Page 1

Item # _____________________________

C.S.I. Section 11420

MODEL 2T2036E

TWO 24 QUART 2/3 JACKETED TILTING

KETTLES ON ELECTRIC BOILER BASE

STANDARD FEATURES

■ Two 2/3 jacketed tilting steam kettles, 24 quart capacity

each.

■ Steam jacketed kettles mounted on 28" high base cabinet

with front full height doors, slip-off stainless steel side and

aluminized rear panel with 6" adjustable legs with anged

feet for anchoring.

■ Fully welded hemispheric bottom kettle with type 304 stainless steel jacket and type 316 stainless steel liner. Jacket

tested to 50 psi (3.4 kg/cm2).

■ Steam control valve on right trunnion leg.

■ 12" single temperature deck mounted faucet.

■ CSD-1 code compliant boiler.

■ Electric 24 KW steam boiler.

■ Requires a 208 or 240 volt, 60 Hz, 3 phase power supply

and a separate 120 volt, 60 Hz, 1 phase control circuit,

3 amp.

■ Water lter system, SPS620V. Includes second year extended

limited water associated parts and labor warranty.

■ One year limited parts and labor warranty.

A2780

ISO9001

Vulcan-Hart Co.

MODEL: 2T2036E Two 24 Quart

SPECIFICATIONS:

Two 24 quart 2/3 jacketed tilting steam kettles mounted on a

36" wide electric boiler base, Vulcan-Hart Model No. 2T2036E.

Steam jacketed kettles mounted on 28" high base cabinet

with front full height doors, slip-off stainless steel side and

aluminized rear panel with 6" adjustable legs with anged feet

for anchoring. Fully welded hemispheric bottom kettle with

type 304 stainless steel jacket and type 316 stainless steel

liner. Jacket tested to 50 psi (3.4 kg/cm2). Steam control valve

on right trunnion leg. 12" single temperature deck mounted

faucet. Requires a 208 or 240 volt, 60 hz, 3 phase power

supply and a separate 120 volt, 60 Hz, 1 phase control circuit,

3 amp.

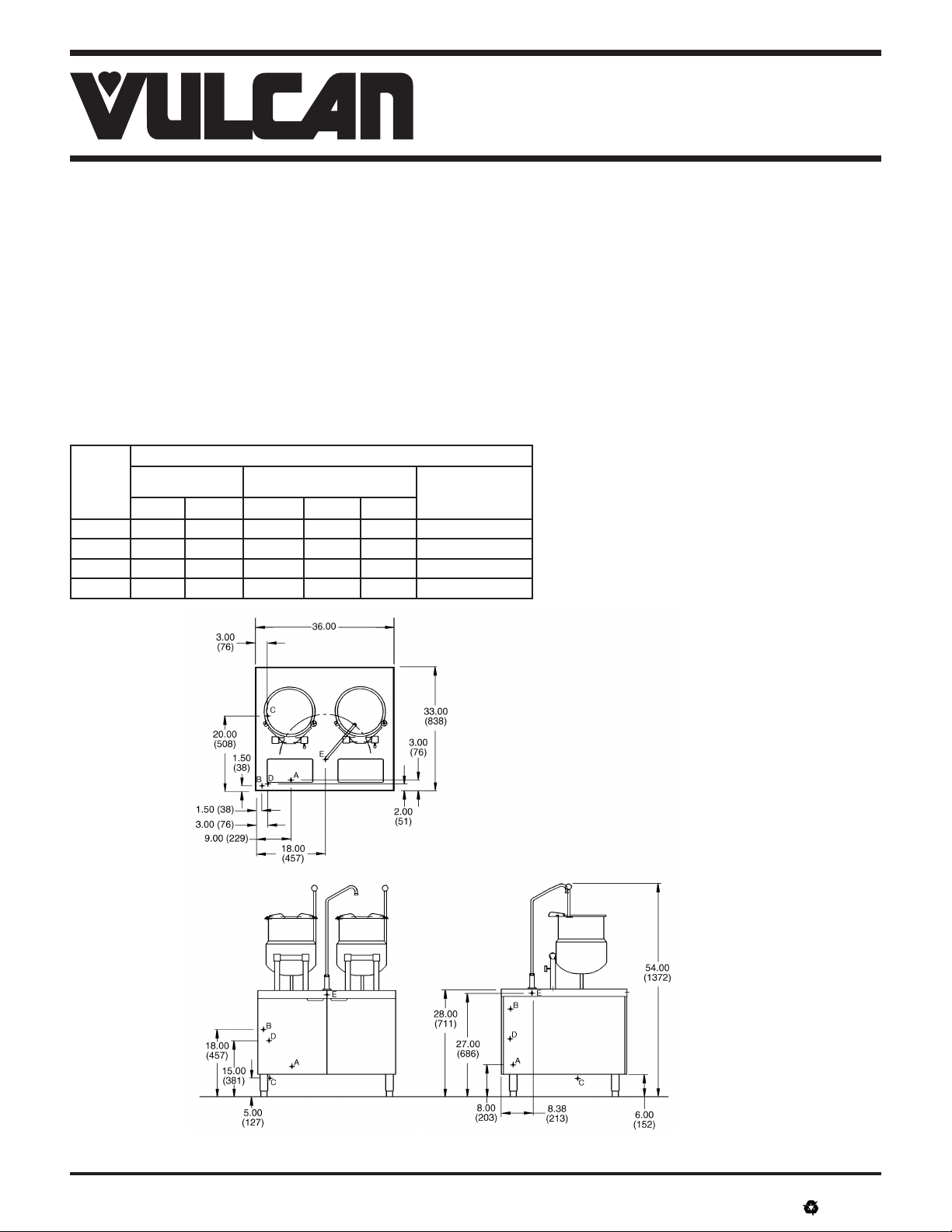

Exterior dimensions:

Cabinet: 36"w x 33"d x 28"h on 6" adjustable legs. Overall

height to the lip of the kettles - 46", to the top of the

handle - 54".

U L listed. Classied by U L to NSF Std. #4. Meets ASME

Code.

OPTIONS

■ Correction package.

- Cabinet door with hasp (lock by others).

- Security type tamper resistant fasteners.

- Front anged feet.

■ Stainless steel nishing back.

■ Tilting kettle strainer (one) (two).

■ 12" dual temperature faucet.

■ Single phase on 24 KW boiler.

■ Stepdown transformer (eliminates 120 volt connection).

■ 36 KW boiler, 3 phase only.

■ 42/48 KW boiler, 3 phase only.

■ 480 volt, 60 Hz, 3 phase, includes stepdown transformer.

■ Mount and interconnect kettle with boiler base at factory.

Includes steam supply piping. Shipped on one skid.

■ Second year extended limited parts and labor warranty.

ACCESSORIES

■ Stainless steel back panel.

■ Lift-off cover (one) (two).

■ Contour measuring strip.

■ Single perforated stainless steel basket (one) (two).

2

/3 Jacketed Tilting Kettles On Electric Boiler Base

F-32379 (10-03)

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201, TEL. 1-800-814-2028

502-778-2791 QUOTE & ORDER FAX: 1-800-444-0602

Page 2

Printed On Recycled Paper

MODEL 2T2036E

TWO 24 QUART 2/3 JACKETED TILTING

KETTLES ON ELECTRIC BOILER BASE

WATER QUALITY STATEMENT:

The fact that a water supply is potable is no guarantee that it is suitable

for steam generation. Your water supply must be within these general

guidelines:

SUPPLY PRESSURE 20 - 60 psig

HARDNESS* less than 3 grains

SILICA less than 13 ppm

TOTAL CHLORIDE less than 4.0 ppm

pH RANGE 7-8

UN-DISSOLVED SOLIDS less than 5 microns

* 17.1 ppm = 1 grain of hardness

Other factors affecting steam generation are iron content, amount of

chloridation and dissolved gases. Water supplies vary from state to state

and from locations within a state. Therefore it is necessary that the local

water treatment specialist be consulted before the installation of any

steam generating equipment.

AMPS PER LINE

KW

INPUT

24 116 100 67 58 29 34

36 NA NA 100 87 44 50

42 NA NA 117 NA NA NA

48 NA NA NA 116 58 67

1 PHASE 3 PHASE

208V 240V 208V 240V 480V

3 PHASE-4 WIRE

220/380V

240/415V

SERVICE CONNECTIONS:

A Electrical Connection for Boiler Heat: Junction box see capacity

chart.

B Electrical Connection for Controls: 120/60/1. 300 watt maximum,

power supply with grounding wire required.

C Drain: Condensate box, compartment and boiler, 11/4" NPT. (Provide

an open air type drain within 12" of condensate box and for best results

at a distance so that steam vapors will not enter the steamer from

underneath the control area. Do not connect solidly to any drain

connection.)

D Cold Water Connections (2):

D1 Treated Cold Water Connection: 1/4" NPT for boiler feed. Inlet

water pressure between 20 and 80 psi.

D2 Untreated Cold Water Connection: 1/4" NPT for condensate

box. Inlet water pressure between 20 and 80 psi.

E Water: For swing faucet, (single) (dual) temperature, 1/4"

tubing.

NOTE:

• Dimensions which locate the above connections have a

tolerance of + or -3" (+ or -75 mm).

• Installationof backow preventers,vacuumbreakersand

other specic code requirements is the responsibility of the

owner and installer. It is the responsibility of the owner and

installer to comply with local codes.

• Plasticdrainsarenotrecommendedduetoinherentlimited

temperatures of the plastic. Boiler purge temperatures may

exceed 180°F. The installer may be required to provide

means to reduce boiler purge water temperature to be that of

the condensate temperature of 140°F or less.

• Thisapplianceismanufacturedforcommercialinstallation

only and is not intended for home use.

NOTE: In line with its policy to continually improve its products, Vulcan-Hart Company reserves the right to change materials and

specications without notice.

F-32379 (10-03)

EQUIPMENT CLEARANCE: Rear: 2" Right: 0" Left: 0"

BRIMFUL CAPACITIES (in 4 oz. servings):

24 quarts / 6 gallons / 22.5 liters - 192 servings.

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201, TEL. 1-800-814-2028

502-778-2791 QUOTE & ORDER FAX: 1-800-444-0602

Loading...

Loading...