Page 1

GRS, GRD, AND GRC 25, 35, 45, 65 AND 85

MODEL

MODEL FRYERS

ML-52077

ML-52078

ML-52079

ML-52080

ML-52081

ML-52082

ML-52306

ML-52307

ML-52139

ML -52308

MODEL GRD35

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791 FORM 30912 (1-95)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO SERVICE AND ADJUST

THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE

SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED FROM THE LOCAL GAS

SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN SHUT OFF VALVE AND CONTACT THE

LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION

OR MODIFICATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ

THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO OPERATE THIS DEVICE.

2

Page 3

TABLE OF CONTENTS

Page

2

Important Safety Information

Codes and Standards Information

Manual Uses Information

Rating Plate Information

Service Warnings

Tools Required for Servici ng

Section I Service Checks & Adjustments

Section II Service Removal and Replacement of Controls

Section III Wiring Information

CODES AND STANDARDS

Vulcan-Hart Fryers are to be installed in accordance with state and local codes, or in the absence of local codes, the National

Fuel Gas Code, ANSI-Z223.1 (latest edition), available from the American Gas Association, Inc., 1515 Wilson Boulevard,

Arlington, VA. 22209 and with ANSI-NFPA Standard #96 (latest edition), Vapor Removal From Cooking Equipment, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

HOW TO USE THIS MANUAL

This Manual is dedicated to the servicing of the GRS, GRD, and GRC Series Vulcan Gas Fryers. The Manual is divided into 3

sections, GRS,GRD, AND GRC SERIES SERVICE CHECKS & ADJUSTMENTS, GRS, GRD, and GRC REMOVAL AND

REPLACEMENT OF COMPONENT PARTS and GRS, GRD AND GRC WIRING INFORMATION. Refer to the Table of Contents

when looking for a specific performance check or procedure. For additional Technical assistance contact the Vulcan Hart Service

Dept. at the phone number shown on the cover of this manual. Read the following rating plate and service warnings before

preforming any service work. Refer to parts manual F30782 to identify service parts for GRS, GRD and GRC Fryers.

Page 3

Page 3

Page 3

Page 3

Page 3

Pages 4-10

Pages 12-60

Pages 61-109

RATING PLATE

The rating plate stating model number, serial number, manufacturing date, gas type, voltage and amperage is located on the

inside fryer door panel.

SERVICE WARNINGS

Hot oil and parts can cause burns, use care when serv icing this appliance. If fryer is pulled from the installation area for servicing,

reinstall the fryer at least 16" away form any open flame appliance with back and sides of fryer 6" away from combustible and 0"

away from noncombustible construction. The high limit is a shut off device which senses the temperature of the appliance to

prevent over heating. The high limit operates independently and will automatically cause equipment shut down should the

primary control fail. If this situation occurs, DO NOT attempt to bypass the high limit.

TOOLS REQUIRED

The following is a listing of tools required to perform the service checks in this manual

1. Standard set of hand tools.

2. Volt Meter with a sensitivity of at least 20,000 ohms per volts.

3. Temperature test er (thermocouple or digital pyrometer).

4. Gas test kit.

3

Page 4

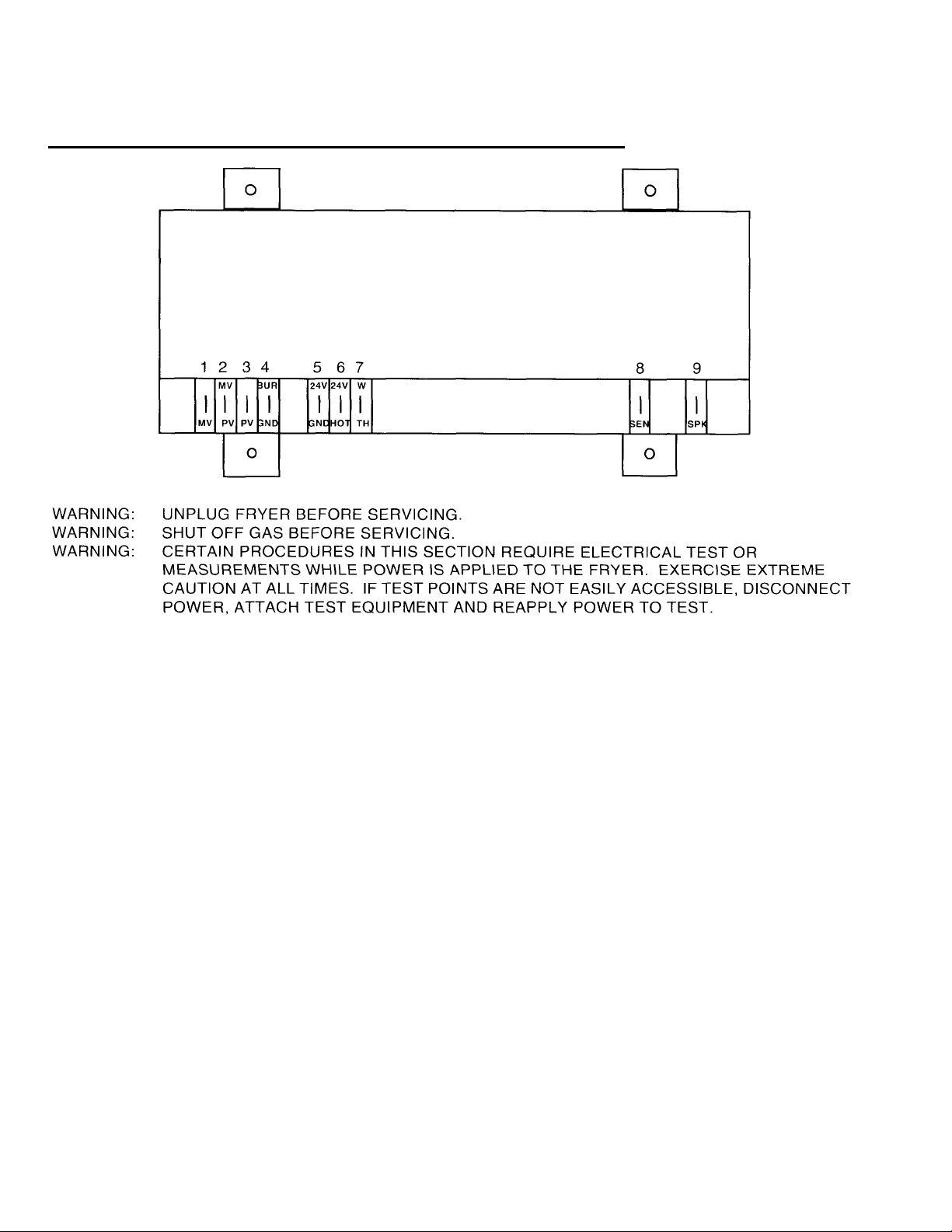

SECTION I

GRS,GRD AND RC SERVICE CHECKS & ADJUSTMENTS

WARNING: UNPLUG FRYER BEFORE SERVICING.

WARNING: SHUT OFF GAS BEFORE SERVICING.

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR

MEASUREMENTS WHILE POWER IS APPLI ED TO THE FRYER. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POINTS ARE NOT EASILY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST

EQUIPMENT AND REAPPLY POWER TO TEST.

VENTILATION CHECKS

NOTE: Do not connect the fryer flue directly to the vent.

CAUTION: The vent of the appliance should be checked every 6 months for restrictions.

GAS SUPPLY CHECKS

NOTE: If gas supply piping system is going to be tested at a test pressure of in excess of 1/2 psig (3.45 Kpa), the fryer and

its individual shut -off valve must be disconnected from the supply line. If the gas supply pipping system is going to

be tested at a test pressure equal to or less than 1/2 psig (3.45Kpa), the individual manual shut -off valve must be

closed during testing.

The fryer burners operate in conjunction with a combination gas valve pressure regulator. Verify that the valve

is set for a rating of 4" Water Column for Natural Gas and 10" Water Column for Propane Gas.

Verify that the facility pressure is at least 5" Water Column for Natural Gas and 11" Water Column for Propane.

Also verify that the gas connection pipe line is at least 1/2" for a single body fryer and

1-1/14" for a battery of fryers.

Verify that the fryer is installed in accordance with all local and state authorities having jurisdiction.

GAS CONNECTION CHECK

1. Insure that facility main gas valve is open.

2. Insure that fryer combination gas valve is open.

3. Using a soap solution check for gas leakage at all gas line connection points.

STORE LINE GAS PRESSURE CHECK

1. Connect manome ter to the manual gas shut off valve pressure tap.

2. Be sure gas supply line is open and that shut off valve is open

3. Manometer reading should be at least 5 in. water column natural (7 in. for battery) and 11 in. water column propane (12 for

battery).

4. If the above is not proven instruct store owner to have pressure problem corrected before performing any other service work

to fryer(s).

4

Page 5

COMBINATION VALVE GAS PRESSURE CHECK

1. Check pressure rating of appliance as stated on the fryer door.

2. Connect a manometer to the pressure tap of the gas combination valve (gas tap is marked on valve).

3. Turn on all appliance burners.

4. Open the pressure tap of the manometer.

5. The manometer reading should match the pressure rating inches water column as stated on the appliance rating plate.

6. If pressure rating is off check the incoming store gas pressure line. If store line pressure is good continue with the following

steps.

7. Remove the regulator adjustment cap from the combination valve.

8. Turn the gas adjustment screw clockwise to increase pressure and counterclockwise to decrease pressure.

9. Adjust pressure so that manometer reading agrees with the rating plate.

ON-OFF ROCKER SWITCH (D.P.S.T.)

1. Unplug fryer.

2. Follow steps under Removal of Control Panels.

3. Note and disconnect wiring from switch.

4 With an ohm meter and switch in the "off" position measure for continuity across the (2) switch pins that were connected to

power. An ohm reading of infinity should be found.

5. With an ohm meter and switch in the "on" position measure for continuity across the (2) switch pins that were connected to

power. An ohm reading of 0 should be found.

6. If readings measured in either steps 4 or 5 do not agree with what is stated in these steps replace the switch.

SIGNAL LIGHT

1. With unit power connected follow steps for Removal of Cooker Control Panel except do not disconnect the control panel

electric supply wire harness.

2. Turn power switch "on".

3. If light fails to illuminate, with a voltage meter measure for voltage of between 110 and 120 volts across the light

connections. If voltage is not found, replace light.

BURNER PILOT CHECK

1. Follow steps 1-8 under Removal of Burner.

2. Follow steps 1-3 under Removal of Burner Pilot and Orifice.

3. Examine the pilot body and orifice for clogging.

4. If clogged blow through one end of device. If clogging is still evident soak in warm water, use small probe or contact cleaner

to clear the obstruction. Do Not enlarge pilot orifice opening. If clogging still persists install new body or orifice as required.

5. Follow steps 1-2 above in reverse to install new parts or reinstall repaired parts.

TRANSFORMER CHECK

1 Follow steps 1-6 under Accessing of Controls Inside the Control Box.

2. Follow Steps 1-4 under Removal of Transformer.

3. With a volt meter and the appliance "on", check the voltage across the load and line terminals. Voltage should match that of

the transformer markings.

EXAMPLE: Transformer marked - PRI. 120V

SEC. 24VAC

Means that the load input reading should be 120V and the line output reading should be 24V.

4. If the readings do not match replace the transformer.

5. If readings do match but transformer problem is still suspected, check for resistance across the load terminal.

5

Page 6

HI LIMIT CHECK

1. Place pyrometer in the tank 1/2" above the crumb screen in the center of the vat.

2. Turn fryer on.

3. Bypass the hi limit by running a jumper wire between pins 13 and 14 on the temperature board. Run the appliance

temperature up to between 465-470 degrees F.

4. Remove bypass jumper, observe reading, the hi limit should trip fryer heating at between the temperatures of 435-465

degrees F. If tripping does not occur replace limit.

FRYER TEMPERATURE CALIBRATION CHECK

1. Turn fryer on and allow temperature to stabilize by letting the fryer cycle on and off, after reaching the set temperature, at

least three times.

2. Place a pyrometer sensor in the tank 1/2" above the crumb screen in the center of the vat.

3. After the stabilizing period the shortening temperature reading of the pyrometer should match the

temperature dial with in plus or minus 10 degrees for GRS Fryers and 5 degrees for GRD and GRC Fryers.

4. If readings are not in tolerance continue with the following steps.

5. Turn temperature dial to a mid range position.

6. Allow temperature to stabilize for several minutes.

7. For GRS Fryers remove temperature dial knob and with a small flat head screwdriver rotate the adjustment screw to match

pyrometer reading clockwise to increase and counterclockwise to decrease setting. One quarter turn will change the

temperature by 18 degrees.

For GRD Fryers using small flat blade screwdriver loosen the temperature control knob set screw. Without moving the shaft

rotate the knob to match the reading of the pyrometer and retighten knob.

8. Check temperature cycling again to insure proper calibration.

BASKET LIFT MICRO SWITCH (Option)

1. Follow steps 1-6 under Removal of Basket Lift Back.

2. Remove switch wiring. Engage the switch and with an ohm meter check for continuity across the common and normally

open circuits. If continuity is not shown replace the switch.

BASKET LIFT MOTOR (Option)

1. Follow steps 1-6 under Removal of Basket Lift Back.

2. Follow steps 1-7 under Removal of Basket Lift Motor.

3. With volt meter and power on check for voltage to the motor.

4. Verify that the motor voltage is proper for the unit voltage as stated on the appliance rating plate.

5. Check the motor wire connections.

6. Unplug the fryer and disconnect the motor wires at the motor terminals.

7. With ohm meter measure the resistance across the terminals. The resistance should be about 28 ohms.

8. If resistance is not correct replace the motor unit.

BASKET LIFT TIMER (Option)

1. Follow steps 1-2 under Removal of Control Panel (Solid State Construction).

2. Check for good wire connection at the terminals.

3. Push power switch "on".

4. With a volt meter check for 24vac across the input terminals of L1 and L2.

5. With a volt meter check for 24vac across the load terminals after setting the timer and pushing the timer button. Reading

should remain constant at 24vac until the timer runs out.

6. If the above readings are not achieved replace timer.

BASKET LIFT ARM ADJUSTMENT (Option)

This is only required if basket lift arm is not properly raising and lowering the fryer baskets correctly into the tank.

1. Turn the fryer off and allow it cool.

2. Remove the fryer baskets.

3. Pull lift arm from the cooker

4. Turn the adjustment bolt, by hand, to the required height.

6

Page 7

FILTER INTER PLUMB DISCARD TUBE (Option)

1. Close the drain valve.

2. Place shortening discard pan under the tube plug end that will be serviced.

3. With a pipe wrench open the plugged end of the tube up.

4. Insert the clean-out rod supplied with the fryer into the opening.

5. Push the rod in and out of the tube to clear any debris that may be clogging the tube.

6. If clean out rod is not long enough, a plumber's snake may be required to dislodge a clog.

Page 8

SECTION I

GRS SERIES (ONLY) SERVICE CHECKS

WARNING: UNPLUG FRYER BEFORE SERVICING.

WARNING: SHUT OFF GAS BEFORE SERVICING.

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR

MEASUREMENTS WHILE POWER IS APPLIED TO THE FRYER. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POINTS ARE NOT EASILY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST EQUIPMENT

AND REAPPLY POWER TO TEST.

CONTROL SYSTEM OVERVIEW:

1. The thermopile (T.P.) provides the total control voltage for this system.

A. One side of the T.P. is connected to the common (C) of the high limit (H.L.).

B. B. The other side of the T.P. is connected to the normal open (N.O.) of the H.L.

C. The "C" of a the H.L. (below the H.L. trip temperature.) is connected through the

normally closed (N.C.) contact of the H.L. through wire #3 to the combination valve

pilot connection (common).

D. The other side of the pilot valve is connected through wire #4 to wire #1 to H.L. N.O.

which holds the pilot valve voltage, closing the gas valve.

2. The thermostat controls heat to the fryer.

A. One side of the millivolt supply is connected through the H.L. system as described

above to the thermostat common (wire #2 ) of the combo valve.

B. The other side of the T.P. is connected from the "N.O." of the high limit to the

thermostat through wire #1.

C. When the thermostat calls for heat (closed circuit) power from the T.P. is then

connected to the other combination valve thermostat connection through wire #2.

D. If the H.L. trips, the T.P. is connected across the 0 OHMS, the output voltage of

the T.P. drops to 0.0 millivolts and the thermostat coil of the combination (combo)

valve drops out shutting the thermostat valve.

3. Total shutdown

A. High limit trip causes 0.0 millivolts to both coils of the combo valve, causing both

valves to close.

D. Pilot relight cannot be accomplished until oil cools sufficiently to allow H.L. to close.

E. C. Any wire in the system being cut or broken will cause shutdown of the system.

QUICK SYSTEMS CHECK:

1. Check MV at wire #'s1&3 and with pilot lighting procedure.

A. If good and pilot lights, then pilot combination combo and H.L. are good.

B. If 0 volts (pilot will not stay lit), check H.L. and open circuit T.P. If good (300MV)

check H.L. If the H.L. is good replace the combo valve.

C. Check for voltage at disconnected T.P. If 0 volts, replace T.P. If good (300MV)

check H.L. If H.L. good, replace combo valve.

2. Turn "On" thermostat -burners should light.

A. If no burner operation, check:

-Voltage at combo valve. If voltage is good replace valve.

- Pilot relight cannot be accomplished until oil cools sufficiently to allow H.L. to close.

B. If 0 volts, check voltage between wire #2 of combo valve and of the thermostat. If good, check resistance of thermostat

and wire #3. If no voltage, check resistance of thermostat and wire #4. If no voltage, check resistance of wire #1 to "N.O." of

high limit.

8

Page 9

SECTION I

GRD AND GRC SERIES (ONLY) SERVICE CHECKS

If erratic ignitor operation is experienced check for the following:

1. If you are experiencing system lock out, reset system by turning power switch off wait several minutes and turn switch on.

2. Check for good metal to metal contact between the pilot bracket and main pilot burner.

3. Check that all lead connections from the ignition module to the ignitor system are solid.

4. Check that GRD (BUR) lead from the module to the pilot burner are solid and that there is not any damage to the wiring. If

damage is detected either replace the ignitor assembly or the ignitor wire with no. 14-18 gauge, moisture-resistant, thermoplastic

insulated wire with a min. 105 degrees C (221 degrees F.) rating.

5. Check the ceramic flame rod insulator of the ignitor for cracks or evidence of extreme heat. If one or both of these conditions are

found replace the pilot ignitor assembly.

6. Check to insure that ignitor boot is not loose or damaged.

If the above visual checks are positive the following checks should be performed using a jumper wire and voltage meter.

CHECKING THE SPARK IGNITION CIRCUIT

WARNING: THE IGNITION CIRCUIT GENERATES OVER 10,000 VOLTS AND ELECTRIC SHOCK CAN RESULT. DO NOT

TOUCH THE STRIPPED END OF JUMPER TO THE SPARK TERMINAL.

NOTE: You will need a short jumper wire made from ignition cable or other heavily insulated wire.

1. Close the manual gas valve.

2. Disconnect the ignition cable at the SPARK terminal on the module.

9

Page 10

3. Push power switch ON and immediately touch one end of the jumper firmly to the GND terminal on the module. Do not touch the

jumper to the SPARK terminal, but, move the free end of the jumper slowly towards the SPARK terminal until a spark is

established.

Pull the jumper slowly away from the SPARK terminal and note the length of the gap when the sparking stops. See table below for

results and action to be taken.

ARC LENGTH ACTION

No arc or arc less than 1/8". Verify power at module input terminal. Replace

module if power is verified.

Arc 1/8" or longer Voltage output is OK.

If you are getting spark but the spark continues after the pilot is lit check the following.

4. Check for ground wire and ignition cable continuity.

5. Check that flame rod is clean.

6. Check for crack in ceramic insulator again.

7. Check that pilot flame covers rod and is steady and blue. Adjust pilot or pilot flame if necessary.

8. If the above are all in good condition replace module.

PILOT CHECK (Pilot will not light)

1. Check that all manual gas valves are open, that supply tubing and pressure are good and pilot orifice is not blocked.

2. Check electrical connections between module and pilot operator on gas combo valve.

3. With volt meter check for 24Vac across PV -MV/PV terminals on module. If voltage is good replace the combo valve. If voltage is

bad replace the module.

BURNER CHECK (Main burner will not light)

1. Check for 24Vac across the MV-MV/PV terminals. If voltage is bad replace the module.

2. Check electric connection between the module and gas combo valve. If good replace the combo valve.

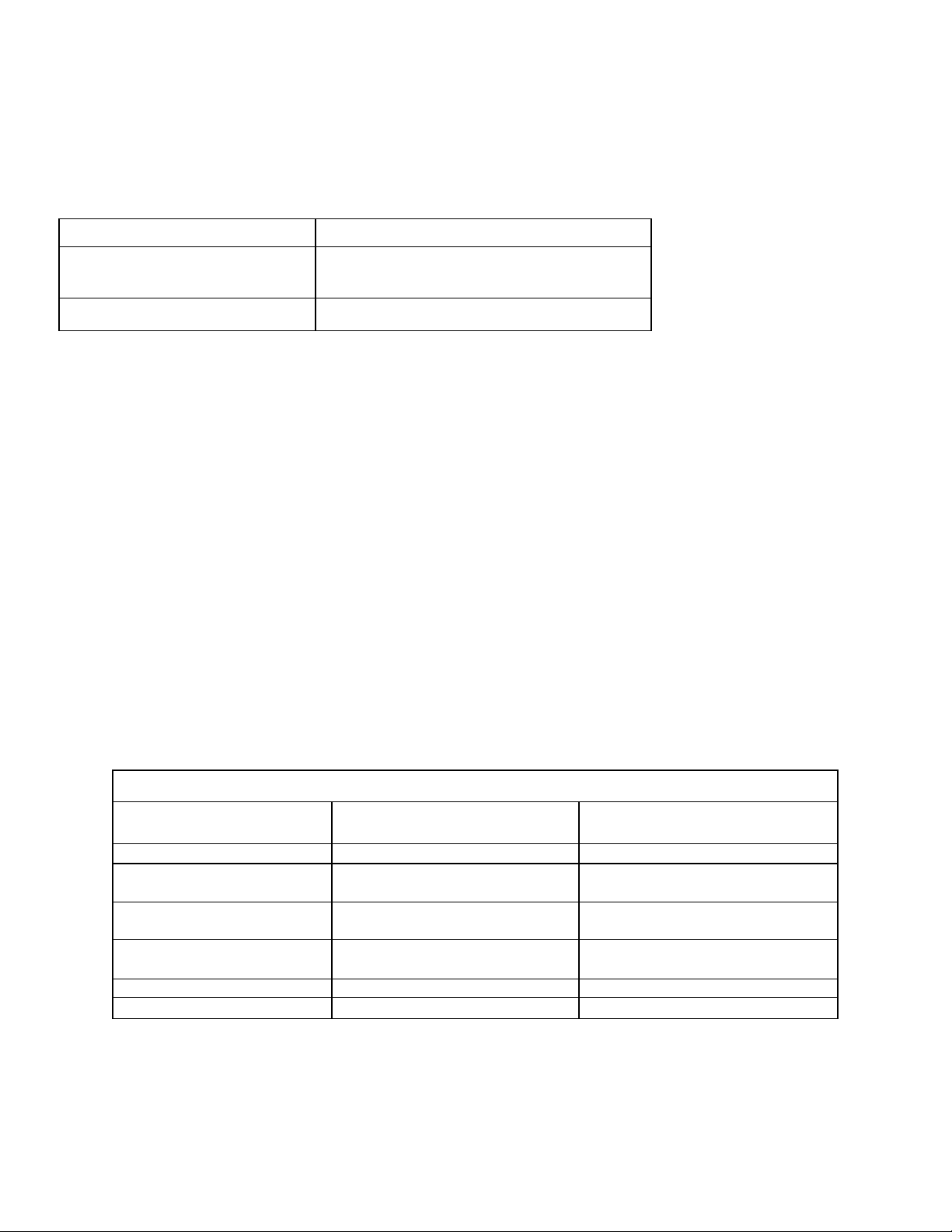

COMPUTER CONTROLLER DIAGNOSTIC CHECKS

The service diagnostics for the GRC Fryer computer is divided into (2) sections NORMAL and SERVICE DIAGNOSTICS. The

normal mode is the usual operating mode of the fryer. The service mode is intended to give the service man more information

regarding the nature of the system's failure.

NORMAL OPERATING MODE CHECKS:

SYSTEM PROBLEM

DISPLAY SYSTEM RESPONSE

OR FAILURE

Ignition IGN. FAILURE Heat off

Low temperature lack of heat LOW TEMP. Heat off

High temperature 1st. limit comes on. HIGH TEMP Heat off

High temperature 2nd limit comes on. CALL SERVICE Hardware limit heat off

Probe CALL SERVICE Heat off

Self-check CALL SERVICE System to back up mode

10

Page 11

SERVICE MODE

Enter the service mode by pressing the product 3 and product 4 keys while turning "on" power to the fryer computer. Display

should now read "SERVICE". In this mode the following display/systems response will be given for the noted error condit ion.

SYSTEMS PROBLEM

OR FAILURE

Ignition IGN FAILURE with Heat off

Low temperature

(lack of heat)

High temperature (1st limit) HI TEMP XXXF Heat off

High temperature (2nd limit) HI TEMP XXXF Hardware limit, heat off

Probe

Self check MICRO FAIL System to backup mode

Self check MICRO FAIL System to back up mode

SYSTEMS TEST

This menu is intended to give the servicer the ability to check the basic parts of the computer interface (i.e the display panel and

keypad). Enter the system test mode by holding down the product 8 and 9 keys while turning on the power for the computer.

Upon entry to the system tests the message panel will read "SYSTEM TESTS". Use up and down arrow keys to choose the

following.

Pressing "EXIT" while in the "SYSTEM TESTS" menu will exist the system test mode and return the computer to the "NORMAL"

operating mode.

DISPLAY SYSTEMS RESPONSE

L or R for split

LO TEMP XXXF

PROBE OPEN R or L PROBE

SH R or L

-VER XXX

-DISPLAY TEST

-KEYPAD TEST

Heat off

Heat off

SOFTWARE VERSION

The disp lay message "VERXXX" tells the version of the software that is installed into the computer. XXX

is a code representing the software revision level. The last two digits represent minor revision sand first

digits represent major revisions. For example version 1.02 would appear as 'VER 102".

DISPLAY TEST

This allows the servicer to test the display characters. Upon entering this test a string of characters will

appear on the display panel. The servicer then uses the up and down arrow keys to scroll through the

following sets of characters:

"0123456789 @"

"ABCDEFGHIJKL"

"MNOPQRSTUVWX"

"YZ<-> * / &?+( )"

Press "EXIT" at any time to terminate the display test mode.

KEYPAD TEST

This allows the servicer to test for proper key functioning. Entering this test will cause the computer to display "PRESS

KEYS". After this display press each key on the keypad. When the key is pressed the message display should match the

depressed key. Pressing "EXIT" at any time will terminate the keypad test and return the computer to the "SYSTEMS

TEST" menu.

11

Page 12

SECTION II

REMOVAL OF CONTROL PANEL AND REPLACEMENT OF

CONTROLS

WARNING UNPLUG FRYER BEFORE SERVICING.

WARNING SHUT OFF GAS BEFORE SERVICING.

WARNING CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR MEASUREMENTS WHILE

CONTROL PANEL (STANDARD MILLIVOLT CONSTRUCTION)

Follow step 1 only if complete disassembly of panel is necessary. Otherwise begin with step 2.

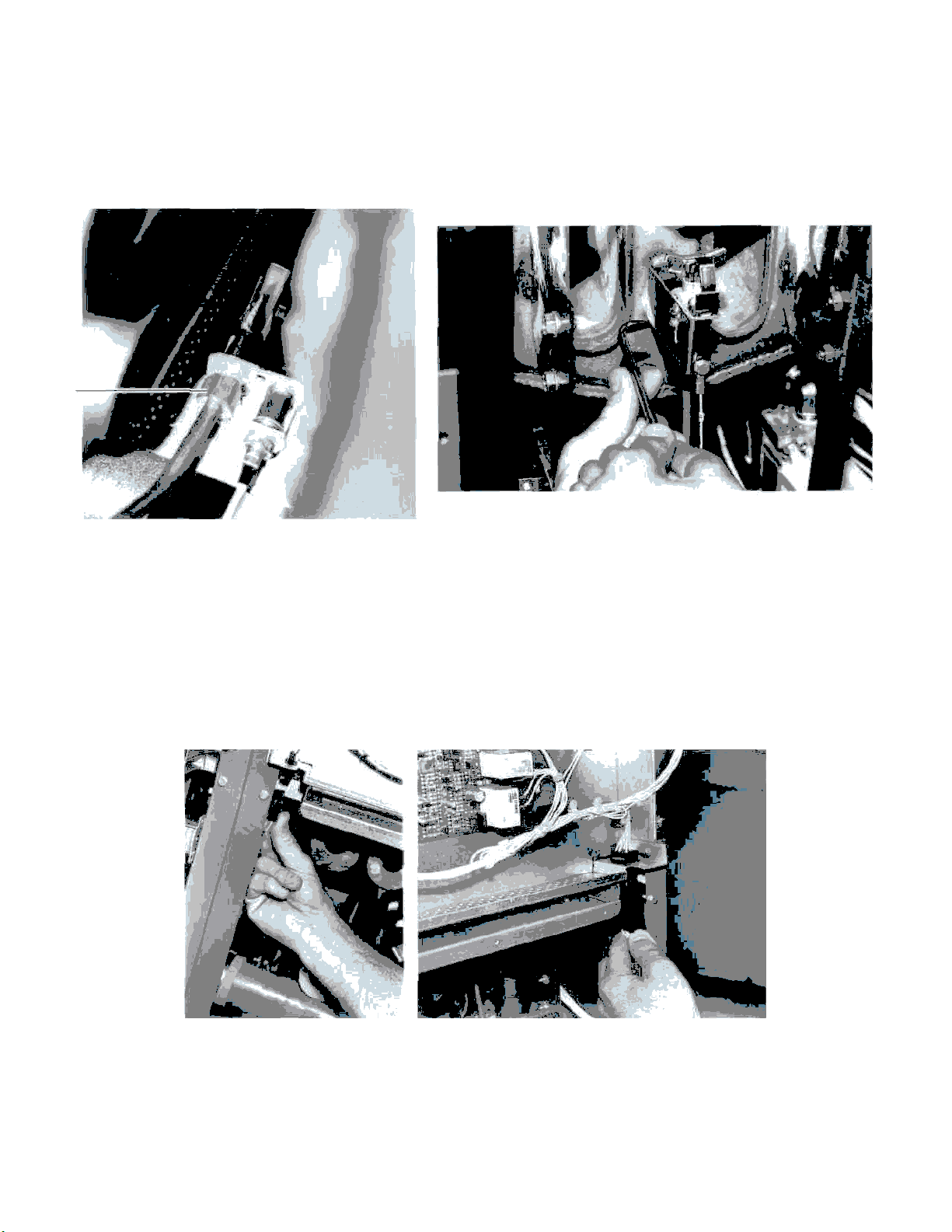

1. Remove the thermostat knob from the control panel and disengage the (2) screws holding the thermostat to the panel. (Fig. 1)

2. With a 1 /4" socket remove (2) #8 hex head screws located in the top left and right hand corners of the control panel. (Fig. 1)

POWER IS APPLIED TO THE FRYER. EXERCISE EXTREME CAUTION AT ALL TIMES. IF TEST POINTS ARE

NOT EASILY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST EQUIPMENT AND REAPPLY POWER TO

TEST.

3. With a 1/4" socket remove (2) #8 sheet metal screws from the under flange of the control panel, carefully lower the panel and

the fryer door from the appliance. (Fig. 2)

12

Page 13

4. Reinstall panel by reversing steps 1-3.

CONTROL PANEL (ELECTRONIC IGNITION)

1. Follow steps 1 through 3 under Standard Millivolt Construction. (Fig. 3)

2. Disconnect basket lift (applicable) or main wire harness before removing the control panel and fryer door.

Fig. 3

CONTROL PANEL (SOLID STATE CONSTRUCTION)

1. Follow steps 2-3 under Standard Millivolt Construction. (Fig. 4)

2. Disconnect basket lift (if applicable) and main wire harness before removing the control panel and fryer door.

3. Reinstall panel by reversing steps 1-2.

Fig. 4

13

Page 14

CONTROL PANEL (COMPUTERIZED).

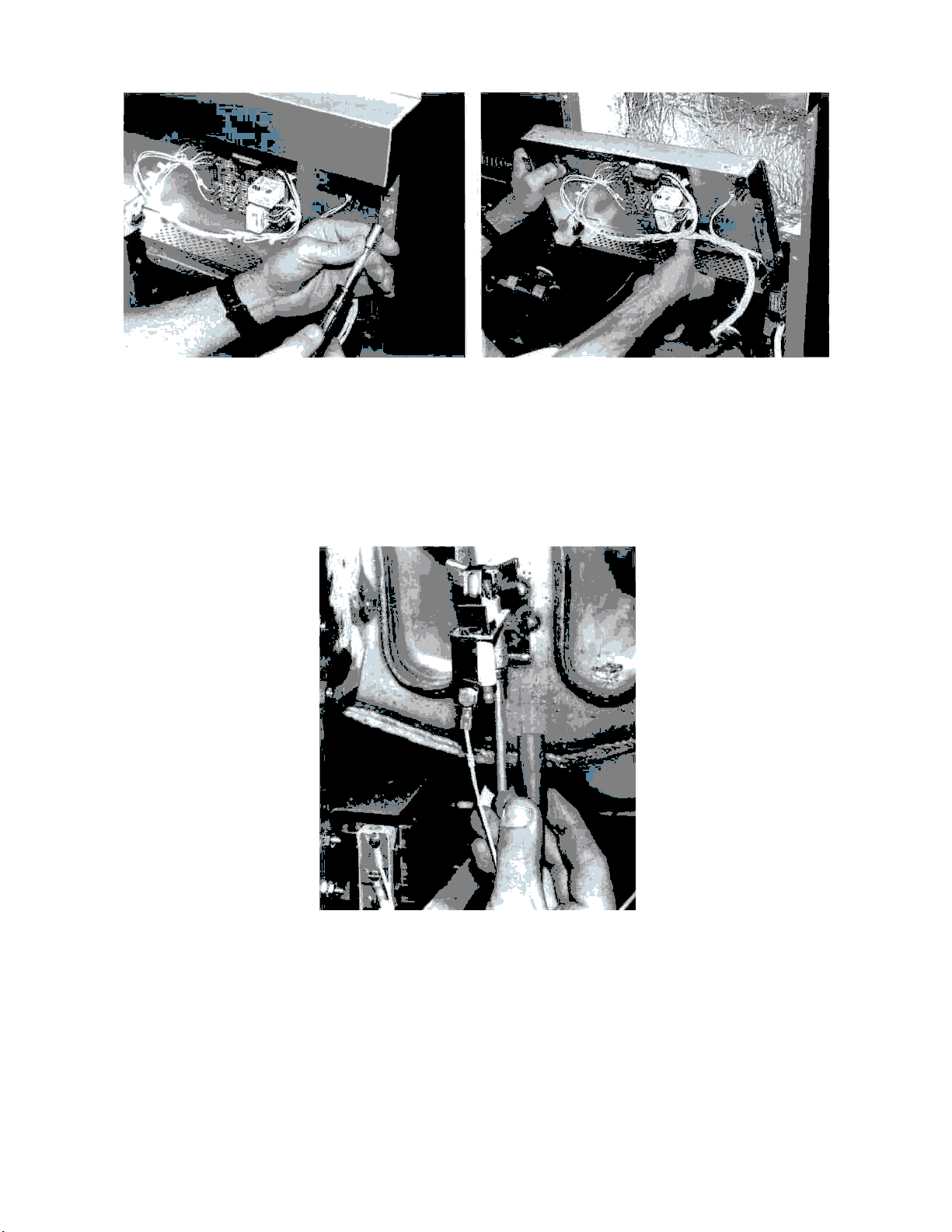

1. Follow steps 1 through 2 under Solid State Construction and disconnect the computer power wiring harness.

(Figs. 5)

Figs. 5

2. To remove the computer disengage (6) 6-32 nuts from the back of the control panel. (Fig. 6)

Fig. 6

3. Reinstall the computer panel by reversing steps 2-3.

NOTE: To avoid breakage, do not over tighten the 6-32 nuts.

14

Page 15

REMOVAL OF CONTROL PANEL HOUSING

1. Follow steps 1-2 under Control Panel (Electronic ignition).

2. With a 5/16" socket remove (4) screws holding the housing to the fryer body sides. (Fig. 7)

Fig. 7

3. Note and disconnect any wiring harnesses from the housing. If millivolt fryer, pull the thermostat wire through the access

hole in the box. (Fig. 8)

Millivolt construction pull thermostat wire

through the access hole in the box.

Fig. 8

4. Pull housing from the fryer.

15

Solid state disconnect wire harness.

Page 16

REMOVAL OF KX THERMOSTAT

1. Drain fry compound from the tank.

2. Follow steps 1-3 under Removal of Control Panel (Standard Millivolts) (Figs. 9)

3. Remove (2) wires from the thermostat.

Figs. 9

5. From inside tank remove (4) #8 screws using a 1/4" socket to disassemble the thermostat bulb and hi limit clamps. (Fig. 10)

Fig. 10

16

Page 17

5. From inside the fryer cabinet, follow the thermostat lead wire to the bulb packing nuts in the bottom of the tank.

With a 5/16" wrench remove the thermostat packing nut and with an 11/16" wrench remove the thermostat bulb

holding nut. (Fig. 11)

Holding Nut Packing Nut

Fig. 11

6. Pull the thermostat bulb from the fryer through the tank bottom. (Fig. 12)

7. Install new thermostat by reversing steps 1-6.

Fig. 12

17

Page 18

REMOVAL OF POTENTIOMETER

Set Screw

1. Follow steps 1-2 under Control Panel (Solid State Construction)

2. With a small flat blade screwdriver loosen the set screw in the potentiometer knob. (Fig. 13)

Fig. 13

3. Pull the knob off of the panel.

4. With a 1/2" wrench remove the potentiometer holding nut from the front of the control panel. (Fig. 14)

Fig. 14

5. Remove the pot wires from the wire harness assembly.

6. Install new pot by reversing steps 1-5.

18

Page 19

REMOVAL OF THERMISTOR PROBE

1. Follow steps 1-5 under Removal of Potentiometer.

2. If necessary remove burners that may be in the way of the thermistor probe hardware in the bottom of the fryer

tank. Refer to Removal of Burner.

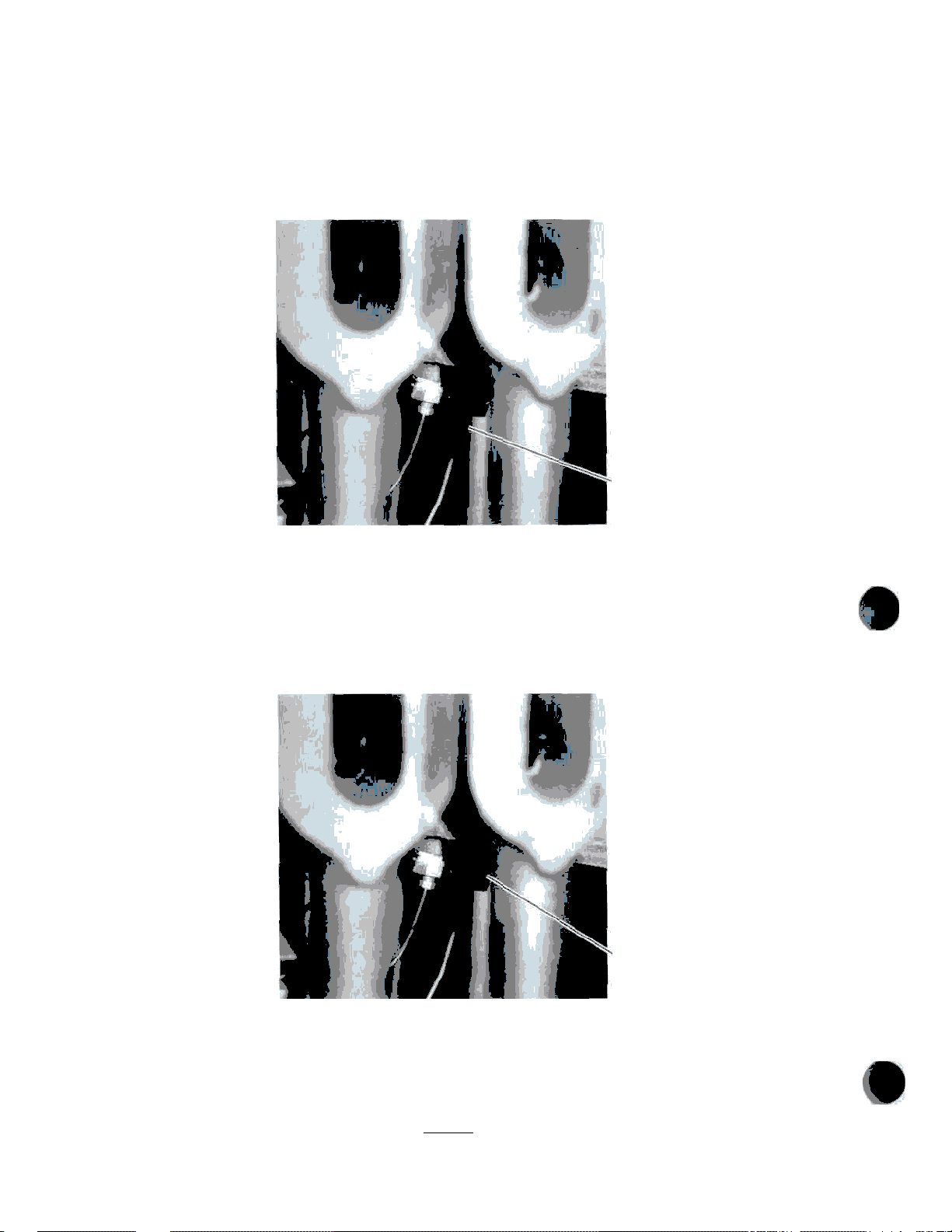

3. With a 1/2" wrench remove the thermistor packing nut. (Figs. 15)

Figs. 15

4. With an 11 /16" wrench remove the potentiometer retaining nut from the bottom of the tank. With a 1 /4" socket

from inside the fryer tank remove (2) #8 sheet metal screws. (Figs. 16)

Retaining Nut

Figs. 16

19

Page 20

5 Pull the thermistor probe lead from the fryer tank and install new Thermistor probe by reversing steps 1-6 (See Fig

12)

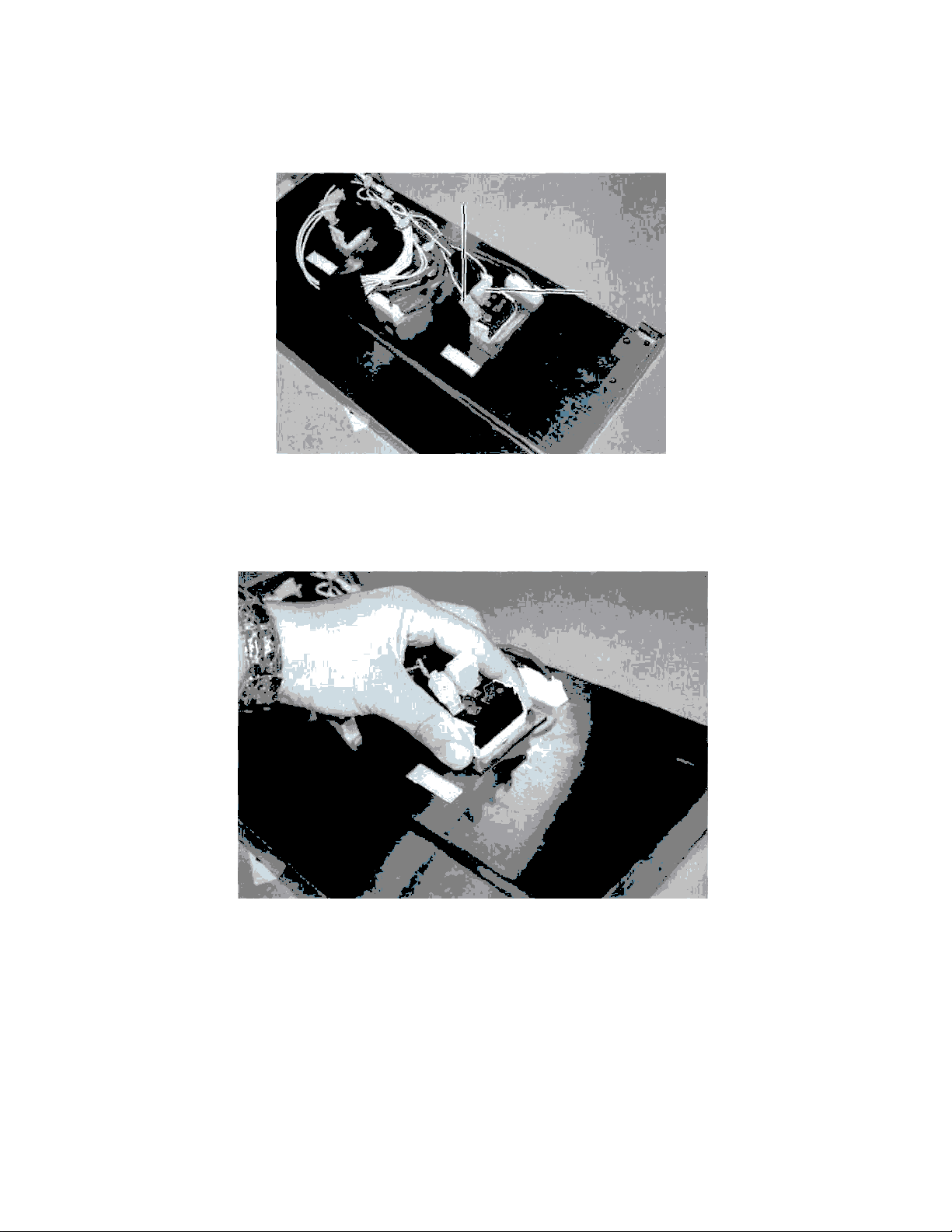

REMOVAL OF COMPUTER

1 Follow steps 1-2 under Control Panel (Computerized)

2 Make sure all wire harnesses are disconnected Remove (6) screw securing the computer to the panel with a 1/4" socket (Fig

17)

Fig. 17

3 Install new computer by reversing 1-2 Use loctite and do not over tighten screws

REMOVAL OF INDICATOR LIGHTS

1 Follow steps 1-2 under Control Panel (Solid State)

2 From the rear of the control panel unscrew the wire cap of light to be replaced

3 Squeeze the tabs on both sides of the indicator light being replaced and pull the light out through the front of the panel

(Figs 18)

4 Reinstall new light by reversing steps 1-3

Figs. 18

20

Page 21

REMOVAL OF ROCKER SWITCHES

1. Follow steps 1-2 under Control Panel (Solid State).

2. From rear of control panel note and remove wire leads from the rocker switch terminals. (Fig. 19)

Fig. 19

3. Press tabs on both sides of the switch and push the switch through the front of the control panel. (Fig. 20)

4. Reinstall new switch by reversing steps 1-3.

Fig. 20

21

Page 22

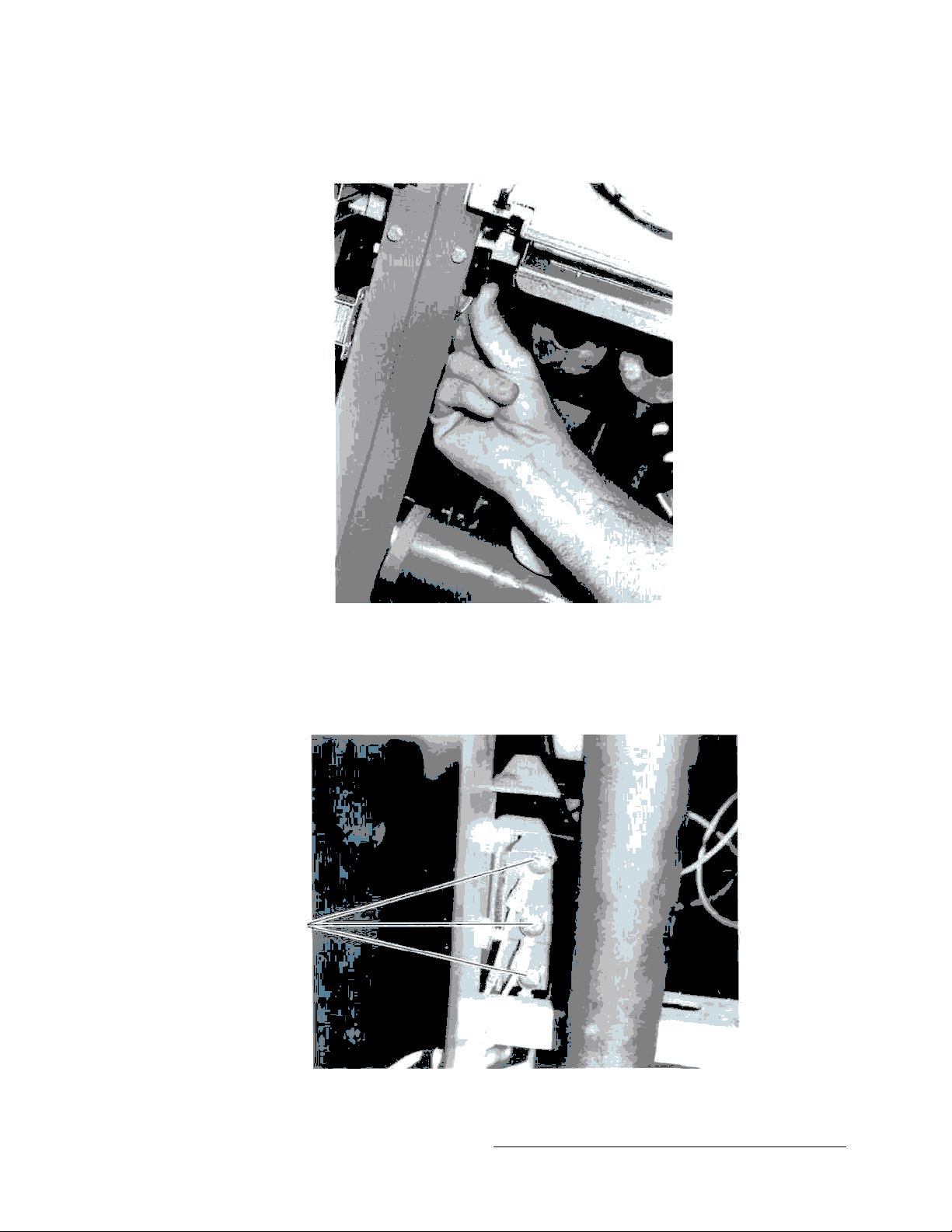

REMOVAL OF HIGH LIMIT

1. Drain shortening from the fryer

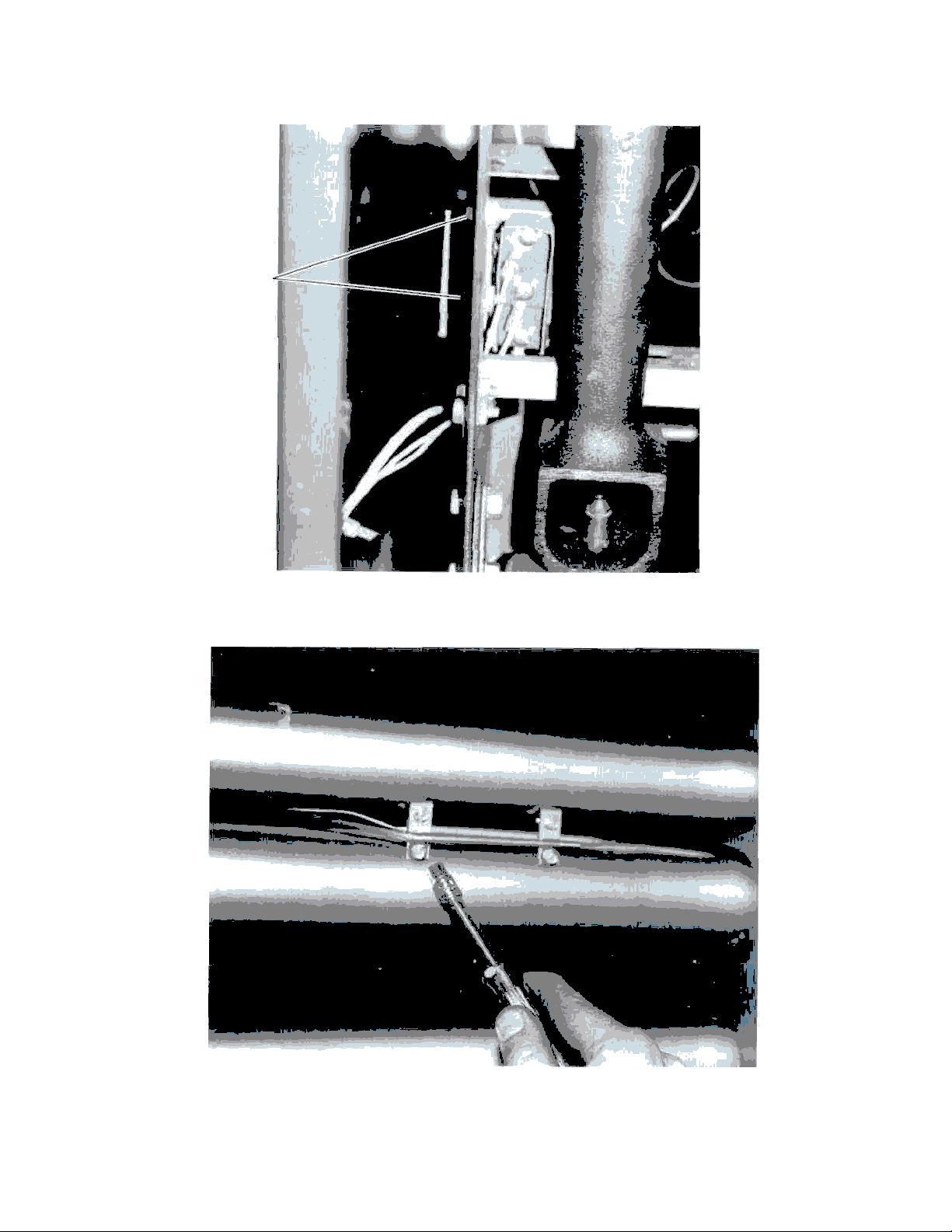

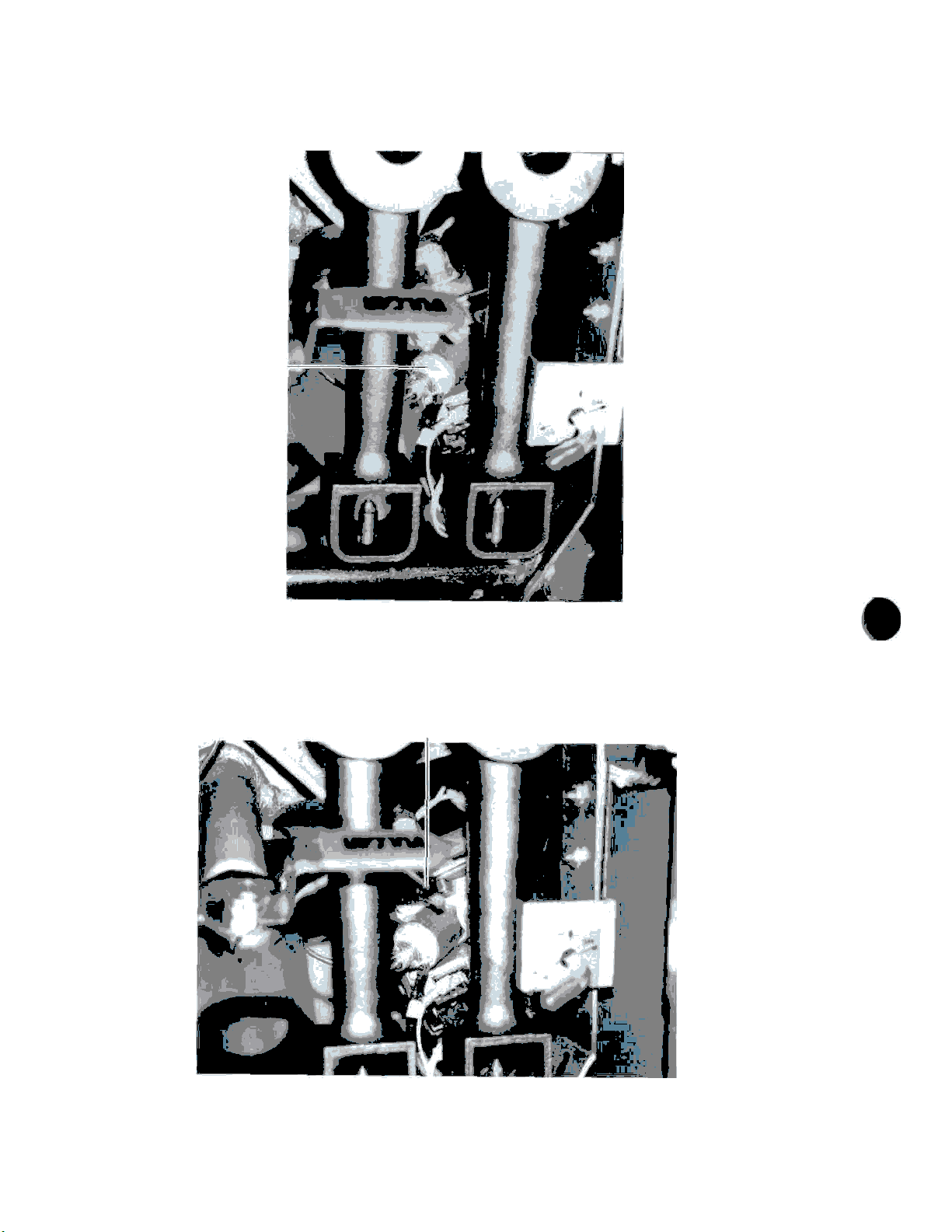

2. Open fryer door and disengage hi limit wire harness located below the control housing to the left side of the fryer

(Fig. 21).

Fig. 21

3. With a flat blade screwdriver note and remove (3) wire leads from the high limit (Fig 22).

Fig. 22

22

Page 23

4. Remove (2) #8 sheet metal screws from the bracket holding the limit in place. (Fig. 23)

Fig. 23

5. From inside the fryer tank, with a 1/4" socket remove (4) #8 screws and holding brackets for the limit bulb. (Fig. 24)

Fig. 24

23

Page 24

6. If necessary for ease of accessibility follow steps 1-8 under Removal of Burner and take out any burner in the

way of the limit bulb packing and retaining nuts.

7. With a 5/16" wrench remove the limit packing nut from the tank bottom. (Fig. 25)

Fig. 25

8. With an 11/16" wrench remove the limit retaining nut from the tank bottom. (Fig. 26)

Fig. 26

24

Page 25

9. Pull the limit bulb out from underneath the fryer tank. (See Fig. 86)

10. Reinstall new high limit by reversing steps 1-9.

REMOVAL OF THERMOPILE (STANDARD MILLIVOLT SYSTEM)

1. Follow steps 1- 3 under Control Panel (Standard Millivolt Construction)

2. With a 1/4" socket disengage (4) #8 hex head screws, pull the thermostat wire from the housing and remove the control

housing. (Figs. 27)

Figs. 27

3. From the high limit disengage the closed and normally open thermopile wire leads. (Fig. 28)

Fig. 28

25

Page 26

4. Refer to steps 1-8 under removal of burner and remove burners as required to access the

thermopile bracket and its hardware.

5. Slide the control housing heat shield down. (Fig. 29)

Fig. 29

6. With a 1/2" wrench remove the pilot tubing from the pilot assembly. (Fig. 30)

Fig. 30

26

Page 27

With an offset flat blade screwdriver remove the pilot assembly from the mounting bracket. (Fig. 31}

8. With a 1/2" wrench remove the thermopile from the pilot assembly. (Fig. 32)

Fig. 31

Fig. 32

9. Reinstall new thermopile by reversing steps 1-8.

27

Page 28

REMOVAL OF PILOT

1. Follow instructions for the Removal of Thermopile.

2. With a 1/2" wrench remove the hex nut on the bottom of the pilot and disconnect the pilot tube. (Figs. 33)

3. With an offset flat blade screwdriver remove the pilot assembly bracket from the fryer. (Figs. 33)

Figs. 33

4. Install the new pilot by reversing steps 1-4.

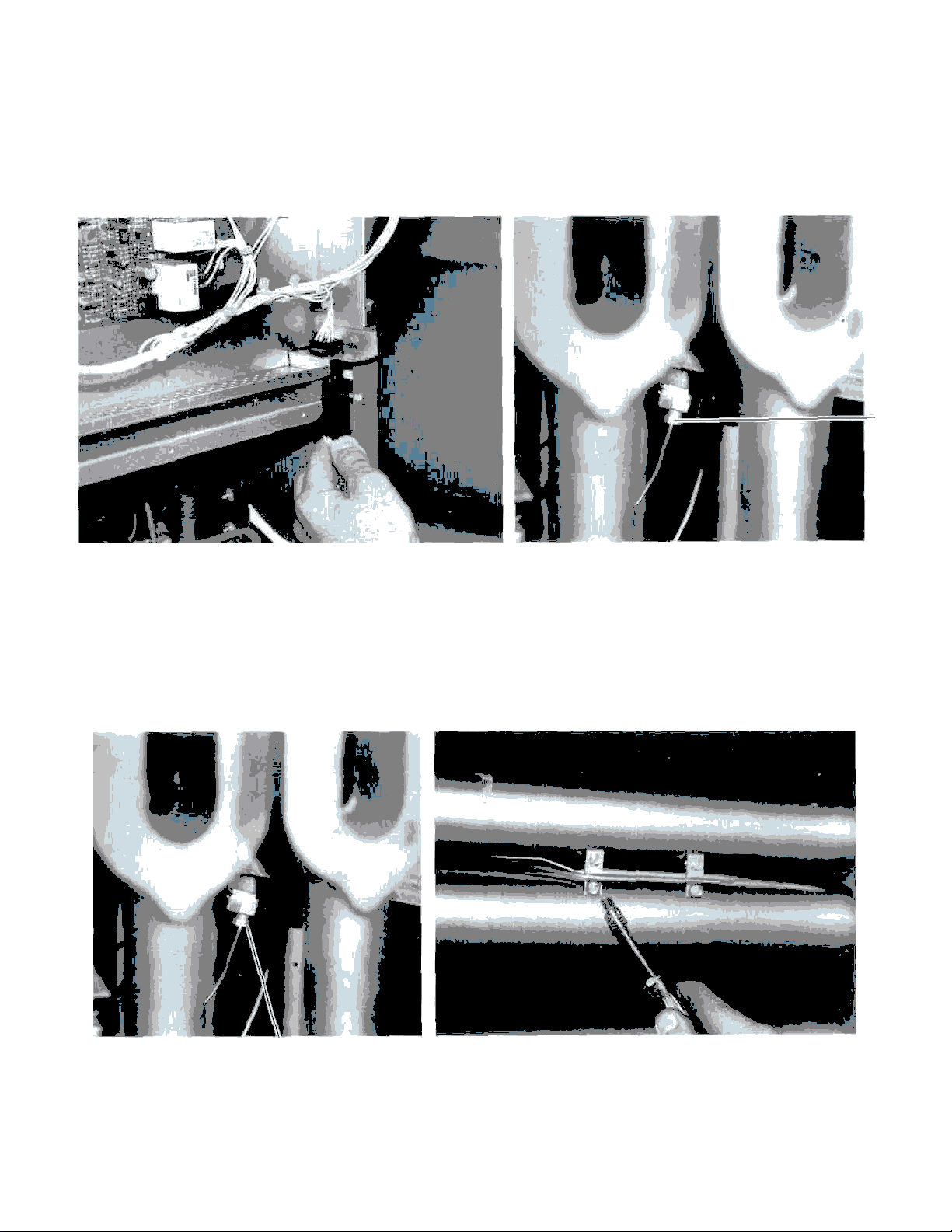

REMOVAL OF IGNITOR ASSEMBLY (SOLID STATE AND ELECTRONIC IGNITION ONLY)

1. Follow steps 1- 3 under Control Panel (Solid State Construction).

2. Note and disengage wire harnesses, with a 5/16" socket remove (4) screws securing the control housing to the fryer and pull

the housing off of the fryer. (Figs. 34)

Figs. 34

28

Page 29

Figs. 34

3. Refer to steps 1-8 under Removal of Burners and disassemble burners as required to access the ignitor

assembly for servicing.

4 Slide the control housing heat shield down. (Fig. 29) 5.

Remove the ignitor boot. (Fig. 35)

Fig. 35

6. Follow steps 6 and 7 under Removal of Thermopile.

7. With a 1/2" wrench remove the ignitor assembly.

8. Install new pilot assembly by reversing steps 1-7.

29

Page 30

REMOVAL OF GAS COMBO VALVE

1. Shut off all gas and electrical power to the unit.

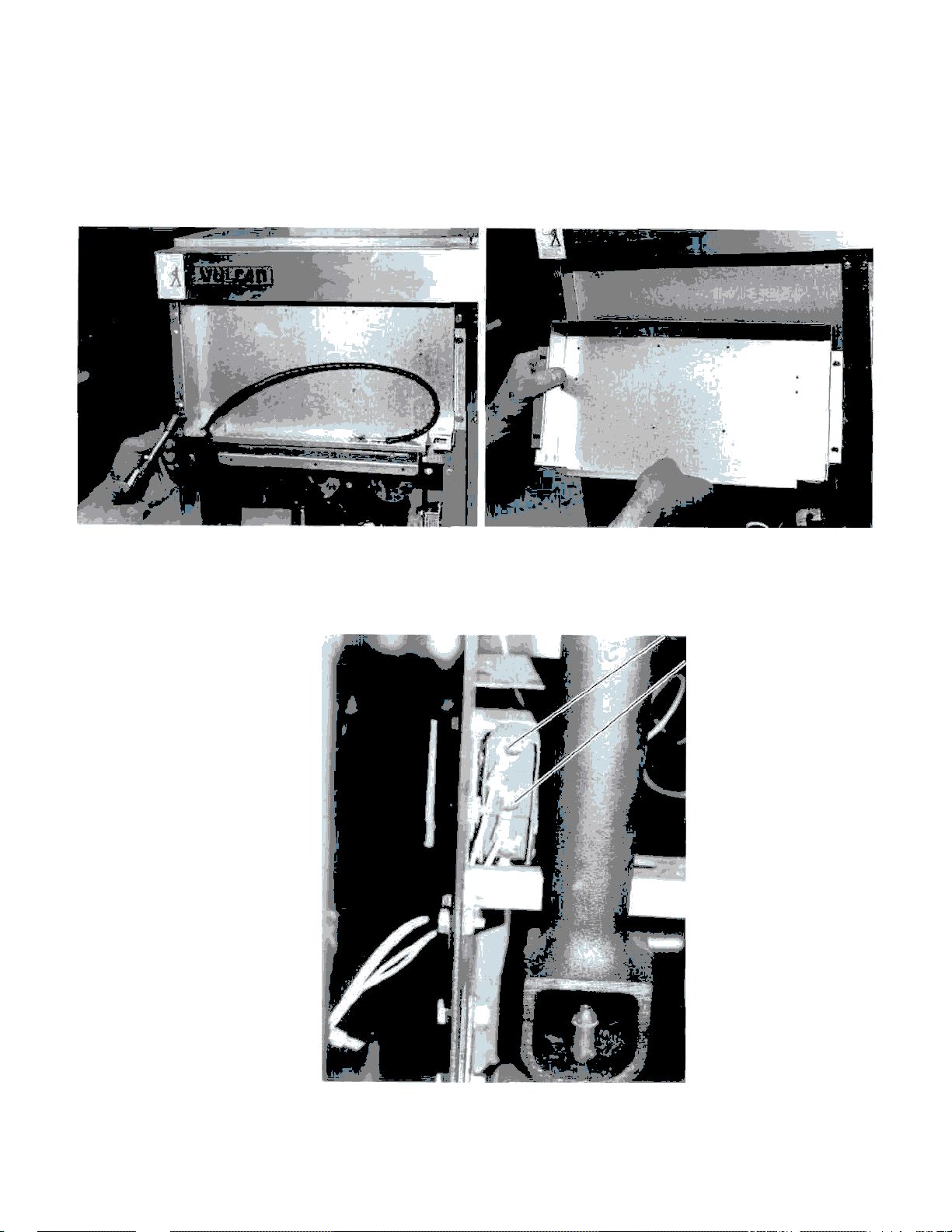

2. Open fryer door and locate valve. (Fig. 36)

Fig. 36

3. Follow steps 1-8 under the Removal of Burners and disassemble any burner obstructing your working area for the combo valve.

4. Note and remove all combination valve wiring.

5. With a 7/16" wrench loosen the pilot tube compression nut. (Fig. 37)

Fig. 37

30

Page 31

The next several steps may require the removal of the Discard drain tubes on fryers with filtering systems. If this applies to the

Union Shown from

fryer being serviced refer to steps 1-7 under Removal of Filter Discard Tubes. 6. With a 3/4" wrench remove the gas line

compression elbow fitting. (Fig. 38)

Fig. 38

7. With channel locks disconnect union in gas line leading from combo valve to the burner manifold and lift valve out of the

fryer. (Fig. 39)

Back of Fryer

Fig. 39

31

Page 32

8. Note and remove any old fittings left on the valve. Keep them for reassembly to the new valve.

9. Install the old fittings removed in step 8 to the new valve.

10. Install the new valve by reversing steps 1- 7.

11. Insure all wiring and gas lines are sec urely installed.

12. Check system with soap and water solution for gas leakage.

REMOVAL BURNER

1. Follow steps 1-3 under Removal of Control Housing (Millivolts).

2. In the GRD and GRC Series Fryer disconnect the control housing harness plug and remove the housing from

the fryer. For the GRS Series Fryer carefully lower the housing out of the way without removing or kinking the

KX thermostat wiring.

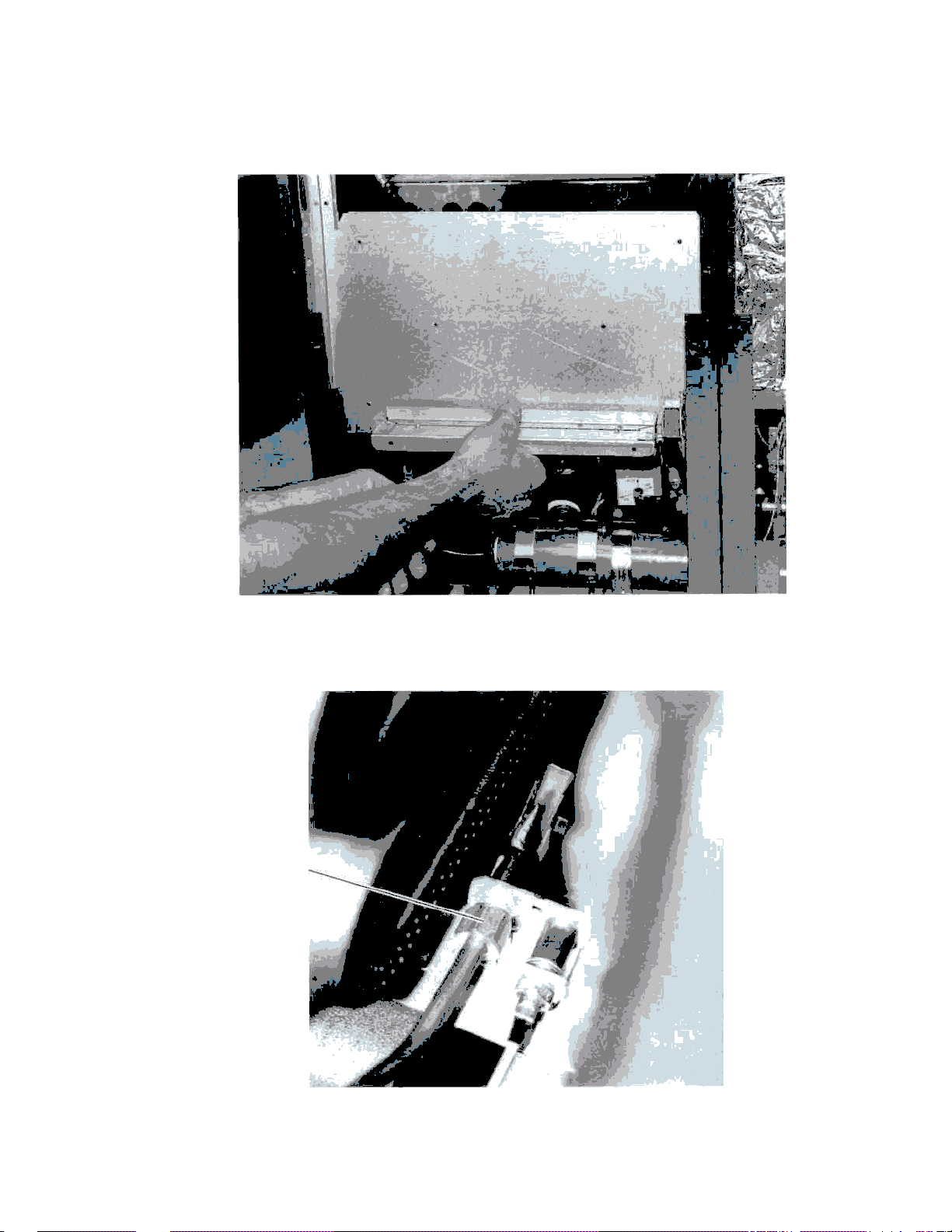

3. With a 5/16" socket remove (4) 10-24 screws holding the heat shield in place.

4. Slide the heat shield down to expose the burner mounting screws. (Fig. 40)

Fig. 40

32

Page 33

5, With a 1/2" socket loosen (2) bolts that attach the burner to the mounting frame. (Fig. 41)

Fig. 41

6. Slide the heat shield back up to its original position.

7. If the fryer is equipped for filtering the discard tube(s) may need to be disconnect at this point. Refer to steps

1-7 under Removal of Discard Tube(s).

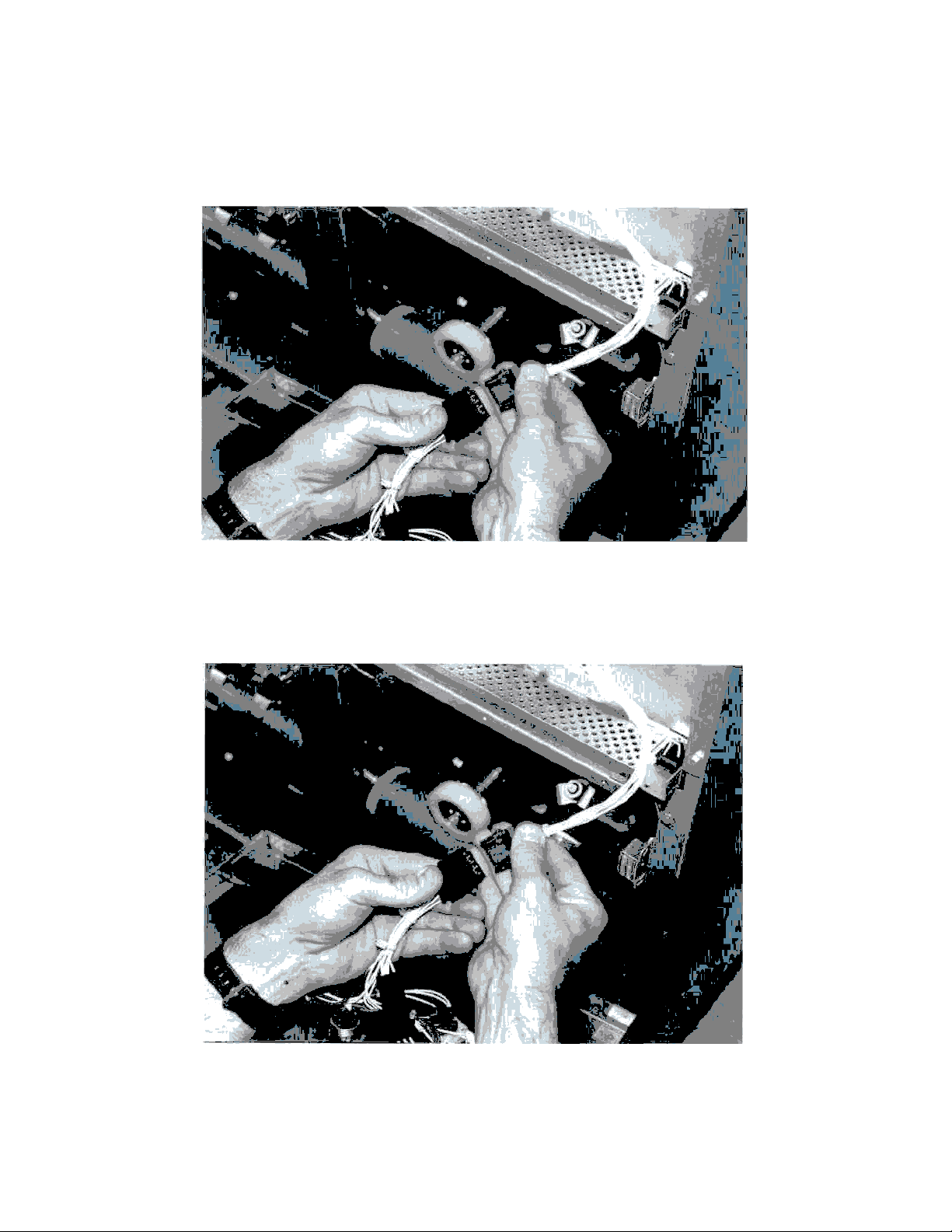

8. With (2) hands grasp the burner body and push it upward over the bullet nose pilot. Then tilt the burner head

back and pull the burner out of the fryer cabinet. (Fig. 42)

9. Reinstall burner by reversing steps 1-8.

Fig. 42

33

Page 34

BULLET NOSE BURNER ORIFICE REPLACEMENT

1. Follow steps 1-8 under Replacement of Burner.

2. Disconnect the burner orifice top from bullet with a 5/16" wrench. The bullet body may be removed with channel

locks. (Figs. 43)

Figs. 43

3. Install new orifice by reversing steps 1-2.

REMOVAL OF FILTER DISCARD TUBE(S) (FILTER INTER PLUMB BATTERY FRYERS)

1. Close all fryer drain ball valves.

2. Place a shortening discard pan under section of the inter plumb being disconnected.

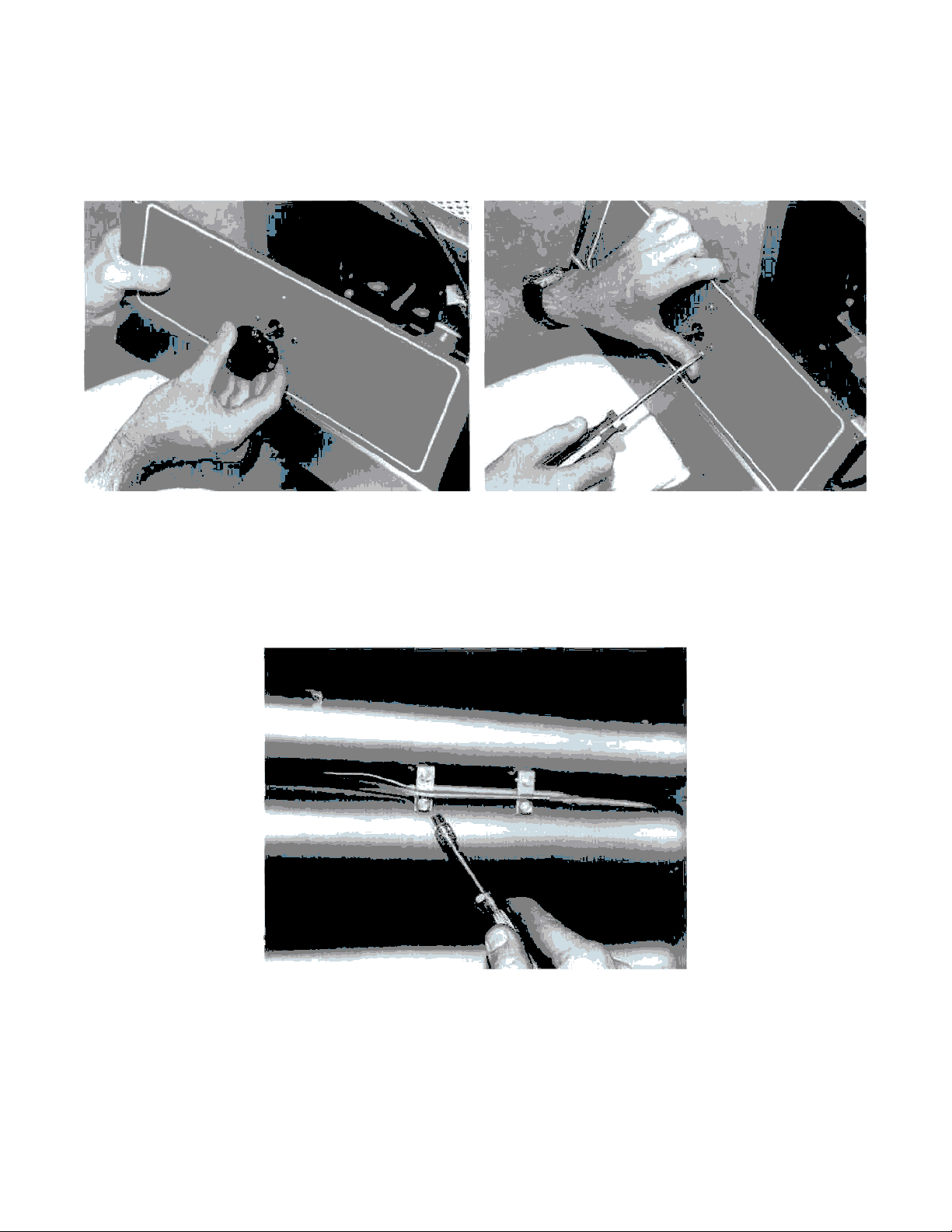

3. With a 7/16" deep throat socket remove the discard tube clamp hardware and the stainless steel collar. Retain all

parts for reassembly. (Figs. 44) Note: GR85 and some filter interplumb fryers are equipped with flange mounted

discard tubes which require the removal of (2) bolts and a gasket.

Figs. 44

34

Page 35

4 Separate the discard tube by sliding the rubber collar down one side of the drain tube. (Fig. 45)

Rubber

Collar

Fig. 45

5. Move the discard pan under the ball valve.

6. With the 7/16" socket remove the clamp hardware securing the tube to the ball valve assembly. Also if the

tube/extension section is located at the end of a battery to facilitate an RO Frymate using a 5/16" socket remove

(1) bolt mounting the tube/extension bracket to the fryer base frame. (Fig. 46)

Fig. 46

35

Page 36

REMOVAL OF POWER SUPPLY BOX (ELECTRONIC IGNITION AND BASKET LIFT MODELS)

1. Disconnect gas line and pull out so that the back is accessible.

2. Disconnect the supply box wire harness (Fig. 47)

Fig. 47

3. From the front of the unit follow steps 1-5 under Removal of ignitor assembly.

4. From rear of unit with 7/16" socket and wrench remove the (2) nuts and bolts holding the supply box to the unit base frame.

(Fig. 48) Note: In the GR25 fryer, the supply box is mounted vertically in the right rear corner of the appliance. To lower the

box remove the holding screw on the bracket.

Fig. 48

36

Page 37

5. Drop the supply box housing out of the bottom of the fryer.

6. To access the controls with a 5/16" socket remove (2) screws from the power supply box top cover. (Fig. 49)

7. Reinstall housing by reversing steps 1-6.

REMOVAL OF IGNITOR MODULE

1. Follow steps 1- 3 under Control Panel (Solid State Construction).

2. Follow steps 1-5 under Removal of Supply Box Housing.

3. With a 5/16" socket remove (2) screws and open the lid to the supply housing. (Fig. 49)

Fig. 49

4. Note and remove all wiring from the ignitor module terminals. (Figs. 50)

Figs. 50

37

Page 38

5. With a 1/4" socket remove (4) #8 sheet metal screws and pull module from the housing. (Fig. 51)

"S and D" Models

Figs.

52

Fig. 51

6. Reinstall new module by reversing steps 1- 5.

REMOVAL OF TRANSFORMER

1. Follow steps 1 - 6 for the Removal of the Supply Box Housing

2. Follow steps 1-2 under Access of Controls Inside the Supply Box.

3. Disconnect all wiring associated with the transformer. Note that "C" models will have (2) transformers

(Figs. 52)

"C" Models

38

Page 39

4. With 1/4" socket remove (2) screws securing the transformer to the control box. (Fig. 53)

Fig. 53

5. Install new transformer by reversing steps 1-4.

REMOVAL OF ELECTRICAL SUPPLY CORD

Note: The power supply line for a fryer with filter inter plumb is located in the rear of appliance housed in a junction box. Disengage

(2) screws mounting the cover to the box, then remove the cord by following steps 3-5 below.

1. Follow steps 1-6 under Removal of Supply Box.

2. Follow steps 1-2 under Access of Controls Inside the Supply Box.

3. From the rear of the box with a flat blade screwdriver remove (2) screws holding the cord mounting clamp to the box. (Figs. 54)

Supply Box Filter Junction Box

Figs. 54

39

Page 40

4. From inside the box disconnect wiring associated with the supply cord.

5. Install the new power supply cord by reversing steps 1-4.

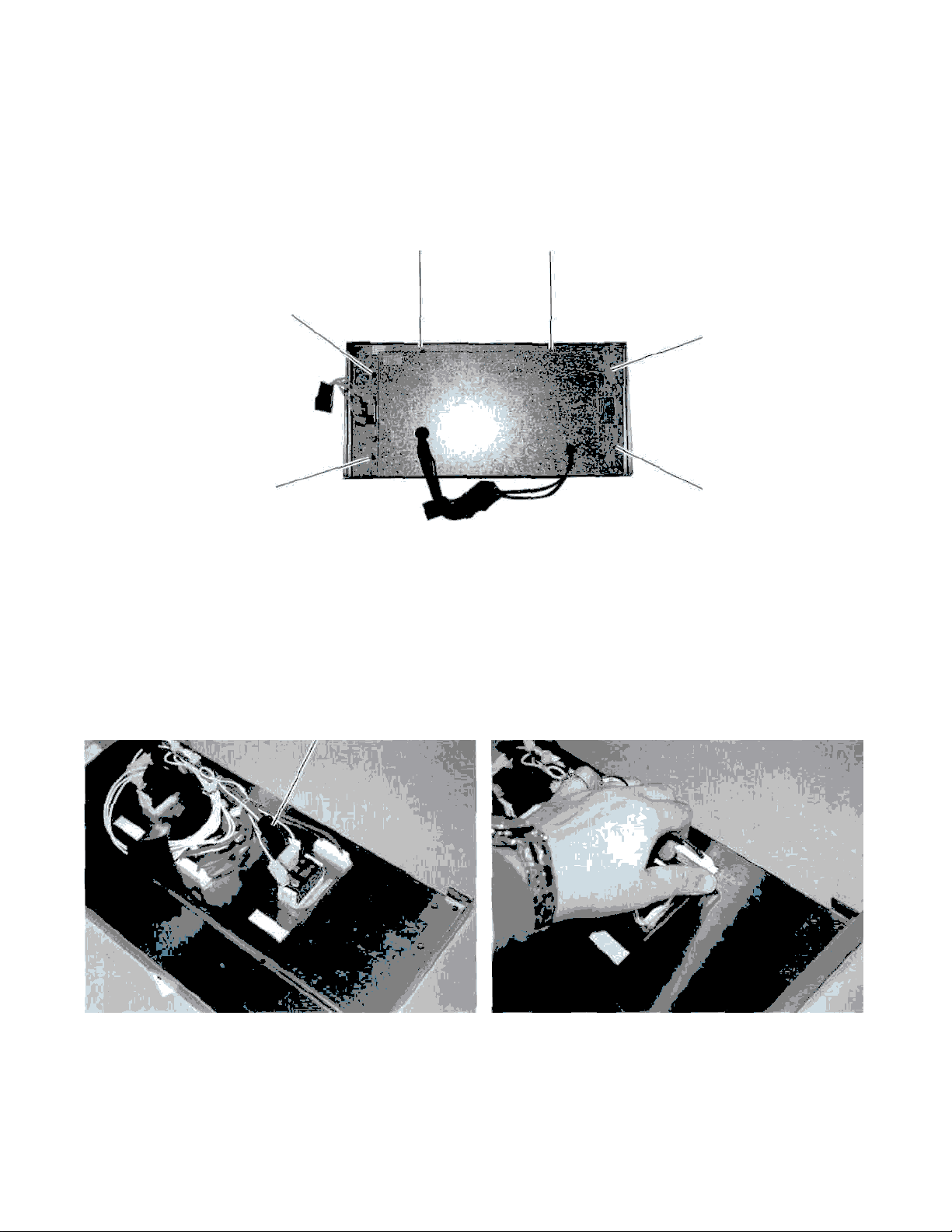

REMOVAL OF BASKET LIFT BACK (OPTIONAL ACCESSORIES)

1. Remove all baskets and basket support racks from tank.

2. Drain appliance tank, disconnect unit power and tipping restraint. Move appliance to an area where the back is

completely accessible.

3. Remove the basket lift arm. (Fig. 55)

Fig. 55

4. Remove (14) screws from the upper back of the basket assembly using a 1/4" socket. (Fig. 56)

Fig. 56

40

Page 41

5. Lift back up and over the lift mechanism. (Fig. 57)

Fig. 57

Disconnect the gas line and remove the lower basket lift back by disengaging (2) screws at each lower side of

the cover and (2) screws from each lower back corner using a 1/4" socket. (Fig. 58)

Fig. 58

41

Page 42

7. To reinstall basket back panels reverse steps 1-6.

REMOVAL OF LIFT ROD MECHANISM

1. Follow steps 1-6 under Removal of Basket Lift Backs

2. With a 1/2" wrench remove the nut that attaches the lift rod to the lift bar. (Fig. 59)

Fig. 59

3. With a 5/16" socket remove (6) screws from the rod mechanism holding bracket. (Fig. 59)

4. Install new lift rod assembly by reversing steps 1-3.

REMOVAL OF BASKET LIFT MOTOR (OPTIONAL ACCESSORY)

1. Follow steps 1-6 under Removal of basket lift backs.

2. Follow steps 1-2 under Removal of lift rod mechanism.

3. Note and remove wiring from the cam switch. (Fig. 60)

Fig. 60

42

Page 43

4. With 5/16" socket remove (2) nut holding the cam lift bracket to the fryer back. (Fig. 61)

5. Remove motor wiring. (Fig. 62)

Fig. 61

43

Page 44

6. With flat blade screwdriver remove (2) screws holding the motor to the cam bracket assembly. (Fig. 63)

Fig. 63

7. Remove the motor from the cooker. To install new motor reverse steps 1-6.

8. Make certain that all wiring is clear from motor cam shaft (wire ties may be required).

REMOVAL OF BASKET LIFT CAM SWITCH (OPTIONAL ACCESSORY)

1. Follow steps 1-6 under Removal of Basket Lift Backs

2. Note and remove wiring. With a standard flat blade screwdriver and a 5/16" wrench remove (2) screws and

holding nut s from the cam switch. (Fig.64)

3. Reinstall by reversing steps 1-2

Fig. 64

44

Page 45

REMOVAL OF BASKET LIFT CAM (OPTIONAL ACCESSORY)

1. Follow steps 1-6 under Removal of Basket Lift Back.

2. With a 1/2" wrench or socket remove the lift bar and cam assembly holding nut. (Fig. 65)

Fig. 65

3. With an alien wrench loosen the cam set screw. (Fig. 66)

Fig. 66

4. With an offset flat blade screwdriver remove the screws mounting the cam to the lift bar. (Fig. 65)

5. Pull the cam from the fryer. Install new cam by reversing steps 1-5.

45

Page 46

REMOVAL OF TANK ASSEMBLY

If the fryer is equipped with automatic basket lifts the lift arm(s) must be removed from the fryer back before the

tank can be removed.

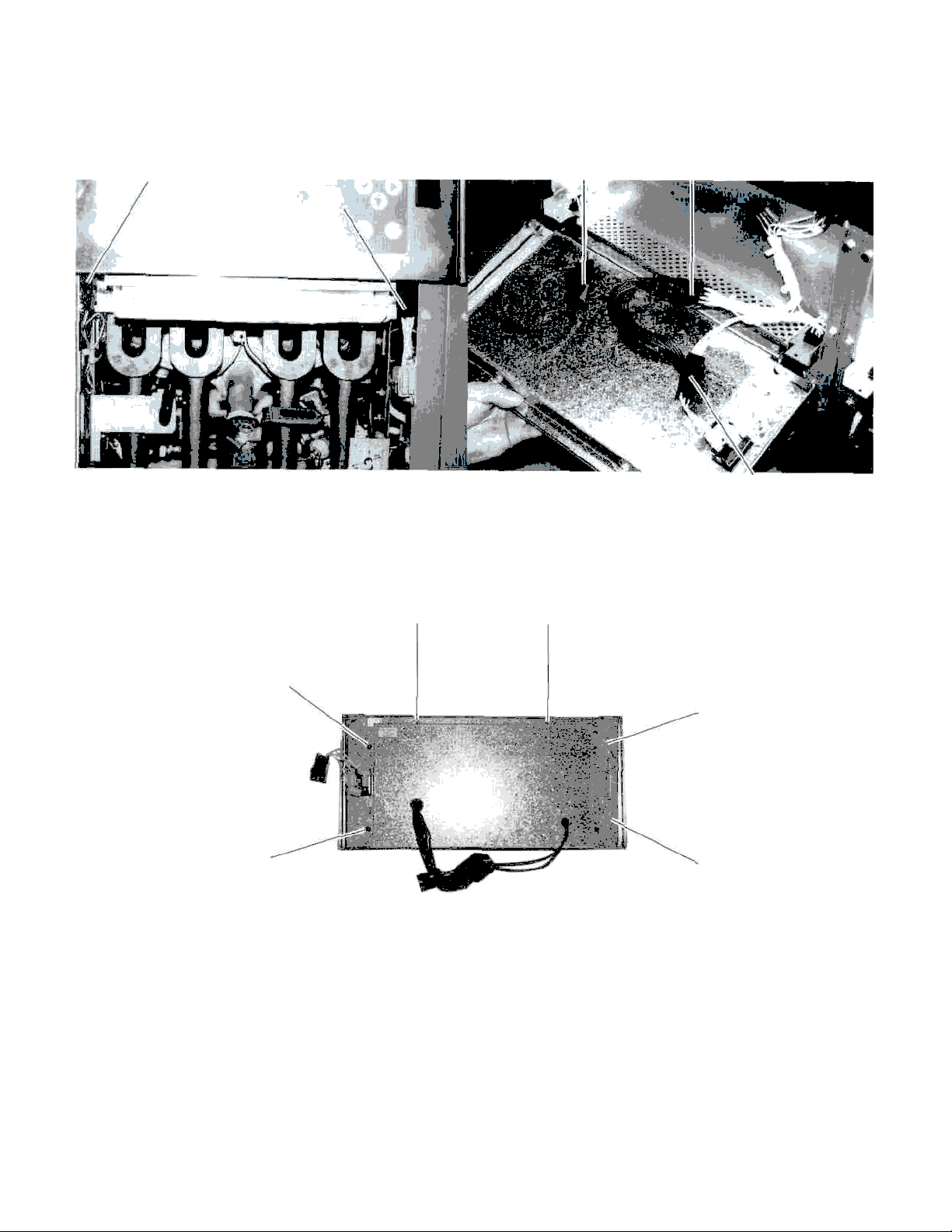

1. Remove fryer baskets and crumb screen. (Figs. 67)

Figs. 67

2. Remove basket hanger. (Fig. 68)

Fig. 68

46

Page 47

If a fryer battery is involved, with a utility knife split the silicon sealant from around the grease strip between the

tanks and remove the stainless grease strip, then split the tank sections apart with a utility knife (Fig 69)

Fig. 69

Follow steps 1-4 under Removal of KX Thermostat (Millivolts) or 1-2 under Removal of Control Panel

(Electronic Ignition) as required for type fryer to be serviced If fryer is using KX thermostat, secure the KX

thermostat body between the fryer burners so that it will not fall when the tank assembly is lifted from the fryer

(Fig 70)

Fig. 70

47

Page 48

5. Follow steps 1-4 under Removal of Control Housing

6. Follow steps 1-7 under Removal of Discard Tube(s).

7. For D and C models with a 7/16" socket and wrench remove (2) nuts from under base frame that secure the manifold

assembly to the frame. For S models with a 3/8" socket remove (1) screw securing the manifold Vee bracket to the base

frame. (Fig. 71)

D and C Model Fryers S Model Fryers

Fig. 71

8. With a 5/16" socket remove (2) screws from the top flue area that

secure the tank back to the flue wrap. (Fig. 72)

Page 49

9. With a 13/16" wrench disconnect the compression elbow from the gas inlet tube. (Fig. 73)

Fig. 73

10. With 5/16" remove (4) screws holding the heat shield in place. (See Fig. 48)

11. Slide the heat shield down. (See Fig. 48)

12. If fryer is inter plumb equipped cut the wire ties holding the oil refill lines together. (Fig. 74) If fryer is without

inter plumb, skip to step 15.

Fig. 74

49

Page 50

13. Disconnect micro switch. (Fig. 75)

Fig. 75

14. With a 13/16" wrench disconnect the oil refill coupling. (Fig. 76)

Fig. 76

50

Page 51

15. Grasp tank from the back at the top of the flue wrap area and lift the entire tank assembly out of the fryer body.

Note that on D and C models the heat shield insulation may catch on the body frame. If this occurs the tank

assembly will not lift out of the unit. Set the tank back into the fryer body and try to align the heat shield to keep

the insulation from catching. (Fig. 77)

Fig. 77

With tank now out side of the fryer body position the tank onto its back so that the component parts may be

removed for reassembly onto the new tank.

16. With a 1/2" socket loosen the bolts holding the burners and insulation box in place. (Fig. 78)

Fig. 78

51

Page 52

17. Remove the burner insulation box. (Fig. 79)

Fig. 79

18. With flat blade screwdriver remove the pilot bracket. (Fig. 80)

Fig. 80

52

Page 53

19. If servicing a D or C model with a 5/16" wrench remove the hi limit packing nut. For S models use a 1/2" wrench. (Fig. 81)

Fig. 81

20. With an 11/16" wrench remove the compression nut securing the limit bulb to the tank. (Fig. 82)

Fig. 82

53

Page 54

21. With an 1/2" wrench remove the thermistor or thermo bulb packing nut. (Fig. 83)

Fig. 83

22. With an 11/16" wrench remove the compression nut holding the thermistor or thermo bulb

to the tank. (Fig. 84)

Fig. 84

54

Page 55

23. With a 1/4" socket from inside the fryer tank remove the hardware and mounting clips holding the hi limit and

thermistor/thermostat bulb to the tank. (Figs. 85)

Figs. 85

24. Pull both the termistor and hi limit probes through the tank bottom and remo ve them from the fryer. (Figs.

86)

High Limit Thermistor/Thermo Bulb

Figs. 86

55

Page 56

25 With a 1/2" wrench remove (4) bolts securing the manifold bracket to the tank assembly (Fig 87)

Fig. 87

26 For fryers housing a filter station with a quick disconnect from the front of unit with a 7/16" socket and wrench remove the

"U" bolt securing the disconnect line to the tank assembly (Fig 88)

Fig. 88

56

Page 57

27. Remove the pull rod handle. (Fig. 89)

Fig. 89

28. With a 7/16" socket remove all the pull rod hardware from the micro switch assembly. (Fig. 90)

Fig. 90

57

Page 58

29 Pull the rod up through the mounting bracket and out of the fryer (Fig 91)

30 Pull the manifold assembly from the fryer (Fig 92)

Fig. 91

Fig. 92

58

Page 59

31 With an adjustable wrench remove the elbow from the tank assembly. (Fig 93)

Fig. 93

32 With a 3/8" socket remove (2) nuts holding the oil return line to the tank assembly (Figs 94)

Figs. 94

59

Page 60

33 With a pipe wrench remove the remove the drain valve and drain pipe assembly from the tank (Fig 95)

Fig. 95

34 With a 3/8" socket remove (4) screws securing the flue box to the tank assembly (Fig 96)

Fig. 96

35 Reverse steps 16-34 to install parts removed from the tank onto the new tank

36 Reverse steps 1-15 to install the tank assembly

60

Page 61

Drwg. No. 419357-1

62

Page 62

63

Page 63

Drwg. No. 419357-2

64

Page 64

65

Page 65

Drwg. No. 419357-3

66

Page 66

67

Page 67

Drwg. No. 419322-1

68

Page 68

69

Page 69

Drwg. No. 419322-2

70

Page 70

71

Page 71

Drwg. No. 419322-3

72

Page 72

73

Page 73

Drwg. No. 419323-1

74

Page 74

75

Page 75

Drwg. No. 419323-2

76

Page 76

77

Page 77

Drwg. No. 419323-3

78

Page 78

79

Page 79

Drwg. No. 419318-1

80

Page 80

81

Page 81

Drwg. No. 419318-2

82

Page 82

83

Page 83

Drwg. No. 419318-3

84

Page 84

85

Page 85

Drwg. No. 419340-1

86

Page 86

87

Page 87

Drwg. No. 419340-2

88

Page 88

89

Page 89

Drwg. No. 419340-3

90

Page 90

91

Page 91

Drwg. No. 419337-1

92

Page 92

93

Page 93

Drwg. No. 419337-2

94

Page 94

95

Page 95

Drwg. No. 419337-3

96

Page 96

97

Page 97

Drwg. No. 419564-1

98

Page 98

99

Page 99

Drwg. No. 419564-2

100

Page 100

101

Loading...

Loading...