Page 1

Model C24GA10

Item # C.S.I. Section 11420

STEAM

C24GA SERIES

GAS CONVECTION STEAMER

ON CABINET BASE

C24GA6-BSC 6 pan capacity basic controls

C24GA6-DLX 6 pan capacity professional controls

C24GA10-BSC 10 pan capacity basic controls

C24GA10-DLX 10 pan capacity professional controls

STANDARD FEATURES

■ Stainless steel exterior.

■ Two stainless steel cooking compartments with coved

interior corners.

■ 125,000 BTU/hr. stainless steel steam generator with

staged water ll.

■ Separate 60 minute timer with constant steam feature for

each compartment.

■ Heavy duty doors and door latch mechanisms.

■ Stainless steel water resistant cabinet base.

■ 6" adjustable stainless steel legs with anged feet.

■ 3⁄4" rear gas connection and gas pressure regulator.

■ Elevation from sea level to 8,999 feet standard.

■ Requires 120/60/1 power supply, 2.0 amps maximum

draw.

■ Split water line connection. Treated and untreated water

connections. 11⁄2" NPT drain connection.

■ One year limited parts and labor warranty.

SPECIFICATIONS

Two compartment gas convection steamer on cabinet base.

Stainless steel exterior. Two stainless steel cooking compartments with coved interior corners. Steam delivered from the

125,000 BTU/hr. high output stainless steel steam generator

with staged water ll. Separate 60 minute timer with constant

steam feature for each compartment. Heavy duty doors and

door latch mechanisms. Stainless steel water resistant cabinet

base. 6" adjustable stainless steel legs with anged feet. 3⁄4" rear

gas connection and gas pressure regulator. Requires 120/60/1

power supply, 2.0 amps maximum draw, with 6 foot power

cord and 3 prong plug. Split water line connection. Treated and

untreated water connections. 11⁄2" NPT drain connection.

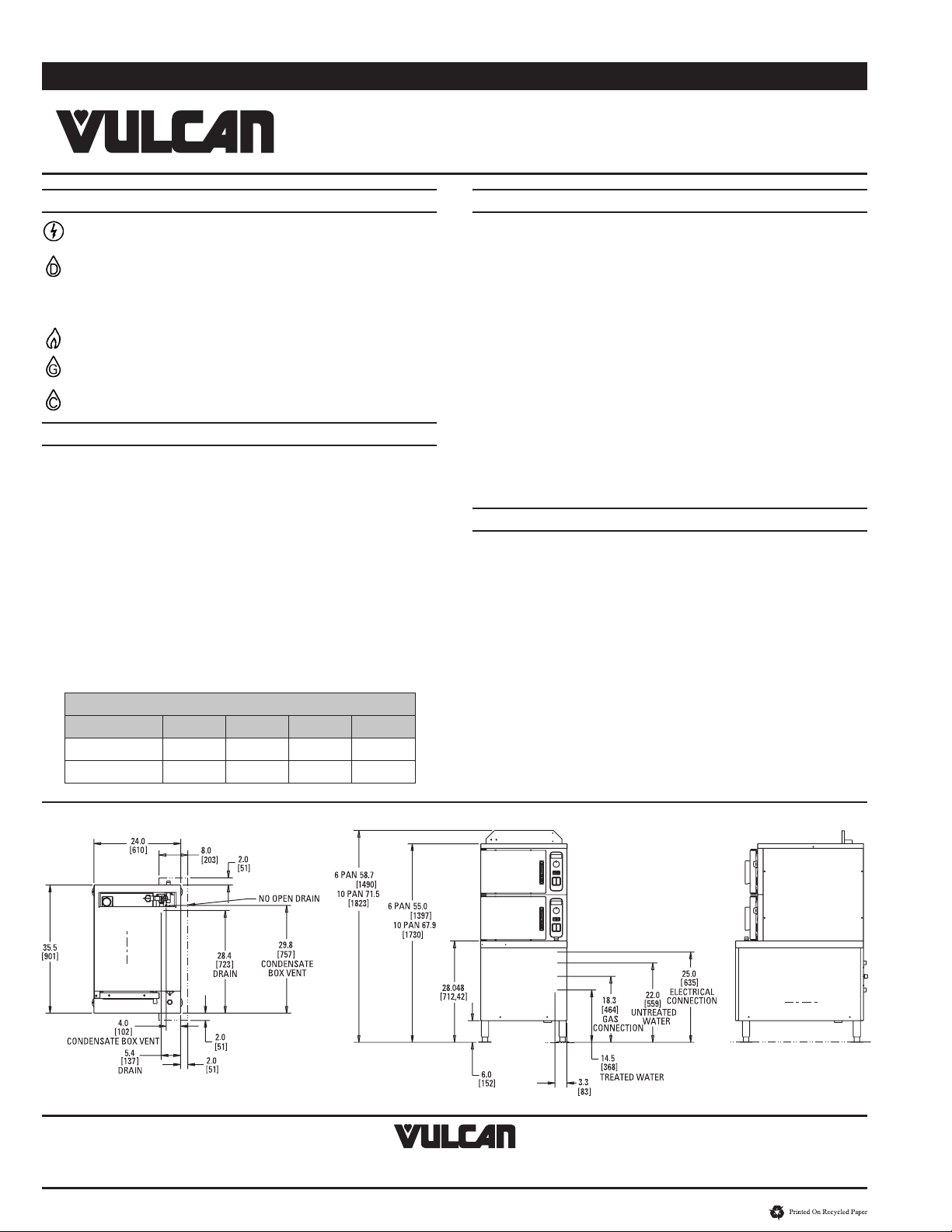

Exterior Dimensions:

6 pan: 24"w x 35.4"d x 59"h on 6" legs.

10 pan: 24"w x 35.4"d x 72"h on 6" legs.

CSA design certied. Certied to NSF Standard #4.

SPECIFY TYPE OF GAS WHEN ORDERING.

OPTIONS

Professional Control Package (Deluxe) includes:

- Superheated Steam System

Second year extended limited parts and labor warranty

contract.

Steamer Security Package, includes controls protected by

lockable cover, perforated ue cover, security fasteners &

tack-welds.

ACCESSORIES (Packaged & Sold Separately)

Stainless steel pan cover. Qty.____.

Removable sliding shelf. Qty.____.

Water treatment system.

a divisi on of IT W Food Equ ipment Group LLC

P.O. Box 696 ■ Louisville, KY 40201 ■ Toll-free: 1-800-814-2028 ■ Local: 502-778-2791 ■ Quote & Order Fax: 1-800-444-0602

F32620 (01/15)

Page 2

STEAM

C24GA SERIES

GAS CONVECTION STEAMER

ON CABINET BASE

SERVICE CONNECTIONS:

Unless otherwise specied, Field Wire Electrical Connection to

be 120/60/1 with grounding wire. Ma ximum amps 2.0.

DRAIN: Condenser box, compartment and generator, 11⁄2" NPT.

(Provide an open air gap type drain within 12" of condenser box

and for best results at a distance so steam vapors will not enter

the steamer from underneath the control area. Do not connect

solidly to any drain connection.)

GAS CONNECTION: 3⁄4" NPT. O.D. supply line required.

GENERATOR WATER SUPPLY: 3⁄4" Hose Bib tting at 20-60

PSI (138-414 kPa) treated water.

CONDENSING WATER SUPPLY: 3⁄4" Hose Bib tting at 20-60

PSI (138-414 kPa) untreated water.

WATER QUALITY STATEMENT:

The fact that a water supply is potable is no guarantee that it is

suitable for steam generation. Your water supply must be within these

general guidelines:

SUPPLY PRESSURE 20 - 60 psig

HARDNESS* less than 3 grains

SILICA less than 13 ppm

TOTAL CHLORIDE less than 4.0 ppm

pH RANGE 7-8

UN-DISSOLVED SOLIDS less than 5 microns

* 17.1 ppm = 1 grain of hardness

Other factors affecting steam generation are iron content, amount

of chloridation and dissolved gases. Water supplies vary from state

to state and from locations within a state. Therefore it is necessary

that the local water treatment specialist be consulted before the

installation of any steam generating equipment

COMPARTMENT PAN CAPACITY

MODEL 1" 21⁄2" 4" 6"

C24GA6 6 3 2 1

C24GA10 10 5 3 2

IMPORTANT:

1. A combination valve with pressure regulator is provided with this

unit. Supply gas pressure should be a minimum: Natural gas 5" -

10.5" W.C., propane gas 11" - 13" W.C.

2. Gas line connecting to unit must be 3⁄4" or larger. If exible

connectors are used, the inside diameter must be at least the

same as the 3⁄4" iron pipe.

3. An adequate ventilation system is required for commercial

cooking equipment. Information may be obtained by writing to the

National Fire Protection Association, Batterymarch Park, Quincy,

MA 02289. When writing, refer to NFPA No. 96.

4. These units are manufactured for installation in accordance with

ANSZ223.1A (latest edition), National Fuel Gas Code. Copies may

be obtained from the American Gas Association, 1515 Wilson

Blvd., Arlington, VA 22209.

5. Clearance: Combustible Non-Combustible

Rear 6" 0"

Left Side 0" 0"

Right Side 0" 0"

NOTE:

• Dimensions which locate the above connections have a tolerance

of + or - 3" (+ or - 75mm). Normal dimensions are in inches.

Dimensions in ( ) are in millimeters.

• Installation of backow preventer's, vacuum breakers and other

specic code requirements is the responsibility of the owner and

installer. It is the responsibility of the owner and installer to comply

with local codes.

• Do not use plastic drains.

• Do not connect this unit to a ground-fault circuit-interrupter (GFCI)

125-volt, single-phase, 15- and 20-ampere receptacle. Electronic

burner ignition systems are prone to nuisance tripping and

possible ignition failure.

• This appliance is manufactured for commercial installation only

and is not intended for home use.

a divisi on of IT W Food Equ ipment Group LLC

P.O. Box 696 ■ Louisville, KY 40201 ■ Toll-free: 1-800-814-2028 ■ Local: 502-778-2791 ■ Quote & Order Fax: 1-800-444-0602

F32620 (01/15)

NOTE: In line w ith its policy to co ntinua lly imp rove its pr oduct s, Vulca n reser ves the right to c hange materia ls and sp ecic ation s withou t notice.

Loading...

Loading...