Page 1

Model K40DLT

Item # C.S.I. Section 11420

STEAM

KDLT SERIES

DIRECT STEAM FLOOR MOUNTED

TILTING 2⁄3 JACKETED KETTLE

K2 0 DLT 20 gallon true working capacity

K40DLT 40 gallon true working capacity

K6 0DLT 60 gallon true working capacity

STANDARD FEATURES

■ Direct steam, stainless steel, 2⁄3 jacketed oor mounted

tilting steam kettle.

■ Ellipsoidal bottom kettle liner formed and fully welded

standard type 316 and type 304 stainless steel exterior.

■ Bar rim (1⁄4 x 5⁄8 inch 20 gallons) (3⁄8 x 1 inch 40 gallons and

greater).

■ Embossed gallon/liter markings.

■ 50 psi (3.4 kg/cm2) steam jacket rating.

■ Stainless steel enclosure for steam control valve, self-

locking tilt mechanism and faucet bracket.

■ Steam control assembly includes condensate return line

strainer and safety valve steam trap.

■ Kettle tilts forward 90° to completely empty.

■ Tubular stainless steel legs with anged feet.

■ One year limited parts and labor warranty.

SPECIFICATIONS

Direct steam, stainless steel, 2⁄3 jacketed oor mounted tilting

steam kettle. Ellipsoidal bottom kettle liner formed and fully

welded type 316 and type 304 stainless steel exterior with

(1⁄4 x 5⁄8 inch 20 gallons) (3⁄8 x 1 inch 40 gallons and greater) bar

rim, embossed gallon/liter markings. 50 psi (3.4 kg/cm2) steam

jacket rating. Stainless steel enclosure for steam control valve,

self-locking tilt mechanism and faucet bracket. Steam control

assembly includes condensate return line strainer and safety

valve steam trap. Kettle tilts forward 90° to completely empty.

Tubular stainless steel legs with anged feet.

UL Classied for sanitation in accordance with ANSI/NSF

Standard #4. Meets ASME code.

OPTIONS

Two inch compression tangent draw-off valve with

perforated strainer.

Two inch plug tangent draw-off valve with perforated

strainer.

Three inch compression tangent draw-off valve with

perforated strainer.

Security facility package:

a. Security type tamper resistant fasteners with tack

welds.

b. Stainless steel step cover over draw-off valve with

chain.

Second year extended limited parts and labor warranty.

ACCESSORIES (Packaged & Sold Separately)

Spring assist hinged stainless steel cover with condensate

ring and drop down lift handle.

Perforated stainless steel basket assembly (single - 20

gal.) (triple - 20, 40 and 60 gallon).

Pouring lip strainer.

Clean-up kit, includes draw-off brush, clean-up brush and

paddle scraper with 40" handle.

Stainless steel 48" whip.

Solid disk.

(12") (18" double jointed) single pantry lead-free faucet.

(12") (18" double jointed) double pantry lead-free faucet.

Double pantry washdown hose with 16" add-on lead-free

faucet with vacuum breaker.

Double pantry washdown hose with vacuum breaker.

Double pantry pot ller and vacuum breaker.

a divisi on of IT W Food Equ ipment Group LLC

P.O. Box 696 ■ Louisville, KY 40201 ■ Toll-free: 1-800-814-2028 ■ Local: 502-778-2791 ■ Quote & Order Fax: 1-800-444-0602

F37455 (01/15)

Page 2

STEAM

KDLT SERIES

DIRECT STEAM FLOOR MOUNTED

TILTING 2⁄3 JACKETED KETTLE

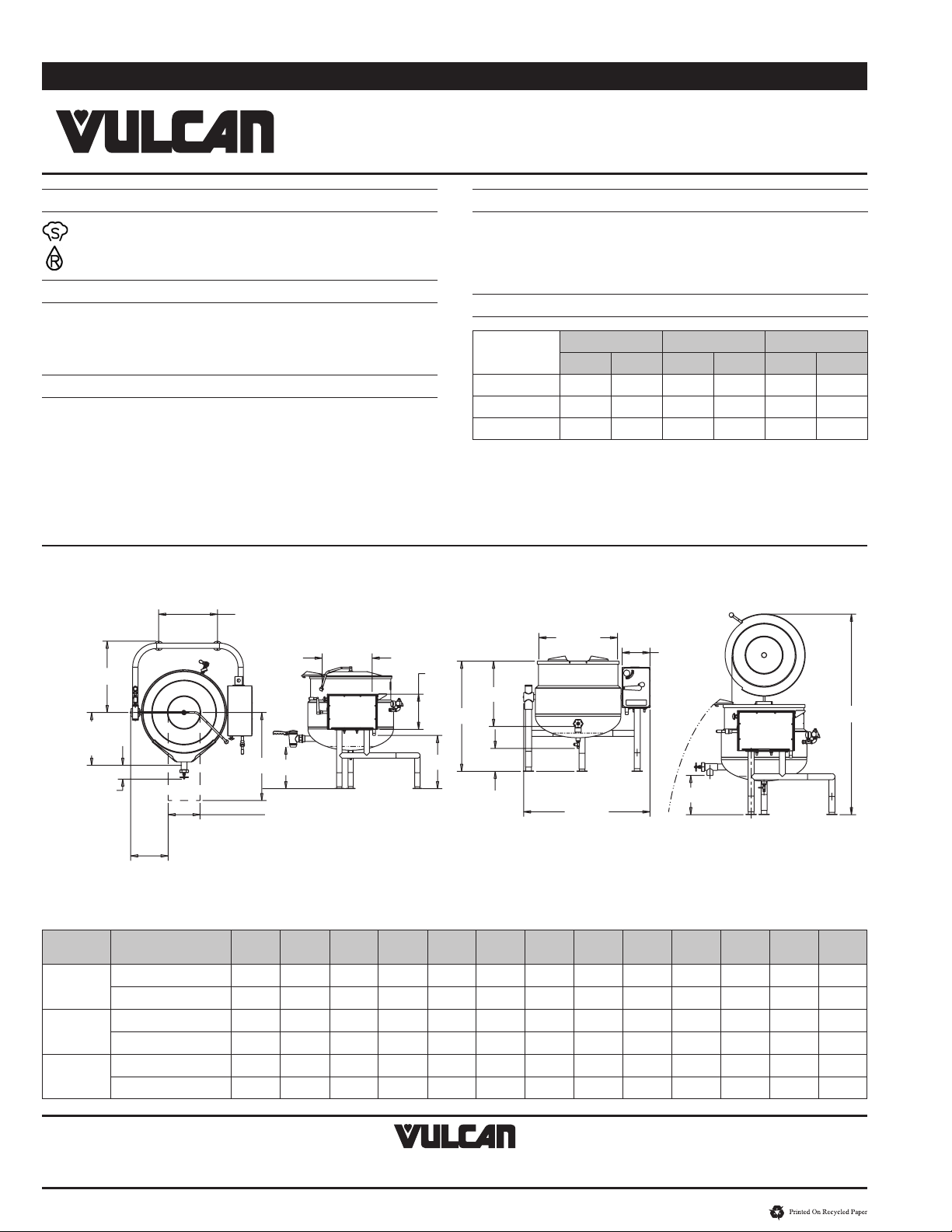

SERVICE CONNECTIONS

Steam supply: 3⁄4" IPS.

Condensate return: 1⁄2" IPS.

TRUE WORKING CAPACITIES (in 4 oz. servings)

80 quarts/20 gallons/76 liters/640 servings

160 quarts/40 gallons/152 liters/1,280 servings

240 quarts/60 gallons/228 liters/1,920 servings

NOTE

• Dimensions which locate the above connections have a tolerance

of + or -3" (+ or -77 mm).

• Installation of backow preventers, vacuum breakers and other

specic code requirements is the responsibility of the owner and

installer. It is the responsibility of the owner and installer to comply

with local codes.

• This appliance is manufactured for commercial installation only

and is not intended for home use.

22.0

(559)

“E”

“F”

(ADD 2” FOR

PLUG VALVE)

5.2

(132)

(ADD 2” FOR

OPEN POSITION)

“N”

(FOR 60 GAL ONLY)

“M”

“L”

12.0

(305)

18.8

(476)

SHOWN WITH OPTIONAL DRAW-OFF VALVE AND

SPRING ASSIST LID COVER

13.2

(335)

DIM “C”

DIM “J”

DIRECT STEAM DATA

Steam supply to the kettles must:

1. Maintain a steady 10 psi ow under operating conditions.

2. Have a minimum ow (see char t) of dry steam.

3. Be adequately trapped to provide dry steam. (See ball oat trap.)

STEAM FLOW RATE AT 10 PSIG AT THE KETTLE

Fast Boil Medium Boil Slow Boil

lbs/hr kg/hr lbs/hr kg/hr lbs/hr kg/hr

20 gallon 48 22 32 15 24 11

40 gallon 96 44 64 29 48 22

60 gallon 143 65 96 44 72 33

DIM “A”

DIM “B”

DIM “H”

DIM “D”

9.1

(230)

DIM “G”

DIM “K”

MODEL

K2 0 DLT

K40DLT

K6 0DLT

CAPACI TY A B C D E F G H J K L M N

20 gallons 21.6 15.2 35.7 37. 8 21.3 16 18.4 11. 9 20.7 61.3 17. 7 28.5 9.9

76 liters 549 386 907 960 543 406 467 302 523 1557 451 726 252

40 gallons 25.8 21.2 36 .1 41.8 24 17.7 12.8 7.5 18.6 65.8 12.1 30.3 12 .1

152 liter s 656 538 917 1062 610 4 51 325 191 473 1671 308 772 308

60 gallons 29.5 23.9 38 .1 45.7 26.8 19.7 15.6 10.9 19.8 72.3 14.9 33 13.8

227 liters 749 607 968 1161 683 500 398 276 503 1836 380 841 352

a divisi on of IT W Food Equ ipment Group LLC

P.O. Box 696 ■ Louisville, KY 40201 ■ Toll-free: 1-800-814-2028 ■ Local: 502-778-2791 ■ Quote & Order Fax: 1-800-444-0602

TRUE WORKING

F37455 (01/15)

NOTE: In line w ith its policy to co ntinua lly imp rove its pr oduct s, Vulca n reser ves the right to c hange materia ls and sp ecic ation s withou t notice.

Loading...

Loading...