Page 1

SERVICE AND PARTS MANUAL

FOR HEAVY DUTY GAS BROILERS

CERAMIC MODELS SUNGLOW MODELS

MODEL FORMERLY MODEL FORMERLY

HCB040 7840AL IR1 IR-71P

HCB44 7844L IR2 IR-72P

HMCB44 M7844L IR44 IR-744P

HCB1 CB-1L

HCB2 CB-2L

Model HCBO40

Model HCB44

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 30534 (02-90) Formerly 114517

Model IR-2

Model IR44

Model IR1

Page 2

GAS BROILERS SERVICE & PARTS

IMPORTANT

OPERATING, INSTALLING AND SERVICE PERSONNEL

Operating information for this equipment has been prepared for use by qualified and/autho-

rized operating personnel.

All installation and service on this equipment is to be performed by qualified, certified, licensed and/

authorized installation or service personnel, with the exception of any part marked with a in front of the

part number.

Service may be obtained by contacting the Factory Service Department, Factory Representative or Local

Service Agency.

DEFINITIONS

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified or authorized operating personnel are those who have carefully read the information in this

manual and are familiar with the equipment’s functions or have had previous experience with the

operation of the equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, a firm, corporation or company which either in person

or through a representative are engaged in, and are responsible for:

1. The installation of gas piping from the outlet side of the gas meter, or the service regulator when the

meter is not provided, and the connection and installation of the gas appliance. Qualified installation

personnel must be experienced in such work, be familiar with all precautions required, and have

complied with all requirements of state or local authorities having jurisdiction. Reference in the United

States of America - National Fuel Gas Code ANSI Z223.1 (Latest Edition). In Canada - Canadian

Standard CAN/CGA-B149.1 NAT. GAS (Latest Edition) or CAN/CGA-B149.2 PROPANE GAS

(Latest Edition).

2. The installation of electrical wiring from the electric meter, main control box or service outlet to the

electric appliance. Qualified installation personnel must be experienced in such work, be familiar

with all precautions required, and have complied with all requirements of state or local authorities

having jurisdiction. Reference: In the United States of America - National Electrical Code ANSI NFPA

No. 70 (Latest Edition). In Canada - Canadian Electric Code Part 1 CSA-C22.1 (Latest Edition).

3. The installation of steam piping from the source of supply to the service inlet of the appliance.

Qualified installation personnel must be experienced in such work, be familiar with all precautions

required, and have complied with all requirements of state or local authorities having jurisdiction.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Vulcan equipment who have been endorsed

by the Vulcan-Hart Corporation. All authorized service personnel are required to be equipped with a

complete set of service and parts manuals and stock a minimum amount of parts for Vulcan equipment.

– 2 –

Page 3

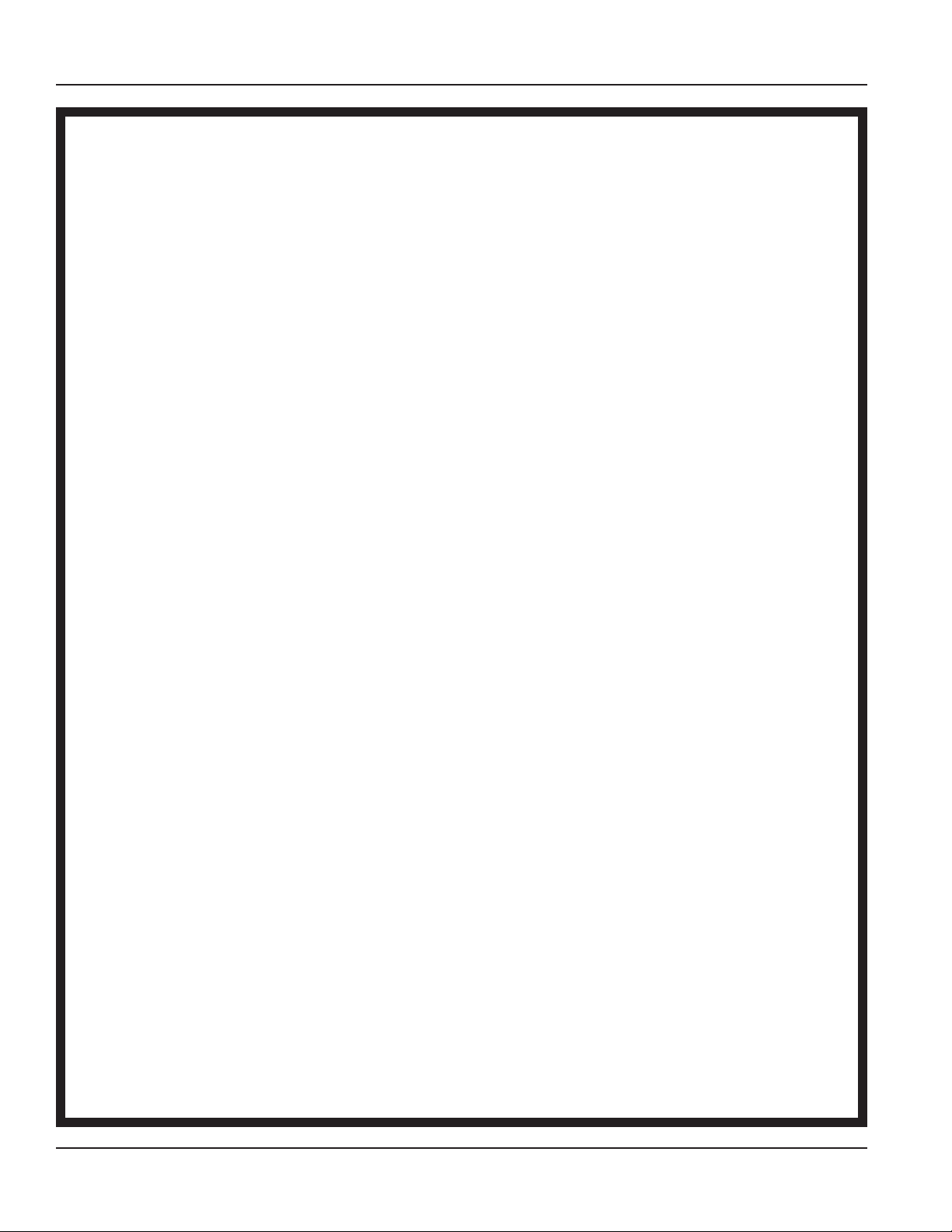

STOP BOLT - INFORMATION

SERVICE & PARTS GAS BROILERS

IMPORTANT

STOP BOLTS MUST BE IN POSITION FOR

SAFE OPERATION OF GRID

IF DAMAGED OR MISSING REPLACE AT ONCE

DO NOT OPERATE GRID WITHOUT BOLTS

Two (2) broiler grid 1⁄4-20 stop bolts and nuts are supplied with each broiler grid to ensure

that the grid is not accidentally pulled completely from the broiler section while hot. One (1)

stop bolt and nut is mounted to the grid carriage RT. and LT. HD. side member through a .281

diameter hole directly in front of the grid stop tab. The stop nuts and bolts are screwed tightly

against the side members and are properly adjusted extending approximately 1⁄2" below the

stop tab as shown in the above photo.

– 3 –

Page 4

GAS BROILERS SERVICE & PARTS

GENERAL INSTRUCTIONS (ALL BROILERS)

PREHEATING

CONVENTIONAL AND SUNGLOW UNITS

It is not necessary to preheat the broiler before using nor

is it necessary to keep the gas on a low setting when not

in use. Broiling temperatures are reached within 90 seconds. Burner life will be extended if the practice of turning

the burners off between cooking periods is practiced.

GRID POSITIONING AND GAS SETTING:

Each operator will find the optimum grid position and gas

setting desired for various products. However, it is recommended that gas input should be reduced first when lower

grid temperatures are desired. Further reduction in grid

temperatures, if necessary, can then be obtained by

lowering the grid position, to any one of the several grid

positions.

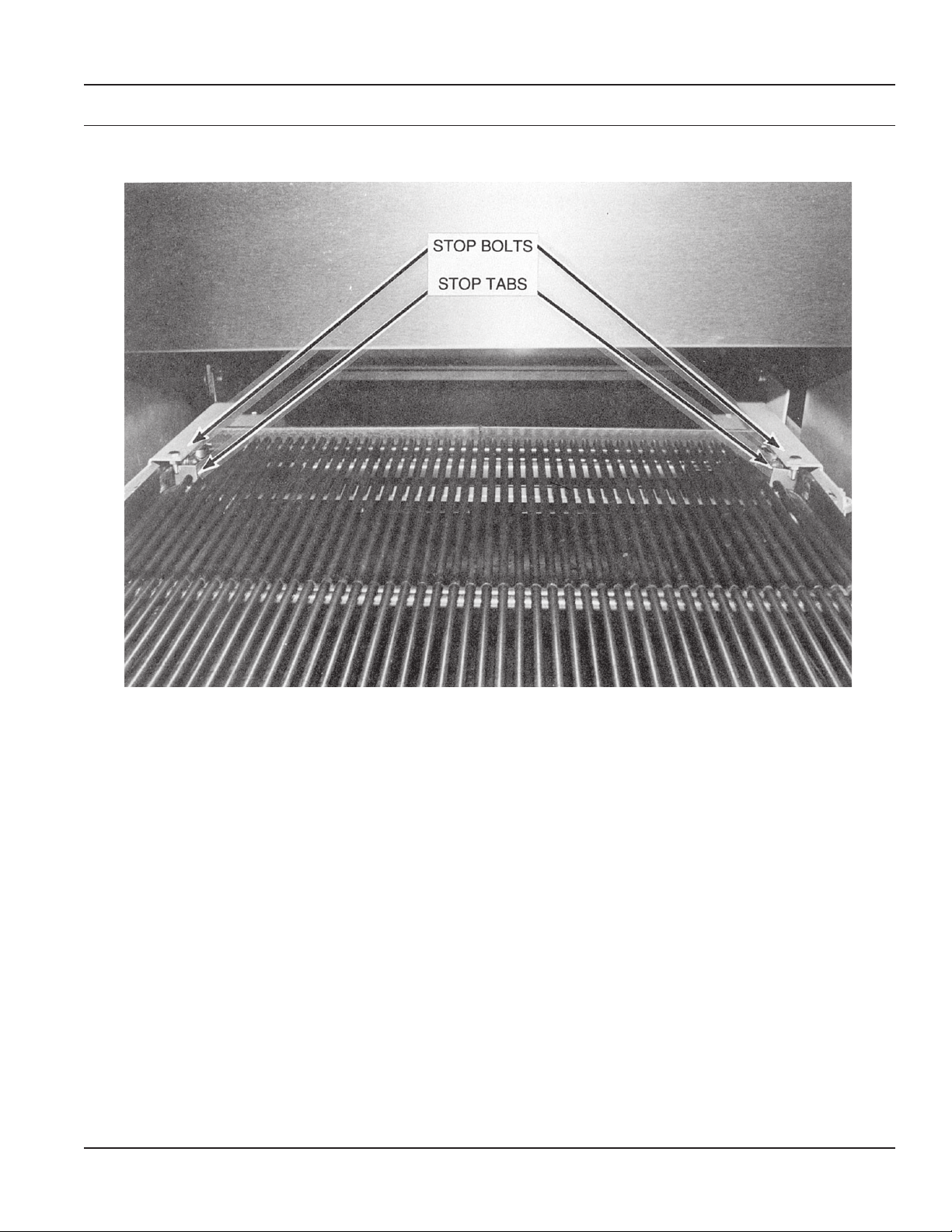

To relocate grid position, grasp the grid lever arm and push

the handle to the right of the index plate. (HCB1, HCB2 and

IR units) (Opposite on HCB040, HCB44 and HMCB44

units). Glide the arm up or down to the desired location.

Push the lever arm handle to the left and lock the arm into

the proper index plate position.

LIGHTING INSTRUCTIONS

(HCB44, HCB040, HMCB44)

1. Remove AuGratin oven bottom, baffle and burner box

cover.

2. Remove oven bottom and baffles - HCB040 only.

3. Remove manifold panel.

4. Turn on the gas supply and check for leaks using a

soap and water solution or other acceptable method.

WARNING: MATCHES, CANDLES OR OTHER

SOURCES OF IGNITION SHOULD NOT BE USED

FOR THIS PURPOSE.

5. Place the ceramics with the projections down, to the

rear of broiler burners. The lugs on the burners will

properly position. The ceramics are sized at the factory.

6. Replace the AuGratin oven baffle and bottom, but

leave the burner box cover off. Turn on the gas valve

and allow the air in the line to be exhausted. When gas

begins to flow, turn the gas valve off and wait 5 minutes

before lighting pilots and burner with a taper. The

burner flame should be sharp when the unit is cold with

a blue cone of flame about 3⁄4" long on Natural Gas and

1

⁄2" long on Propane Gas. The flame will soften out and

curl around the ceramics as the broiler gets hot. The

length of the flame is determined by the adjustment of

the nozzle. The sharpness of the flame is determined

by the air shutter adjustment.

7. Adjust broiler pilots at the pilot valve on the left end of

the pilot manifold pipe. Adjust the flame to approximately 3/4" long. Replace the burner box front.

8. Adjust the oven pilot and burner on Model HCB040.

See heat control instructions for proper adjustment of

minimum bypass setting.

9. Replace the manifold panel and other parts that had

been removed.

CARBONIZATION OF CERAMICS

If the ceramics take on a black sooty accumulation, the

burners are receiving an insufficient amount of air. The

cure is to open the air shutters further. If carbonization

occurs during initial adjustment, it will burn off as soon as

proper adjustment is achieved.

BURNER PERFORMANCE

If, after a period of satisfactory operation, the burner flame

characteristics should change or the length of burner

flame should be reduced, either the air mixer opening or

the gas valve orifice has become restricted. The burners

should be cleaned every 60 days or more often as

required.

OVEN LIGHTING INSTRUCTIONS (HCB040)

1. If the pilot is out, turn the burner “off”, wait 5 minutes

before relighting.

2. Depress the button and ignite the pilot, hold 30 seconds until pilot remains “on”.

3. Turn knob to “on” for oven burner, set the thermostat

dial to desired temperature.

4. For a complete shutdown, turn the knob to “off” and the

pilot to “on”.

The above instructions may also be found on the oven

control panel of the unit.

– 4 –

Page 5

MODEL NUMBERS HCB1 and HCB2

LIGHTING INSTRUCTIONS

1. Remove burner box front cover and turn on the gas

supply and check for leaks using a soap and water

solution or other acceptable method.

WARNING: MATCHES, CANDLES OR OTHER

SOURCES OF IGNITION SHOULD NOT BE USED

FOR THIS PURPOSE.

2. Place the ceramics with the projections down, to the

rear of broiler burners. The lugs on the burners will

properly position. The ceramics are sized at the factory.

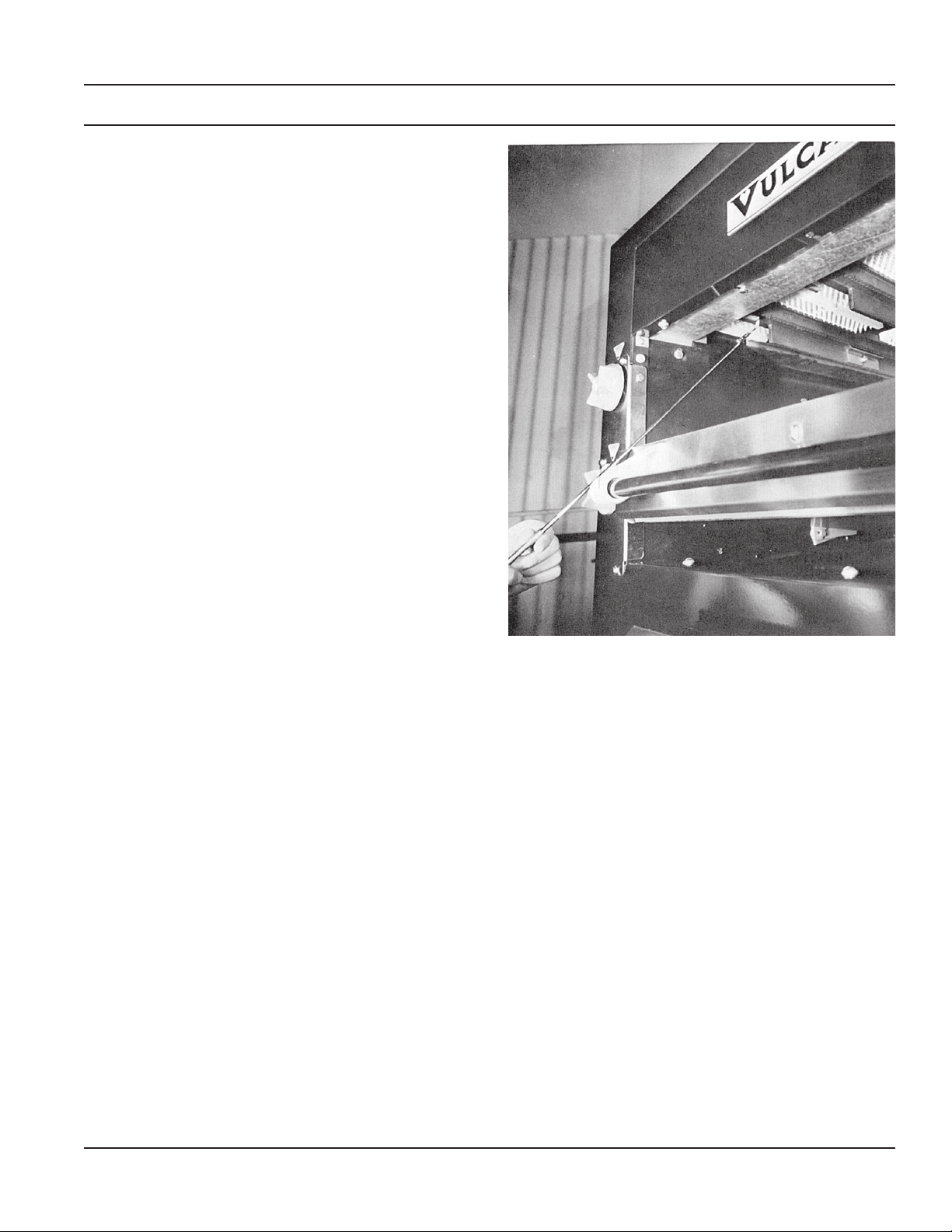

3. Turn on the gas valve and allow the air in the line to be

exhausted. When gas begins to flow, turn the gas valve

off and wait 5 minutes before lighting the pilots and

burner with a taper. The burner flame should be sharp,

when the unit is cold, with a blue cone of flame about

3

⁄4" long on Natural Gas and 1⁄2" long on Propane Gas.

The flame will soften out and curl around the ceramics

as the broiler gets hot. The length of the flame is

determined by the adjustment of the nozzle. The

sharpness of the flame is determined by the air shutter

adjustment. (See Detail A)

SERVICE & PARTS GAS BROILERS

PILOT BURNER ADJUSTMENT

Turn the pilot burner valve on. The valve is located in the

lower compartment. Each burner is provided with a standing pilot burner. Adjust the pilot flame to approximately 3⁄4"

flame height. The adjusting valve is installed in the inlet of

the pilot burner manifolding located behind the removable

front panel above the grid area.

CARBONIZATION OF CERAMICS

If the ceramics take on a black sooty accumulation, the

burners are receiving an insufficient amount of air. The

cure is to open the air shutters further. If carbonization

occurs during initial adjustment, it will burn off as soon as

proper adjustment is achieved.

BURNER PERFORMANCE

If, after a period of satisfactory operation, the burner flame

characteristics should change or the length of burner

flame should be reduced, either the air mixer opening or

the gas valve orifice has become restricted. The burners

should be cleaned every 60 days or more often as

required.

DETAIL A

– 5 –

Page 6

GAS BROILERS SERVICE & PARTS

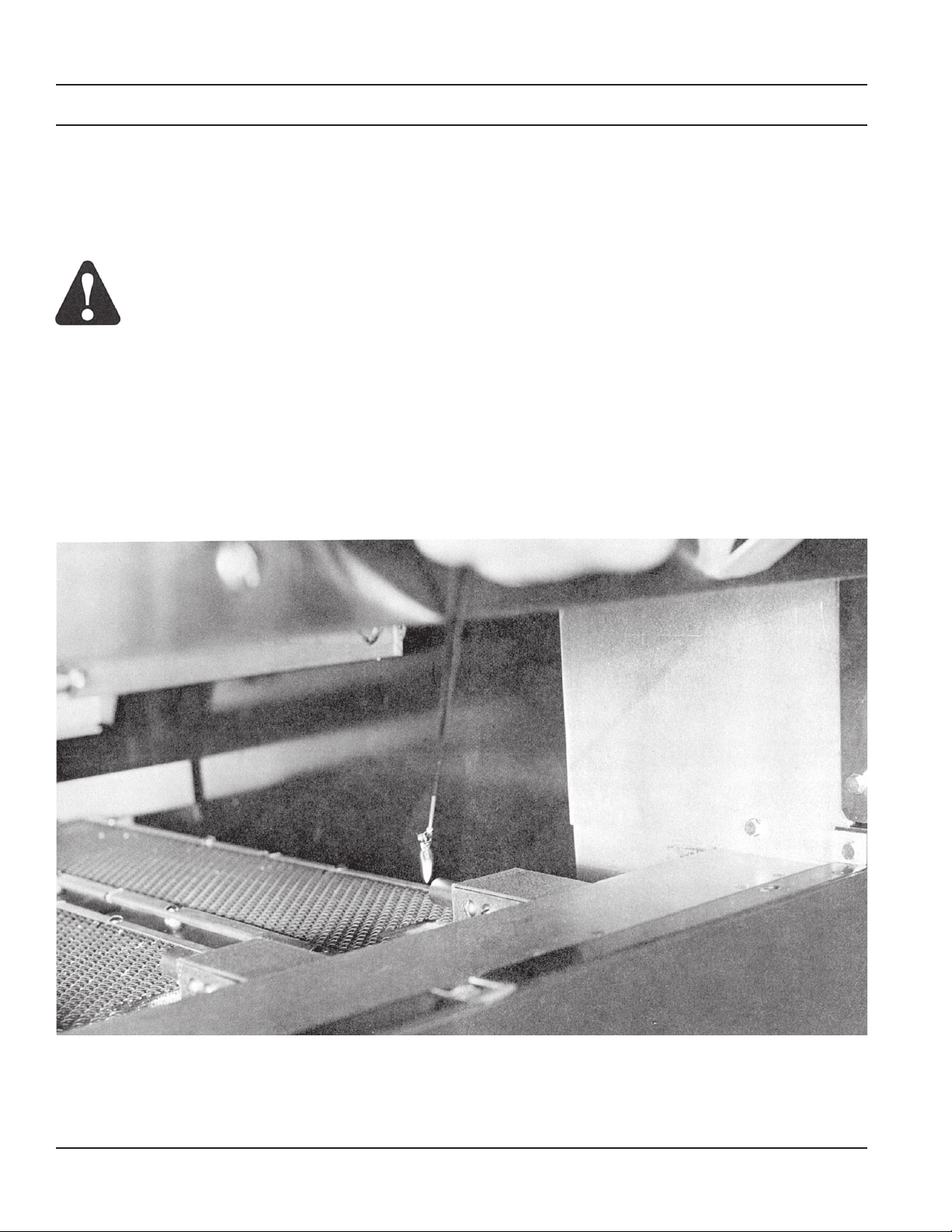

MODEL NUMBERS IR1, IR2, IR44 (INFRARED)

LIGHTING INSTRUCTIONS (SEE DETAIL B)

1. Remove the burner box cover.

2. Turn on the gas supply and check for leaks using a

soap and water solution or other acceptable method.

WARNING: MATCHES, CANDLES OR

OTHER SOURCES OF IGNITION SHOULD

NOT BE USED FOR THIS PURPOSE.

3. Turn the pilot burner “B” valve (located in the lower left

hand compartment) “on” and light pilots (one pilot per

burner) with a taper.

4. If the pilots go out, turn “off” the “B” valve and wait

5 minutes to allow gas to dissipate. Then repeat step 3.

PLACING THE UNIT INTO OPERATION

1. Flip the toggle switch located on the lower front center

panel to the “on” position.

2. Turn the burner valve to the desired setting.

SHUTDOWN INSTRUCTIONS

NIGHTLY

1. Turn the burner valve “off”.

2. Flip the toggle switch to the “off” position.

SEASONAL

1. Perform steps 1 and 2 of the nightly shutdown instructions, then turn the pilot “B” valve “off”.

DETAIL B

– 6 –

Page 7

MODEL NO.’S IR1, IR2, IR44 (INFRARED) (CONT’D)

SERVICE & PARTS GAS BROILERS

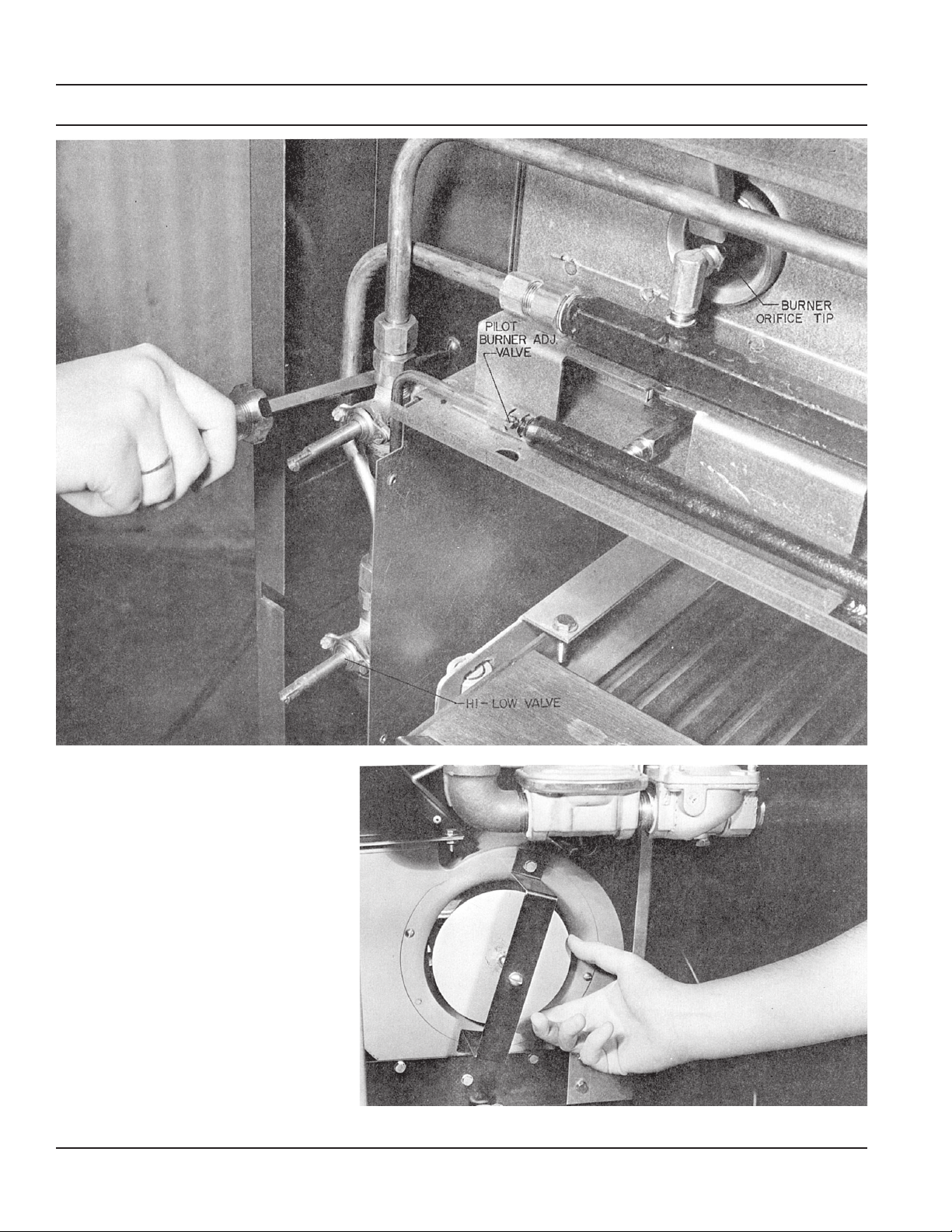

PILOT BURNER ADJUSTMENT

Turn the pilot burner “B” valve on. The valve is located in

lower compartment.

Each burner is provided with a standing pilot burner. Adjust

the pilot flame to approximately a 3⁄4" flame length. The

adjusting valve is installed in the inlet of the pilot burner

manifolding located behind the removable front panel

above the grid area.

(See Detail C & D)

MAIN BURNER ADJUSTMENT

Orifices (1 per burner) are located in the front of each

burner venturi, behind a removable front panel above the

grid area. Each burner is controlled by either a “Hi-Lo”

valve (IR1 & IR2), or a “Hi-Med-Lo” (IR44) and an orifice.

(See Detail D)

MAIN BURNER VALVE ADJUSTMENT

The “high” position is fixed and cannot be adjusted. The

“low” position may be adjusted to obtain the minimum

stable flame. In order to adjust the “low” setting, turn the

knob to low, remove the knob and rotate the adjusting

screw, located in the center shaft of the valve, clockwise to

decrease and counterclockwise to increase the burner

flame.

(See Detail D)

OPERATING

Check the unit to be sure standing pilots, one per burner,

are burning. Turn the toggle switch to the “on” position and

wait for the red indicating light to come on, then turn the

valve “on” for the desired burner and heat. (See Detail C)

CARBON ACCUMULATION ON BURNER SCREEN

If the burner screens take on a black sooty accumulation,

the burners are receiving an insufficient amount of air.

Increase the air supply at blower inlet. Carbon will burn off

as soon as proper adjustment is made.

CLEANING AND LUBRICATION

Dust and lint should be cleaned from the blower fan blades

periodically to maintain the greatest air flow and to prevent

carboning the burners.

The blower motor should be lubricated periodically using

an oil recommended by the motor manufacturer.

AIR ADJUSTMENT

Although air adjustment is made at the factory before the

unit is shipped, it may be necessary to re-adjust after

installation is made. All of the air required for combustion

is supplied by the blower through an air duct on the left

side. A single air adjustment is provided at the air intake to

the blower (IR44) or behind each “right” burner valve (IR1

& IR2). No other adjustment is provided or necessary.

(See Detail D & E)

Burners or infrared generators should burn with uniform

radiant heat and without any flame curling around the

sides of the burner.

Decrease the air supply to eliminate darkened areas.

NOTE: Insufficient air may keep the pressure switch

opened and the solenoid valve will not open to supply gas

to the unit. Increase the air supply to obtain proper operation. (IR44 only).

DETAIL C

– 7 –

Page 8

GAS BROILERS SERVICE & PARTS

MODEL NO.’S IR1, IR2, IR44 (INFRARED) (Cont’d)

DETAIL D

DETAIL E

– 8 –

Page 9

SERVICE & PARTS GAS BROILERS

TROUBLE SHOOTING THE HCB040 OVEN

PROBLEM POSSIBLE CAUSE

OVEN

TOO MUCH BOTTOM HEAT INSUFFICIENT HEAT INPUT

OVER ACTIVE FLUE

UNEVEN BAKE TEMPERATURE TOO LOW

IMPROPER OPERATION

SIDE BURNING IMPROPER BY-PASS SETTING

FLUCTUATING GAS PRESSURE

TOO MUCH TOP HEAT TEMPERATURE TOO HIGH

FAULTY VENTILATION

EXCESSIVE HEAT INPUT

THERMOSTAT NEEDS CALIBRATION

UNEVEN BAKE-SIDE TO SIDE APPLIANCE NOT LEVEL SIDE TO SIDE

OVEN BURNER, BOTTOM OR BAFFLES

IMPROPERLY INSTALLED

PULLING TO EDGE OF FAN WARPED PANS

OVEN NOT LEVEL

DOOR NOT CLOSING PROPERLY

UNEVEN BAKE-FRONT TO REAR OVER ACTIVE FLUE

UNIT NOT LEVEL, FRONT TO BACK

DRIED OUT PRODUCTS TEMPERATURE TOO LOW

BAKING TIME TOO LONG

THERMOSTAT CALIBRATION

PILOT OUTAGE PILOT FLAME TOO LOW

RESTRICTION IN PILOT ORIFICE

MALFUNCTIONING SAFETY VALVE THAT

OPERATES IN CASE OF PILOT OUTAGE

EXCESSIVE MEAT SHRINKAGE ROASTING TEMPERATURE TOO HIGH

TOP BURNER OPERATION

IMPROPER BURNER COMBUSTION

IMPROPER VENTILATION

EXCESSIVE VALVE HANDLE TEMPERATURE POOR DOOR FIT

OVEN DOOR LEFT OPEN

STICKING TOP BURNER VALVES

POOR IGNITION INSUFFICIENT INPUT

POOR AIR TO GAS ADJUSTMENT

RESTRICTION IN PILOT ORIFICE

RESTRICTION IN MAIN BURNER IGNITION

PORT RESTRICTION IN CONTROL VALVE

RESTRICTION IN GAS ORIFICE

– 9 –

Page 10

GAS BROILERS SERVICE & PARTS

TROUBLE SHOOTING - BROILERS

PROBLEM POSSIBLE CAUSE

UNEVEN BROILING TEMPERATURE TOO LOW

SIDE BURNING IMPROPER OPERATION

FLUCTUATING GAS PRESSURE

TOO MUCH TOP HEAT TEMPERATURE TOO HIGH

FAULTY VENTILATION

EXCESSIVE HEAT INPUT

OVER-RATED (PRESSURE HIGH OR

ORIFICE TOO LARGE)

UNEVEN BROIL SIDE TO SIDE UNIT NOT LEVEL SIDE TO SIDE

BROILER BURNER OR CERAMICS

IMPROPERLY INSTALLED

UNEVEN BROIL FRONT TO BACK UNIT NOT LEVEL FRONT TO BACK

DRIED OUT PRODUCTS BROILING TIME TOO LONG

OVER-RATED (PRESSURE HIGH OR

ORIFICE TOO LARGE)

PILOT OUTAGE PILOT FLAME TOO LOW

RESTRICTION IN PILOT ORIFICE

POOR IGNITION INSUFFICIENT INPUT

POOR AIR TO GAS ADJUSTMENT

RESTRICTION IN MAIN BURNER IGNITION PORT

PILOT ADJUSTMENT IS INCORRECT

– 10 –

Page 11

REPLACEMENT PARTS ORDERING

SERVICE & PARTS GAS BROILERS

NOTE: The following information must accompany a

replacement parts order or it cannot be filled.

A. Model and Style number

B. Type of Gas

C. Appliance finish, Black or Stainless Steel

(If applicable to part being replaced)

D. Blower/Motor - Volts, amps, and Hz. When applicable.

This information can be found on the rating plate of all

units.

Parts may be ordered from the Dealer, Service Agency or

Parts Depots.

– 11 –

Page 12

GAS BROILERS SERVICE & PARTS

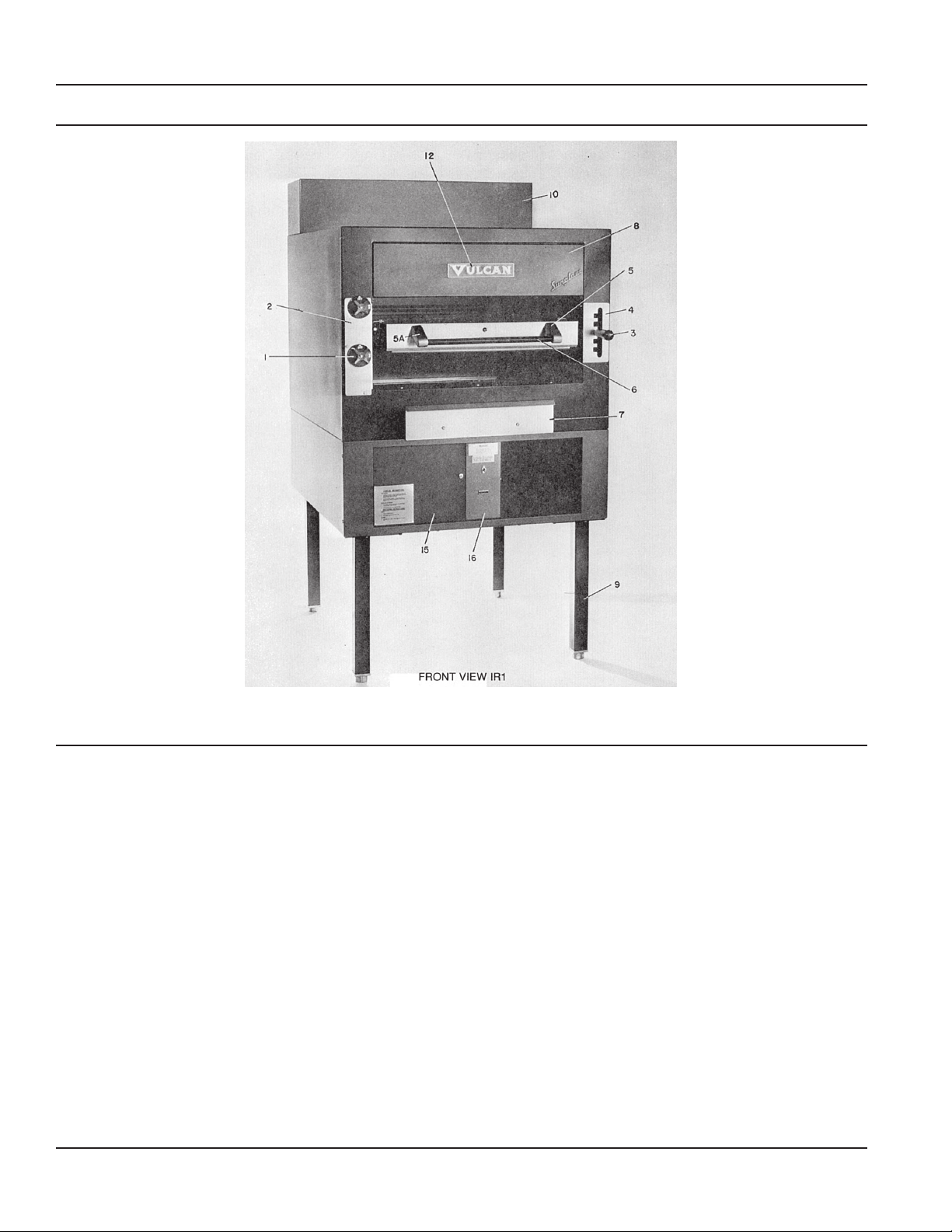

PARTS - FRONT VIEW IR1

IR1

ITEM NO. DESCRIPTION PART NO. QTY.

1 Burner Valve Knob (on-off) 107727-3 2

2 Burner Knob Cover Plate 114269-1 1

3 Grid Arm Handle 107785-2 1

4 Grid Arm Cover Index Plate 113609 1

5 Right Grid Post 104549-5 1

5A Left Grid Post 104549-6 1

6 Grid Handle 108246-1 1

7 Grease Collector Front 108161-1 1

8 Burner Shield Cover (Top) 111144-G1 1

9 Legs 113383-G1 4

9A Legs S.S. 111383-G2 4

10 Flue Riser 108218-5 1

11 Drip Tray Assembly (NS) 111040-G1 1

12 Vulcan Nameplate 105773-1 1

13 Grease Collector Assem. (NS) 107673-G1 1

14 I.D.TAB “R” 114639-1 1

14A I.D. TAB “L” 114639-2 1

15 Blower Cover Assembly 109030-G3 1

16 Lock Panel 3.0323-2 1

(NS) Not Shown

– 12 –

Page 13

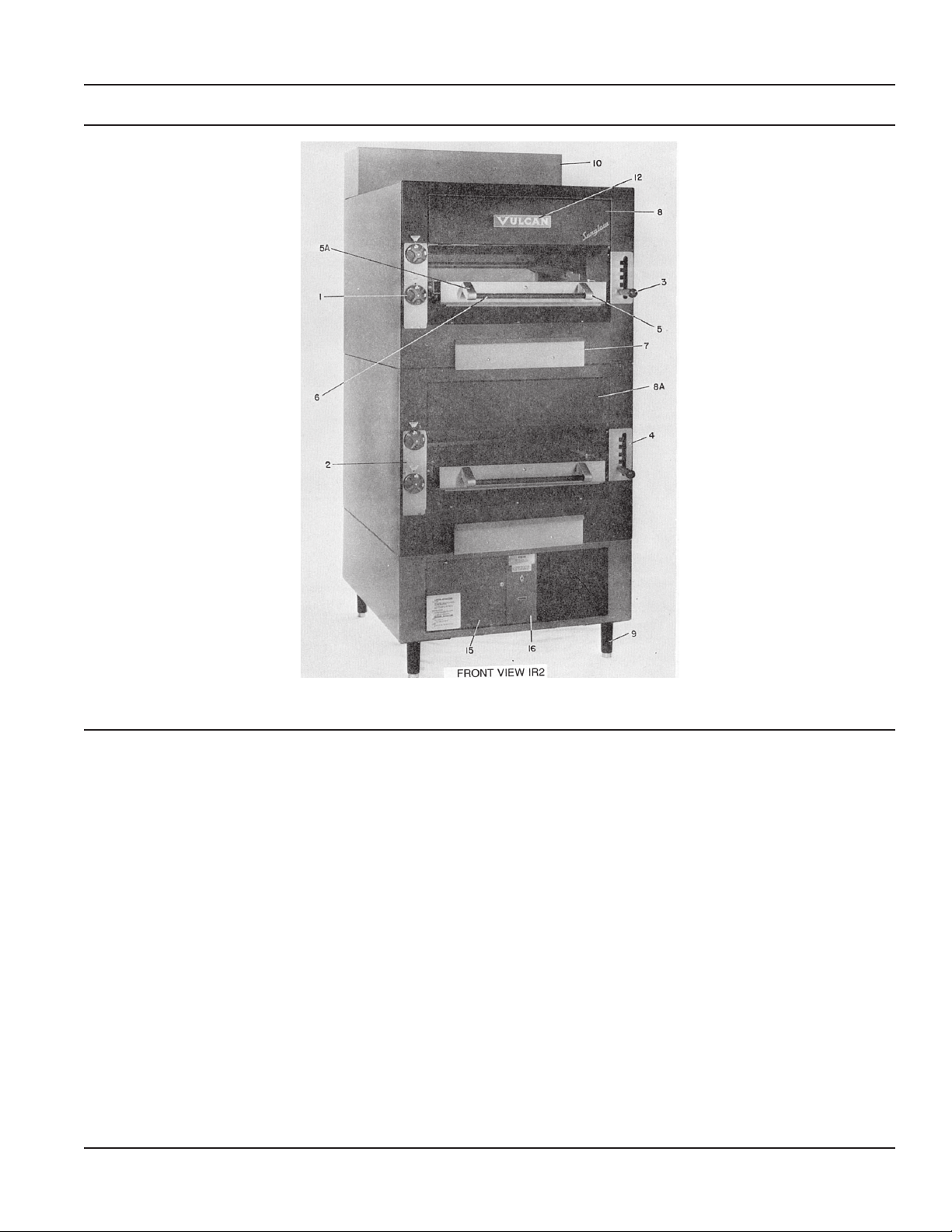

PARTS - FRONT VIEW IR2

SERVICE & PARTS GAS BROILERS

IR2

ITEM NO. DESCRIPTION PART NO. QTY.

1 Burner Knob (On-Off) 107727-3 4

2 Burner Knob Cover Plate 114269-1 2

3 Grid Arm Handle 107785-2 1

4 Grid Arm Cover Index Plate 113609-2 2

5 Right Grid Post 104549-5 1

5A Left Grid Post 104549-6 1

6 Grid Handle 108246-1 1

7 Grease Collector Front 108161-1 1

8 Burner Shield Cover (Top) 111144-G1 1

8A Burner Shield Cover (Bottom) 111144-G3 1

9 Legs 109840-1 4

9A Legs S.S. 109840-2 4

10 Flue Riser 108218-5 1

11 Drip Tray Assembly (NS) 111040-G1 1

12 Vulcan Nameplate 105773-1 1

13 Grease Collector Assembly (NS) 107673-G1 1

14 I.D. Knob Tab “R” (New style not shown) 114639-1 2

14A I.D. Knob Tab “L” (New style not shown) 114639-2 2

15 Blower Cover Assembly 109030-G3 1

16 Lock Panel 3.0323-2 1

(NS) Not Shown

– 13 –

Page 14

GAS BROILERS SERVICE & PARTS

PARTS - OLD STYLE GRID ASSEMBLY HCB040

HCB040

ITEM NO. DESCRIPTION PART NO. QTY.

1A Burner Valve Knob 102951 2

3 Grid Arm Handle (Old style shown) 107785-2 1

4 Grid Arm Cover/Index Plate 113609-2 2

5 Right Grid Post 104549-5 1

5A Left Grid Post 104549-6 1

6 Grid Handle 108246-1 1

9 (Adj.) Legs 109840-1 4

9A (Adj.) Legs (SS) 109840-2 4

12 Vulcan Nameplate 105773-1 2

19 Manifold Cover Assembly 109776-G1 1

19A Manifold Cover Assembly (SS) 109776-G2 1

20 Augratin Oven Door Assembly 105488-G1 1

20A Augratin Oven Door Assembly (SS) 105488-G2 1

21 Right Oven Door Post 104549-1 1

21A Left Oven Door Post 104549-2 1

22 Oven Door Handle 101847-1 1

23 Lower Burner Cover 105499-1 1

23A Lower Burner Cover (SS) 105499-2 1

28 Oven Handle (Lower) 109793-1 1

29 Right Door Post 109790-1 1

29A Left Door Post 109790-2 1

30 Control Panel 107699-3 1

30A Control Panel 107699-4 1

31 Valve Handle (Red) 102958 1

32 Lower Front Panel 109694-1 1

32A Lower Front Panel (SS) 109694-2 1

33 Oven Door Assembly 109791-G1 1

33A Oven Door Assembly (SS) 109791-G2 1

184 Grease Collector Front 109873-1 1

(SS) Stainless Steel

Photo shows old style grid handle assembly.

– 14 –

Page 15

PARTS - FRONT VIEW HCB 040

SERVICE & PARTS GAS BROILERS

– 15 –

Page 16

GAS BROILERS SERVICE & PARTS

PARTS - FRONT VIEW IR44

– 16 –

Page 17

SERVICE & PARTS GAS BROILERS

PARTS - FRONT VIEW IR44

IR44

ITEM NO. DESCRIPTION PART NO. QTY.

1A Burner Valve Knob Hi-Med-Lo 107727-4 2

3 Grid Arm Handle 107785-2 1

5 Right Grid Post 104549-6 1

5A Left Grid Post 104549-5 1

6 Grid Handle 107785-2 1

9 Adjustable Leg 109840-1 4

9A Adjustable Leg (SS) 109840-2 4

10 Flue Riser 114878-G1 1

11 Drip Tray Assembly (NS) 111040-G1 1

12 Vulcan Nameplate 105773-1 1

17 Left Hand Door Panel Assembly 112945-G1 1

17A Lt. Hd. Door Panel Assembly (SS) 112945-G3 1

18 Rt. Hd. Door Panel Assembly 112945-G2 1

18A Rt. Hd. Door Panel Assembly (SS) 112945-G4 1

19 Manifold Cover Assembly 109653-3 1

19A Manifold Cover Assembly (SS) 109653-4 1

20 Augratin Oven Door Assembly 105488-G1 1

20A Augratin Oven Door Assembly (SS) 105488-G2 1

21 Right Oven Door Post 104549-1 1

21A Left Oven Door Post 104549-2 1

22 Door Handle 101847-1 1

23 Burner Box Cover 105499-3 1

23A Burner Box Cover (SS) 105499-4 1

24 Pilot Light 111496-E4 1

25 Toggle Switch 21011-20 1

26 Lt. Door Panel Lining (NS) 112942-1 1

26A Lt. Door Panel Lining (NS) (SS) 112942-3 1

27 Rt. Door Panel Lining (NS) 112942-2 1

27A Rt. Door Panel Lining (NS) (SS) 112942-4 1

28 Low Profile Flue Rise (NS) 114878-1 1

28A Low Profile Flue Rise (NS) (SS) 114878-2 1

206 Cabinet Door Handle 108615-1 2

(NS) Not Shown

(SS) Stainless Steel

– 17 –

Page 18

GAS BROILERS SERVICE & PARTS

PARTS - FRONT VIEW HCB44

– 18 –

Page 19

SERVICE & PARTS GAS BROILERS

PARTS - FRONT VIEW HCB44

HCB44

ITEM NO. DESCRIPTION PART NO. QTY.

1A Burner Valve Knob 102957 2

3 Grid Arm Handle (Old style shown) 107785-2 1

4 Grid Arm Cover/Index Plate 113609-2 2

5 Right Grid Post 104549-5 1

5A Left Grid Post 104549-6 1

6 Grid Handle 108246-1 1

9 Adj. Leg 109840-1 4

9A Adj. Leg (SS) 109840-2 4

17 Door Panel Assembly, Left 112945-G1 1

17A Door Panel Assembly, Left (SS) 112945-G3 1

18 Door Panel Assembly, Right 112945-G2 1

18A Door Panel Assembly, Right (SS) 112945-G4 1

19 Manifold Cover Assembly 109776-G1 1

19A Manifold Cover Assembly (SS) 109776-G2 1

20 Augratin Oven Door Assembly 105488-G1 1

20A Augratin Oven Door Assembly 105488-G2 1

21 Right Oven Door Post 104549-1 1

21A Left Oven Door Post 104549-2 1

22 Oven Door Handle 101847-1 1

26 Left Door Liner (NS) 112942-1 1

26A Left Door Liner (NS) (SS) 112942-3 1

27 Right Door Liner (NS) 112942-2 1

27A Right Door Liner (NS) (SS) 112942-4 1

29 Lower Burner Cover 105499-1 1

29A Lower Burner Cover (SS) 105499-2 1

206 Door Handle 108615-1 2

(NS) Not Shown

(SS) Stainless Steel

Photo shows old style grid handle assembly

– 19 –

Page 20

GAS BROILERS SERVICE & PARTS

PARTS - FRONT VIEW HCB2

– 20 –

Page 21

PARTS - FRONT VIEW HCB2

SERVICE & PARTS GAS BROILERS

HCB1 HCB2

ITEM NO. DESCRIPTION PART NO. QTY. PART NO. QTY.

1 Burner Knob (On-Off) 107727-3 2 107727-3 4

2 Burner Knob Cover Plate 114269-1 1 114269-1 2

4 Grid Arm Cover Index Plate 113609-1 1 113609-1 2

5 Right Grid Handle Post 104549-5 1 104549-5 1

5A Left Grid Handle Post 104549-6 1 104549-6 1

6 Grid Handle 108246-1 1 108246-1 1

7 Grease Collector Front 108161-1 1 108161-1 2

8 Burner Shield Cover (Top) 108132-G3 1 108132-G3 1

8A Burner Shield Cover (Bottom) 108132-G5 1

9 Adj. Legs 109840-1 4 109840-1 4

9A Adj. Legs (SS) 109840-2 4 109840-2 4

10 Flue Riser 108218-5 1 108218-5 1

11 Drip Tray Assembly 111040-G1 1 111040-G1 1

12 Vulcan Nameplate 105773-1 1 105773-1 1

13 Grease Collector Assembly (NS) 107673-G1 1 107673-G1 1

14 I.D. Knob Tab “L” (Old style shown) 114639-2 1 114639-2 2

14A I.D. Knob Tab “R” (Old style shown) 114639-1 1 114639-1 2

29 Grid Arm Handle 107785-2 1 107785-2 1

(NS) Not Shown

(SS) Stainless Steel

Front View HCB1 Not Shown

– 21 –

Page 22

GAS BROILERS SERVICE & PARTS

PARTS - REAR VIEW IR1, IR2, IR44

ITEM IR1 IR2 IR44 HCB1 HCB2

NO. DESCRIPTION PART NO. QTY. PART NO. QTY. PART NO. QTY. PART NO. QTY. PART NO. QTY.

30 Body Back (Upper) 108210-3 1 108210-3 1

31 Body Back (Lower) 108210-1 1 108210-1 1 108210-1 1 108210-1 1

32 Body Back (Cabinet) 108987-G1 1 108987-G1 1 113500-F280 1 113500-F280 1

33 Inlet Pipe 113500-F280 1 113500-F280 1 113500-F2801 113500-F280 1

34 Elec. Supply Cord 105016-1 1 105016-1 1 105016-1 1 105016-1 1 105016 1

35 Elec. Cover Plate 108647-1 1 108647-1 1

36 Body Back 109896-1 1

– 22 –

Page 23

PARTS - FRONT VIEW FRAME REMOVED IR1 & IR2

SERVICE & PARTS GAS BROILERS

IR1 IR2

ITEM NO. DESCRIPTION PART NO. QTY. PART NO. QTY.

37 Air Channel Cover 115091-1 1 115091-1 2

38 Front Burner Shield Assembly 115095-G1 1 115095-G1 2

39 Fitting 1⁄2 CC to 1⁄2 MPT 3.0901-2 2 3.0901-2 4

40 Burner Sub-Manifold 114861-1 2 114861-1 4

41 Right Hand Burner Tube 115133-1 1 115133-1 2

42 Left Hand Burner Tube 115134-1 1 115134-1 2

43 Close Nipple 1⁄8" 113500-A6 4 113500-A6 8

44 Pilot Elbow Burner 105643-F 4 105643-F 8

44A Orifice Spud (Nat.) 10901-44 4 10901-44 8

44B Orifice Spud (PROPANE) 10901-55 4 10901-55 8

44C Orifice Spud (BUTANE) 10901-56 4 10901-56 8

45 Air Transition Box 115089-1 1 115089-1 1

46 Pressure Switch Tubing 109759-2 1 109759-2 1

47 Blower Motor 113552-1 1 113552-1 1

48 Solenoid 111497-F6 1 111497-F6 1

49 Regulator 108279-1 1 108279-1 1

50 Lock Panel 3.0323-2 1 3.0323-2 1

51 Toggle Switch 3.1500/ 1 3.1500/ 1

21922-20 21922-20

52 Signal Light 111496-E4 1 111496-E4 1

300 Pilot Shield (NS) 115807-1 4 115807-1 8

(NS) Not Shown

– 23 –

Page 24

GAS BROILERS SERVICE & PARTS

PARTS - FRONT VIEW FRAME REMOVED HCB2

HCB1 HCB2

ITEM NO. DESCRIPTION PART NO. QTY. PART NO. QTY.

44A Pilot Elbow Burner Nozzle (NAT.) 105643-A42 4 105643-A42 8

44B Pilot Elbow Burner Nozzle (PROPANE) 105643-F53 2 105643-F53 4

53 Elbow Street 1⁄2" x 3⁄8" 114812-1 2 114812-1 4

54 Pilot Manifold Assembly 111463-G1 1 111463-G1 2

55 Grid Arm Lifting Assembly 113607-G1 1 113607-G1 2

56 Upper Lever Arm Assembly 108870-G1 1 108870-G1 2

57 Lower Lever Arm Assembly 108774-G1 1 108774-G1 2

58 Grid Carriage Assembly 111038-G1 1 111038-G1 2

59 Roller Bearing Without Shaft (NS) 105655-1 2 105655-1 4

60 Roller Bearing With Shaft 105655-3 2 105655-3 4

61 Rt. Hd. Burner Tubing 108078-1 1 108078-1 2

62 Rt. Burner Tubing Valve to 108328-1 1 108328-1 1

Double CC Fitting

63 Lt. Burner Tubing Fitting to Valve 108329-1 1 108329-1 1

64 Burner Valve 107789-1 2 107789-1 4

65 Sub - Manifold Assembly 108076-G1 1 108076-G1 2

66 Spring Lifting Arm (Inner) 107724-1 2 107724-1 4

67 Spring Lifting Arm (Outer) 101992-2 2 101992-2 4

68 Fitting CC 3⁄8" to 1⁄2" CC 3.0131-3 2 3.0131-3 4

69 Pilot Valve 3.0130-2 2 3.0130-2 4

70 Fitting Straight 1⁄2" x 5⁄8" CC; 3.0131-2 2 3.0131-2 4

71 Fitting Straight Double 1⁄2" CC 3.0901-3 2 3.0901-3 4

72 Elbow 1⁄8" NPS x 1⁄4" CC 114800-3 1 114800-3 2

73 Pilot Tube Valve to CC Elbow 115229-1 1 115229-1 2

74 1" Manifold Pipe 108199-1 1 108199-1 2

75 Elbow Reducing 1" x 3⁄4" 114812-4 2 114812-4 4

– 24 –

Page 25

PARTS - GRID ASSEMBLY HCB2

SERVICE & PARTS GAS BROILERS

HCB1 HCB2 HCB040 HCB44

ITEM NO. DESCRIPTION PART NO. QTY. PART NO. QTY. PART NO. QTY. PART NO. QTY.

147 Grid Final Assembly 111050-G1 1 111050-G1 2 111050-G1 1 111050-G1 1

149 DripShieldRod (NS) 108111-2 1 108111-2 2 108111-2 1 108111-2 1

150 Lifting Arm Assembly (NS) 113607-G1 1 113607-G1 2 113607-G1 1 113607-G1 1

151 Burner Assembly 111551-G1 4 111551-G1 8 111551-G1 4 111551-G1 4

152 Burner Side Ceramics 104146-1 8 104146-1 16 104146-1 8 104146-1 16

153 Burner Center Ceramics 104145-1 12 104145-1 24 104145-1 12 104145-1 12

154 Lever Arm Bearing (NS) 107769-2 1 107769-2 2 107769-2 1 107769-2 1

155 Grid Stop Bolt Hex 104083-6 3 104083-6 6 104083-6 3 104083-6 3

Head 1⁄4" x 11⁄4"

156 Grid Carriage 111038-G1 1 111038-G1 2 111038-G1 1 111038-G1 1

– 25 –

Page 26

GAS BROILERS SERVICE & PARTS

PARTS - UPPER MAINFOLD ASSEMBLY HCBO40

HCB040

ITEM NO. DESCRIPTION PART NO. QTY.

69 Pilot Valve 104738-3 4

184 Grease Collector Front Panel (SS) 109873-1 1

184A Grease Collector Front Panel 109873-2 1

185 Grease Collector Assembly (SS) 109899-G2 1

185A Grease Collector Assembly 109899-G1 1

186 Pilot Orifice Spud Nat. (NS) 109125-1 4

186A Pilot Orifice Spud Mixed (NS) 109125-2 4

186B Pilot Orifice Spud Propane (NS) 109125-3 4

187 Burner Valve 108379-1 2

188 Burner Valve Tube, Rt. 108079-1 1

188A Burner Valve Tube, Lt. 108079-2 1

189 Pilot Supply Tube 111696-1 1

190 Elbow Nozzle Nat. Gas (NS) 105643-A32 4

190A Elbow Nozzle Propane Gas (NS) 105643-F53 4

190B Elbow Nozzle Butane Gas (NS) 105643-F54 4

(NS) Not Shown

(SS) Stainless Steel

– 26 –

Page 27

PARTS - IR44 WITH MANIFOLD COVER DROPPED

SERVICE & PARTS GAS BROILERS

IR44

ITEM NO. DESCRIPTION PART NO. QTY.

127 Drop Pipe 3⁄4" x 121⁄2" LG• 108425-1 1

128 Sub-Manifold 108422-G1 1

129 Valve HI-MED-LO (PROPANE) 108119-1L 2

129A Valve HI-MED-LO (NAT.) 108119-1N 2

130 Elbow 3⁄4" 90° 114798-5 1

– 27 –

Page 28

GAS BROILERS SERVICE & PARTS

PARTS - BURNER TUBING ASSEMBLY LT. & RT. IR44

IR44

ITEM NO. DESCRIPTION PART NO. QTY.

29 Grid Handle 107785-2 2

110 Burner Tubing 114863-1 2

111 Fitting 1⁄2 x 1⁄2 CC 3.0901-3 2

112 Lt. Hd. Burner Tubing 114749-1 1

113 Rt. Hd. Burner Tubing 114866-1 1

– 28 –

Page 29

PARTS - PILOT MANIFOLD ASSEMBLY IR44

SERVICE & PARTS GAS BROILERS

IR44

ITEM NO. DESCRIPTION PART NO. QTY.

44 Elbow Pilot Nozzle 105643-F 4

44A Orifice Spud (NAT.) 10901-44 4

44B Orifice Spud (PROPANE) 10901-55 4

44C Orifice Spud (BUTANE) 10901-56 4

89 Pilot Manifold Assembly 114860-1 1

135 Pilot Tube - Adj. Valve to 1/4" CC 114776-1 1

136 Burner Sub Assembly 114861-1 2

137 Front Burner Shield Assembly 114753-G1 1

138 Air Closure 114870-1 1

300 Pilot Shield (NS) 115807-1 4

(NS) Not Shown

– 29 –

Page 30

GAS BROILERS SERVICE & PARTS

PARTS - AUGRATIN OVEN COMPARTMENT IR44

IR44

ITEM NO. DESCRIPTION PART NO. QTY.

22 Handle 101847-1 1

23 Burner Box Cover 105499-3 1

139 Augratin Oven Bottom Baffle Assembly 105522-G1 1

140 Lt. Hd. Side Lining Assembly 105489-G2 1

141 Rt. Hd. Side Lining Assembly 105489-G3 1

142 Post, Left Hand 104549-2 1

143 Post, Right Hand 104549-1 1

144 Oven Door Assembly 105488-G1 1

145 Oven Rack (Augratin Oven) 104074-2 1

146 Oven Bottom Assembly (Augratin) 105123-G3 1

– 30 –

Page 31

PARTS - CONTROL PANEL

SERVICE & PARTS GAS BROILERS

IR44

ITEM NO. DESCRIPTION PART NO. QTY.

131 Control Panel 109653-5 1

132 Knob HI - MED - LO 107727-4 2

133 Signal Light 111496-E4 1

134 Toggle Switch 21022-20 1

– 31 –

Page 32

GAS BROILERS SERVICE & PARTS

PARTS - GRID ASSEMBLY HCBO40 & HCB44

HCB040 HCB44

ITEM NO. DESCRIPTION PART NO. QTY. PART NO. QTY.

147 Grid Final Assembly 111050-G1 1 111050-G1 1

148 Grid Drip Shield 111040-G1 1 111040-G1 1

149 Drip Shield Rod 111280-1 1 111280-1 1

150 Lifting Arm Assembly 1113612-G1 1 113612-G1 1

– 32 –

Page 33

SERVICE & PARTS GAS BROILERS

PARTS - AUGRATIN OVEN SECTION HCBO40 & HCB44

PARTS - AUGRATIN OVEN BAFFLE IR44, HCB44 & HCBO40

IR44 QTY. HCB040 QTY. HCB44 QTY.

ITEM NO. DESCRIPTION PART NO. PART NO. PART NO.

139 Oven Bottom Baffle Assembly 105522-G1 1 105522-G1 1 105522-G1 1

140 Oven Side Lining Assem., Lt. Hd. 105489-G2 1 105489-G2 1

140A Oven Side Lining Assem., Lt. Hd. (SS) 105489-G4 1 105489-G4 1

141 Oven Side Lining Assem., Rt. Hd. 105489-G1 1 105489-C1 1

141A Oven Side Lining Assem., Rt. Hd. 105489-G3 1 105489-G3 1

144 Augratin Oven Door Assembly 105488-G1 1 105488-G1 1

144A Augratin Oven Door Assembly (SS) 105488-G2 1 105488-G2 1

145 Oven Rack 104074-2 1 104074-2 1

146 Oven Bottom Assembly 105123-G3 1 105123-G3 1

(SS) Stainless Steel

– 33 –

Page 34

GAS BROILERS SERVICE & PARTS

PARTS - OVEN MANIFOLD & CONTROLS HCBO40

HCB040

ITEM NO. DESCRIPTION PART NO. QTY.

156 Pilot Valve 104193-1 1

157 Burner Valve 108379-1 1

158 J Hook 113091-1 2

159 Bell Crank 103956-1 2

160 Oven Door Spring 112014-2 1

161 Bell Crank Pin 103971-1 2

162 Pilot Outage Protection Valve 107798-4 1

163 Thermostat 107522-1 1

164 Filter 105922-1 1

165 Pilot Tubing Shut Off to Filter 109822-1 1

166 Pilot Tubing Filter to Tubing 109823-1 1

167 Pilot Tubing Shut Off to Pilot (NS) 113348-1 1

168 Oven Burner Tubing 109824-1 1

169 Pilot Tubing Pilot Valve to Shut Off 107846-1 1

170 Oven Door Hook, Right 105618-2 1

171 Oven Door Hook, Left 105618-1 1

172 Oven Burner Nozzle (NAT.) (NS) 3.0702-2 1

172A Oven Burner Nozzle (PROPANE) (NS) 3.0702-F 1

173 Oven Orifice Spud Propane 10901-49 1

173A Oven Orifice Spud Butane 10901-50 1

(NS) Not Shown

– 34 –

Page 35

PARTS - OVEN BAFFLE ASSEMBLY

SERVICE & PARTS GAS BROILERS

HCB040

ITEM NO. DESCRIPTION PART NO. QTY.

174 Oven Bottom Baffle 105124-5 1

175 Foil Face Insulation 105928-4 1

176 Oven Bottom Insulation Pan 109787-1 1

176A Oven Bottom Insulation Pan (SS) 109787-2 1

(SS) Stainless Steel

– 35 –

Page 36

GAS BROILERS SERVICE & PARTS

PARTS - OVEN SECTION HCBO40

HCB040

ITEM NO. DESCRIPTION PART NO. QTY.

177 Burner Assembly (Oven) 109819-G1 1

178 Upper Rt. Aeration Pan 109677-1 1

178A Upper Rt. Aeration Pan (SS) 109677-2 1

178B Upper Lt. Aeration Pan 109677-3 1

178C Upper Lt. Aeration Pan 109677-4 1

179 Lighting Hole Cover 111928-1 2

179A Lighting Hole Cover (SS) 111928-2 2

180 Oven Bottom Assembly 105123-G3 1

181 Oven Rack 104047-2 2

182 Oven Side Lining Assem., Lt. Hd. 109778-G2 1

182A Oven Side Lining Assem., Lt. Hd. (SS) 109778-G4 1

183 Oven Side Lining Assem., Rt. Hd. 109778-G1 1

183A Oven Side Lining Assem., Rt. Hd. (SS) 109778-G3 1

(SS) Stainless Steel

– 36 –

Page 37

PARTS - PILOT ASSEMBLY IR1, IR2, IR44

SERVICE & PARTS GAS BROILERS

IR1 IR2 IR44

ITEM NO. DESCRIPTION PART NO. QTY. PART NO. QTY. PART NO. QTY.

69 Pilot Adj. Valve 104738-3 1 104738-3 2 104738-3 1

89 Pilot - Sub Manifold 114860-1 1 114860-1 2 114860-1 1

90 Pilot Tube 114748-1 4 114748-1 8 114748-1 4

91 Fitting 1⁄8" MPT x 1⁄4" CC 114700-1 4 114700-1 8 114700-1 4

92 Pilot Orifice 114795-4 4 114795-4 8 114795-4 4

93 Pilot Support Housing 114862-1 4 114862-1 8 114862-1 4

94 Pilot Burner Nozzle (NAT.) 114795-1 4 114795-1 8 114795-1 4

94A Pilot Burner Nozzle (PROPANE) 114795-2 4 114795-2 8 114795-2 4

– 37 –

Page 38

GAS BROILERS SERVICE & PARTS

PARTS - MANIFOLD ASSEMBLY (TOP) IR2

ITEM NO. DESCRIPTION IR2 QTY.

PART NO.

95 Fitting 3⁄8" x 1⁄2" CC 3.0130-3 2

96A HI-LO Valve 110610-5 2

97 Manifold Pipe Assembly 108199-G2 1

102 Elbow - Reducing 3⁄4" x 1" LG. 114812-4 1

114 Elbow - Reducing 1⁄4" x 3⁄8" 114812-1 2

115 Close Nipple 1⁄4" 113500-B7 2

116 Nipple 3⁄4" x 61⁄4" LG. 113500-E50 1

117 Nipple Closed 3⁄4" 113500-E11 1

118 Union - Male Female 1" 114803-2 1

119 Elbow - Reducing 1⁄2" x 3⁄4" 114812-3 2

120 Nipple 1⁄2" x 21⁄2" LG. 113500-D20 1

121 Union 1⁄2" 114797-4 1

122 Elbow 1⁄2" 90° 114798-4 1

123 Fitting 1⁄2" x 5⁄8" CC 114700-6 2

124 Tubing 5⁄8" 109298-1 1

125 Elbow - Reducing 3⁄4" 114812-3 1

– 38 –

Page 39

SERVICE & PARTS GAS BROILERS

PARTS - MANIFOLD ASSEMBLY (BOTTOM) IR1 & IR2

IR1 IR2

ITEM NO. DESCRIPTION PART NO. QTY. PART NO. QTY.

95 Fitting 3⁄8" x 1⁄2" CC 3.0130-3 2 3.0130-3 2

96 HI-LOW Valve 110610-5 2 110610-5 2

97 Manifold Assembly 108199-G2 1 108199-G2 1

98 Union 1" Male- Female 114803-2 2 114803-2 2

99 Tee Reducing 1" x 1" x 3⁄4" 114789-1 1 114789-1 1

100 Pipe Plug 3⁄4" 114799-4

101 Nipple 1" x 12" LG. 113500-F96 1 113500-F96 1

102 Elbow Reducing 3⁄4" x 1" 114812-4 2 114812-4 2

103 “B” Valve 104949-1 1 104949-1 1

104 Pilot Tube 115156-1 1 115156-1 1

105 Solenoid 111497-F6 1 111497-F6 1

106 Regulator (PROPANE) 108279-3 1 108279-3 1

106A Regulator (NAT.) 108279-1 1 108279-1 1

107 Pipe 1" x 35" LG. 113500-F280 1 113500-F280 1

108 Nipple 3⁄4" x 1-LG. 113500-E8 3 113500-E8 3

109 Elbow Fitting 1⁄8" x 1⁄4" CC 114800-3 1 114800-3 1

NOTE: Photo shows street El Manifold Construction.

Proper construction uses (2) 3⁄4" x 1" reducing elbows 114812-4 with (2) nipples 3⁄4" x 1" 113500-E8.

Select For

[ ]

Proper Gas

– 39 –

Page 40

GAS BROILERS SERVICE & PARTS

PARTS - BLOWER MOTOR IR1 & IR2

IR1 IR2

ITEM NO. DESCRIPTION PART NO. QTY. PART NO. QTY.

47 Blower & Motor 113552-1 1 113552-1 1

48 Solenoid 111497-F6 1 111497-F6 1

49 Regulator (NAT.) 108279-1 1 108279-1 1

49A Regulator (PROPANE) 108279-3 1 108279-3 1

50 Lock Panel 3.0323-2 1 3.0323-2 1

51 Toggle Switch 3.1108 1 3.1108 1

52 Signal Light 111496-E4 1 111496-E4 1

191 Tomic Connector 3⁄8" 106774-4 4 106774-4 4

192 Conduit 10" Long 114540-B10 1 114540-B10 1

193 Pressure Switch 109254-1 1 109254-1 1

– 40 –

Page 41

PARTS - MANIFOLD CONTROLS IR44

SERVICE & PARTS GAS BROILERS

ITEM NO. DESCRIPTION IR44

PART NO. QTY.

47 Blower & Motor 113552-1 1

48 Solenoid 111497-F3 1

49 Regulator (NAT) 108279-1 1

49A Regulator (PROPANE) Select for Proper Gas 108279-2 1

130 Elbow 3⁄4" 90° 114798-5 1

193 Pressure Switch 114755-1 1

194 Air Disc 109696-G1 1

195 Disc Support 113551-1 1

196 Street El 3⁄4" 114811-2 1

197 Air Tube 114867-1 1

198 Union 3⁄4" Male - Female 114803-1 2

199 Support Angles, Left 113550-1 1

199A Support Angles, Right 113550-2 1

200 Bracket 113556-1 1

201 Riser Pipe 3⁄4" x 83⁄4" 113500-E70 1

202 Pipe 3⁄4" x 133⁄16" 113500-E106 1

204 Nipple - Closed 3⁄4" 113500-E11 1

205 Grease Pan 100994-G1 1

206 Air Duct Cover 114757-3 1

207 Air Duct (NS) 114756-1 1

208 Drop Pipe 3⁄4" x 121⁄2" 113500-E100 1

[ ]

– 41 –

Page 42

GAS BROILERS SERVICE & PARTS

PARTS - BURNER ASSEMBLY IR1 & IR2

IR1 IR2

ITEM NO. DESCRIPTION PART NO. QTY. PART NO. QTY.

76 Infrared Burner Assembly 114754-1 4 114754-1 8

– 42 –

Page 43

SERVICE & PARTS GAS BROILERS

PARTS - BURNER ASSEMBLY & CERAMICS HCB1 & HCB2

HCB1 HCB2

ITEM NO. DESCRIPTION PART NO. QTY. PART NO. QTY.

151 Burner Assembly 111551-G1 4 111551-G1 8

152 Burner Ceramic- Sides 104146-1 8 104146-2 16

153 Burner Ceramic-Center 104145-1 12 104145-1 24

– 43 –

Page 44

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

Loading...

Loading...