Page 1

INSTALLATION, SERVICE & PARTS

MANUAL FOR

7801A, 7802A & M7801A

ROASTING OVENS

VULCAN-HART CORPORATION, 3600 NORTH POINT BOULEVARD, BALTIMORE, MARYLAND 21222

Page 2

IMPORTANT

OPERATING, INSTALLATION AND SERVICE PERSONNEL

Operating information for this equipment has been prepared for use by qualified and/or authorized

operating personnel.

All installation and service on this equipment is to be performed by qualified, certified, licensed

and/or authorized installation or service personnel, with the exception of any marked with a œ in

front of the part number.

Service may be obtained by contacting the Factory Service Department, Factory Representative

or Local Service Agency.

DEFINITIONS

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified or authorized operating personnel are those who have carefully read the information in

this manual and are familiar with the equipment's functions or have had previous experience with

the operation of the equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, a firm, corporation or company which either in

person or through a representative are engaged in, and are responsible for:

1. The installation of gas piping from the outlet side of the gas meter, or the service regulator

when the meter is not provided, and the connection and installation of the gas appliance.

Qualified installation personnel must be experienced in such work, be familiar with all

precautions required, and have complied with all requirements of state or local authorities

having jurisdiction. Reference in the United States of America - National Fuel Gas code ANSI

Z223.1 (Latest Edition). In Canada-Canadian Standard CAN1-B149.1 NAT. GAS (Latest

Edition) or CAN1-B149.2 PROPANE (Latest Edition).

2. The installation of electrical wiring from the electric meter, main control box or service outlet to

the electric appliance. Qualified installation personnel must be experienced in such work, be

familiar with all precautions required, and have complied with all requirements of state or local

authorities having jurisdiction. Reference: In the United States of America-National Electrical

Code ANSI NFPA No. 70 (Latest Edition). In Canada-Canadian Electrical Code Part 1 CSAC22.1 (Latest Edition).

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Vulcan equipment who have been

endorsed by the Vulcan-Hart Corporation. All authorized service personnel are required to be

equipped with a complete set of service parts manuals and stock a minimum amount of parts for

Vulcan equipment.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected and

packed by skilled personnel before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE — Be certain this is noted on freight bill or express receipt

and signed by person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY — Regardless of extent of damage.

3. CONCEALED LOSS OR DAMAGE — If damage is unnoticed until merchandise is

unpacked, notify transportation company or carrier immediately, and file "concealed damage"

claim with them. This should be done within (15) days of date of delivery is made to you. Be

sure to retain container for inspection.

We cannot assume responsibility for damage or loss incurred in transit. We will, however, be

glad to furnish you with necessary documents to support your claim.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

Page 3

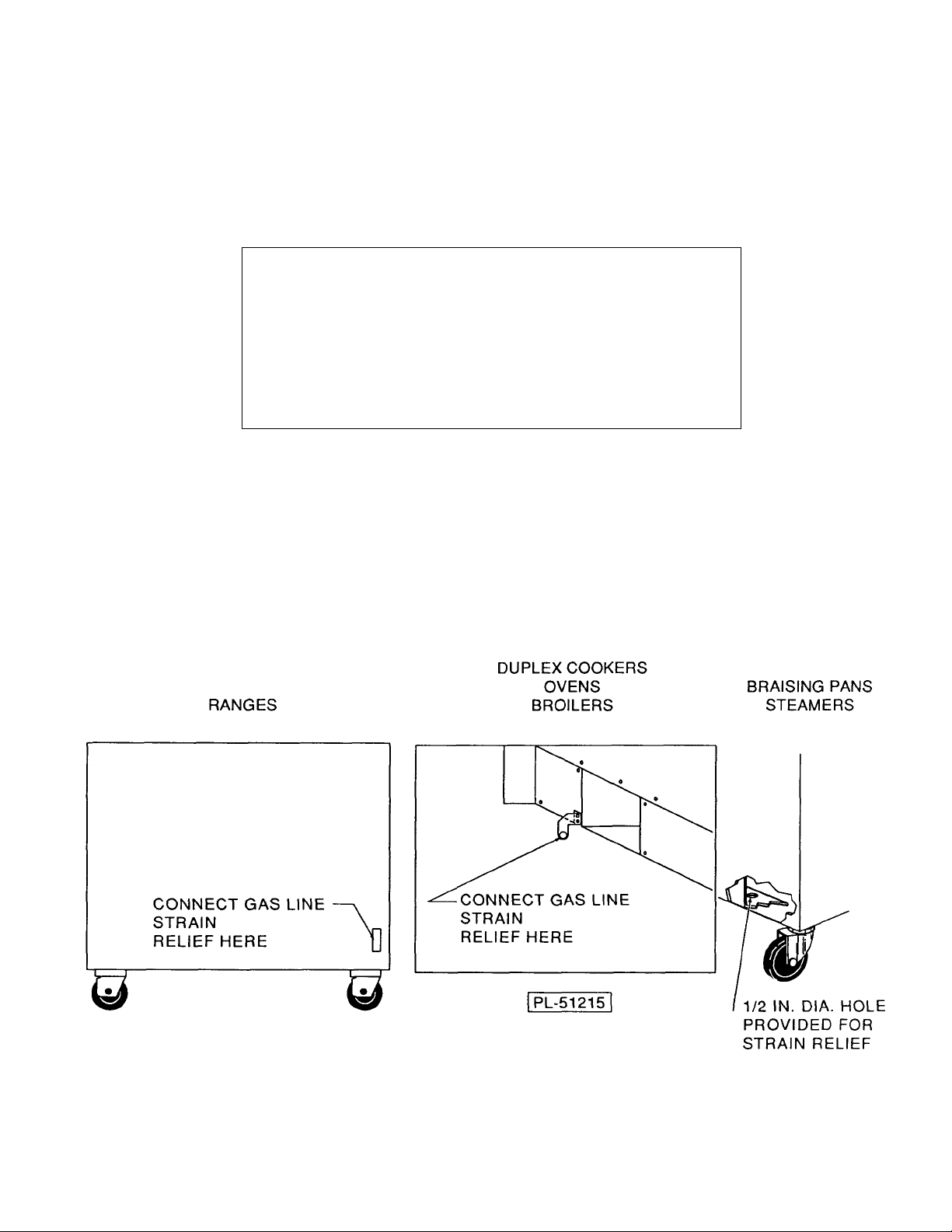

ADDENDUM GAS COOKING EQUIPMENT MANUALS

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION

OR MODIFICATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ

THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

Clearances listed in this manual apply to combustible and non-combustible materials. H Series Gas Range

clearances are now 9" at the sides and 6" at the rear.

If machine is equipped with casters, the installer must provide a restraining device for the gas line to limit

movement of the equipment without depending on the connector and/or any quick-disconnect device or its

associated piping to limit movement of the equipment. Attach the restraining device to the rear of the

machine where shown below.

Page 4

IMPORTANT NOTES FOR ALL VULCAN APPLIANCES

1. These units are produced with the best possible workmanship and material. Proper installation is vital if best

performance and appearance are to be achieved. Installer must follow the installation instructions carefully.

2. Information on the construction and installation of ventilating hoods may be obtained from the "Standard for the

installation of equipment for the removal of smoke and grease laden vapors from commercial cooking equipment,"

NFPA No. 96 (latest edition) available from the National Fire Protection Association, Battery March Park, Quincy

MA 02269.

3. For an appliance equipped with a flexible electric supply cord, the cord is equipped with a three prong (grounding)

plug. This grounding plug is for your protection against shock hazard and should be plugged directly into a properly

grounded three prong receptacle. Do not cut or remove the grounding prong from this plug. If the appliance is not

equipped with a grounding plug, and electric supply is needed, ground the appliance by using the ground lug

provided (refer to the wiring diagram).

(FOR GAS APPLIANCES ONLY)

4. Do not obstruct the air flow into and around the appliance. This air flow is necessary for proper combustion of

gases and for ventilation of the appliance. Provisions for ventilation of incoming air supply for the equipment in the

room must be in accordance with National Fuel Gas Code ANSI Z223.1 (latest edition).

5. Do not obstruct the flow of flue gases from the flue duct (when so equipped) located on the rear (or sides) of the

appliance. It is recommended that the flue gases be ventilated to the outside of the building through a ventilation

system installed by qualified personnel.

6. For an appliance equipped with casters, (1) the installation shall be made with a connector that complies with the

Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 (latest edition), and Addenda, Z21.69a (latest

edition), and a quick-disconnect device that complies with the Standard for Quick-Disconnect Devices for Use With

Gas Fuel, ANSI Z21.41 (latest edition), and Addenda, Z21.41 a (latest edition) and Z21.41 b (latest edition), and (2)

adequate means must be provided to limit the movement of the appliance without depending on the connector and

the quick-disconnect device or its associated piping to limit the appliance movement. If disconnection of the

restraint is necessary, reconnect this restraint after the appliance has been returned to its originally installed

position.

7. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 psig (3.45 k Pa).

8. The appliance must be isolated from the gas supply system by closing its individual manual shutoff valve during

any pressure testing of the gas supply system at test pressures equal to or less than 1/2 psig (3.45 k Pa).

CAUTIONS

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS EQUIPMENT OR ANY OTHER APPLIANCE.

1. KEEP THE APPLIANCE FREE AND CLEAR FROM ALL COMBUSTIBLE SUBSTANCES.

2. IN THE EVENT A GAS ODOR IS DETECTED, SHUT UNIT(S) DOWN AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER

FOR SERVICE.

3. POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION MAY BE OBTAINED FROM A

LOCAL GAS SUPPLIER.

Page 5

7800 SERIES RANGES-INSTALLATION, SERVICE

AND PARTS MANUAL INDEX

Vulcan ranges and ovens are produced with the best possible

workmanship and material. Proper usage and maintenance will

result in many years of satisfactory performance.

DESCRIPTION PAGE

The manufacturer suggests that you thoroughly read this entire

manual and carefully follow all of the instructions provided.

DEFINITIONS OF PERSONNEL (Operating, Installation & Service)

and SHIPPING DAMAGE CLAIM PROCEDURE

CAUTIONS 1

INDEX 2

BUMPER BAR INSTALLATIONS (SG UNITS ONLY) 3

UNCRATING INSTRUCTIONS 4

UNIT INSTALLATION 4,5

(ALSO SEE INSERT SHEET A)

OVEN TEMPERATURE CONTROLS SG-7800 & 7800 6, 7

TEMPERATURE CONTROL RECALIBRATION 8,9

PILOT LIGHTING & ADJUSTMENT (ALL TOP BURNERS) 9

PILOT LIGHTING (OVEN SECTION) 10

AUTOMATIC SAFETY PILOT INSTRUCTIONS 10, 11

TROUBLE SHOOTING (PROBLEMS & CAUSES) 12

REPLACEMENT PARTS LIST 13, 14, 15

REPLACEMENT PARTS DRAWING (SEE INSERT SHEET B)

WIRING DIAGRAM—SG 18

REVISION PAGE (Inside Back Cover)

(Inside Front Cover)

The following appliances are to be installed with a six-inch clearance at the sides and rear to combustible

construction: 7860A, 7860-45A, M7860, M7860-45, M7860-72, 7860-72A, 860, M860, SG-7860A, SG-7860-72A,

SG-7860-45A, 7830A, M7830, SG-7830A, 7872A, 7872-45A, M7872-45, SG-7872A, SG-7872-45A, 872, M872,

M7872, 7801, M7801, and 7802.

The following appliances are to be installed only in non-combustible locations: 845, M845, 7845A, M7845,

7856A, SG-7856A, M7856, 7854A, SG-7854A, and M7854.

A rating plate is located on the control panel of this unit.

The rating plate states the model number, serial number

Motors in Vulcan convection ovens are permanently

lubricated and require no additional maintenance.

and type of gas unit requires.

2

Page 6

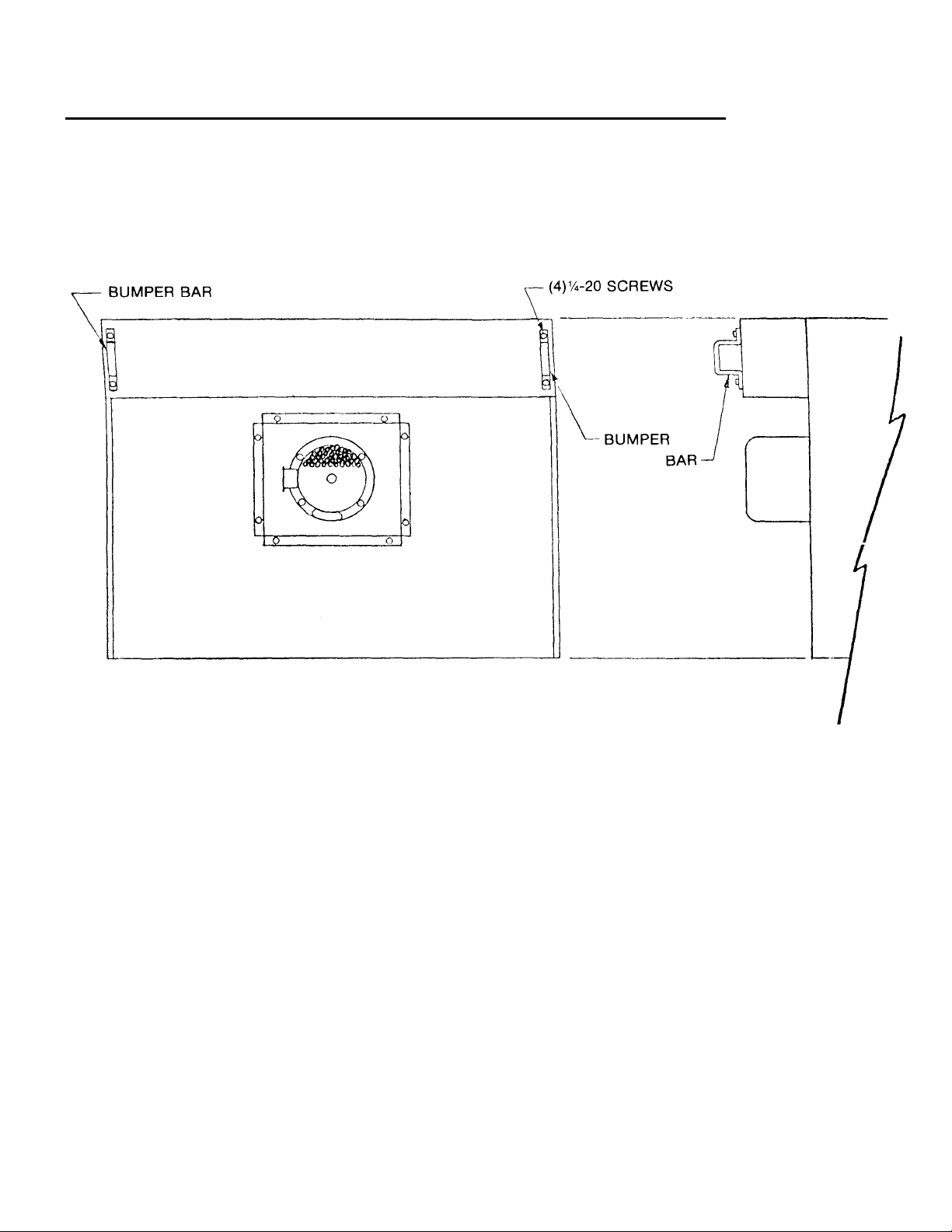

BUMPER BAR INSTALLATION 7800 SERIES UNITS

INSTALLATION PROCEDURE:

1. REMOVE EXISTING 1/4-20

SCREWS INDICATED.

2. POSITION BUMPER BARS AS SHOWN

3. REPLACE 1/4-20 SCREWS AND

SECURE BUMPER BARS AS SHOWN.

3

WARNING:

FAILURE TO INSTALL BUMPER BARS MAY

CAUSE MOTOR DAMAGE AND WILL VOID

WARRANTY.

Page 7

INSTALLATION INSTRUCTIONS FOR VULCAN 7800 SERIES

(INCLUDES ALL UNITS WITH OR WITHOUT OVENS

i.e. MODULAR & EXPANDOS.)

THE VULCAN RANGE IS PRODUCED WITH THE

BEST POSSIBLE WORKMANSHIP AND

UNCRATING INSTRUCTIONS

NOTES:

A. Pipe joint compounds used when connecting

appliances to gas should be resistant to the action of L.P.

Gases.

B. Pipe joints should be tested for leaks with a soap and

water solution before operating the unit.

C. SG 7800 Ranges are equipped with a three prong

(grounding) plug for your protection against shock hazard

and should be plugged directly into a properly grounded

three prong receptacle. Do not cut or remove the

grounding prong from this plug.

D. Snorkel Range Ovens require a minimum of 6"

clearance at the rear Snorkel Range Ovens may not be

included in a back to back set up.

1. Uncrate units carefully and place in the approximate

location they will occupy in the battery. Remove all

shipping wire and wood blocking.

2. On hot, even heat, and open top ranges, remove top

castings (A) and rear top plates (B). Identify top

castings so they are replaced in the same positions

and on same range as when received from factory.

MATERIALS. PROPER INSTALLATION IS VITAL

IF BEST PERFORMANCE AND APPEARANCE IS

T0 BE ACHIEVED. PLEASE FOLLOW THESE

INSTRUCTIONS CAREFULLY. LETTERS (A, B,

ETC.) IN THE FOLLOWING INSTRUCTIONS

REFER TO THE INSTALLATION DRAWING. SEE

INSERT A.

3. Remove oven bottom and baffles (C).

4. Remove upper manifold panel (D).

5. Removal of the shipping bracket (E) is necessary on

the corner of the range where a high shelf support

casting is to be bolted. On units equipped with a back

guard it is not necessary to remove either shipping

bracket as they will be used for support when remounting the rear top plate and back guard splasher

back (step 12).

6. Place first appliance in exact position in battery and

line up. If on "Standard " legs adjust leg heights by

turning leg feet (P) until all contact the floor. If "Less

Legs" or "On Toe Base" screw leveling bolts (F) down

until bolts contact the floor. Using carpenter level, level

up appliance from front to rear, also from side to side.

This operation is one of the most important installation

practices. No floor is level and variations of from one

to three inches in a room is common. Unless

appliances are level, difficulty will be encountered in

lining up the manifold pipe (G) and appliances will not

butt tightly.

UNIT INSTALLATION PROCEDURES

1. Move next appliance into position and level up as

explained above. Engage union nut on manifold pipe

with male fitting on next appliance and draw up union

nut hand tight. Be sure appliances butt both front and

rear. If manifolds do not line up, then ranges are not

level. Do not adjust manifold brackets (H) to make

manifolds line up, except in extreme cases, because

this will cause gas valves not to line up perfectly with

manifold cover holes. Bolt top frames together using

10-24 x 1/2" bolts (R) (Packed in cloth bag in range

oven.)

2. Continue leveling up, connecting manifold pipe and

bolting top frames of ranges together until all

appliances in battery are connected, then tighten

manifold unions gas tight. Use wrench to keep section

of union assembled to pipe from rotating. Failure to do

this may result in misalignment of valve stems.

3. Uncrate high shelves or back guards and remove

splasher backs (J).

4. Place high shelf or back guard in position and bolt

5. Bolt high shelves together by bolting through shelf

6. Replace back tops (B) and splasher backs (J).

7. If front plates (N) do not line up perfectly, adjust be

IMPORTANT NOTE:

Snorkel Range Ovens are supplied with a cord and

grounding plug assembly and must be plugged into the

proper receptacle before turning on gas.

down (high shelf) support castings (K) or (backguard)

mounting brackets (L). Bolts for mounting high shelf or

back guard are shipped in mounting holes. Just

remove and use to attach castings or brackets.

brackets (M). Bolts are in cloth bag attached to shelf.

means of bolts under front plate. Similar front

adjustment is provided for the one piece cast iron

griddle (7860A & 7860TA).

4

Page 8

UNIT INSTALLATION PROCEDURES (Cont'd.)

11. Adjust top burner pilot flames to a point where only a

trace of yellow remains, this adjustment insures the

best operating conditions.

12. The pressure regulator must be A.G.A. design

certified. Regulators must have regulation capacity for

total connected load. Regulator must have pressure

adjustment range to allow adjustment for manifold

pressure marked on unit rating plate. Unless manifold

pressure on all connected appliances is the same, a

separate regulator must be supplied for all unit(s)

having different manifold pressures.

Hi-lnput Open Top Burner & Nozzle Relationship

8. Be sure all burner and pilot valves are in a closed

position. Turn on gas supply and check for leaks. Turn on

top burner valves and allow air in line to be exhausted.

When gas begins to flow turn valves off and wait five (5)

minutes before lighting pilots.

9. Remove oven control panel (0). Control panels should be

identified and replaced on their respective units. This will

assure proper identification when repair parts are

ordered. Caution must be taken when removing the

oven control panel on a Snorkel Range.

5

Page 9

OVEN TEMP. CONTROLS 7800 SERIES

OVEN TEMPERATURE CONTROLS 7800

INSTRUCTIONS FOR ROBERTSHAW MODEL FDO

HEAVY DUTY FLAME MASTER OVEN CONTROL. This

model FDO is a precision made instrument, carefully set

at the factory to accurately control oven temperatures

from 500 degrees down to 150 degree F. All adjustments

are accessible from front of appliance after removing dial.

To remove dial, grasp knob portion and pull straight out.

BY-PASS ( MINIMUM BURNER) FLAME (Refer to figure

1) This adjustment must be made at the time the appliance is installed. To adjust this flame:

(Be sure oven burner pilot flame is ignited.)

1. With oven cold, turn dial counterclockwise slowly from "off" until main

burner gas snaps on.

2. Remove dial.

3. With a screw driver, turn "by-pass adjustment screw" counterclockwise to

increase the by-pass flame or clockwise to

decrease it until flame over entire burner is

approximately 1/8" high.

4 . Replace dial. CAUTION While making this adjustment,

if the oven should become heated while the dial is set

at a low range (below 350), the bypass flame will shut

off completely. If this occurs, turn dial counterclockwise

slowly until by-pass gas snaps on. Then check by-pass

adjustment as stated above.

OVEN TEMPERATURE CONTROLS SG-7800

1 . SG 7800 ovens are equipped with a Robertshaw KX

series snap-action thermostat. This model KX is a

precision made instrument, carefully set at the factory

to accurately control oven temperatures from 500

degrees down to 150 degrees. All adjustments are

accessible from front of appliance after removing dial.

To remove dial, grasp knob portion and pull straight

out.

2 . Replace oven control panel (check identification so

that each panel is returned to its respective unit) oven

baffles and oven bottom.

3 . Replace upper manifold panel, position brick in units

where necessary (see below) and replace top

casting, check identification so that each may be

returned to its respective original unit as received

from the factory.

4. After installing frytop adjust to control grease

drainage by adjusting leveling bolts, two (2), one (1)

each rear corner of frytop.

6

Page 10

OVEN TEMPERATURE CONTROL 7800 SERIES

THERMOSTATICALLY CONTROLLED GRIDDLE,

INSTALLATION

Set metal brick supports in place, narrow ones (1) each

side with smooth surface down and oval holes to outside,

wide ones in center with smooth surface down, triangle

shaped brick (4) set in place (2) each side as shown on

page 8. Two (2) large brick with no holes set in center

support. Four (4) large with cut out in one end and notch

on one surface set to the front and rear of each thermostat

with notch part of brick over thermostat shield bracket.

Before setting griddle in place make sure thermostat bulb

extends above end of shield (see fig. 2). Bulb is spring

loaded and should move up and down freely when

pressed with hand. This will insure good thermostat bulbto-griddle contact and accurate temperature control. When

setting griddle in place make sure that shield surrounding

bulb sets within horseshoe shaped ring on under side of

griddle. Adjust bolts (2) at rear of griddle for proper grease

drainage.

the thermostat is a slotted screw adjustment marked "B"

see figure 1. This will adjust the by-pass gas only,

counter clockwise to increase clockwise to decrease,

adjust flame to approximately 1/8" high over entire

burner.

BY-PASS FLAME ADJUSTMENT, GRIDDLE

BURNER

Make sure top pilots are lit. Turn on gas and set thermostat at 300 degrees. When griddle reaches this

temperature burner main gas supply will shut off

permitting only by-pass gas to flow. On the front of

7

Page 11

TEMPERATURE CONTROL CALIBRATION

OVEN TEMPERATURE CONTROL RECALIBRATION

Field recalibration is seldom necessary, and should not

be resorted to unless experience with cooking results,

definitely proves that the control is not maintaining the

temperature to which the dial is set. To check oven

temperatures when recalibrating use a Robertshaw Test

Instrument or a reliable mercury oven thermometer.

(Refer to figure 1 or figure 2)

FDO RECALIBRATION

1. Place the thermocouple of test instrument or

thermometer in the middle of the oven.

2. Light main burner.

3. Turn dial to 400 mark and allow oven to heat until

flame cuts down to by-pass.

4. After burner has been on sufficiently long enough to

cut down to by-pass flame, check oven temperature.

The control should be recalibrated if

your reading is not within 15 degrees of the dial

setting. If recalibration is required, proceed as follows:

5. Remove dial.

6. With a screw driver, loosen the two calibration screws

until calibration plate moves independently of the

control.

7. Turn calibration plate until mark corresponding to test

instrument or thermometer reading is in line with

center of pointer "A" and while holding in this position,

tighten calibration screws firmly.

8. Replace dial.

9. NOTE: - If the above adjustment is prevented by the

two loosened calibration screws being in contact with

the ends of the screw clearance slots in the calibration

plate, remove the screws and after turning the

calibration plate to the proper location, reassemble

screws in the other tapped holes designed for them.

8

Page 12

TEMPERATURE CONTROL RECALIBRATION (Cont'd.)

KX RECALIBRATION

1. Place the thermocouple of test instrument on the

thermostat bulb. Close oven door.

2. Light the main burner by turning thermostat to 500°

dial setting.

3. Allow the oven to heat until flame cuts off. After

several cycles, check temperature. If the temperature

does not read within 15 degrees of the dial setting,

recalibrate as follows:

4. Pull dial straight off dial shaft without turning.

5. Turn screw "A" clockwise to decrease

temperature and counterclockwise to increase

temperature.

NOTE: 1/4 turn of screw "A" represents a

temperature shift of 35°F.

PILOT LIGHTING & ADJUSTMENT (ALL TOP BURNERS)

To light range top burners, remove top section so that pilots

may be reached. Turn one burner valve "ON" to remove air

from lines. Turn burner "OFF" when gas begins to flow.

Using a taper, light top section pilots. Even though pilots

are pre-adjusted at the factory, field adjustments may be

necessary. To adjust pilots up or down, remove unit

manifold cover and using a screwdriver rotate adjusting

screw in pilot valve on manifold clockwise to decrease

flame and counterclockwise to increase flame.

9

Page 13

LIGHTING, OPERATION and SHUTTING DOWN

(OVEN SECTION)

LIGHT OVEN BURNER AS FOLLOWS:

1. OPEN MAIN GAS SUPPLY

2. TURN BURNER VALVE "ON" TO PURGE AIR FROM

LINE. TURN VALVE "OFF" WHEN GAS BEGINS TO

FLOW.

3. OPEN OVEN DOOR AND LIFT LIGHTING HOLE COVER

LOCATED ON THE LOWER FRONT COVER. WHILE

DEPRESSING SAFETY BUTTON LOCATED ON THE

UNIT OVEN CONTROL PANEL, USING A TAPER IGNITE

OVEN PILOT. CONTINUE TO HOLD SAFETY BUTTON

IN FOR APPROXIMATELY 30 SECONDS SO THAT

PILOT WILL REMAIN LIT.

4. IF PILOT DOES NOT LIGHT, TURN BURNER VALVE

"OFF", WAIT FIVE MINUTES THEN REPEAT STEPS 2

AND 3.

5. FOR SEASONAL UNIT SHUTDOWN:

A. REMOVE MANIFOLD PANEL AND TURN

OFF PILOT BURNER VALVES.

B. REMOVE OVEN CONTROL PANEL AND

CLOSE PILOT ADJUSTMENT ON SAFETY

VALVE.

C. MAKE SURE ALL BURNER VALVES AND

MAIN SUPPLY VALVES ARE OFF.

D. TO RETURN UNITS TO OPERATION

REPEAT STEPS 14 THRU 19 ON PAGES 6

AND 7.

LIGHTING, OPERATION and SHUTTING DOWN.

(OVEN SECTION SG UNITS ONLY)

LIGHT OVEN BURNER AS FOLLOWS:

1. TURN OVEN VALVE "ON".

2. IF PILOT IS OUT, TURN POWER SWITCH "OFF", WAIT 5

MINUTES BEFORE LIGHTING.

3. OPEN OVEN DOOR AND LIFT LIGHTING HOLE COVER

WHILE DEPRESSING SAFETY BUTTON, LOCATED ON

THE UNIT OVEN CONTROL PANEL USING A TAPER,

IGNITE OVEN PILOT. CONTINUE TO HOLD SAFETY

BUTTON IN FOR APPROXIMATELY 30 SECONDS SO

THAT PILOT WILL REMAIN LIT.

4. TURN POWER SWITCH A "ON"

5. SET THERMOSTAT TO DESIRED TEMPERATURE.

6. FOR COMPLETE SHUTDOWN, TURN OVEN VALVE,

POWER SWITCH AND THERMOSTAT "OFF" AND

EXTINGUISH PILOT.

AUTOMATIC SAFETY PILOT INSTRUCTIONS

CLEANING

1 . To clean pilot limiting orifice, turn "off" gas supply to

unit. Disconnect pilot tubing at the pilot burner body.

The orifice is then accessible at the body end of the

pilot burner and can be removed for cleaning. Clean

spud taking care not to enlarge the orifice hole.

SERVICE INSTRUCTIONS: (See Figure 2)

To clean valve disc and seat, turn "off"

thermostat or burner valve. Remove cap and

clean the valve disc and metal seat in the

valve body with a lint-free cloth.

2 . If valve fails to open with good pilot flame

impingement, return control to factory for

repairs.

10

Page 14

AUTOMATIC SAFETY PILOT INSTRUCTIONS

3 . Do not remove interrupter valve for field

service.

NOTE: Make certain gas line to inlet of control is

purged of air and that gas flow is available at

this point.

THERMOSTATICALLY CONTROLLED GRIDDLE,

RECLAIBRATION

Field recalibration is seldom necessary and should not be

resorted to unless cooking results definitely prove that

griddle surface temperature and thermostat setting do not

agree. To check griddle temperature use an accurate

"surface temperature thermometer" in the following

manner.

1. Locate thermometer in center of griddle

from front to rear: on 17" wide units use 1 and

center from side-to-side, on 34" wide units

use two (2) thermometers one (1) 8 1/2 " from

each side of griddle.

2. Set thermostat dial to 400 degrees and

allow griddle to heat thoroughly. When the

griddle is completely heated and the burner

is on by-pass gas check the thermometer

reading against the thermostat dial setting.

If the difference between the reading

exceeds 15 degrees the thermostat should

be recalibrated. Example: With the thermostat dial at 400 degrees and a thermometer reading of less than 385 degrees

or more than 415 degrees the thermostat

should be recalibrated.

Make note of number of degrees thermostat is off.

Remove thermostat dial and loosen calibration

screws, see drawing, until plate moves freely. Turn

calibration plate the required number of degrees

counter clockwise if the thermometer reading was

higher than the dial setting or clockwise if the

thermometer reading was lower than the dial

setting. Hold calibration plate in desired position

and tighten plate screws firmly. The number of

degrees between letters on calibration plate is 50

degrees Fahrenheit.

RECALIBRATION PROCEDURE

11

Page 15

TROUBLE SHOOTING (PROBLEMS & CAUSES)

PROBLEM PROBABLE CAUSES

OVEN

TOO MUCH BOTTOM HEAT INSUFFICIENT HEAT INPUT

UNEVEN BAKE TOO LOW TEMPERATURE

SIDE BURNING IMPROPER BY-PASS SETTING

TOO MUCH TOP HEAT TOO HIGH TEMPERATURE

UNEVEN BAKE-SIDE TO SIDE APPLIANCE NOT LEVEL SIDE TO SIDE

UNEVEN BAKE-FRONT TO REAR OVER ACTIVE FLUE

DRIED OUT PRODUCTS TOO LOW TEMPERATURE

PILOT OUTAGE PILOT FLAME TOO LOW

TOP BURNER OPERATION

IMPROPER BURNER COMBUSTION

EXCESSIVE VALVE HANDLE POOR DOOR FIT

TEMPERATURES OVEN DOOR LEFT OPEN

STICKING TOP BURNER VALVES

POOR IGNITION INSUFFICIENT INPUT

OVER ACTIVE FLUE

IMPROPER OPERATION

FLUCTUATING GAS PRESSURE

FAULTY VENTILATION

EXCESSIVE HEAT INPUT

THERMOSTAT CALIBRATION

OVEN BURNER, BOTTOM OR BAFFLES

IMPROPERLY INSTALLED

UNIT NOT LEVEL, FRONT TO BACK

DOOR NOT CLOSING PROPERLY

TOO LONG BAKING TIME

THERMOSTAT CALIBRATION

RESTRICTION IN PILOT ORIFICE

MALFUNCTIONING SAFETY VALVE

IMPROPER VENTILATION

POOR AIR-GAS ADJUSTMENT

RESTRICTION IN PILOT ORIFICE

RESTRICTION IN MAIN BURNER IGNITION PORT

12

Page 16

REPLACEMENT PARTS LIST

Part Numbers

Part Numbers

REPLACEMENT PARTS ORDERING

1 . THE FOLLOWING INFORMATION MUST ACCOMPANY A REPLACEMENT PARTS ORDER OR IT CANNOT BE

FILLED.

A. MODEL AND STYLE NUMBER

B. TYPE OF GAS.

C. APPLIANCE FINISH, PERMAFINISH, STAINLESS STEEL, ETC. (IF APPLICABLE TO PART TO

BE REPLACED.)

THIS INFORMATION CAN BE FOUND ON THE INSTRUCTION PLATE ON FRONT OF THE UNIT. PARTS

MAY BE ORDERED FROM YOUR DEALER, SERVICE AGENCY, OR THE FACTORY. ORDERS TO THE

FACTORY SHOULD BE ADDRESSED:

VULCAN-HART CORPORATION

REPAIR PARTS DEPARTMENT

3600 NORTH POINT BLVD.

BALTIMORE, MARYLAND 21222 U.S.A.

7800L SERIES RANGE REPLACEMENT PARTS LIST

ALL UNITS WITH OVENS

13

Item

1 107798-4 107798-4 Safety Valve

2 107522-1 FDO Thermostat (Oven)

111506-3 KX Thermostat (Oven N.S.

3 107789-1 Oven Valve

111497-F1 Solenoid Valve N.S.

4 109819-G2 Oven Burner

113957-1 Oven Burner N.S.

5 109125 109125 Oven Pilot Burner N.S.(See page 17)

6 112014-2 112014-2 Oven Door Spring

113091-1 113091-1 "J" Hook N.S.

113090-1 113090-1 Spring Bracket N.S.

8 105618-1 105618-1 Right Door Hook N.S.

105618-2 105618-2 Left Door Hook

9 103956-1 103956-1 Bell Crank

10 102957 102957 Plated Valve Handle

10.1 102958 Red Valve Handle

11 103981-1 103981-1 Hinge Pin One Used On

SG7800

103981-2 Hinge Pin

12 104629-2 104629-2 Hinge Pin Bearing

13 103971-1 103971-1 Bell Crank Pin

14 104074-2 Oven Rack

113991-1 Oven Rack N.S.

15 105123-G3 Oven Bottom N.S.

16 105124-5 Oven Bottom Baffle

16.1 109787 Oven Bottom Insulating Pan

17 105928-4 Oven Bottom Foil Insulation

18 109793-1 109793-1 Oven Door Handle

19 109790-1 109790-1 Right Hand Door Post

109790-2 109790-2 Left Hand Door Post

20 7940 7940 Ring 7830A, SG7830A

21 6993 6993 Lid 7830A, SG7830A

22 105817-1 105817-1 Half Cover Plate 7830A, SG7830A

23 109414-G1 109414-G1 Inner Burner 7830A, SG7830A

24 109413-01 109413-G1 Middle Burner 7830A, SG7830A

25 109412-G1 109412-G1 Outer Burner 7830A, SG7830A

26 109839 109839 Top Pilot Burner 7830A, SG7830A

27 109557-3 109557-3 Top Pilot Valve 7830A,45A,72A

60A, SG7830A

45A, 72A, 60A

7800

SG 7800

Description Remarks

Page 17

Insert B

Page 18

REPLACEMENT PARTS LIST

109557-4 109557.4 3/16 Top Pilot Valve 7856A, 54A, 53-72A

SG7856A, 54A

53-72A

104738-2 104738-2 3/16 Single Top Pilot Valve 7856A, SG7856A

28 102601 102601 Top Burner Valve 7830A, SG7830A

29 109433-1 109433-1 Top Aeration Plate 7845A, SG7845A

30 109432-1 109432-1 Top Grate 7845A, SG7845A

31 109416-1 109416-1 Burner Venturi (Lower) 7845A, SG7845A

31.1 109417-1 109417-1 Burner Head (Top) 7845A, SG7845A

32 102077-2 102077-2 Top Burner Valve 7860TA, SG7860TA

33 3.0400-4 3.0400-4 Elbow 7860TA, SG7860TA

34 108379-2 108379-2 Top Burner Valve 7845A, SG7845A

108379-1 108379-1 Top Burner Valve 7856A, SG7856A

35 104772-1 104772-1 Top Plate 7872A, SG7872A

37 110889-G40 110889-G40 Griddle Plate Assembly 7860A,7860TA

SG7860A, SG7860TA

38 105831-G3 105831-G3 Hot Top Burner 7860TA, 60A, 72A

SG7860Ta, 60A,

72A

39 104193-1 104193-1 Top Pilot Valve SG7860TA

40 108379-2 108379-2 Top Burner Valve 7860A, 72A,

SG7860A, 72A

41 109316-1 109316-1 Top Thermostat 7860TA, SG7860TA

42 110889-G36 10889-G36 17" Griddle Assembly 7860-45A, 60T-45,

SG7860-45,

60T-45A

43 105157-G2 105157-G2 Brick Set 7830A, SG7830A

44 105848-1 105848-1 Center Brick 7860A, 72A

SG7860A, 72A

44.1 105848-2 105848-2 Center Brick 7860A, SG7860A

45 106241-1 106241-1 Side Brick 7860A,72A,60TA

SG7860A, 72A, 60TA

46 109808 109808 Manifold Cover 7860A, 72A,

SG7860A, 72A

Unit And Finish Spec. Finish

47 109652 109652 Manifold Cover Must Be specified 7830A, SG7830A

When Ordering Spec. Finish

48 109692 109692 Manifold Cover 7845A, SG7845A

Spec. Finish

113856-1 113856-1 Manifold Cover 7856A, SG7856A

Spec. Fin. N.S.

49 113747-1 113747-1 Burner Tray Handle 7845A,56A

SG7845A, 56A

Spec Finish

113746-1 113746-1 Burner Tray Handle Supports N.S.

49.1 109888 109888 Burner Tray Spec. Unit & Finish

50 71732 71732 Lid Lifter 7830A, SG7830A

51 109682 109682 Grease Collector Assembly Spec. Unit & Finish

52 109778 109778 Side Lining Spec. Unit

Spec. Rt. or Lt.

53 109791 109791 Oven Door Assembly Spec. Unit & Finish

113776-G1 113776-G1 Rear Burner Assembly 7856A, SG7856A N.S.

113776-G2 113776-G2 Front Burner Assembly 7856A, SG7856 N.S.

113979-1 Oven Rack Support N.S.

114001-1 Air Director N.S.

113990-G1 Fan Cover Assembly N.S.

3.1300-7 Fan N.S.

113994-1 Motor N.S.

113866-G1 113866-G1 Top Pilot Assembly 7856A, SG7856A N.S.

113773-1 113773-1 Top Grate 7856, SG7856A N.S.

113787-1 113787-1 Nozzle Extension 7856A, SG7856A N.S.

111496-B1 On/Off Switch N.S.

111496-E4 Warning Light N.S.

105016-1 Supple Cord N.S.

14

Page 19

REPLACEMENT PARTS LIST

ORIFICE

PART No. DESCRIPTION Gas Burner

7830 VALVES

102601-44A VALVE, TOP BURNER ADJ. NAT. OUTER 44 (.086)

102601-56F VALVE, TOP BURNER FIXED L/P BUT. OUTER 55 (.052)

102601-55F VALVE, TOP BURNER FIXED L/P Prop. OUTER 54 (.050)

102601-48A VALVE, TOP BURNER ADJ. NAT. MIDDLE 48 (.076)

102601-59 F VALVE, TOP BURNER FIXED L/P. BUT. MIDDLE 58 (.042)

102601-57F VALVE, TOP BURNER FIXED L/P PROP. MIDDLE 56 (.047)

102601-53A VALVE, TOP BURNER ADJ. NAT. INNER 53 (.060)

102601-66 F VALVE, TOP BURNER FIXED L/P BUT. INNER 65 (.035)

102601-64F VALVE, TOP BURNER FIXED L/P PROP. INNER 63 (.037)

14033Y-55 NOZZLE, STRAIGHT FIXED L/P

12685-A44 NOZZLE, STRAIGHT ADJ. NAT.

104079-35A NOZZLE, TOP BURNER ADJ. NAT.

104079-53F NOZZLE, TOP BURNER FIXED L/P BUT. 1/16 (.062)

104079-52F NOZZLE, TOP BURNER FIXED L/P PROP.

3.0702-F49 NOZZLE, OVEN BURNER, FIXED L/P PROP.

3.0702-F50 NOZZLE, OVEN BURNER, FIXED L/P BUT.

3.0702-2 NOZZLE, OVEN BURNER, ADJ. NAT.

109125.1 PILOT BURNER, OVEN NAT.

109125.3 PILOT BURNER, OVEN L/P

109839-1 PILOT BURNER NAT.

109839-3 PILOT BURNER L/P

14033Y-56 NOZZLE, STRAIGHT FIXED L/P

12685-49 NOZZLE, STRAIGHT ADJ. NAT.

104079-A36 NOZZLE, OVEN BURNER ADJ. NAT.

104079-F50 NOZZLE, OVEN BURNER FIXED L/P PROP.

109125-1 PILOT BURNER, OVEN NAT.

109125-3 PILOT BURNER, OVEN L/P PROP.

7860 & 7872 NOZZLES

7845 NOZZLES

7800 OVEN NOZZLES AND PILOT BURNERS

7800 TOP PILOT BURNERS

7856A NOZZLES

SG 7800 OVEN NOZZLESAND PILOT BURNERS

Drill Size No.

7830

55 (.052)

44 (.086)

32 (.116)

51 (.067)

48 (.076)

49 (.073)

26 (.147)

77 (.018)

(.009)

77 (.018)

(.010)

56 (.046)

49 (.073)

36 (.106)

50 (.070)

77 (.018)

(.009)

15

Page 20

COOKING CHART

RECOMMENDED TEMPERATURES, TIMES AND LOADS FOR BAKING

MINUTES

NO.

OF RACKS

CONTROL

IMPORTANT

Recommended temperatures, times, number of racks and

load control settings are intended as a guide only.

Adjustments must be made to compensate for variations in

recipes, ingredients, installation and personal preference in

product appearance

RECOMMENDED TEMPERATURES,

TIMES AND LOADS FOR ROASTING

Meat roasting is most satisfactory at temperatures of 225° to

325° F. for Beef, Lamb, Poultry and Ham; 325° to 350° for

fresh Pork as recommended by USDA and American Meat

Institute

ROASTING TEMPERATURE CHART

PRODUCT

TEMPERATURE

Standing Rib Roasts—Oven Ready 250° F HI

Rolled Rib Roasts—20 to 22 Lbs 275°F HI

Veal Roast—15 Lbs 300° F HI

Turkeys—15 to 20 Lbs 300° F HI

Meal Loaf—8 to 10 Lbs 350° F HI

A pan of water (approximately 12" x 20" x 1") may be placed

in the oven bottom. This water supplies humidity to reduce

shrinkage. Water should be added if necessary during

roasting.

Roasting pans should be no deeper than necessary to hold

drippings, usually 2" to 2 1/2".

Cooking time and shrinkage may vary with roasting

temperature, cut and grade of meat and degree of doneness.

Smaller cuts will generally show greater time savings than

larger cuts at a given temperature.

LOAD

CONTROL

SETTING

APPROXIMATE TIMES

3 to 4 Hrs —Rare

4 to 4 1/2 Hrs —Med

4 Hrs.—Med

3 Hrs —Med Well

3 Hrs

45 to 60 Minutes

PRODUCT TEMPERATURE TIME IN

Cakes

Sheet Cakes 18 x 26 x 1" Pan

5

Scaled 4 1/2 to 6 Lbs Per Pan 325° to 360° F 20 to 23 4

Scaled 6 to 7 1/2 Lbs Per Pan 335° to 350° F 22 to 25 4

LOAD

Med+ to

Med to

Med to

Sheet Cakes 18 x 26 x 2" Pan 300° to 325° F 25 to 35 3 MedEquals 2-12 x 18 x 2" Pans

Scaled 10 to 12 Lbs Per 18 x 26 x 2" Pan

or 5 to 6 Lbs Per 12 x 18 x 2" Pan

Angel or Sponge Cakes

Sheet Pans 18 x 26 x 1" 300° to 325° F 15 to 20 4 Lo+

Scaled 5 to 6 Lbs Per

Loaf or Tube Pans 315° to 340°F 20 to 30 3-4 Med-to Lo

Cup Cakes 350° to 400° 6 to 12 4

Frozen Fruit Pies 350° to 375°F 30 to 45 4

3 Med-

Pumpkin or Custard Pies 300° to 350° F 30 to 45 4

Cobblers

3

Med to

Med to

Med to

Med-to

12 x 18 x 2" or 12 x 20 x 2 1/2" 350° to 400° F 30 to 45 4 Med

Meringue Pies 350° to 425° F 6 to 10 4

Fruit Turnovers 350° to 375° F 15 to 25 5

18 x 26 x 1" Pans

Cookies

Rolled or Pressed 350° to 400° F 6 to 12 5

Drop 350° to 400° F 6 to 15 5

Brownies 350° F 12 to 20 5

Rolls-1 Oz 350° to 400° F 5 to 10 4

Rolls—11/2 to 2 1/2 Ozs 350° to 400° F 8 to 15 4

3 Med-

Med to

3

2

Med to

Med to

Med to

4

3

Med to

Med- to

Med to

4

3 Lo+

Med- to

Med to

4

3 Lo+

Med-to

Med to

4

Med- to

Med to

3 Med-

Med to

3

Med- to

Loaf Bread—1 Lb. 325° to 375° F 20 to 40 3 (30 Pans) Med 2 (20 Pans) Lo+

NOTE: Pies and Cobblers; Fruit, Custard and Pumpkin Pies in tins, should be placed on 18x26x 1" Pans for

16

Page 21

COOKING CHART (Continued)

TIME IN

NO.

Yeast Bread*

RECOMMENDED TEMPERATURES, TIMES AND LOADS MISCELLANEOUS PRODUCTS

Baked Po

tatoes

RECOMMENDED TEMPERATURES, TIMES AND LOADS FOR BAKING

PRODUCT TEMPERATURE

Note: Yeast Breads should be fully proofed for best

Sweet Rolls & Danish Pastries 325° to 375° F 5 to 15 4 Med to Med 3 Med-to Lo+

Quick Breads

Biscuits 350° to 400° F 5 to 15 4 Med to MedRolled 1/2'' Thick 3 Med-to Lo+

Muffins 325° to 375° F 6 to 18 4 Med 3 Med-to Lo+

Corn Bread

5 to 7 Lbs Per Pan 335° to 400° F 10 to 20 4 Med to MedPer 18 x 26 x 1" Pan

8 to 20 Lbs Per 18 x 26 x 2" 335° to 400° F 15 to 25 4 Med to Med 3 Med-to Lo+

Corn Muffins 335° to 385° F 10 to 20 4 Med to Med 3 Med to Lo+

OVEN BROILING OR FRYING

Hamburger Patties

8 Per Lb 400° to 450° F 5 to 6 4 to 6 Hi- to Med+

Med Well Done 2 & 3 Med+ to Med

6 Per Lb 400° to 450° F 7 to 10 4 to 6 Hi to Hi 2 & 3 Hi- to Med+

4 Per Lb 375° to 450° F 8 to 12 4 to 6 Hi

2 & 3 Hi- to Med+

Fish Sticks & Portion—Frozen Breaded

1 Oz 350° to 400° F 6 to 10 4 Hi- to Med

2 & 3 Med+ to Med2 1/2 to 3 Ozs 350° to 375° F 8 to 15 4 Med+ to Med

2 & 3 Med to MedChicken Pieces—Broiler or Oven Fried

2 to2 1/2Lb Bird 375° to 425°F 8 to 15 4 to 5 Hi- to Med

2 & 3 Med+ to Med2 1/2 to 3 Lb Bird 350° to 400° F 15 to 25 4 Med+ to Med

2 & 3 Med to MedLobsters—1 to 11/2" Lb 400° to 450° 8 to 14 2 to 4 Hi to Med

Lobster Tails—Frozen

1/2 to 3/4 Lb 350° to 400° F 10 to 15 2 to 4 Hi- to Med

REHEATING PREPARED FOODS

Frozen French Fries 400° to 450° F 6 to 8 4 Hi- to Med

2 to 3 Med+ to MedFrozen Lunches (TV Dinners) 350° to 400° F 10 to12 4 to 5 Hi to Med

2 to 3 Med+ to MedFrozen Entrees (3/4" to 1" Thick) 300° to 350° F 10 to 20 2 to 5 Hi to Med

Frozen Meals (8 Oz ) Foil Pkg 350° to 400° F 20 to 30 2 to 5 Hi

CASSEROLES

Food Service Pans

2" to 3" Deep 325° to 375° F 15 to 25

3" to 4" Deep 325° to 375° F 20 to 35 2 to 4 Med+ to MedRamikins or Foil Pans 350° to 400° F 5 to 6 4 to 5 Hi to Med+

Up to 1 1/2" Deep 2 t0 4 Med+ to Med

*(Frozen 10 to 15 Minutes)

LOAD

120 Count Per 50 Lbs 400° to 450° F 20 to 25 2 to 5 Hi- to Med

100 Count Per 50 Lbs 400° to 450° F 25 to 40 2 to 5 Med+ to Med

80 Count Per 50 Lbs 400° to 425° F 30 to 50 2 to 5 Med+ to MedPizzas—Frozen or with Prebaked Crust 425° to 475° 5 to 10 4 Hi- to Med

2 & 3 Med to MedMelted Cheese Sandwiches 400° to 425° F 8 to 10 4 Hi- to Med

2 &3 Med+ to Med-

NOTES ON SPECIAL PROCEDURES FOR BAKING

Yeast Bread: Cooking starts immediately in the convection oven. Yeast Breads do not usually rise as much In the convection oven

as in a conventional oven. It is. therefore, usually necessary to allow fuller proof. 2 1/2 to 3 times Increase in volume for the best

results. Pies: When baking pies in your convection oven, 3 or 4 pies should be put on an 18 x 26" sheet or bun pan. This

procedure helps the bottom crust to bake, makes handling easier and reduces the possibility of boil over spoiling the appearance

of the pies on the lower racks.

17

Page 22

WIRING DIAGRAM—7800 SERIES

REV# DATE SIGN

1 DML

6/3/80

8/2/80

2

3 9/11/8 RWR

DML

18

Loading...

Loading...