Page 1

COMBI

GAS BOILERLESS COMBI OVEN STEAMER

Model ABC7G

(shown on stand)

NSF/ANSI 4

ANS Z83.11 / CSA 1.8

SPECIFICATIONS

Vulcan Combi Oven, Gas, Boilerless, 7 level full size combi, Model

ABC7G. Engineered and assembled with pride in USA. Just three

knobs, no modes, only temperature, time and humidity for ultimate

ease of use. Humidity level control automatically adjusts after setting

temperature. Precision Humidity Control ensures accurate humidity

for repeatable results while providing efciency in energy and water

usage. Multiple cooking capabilities from one piece of equipment:

Baking, Steaming, Roasting, Air-Fry, Rethermalization, Proong, Finishing, Poaching, Stewing, Low Temp and Defrosting results. Direct

steam creation for optimized cooking capability and production with

minimal energy and water consumption. Auto-reversing fan with electrical braking system on fan motor. Large LED displays for temperature,

time and humidity controls. Visual recall display of actual temperature

and humidity LED’s. Timer reloads for batch cooking after completion of timed cycle. Flashing door lights & audible alarm system alert

user when cooking cycle nished. Halogen lights (3) built into door

behind heat reective inner glass. Standard with rack guides and

(4) unique stainless steel wire racks with cutout design for easy access

to pans. Maximum capacity of (7) racks for a total of (7) 18" x 26" or

(14) 12" x 20" pans. Machine diagnostics accessed thru controls or

via USB. Cool to the touch & energy efcient heat reective tempered

glass door. All stainless steel interior cooking compartment, top, sides

and fully insulated. One year limited parts and labor warranty.

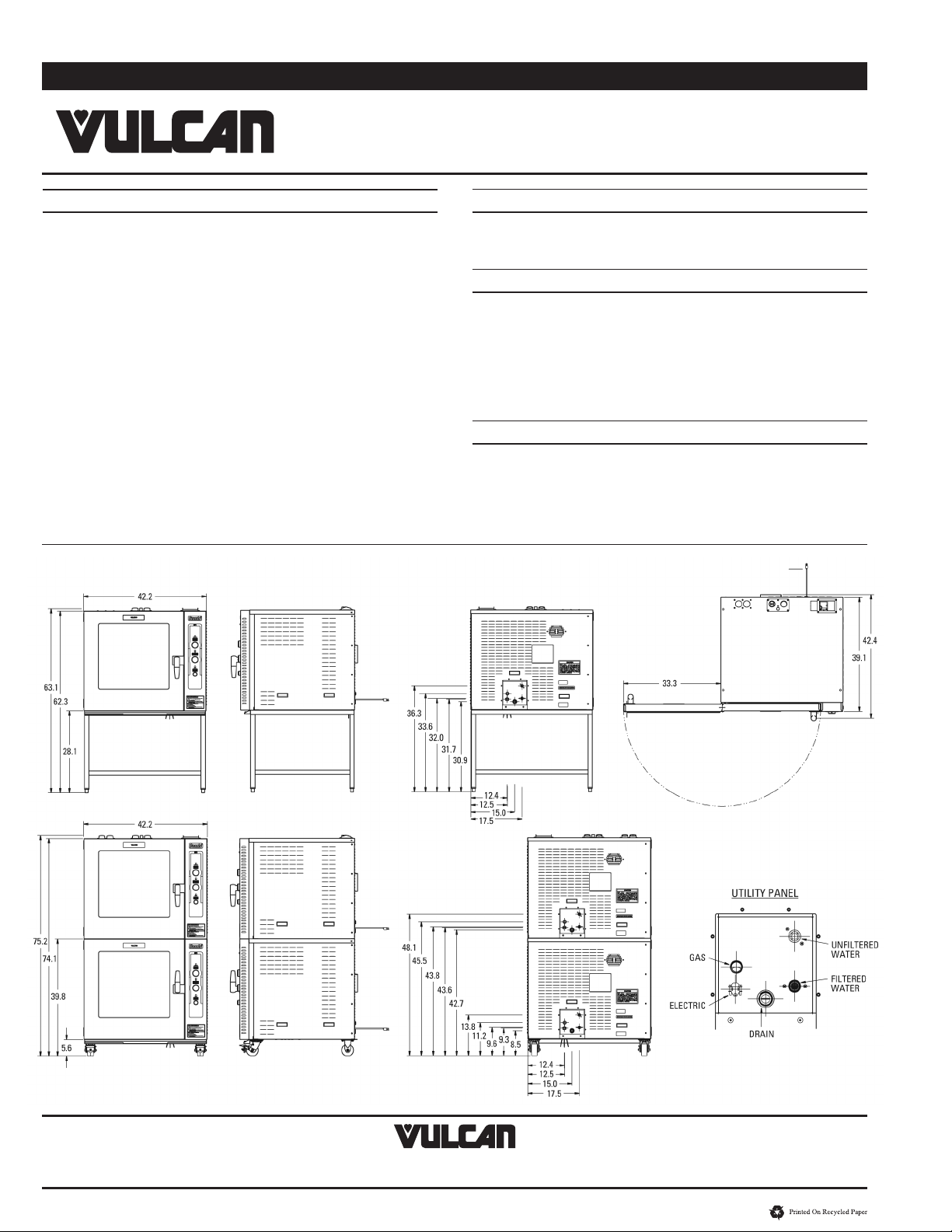

Exterior Dimensions:

Combi: 35"H x 42.2"W x 43.3"D

Stand & Combi: 63.1"H x 42.2"W x 43.3"D

Stacked Combi: 75.2"H x 42.2"W x 43.3"D

Item # C.S.I. Section 11420

ABC SERIES

ABC7G-NAT

STANDARD FEATURES

■ Engineered and assembled with pride in Louisville, Kentucky,

USA.

■ Just three knobs, no modes, only temperature, time and humidity.

■ Patent-pending humidity level control automatically adjusts after

setting temperature.

■ Exclusive Precision Humidity Control ensures accurate humid-

ity for repeatable results while providing efciency in energy and

water usage.

■ Multiple cooking capabilities from one piece of equipment:

Baking, Steaming, Roasting, Air-Fry, Rethermalization, Proong,

Finishing, Poaching, Stewing, Low Temp and Defrosting results.

■ Boilerless combi which uses direct steam creation for optimized

cooking capability and production with minimal energy and water

consumption.

■ Auto-reversing fan with electronic braking system on fan motor.

■ Large LED displays for temperature, time and humidity controls.

- Temperature range: 80-450°F

- Timer range: continuous (--:--) up to 23:59 hours and minutes

- Humidity range: 0-100%

■ Visual recall display of actual temperature and humidity LED’s.

■ Timer reloads for batch cooking after completion of timed cycle.

■ Flashing door lights & audible alarm system alert user when cook-

ing cycle nished.

■ Halogen lights (3) built into door behind heat reective inner glass.

■ Standard with rack guides and (4) unique stainless steel wire

racks with cutout design for easy access to pans.

■ Machine diagnostics accessed thru controls or via USB.

■ Cool to the touch & energy efcient heat reective tempered

gl ass d oor.

■ All stainless steel interior cooking compartment, top, sides and

fully insulated.

■ One year limited parts and labor warranty (two year K-12).

OPTIONS

Hollow Carbon Filter System (Minimum Filtration For Warranty):

- CB15K-SYSTEM – 15,000 gal.

- CB30K-SYSTEM – 30,000 gal.

Water Softening (CBK system required for use with WS system)

- WS-40 - 40 lb capacity

- WS-80 - 80 lb capacity

Second year extended limited parts and labor warranty contract.

ACCESSORIES (Packaged & Sold Separately)

GASKIT-ABC – Propane & altitude kit (2,000-10,000 ft.)

ADDRACK-ABC1 – (1) One additional wire rack

ADDRACK-ABC3 – (3) Three additional wire rack kit

1220-BASKET – Fry Basket 12”x20”

Stands & Stacking Kits include: (1) Spray Hose and Drip Tray Kit

- STACK-ABC/G – Gas stacking kit for two ABC7G combis.

- STACK-ABC/CONV – Stack kit for combi/convection.

- STAND-ABC/SS – Stainless steel open frame stand.

HOSEWTR-3/4BBV - s/s ex water hose 72” length, ¾” female

NSHT (2 per unit recommended).

a divisi on of IT W Food Equ ipment Group LLC

P.O. Box 696 ■ Louisville, KY 40201 ■ Toll-free: 1-800-814-2028 ■ Local: 502-778-2791 ■ Quote & Order Fax: 1-800-444-0602

F47104 (11/15)

Page 2

COMBI

ABC SERIES

GAS BOILERLESS COMBI OVEN STEAMER

WATER QUALITY STATEMENT:

The fact that a water supply is potable is no guarantee that it is suitable

for steam generation. All steam equipment is subject to contamination

and failure due to chemical and mineral content found in water. A suitable

Hobart Water Treatment System and regular lter replacements coupled

with routine deliming is the recommended minimum. Damage as a result

of poor water quality or lack of required owner/operator maintenance is

the responsibility of the owner/operator.

Your water supply must be within these general guidelines:

DYNAMIC WATER PRESSURE 30 - 60 psig

HARDNESS* 1 - 3 grains

SILICA less than 13 ppm

TOTAL CHLORIDE less than 30 ppm

pH RANGE 7-8

CHLORINE & CHLORAMINE 0 ppm

ALKALINITY less than 20 ppm

TDS less than 60 ppm

UN-DISSOLVED SOLIDS less than 5 microns

* 17.1 ppm = 1 grain of hardness

Other factors af fecting steam generation are iron content, amount of

chlorination and dissolved gases. Water supplies var y from state to state

and from locations within a state. Therefore it is necessary that the local

water treatment specialist be consulted before the installation of any

steam generating equipment.

USER RESPONSIBILITY:

The product must be installed, cleaned and maintained as described in

the Manual furnished with the product. It is the responsibilit y of the owner

and installer to comply with local codes.

SERVICE CONNECTIONS:

Water: 3⁄4" NSHT female split water line connections (ltered and

unltered).

Drain: 1" NPT male connection piped to open drain, 60" maximum length

before open air gap and not more than two bends or elbows.

Electrical: 120 Volt, 15 Amp,NEMA 5-15P plug and cord.

Gas: 80,000 BTU, 3⁄4" NPT female connection. Supply gas pressure

should be: Natural gas 5" - 10.5" W.C.; Propane gas 11" - 13" W.C.

NOTE:

Clearance: Left 1", Back 4", Right 3" required, 18" recommended for

service access on right side.

Not recommended for ground-fault circuit-interrupter (GFCI) 125-volt,

single-phase, 15- and 20-ampere receptacle. Electronic burner ignition

systems are prone to nuisance tripping and possible ignition failure.

MACHINE WEIGHT: 600 lbs.

a divisi on of IT W Food Equ ipment Group LLC

P.O. Box 696 ■ Louisville, KY 40201 ■ Toll-free: 1-800-814-2028 ■ Local: 502-778-2791 ■ Quote & Order Fax: 1-800-444-0602

F47104 (11/15)

NOTE: In line w ith its policy to co ntinua lly imp rove its pr oduct s, Vulca n reser ves the right to c hange materia ls and sp ecic ation s withou t notice.

Loading...

Loading...