Page 1

HGB(M) AND GHCB

GAS CHARBROILERS

MODELS

HGB34 ML-135520

HGB50 ML-135521

HGB60 ML-135522

HGB34M ML-135524

HGB50M ML-135525

GHCB34S ML-135526

INSTALLATION &

OPERATION MANUAL

GHCB51S ML-135527

PRIOR MLS COVERED

IN THIS CATALOG

HGB34 ML-27850

HGB50 ML-27851

HGB60 ML-27852

HGB71 ML-27853

HGB34M ML-27885

HGB50M ML-27886

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

HGB60M ML-27887

HGB71M ML-27888

GHCB34S ML-52245

GHCB51S ML-52247

GHMCB34 ML-52244

GHMCB51 ML-52246

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

P.O. BOX 696, LOUISVILLE, KY 40201-0696

TEL. (502) 778-2791

FORM 35600 Rev. A (2-05)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN SHUTOFF VALVE AND CONTACT THE LOCAL

GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

MODULAR CHARBROILERS MUST BE MOUNTED ON NONCOMBUSTIBLE LEVEL SURFACE.

LEGS AND CASTERS ARE NOT AVAILABLE ON MODULAR CHARBROILERS.

© VULCAN-HART, 2005

– 2 –

Page 3

Installation, Operation and Care of

HGB(M) and GHCB Gas Charbroilers

SAVE THESE INSTRUCTIONS

GENERAL

Vulcan-Hart Gas Charbroilers feature heavy-duty, cast-iron burners; input rating is 16,000 BTU/hr. per

burner. Each burner is controlled by an adjustable gas valve. Baffles suspended beneath the burners

reflect the heat upward, maintaining a cool zone under the burner. Special cast-alloy radiants are

located directly above each burner to maintain uniform temperature. Radiants are easily removed for

cleaning when cool.

5

Heavy-duty, cast-iron top grates (5

grid surface to be level or sloped. Grooves, cast in the top grates, permit fat runoff and reduce flaring

when tilted toward the front.

The gas control valves can be adjusted to provide ideal sectional broiling results.

HGB AND GHCB SERIES CHARBROILERS

/16" wide) (135 mm) are reversible to allow all or part of the cooking

Model Width (inches) (mm) Number of Burners Btu Input Rating

HGB34(M)/GHCB34S 34 (864) 6 96,000

HGB50(M) 50 (1270) 9 144,000

GHCB51S 51 (1295) 9 144,000

HGB60(M) 605/8 (1539) 12 192,000

HGB71(M) 713/8 (1814) 14 224,000

ACCESSORIES

• Stainless steel splasher guard (HGB and HGBM only)

• 12" work shelf (HGB and HGBM only)

• Four swivel casters (HGB and GHCB only)

• Griddle plate 18" D x 13

• Banking kit—joins any two charbroilers together

• Grate lifter

• Rod grate (

• Rod grate scraper

• Flexible gas hose with quick disconnect and restraining device. (GHCB) (Consult price book

for available sizes.)

1

/2" steel rod on 3/4" centers) in lieu of cast-iron grate

3

/4" W x 1/2" Thk. (HGB and HGBM only)

– 3 –

Page 4

INSTALLATION

Before installing, verify that the type of gas (natural or propane) agrees with the specifications on the

data plate located behind the lower front cover, riveted to the center support of the burner box bottom

(HGB models), or between the grease pan guides, riveted to the left corner of the lower front cover

(GHCB models). Be sure the unit is built for the installation elevation.

UNPACKING

The charbroiler was carefully inspected before leaving the factory. The transportation company

assumes full responsibility for safe delivery upon acceptance of the shipment. Immediately after

unpacking, check for possible shipping damage. If the charbroiler is found to be damaged after

unpacking, save the packaging material and contact the carrier within 7 days of delivery.

Do not use the drawers or handles to lift or move the charbroiler.

LOCATION

The equipment area must be kept free and clear of combustible substances. A minimum 2" (51 mm) of

clearance to combustibles must be provided at the rear of all broilers; no side clearance is required for

combustibles or noncombustibles. The HGB(M) is to be installed only on noncombustible floors. The

GHCB is suitable for installation on combustible floors.

Install the charbroiler in an area that has sufficient air supply for combustion of the gas at the burners.

Provide adequate clearance for air openings into the combustion chamber. Do not obstruct the flow of

combustion and ventilation air.

Do not permit fans to blow directly at the charbroiler and, wherever possible, avoid open windows next

to the sides or back. Avoid wall-type fans that create air cross currents within the room.

Legs

Legs (6-inch [152 mm] stainless steel) or casters are factory assembled onto the bottom of the

charbroiler as specified on order.

Modular Broilers

Models HGB34M, HGB50M, HGB60M and HGB71M must be installed on a noncombustible, level

counter or stand. No adjustment is provided.

When a modular broiler is installed on a counter, it must be sealed to the counter with an NSF-approved

sealant.

INSTALLATION CODES AND STANDARDS

Install this equipment in accordance with:

In the United States

1. State and local codes, or in the absence of local codes, with:

2. National Fuel Gas Code, ANSI-Z223.1 (latest edition), available from The American Gas

Association, Inc., 1515 Wilson Boulevard, Arlington, VA 22209.

3. National Electrical Code ANSI/NFPA70 (latest edition) (if applicable).

– 4 –

Page 5

In Canada

1. Local codes.

2. CSA B149.1 Natural Gas and Propane Installation Code.

3. CSA C22.1 Canadian Electrical Code.

The above are available from the Canadian Standard Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

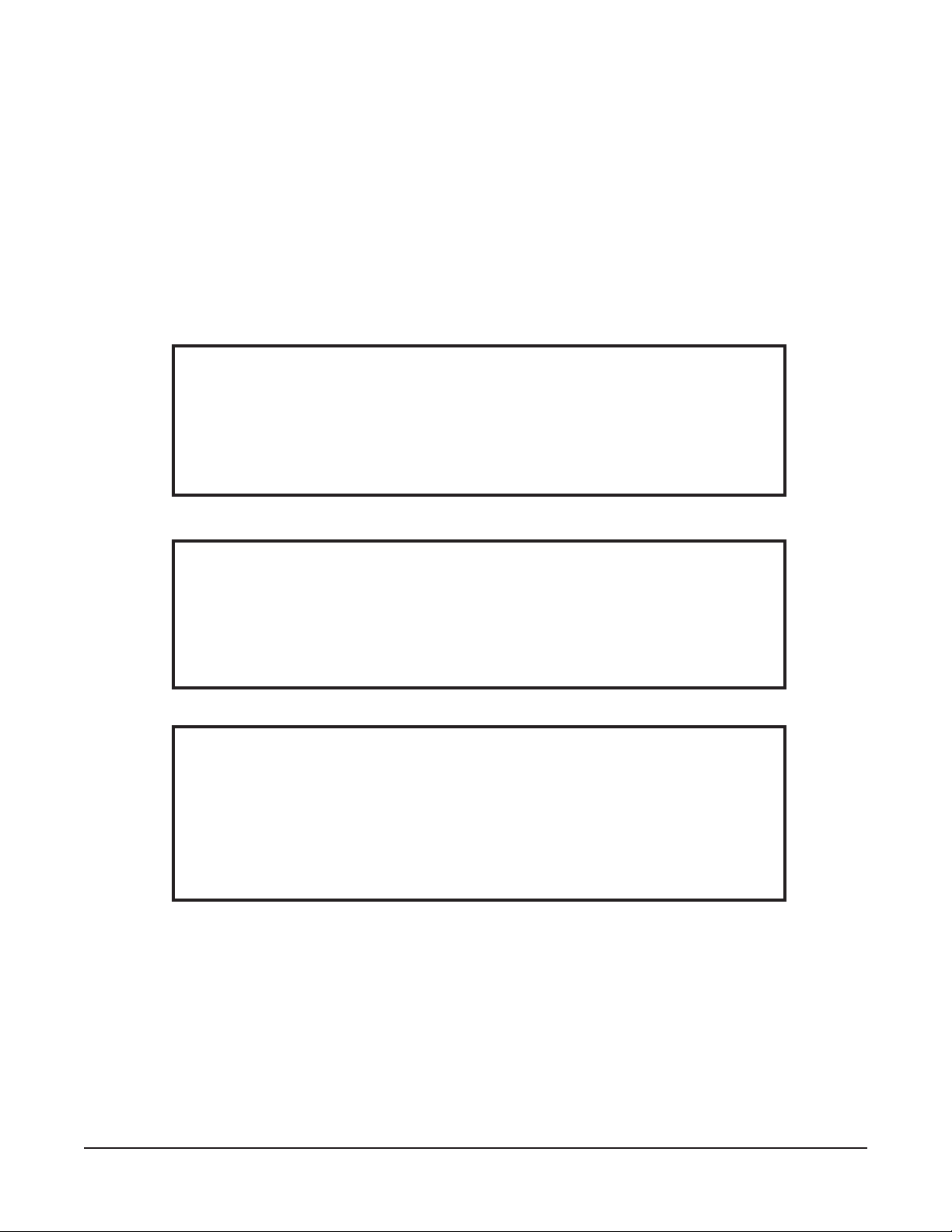

Casters (Optional)

Optional casters may be obtained. Appliance will require four (4) swivel casters, two (2) of which must

be braking casters.

Appliances Mounted on Casters

Appliances mounted on casters must use a flexible connector

(not supplied by Vulcan) that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21.69 •

CSA 6.16 and a quick-disconnect device that complies with

the Standard for Quick-Disconnect Devices for Use With

Gas Fuel, ANSI-Z21.41 • CSA 6.9. In addition, adequate

means must be provided to limit movement of the appliance

without depending on the connector and the quickdisconnect device or its associated piping to limit appliance

movement. Attach the restraining device at the rear of the

appliance as shown in Fig. 1.

If disconnection of the restraint is necessary, turn off the

gas supply before disconnection. Reconnect this restraint

Fig. 1

prior to turning the gas supply on and returning the aplliance

to its installation position.

Note: If the appliance is installed on casters and is moved for any reason, it is recommended that the

appliance be releveled front to back and side to side to achieve desired cooking results. If the casters

supplied are not leveling type casters, then the flooring must be adjusted or the appliance may need

to be moved to a level location of operation.

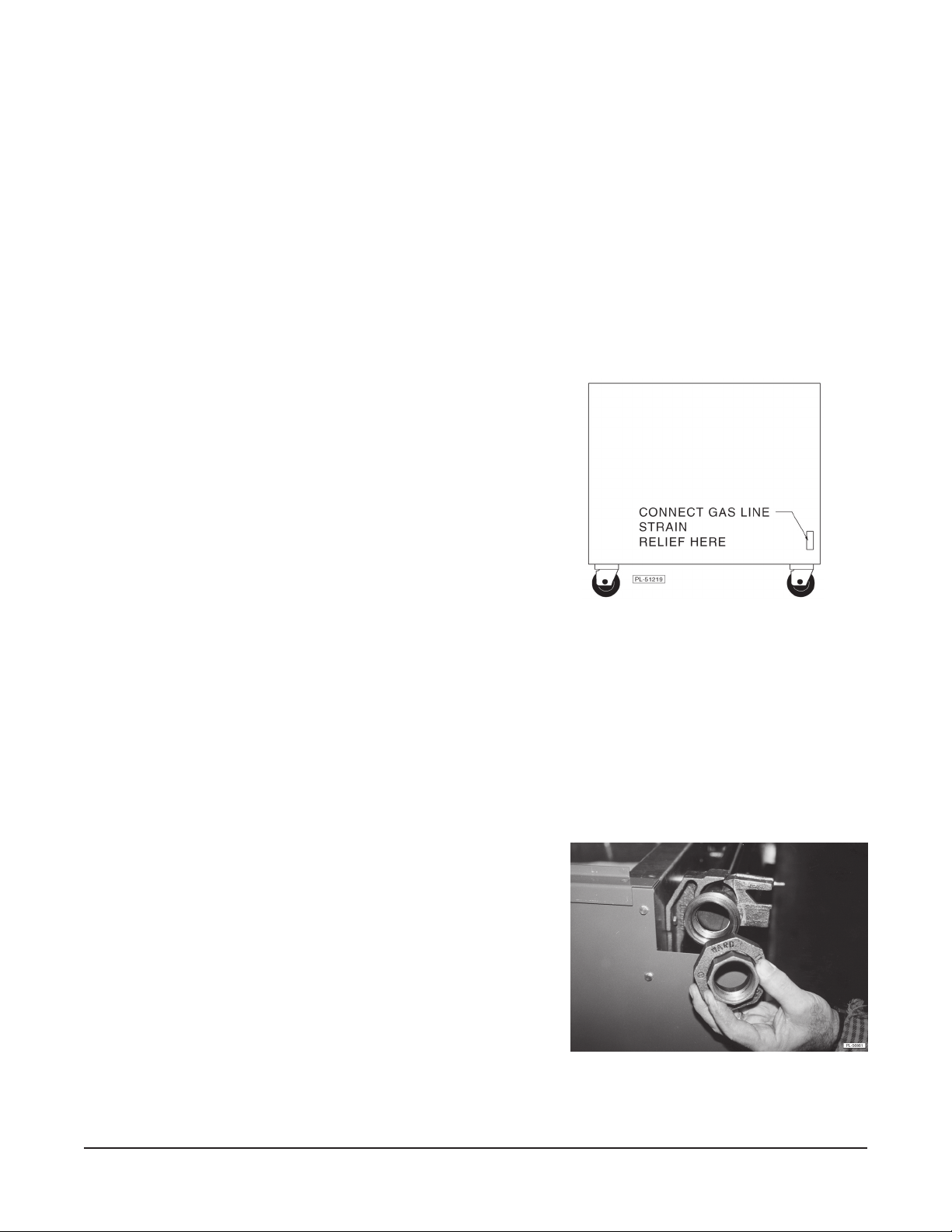

Battery Installation (GHCB Only)

Since January 5, 1998, Vulcan-Hart appliances have

changed from using Stockham gas unions to Ward (Fig. 2).

If you are installing a new battery range to an existing field

appliance, the union on the existing field appliance must be

checked against the union being used on the new range.

The union manufacturer's name around the face surface of

the union nut must match. If the new range has been

shipped using a Ward union and the old appliance has

something different—i.e., Stockham—it must be replaced

with a Ward union. Failure to replace this union could result

in a gas leak.

Extra Ward unions must be ordered through an Authorized

Vulcan Parts Depot.

– 5 –

Fig. 2

Page 6

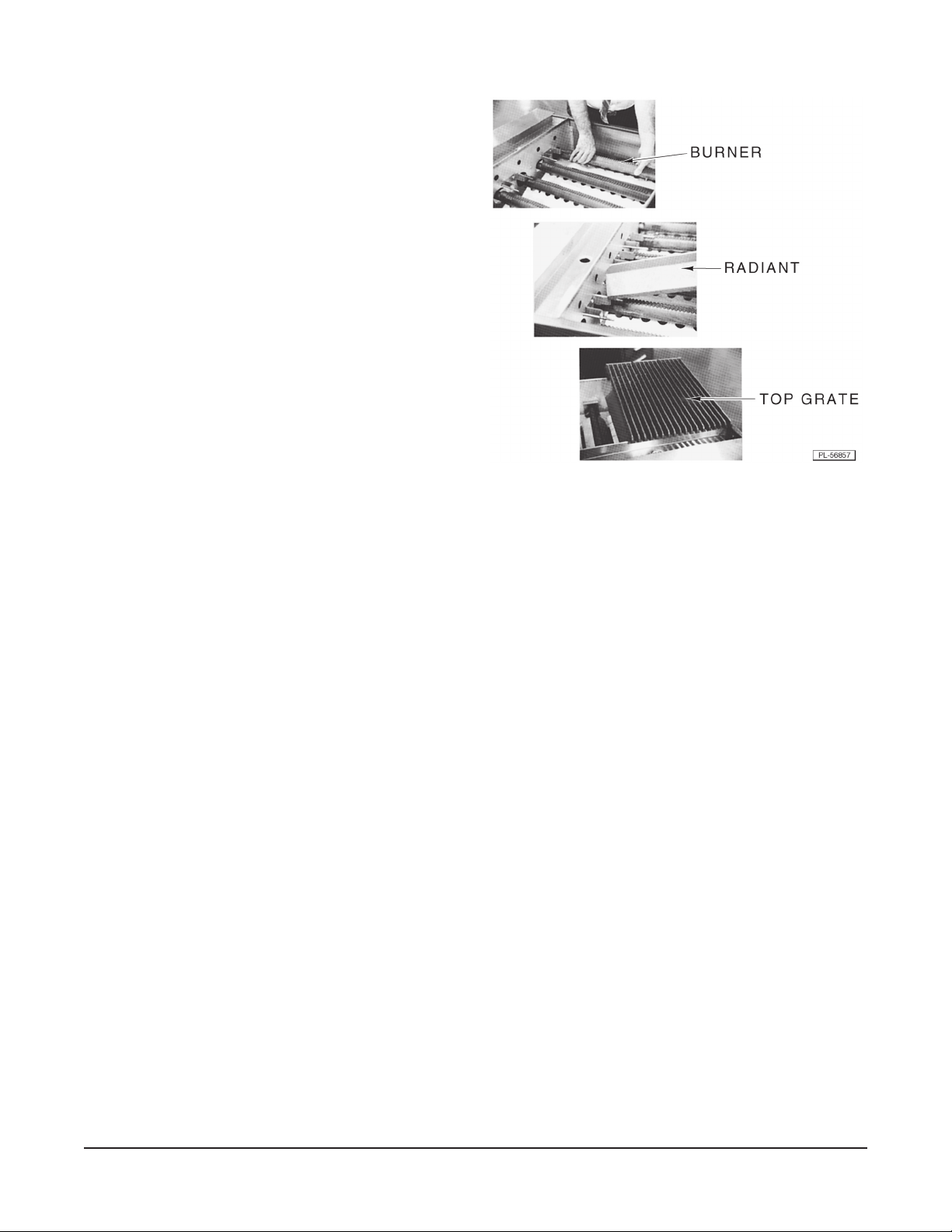

ASSEMBLY

Burners, radiants and top grates shipped with the

appliance will be packaged in a box within the

cabinet section of a cabinet base model. These

items will be packaged in a box and shipped in the

top of the appliance on open base and modular

models. These items must be assembled during

installation. See (Fig. 3).

Fig. 3

GAS CONNECTIONS

CAUTION: All gas supply connections and any pipe joint compound must be resistant to the

action of liquefied petroleum gases.

The gas inlet location for the GHCB broiler is located at the middle rear of the broiler. The gas inlet

location for the HGB broiler is in the rear, offset to the left side of the broiler. Codes require that a gas

shutoff valve (not included) be installed in the gas line ahead of the charbroiler. The gas supply line must

1

/4" (32 mm) NPT (inside diameter). Make sure the pipes are clean and free of obstructions, dirt and

be 1

piping compound.

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

After piping has been checked for leaks, fully purge gas pipes to remove air.

GAS PRESSURES AND ORIFICES

The standard orifices are set at 6" W.C. (Water Column) pressure for natural gas and 10" W.C. (Water

Column) pressure for propane.

TESTING THE GAS SUPPLY PIPING SYSTEM

When test pressures exceed

1

/2 psig (3.45 kPa), the charbroiler and an individual shutoff valve must

be disconnected from the gas supply piping system.

1

When test pressures are

/2 psig (3.45 kPa) or less, the charbroiler must be isolated from the gas supply

piping system by closing its individual shutoff valve.

– 6 –

Page 7

LEVELING THE CHARBROILER

Once gas connections have been made, place a spirit level on top of the charbroiler. Adjust the legs

to make sure that the charbroiler is level front to back and side to side in the final installed position.

No adjustment is required for modular broilers.

FLUE CONNECTIONS

The charbroiler must be located under a hood that has an adequate connection to an exhaust duct. The

hood must extend 6" (152 mm) beyond charbroiler sides.

Adequate ventilation must be provided and must comply with NFPA Standard #96 (latest edition) and

with local codes.

Clearance above the charbroiler should be adequate for products of combustion to be removed

efficiently. An 18" (457 mm) minimum clearance should be maintained between the flue vent and the

filters of the hood venting system.

Adequate air should be provided in the kitchen to replace air taken out by the ventilating system. This

will prevent charbroiler function from being affected by a reduced atmospheric pressure.

CLEAN BEFORE FIRST USE

Using a noncorrosive, grease-dissolving cleaner, clean the protective metal oils from all surface parts.

Follow the directions of the cleaner manufacturer. Rinse all parts thoroughly and wipe dry with a soft

clean cloth. Reseason cast-iron parts immediately to prevent rusting.

Seasoning

Lightly season the top grates and the griddle and the backsplash, if present, with a thin layer of cooking

oil. This should also be done after every cleaning.

– 7 –

Page 8

OPERATION

WARNING: HOT PARTS CAN CAUSE BURNS. USE CARE WHEN OPERATING THE BROILER.

LIGHTING THE MANUAL GAS PILOT

Adjustment of the pilot light must be performed by a qualified Vulcan-Hart installation or service person.

The flame adjustment must be made at the time of installation.

1. Turn main gas supply ON.

2. Wait 30 seconds and, using a lighted taper, light the pilots. The pilot for each burner must be lit

(Fig. 4).

3. If pilot fails to light, turn main gas supply OFF. Wait 5 minutes and repeat.

Fig. 4

Nightly Shutdown

Turn burner valves OFF; pilots will remain lit.

Complete Shutdown

1. Turn burner valves OFF.

2. Turn main gas supply OFF; pilots will go out.

– 8 –

Page 9

CONTROLS (FIG. 5) – HGB(M) BROILERS

OFF — Horizontal when off.

ON — Turn valve handle counterclockwise 90 degrees so it is

vertical to open the burner gas valve completely. Adjust

the valve between OFF and ON positions to moderate the

heat.

Fig. 5

CONTROLS (FIG. 6) – GHCB BROILERS

OFF — Turn the knob to the right.

LO — Turn the knob to the left.

HI — Turn the knob straight up to the 12-o'clock position.

The burner heat may be controlled by turning the valve knob anywhere between the OFF and LO

positions. The burner heat will be more intense between OFF and HI and less intense between HI and

LO.

Fig. 6

Preheat – HGB(M) and GHCB Broilers

Turn burners fully on for 20 to 25 minutes to allow the broiler to preheat. Valves should be turned to a

lower position to maintain grid temperature between 525°F and 625°F (274°C and 330°C) for optimum

broiling.

CAUTION: Leaving the valves fully on beyond the recommended preheat time will produce grid

temperatures above 1000°F (538°C), which can cause radiants to warp.

Positioning the Top Grates

The top grates have two positions. With one side up, the grids are horizontal (flat). With the other side

up, the grates slope toward the front. Use the sloped grate for most broiling to allow the groove on each

side of the grid bars to catch the melted fat and allow it to flow to the trough in front. The grease will then

flow through an opening to the grease drawer.

Do not allow the meat being broiled to catch fire as this results in a poor flavor. Fatty meats may require

reduced temperatures to minimize flames.

– 9 –

Page 10

CLEANING

• Keep the broiler clean.

• Clean the grate grooves with the wire brush provided.

• Empty the grease drawer frequently.

Top Grates

Clean the top grates daily on both the top and bottom surfaces with a good wire brush or burlap or other

grease-absorbing material to remove spillover, grease and so forth before it burns in. Avoid a crust on

the top of the grill: It looks unsightly and slows cooking speed (scrape off if necessary). Burn off grates

at full input after cleaning. Season grates before cooking, see Seasoning on page 8.

Burner Radiants

To prevent continuous smoking, keep the charbroiler clean. Never allow grease or fat to accumulate.

Clean burner radiants daily with a good wire brush. The radiants may be cleaned in place or removed

for a more thorough cleaning. Steel wool may be used for more stubborn spots.

Grease Trough and Drawer

Empty and clean the grease trough, and drain the drawer thoroughly at least once every day.

Exterior Surfaces

Clean all exposed surfaces of the entire charbroiler thoroughly at the end of each day. Stainless steel

may be cleaned with a damp cloth; stubborn soil may be removed with detergent and warm water.

– 10 –

Page 11

MAINTENANCE

WARNING: HOT PARTS CAN CAUSE BURNS. USE CARE WHEN MAINTAINING THE BROILER.

BURNERS

If, after a period of satisfactory operation, burner flame characteristics should change or length of flame

should be reduced, burner ports may have become restricted. Burners should be cleaned at least every

60 days and more often if required. To clean burners, remove and boil in a strong solution of lye water

for about 15 minutes. Ports can be opened with a sharp-pointed instrument or proper-sized drill bit. Be

careful not to increase the size of the burner ports.

If the mixer openings or pilot orifices need cleaning, contact your Vulcan gas service technician. This

should be done at least every 6 months and more often if necessary.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this model, contact the Vulcan-Hart Service

Agency in your area (refer to our website, www.vulcanhart.com for a complete listing of Authorized

Service and Parts depots).

When calling for service, the following information must be available: model number, serial number,

manufacture date code (MD) and voltage.

– 11 –

Page 12

FORM 35600 Rev. A (2-05) PRINTED IN U.S.A.

– 12 –

Page 13

MODE D’INSTALLATION ET

MODE D’EMPLOI

GRILLOIR AU GAZ DE TYPE

CHARBON DE BOIS HGB (M) ET GHCB

MODÈLES

HGB34 ML-135520

HGB50 ML-135521

HGB60 ML-135522

HGB34M ML-135524

HGB50M ML-135525

GHCB34S ML-135526

GHCB51S ML-135527

ANCIENNEMENT, LES PIÈCES PORTAIENT

LES NUMÉROS DE ML SUIVANTS :

HGB34 ML-27850

HGB50 ML-27851

HGB60 ML-27852

HGB71 ML-27853

HGB34M ML-27885

HGB50M ML-27886

Pour de plus amples détails concernant Vulcan-Hart ou pour repérer le détaillant de

pièces et de service autorisé le plus près, visiter notre site Web à : www.vulcanhart.com

VULCAN-HART P.O. BOX 696, LOUISVILLE, KY 40201-0696

UNE DIVISION DE GROUPE ITW ÉQUIPEMENT ALIMENTAIRE, LLC TÉL. (502) 778-2791

WWW.VULCANHART.COM F35600 RÉv. A (02-05)

HGB60M ML-27887

HGB71M ML-27888

GHCB34S ML-52245

GHCB51S ML-52247

GHMCB34 ML-52244

GHMCB51 ML-52246

GHCB34S

HGB34

Page 14

MESURES DE SÉCURITÉ IMPORTANTES

CE MANUEL A ÉTÉ PRÉPARÉ À L’INTENTION D’UN PERSONNEL QUALIFIÉ ET AUTORISÉ À

INSTALLER DES APPAREILS FONCTIONNANT AU GAZ ET À EFFECTUER LE DÉMARRAGE

INITIAL CHEZ LE CLIENT DE MÊME QUE LE RÉGLAGE DES APPAREILS CONCERNÉS DANS

CE MANUEL.

AFFICHER À UN ENDROIT VISIBLE LES PREMIERS SOINS À ADMINISTRER À TOUTE

PERSONNE AYANT RESPIRÉ LES GAZ QUE CET APPAREIL DÉGAGE. ON PEUT SE

PROCURER CES INFORMATIONS CHEZ LE FOURNISSEUR DE GAZ LE PLUS PRÈS.

IMPORTANT

EN CAS D’ODEURS DE GAZ, ÉTEINDRE L’APPAREIL PAR

LE ROBINET D’ARRÊT PRINCIPAL ET COMMUNIQUER

AVEC LA COMPAGNIE DE GAZ LA PLUS PRÈS OU

AVEC LE FOURNISSEUR DE GAZ ATTITRÉ POUR

L’ENTRETIEN.

MESURE DE SÉCURITÉ

NE PAS RANGER NI UTILISER DE L’ESSENCE NI TOUT

AUTRE LIQUIDE OU VAPEUR INFLAMMABLE À

PROXIMITÉ DE CET APPAREIL OU DE TOUT AUTRE

APPAREIL.

AVERTISSEMENT

L’INSTALLATION, LE RÉGLAGE, LA MODIFICATION

ET L’ENTRETIEN INCORRECTS DE CET APPAREIL

PEUVENT CAUSER DES DOMMAGES MATÉRIELS,

DES BLESSURES ET MÊME LA MORT. LIRE LES

INSTRUCTIONS D’INSTALLATION, DE FONCTIONNEMENT

ET D’ENTRETIEN AVANT DE PROCÉDER À TOUTE

INSTALLATION OU TOUT ENTRETIEN.

EN CAS DE PANNE DE COURANT, NE PAS FAIRE

FONCTIONNER CET APPAREIL.

INSTALLER LES GRILLOIRS MODULAIRES SUR UNE SURFACE NON COMBUSTIBLE

UNIQUEMENT. LES PATTES ET LES ROULETTES NE SONT PAS DISPONIBLES SUR

CES MODÈLES.

© COMPAGNIE VULCAN-HART, 2005

– 2 –

Page 15

Installation, fonctionnement et entretien

Grilloirs au gaz de type charbon de bois

des séries HGB (M) et GHCB

DOCUMENT À CONSERVER.

GÉNÉRALITÉS

Les grilloirs au gaz de type charbon de bois Vulcan-Hart sont pourvus de brûleurs à service intense en

fonte de 16 000 BTU/h commandés par un robinet à gaz réglable. Des déflecteurs fixés au-dessous

des brûleurs réfléchissent la chaleur vers le haut de façon à maintenir une zone froide sous les

brûleurs. Des éléments radiants en fonte alliée de conception unique sont placés directement en

dessous de chaque brûleur afin de maintenir une température uniforme. Ces éléments s’enlèvent

facilement aux fins de nettoyage lorsqu’ils sont froids.

Les grilles sont formées de sections réversibles en fonte robuste de 135 mm (5 5/16 po) de largeur

qui permettent l’utilisation de toute la surface de cuisson ou d’une partie seulement, procurant ainsi

une grande souplesse d’utilisation (de niveau ou inclinée). Des rainures de récupération moulées

dans chaque lame et inclinées vers l’avant facilitent l’écoulement de la graisse.

Les robinets à gaz sont réglables pour un rendement optimal.

GRILLOIRS AU GAZ DE TYPE CHARBON DE BOIS DES SÉRIES HGB ET GHCB

Modèle Largeur mm(po) Nombre de brûleurs Début (BTU)

HGB34(M)/GHCB34S 864 (34) 6 96 000

HGB50(M) 1 270 (50) 9 144 000

GHCB51S 1 295 (51) 9 144 000

HGB60(M) 1 539 (605/8) 12 192 000

HGB71(M) 1 814 (713/8) 14 224 000

ACCESSOIRES

• Écran anti-éclaboussures en acier inoxydable (HGB et HGBM seulement)

• Tablette de travail de 305 mm (12 po) (HGB et HGBM seulement)

• Quatre roulettes pivotantes (HGB et GHCB seulement)

• Plaque à frire de 457 P x 349 L x 13 mm E (18 x 13 3/4 x 1/2 po) (HGB et HGBM seulement)

• Nécessaire de raccordement de grilloirs (pour le raccordement de deux appareils)

• Poignée pour section de grille

• Grille à tige (tige en acier de 13 mm [1/2 po] sur centres de 19 mm [3/4 po]) au lieu de grilles

en fonte

• Racloir de grille à tige

• Tuyau flexible à gaz muni d’un raccord à débranchement rapide et d’un dispositif de retenue

(GHCB). (Consulter la liste de prix pour les grandeurs offertes)

– 3 –

Page 16

INSTALLATION

Avant de procéder à l’installation, s’assurer que le type de gaz (naturel ou propane) de l’immeuble

correspond aux spécifications de la plaque signalétique derrière le couvercle avant inférieur et rivetée

au support central du bas de la boîte du brûleur (modèles HGB), ou entre les guides du tiroir de

propreté, et rivetée au côté gauche du couvercle avant inférieur (modèles GHCB). S’assurer que

l’appareil a été conçu pour l’altitude où il est installé.

DÉBALLAGE

Avant de quitter l’usine, cet appareil a été inspecté soigneusement. Le transporteur est entièrement

responsable de la livraison de l’appareil. Immédiatement après avoir déballé l’appareil, vérifier s’il n’a

pas été endommagé lors du transport. En cas de dommages, conserver le matériel d’emballage et

aviser le transporteur dans les 15 jours suivant la date de réception.

Ne pas soulever ni déplacer l’appareil par les tiroirs ou les poignées.

EMPLACEMENT

Aucune substance combustible ne doit se trouver à proximité de l’appareil. Observer un dégagement

d’au moins 51 mm (2 po) derrière l’appareil pour le branchement du gaz; aucun dégagement n’est

requis de chaque côté. Installer le grilloir HGB(M) sur une surface non combustible uniquement. Le

modèle GHCB peur s’installer sur une surface combustible.

S’assurer d’une ventilation suffisante dans le local pour permettre la combustion des gaz.

Installer le grilloir de manière à ne pas obstruer l’air nécessaire à la combustion et à la ventilation.

Observer un dégagement suffisant autour des ouvertures d’approvisionnement d’air de la chambre de

combustion.

Veiller à ce que les ventilateurs ne soufflent pas directement sur le grilloir et, dans la mesure du

possible, ne pas ouvrir les fenêtres à proximité de l’appareil ni utiliser des ventilateurs muraux qui

produisent des courants d’air.

Pattes

Les pattes ou roulettes en acier inoxydable de 152 mm (6 po) sont assemblées en usine sous l’appareil

conformément à la commande du client.

Grilloirs modulaires

Installer les modèles HGB34M, HGB50M, HGB60M et HGB71M uniquement sur un support ou un

comptoir incombustible de niveau. Aucun réglage n’est requis.

Pour l’installation sur un comptoir, fixer l’appareil au moyen d’un adhésif homologué par la NSF.

CODES D’INSTALLATION ET NORMES

L’installation de cet appareil doit être conforme aux codes suivants :

L’installation de votre cuisinière Vulcan doit se faire selon les codes suivants :

Aux États-Unis :

1. Codes locaux

2. Norme ANSI/Z223.1 (dernière édition) du National Fuel Gas Code dont on peut se procurer un

exemplaire auprès de l’American Gas Association Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. Norme ANSI/NFPA-70 (dernière édition) du National Electrical Code (si applicable).

– 4 –

Page 17

Au Canada :

1. Codes locaux.

2. Norme CSA B149.1 du Code d’installation des appareils fonctionnant au gaz naturel et propane

(si elle s’applique).

3. Norme CSA et C22.1 du Code canadien de l’électricité (dernière édition).

On peut se procurer un exemplaire des normes ci-dessus auprès de l’Association canadienne de

normalisation, 5060 Spectrum Way, Bureau 100, Mississauga, Ontario, Canada L4W 5N6.

Roulettes (en option)

Des roulettes sont offertes en option. L'appareil requiert 4 roulettes pivotantes dont deux à frein.

Appareil installé sur roulettes

Si l’appareil doit être installé sur des roulettes, se munir

d’un connecteur flexible (non fourni par Vulcan) conforme

aux normes ANSI-Z21.69 ou CSA 6.16 sur les connecteurs

des appareils au gaz mobile et d’un raccord à

débranchement rapide conforme aux normes ANSI-Z21.41

ou CSA 6.9. En plus, prendre les moyens nécessaires

pour limiter le mouvement de l’appareil sans devoir compter

sur le connecteur ou le raccord à débrayage rapide, ni

même sur la tuyauterie pour le garder immobile. Fixer le

FIXER LA CHAÎNE

DE RETENUE DE

LA CONDUITE

D’ALIMENTATION

EN GAZ ICI

dispositif de retenue à l’arrière de la cuisinière (Fig. 1).

S’il s’avère nécessaire de détacher le dispositif de retenue,

couper l’alimentation en gaz de l’appareil. Le rattacher

avant de rétablir l’alimentation en gaz et de remettre

Fig. 1

l’appareil en position d’exploitation.

Nota : Si la cuisinière est installée sur des roulettes et doit être déplacée pour une raison ou une autre,

il est conseillé de la niveler à nouveau d’avant en arrière et d’un côté à l’autre. Si les roulettes fournies

ne sont pas des roulettes de nivelage, ajuster le plancher en conséquence ou déplacer l’appareil à un

autre endroit.

Installation en série (GHCB seulement)

Depuis le 5 janvier 1998, Vulcan-Hart n’utilise plus

des raccords-unions de gaz Stockham, mais uniquement

des raccords-unions Ward (Fig. 2). Pour le raccordement

en batterie d’une nouvelle cuisinière à une cuisinière

déjà en place, vérifier que le nom du fabricant gravé

sur les raccords-unions des deux appareils est le même.

Si la nouvelle cuisinière est pourvue d’un raccord-union

Ward, mais que le raccord-union de la cuisinière en

place est différent, par exemple Stockham, remplacer

celui-ci par un raccord-union Ward, faute de quoi cela

risque de causer une fuite de gaz.

Commander votre raccord-union du service de l’entretien

Vulcan le plus près.

Fig. 2

– 5 –

Page 18

ASSEMBLAGE

Les brûleurs, éléments radiants et grilles expédiés

avec l’appareil sont emballés dans une boîte placée

à l’intérieur d’une section du meuble, si c’est un

modèle sur meuble, et sur le dessus d’un appareil

à base ouverte et modulaire. Les assembler au

moment de l’installation (Fig. 3).

BRANCHEMENT DU GAZ

BRÛLEUR

ÉLÉMENT RADIANT

GRILLE

Fig. 3

ATTENTION : Tous les raccords d’alimentation de la conduite de gaz et la pâte à joints de

tuyaux doivent résister à l’action du gaz propane.

L’entrée de gaz se trouve à l’arrière du grilloir, en plein centre sur le modèle GHCB et décalée à droite

sur le modèle HGB). Conformément aux exigences des codes, installer un robinet d’arrêt (non fourni)

dans la conduite de gaz, en amont de l’appareil. Un régulateur de pression du gaz est fourni avec

l’appareil pour son installation sur la canalisation de gaz. La conduite de gaz doit avoir au moins

32 mm (1 1/4 po) de diamètre intérieur. S’assurer que les tuyaux sont propres et qu’ils ne comportent

aucun corps étranger ni trace de saleté ou de pâte à joints.

AVERTISSEMENT : AVANT DE PROCÉDER À L’ALLUMAGE, FAIRE CIRCULER DE L’EAU

SAVONNEUSE DANS TOUS LES JOINTS DE LA CONDUITE DE GAZ POUR S’ASSURER

QU’ILS NE PRÉSENTENT AUCUNE FUITE. NE PAS SE SERVIR D’UNE FLAMME NUE.

Après avoir enrayé toute possibilité de fuite, purger la conduite de gaz pour évacuer tout l’air qu’elle

contient.

PRESSIONS ET ORIFICES DE GAZ

Les orifices standard sont réglés à une pression de 1,49 kPa (6 po de colonne d’eau) pour le gaz

naturel et de 2,49 kPa (10 po de colonne d’eau) pour le gaz propane.

ESSAIS DE LA CANALISATION DE GAZ

Si la pression de la canalisation de gaz est supérieure à 3,45 kPa (1/2 psig) lors d’essais de pression,

débrancher le grilloir et son robinet d’arrêt de la conduite de gaz.

Lorsque la pression d’essai est égale ou inférieure à 3,45 kPa (1/2 psig), isoler l’appareil de la

canalisation de gaz en fermant son robinet manuel.

– 6 –

Page 19

NIVELAGE DU GRILLOIR

Une fois le branchement du gaz effectué, déposer un niveau à bulle d’air sur le dessus du grilloir.

Mettre l’appareil de niveau d’avant vers l’arrière, puis latéralement en réglant les pieds.

Aucun réglage n’est nécessaire pour les grilloirs modulaires.

CONDUIT D’ÉVACUATION

Placer le grilloir sous une hotte appropriée raccordée à un conduit d’évacuation. Celle-ci doit

dépasser les côtés du grilloir de 152 mm (6 po).

S’assurer d’une ventilation suffisante conformément à la norme NFPA n× 96 (dernière édition) et aux

codes concernés en vigueur.

Un dégagement approprié est requis au-dessus de l’appareil pour l’évacuation efficace des gaz

brûlés. Observer un dégagement minimum de 457 mm (18 po) entre le conduit d’évacuation et les

filtres de la hotte.

La cuisine doit être suffisamment aérée pour que l’air évacué par le système de ventilation soit

remplacé par de l’air frais, faute de quoi une pression atmosphérique insuffisante empêchera le bon

fonctionnement du grilloir.

AVANT UNE PREMIÈRE UTILISATION

Nettoyer tous les composants de surface au moyen d’un produit de nettoyage et de dégraissage sans

acide pour enlever toute trace du film protecteur d’huile. Suivre les indications du fabricant. Rincer

à fond tous les composants et les essuyer avec un chiffon propre et doux. Réapprêter les plaques en

fonte immédiatement pour empêcher la rouille.

Apprêtage

Appliquer une mince couche d’huile de cuisson sur les grilles, la plaque à frire et le panneau antiéclaboussures (si le grilloir en est pourvu d’un). Répéter après chaque nettoyage.

– 7 –

Page 20

FONCTIONNEMENT

AVERTISSEMENT : LES COMPOSANTS CHAUDS PEUVENT CAUSER DES BRÛLURES.

EXERCER UNE EXTRÊME PRUDENCE LORS DE L’EXPLOITATION DU GRILLOIR.

ALLUMAGE DE LA VEILLEUSE DU ROBINET DE GAZ MANUEL

Le réglage de la veilleuse doit être effectué par un technicien Vulcan-Hart qualifié. Le réglage de la

flamme doit être effectué au moment de l’installation.

1. Ouvrir le robinet de gaz principal.

2. Attendre 30 secondes, puis allumer les veilleuses au moyen d’une bougie. Toutes les veilleuses

devraient s’allumer (Fig. 4).

3. Si une veilleuse refuse de s’allumer, fermer le robinet de gaz principal. Attendre cinq minutes

et reprendre les étapes ci-dessus.

ALLUMER LES VEILLEUSES

AU MOYEN D’UNE BOUGIE

Fig. 4

Arrêt nocturne

Fermer les robinets de gaz; les veilleuses devraient rester allumées.

Arrêt prolongé

1. Fermer les robinets des brûleurs.

2 Fermer le robinet de gaz principal; les veilleuses devraient s’éteindre.

– 8 –

Page 21

COMMANDES (FIG. 5) – GRILLOIRS HGB (M)

OFF (arrêt) – à l’horizontale lorsque l’appareil est éteint.

MARCHE

ARRÊT

ON (marche) – Tourner le bouton du robinet de gaz de 90 degrés dans le

sens contraire des aiguilles d’une montre jusqu’à la verticale

pour l’ouvrir complètement. Le régler entre les positions

OFF et ON (marche et arrêt) pour réduire la chaleur.

Fig. 5

COMMANDES (FIG. 6) – GRILLOIRS GHCB

OFF (arrêt) – Tourner le bouton vers la droite.

LO (bas réglage) – Tourner le bouton vers la gauche

HI (réglage élevé) – Tourner le bouton complètement vers le haut jusqu’à la position 12 h.

On peut contrôler la chaleur du brûleur en tournant le bouton du robinet n’importe où entre les

positions OFF (arrêt) et LO (bas réglage). La chaleur des brûleurs sera plus intense entre les

positions OFF (arrêt) et HI (réglage élevé) et moins intense entre les positions HI (réglage élevé)

et LO (bas réglage).

RÉGLAGE ÉLEVÉ

ARRÊT

BAS RÉGLAGE

Fig. 6

Préchauffage – Grilloirs HGB (M) et GHCB

Ouvrir les brûleurs complètement de 20 à 25 minutes pour le préchauffage du grilloir. Régler à un

niveau inférieur pour le maintien de la grille à une température variant entre 274 et 330 °C (525 et

625 °F) et l’obtention de résultats optimums.

ATTENTION : Si les robinets demeurent complètement ouverts plus longtemps que le temps de

préchauffage recommandé, la température des grilles atteindra plus de 538 °C (1 000 °F), ce qui

risque de causer le gauchissement des éléments radiants.

Mise en place des grilles

Les grilles se placent de deux façons. D’un côté, les lames sont à l’horizontale et, de l’autre, elles

s’inclinent vers l’avant. Pour la plupart des tâches, placer les grilles en position inclinée. De cette

façon, une bonne partie de la graisse s’écoule dans le collecteur à l’avant du grilloir par les rainures

de récupération de la graisse des lames pour ensuite être acheminée dans le tiroir de propreté par

l’orifice de vidange.

Ne pas griller la viande jusqu’à ce qu’elle s’enflamme, ce qui risque d’en entraver la qualité. Pour les

viandes grasses, il peut s’avérer nécessaire de baisser légèrement l’intensité des brûleurs pour éviter

que la flamme ne s’élève trop.

– 9 –

Page 22

NETTOYAGE

• Garder l’appareil propre.

• Nettoyer les rainures de récupération de la graisse au moyen de la brosse métallique fournie.

• Vider le tiroir de propreté fréquemment.

Grilles

À tous les jours, nettoyer les faces supérieure et inférieure des grilles à l’aide d’une bonne brosse

métallique ou d’un produit qui absorbe la graisse pour enlever les débordements, la graisse, etc. avant

qu’ils cuisent. Veiller à ce qu’aucune croûte ne se forme sur la plaque, car en plus de donner mauvaise

apparence, les croûtes augmentent le temps de cuisson (racler au besoin). Faire chauffer les grilles

au maximum après leur nettoyage (Se référer à la section Apprêtage en p. 7).

Éléments radiants

Pour empêcher le grilloir de fumer continuellement, le garder propre. Ne jamais laisser de graisse ou

matière grasse s’accumuler. Nettoyer quotidiennement les éléments radiants des brûleurs à l’aide

d’une bonne brosse métallique. Les nettoyer en place ou les enlever pour un nettoyage plus en

profondeur. Utiliser un tampon à récurer métallique pour les taches rebelles.

Rainure de récupération de la graisse et tiroir de propreté

Vider et laver à fond la rainure de récupération de la graisse, le tuyau de vidange et le tiroir de propreté

au moins une fois par jour.

Surfaces extérieures

Nettoyer à fond toutes les surfaces exposées de l’appareil à la fin de chaque journée. Nettoyer l’acier

inoxydable à l’aide d’un chiffon humide propre et enlever les taches rebelles au moyen d’eau chaude

et de détergent.

– 10 –

Page 23

ENTRETIEN

AVERTISSEMENT : LES COMPOSANTS CHAUDS PEUVENT CAUSER DES BRÛLURES.

EXERCER UNE EXTRÊME PRUDENCE LORS DE L’ENTRETIEN DU GRILLOIR.

BRÛLEURS

Une diminution de la longueur de la flamme ou une modification de ses caractéristiques après une

période d’utilisation satisfaisante indique une obstruction des orifices des brûleurs. Nettoyer les

brûleurs à tous les 60 jours ou plus souvent au besoin. Pour ce faire, les faire bouillir dans une forte

solution d’eau et d’hydroxyde de sodium (soude caustique) pendant environ 15 minutes. Déboucher

les ouvertures à l’aide d’un instrument pointu ou d’un foret de grosseur appropriée. Prendre bien soin

de ne pas agrandir les orifices des brûleurs.

Si un nettoyage des ouvertures du mélangeur d’air ou des lumières de veilleuses s’avère nécessaire,

communiquer avec le service de l’entretien Vulcan. Ce nettoyage doit être fait à tous les six mois ou

plus souvent au besoin.

SERVICE DE L’ENTRETIEN ET PIÈCES DE RECHANGE

Pour l’entretien de l’appareil ou pour obtenir des renseignements sur des pièces de rechange,

communiquer avec le service de l’entretien Vulcan-Hart le plus près (pour une liste complète de nos

succursales de service de l’entretien et de pièces autorisées, visiter notre site Web à l’adresse :

www.vulcanhart.com)

Lors d’une demande de service, fournir les renseignements suivants : le numéro de modèle, le numéro

de série, la date de fabrication, le type de gaz et d’alimentation électrique.

– 11 –

Page 24

F35600 RÉv. A (02-05) IMPRIMÉ AUX É.-U.

– 12 –

Loading...

Loading...