Page 1

VULCA

INSTALLA

399A·77R

ION.

SERVICE

MA

&

UAL

& 319A·77R

GAS

PARTS

FOR

SE

IES

OVENS

VULCAN-HART CORPORATION, 3600 NORTH

POINT

BOULEVARD, BALTIMORE,

MARYLAND

21222

Page 2

IMPORTANT

OPERATING, INSTALLING AND SERV,ICE PERSONNEL

Operating information for this equipment has been prepared for use by qualified and/or authorized

operating personnel.

All installation and service on this equipment is to be performed by qualified, certified, licensed

and/or authorized installation or service personnel, with the exception

front of the part number.

of

any marked with a 0

in

Service may

or Local Service Agency.

be

obtained by contacting the Factory Service Department, Factory Representative

DEFINITIONS

QUALIFIED ANO/OR AUTHORIZED OPERATliNG PERSONNEL

Qualified or authorized operating personnel are those who have carefuHy read the information

this manual and are familiar with the equipment's functions or have had previous experience with

the operation of the equipment covered

QUALIFIED fNST

Qualified installation personnel are individuals, a firm, corporation or company which either

person or through a representative are engaged in, and are responsible for:

1.

The installation of gas piping from the outlet side of the gas meter, or the service regulator

when the meter

Qualified installation personnel must be experienced

required, and have complied with

Reference

Canada-Canadian Standard CAN. 1-B149.1-M80 (Nat. Gas) orCAN. 1-B149.2-M80 (Propane).

ALLA

TION PERSONNEL

is

not provided, and the conneciton and installation of the gas appliance.

in

the United States

in

this manual.

in

such work,

all

requirements of state or local authorities having jurisdiction.

of

America - Nabonal Fuel Gas code ANSI Z223.1-1984.

be

familiar with all precautions

2. The installation of electrical wiring from the electric meter, main control box or service outlet to

the e'lectric appliance. Qualified installation personnel must be experienced

familiar with all precautions required, and have complied with all requirements of state or local

authorities having jurisdiction. Reference:

Code ANSI NFPA

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Vulcan equipment who have been

endorsed by the Vulcan-Hart Corporation. All authorized service personnel are required to be

equipped with a complete set of service parts manua'is and stock a minimum amount of parts for

Vulcan equipment.

No.

70 1984.

In

Canada-Canadian Electricall Code Part 1 CSA-C22.1-1986.

In

the United States of America-National Electrical

in

such work, be

in

in

In

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment

packed by skilled personnel before leaving the factory. The transportati.on company assumes full

responsibility for safe delivery upon acceptance of this shipment.

If

shipment

1. VISIBLE LOSS

signed by person making dehvery.

2.

FILE CLAIM FOR DAMAGES IMMEDrATELY - Regardless of extent of damage.

3.

CONCEALED

notify transportation company or carrier immediately, and file "concealed damage" claim with

them. This should be done within (15) days of date of delivery is made

container for inspection.

We cannot assume responsibility for damage or loss incurred

glad to furnish you with necessary documents to support your claim.

arrives

damaged:

OR

DAMAGE -

lOSS

PLEASE RETAIN THIS

OR DAMAGE - If damage is unnoticed until merchandise

Be

certain this is noted on freight bill or express receipt and

MANUAL

in

this shipment was carefuilly inspected and

is

unpacked,

to

you. Be sure to retain

in

transit. We will, however, be

FOR FUTURE REFERENCE

Page 3

CAUTIONS

Vulcan

Plate.

(ANSI-Z223.1-1984 National Fuel Gas Code). Copies may be obtained from: The American Gas

Association,

(CAN. 1-B149.1-M80 (Nat.) or CAN. 1-B149.2-M80 (Propane) Canadian Standards.) Copies may be

obtained from: The Canadian Gas Association, 55 Scarsdale Road, Don Mills, Ontario, Canada

M3B2R3.

The

Information

"Standard

Vapors from

Fire

In

gas

The

obstruct

positioned

This

air

In

Units equipped for 120 volt

power switch off.

gas

units are

For

proper

Inc.,

following

Protection

the

event

company

areas surrounding the front, rear and sides of the unit should be kept clear so as not to

appliance is to be installed in an area with

openings

the event of a power failure, the pilots will remain lit and the unit will continue to function.

clause

on

the

for

the

Commercial

a gas odor is detected,

or

the flow of air

for easy

into the combustion

manufactured

installation

1515

construction

Installation

Association,

gas

accessibility

DO NOT attempt to operate unit until power is restored.

Wilson

pertains

supplier

necessary

only

Cooking Equipment",

Attention

Batterymarch

operation

for use with the

procedures

Blvd.,

to

units being installed in

and installation of ventilating

of

Equipment

Publication

shut

down units at main shut off valve and

for service.

for

good

for servicing.

chamber

will

in

Arlington,

for

Park, Quincy, MA

combustion

of the unit.

automatically

type

the

United

Virginia

the

Removal

NFPA

adequate

No.

Services.

and

of

gas

specified

States

22209.

the

United

hoods

96-1984

unit

air supply and

shut down. Should this happen, turn

may

of

Smoke

available from the National

02269

operation. Unit should also be

on

the

of

America

In

Canada,

States

be

obtained

and

Grease

contact

adequate

unit

Rating

refer

refer

of America.

from the

Laden

the local

clearance

to:

to:

for

PEEL THIS ADHESIVE BACKED STICKER AWAY FROM ITS BACKING

IN

THE

SHUT

AND

GAS

FOR

YOUR

SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN VICINITY

OF THIS EQUIPMENT OR ANY OTHER APPLIANCE.

IN

AND PLACE

VIEW OF EQUIPMENT OPERATOR

IMPORTANT

EVENT

DOWN

CONTACT

SUPPLIER

A GAS

UNITS

THE

FOR

ODOR

AT MAIN

IS

SHUT

DETECTED,

OFF

LOCAL GAS COiMPANY OR

SERVICE.

VALVE

Page 4

319A-77R & 399A-77R INSTALLATION, SERVICE

AND

Vulcan Ovens are

workmanship

tenance will result in

performance.

PARTS

and material. Proper use and

MANUAL

produced

many

DESCRIPTION

DEFINITIONS

SHIPPING

CAUTION NOTES

SECTION I (INSTALLATION

CONNECTING

PILOT

SECTION

OVEN

THERMOSTAT

RECALIBRATE

OF

PERSONNEL (Operation, Installation & Service) and

DAMAGE

ADJUSTMENT

II (SERVICE

LIGHTING & SAFETY

CLAIM

UNIT

INSTRUCTIONS)

OVEN

with

the best possible

years

INSTRUCTIONS)

TO

GAS/MAIN

CONTROL

of

PROCEDURE

PILOT

main-

satisfactory

BURNER

AND

The

manufacturer

this entire manual and

instructions

suggests that you

provided.

carefully

thoroughly

follow

all

of

read

the

PAGE

(Inside Front Cover)

2

3

4

5

6

SECTION

Model

Model

A

Rating

Serial

This

construction.

III (PARTS)

319A·77R

399A·77R

Plate

Number

unit

is

to

is

and

be

is a single

is a double

located

installed

Type

on

of

with

deck

deck

the

Gas

oven.

oven.

inside

that

a 6 in.

lower

front

the

unit

clearance

control

requires.

at

the

cover.

sides

and

The

a 6 in.

Rating

clearance

Plate

states

at

the

the

rear

Model

to

Number,

combustible

7-10

Page 5

CONNECTING

UNIT

TO

& PILOT ADJUSTMENT

1.

CONNECT

Each

unit

gas

indicated

lower

panel.

NOTE:

A. Pipe

appliances

LP.

gases.

B.

Pipe

and

water

use matches

C.

Standard

are

equipped

with a preset

is

joint

to gas

joints

solution

UNIT

TO

factory

Check

or

units

with

outlet

equipped

on

the range

type

compounds

should

should

before

flame to test.

for

fixed

pressure of 3.7" W.C.

GAS

for

use

with

rating

of

be resistant to the action of

be tested

operating

use on Natural

orifices

plate located

gas

supply

used

when

for

and pressure

available.

connecting

leaks

with

the

unit. Do

or

Mixed Gases

Units

GAS/MAIN BURNER

on

the

type

on

a soap

regulator

for use

of

the

not

propane

pressure

W.C.

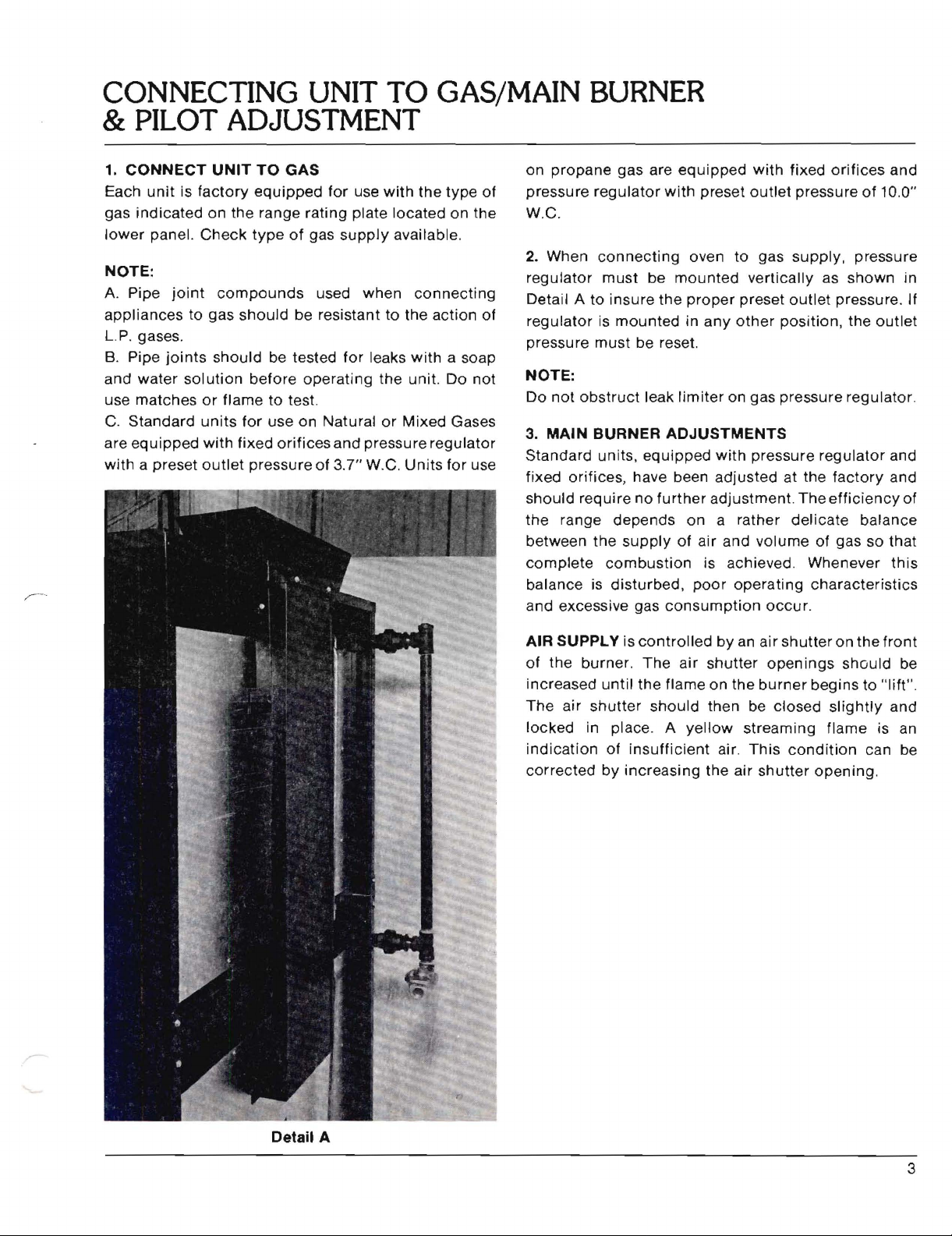

2.

When

regulator

Detail A

regulator

pressure

NOTE:

Do

not

3. MAIN BURNER

Standard units,

fixed orifices, have been adjusted at the

should

the

range depends on a rather

between the

complete

balance is

and excessive gas

gas are

regulator

connecting

must

to

insure

is

mounted

must

obstruct

require

supply

combustion

disturbed,

be

the

be reset.

leak

equipped

no

further

equipped

with

preset

oven to gas

mounted

proper

in

any

limiter

ADJUSTMENTS

of air and

is achieved Whenever

poor

consumption

with

fixed

outlet

supply,

vertically

preset

other

on gas pressure regulator.

with

adjustment.

operating

outlet

position,

pressure

delicate

volume

occur.

orifices

pressure

The

characteristics

of

pressure

as

shown

pressure. If

the

regulator

factory

efficiency

balance

of gas

so

outlet

and

10.0"

in

and

and

of

that

this

AIR SUPPLY is

of

the

burner.

increased

The

locked

indication

corrected

until

air

shutter

in place. A

of

by

increasing

controlled

The

air

the

flame on

should

yellow

insufficient

by

an air

shutter

the

then be

streaming

air.

This

the air

shutter

openings

burner

closed

condition

shutter

on the

should

begins to

slightly

flame

can be

opening.

front

be

"11ft".

and

is an

Detail A

3

Page 6

OVEN LIGHTING & SAFETY PILOT

NOTE:

4.

Remove

the

under

valve

pilot

burner

pilot will still

pilot. Remove

adjusting

Grayson

OVEN

LIGHTING

lower

side. Refer to Detail B. Depress red valve

each oven and

button

to

heat

off, then

screw

safety valve

panel and

depressed

the

thermocouple

wait

not

stay lit,

dust

cap above red

for

pilot

shown

& SAFETY

swing

ignite

five

pilot. See Detail C. Keep

for

one

ti

minutes

insufficient

gas. See

PILOT

lighting

minute

p.

If

hole

button

after

pilot

goes out, tu

before

Detail

relighting.

gas is reaching

button

to

C.

cover

"A"

lighting

expose

Detail B

to

rn

If

PILOT

1.

Remove

2.

Adjust

3.

Replace

GRAYSON

BURNER

pilot

pilot

key

pilot

Detail C

ADJUSTMENT:

adjustment

to

provide

adjustment

cap

properly

cap

GENERAL

B.

(Grayson)

sized flame.

B.

(Grayson)

A

B

4

Page 7

THERMOSTAT

DIAL

ASSEMBLY

01

AL

FOU~

SLEEVEHOTCHES

PILOT

AO~UITOR

"ETAL

DIAL

5.

THERMOSTAT

To

Adjust

When

dial

the

By-Pass Flame:

the

oven reaches

is

set, the oven

amount

temperature.

pass

enough

maintain

carefully

this

and

IH~

T

(Minimum

the

temperature

control

required

to

cuts

keep

Always, however,

gas

to

keep

the

entire

minimum

accurately,

flame, the by-pass

as

follows

down

the

the

burner

Burner

at

the

flow

oven at

control

must

- Detail

Flame)

which

of

gas

must

lighted.

be set

D.

Detail D

the

to

that

by-

To

IlETAINE~

TE ..PERATURE

1.

Light

2.

After

beyond

3.

Remove dial and bezel.

4.

With a screwdriver,

counterclockwise

decrease it,

over

the

5.

Replace bezel and dial,

locks

in

"AIlKS

the

oven

5 minutes,

first

mark

until

there

entire

the

burner.

"Off"

burner,

turn

on dial

to

position.

then

dial

clockwise

(Shown

turn

increase

is a

flame

turning

lolOUHTING FLANGE

turn

dial

to

to

point

by "X").

by-pass

the

flame,

clockwise

approximately

dial

clockwise

"Broil".

slightly

adjustor

Ve"

until

to

high

it

5

Page 8

RECALIBRATE OVEN CONTROL

TO RECALIBRATE OVEN

The

oven is a

calibrated

dial

settings

recalibration

resorted

cooking

maintaining

Recalibration

the by-pass

To

check

test

Place

thermometer

1.

Remove dial and push metal insert (See Detail D).

2.

Replace dial,

burner.

3.

After

oven temperature. Oven

short a time

to

see

to

results

oven

instrument

the

burner

the

precision

at

the

factory -that

match actual oven temperatures. Field

is

seldom

unless

definitely

the

temperatures

should

flame

has been adjusted.

temperatures

or

a reliable

thermocouple

in

the

middle

turn

has been on

as

possible. Use a

thermometer

CONTROL

instrument.

is, it is so adjusted

necessary, and

considerable

proves

to

not

be

undertaken,

when

mercury

of

test

of

the oven.

to

400 mark, and

about

door

should

flashlight,

reading clearly.

It is

should

experience

that

the

control

which

the dial is set.

however, until

recalibrating,

thermometer.

instrument

15

minutes

be open

if necessary,

carefully

light

that

not

be

with

is

not

use a

or

the

oven

check

for

4.

Continue

intervals, until

degrees

The

control

not

within

If

recalibration

taken are these:

5.

Hold

dial, and push

(Do

not

6.

While

screwdriver, turn dial

temperature

thermometer.

stem

...

replace dial insert.

7.

Set dial at 450 mark.

as

instructed

not

within

it means

as

control

should

to

two

of

each other.

should

10

degrees

is required, the

dial

firmly,

calibration

turn

this stem.)

holding

as

in (3) and (4).

20 degrees

that

the

be replaced.

check

shown

Release pressure on

sensing

temperature, at

successive readings are

be

recalibrated

of

the dial

insert

calibration

screwdriver

stem (See Detail C)

until

it

is set at

by

your

Check

of

oven

If

the dial

element

if

setting

additional

stem in

test

temperature

the oven

setting

is

inoperative

your

through

the

5-minute

within

reading is

(400 degrees).

steps

to

be

center

inward

firmly

actual oven

instrument

calibration

temperature

(450 degrees),

with

again,

and

or

the

5

is

6

Page 9

EXTERIOR

BODY

PARTS

4

2

__

...

--

/5

~

.~

...

,:;~

Description

1.

+

6"

Legs

+

6"

Legs (SS)

2.

3.

4.

5.

SS: Stainless Steel

+:

Specify

Model

Model

Manifold

Lower

+ Flue

+ Flue

+ Oven

+Oven Dial

No. 319A-77R is a

No. 399A-77R is a

Panel

Deflector

Deflector

Dial(Fahrenheit)

Finish

or

Cover

Assembly

Assembly

(SS)

Celcius(Optional)

Type

Single

Double

Deck Oven

Deck Oven

319A-77R

Not

3

Shown

7

Page 10

PILOT & BURNER TUBE ARRANGEMENT

319A-77R

Description 399A-77R

6.

7.

8.

9.

10.

11

13.

14.

15.

16.

NS-Not

Bell

Crank

Turnbuckle & Hooks

Oven

Door

.

Safety

Burner

Spring

Burner

Burner

Pilot

Pilot

Shown

Valve

Nozzle

Clip

Tube

Tube

Tube

Tube

Spring

Safety

Elbow

Elbow

Safety

To

To

To

Nozzle

To

Safety

Safety

Pilot

103956-1

3.0122/

12932

104053-1

105569-2

104079-F

113371-1

113370-1 113370-1

113242-1

113330-1

113328-1

319A-77R

399A~77R

103956-1

3.0122/

12932

104053-1

105569-2

104079-F

113371-1

113242-1

113330-1

113328-1

55

55

<,-)

8

Page 11

OVEN

BOTTOM

& BURNERS

SHOWING

PILOT,

THERMOCOUPLE

Descriplion

17.

+ Pilot (Nat. & Mixed)

+ Pilot (L.P. Gas)

18.

19.

20. Oven

21.

22. "V" Baffle (NS)

+:

Specify type

NS:

Thermocouple

Secondary

Oven

Not

Shown

Burner

Bottom

of

gas

Air

Pan

Assembly

(NS)

319A-77R

399A-77R 399A-77R

112787-1 112787-1

112787-2 112787-2

112788-1 112788-1

113165-1 113165-1

113225-G1 113225-G1

113234-1 113234-1

113228-1 113228-1

319A-77R

SS

SS

9

Page 12

OVEN DOOR PARTS

31

Description

6,

7,

8.

24.

25,

26.

29,

30.

31.

32. Left

33.

34.

Bell

Turnbuckle & Hooks

Oven

Bell

Hinge

Cotter

Oven

Oven

Oven

Right

Left

Right

Y;3

Crank

Door

Spring

Crank

Door

Bell

Pin

Pin

Door

Door

Door

Door

Crank

Bell

Pin

Assembly

Assembly

Handle

Handle

Handle

Hook

Crank

Hook

Post

Post

26

r

~

(Ref,)

(Ref.) (SS)

.7

2\1'

.......-

319A-77R 319A-77R

399A-77R

103956-1

3.0122/

12932

104053-1

103971-1

113201-1

10597

113267-G1

-

113257-1

113416-1

113416-2

113381-2

113381-1

a

399A-77R

103956-1

3.0122/

12932

104053-1

103971-1

113201-1

10597

113267-G2

113257-1

113416-1

113416-2

113381-2

113381-1

6

55

55

'-....--"

/

Ref: Reference

SS: Stainless Steel

10

Number

for

Complete

Assembly

Page 13

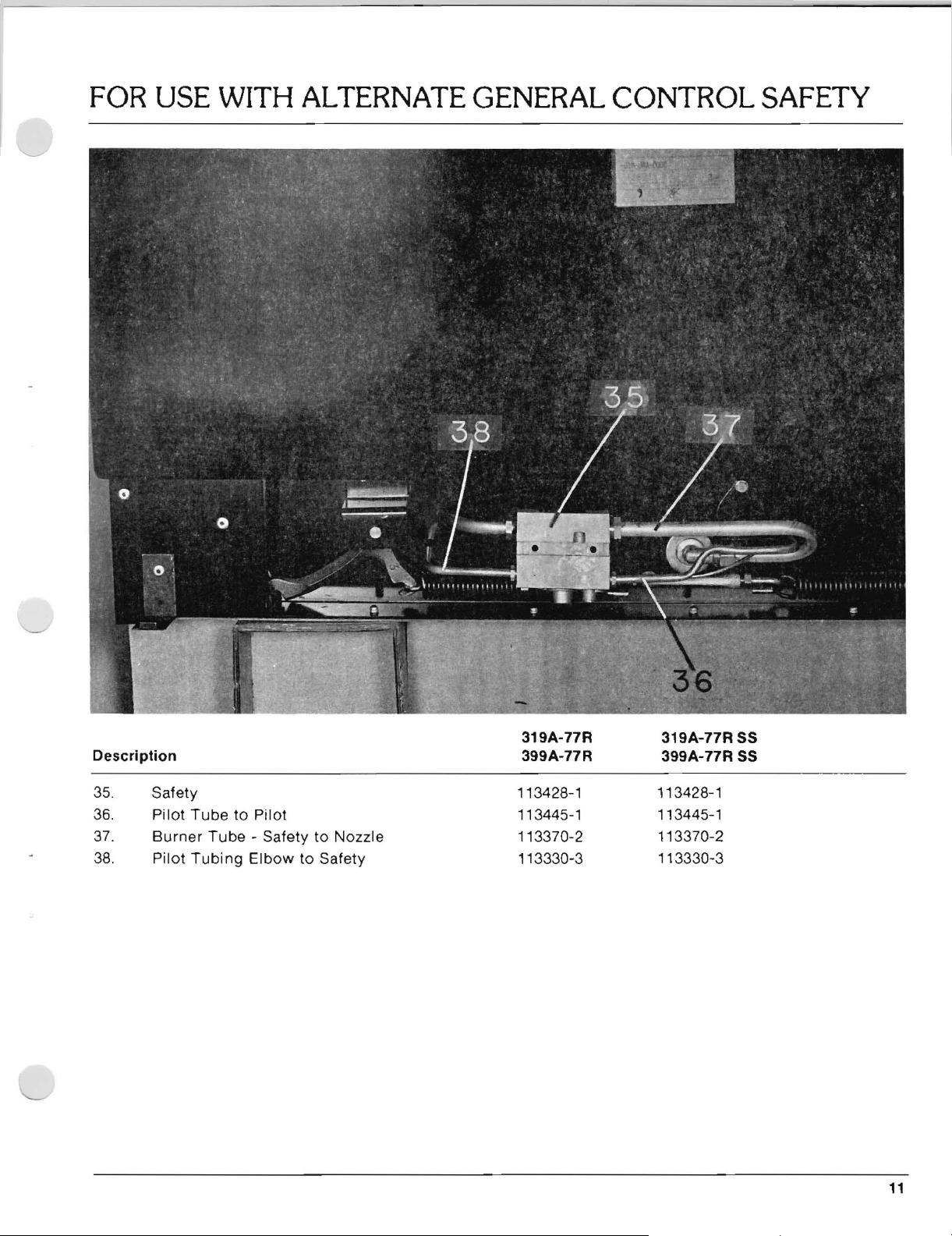

FOR USE

WITH

ALTERNATE GENERAL

CONTROL

SAFETY

319A-77R

Description 399A-77R

35.

36.

37.

38.

Safety

Pilot

Tube

Burner

Pilot

TUbing

to

Tube·

Pilot

Safety

Elbow

to Nozzle

to

Safety

113428-1

113445-1

113370-2

113330-3

319A-77R SS

399A-77R SS

113428-1

113445-1

113370-2

113330-3

11

Page 14

MANU'AL

PA:RT

NO.: 113902

REV.

SUB

BLOCK

. DATE

SIGN

FOR MODELS: 319A-77R

& 399A-77R

DESCRIPTION: Installation, Service,

And Parts Manual

1

2/2/82

DML

I

Loading...

Loading...