Page 1

SERVICE MANUAL

VK and TR GAS FRYERS W/Wo

KleenScreen PLUS

VK Series

TR Series

®

- NOTICE -

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Vulcan-Hart 3600 North Point Blvd Baltimore, MD 21222

F45474 (0413)

Page 2

VK and TR GAS FRYERS W/Wo KleenScreen PLUS

TABLE OF CONTENTS

GENERAL .................................................................................................. 4

INTRODUCTION ....................................................................................... 4

MODEL AND ML NUMBERS ............................................................................ 4

MODELS, FEATURES AND OPTIONS .................................................................. 5

KLEENSCREEN PLUS FILTRATION SYSTEM: (KSP) ................................................... 5

SERIAL NUMBER LOCATION .......................................................................... 6

CONTROL PANELS .................................................................................... 6

INSTALLATION ........................................................................................ 7

OPERATION ........................................................................................... 7

CLEANING ............................................................................................. 7

TOOLS ................................................................................................. 7

SPECIFICATIONS ...................................................................................... 7

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 9

COVERS AND PANELS ................................................................................ 9

CONTROL PANEL (SOLID STATE AND COMPUTER) .............................................. 9

BASKET LIFT COVERS ............................................................................ 9

ANALOG CONTROL .................................................................................. 10

INTERFACE CONTROL - D AND C SERIES ........................................................... 11

POWER SWITCH - D AND C SERIES ................................................................. 11

TEMPERATURE PROBE .............................................................................. 11

HIGH LIMIT THERMOSTAT ........................................................................... 12

POWER SUPPLY BOX ................................................................................ 13

POWER SUPPLY BOX COMPONENTS BEFORE 12/1/12 .............................................. 14

IGNITION MODULE ............................................................................... 14

BLOWER CONTROL BOARD ..................................................................... 14

TIME DELAY TIMERS ............................................................................. 14

BLOWER RELAY ................................................................................. 14

FILTER RELAYS (24 VAC AND 120 VAC) ......................................................... 14

120 VOLT TRANSFORMER ....................................................................... 15

POWER SUPPLY BOX COMPONENTS AFTER 12/1/12 ............................................... 15

120 VOLT TRANSFORMER ....................................................................... 15

CONTROL BOARD ................................................................................ 16

FILTER RELAYS .................................................................................. 16

BURNER ASSEMBLY ................................................................................. 16

GAS VALVE .......................................................................................... 17

BASKET LIFT TUBE .................................................................................. 17

BASKET LIFT MOTOR ................................................................................ 18

BASKET LIFT CAM SWITCH .......................................................................... 19

BASKET LIFT CAM ................................................................................... 19

FILL SOLENOID VALVE (KSP) ........................................................................ 19

FILTER HOSE SWITCH (KSP) ........................................................................ 20

FILTER PUMP AND MOTOR (KLEENSCREEN FRYERS ONLY) ....................................... 20

DRAIN VALVE INTERLOCK SWITCH (DVI) ............................................................ 21

FRY TANK ............................................................................................ 22

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 24

ELECTRIC CONNECTIONS ........................................................................... 24

HARMONIC TONE .................................................................................... 24

TEMPERATURE PROBE FAULT CODES .............................................................. 24

TEMPERATURE PROBE TEST ....................................................................... 24

COOKING CONTROL CALIBRATION .................................................................. 25

FLAME SENSE CURRENT CHECK PRIOR TO 12/1/12 ................................................ 25

FLAME SENSE CURRENT CHECK AFTER 12/1/12 .................................................... 26

ELECTRONIC IGNITION CONTROL ................................................................... 26

IGNITION MODULE LOCKOUT .................................................................... 26

ELECTRONIC IGNITION SYSTEM ................................................................ 27

F45474 (0413) Page 2 of 54

Page 3

VK and TR GAS FRYERS W/Wo KleenScreen PLUS

MODULATING GAS VALVE ADJUSTMENTS .......................................................... 27

BASKET LIFT ARM ADJUSTMENT .................................................................... 27

SOLID STATE CONTROL ............................................................................. 28

OPERATION ...................................................................................... 28

SERVICE PROGRAMMING ....................................................................... 28

ERROR MESSAGES .............................................................................. 28

ENTER SERVICE MODE .......................................................................... 28

ALARM MESSAGES .............................................................................. 30

COMPUTER CONTROL ............................................................................... 31

OPERATION ...................................................................................... 31

SERVICE PROGRAMMING ....................................................................... 31

ENTER SERVICE SETTING MODE ................................................................ 31

ALARM MESSAGES .............................................................................. 35

DISPLAY, LED AND KEYPAD TEST - COMPUTER CONTROL ......................................... 36

BLOWER CONTROL BOARD SETTINGS .............................................................. 36

HIGH/LOW FIRE TIMER SETTING .................................................................... 36

AIR FILTER ........................................................................................... 37

SPARK GAP SETTING BEFORE 12/1/12 .............................................................. 37

SPARK GAP SETTING AFTER 12/1/12 ................................................................ 38

ELECTRICAL OPERATION ................................................................................ 39

COMPONENT FUNCTION - FRYER CONTROLS ...................................................... 39

COMPONENT FUNCTION - KLEENSCREEN FILTER CONTROLS ..................................... 40

COMPONENT LOCATION ............................................................................. 40

SEQUENCE OF OPERATION - A SERIES - AFTER 12/1/12 ............................................ 41

SEQUENCE OF OPERATION D AND C SERIES ....................................................... 42

SCHEMATIC DIAGRAMS ............................................................................. 44

WIRING DIAGRAMS .................................................................................. 48

TROUBLESHOOTING ..................................................................................... 53

TROUBLESHOOTING ................................................................................. 53

© VULCAN 2013

Page 3 of 54 F45474 (0413)

Page 4

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - GENERAL

GENERAL

INTRODUCTION

This service manual covers the specific service information related to the models listed in the chart below. The VK

and TR series gas fryers come equipped with solid state analog (A), solid state digital (D) or programmable computer

(C) controls. This manual covers single floor model fryers, battery fryers as well as fryers with the KleenScreen

PLUS® Filtration System. All pictures and illustrations will be of a 2VK45 unless otherwise noted.

All of the information, illustrations and specifications contained in this manual are based on the latest product

information available at the time of printing.

MODEL AND ML NUMBERS

MODEL ML # MODEL ML # MODEL ML #

1VK45A 136885 1VK45D 136886 1VK45C 136887

1VK65A 136888 1VK65D 136889 1VK65C 136890

1VK85A 136891 1VK85D 136892 1VK85C 136893

1VK45AF 136684 1VK45DF 136895 1VK45CF 136896

1VK65AF 136897 1VK65DF 136898 1VK65CF 136899

1VK85AF 136900 1VK85DF 136901 1VK85CF 136902

2VK45AF 136903 2VK45DF 136904 2VK45CF 136905

2VK65AF 136906 2VK65DF 136907 2VK65CF 136908

2VK85AF 136909 2VK85DF 136910 2VK85CF 136911

3VK45AF 136912 3VK45DF 136913 3VK45CF 136914

3VK65AF 136915 3VK65DF 136916 3VK65CF 136917

3VK85AF 136918 3VK85DF 136919 3VK85CF 136920

4VK45AF 136921 4VK45DF 136922 4VK45CF 136923

4VK65AF 136935 4VK65DF 136941 4VK65CF 136937

4VK85AF 136938 4VK85DF 136939 4VK85CF 136940

1TR45A 136946 3TR45CF 136959 3TR65CF 136972

1TR45AF 136947 4TR45CF 136960 1TR85A 136973

2TR45AF 136948 1TR65A 136961 1TR85AF 136974

3TR45AF 136949 1TR65AF 136962 2TR85AF 136975

4TR45AF 136950 2TR65AF 136963 3TR85AF 136976

1TR45D 136951 3TR65AF 136964 1TR85D 136977

1TR45DF 136952 1TR65D 136965 1TR85DF 136978

2TR45DF 136953 1TR65DF 136966 2TR85DF 136979

3TR45DF 136954 2TR65DF 136967 3TR85DF 136980

4TR45DF 136955 3TR65DF 136968 1TR85C 136981

F45474 (0413) Page 4 of 54

Page 5

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - GENERAL

MODEL ML # MODEL ML # MODEL ML #

1TR45C 136956 1TR65C 136969 1TR85CF 136982

1TR45CF 136957 1TR65CF 136970 2TR85CF 136983

2TR45CF 136958 2TR65CF 136971 3TR85CF 136984

4TR65AF 136985 4TR65DF 136986 4TR65CF 136987

4TR85AF 136988 4TR85DF 136989 4TR85CF 136990

MODELS, FEATURES AND OPTIONS

MODELS, FEATURES AND OPTIONS

FEATURES OPTIONS

MODEL

1VK/TR45A /D / C /

AF / DF / CF

1VK/TR65A / D / C

AF / DF / CF

1VK/TR85A / D / C /

AF / DF / CF

2VK/TR45AF / DF /

CF

3VK/TR45AF / DF /

CF

4VK/TR45AF / DF /

CF

2VK/TR65AF / DF /

CF

3VK/TR65AF / DF /

CF

4VK/TR65AF / DF /

CF

2VK/TR85AF / DF /

CF

3VKTR85AF / DF / CF 63.0" 85 - 90 90,000 SINGLE OR DUAL

4VK/TR85AF / DF /

CF

FRYER WIDTH

(INCHES)

15.5" 45 - 50 70,000 SINGLE OR DUAL

21.0" 65 - 70 80,000 SINGLE OR DUAL

21.0" 85 - 90 90,000 SINGLE OR DUAL

31.0" 45 - 50 70,000 SINGLE OR DUAL

46.5" 45 - 50 70,000 SINGLE OR DUAL

62.0" 45 - 50 70,000 SINGLE OR DUAL

42.0" 65 - 70 80,000 SINGLE OR DUAL

63.0" 65 - 70 80,000 SINGLE OR DUAL

84.0" 65 - 70 80,000 SINGLE OR DUAL

42.0" 85 - 90 90,000 SINGLE OR DUAL

84.0" 85 - 90 90,000 SINGLE OR DUAL

KLEENSCREEN PLUS FILTRATION

SYSTEM: (KSP)

The KleenScreen PLUS® filtration system is

integrated into the VK Series fryer battery. The filter is

housed in a pullout drawer assembly at the base of

SHORTENING

CAPACITY PER

FRYER (POUNDS)

the fryer. The filtering components in the drawer

include a stainless steel filter tank, a stainless steel

mesh filter screen with a stainless steel insert, a

suction tube and a knurled knob that holds the

assembly together. In addition, the KSP comes with a

second filtering system; a microfilteration fabric

envelope (3), a dedicated stainless steel insert and

stainless steel clip that holds the assembly together.

Page 5 of 54 F45474 (0413)

BTU/HR/SECTION

AUTOMATIC

BASKET LIFTS

Page 6

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - GENERAL

With the filter drawer closed, a self-sealing oil return

line provides the path to return the filtered shortening

back into the fry tank.

This system is designed to provide a through and easy

method to filter the shortening. Some of the benefits

include:

• Self-contained system eliminating the use of

external filter equipment

• Paperless filtering system

• Easy to clean and low maintenance

• Extends the life of the shortening

KSP fryer batteries are standard in single and up to a

maximum of a four fryer battery in most cases.

Batteries are made up of only fryers, no warming

stations.

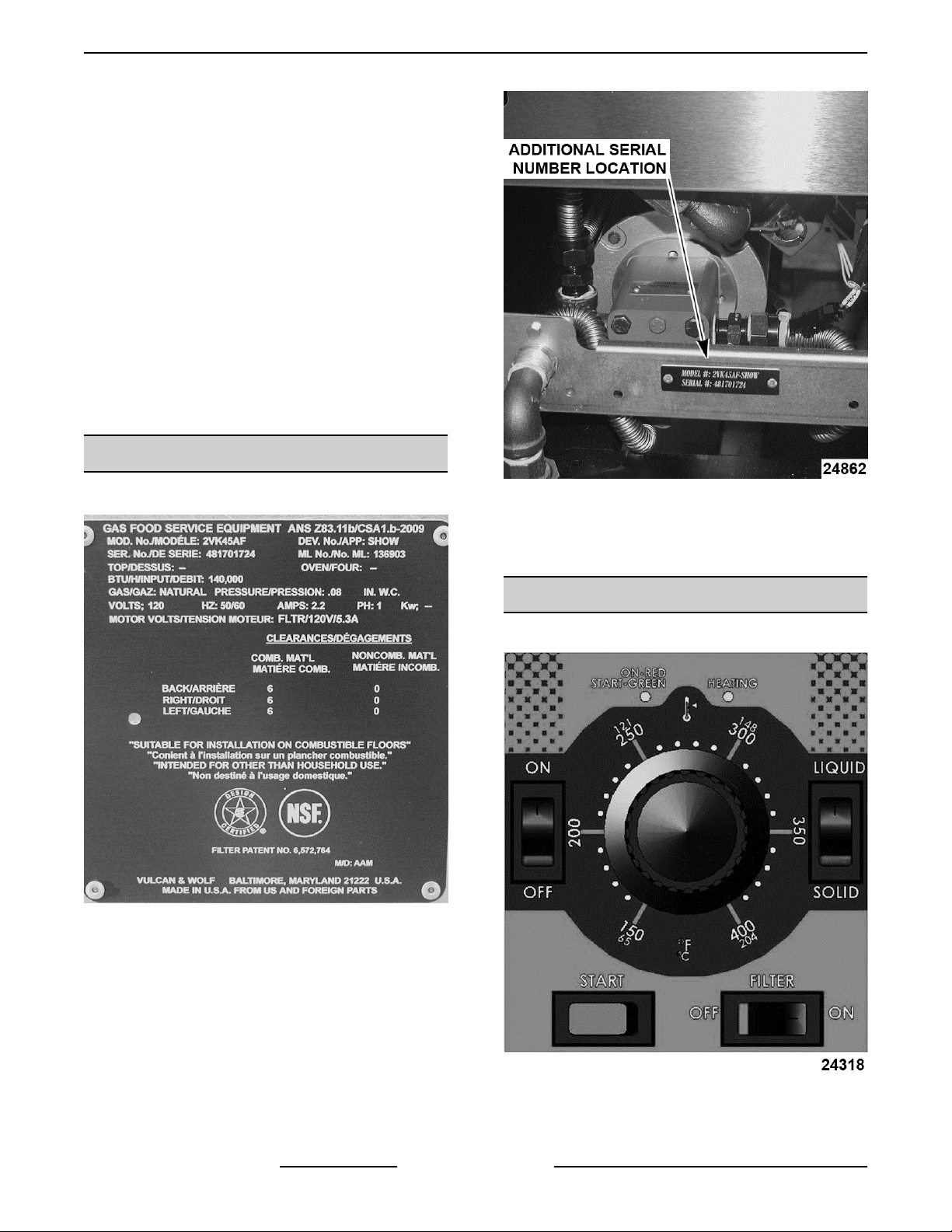

SERIAL NUMBER LOCATION

Serial number plate is attached to door of fryer.

Fig. 1

Fig. 2

This serial number plate is attached to bottom rear

support panel. This plate is pop riveted to support

panel and should not come off.

CONTROL PANELS

This serial number plate supplies more than the serial

number. It also contains electric requirements, gas

requirements, clearances and agency approvals. This

plate is pop riveted to the door and should not be

removed. However the door sometimes comes off and

can become misplaced. If that happens there is a

second serial number location on fryer.

F45474 (0413) Page 6 of 54

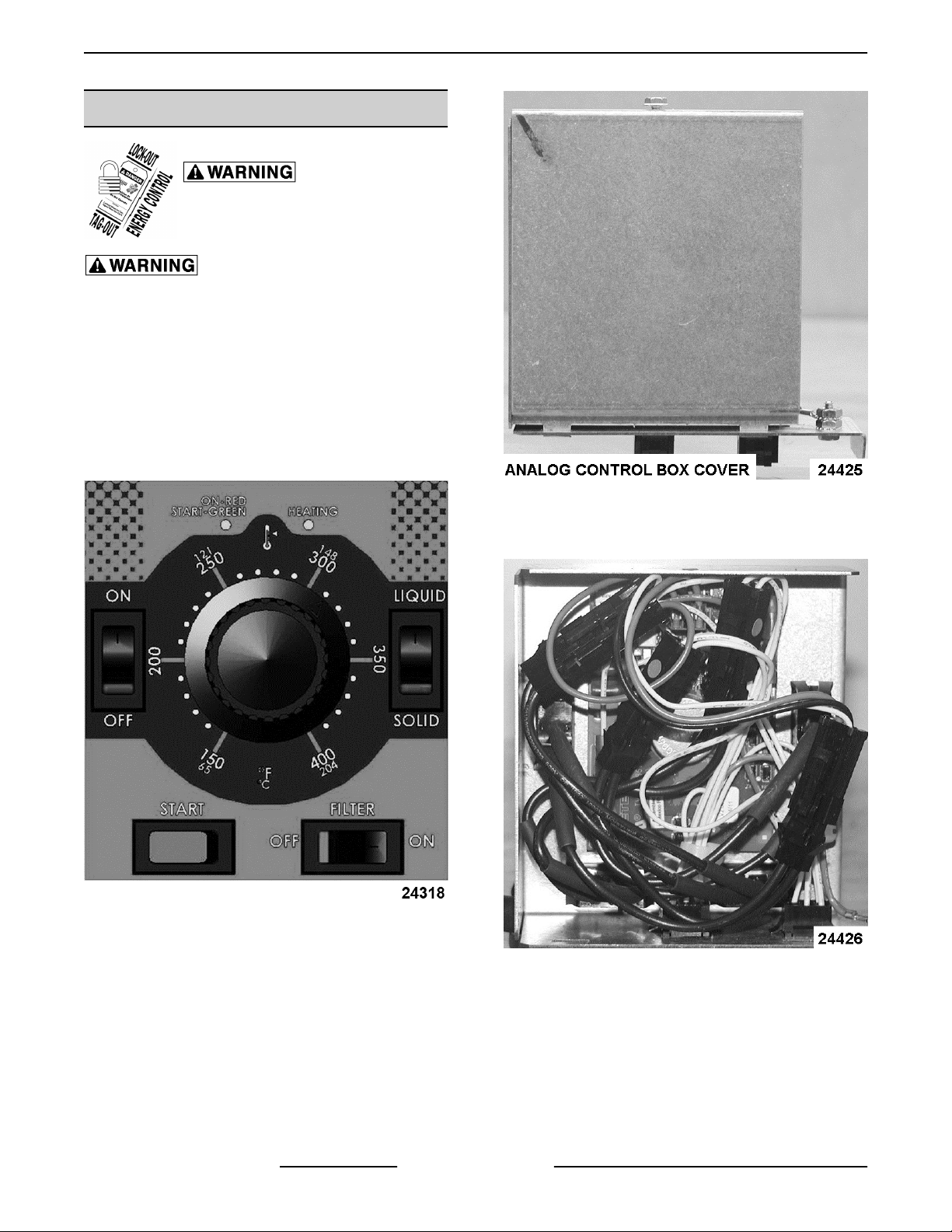

ANALOG CONTROL

Page 7

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - GENERAL

• VOM with A.C. current tester (any quality VOM

with a sensitivity of at least 20,000 ohms per volt

can be used).

SPECIAL

• Temperature tester (thermocouple type)

• Manometer.

• Combustion Analyzer

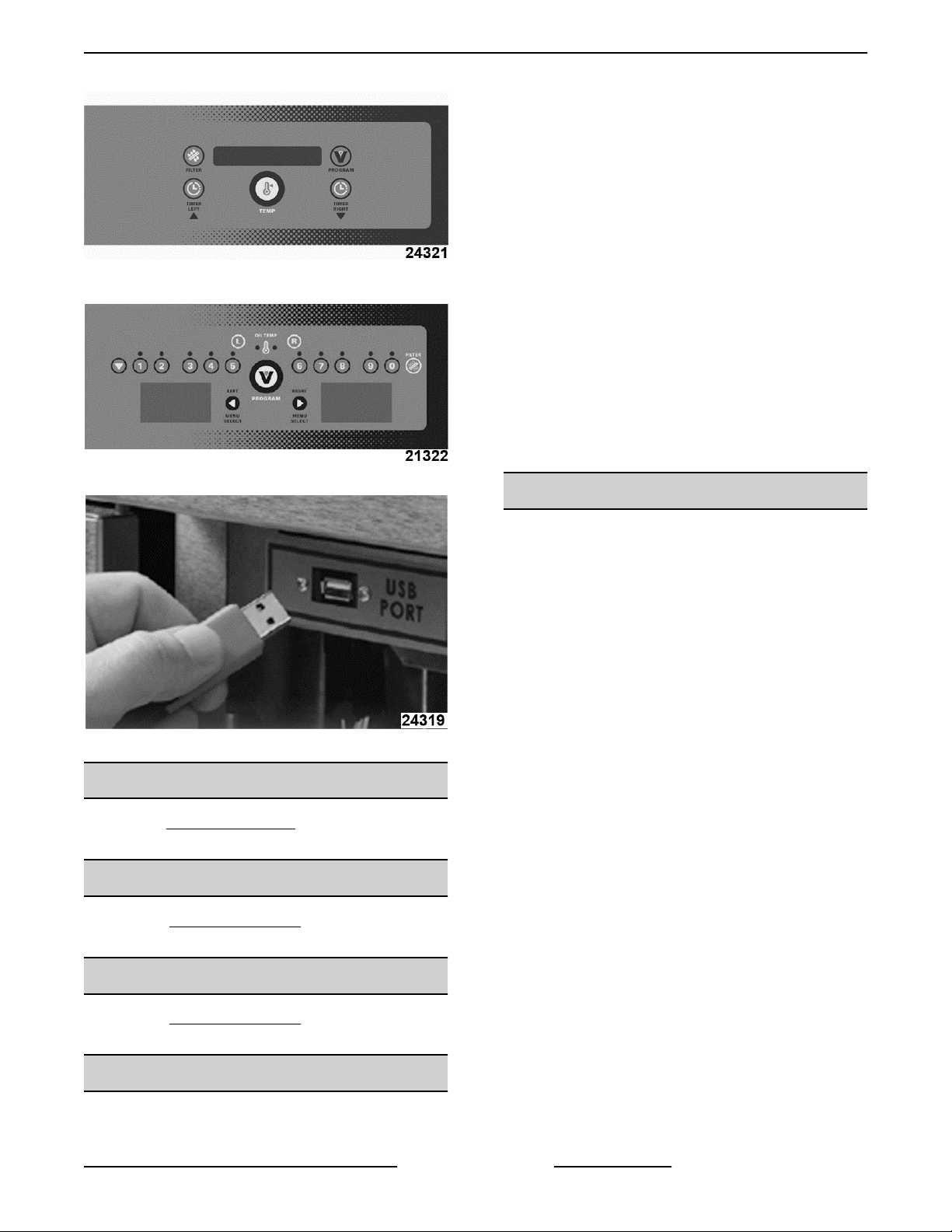

SOLID STATE CONTROL

COMPUTER CONTROL

• Set of Metric Hex Wrenches (must include a 2

mm wrench)

• Set of jewelers screwdrivers

• Field service grounding kit P/N TL- 84919.

• Burndy pin extraction tool RX2025 GE1; Newark

Electronics Catalog Number 16F6666. Used for

removing pin terminals on Burndy connectors.

• Thumb Drive (part number 443444) (Customer to

supply program for uploading menu items)

SPECIFICATIONS

ELECTRICAL:

• 120VAC supply.

• Filter motor/pump

• Basket lift motors

• Transformer

• 24VAC transformer

• Fryer controls

USB Port

INSTALLATION

Refer to the Instruction Manual for detailed installation

instructions.

OPERATION

Refer to the Instruction Manual for specific operating

instructions.

CLEANING

Refer to the Instruction Manual for specific cleaning

instructions.

TOOLS

STANDARD

• Standard set of hand tools.

Page 7 of 54 F45474 (0413)

• Basket lift relays

• Filter relay

MANIFOLD GAS PRESSURES (per fryer section)

• Natural - 0.08" W.C.

• Propane - 0.08" W.C.

BUILDING SUPPLY PRESSURE (MAX)

• Natural Single Fryer - 6" W.C.

Natural Battery Fryer - 8" W.C.

• Propane Single and Battery Fryers - 11" W.C.

NOTE: Natural and propane gases listed above are

maximum supply pressures. On fryers built before

12/1/12 a separate gas regulator must be used for

pressures exceeding maximum (not supplied with

Page 8

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - GENERAL

unit). On fryers built after 12/1/12 an incoming gas

pressure regulator is installed on the fryer.

VKINPUT BTU RATING

VK SERIES BTU/HR/SECTION

VK45A, VK45AF, VK45D,

VK45DF, VK45C,

VK45CF

VK65A, VK65AF, VK65D,

VK65DF, VK65C,

VK65CF

VK85A, VK85AF, VK85D,

VK85DF, VK85C,

VK85CF

TR INPUT BTU RATING

TR SERIES BTU/HR/SECTION

TR45A, TR45AF, TR45D,

TR45DF, TR45C,

TR45CF

TR65A, TR65AF, TR65D,

TR65DF, TR65C,

TR65CF

TR85A, TR85AF, TR85D,

TR85DF, TR85C,

VK85CF

70,000

80,000

90,000

70,000

80,000

90,000

F45474 (0413) Page 8 of 54

Page 9

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

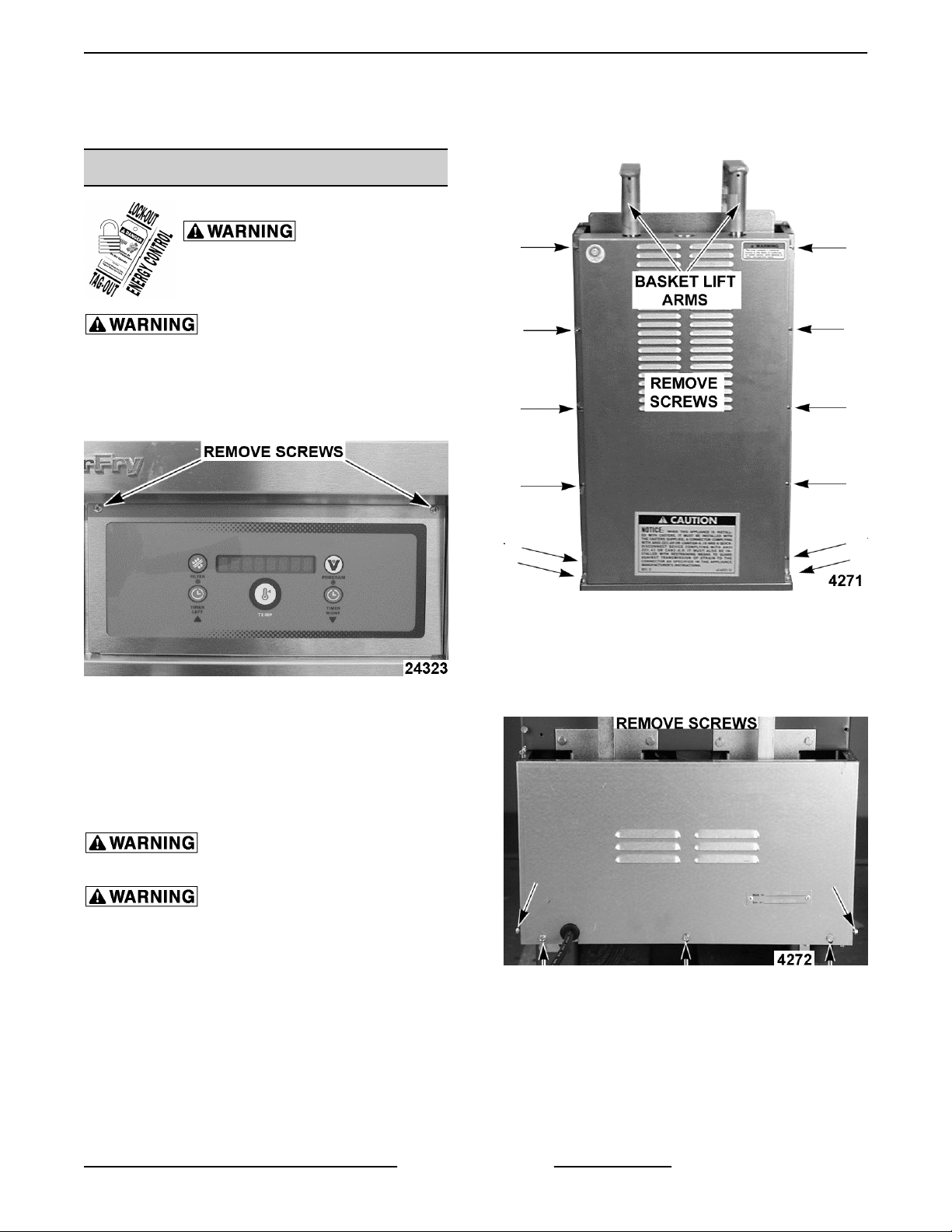

COVERS AND PANELS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

Control Panel (Solid State and Computer)

1. Remove screws at top of control panel and rotate

panel downwards.

Fig. 7

2. Disconnect wiring harness then lift panel off.

NOTE: The cooking control, control box, interface

board and wiring harness are now accessible.

3. Reverse procedure to install.

Basket Lift Covers

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

NOTE: This procedure applies to fryers with

automatic basket lift option only.

1. Remove basket assembly lift arms from support

rods.

Fig. 8

A. Lift upper cover over support rods and place

cover to the side.

3. Remove screws securing lower cover to motor

mounting base.

Fig. 9

4. Reverse procedure to install.

2. Remove screws securing upper cover to flue

wrap.

Page 9 of 54 F45474 (0413)

Page 10

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

ANALOG CONTROL

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

1. Open the door.

2. Unplug wiring harnesses from bottom of control

box.

3. Remove control box from frame of fryer.

4. Loosen set screw in control knob and remove

from shaft.

Fig. 11

Fig. 10

5. Remove control box cover.

6. Disconnect lead wires as necessary to remove

control.

Fig. 12

7. Remove screws from front of control panel and

F45474 (0413) Page 10 of 54

remove control.

Page 11

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

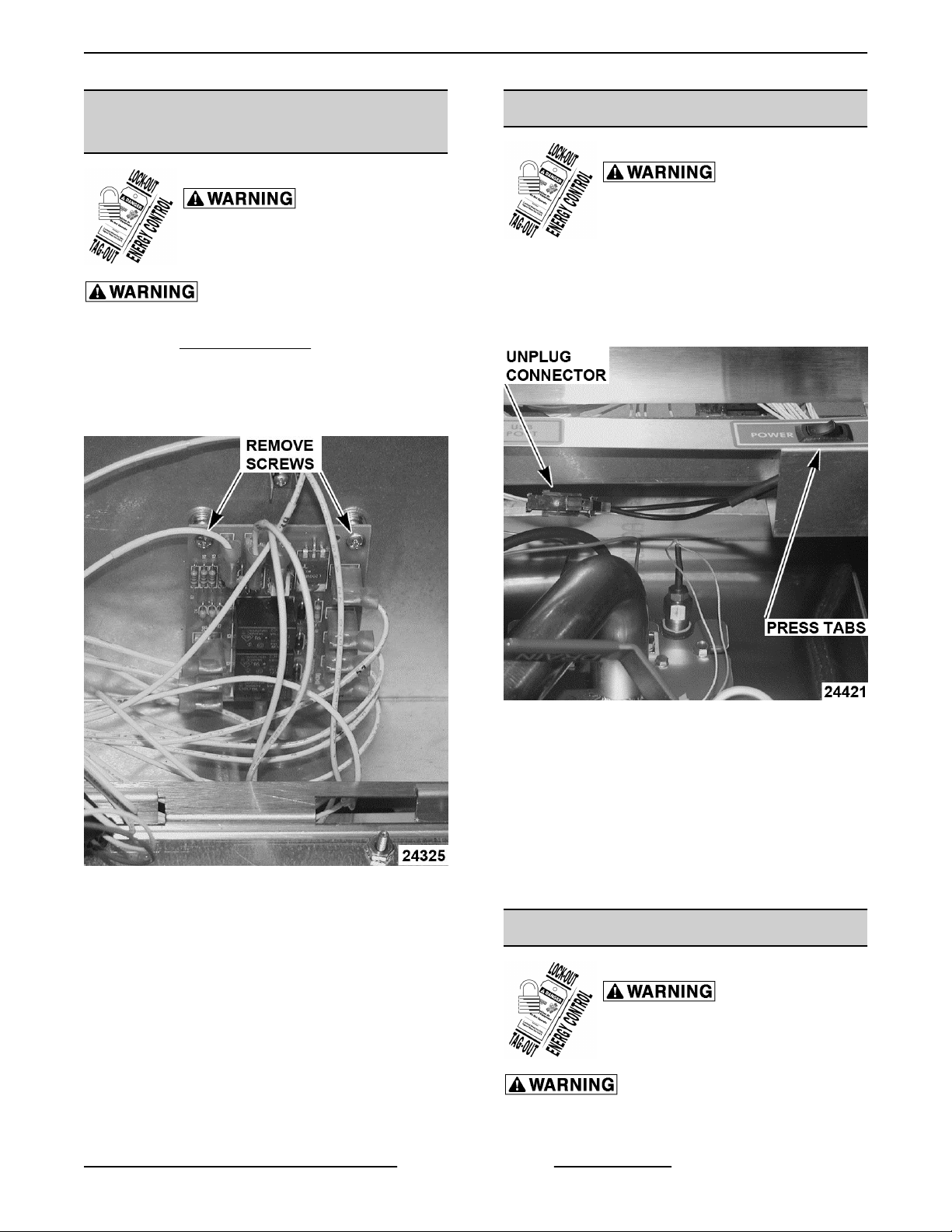

INTERFACE CONTROL - D and C

SERIES

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

1. Remove CONTROL PANEL.

2. Note lead wire locations and remove wiring.

3. Remove screws securing control to fryer and

remove.

POWER SWITCH - D and C SERIES

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

NOTE: This procedure is for solid state and computer

controls. Power switch for analog controls is part of the

analog control box.

1. Open fryer door to access power switch.

Fig. 13

4. Reverse procedure to install and check for proper

operation.

Fig. 14

2. Unplug power switch connector.

3. Reach behind power switch and press tabs on

both sides of power switch to remove switch.

NOTE: Power switch is removed from front of the

panel.

4. Reverse procedure to install new power switch.

5. Check operation of machine.

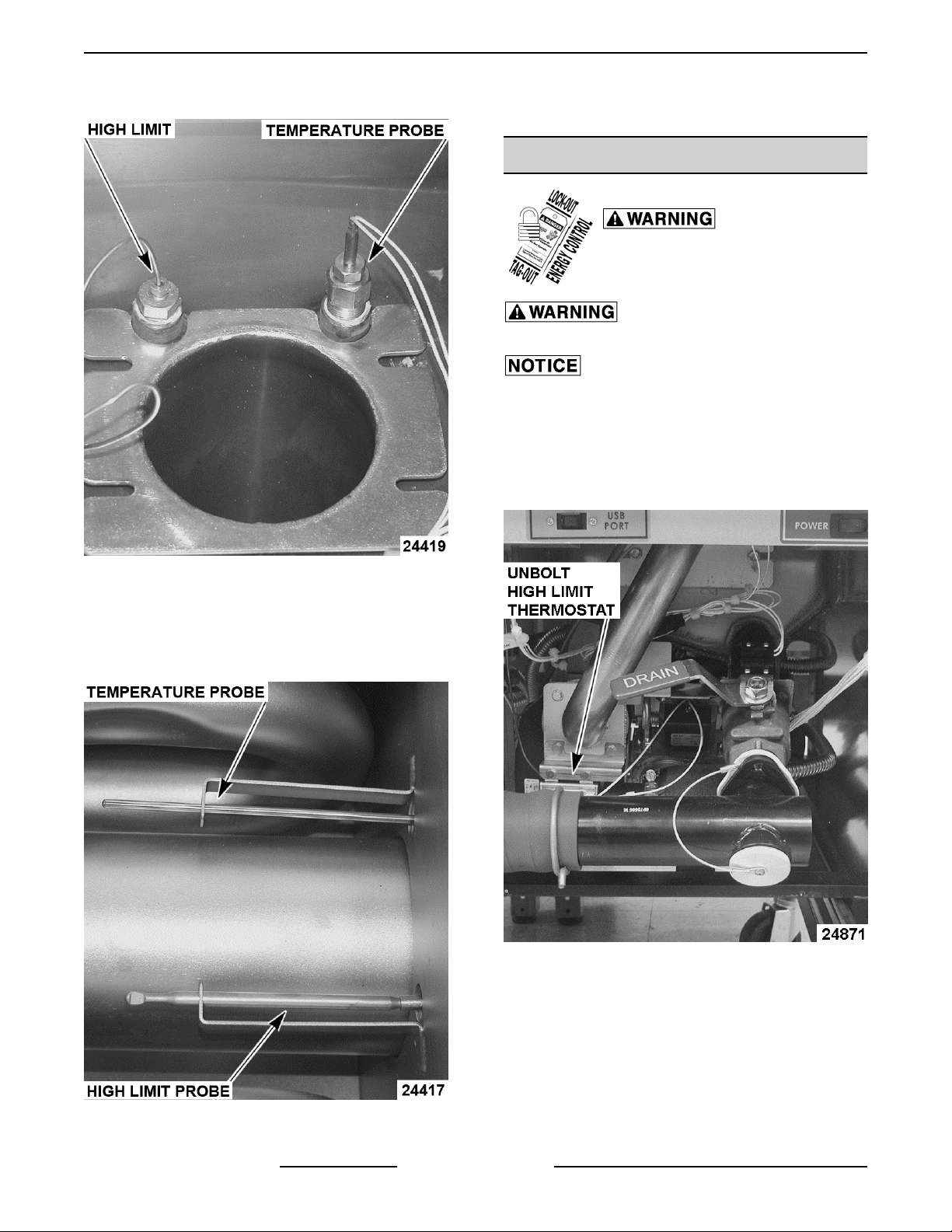

TEMPERATURE PROBE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

1. Drain shortening from fryer tank.

Page 11 of 54 F45474 (0413)

Page 12

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

2. Unplug temperature probe lead wire connector.

4. Install new probe making sure that probe is

installed into bracket shown.

HIGH LIMIT THERMOSTAT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

Do not sharply bend or kink the high limit

capillary tube or damage may occur.

1. Drain shortening from fryer tank.

2. Disconnect lead wires from high limit thermostat.

3. Remove screws securing high limit to mounting

bracket.

Fig. 15

NOTE: This picture shows the probes with the burner

removed.

3. Loosen compression nut and remove probe from

fryer.

Fig. 17

4. Remove the capillary tube retaining and packing

nuts.

Fig. 16

F45474 (0413) Page 12 of 54

Page 13

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

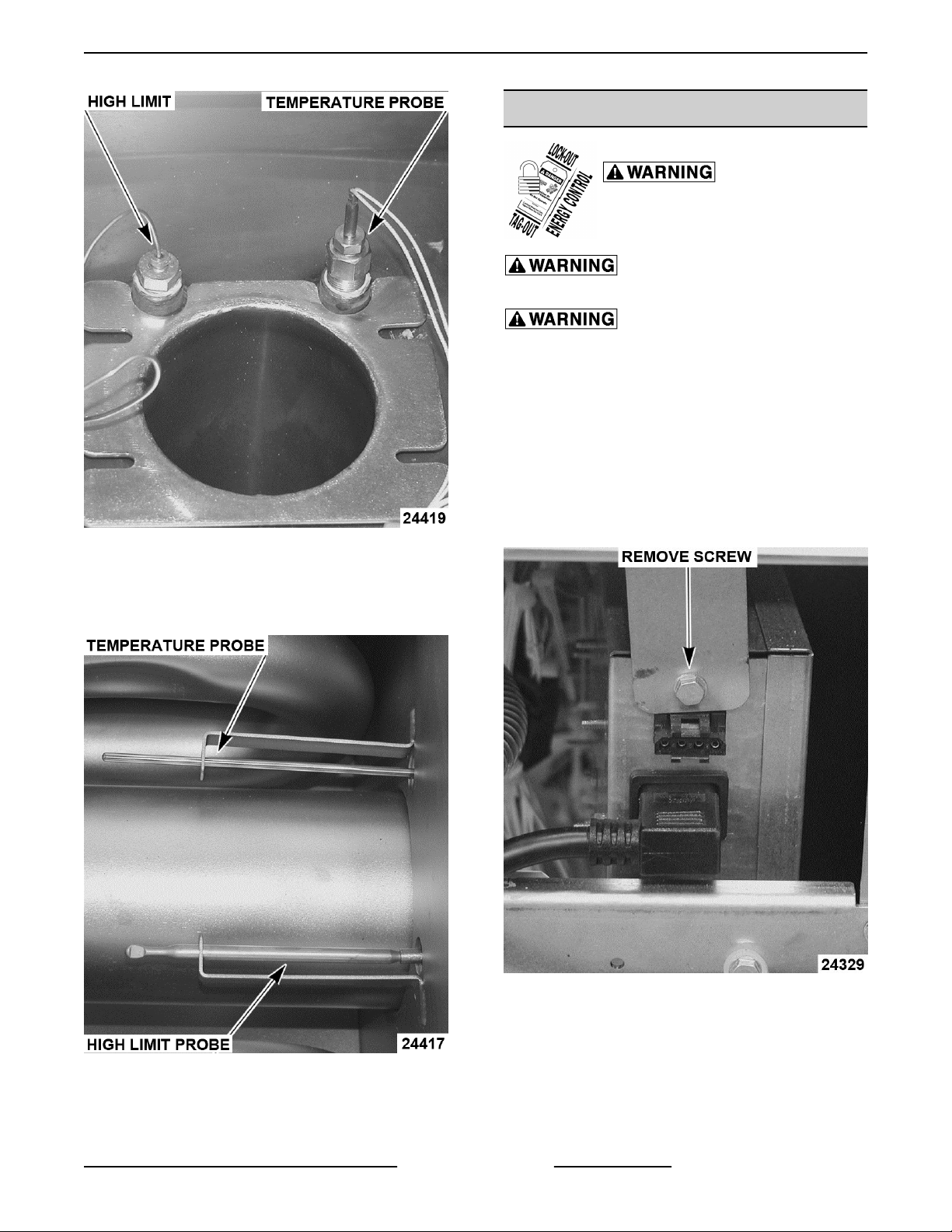

POWER SUPPLY BOX

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

NOTE: The power supply box must be removed to

access the following components: ignition module, all

24 volt relays, blower control board, both time delay

timers, 120 volt transformer.

1. Access rear of fryer and remove screw holding

power supply box to support bracket. The box will

Fig. 18

lower to clear bracket.

NOTE: This picture shows the probes with the burner

removed.

5. Slide high limit probe out of fry tank.

Fig. 19

Fig. 20

2. Access front of fryer to slide power supply box

toward rear of fryer to disconnect from front

support bracket.

6. Reverse procedure to install and check for proper

operation.

Page 13 of 54 F45474 (0413)

Page 14

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 23

5. Reverse procedure to install.

POWER SUPPLY BOX

COMPONENTS BEFORE 12/1/12

Fig. 21

3. Unplug all connecters from power supply box and

remove box from under fryer.

4. Remove cover to access power supply box

components.

NOTE: The ignition module, blower control board and

the time delay timers will not be available to the field

any longer. If any one of these items fail, replace

power supply box. However, the filter relays and the

transformer are still available and can be replaced in

the field.

Ignition Module

Replace with updated Power Supply Box Assembly.

Blower Control Board

Replace with updated Power Supply Box Assembly.

Time Delay Timers

Replace with updated Power Supply Box Assembly.

Blower Relay

Replace with updated Power Supply Box Assembly.

Filter Relays (24 VAC and 120 VAC)

1. Remove POWER SUPPLY BOX.

2. Note location of all wiring to the relay and remove

wiring.

3. Remove screw and remove relay from box.

Fig. 22

F45474 (0413) Page 14 of 54

Page 15

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 24

4. Reverse procedure to install new relay.

5. Reinstall power supply box and check operation.

120 Volt Transformer

1. Remove POWER SUPPLY BOX.

2. Note location of wiring on 120 volt transformer

and remove wiring.

3. Remove screws and remove transformer from

the box.

Fig. 25

4. Reverse procedure to install new transformer.

5. Reinstall power supply box and check operation.

POWER SUPPLY BOX

COMPONENTS AFTER 12/1/12

NOTE: Power supply boxes built after 12/1/12 have

different components in them. The 24 volt electronic

ignition relay, blower control board, ignition module

and both time delay relays are replaced by a single

control board.

NOTE: The new ignition module will not have a

separate flame sense rod and wire. Ignition module

will rectify flame through high voltage wire.

120 Volt Transformer

1. Remove POWER SUPPLY BOX.

2. Note location of all wiring and remove wiring from

transformer.

3. Remove four screws and remove transformer

from box.

Page 15 of 54 F45474 (0413)

Page 16

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

5. Reinstall power supply box and check operation.

Filter Relays

1. Remove POWER SUPPLY BOX.

2. Note location of wiring to the relays and remove

wiring.

Fig. 26

4. Reverse the procedure to install new

transformer.

5. Reinstall power supply box and check operation.

Control Board

1. Remove POWER SUPPLY BOX.

2. Note location of wiring to relay control board and

remove wiring.

Fig. 28

3. Remove screws and remove from box.

4. Reverse the procedure to install new relays.

5. Reinstall power supply box and check operation.

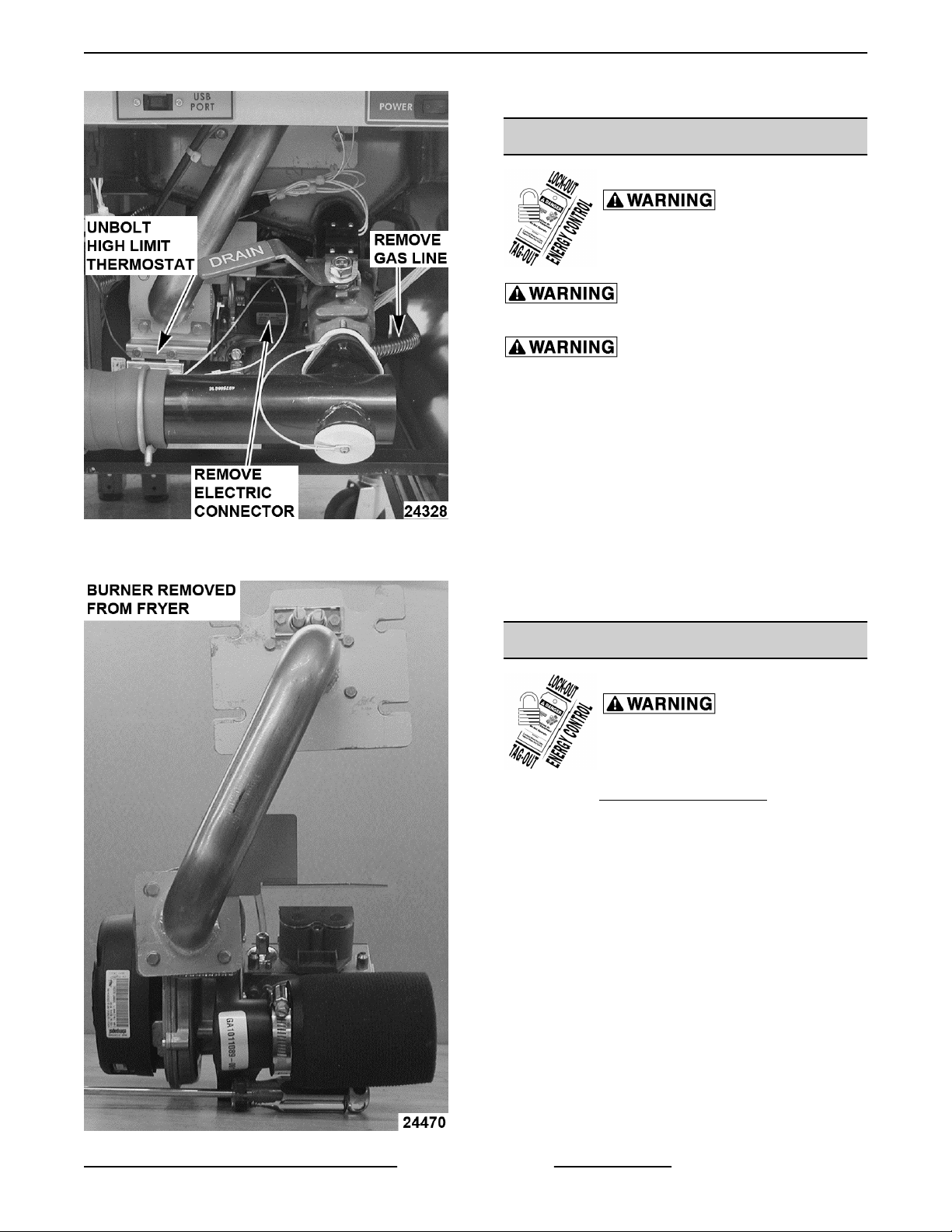

BURNER ASSEMBLY

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove gas line from gas valve.

2. Remove electric plug connector from gas valve.

3. Unbolt high limit thermostat clamp from transfer

Fig. 27

3. Remove screws and remove from box.

4. Reverse the procedure to install new relay

control board.

F45474 (0413) Page 16 of 54

tube.

Page 17

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

5. Reverse procedure to reinstall burner.

GAS VALVE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

The gas valve is considered part of the burner

assembly. If the gas valve fails and needs to be

replaced, you must order a complete blower/gas valve

assembly (burner). The reason for this is every blower/

gas valve assembly (burner) is set up at the factory to

Fig. 29

4. Remove bolts and remove burner from fryer.

operate at the most efficient level possible. This set up

procedure cannot be duplicated in the field. If you feel

that the gas valve is not set up correctly or not

operating correctly, call product service and they will

help solve the problem.

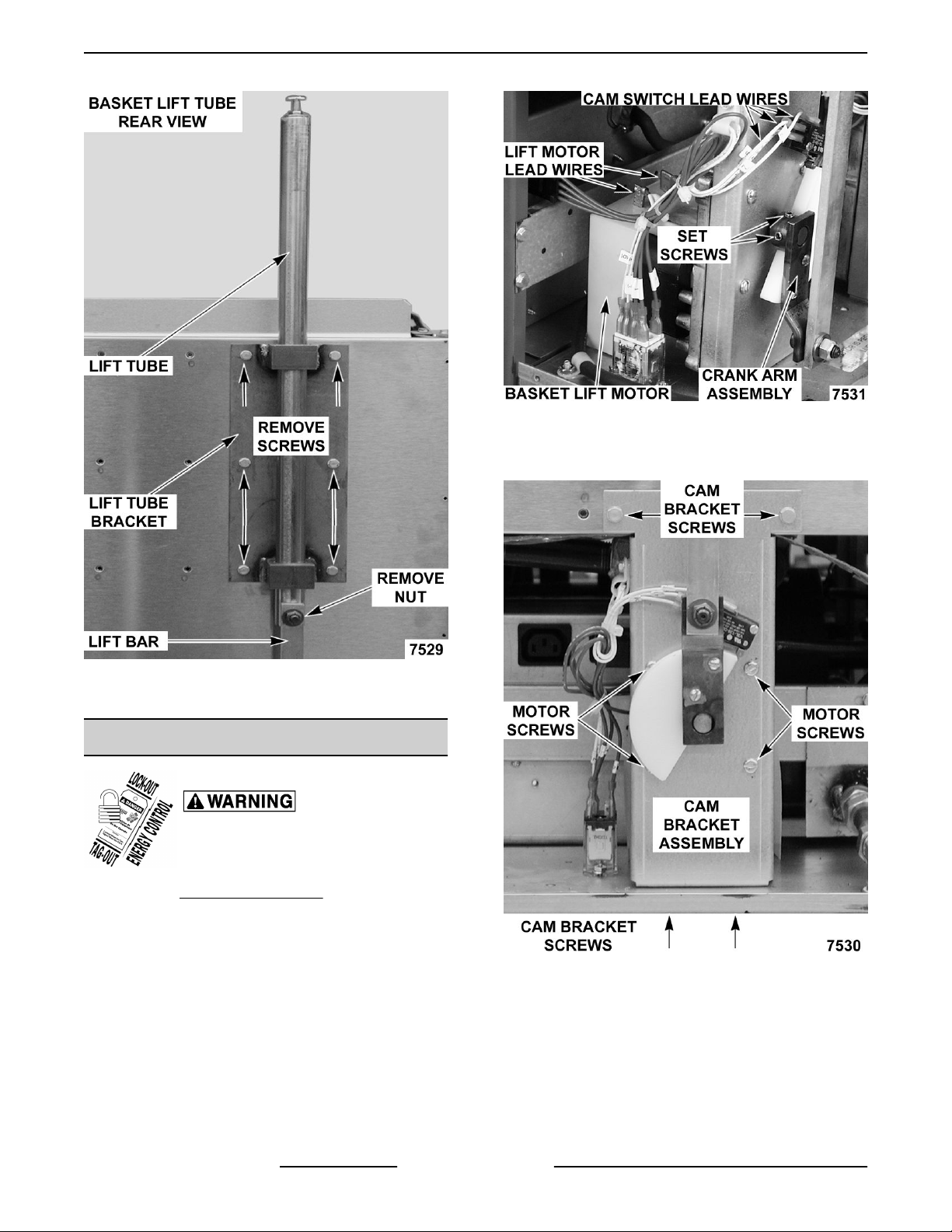

BASKET LIFT TUBE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove

2. Remove nut securing lift bar to lift tube.

3. Remove screws securing lift tube bracket to fryer

then remove bracket and lift tube.

BASKET LIFT COVERS.

Fig. 30

Page 17 of 54 F45474 (0413)

Page 18

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 32

4. Remove screws securing basket lift motor to cam

bracket, then remove motor from bracket.

Fig. 31

4. Reverse procedure to install.

BASKET LIFT MOTOR

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove

2. Disconnect lead wires from cam switch and

basket lift motor.

3. Loosen set screws securing crank arm assembly

to basket lift motor shaft.

BASKET LIFT TUBE.

Fig. 33

5. Reverse procedure to install and check for proper

operation.

NOTE: After reinstalling motor keep all wire leads

clear from moving parts.

F45474 (0413) Page 18 of 54

Page 19

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

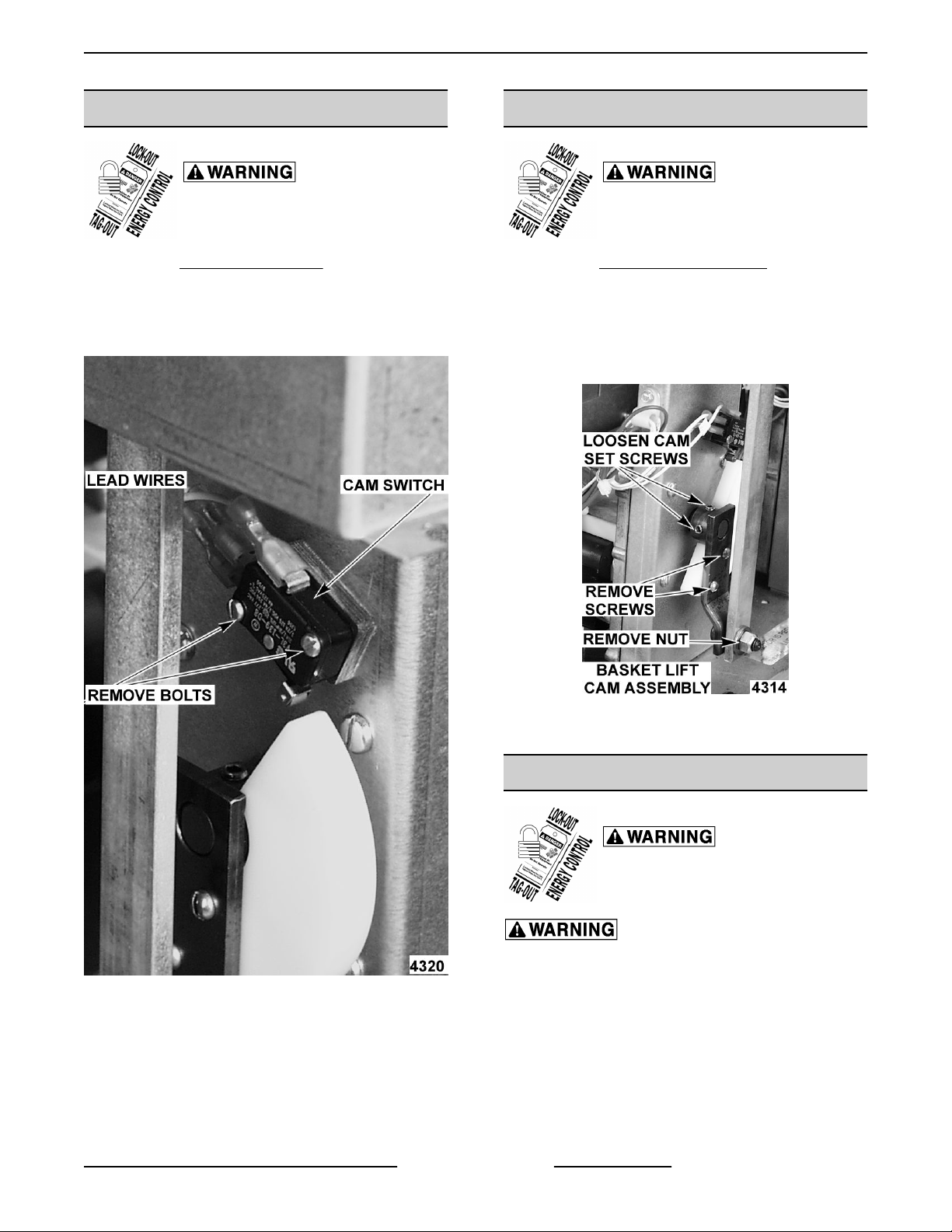

BASKET LIFT CAM SWITCH

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove BASKET LIFT TUBE.

2. Disconnect lead wires from cam switch.

3. Remove screws securing cam switch to cam

bracket.

BASKET LIFT CAM

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove BASKET LIFT COVERS.

2. Remove nut securing lift bar to cam assembly.

3. Loosen cam set screw.

4. Remove screws securing cam to the crank arm

assembly.

Fig. 34

4. Reverse procedure to install.

Fig. 35

5. Reverse procedure to install.

FILL SOLENOID VALVE (KSP)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

1. Remove filter tank from fryer.

2. Access fill solenoid valve.

3. Loosen union at rear of valve,

4. Remove bolts securing valve and remove valve

from the fryer.

Page 19 of 54 F45474 (0413)

Page 20

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 37

Fig. 36

5. Reverse procedure to reinstall valve.

FILTER HOSE SWITCH (KSP)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Open fryer door to access filter hose switch.

2. Unplug lead wire connections.

3. Press tabs on rear of switch and push out front of

fry cabinet.

4. Reverse procedure to install new switch.

FILTER PUMP AND MOTOR

(KLEENSCREEN FRYERS ONLY)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Access rear of fryer.

2. Remove four bolts holding serial plate bracket,

and carefully lower bracket.

3. Disconnect both hoses from filter pump.

F45474 (0413) Page 20 of 54

Page 21

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 38

4. Disconnect electric connections to filter pump

motor.

5. Unbolt filter pump motor from fryer frame.

6. Carefully remove filter pump assembly through

rear of fryer.

7. Reverse procedure to reinstall filter pump

assembly.

DRAIN VALVE INTERLOCK

SWITCH (DVI)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

1. Open fryer section door.

2. Locate drain valve switch

3. Remove nut holding drain valve handle and

remove handle.

Fig. 39

NOTE: Make sure drain handle is in closed position.

If fry tank is full of shortening, carefully remove drain

handle. Make sure you do not turn handle to open

position. Doing so will allow shortening to drain on

floor or you.

4. Remove drain valve interlock switch bracket from

valve.

5. Remove screws holding the drain valve interlock

switch on bracket and take switch from bracket.

Page 21 of 54 F45474 (0413)

Page 22

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

A. Remove hose clamp from rubber boot.

B. Remove drain piping from drain valve.

Fig. 40

6. Unplug drain valve interlock switch from wiring

harness and remove switch from fryer.

7. Reverse procedure to install and check for proper

operation.

FRY TANK

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

Fig. 41

5. Remove drain valve from fry tank.

1. Remove BURNER ASSEMBLY.

2. Remove both HIGH LIMIT THERMOSTAT and

TEMPERATURE [ROBE.

3. Remove DRAIN VALVE INTERLOCK SWITCH.

4. Remove drain assembly from drain valve.

F45474 (0413) Page 22 of 54

6. Loosen and disconnect the oil return line, if

Fig. 42

equipped with filter system.

Page 23

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 45

A. Cover plate is glued to tank and will have to

be pried off.

Fig. 43

7. Remove fry tank bolt down bracket.

Fig. 44

8. Remove fry tank cover plate.

B. Order a replacement plate prior to replacing

fry tank.

9. If basket lifts are installed, they will have to be

removed from rear of tank.

10. Remove tank from fryer.

Fig. 46

11. Reverse order of this procedure to install new fry

tank.

Page 23 of 54 F45474 (0413)

Page 24

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

Certain procedures in this section require electrical test or measurements while

power is applied to the machine. Exercise extreme caution at all times. If test points are not easily

accessible, disconnect power and follow lockout / tagout procedures, attach test equipment and

reapply power to test.

ELECTRIC CONNECTIONS

The VK series fryers are supplied with a 120Volt cord

and three prong plug. If local electrical codes require

that these fryers be plugged into a Ground Fault

Interrupter or GFI. You must use GFI part number

913053. Other GFI outlets may not have the correct

tolerance for the spark to ground ignition system

employed with the VK series fryers.

HARMONIC TONE

Harmonic Tone (hum) at First Start

At first start, fryer will begin heating in low fire. There

will be a harmonic tone that is NORMAL to hear. As

fryer continues to heat, harmonic tone will dissipate

and become less noticeable. When fryer reaches

135°F (end of melt cycle), fryer will heat on high fire

and blower speed will increase.

TEMPERATURE PROBE FAULT

CODES

CONTROL TYPE FAULT

An open will display PROBE

COMPUTER

OPEN and a short or high

temperature condition will

display PROBE SHORT.

TEMPERATURE PROBE TEST

To Check:

1. Turn power switch off.

2. Disconnect the temperature probe plug behind

the burner.

The temperature probe is used for both the solid state

control and the computer control. The probe is an RTD

(resistance temperature detector) of the thermistor

type. As temperature increases the resistance value

decreases.

Probe Fault

If a temperature probe fault or high temperature

condition occurs, a fault message will be displayed

and the electronic alarm will sound continuously. The

heat demand and basket lift outputs are de-activated.

If a cooking cycle is in process (timer active), it will be

cancelled and the key pad disabled.

This will continue until the fault clears, power is cycled

or problem resolved.

CONTROL TYPE FAULT

An open will display Prob and

SOLID STATE

F45474 (0413) Page 24 of 54

a short or high temperature

condition will display HI.

3. Test the probe using a VOM to measure

Fig. 47

resistance. Connect the meter leads to the wires

removed in step 2.

A. If the measured resistance values are within

the allowable range, the probe is functioning

properly. Reverse procedure to install.

Page 25

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

B. If the measured resistance values are

outside the allowable range, install a

replacement probe and check for proper

operation.

TEMPERATURE (°F) RESISTANCE (Ω)

77 90,000 - 110,000

350 604 - 836

1

415

2

460

1

High temperature alarm level for the cooking

controls

2

Shorted probe equivalent temperature

302 - 369

191 - 233

COOKING CONTROL

CALIBRATION

NOTE: Verify condition of temperature probe as

outlined under TEMPERATURE PROBE TEST

before proceeding.

1. Check the level of shortening in fry tank. The level

must be between the MIN & MAX fill lines before

proceeding.

2. Allow shortening to cool below 300°F.

3. Place a thermocouple in the geometric center of

the fry tank one inch below the shortening

surface.

4. Set the cooking control to 350°F and turn the fryer

on.

5. Monitor the heat indicator lamp. When cooking

control is calling for heat, lamp will be on. If

cooking control is satisfied, lamp will be off.

Analog Control - Heat light is to right of zero on

temperature scale.

Solid State Control - Decimal point of first

character indicates heat on when lit.

Computer Control - Two LED lamps on the Oil

Temp key that indicate heat on.

NOTE: Agitate the shortening, to eliminate any cold

zones.

A. Allow cooking control to cycle three times to

stabilize shortening temperature.

6. Calculate the average temperature by adding the

temperature reading when the heat lamp goes

out to the temperature reading when the heat

lamp comes on & divide this answer by 2.

[ Temp. (Lamp off) + Temp. (lamp on) ] ÷ 2 =

Average Temp. Example: 360° + 340° ÷ 2 =

350°F.

The average temperature should be 350°F (±

5°F).

A. If the average temperature reading is within

tolerance, cooking control is properly

calibrated.

B. If the average temperature reading is out of

tolerance, perform the following:

1) Analog Control - Remove knob and

turn adjustment screw

counterclockwise to increase

temperature and clockwise to

decrease temperature.

2) Solid State Control - Adjust OFFSET

TEMPERATURE.

3) Computer Control - Adjust OFFSET

TEMPERATURE.

7. Repeat the average temperature calculation for

up to three attempts. Allow the cooking control to

cycle at least two times between adjustments

before performing the calculation.

8. If calibration is unsuccessful, the cooking control

may be malfunctioning and cannot be adjusted

properly. Install a replacement cooking control

and check calibration.

FLAME SENSE CURRENT CHECK

PRIOR TO 12/1/12

Certain procedures in this section

require electrical test or measurements while power is

applied to the machine. Exercise extreme caution at

all times. If test points are not easily accessible,

disconnect power and follow lockout / tagout

procedures, attach test equipment and reapply power

to the test.

1. Remove cover of power supply box.

2. Locate red flame sense wire.

B. Record meter reading from thermocouple

when the cooking control cycles off and on

for at least two complete heating cycles.

Page 25 of 54 F45474 (0413)

Page 26

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

2. Locate two pins (FC- and FC+) on side of the

ignition/ blower control board.

Fig. 48

3. Remove the red flame sense wire.

4. Place one Microamp meter lead on the red wire.

5. Place the other meter lead on the terminal you

removed the red flame sense wire from.

6. Power up the fryer and have it call for heat.

7. You should receive a minimum Microamp

reading of at least 1.0 microamp.

8. If the reading is greater or equal to the value

given, then the flame sense current is within

tolerance.

9. If the reading is lower than the value given, then

troubleshoot the flame sense circuit.

NOTE: If the reading is below 0.0 microamps, reverse

the meter leads and take another reading.

FLAME SENSE CURRENT CHECK

AFTER 12/1/12

Certain procedures in this section

require electrical test or measurements while power is

applied to the machine. Exercise extreme caution at

all times. If test points are not easily accessible,

disconnect power and follow lockout / tagout

procedures, attach test equipment and reapply power

to the test.

1. Remove cover from power supply box.

Fig. 49

3. Set your multi meter for Microamps and place

meter leads on two pins.

4. Restart the fryer and read the microamps as the

fryer is sparking.

NOTE: The only time you will be able to read the

microamps is when the fryer is sparking. When the

spark quits the reading will go away. You may only

have several seconds to obtain this reading.

5. The flame sense current must be at least 2.0 to

3.0 microamps, and the reading must be steady.

6. If reading is below 1.3 microamp or unsteady,

check pilot flame and electrical connections.

ELECTRONIC IGNITION CONTROL

NOTE: This procedure applies to all fryers.

Ignition Module Lockout

This happens when fryer is unable to detect flame

sense. The electrode will try to ignite one time. When

F45474 (0413) Page 26 of 54

Page 27

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

flame has not been detected within 5 seconds red light

on ignition module will blink.

Fig. 50

"A" style controller: Red light will blink and blower will

continue to run until power has been turned off.

"C" and "D" style controllers: Red light will continue to

blink, but blower will shut down after a number of

seconds and a loud "beep" will continue to sound until

fryer is powered down.

Electronic Ignition System

MODULATING GAS VALVE

ADJUSTMENTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

The modulating gas valve is adjusted at the factory

and requires no adjustments. If the modulating gas

valve needs to be replaced, the new gas valve from

the parts depot will be adjusted property and will only

need to have the gas pressure verified coming into the

gas valve.

All fryers built after 12/1/12 will have gas regulators

installed on the incoming gas line. The gas pressure

on the new gas vales will not have to be checked.

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times. If test points are not

easily accessible, disconnect power

and follow lockout / tagout procedures,

attach test equipment and reapply

power to test.

1. Access burner electrode.

2. Remove ignition wire from burner electrode.

3. Fasten metal end of ignition wire about ¼ away

from a grounded metal surface on fryer.

4. Try to light the burner.

5. You should be able to see a spark. If no spark,

check ignition module in power supply box.

BASKET LIFT ARM ADJUSTMENT

1. With shortening at room temperature, verify the

shortening level is between MIN & MAX lines in

fry tank. Add shortening as needed.

NOTE: Shortening will expand when heated. Do not

fill the fry tank past the MAX line.

2. Turn power switch on and set temperature to

350°F. Allow the shortening to reach set

temperature.

3. Check basket lift operation.

A. If necessary, adjust as outlined below.

4. When basket is in the up position, the bottom of

the basket should be out of the shortening. When

basket is in the down position, the bottom of the

basket should clear the crumb screen and the

product should be submerged.

A. To adjust, remove basket arm from lift shaft,

loosen stop nut and turn height adjustment

bolt to raise or lower basket arm as required.

Both baskets should be same height.

B. Tighten stop nut when complete.

NOTE: If adjustment is to low, when the basket is

lowered, it will disengage from basket arm

Page 27 of 54 F45474 (0413)

Page 28

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

Error Messages

Refer to ALARM MESSAGES at end of section.

Enter Service Mode

NOTE: Control heat demand output signal is off and

heat/ignition status input signal is ignored.

1. Cycle power switch. When the program version

number is displayed, press PROGRAM key to

enter Service Mode.

A. Beeper chirps on each successful keypress.

2. To scroll through each of the program items,

press PROGRAM key and release.

A. To reset all service mode program items to

factory default, press and hold TEMP key for

2 seconds.

3. To exit Service Mode and save selections, press

PROGRAM key and hold for 1 second. Fryer

returns to normal operation and display shows

Fig. 51

the current heating mode based on shortening

temperature:

SOLID STATE CONTROL

• MELT L (liquid; default) or Melt S (solid) if

Operation

Use service information in this section when servicing

a fryer with a solid state control. Refer to instruction

manual for specific operating instructions.

NOTE: In operator programming mode, control can

be reset to it's default values by pressing the TEMP

key for 2 seconds.

shortening temperature is below 135°F.

• HEATING if no melt is selected and

shortening temperature is below set point.

• Fryer set point temperature if actual

shortening temperature is within set point

range.

Service Programming

Solid state control Service Mode is used to perform

system diagnostic tests or edit programs that affect

the fryers operation.

Control Programming

PROGRAM

ITEM

KEY SEQUENCE

DISPLAY

1

Brand Name Press left or right basket to select display name. Hobart or Vulcan

Temperature

Display Mode

Press left or right basket to select temperature unit of measure. DEG F OR C

Press left or right basket to select fryer type.

Boil or Filter

Function

Boil key overlay = stand alone fryer.

BOIL OR FILTER

Filter key overlay = filtering system fryer batteries.

ELECTRIC or

GAS or Gas*

(Star)

OFS 00F (always

in °F)

Fryer Type

Calibration

Offset

Press left or right basket to select fryer energy source (electric or gas heat)

Gas Star must be selected for VK and TR Fryers

4

Press left basket to increase or right basket to decrease offset temperature

(range -20 to 20)

2

F45474 (0413) Page 28 of 54

Page 29

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

Control Programming

PROGRAM

ITEM

KEY SEQUENCE

DISPLAY

1

Press left basket to increase or right basket to decrease cooking cycle lockout

Low Cook

Temp Lockout

temperature (range 30 to 50F)

NOTE: Prevents cook timers from starting if actual shortening temperature is

2

LOCKO 40

(always in °F)

not within the lockout temperature setting.

NOTE: The program items listed below are for verifying settings only. Do not change the default setting for these

program items.

PROGRAM

ITEM

KEY SEQUENCE

DISPLAY

1

Press left basket to increase or right basket to decrease instant on time.

Instant On

Time (heat)

NOTE: At the start of a cook cycle, the heat output will be activated for this time

INSTO 20

(range 0 to 20 seconds).

Press left basket to increase or right basket to decrease melt cycle time.

3

MLTG

1 16

(Liq)

(Melt

ON)

Gas Fryers

08

(Sol)

Adjustment Range:

MLTG

Melt ON - 0 to 20 seconds; Melt OFF - 0 to 30 seconds.

0 18

(Liq)

(Melt

OFF)

Melt Cycle On/

Off Times

26

(Sol)

MLTE

1 04

(Liq)

(Melt

ON)

Electric Fryers

02

(Sol)

Adjustment Range:

MLTE

Melt ON - 0 to 2 seconds; Melt OFF - 10 to 30 seconds.

0 11

(liq)

(Melt

OFF)

13

(Sol)

Proportional

Offset

Proportional

Gain

Derivative Gain

Integral Gain

Integral Limit

Press left basket to increase or press right basket to decrease proportional

offset (range 0 to 30).

Press left basket to increase or right basket to decrease proportional gain

(range 0 to 30).

Press left basket to increase or right basket to decrease derivative gain (range

0 to 30).

press left basket to increase or right basket to decrease integral gain (range 0

to 30).

Press left basket to increase or right basket to decrease integral limit (range 0

to 255).

POFST 02

PGAIN 24

DGAIN 20

IGAIN 08

ILIM 255

Page 29 of 54 F45474 (0413)

Page 30

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

Control Programming

PROGRAM

ITEM

1

Default value shown in bold type.

2

Temperature will change in one degree increments, accelerating if the

KEY SEQUENCE

button is held.

NOTES

3

Time will change in one second increments, accelerating if the button

is held.

4

Gas* and Gas Star are the same value. The Solid State Display cannot

show an asterick(*).

Display Test

1. Cycle power switch. When FRYERS is

displayed, press PROGRAM key.

A. Display shows DSP TEST.

2. To exit test, press and hold the PROGRAM key

for one second.

Alarm Messages

Alarms take precedence over any other controller

mode or function (except drain valve function).

B. Press PROGRAM key again to light all the

display segments in the first character.

DISPLAY

1

C. Continue pressing PROGRAM key until the

display segments for all eight characters are

tested.

ALARMS DESCRIPTION

If an open probe is detected, the heat demand (heat on) and basket lift outputs are

disabled. Any cooking in progress is cancelled and all operator buttons are disabled.

OPEN PROBE

the display alternates OPEN PROBE and the electronic alarm will sound

continuously.

NOTE: A temperature of 460°F is an open probe equivalent.

If a shorted probe is detected, the heat demand (heat on) and basket lift outputs are

disabled. Any cooking in progress is cancelled and all operator buttons are disabled.

SHORTED PROBE

The display alternates SHORTED PROBE and the electronic alarm will sound

continuously.

NOTE: A temperature of 460°F or greater is a shorted probe equivalent.

If the temperature is greater than or equal to 415°F, the heat demand (heat on) and

basket lift outputs are disabled. Any cooking in progress is cancelled and all operator

HI TEMP

buttons are disabled. The display alternates HIGH TEMP and the electronic alarm

will sound continuously. Normal fryer operation resumes when the temperature

drops below the high temperature alarm level.

If the ignition status input to the control is not active (24VAC = active), the display

IGNITION STATUS (gas

models only)

shows NO PILOT. If the input remains inactive for greater than 90 seconds, the

display will alternate IGNITION LOCKOUT, the electronic alarm will sound

continuously, and the controller will be disabled (all outputs including heat demand

off) until power is cycled.

F45474 (0413) Page 30 of 54

Page 31

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

ALARMS DESCRIPTION

When drain valve is opened, the DVI switch contacts open, and the 24VAC input to

the control is removed. The heat demand (heat on) and basket lift outputs are

disabled. Any cooking in progress is cancelled and all operator buttons are disabled.

The display will show DRAINING.

Press FILTER key and hold for 3 seconds to begin filtering (pump on). Control is

DRAIN VALVE INTERLOCK

(DVI) Filtering System Fryer

Batteries (Filter Key)

signaled that filtering has started.

When the drain valve is closed, the DVI switch contacts close, and the 24VAC input

to the controller is restored. The heat demand (heat on) and all operator buttons will

remain disabled and the display will show FILL VAT.

To resume operation, allow the tank to fill with shortening between the MIN and MAX

lines. Press FILTER key to turn the pump motor off. Control is signaled that filtering

has stopped and the tank is full, Display will ask VAT FULL HIT TEMP. Press TEMP

key after confirming the shortening is at the proper level and to resume heating.

When drain valve is opened, the DVI switch contacts open, and the 24VAC input to

the control is removed. The heat demand (heat on) and basket lift outputs are

disabled. Any cooking in progress is cancelled and all operator buttons are disabled.

The display will show DRAINING.

DRAIN VALVE INTERLOCK

(DVI) Stand Alone Fryers

(Boil Key)

PROGRAM LOST RECHECK

IGNITION STATUS

GAS Selected incorrectly

under service settings - type

When the drain valve is closed, the DVI switch contacts close, and the 24VAC input

to the controller is restored. The heat demand (heat on) and all operator buttons will

remain disabled and the display will show FILL VAT HIT TEMP.

To resume operation, allow the tank to fill with shortening between the MIN and MAX

lines. Press TEMP key. Display will ask VAT FULL HIT TEMP. Press TEMP key a

second time after confirming the shortening is at the proper level and to resume

heating.

When the program has detected errors in the data that is stored in the controls non

volatile memory (EEPROM), the control will automatically reload the factory default

settings. Display will alternate the alarm message until program mode is entered

then exited or power is cycled to control.

After 20 seconds in normal operation mode. IGNITION LOCKOUT will be shown on

the display and the alarm will sound continuously.

Enter SERVICE SETTINGS and select GAS* as the type.

COMPUTER CONTROL

Operation

For operating instructions and programming, refer to

OPERATOR MANUAL and computer controls

programing start guide.

Service Programming

The computer controls service settings mode is used

to select the settings that affect fryer operation and to

perform fryer diagnostic tests.

Enter Service Setting Mode

Fig. 52

Page 31 of 54 F45474 (0413)

Page 32

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

Fig. 54

NOTE: The controls heat demand output signal is off

and the heat/ignition status input signal is ignored if

the fryer is in cook mode or idling.

1. Turn power switch on and when the program

revision is displayed, press PROGRAM to enter

Service Setting Mode.

A. The SERVICE SETTINGS are shown on the

left and right display screens.

2. Verify the settings shown on the display screen

are correct for the fryer being serviced.

3. To change a service setting.

A. Press the desired product number key (1

thru 6) on the control panel that corresponds

to the service setting number on the display

screen.

1) Beeper chirps on each successful key

press and all LED's are off. When a

service item is selected, only the keys

required to change the setting are

active.

B. Press toggle key to alternate between

available selections, or use product number

keys where indicated to enter a value. The

current selection will be "blinking".

C. Press PROGRAM key to save the selection

- "Blinking" stops.

D. Access the other service settings as

necessary.

4. To enter DIAGNOSTICS mode, press product

number key 7 on the control panel.

Fig. 55

Fig. 56

A. Press the desired product number key (1, 2,

3, 4, & 6) on the control panel that

corresponds to the diagnostic test number

on the display screen to check the output

signal to the component.

1) Press the same product number key

again to turn the output off.

NOTE: Item 5 (drain) displays the real time status and

does not require pressing the corresponding product

number key. Item 3 (heater) - The output signal will be

active for 3 seconds (heat on) then turn off.

B. For item 6 DISPLAY: - change the setting as

desired.

1) Press product number key 6 to access

the display screen adjustment settings.

2) Press the left or right arrow key on the

PROGRAMMING MENU SELECTION

screen to select the screen to adjust.

Display shows "THIS LCD

SELECTED".

F45474 (0413) Page 32 of 54

Page 33

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

c. CONTRAST - Press the L key on

the keypad to lower the contrast or

press the R key on the keypad to

raise the contrast.

4) Press PROGRAM key to return to

DIAGNOSTICS MODE.

5. To exit SERVICE SETTINGS MODE and return

to normal operation, keypress PROGRAM key.

A. Display reverts to product menu items.

Fig. 57

3) To adjust the selected screen:

a. BACKLIGHT - Press toggle key to

turn display backlight ON or OFF.

b. PIXEL MODE - Press product key

number 1 two times to change

display from white background

with black letters to black

background with white letters.

Press the key again to change it

back to original setting.

SERVICE

SETTINGS

KEY SEQUENCE

DISPLAY

ITEM

FLASHES

1

DESCRIPTION

Press 1 to change brand name.

1. Brand

2. Celsius

3. Mode

4. Type

Press toggle key to select HOBART or VULCAN.

Press PROGRAM Key to save the selection.

Press 2 to change temperature scale.

Press toggle key to select NO or YES.

Press PROGRAM Key to save the selection.

Press 3 to change fryer mode.

Press toggle key to select BOIL or FILTER.

Press PROGRAM Key to save the selection.

Press 4 to change energy source.

Press toggle key to select ELECTRIC, GAS or GAS*.

NOTE: VK and TR Gas Fryers MUST be set to

GAS*.

Press PROGRAM Key to save the selection.

VULCAN Brand name at power on

Temperature °F/°C

NO

No = Fahrenheit

Yes = Celsius

Boil or Filter

Boil

Boil key = Stand alone fryer

Filter key = Filter system

battery

ELECTRIC Electric or Gas

Page 33 of 54 F45474 (0413)

Page 34

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE

SETTINGS

5

Temp Offset

6. Baskets

7. Diagnostics

1.) L Basket

2.) R Basket

3.) Heater

DISPLAY

KEY SEQUENCE

ITEM

FLASHES

1

DESCRIPTION

Press 5 to change offset temperature.

Press toggle key to change offset value to (+) or (-)

(positive or negative).

Enter the offset value using the number keys on the

keypad.

NOTE: Offsets the actual oil temp sensed by the

OFF 00 F

(always in

°F)

Degrees Fahrenheit and

positive zero are the

defaults.

temperature probe during calibration. Enter a positive

number to decrease the actual oil temperature; or a

negative number to increase the oil temperature.

Press PROGRAM Key to save the selection.

Press 6 to change the number of basket lifts.

Press toggle key to select 0, 1, or 2.

2 Display shows 0, 1 or 2

Press PROGRAM Key to save the selection.

Press 7 to enter diagnostic mode (outputs for heat,

basket lifts and cooking timers remain off).

___

DIAGNOSTICS

(shown on display screen)

Press 1 to toggle left basket lift output to lower the lift. DOWN Lowers basket

Press 1 again to raise the lift. UP Raises basket

Press 2 to toggle right basket lift output to lower the

lift.

DOWN Lowers basket

Press 2 again to raise the lift. UP Raises basket

Press 3 to turn heat output ON for 3 seconds only.

OIL TEMPERATURE LED's light with heat demand.

On then

OFF

Gas burner or heating

elements turn on then off.

4.) Filter

5.) Drain

Press 4 to turn filter output ON. ON Pump motor on

NOTE: Filtering system fryer batteries only

Press 4 again to turn output OFF. OFF Pump motor off

Display indicates the position of the drain valve. (DVI

switch input to control) (keypress not required).

CLOSED

Manually change valve position to test, and display

will update.

Drain valve open OPEN

Drain valve closed CLOSED

F45474 (0413) Page 34 of 54

Page 35

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE

SETTINGS

KEY SEQUENCE

Press 6 to adjust the left and right display screen

settings. Refer to LCD display screen picture under

ENTER SERVICE SETTINGS MODE.

Press the left or right arrow key on control panel to

select the screen to adjust.

To adjust the selected screen:

• BACKLIGHT - Press toggle key to turn display

6.) Display

backlight ON or OFF.

• PIXEL MODE - Press product key number 1 two

times to change display from white background

with black letters to black background with white

letters. Press the key again to change it back to

original setting.

• CONTRAST - Press the L key on the keypad to

lower the contrast or press the R key on the

keypad to raise the contrast.

Exit Diagnostic

and Service

Mode

NOTES:

Press PROGRAM Key to exit the selected

DIAGNOSTICS test and return to Service Settings

Mode.

1

Default values shown in bold.

Alarm Messages

The alarms take precedence over any other controller

mode or function (outputs off, active timers canceled).

ALARMS DESCRIPTION

If a temperature probe fault occurs, the alarm sounds continuously and the

display shows PROBE on the left display and either OPEN or SHORT on the

right display. This alarm state will remain until the fault clears or power switch

PROBE FAULT

is cycled.

DISPLAY

ITEM

FLASHES

1

DESCRIPTION

N/A THIS LCD SELECTED

SERVICE SETTINGS

N/A

(shown on display screen)

IGNITION STATUS

GAS -Selected under service

settings - Type.

IGNITION STATUS

GAS Selected incorrectly under

service settings - Type.

• OPEN - Probe detects temperature less than 40°F.

• SHORTED - Probe detects temperature greater than 460°F.

If the ignition status input is not present, both displays show IGNITION

LOCKOUT. If the input comes back in less than 8 seconds, the displays will

revert to normal operation.

If the input remains inactive for more than 90 seconds, IGNITION LOCKOUT

will be shown on the left display and CHECK GAS SUPPLY will be shown right

display, and the alarm will sound continuously. This alarm state will remain until

power switch is cycled.

After 20 seconds in normal operation mode, IGNITION LOCKOUT will be

shown on the left display and CHECK GAS SUPPLY will be shown right display,

and the alarm will sound continuously.

Enter SERVICE SETTINGS and select GAS* as the type

Page 35 of 54 F45474 (0413)

Page 36

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

DISPLAY, LED AND KEYPAD TEST

- COMPUTER CONTROL

1. Press and hold the 5 key while turning power on

to Initiate test. Release the 5 key during display

of software revision level and all LED<s and

display segments should light.

2. For each number key (1-9, & 0) pressed, the

corresponding value is displayed in each

character position on the left and right display.

(i.e.5 key shows 55555555 55555555).

NOTE: Beeper chirp’s for as long as key is held.

3. For each function key pressed, the following

values are displayed in each character position

on the left and right display:

L (left) L Cook

R (right) R Cook

TEMPERATURE Temp

PROGRAM (V) Program

TOGGLE Toggle

BOIL

FILTER D (Kleenscreen fryers)

LEFT TIME < (Left Arrow)

RIGHT TIME > (R Arrow)

4. Turn power off to exit test.

B (single floor model

fryers)

NOTE: For fryers built after 12/1/2012, there are no

adjustments for blower settings, The Ignition/Blower

control board is preprogrammed. If a fryer built before

12/1/12 has been converted to the new Ignition/

Blower control board, there will be no adjustments.

HIGH/LOW FIRE TIMER SETTING

Fig. 58

BLOWER CONTROL BOARD

SETTINGS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

NOTE: This procedure for fryers built before

12/1/2012.

Whenever you have problems with the blower motor

make sure the following adjustments are correct.

1. SW2: Set the SW2 potentiometer to the number

2 setting.

2. SW4: Set the SW4 potentiometer to the number

4 setting.

3. Dip switches: Set the fourth switch (the one

closest to the potentiometers) to the up position.

F45474 (0413) Page 36 of 54

NOTE: This procedure is for fryers built before

12/1/2012

Whenever you have problems with high or low firing

of the burner make sure the following adjustments are

correct.

NOTE: To set the fire timers use a jeweler's flathead

screwdriver.

NOTE: The timer closest to the ignition module is the

low fire timer, and the one closest to the bottom is the

high fire timer.

1. Low fire timer: Set the low fire timer for 2

2. High fire timer: Set the high fire timer for 8

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

seconds.

seconds.

Page 37

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

Fig. 60

SPARK GAP SETTING BEFORE

12/1/12

Fig. 59

NOTE: For fryers built after 12/1/12, the fire timers

are replaced by a Ignition/Blower control board. The

high and low fire time settings are programmed into

the control board. If a fryer built before 12/1/12 has

been converted to the new Ignition/Blower control

board, there will be no adjustments.

AIR FILTER

A dirty air filter will prevent the correct amount of air

intake for the blower. The results are poor combustion

resulting in the fryer "puffing" severely.

To clean the air filter, remove the filter by pulling it off.

The clamp is only hand tightened. Clean air filter in

dishwasher or in sink with hot soapy water. Make sure

air filter is completely dry prior to reinstalling, making

sure that the filter is snug onto the blower intake. Make

sure NOT to tighten the clamp more than hand tight.

Fig. 61

The spark igniter rod should be set between 1/8" and

3/16" away from the mesh burner. This gap will allow

the igniter to produce the optimal spark required to

ignite the burner.

Page 37 of 54 F45474 (0413)

Page 38

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - SERVICE PROCEDURES AND ADJUSTMENTS

2. The spark igniter rod should be set with a gap

between the rod and the burner mesh of 1/16 of

an inch.

insert picture here

3. There should be a gap of 1/8 of an inch between

the igniter rod and the ground rod.

Fig. 62

If the spark igniter rod is not adjusted correctly the gas

could build up in the burner assembly and cause a

delayed ignition of the burner. The resulting "puffing"

could result in damage to the fryer.

NOTE: If the power supply box has been converted

to the new controls, the spark igniter rod should be

replaced with the new style spark rod.

SPARK GAP SETTING AFTER

12/1/12

1. Insure the spark igniter is installed properly on

the burner.

Fig. 64

4. This igniter sparks to the ground rod. To insure

we have a proper ground, we put a wire on the

ground rod terminal and secure it to the burner.

Fig. 65

Fig. 63

F45474 (0413) Page 38 of 54

Page 39

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION - FRYER CONTROLS

Ignitor/ Ground (After

12/1/12) ..............

Ignition/Blower control

board (After 12/1/12) ...

Analog (A), Solid State

(D) or Computer

Cooking Control (C) ...

Control Interface

Board (D and C fryers

only) .................

Transformer .......... Supplies 24VAC to the cooking control, also supplies power to ignition control module.

Power Switch ........ Supplies power to control circuit for fryer operation and filtering.

Modulating Gas Valve ...Allows the gas flow to modulate between low and high flame when gas valve coil is

High Limit Thermostat ...Prevents the shortening from reaching temperatures over 450°F (auto reset @ 415°F).

Ignites the gas burner and senses the presence of a flame. The flame presence generates

a micro-amp flame sense current that is rectified to the ignition control module.

Provides the output signal interface from the cooking control to operate the burner blower

motor in low or high speeds, controls and monitors gas burner ignition. Monitors the

presence of a flame and supplies an ignition status input signal to the cooking control,

Monitors and evaluates input signals to the control: Activates heat output signal to

maintain shortening temperature; counts product cook time(s) and signals the electronic

alarm at the end of a cooking cycle; activates the left and right lift output signal to operate

the basket lifts(s); and activates filter output signal to power the fill solenoid valve.

NOTE: By utilizing the same wiring harness connections D and C controls are

interchangeable between fryers.

Provides the output signal interface from the cooking control to regulate gas heating,

basket lift operation and fill solenoid valve operation. The board components consist of

a heat control Triac and K1, K2 & K3 N.O. relays.

Transformer is energized when power switch is turned on.

energized.

Serves as a backup to the cooking control’s high temperature alarm setting of 415°F

(normal operation resumes when temperature falls below this point).

Temperature Probe ... Senses temperature of shortening. Converts the temperature into a resistance valve

which is monitored by the cooking control. The probe is an RTD (resistance temperature

detector) of the Thermistor type. As temperature increases the resistance value

decreases.

Drain Valve Interlock

Switch (DVI) ..........

Ignition Control

Module (Before

12/1/12) ..............

Ignitor/Flame Sense

(Before 12/1/12) ......

Burner Time Delay

Relays (Before 12/1/12)

........................

Blower Relay (Before

12/1/12) ..............

Blower Control Board

(Before 12/1/12) ......

A magnetic reed switch mounted on the manual drain valve that supplies a drain valve

position signal (open/closed) to the cooking control. When drain valve is open, the drain

interlock input to the control is removed (magnetic reed switch contacts open). This

prevents gas burners from coming on with the fry tank empty.

Controls and monitors gas burner ignition. Monitors the presence of a flame and supplies

an ignition status input signal to the cooking control.

Ignites the gas burner and senses the presence of a flame. The flame presence generates

a micro-amp flame sense current that is rectified to the ignition control module.

These relays are used in conjunction with the burner either in high or low fire settings.

When the relay coil is energized, it supplies voltage to operate the burner blower motor.

Provides the output signal interface from the cooking control to operate the burner blower

motor in low or high speeds. The board components consist of 4 dip switches, SW2 and

SW4.

Page 39 of 54 F45474 (0413)

Page 40

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - ELECTRICAL OPERATION

COMPONENT FUNCTION - KLEENSCREEN FILTER CONTROLS

Fill Solenoid Valve ... When energized by filter key, the solenoid valve opens to allow the flow of shortening

thru filtering system.

Pump Motor .......... Operates pump to circulate shortening through filtering system.

Drain Valve Interlock

Switch (DVI) ..........

R1 Pump Motor Relay ... When 24VAC relay coil is energized by filter key, supplies 120VAC to pump motor; and

R2 Fill Relay ......... When 24VAC relay coil is energized by filter key, supplies 24VAC to the fill solenoid valve

A magnetic reed switch mounted on the mechanical discard valve that closes when

discard valve handle is extended to discard the shortening. Prevents R2 filter relay N.C.

contacts from suppling power to the fill solenoid valve when filter key is pressed.

fill solenoid valve (thru R2 fill relay N.C. contacts.

to open the valve and allow shortening to flow thru filter system.

COMPONENT LOCATION

Fig. 66

Fig. 67

Fig. 68

F45474 (0413) Page 40 of 54

Page 41

VK and TR GAS FRYERS W/Wo KleenScreen PLUS - ELECTRICAL OPERATION

E. Shortening at proper level in fry tank and

below last set point temperature used.

F. Manual drain valve closed (drain valve

interlock switch N.O. is closed).

G. High limit thermostat closed.

2. Turn power switch on.

A. 24VAC transformer energized.

3. Analog control is powered 24VAC.

4. Start switch is closed (momentary).

Fig. 69

Fig. 70

SEQUENCE OF OPERATION - A

SERIES - AFTER 12/1/12