Page 1

ASSEMBLY INSTRUCTIONS

TALL FOOT & SKID PLATE — KIT NO. 873255

This kit is used on the following Hobart slicer models: 1912RB, 2912SC and 2912B. The skid plates

keep the slicer feet in their proper locations on the counter or table.

PART NO. NAME OF PART AMT.

873255 TALL FOOT & SKID PLATE KIT (complete) ....................... 1

875371 Foot – Tall ................................................................................. 4

478688 Skid Plate .................................................................................. 2

SD-024-29 Screw – Sheet Metal ................................................................ 4

SC-022-68 Screw – Machine Screw (flat head) ........................................ 4

WL-006-06 Lockwasher............................................................................... 4

NS-011-23 Nut ............................................................................................. 4

F-34716 Rev.B Assembly Instructions.............................................................. 1

WARNING: DISCONNECT ELECTRICAL POWER.

5

Unscrew the short feet used during shipping and replace them with the 1

kit. Raise the right side of the slicer using the Lift Lever. Replace the feet on the right side of the slicer.

Lower the slicer back to the table or counter by retracting the Lift Lever. Raise the left side of the slicer

and use a block of wood, a book or other suitable material to support the slicer while the left short feet

5

are removed and replaced with the 1

/8" tall feet.

/8" tall feet supplied with the

1. Place the slicer in final operating location on table or counter.

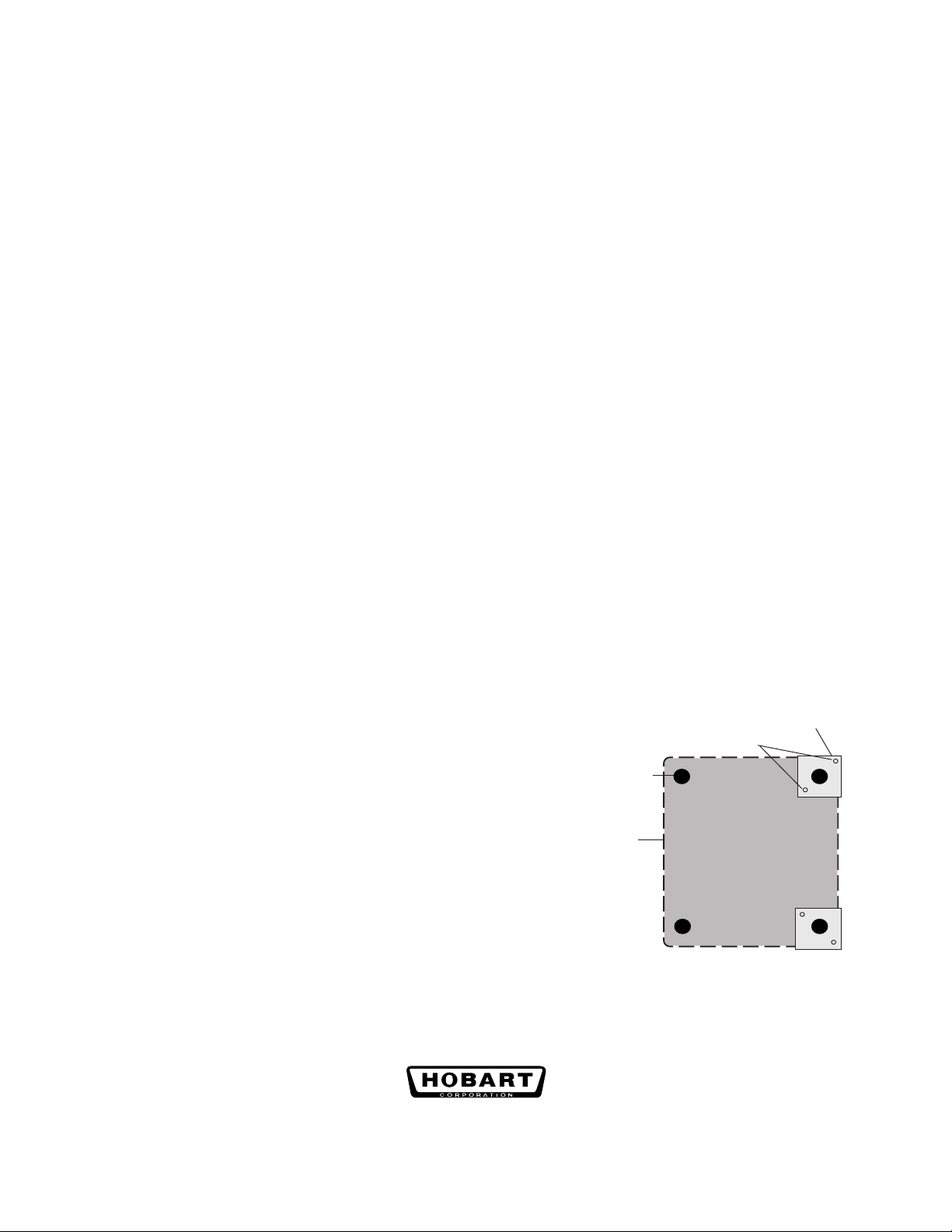

2. Locate skid plates under feet on right side of slicer (Fig. 1).

3. Mark hole locations for each skid plate — use skid plates for templates.

NOTE: Before drilling holes in countertop, check for any

possible obstructions under the table or counter such as

wires or conduit. If necessary, relocate skid plates and

re-mark holes before drilling.

SLICER FEET

HOLE LOCATIONS

4. If using sheet metal screws, drill two 0.159" diameter

holes (use #21 drill) per skid plate and install both skid

plates.

SLICER BASE

If using machine screws, lockwashers and nuts, drill

two 0.201" diameter holes (#7 drill) per skid plate and

install both skid plates.

5. Return the slicer to its operating position with two feet

retained by skid plates.

SKID PLATE

Fig. 1

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

FORM 34716 Rev. B (Feb. 2002) PRINTED IN U.S.A.

www.hobartcorp.com

Loading...

Loading...