’une construction combustible à

combustible à une distance minimale de 6 po (15 cm) dans les côtés et 6 po (15 cm) à l’arrière.

Une cuisinière à brûleurs standards de 20 000 BTU doit être éloignée d’une construction

substance combustible.

La zone autour de l’équipement doit être exempte de toute

EMPLACEMENT

l’installation. Contactez votre détaillant ou la société Vulcan-Hart immédiatement.

Si l’alimentation et les exigences de l’équipement ne sont pas compatibles, ne commencez pas

la cuisinière.

spécifications de la plaque signalétique fixée sous le plan de cuisson de gauche sur le panneau latéral de

Avant l’installation, assurez-vous que le type d’alimentation gazier (naturel ou propane) est conforme aux

l’endroit où elle sera installée. Retirez tous les fils et les cales de bois du transport.

Déballez la cuisinière avec soin et placez-la dans un espace de travail accessible le plus près possible de

5. Avisez le Service à la clientèle de Vulcan immédiatement en faisant le (800) 814-2028.

4. Les cuisinières ne doit pas avoir été déplacé, installé ou modifié.

3. Pour fins d’ inspection, tout le m atériel d’emballage original doit être c onservé.

suivi en confirmant les faits par écrit ou par communication électronique.

assurez le

découverte des dommages (ind iquez l’heure, la date et à qui vous avez parlé) et

la

2. Les gens du terminus local du transporteur doivent être avisés immédiatement lors de

1. Le transporteur doit être averti dans les 5 jours ouvrables suivant la réception.

S’il s’avère que les cuisinières a été endommagé, veuillez suivre les procédures suivantes :

après la livr aison, vérifiez s’i l a effect ivement subi des dom mages pen dant le tra nsport.

transporteur prend l’entièr e r esponsabi lité de le livrer en tout e s écurité. Immédiatemen t

Les cuisinières a été insp ecté avant de quit ter l’usine. En acc eptant sa livra ison, le

DÉBALLAGE

INSTALLATION

consignes qui y sont énoncées.

Le fabricant vous conseille de lire tout ce manuel minutieusement et d’observer attentivement toutes les

de nombreuses années de performances satisfaisantes.

L’installation, l’utilisation et un entretien adéquats de votre cuisinière aura pour résultat de vous procurer

Les cuisinières Vulcan ont été fabriquées avec des matériaux et de la main d’œuvre de qualité.

CONSERVEZ CE MANUEL POUR RÉFÉRENCES FUTURES

DE LA GAMME MG

CUISINIÈRES AU GAZ MODULAIRES POUR RESTAURANTS

Installation, mode d’emploi et entretien

Page 29

MODÈLES DES CUISINIÈRES AU GAZ POUR RESTAURANTS MODULAIRES DE LA

GAMME G….………………………………………………………………………………………...

3

INSTALLATION……………………………………………………………………………………...

5

Déballage……...…………………………………………………………………...............

5

Emplacement…...…………………………………………………………………………..

6

Codes et standards d’installation.……………………..………………………………….

6

Assemblage.…...…………………………………………………………………..............

6

Mise de niveau………………………………………………………………….................

11

Raccordements du gaz…………………………………………………………...............

11

Testage du système d’arrivée du gaz……………………………………………………

12

Raccordements du conduit de cheminée………………………………………………..

12

Allumage et extinction des veilleuses...………………………………………………….

12

MODE D’EMPLOI……………………………………………………………………………………

14

Les contrôles ………………………………………………………………………………

14

Avant la première utilisation……………………………………………………………….

14

Le réchauffement...…………………………………………………………….…………..

14

Nettoyage…………………………………………………………………….……………..

15

ENTRETIEN ….……………………………………………………………………………………..

16

4

__________________________________________________________________________________

TABLE DES MATIÈRES

Page 30

3

__________________________________________________________________________________

GAMME MG POUR RESTAURANTS

MODÈLES DES CUISINIÈRES AU GAZ MODULAIRES

Page 31

L’installation, le réglage, la modification et l’entretien

incorrects de cet équipement peuvent causer des dommages matériels, des

blessures ou la mort. Lire très attentivement les instructions d’installation,

de fonctionnement et d’entretien avant de procéder à l’installation ou à

l’entretien de cet appareil.

IMPORTANT

SI VOUS DÉTECTEZ UNE ODEUR DE GAZ, ÉTEIGNEZ L’APPAREIL EN

FERMANT LE ROBINET D’ARRÊT PRINCIPAL ET CONTACTEZ LE

SERVICE DE L’ENTRETIEN DE LA SOCIÉTÉ DE GAZ LOCALE OU DE

VOTRE FOURNISSEUR DE GAZ.

POUR VOTRE SÉCURITÉ

NE PAS ENTREPOSER NI UTILISER DE L’ESSENCE OU AUTRE

VAPEURS OU LIQUIDES INFLAMMABLES PRÈS DE CET APPAREIL OU

DE TOUT AUTRE APPAREIL.

2

__________________________________________________________________________________

APPAREIL.

EN CAS DE PANNE DE COURANT, N’ESSAYEZ PAS DE FAIRE FONCTIONNER CET

FOURNISSEUR DE GAZ DE VOTRE LOCALITÉ.

DÉTECTION D’UNE ODEUR DE GAZ. VOUS POUVEZ OBTENIR CES CONSIGNES DU

AFFICHEZ DANS UN ENDROIT BIEN EN VUE LES CONSIGNES À SUIVRE EN CAS DE

CE MANUEL.

DÉMARRAGE INITIAL ET AUX RÉGLAGES SUR LES LIEUX DE L’APPAREIL DÉCRIT DANS

IMPORTANT POUR VOTRE SÉCURITÉ

L’INSTALLATION D’ÉQUIPEMENTS CHAUFFÉS AU GAZ ET QUI DEVRAIT PROCÉDER AU

CE MANUEL A ÉTÉ PRÉPARÉ À L’INTENTION D’UN PERSONNEL QUALIFIÉ POUR

Page 32

© Groupe ITW Équipement alimentaire, SARL

3600 North Point Blvd.

Baltimore, MA 21222

GARDEZ CE MANUEL POUR RÉFÉRENCE FUTURE

FORMULAIRE F-30832 (10-15)

MODÈLES

MG12 ML-52549

MG24 ML-52514

MG36 ML-52522

MG48 ML-52523

MG60 ML-52524

Pour obtenir des renseignements supplémentaires au sujet de Vulcan-Hart

ou pour trouver un fournisseur de pièces et service autorisé dans votre

région, veuillez visiter notre site web à www.vulcanequipment.com

GAMME MG POUR RESTAURANTS

MODE D’EMPLOI CUISINIÈRES AU GAZ MODULAIRES

MANUEL D’INSTALLATION &

Loading...

Loading...