Page 1

INSTALLATION &

OPERATIONAL MANUAL

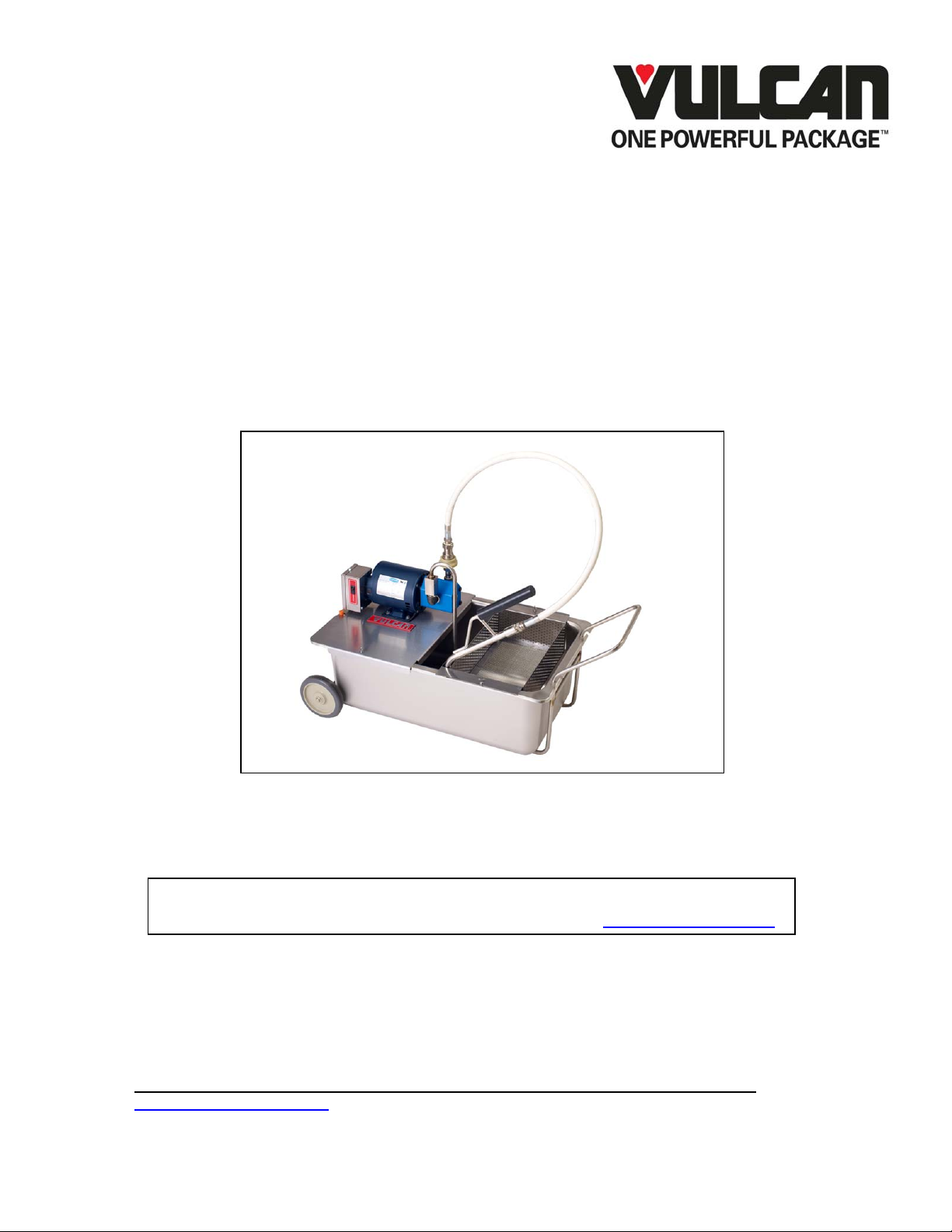

MOBILE FILTER

MF ML-136873

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART 3600 NORTH POINT BLVD.

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC BALTIMORE, MD 21222

WWW.VULCANHART.COM F-32966 Rev. B (10-09)

Page 2

MF SERIES MOBILE FILTER

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

IMPORTANT FOR YOUR SAFETY………………………………………. 2

GENERAL…………………………………………………………… 3

INSTALLATION …………………………………………………… 3

UNPACKING………………………………………………………… 3

INSTALLATION CODES AND STANDARDS………………………………. 4

CODES AND STANDARDS……………………………………….. 4

ELECTRICAL CONNECTIONS………………………………………… 4

ELECTRICAL DATA………………………………………………. 4

ASSEMBLY………………………………………………………………… 5

FILTER SCREEN……………………………………………………. 6

SUCTION TUBE ………………………………………………………. 6

MICRO-FILTRATION ENVELOPE………………………………. 6

POWER PUG OUTLET…………………………………………… 7

POWER SWITCH……………………………………………………. 7

SUCTION TUBE ENGAGEMENT…………………………………….. 8

MOTOR / PUMP RESET…..…………………………………….. 8

LOCKING THUMB SCREWS……………………………….............. 8

OPERATION……………………………………………………………….. 9

CLEANING ………………….…………………………………….. 9

TOUBLESHOOTING…………………………………………………………….10

TABLE OF CONTENTS

VULCAN-HART F-32966 Rev. B (10-09)

-2-

Page 3

MF SERIES MOBILE FILTER

INSTALLATION & OPERATION FOR MF MOBILE FILTERS

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

The MF mobile filter can handle up to 110 pounds (50 kilograms) of frying compound. It is

recommended to only filter one fryer at a time. The motor/pump is rated at 1/3 HP and 8.0 gallons

(19 liters) per minute. The mobile filter is constructed of stainless steel and the filter pan is

removable for ease of cleaning. It is recommended to use only with liquid shortening .

Before installing, verify that the electrical service agree with the specifications on the rating plate

located on the mobile filter. If the supply and equipment requirements do not agree, do not proceed

with the installation. Contact your dealer immediately.

GENERAL

INSTALLATION

UNPACKING

The MF was carefully inspected before leaving the factory. Upon acceptance of the

shipment, the transportation company assumes full responsibility for safe delivery.

Immediately after unpacking the filter, check for possible shipping damage. If the filter is

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Check that the following have been included:

Primary Crumb Basket

Hi Temperature Discard Hose

Manual & Warranty (Keep Manual in a safe place for future reference)

Stainless Steel Mesh Filter Screen with insert

Required:

14 Gauge 5-15P plug extension cord (not supplied with mobile filter).

VULCAN-HART F-32966 Rev. B (10-09)

-3-

Page 4

MF SERIES MOBILE FILTER

This mobile filter must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from the

National Fire Protection Association, Batterymarch Park, Quincy, MA. 02269.

In Canada:

1. Local codes.

2. CSA C22.1 Canadian Electrical Code (latest edition).

The above are available from the Canadian Standard Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

Electrical Connections:

Electrical and grounding connections must comply with the

applicable portions of the National Electrical code and/or other local electrical codes.

Appliances equipped with a flexible electrical supply cord are

provided with a three-prong grounding plug. It is imperative that this plug be

connected into a properly grounded three-prong receptacle. If the receptacle is not

the proper grounding type, contact an electrician. Do not remove the grounding

prong from the supply cord.

Refer to the electrical diagram attached to the inside of the front cover of the mobile filter.

INSTALLATION CODES AND STANDARDS

ELECTRICAL DATA

Model Volts / Hz / Ph Motor Amps

MF 120 / 60 / 1 5.4

VULCAN-HART F-32966 Rev. B (10-09)

-4-

Page 5

MF SERIES MOBILE FILTER

Record your serial number for future reference in the space provided below. This

information can be found on the data plate.

Model No: MF

Device No: MF-1

Serial No: ________________________________

Electrical diagram located on motor/pump.

1. After unpacking, wash the filter pan, crumb basket and filter screen assembly. Make

sure you remove the insert located inside the filter screen. Use dishwashing

detergent and warm water, (parts are dishwasher safe). Rinse the filter pan, crumb

basket and filter screen components completely and wipe all parts dry with a clean

cloth.

2. Place the filter pan onto the carriage frame.

3. Position the filter screen assembly into the filter pan so that the suction tube engages

into the suction receptacle block.

4. Place the primary crumb basket onto the filter pan and secure with thumb screws.

ASSEMBLY

VULCAN-HART F-32966 Rev. B (10-09)

-5-

Page 6

MF SERIES MOBILE FILTER

Suction Tube

Filter Screen

Filter Insert

Stainless Steel Suction Tube

Mesh Screen

Micro-Filtration

Fabric Envelope

(Available Accessory)

Knurled Bottom

Fitting

VULCAN-HART F-32966 Rev. B (10-09)

-6-

Page 7

MF SERIES MOBILE FILTER

Fig. 3 Fig. 1

Fig. 4

Fig. 2

Fig. 5

Fig 1.

Power Plug Outlet

male plug outlet.

Fig. 2

Fig. 3

- Plug female end extension cord into

Power Switch

VULCAN-HART F-32966 Rev. B (10-09)

-7-

Page 8

MF SERIES MOBILE FILTER

Proper Suction Tube Engagement

With Receptacle Block

Hose Connection - Male

Fig. 4

Motor / Pump Reset

Fig. 5

Locking Thumb Screws

The motor/pump supplied

with this filter has a thermal

overload protection circuit

that senses and overload

condition.

If the thermal overload protection is tripped, wait 5

minutes allowing the motor to cool. Then reset the

motor by pushing in the red button.

Close View

VULCAN-HART F-32966 Rev. B (10-09)

-8-

Page 9

MF SERIES MOBILE FILTER

Hot oil and parts can cause burns. Use care when operating,

cleaning and servicing the filter.

1. Recommend: Add oil treatment media to the oil prior to filtering. Add 4 oz. (65 g) of filter

compound (diatomaceous earth) to the hot oil in the fry tank and gently stir.

2. Position the mobile filter close to the fryer. Assemble the drain extension to the

fryer’s drain valve. The drain extension should be positioned over the primary crumb

basket.

3. Check power supply cord making sure that it is properly connected.

4. Attach the fill/discard oil hose to the male quick disconnect and check that it is

engaged properly.

5. Open the drain of the fryer slowly. Oil will pass through the crumb screen and begin

filling up the filter pan. Empty the fryer completely. Remove any large debris left in

the fry tank and any crusty sediment around the fry tank sides.

6. Before starting the motor/pump, hold the fill/discard oil hose over the fryer. Press the

start button and oil will begin coming out of the hose.

7. Use the hose to help wash the debris down into the filter pan, close the drain valve of

the fryer. The fryer will begin to fill with filtered oil. Oil should not exceed the MAX oil

level indicator.

8. When filter pan is empty turn off the motor/pump. Let the oil drain from the oil hose.

Place hose nozzle into its holster, Fig. 6

Fig. 6

OPERATION

Hose Nozzle in Holster

VULCAN-HART F-32966 Rev. B (10-09)

-9-

Page 10

MF SERIES MOBILE FILTER

CLEANING:

Disconnect electrical power supply to the mobile filter and follow

lockout /tag out procedures.

1. Remove the crumb basket and empty and debris into the trash. Turn the thumb

screws to remove the crumb basket from the filter pan.

2. Remove the filter screen assembly. Scrape debris from the filter screen. Then

remove the insert by unlatching the metal strap. Clean all parts thoroughly.

3. Remove debris from the bottom of the filter pan and discard. Clean all parts

thoroughly.

4. To clean filter pan remove the thumb screws and using the handles, remove the

entire motor/pump assembly. Lift filter pan off of its cradle. The filter pan is

dishwasher safe.

5. Reassemble all filter components after being dried thoroughly.

Oil not filtering or discarding: Motor/Pump is on:

1. Suction tube is not seated in receptacle block.

2. Filter Screen is clogged and needs cleaning.

3. Shortening is too thick / cool and needs to be heated up to a minimum of 300 °F.

Motor / Pump is not running:

1. Check 120 V power connections and circuit breakers.

2. Filter switch is not turned on.

Service in the US and Canada

For genuine factory parts and service contact:

1-888-4HOBART or 1-800-298-1862

TROUBLESHOOTING

VULCAN-HART F-32966 Rev. B (10-09)

-10-

Loading...

Loading...