Page 1

Model K40ELT

Item # C.S.I. Section 11420

STEAM

KELT SERIES

ELECTRIC FLOOR MOUNTED

TILTING 2⁄3 JACKETED KETTLE

K2 0 ELT 12 KW, 20 gallon true working capacity

K40ELT 18 KW, 40 gallon true working capacity

K6 0E LT 18 KW, 60 gallon true working capacity

STANDARD FEATURES

■ Electric self-contained, stainless steel, 2⁄3 jacketed oor

mounted tilting steam kettle.

■ Ellipsoidal bottom kettle liner formed and fully welded

standard type 316 and type 304 stainless steel exterior.

■ Heavy bar rim (1⁄4 x 5⁄8 inch 20 gallons) (3⁄8 x 1 inch 40

gallons and greater).

■ Embossed gallon/liter markings.

■ 50 psi (3.4 kg/cm2) steam jacket rating.

■ Stainless steel enclosure for “water resistant” controls,

self-locking tilt mechanism and faucet bracket.

■ Controls include a power switch, power “on” light, solid

state temperature control, vacuum/pressure gauge,

pressure relief valve, low water light and low water

shut-off.

■ Kettle tilts forward 95° to completely empty.

■ Tubular stainless steel legs with anged feet.

■ One year limited parts and labor warranty.

SPECIFICATIONS

Electric self-contained, stainless steel, 2⁄3 jacketed oor mounted tilting steam kettle. Ellipsoidal bottom kettle liner formed

and fully welded type 316 and type 304 stainless steel exterior

with (1⁄4 x 5⁄8 inch 20 gallons) (3⁄8 x 1 inch 40 gallons and greater)

bar rim, embossed gallon/liter markings. 50 psi (3.4 kg/cm2)

steam jacket rating. Stainless steel enclosure for controls, selflocking tilt mechanism and faucet bracket. Controls include a

power switch, power “on” light, solid state temperature control,

vacuum/pressure gauge, pressure relief valve, low water light

and low water shut-off. Kettle tilts forward 90° to completely

empty. Tubular stainless steel legs with anged feet.

UL listed. UL Classied for sanitation in accordance with

ANSI/NSF Standard #4. Meets ASME code.

OPTIONS

Two inch compression tangent draw-off valve with

perforated strainer.

Two inch plug tangent draw-off valve with perforated

strainer.

Three inch compression tangent draw-off valve with

perforated strainer.

Security facility package:

a. Security type fasteners with tack welds.

b. Stainless steel step over draw-off valve with chain.

c. Controls cover

d. Chained crank handle

480 volt, 60 Hz, 3 phase power supply.

Increase to 24 kW for 40 - 60 gallon models (3 phase only).

Second year extended limited parts and labor warranty.

ACCESSORIES (Packaged & Sold Separately)

Spring assist hinged stainless steel cover with condensate

ring and drop down lift handle.

Perforated stainless steel basket assembly (single – 20

gallon) (triple – 20 through 60 gallon).

Pouring lip strainer.

Clean-up kit, includes draw-off brush, clean-up brush and

paddle scrapper with 40" handle.

Stainless steel 48" whip.

Non-perforated strainer.

(12") (18" double jointed) single pantry lead-free faucet.

(12") (18" double jointed) double pantry lead-free faucet.

Double pantry washdown hose with 16" add-on lead-free

faucet with vacuum breaker.

Double pantry washdown hose with lead-free vacuum

br e a ker.

Double pantry pot ller with lead-free vacuum breaker.

a divisi on of IT W Food Equ ipment Group LLC

P.O. Box 696 ■ Louisville, KY 40201 ■ Toll-free: 1-800-814-2028 ■ Local: 502-778-2791 ■ Quote & Order Fax: 1-800-444-0602

F37457 (01/15)

Page 2

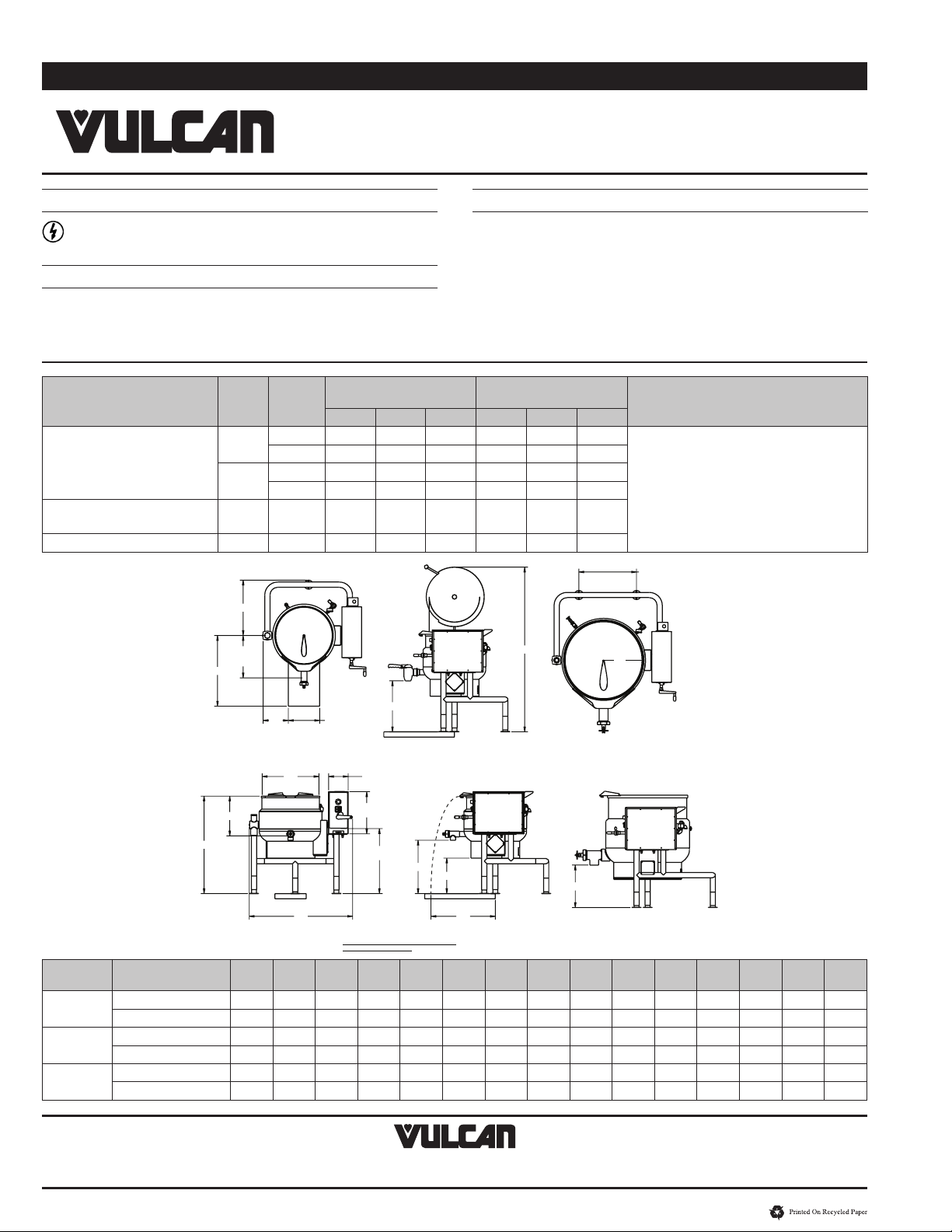

STEAM

(2" COMPRESSION VALVE)

"D"

"A"

"C"

7.5

[191]

"J" ELEC

CONNECTION

16.2

[410]

"B"

"G"

"H"

"S"

"M

SHOWN WITH OPTIONAL DRAW-OFF VALVE

(2" COMPRESSION VALVE)

"R"

SHOWN WITH OPTIONAL DRAW-OFF VALVE

(3" COMPRESSION VALVE)

KELT SERIES

ELECTRIC FLOOR MOUNTED

TILTING 2⁄3 JACKETED KETTLE

SERVICE CONNECTIONS

Electrical connection: Single point supply 11⁄8" (29 mm) dia.

(3⁄4" conduit).

NOTE:

• Dimensions which locate the above connections have a tolerance

of + or -3" (+ or -75 mm).

• Installation of backow preventers, vacuum breakers and other

TRUE WORKING CAPACITIES (in 4 oz. servings)

specic code requirements is the responsibility of the owner and

installer. It is the responsibility of the owner and installer to comply

80 quarts/20 gallons/76 liters/640 servings

120 quarts/40 gallons/152 liters/1,280 servings

160 quarts/60 gallons/228 liters/1,920 servings

with local codes.

• This appliance is manufactured for commercial installation only

and is not intended for home use.

MINIMUM CIRCUIT

MODEL kW PHASE

12

K2 0 E LT

16

1 57. 7 — – 75 — —

3 33.3 — 14.4 45 — 20

1 — 66.7 — — 85 —

3 — 38.5 — — 50 —

AMPERAGE PER LINE

208V 240V 480V 208V 240V 480V

AMPACIT Y

Standard K40ELT, K60ELT 18 3 50.0 43.3 21.7 65 55 30

Optional K40ELT, K60ELT 24 3 66.6 5 7. 7 28.9 85 75 40

"E"

ADD 2" FOR

PLUG VALVE

"

"F"

"K"

Shipped for 208/50/60/3 electrical service.

Can be eld converted to 208/50/60/1

and 240/50/60/3 and 240/50/60/1

22.1 [562]

(FOR 60 GAL. ONLY)

"N"

"B"

"C"

12.0

[305]

"A"

"D"

"L"

SHOWN WITH OPTIONAL DRAW--OFF VALVE

(2" PLUG VALVE) AND SPRING ASSIST LID

7.5

[191]

16.2

[410]

"J" ELEC

CONNECTION

SHOWN WITH OPTIONAL DRAW-OFF VALVE

"G"

"H"

"R"

"S"

SHOWN WITH OPTIONAL DRAW-OFF VALVE

(3" COMPRESSION VALVE)

TRUE WORKING

MODEL

K2 0 E LT

K40ELT

K6 0 E LT

CAPACI TY A B C D E F G H J K L M N R S

20 gallons 21.8 15 .4 37. 4 39.7 21.3 16.3 20.5 13.6 24.9 63.2 19.6 2 7.1 9.7 25 .1

76 liters 554 391 950 1008 541 414 521 345 632 160 5 498 688 246 638

40 gallons 25.8 21. 2 39.7 43.5 24.0 18 .1 16. 9 12.0 22.9 69.4 16.0 3 2 .1 11.7 15.9 3 0 .1

152 l iters 655 538 100 8 110 5 610 460 429 305 582 1763 406 815 297 404 765

60 gallons 29.7 2 4.1 43.1 4 7. 5 26.8 20.3 17. 3 10. 8 24.3 76.6 16.6 34.8 13.8 16.3 32.8

227 liters 754 612 109 5 1207 681 516 439 2 74 6 17 1946 422 884 351 414 833

a divisi on of IT W Food Equ ipment Group LLC

P.O. Box 696 ■ Louisville, KY 40201 ■ Toll-free: 1-800-814-2028 ■ Local: 502-778-2791 ■ Quote & Order Fax: 1-800-444-0602

F37457 (01/15)

NOTE: In line w ith its policy to co ntinua lly imp rove its pr oduct s, Vulca n reser ves the right to c hange materia ls and sp ecic ation s withou t notice.

Loading...

Loading...