Page 1

INSTALLATION &

OPERATION MANUAL

GAS RESTAURANT RANGES

90 SERIES AND VG SERIES

MODEL

24L ML-52947

36L ML-52948

481L ML-52950

148L ML-52951

60L ML-52952

260L ML-52954

VG24 ML-114553

VG36 ML-114554

VG60 ML-114555

VG260 ML-114557

PRIOR MLS COVERED

IN THE CATALOG

48L ML-52949

160L ML-52953

VG48 ML-114957

VG160 ML-114556

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

MODEL VG36

MODEL 36L

P.O. BOX 696, LOUISVILLE, KY 40201-0696

TEL. (502) 778-2791

F-31055 Rev. E (04-05)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

— 2 —

Page 3

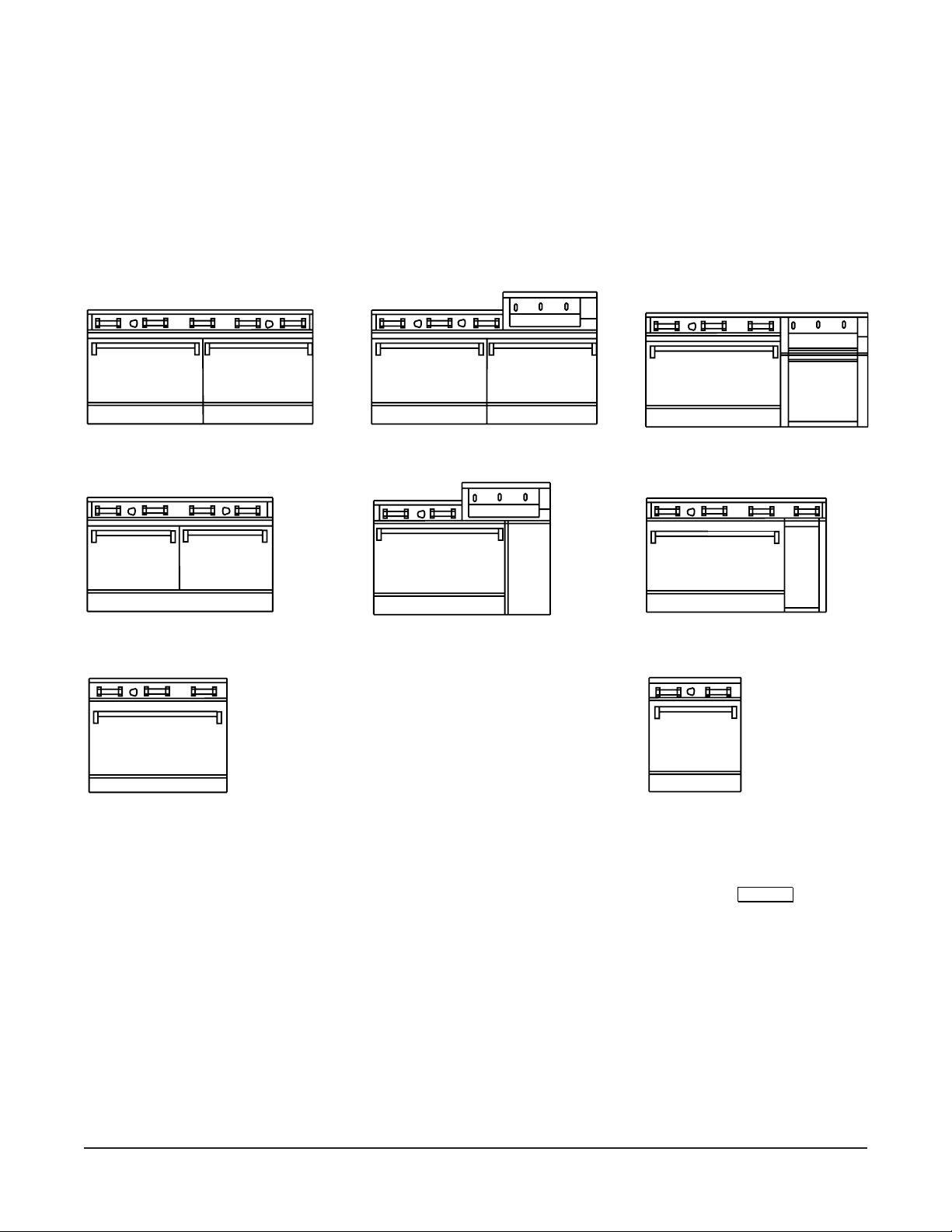

GAS RESTAURANT RANGE MODELS

60L, 60LC, 60LCC

VG60

*

48L/VG48

36L, 36LC

VG36

260L, 260LC, 260LCC

VG260

148L, 148LC

160L, 160LC

*

VG160

481L, 481LC

24L

VG24

PL-53007

NOTE: References to 90 Series Convection Ovens will include only the following models: 36LC, *148LC, 481LC,

60LC, 60LCC, *160LC, 260LC or 260LCC.

* Indicates discontinued model.

— 3 —

Page 4

Installation, Operation and Care of

GAS RESTAURANT RANGES

90 SERIES AND VG SERIES

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

GENERAL

Vulcan ranges and ovens are produced with quality workmanship and material. Proper installation,

usage and maintenance of your range will result in many years of satisfactory performance.

Vulcan-Hart suggests that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

INSTALLATION

UNCRATING

This range was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the range is found to be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

Uncrate unit carefully and place in a work-accessible area as near to its final installed position as

possible. Remove all shipping wire and wood blocking.

Before installing, check the electrical service (convection oven series ranges only) and type of gas

supply (natural or propane) to make sure they agree with the specifications on the rating plate located

on the inside of the lower kick panel. If the supply and equipment requirements do not agree, do not

proceed with the installation. Contact your dealer or Vulcan-Hart Company immediately.

LOCATION

The equipment area must be kept free and clear of combustible substances.

The range, when installed, must have a minimum clearance from combustible construction of 6" (152 mm)

at the sides and 6" (152 mm) at the rear. Clearance from non-combustible construction is 0" at the sides

and 6" (152 mm) at the rear.

The installation location must allow adequate clearances for servicing and proper operation. A

minimum front clearance of 40" (1016 mm) is required.

The range must be installed so that the flow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber must be provided. Make sure there

is an adequate supply of air in the room to allow for combustion of the gas at the burners.

— 4 —

Page 5

INSTALLATION CODES AND STANDARDS

Ranges must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI/Z223.1 (latest edition). Copies may be obtained from The American

Gas Association, Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from The

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

4. Vapor Removal From Cooking Equipment

, NFPA-96 (latest edition). Copies may be obtained from

The National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CSA B149.1 Natural Gas and Propane Installation Code.

3. CSA C22.1 Canadian Electric Code.

4. CSA C22.2 Canadian Electric Code.

The above are available from the Canadian Standard Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

ASSEMBLY

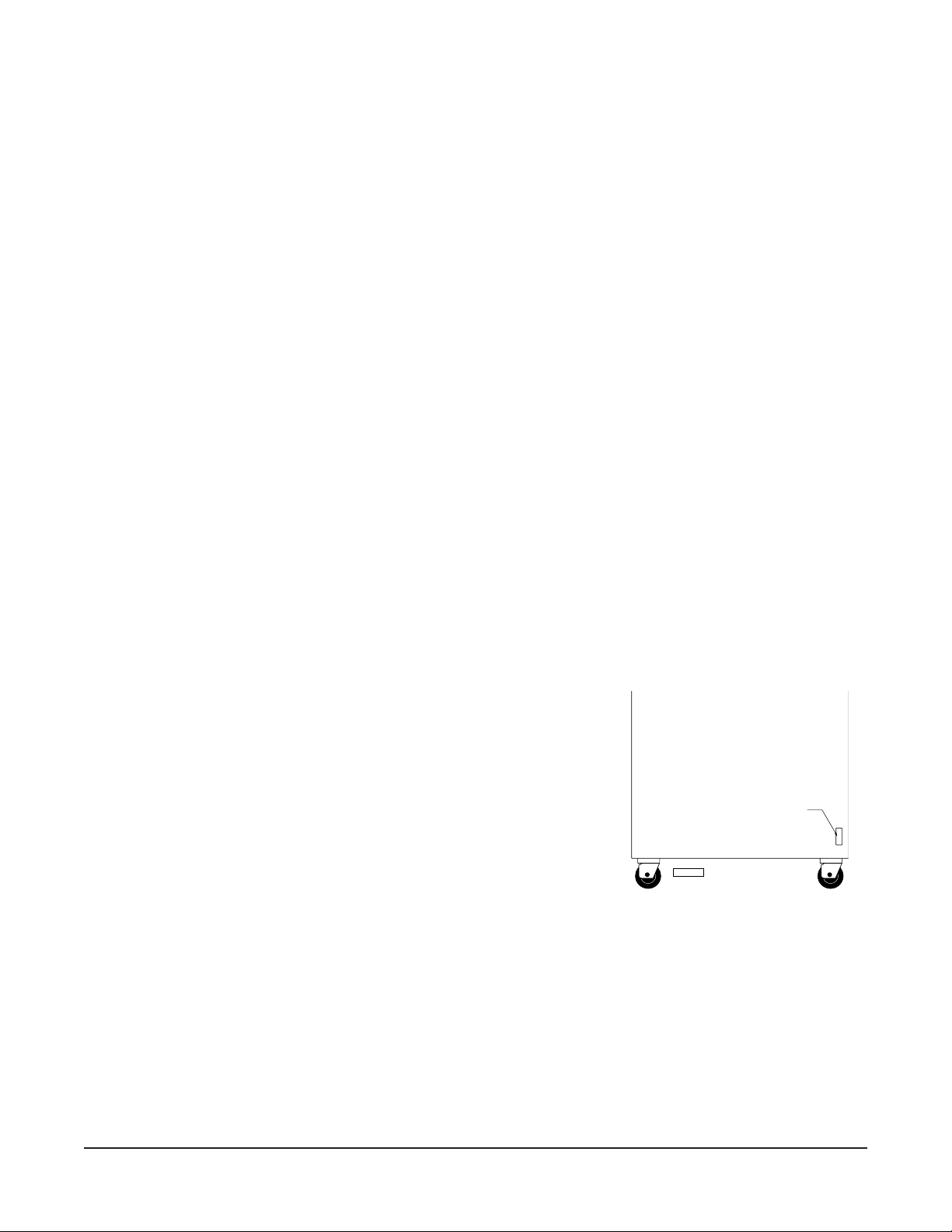

Ranges Mounted on Casters

Ranges mounted on casters must use a flexible connector (not

supplied by Vulcan) that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI-Z21.69 • CSA 6.16

and a quick-disconnect device that complies with the

Standard for Quick-Disconnect Devices for Use With Gas

Fuel, ANSI-Z21.41 • CSA 6.9. In addition, adequate means

must be provided to limit movement of the appliance without

depending on the connector and the quick-disconnect device

CONNECT GAS LINE

STRAIN

RELIEF HERE

or its associated piping to limit appliance movement. Attach the

restraining device at the rear of the range as shown in Fig. 1.

PL-51219

Remove two screws from the rear of the range and install the

Fig. 1

tie-down strap shipped with the casters using these screws

(Fig. 1). Attach the gas line strain relief to the tie-down strap at the rear of the range (Fig. 1).

If disconnection of the restraint is necessary, turn off the gas supply before disconnection. Reconnect

this restraint prior to turning the gas supply on and returning the range to its installation position.

Separate instructions for installing casters to the range are included with the casters.

Note: If the range is installed on casters and is moved for any reason, it is recommended that the range

be releveled front to back and side to side.

— 5 —

Page 6

Bumper Bars (Convection Oven Ranges Only)

CAUTION: Failure to install bumper bars may cause motor damage and will void the

warranty.

Remove existing #10 screws. Position bumper bars (supplied) as shown. Replace #10 screws and

secure bumper bars (Fig. 2).

REAR VIEW OF RANGE

NOTES:

1. Bumper bars required for all

Convection Oven Ranges.

2. Restraining device required for

all ranges with casters.

3. Restraining device not supplied by

unit manufacturer.

RESTRAINING DEVICE

#10 SHEET METAL SCREW

BUMPER BAR

PL-50109

Fig. 2

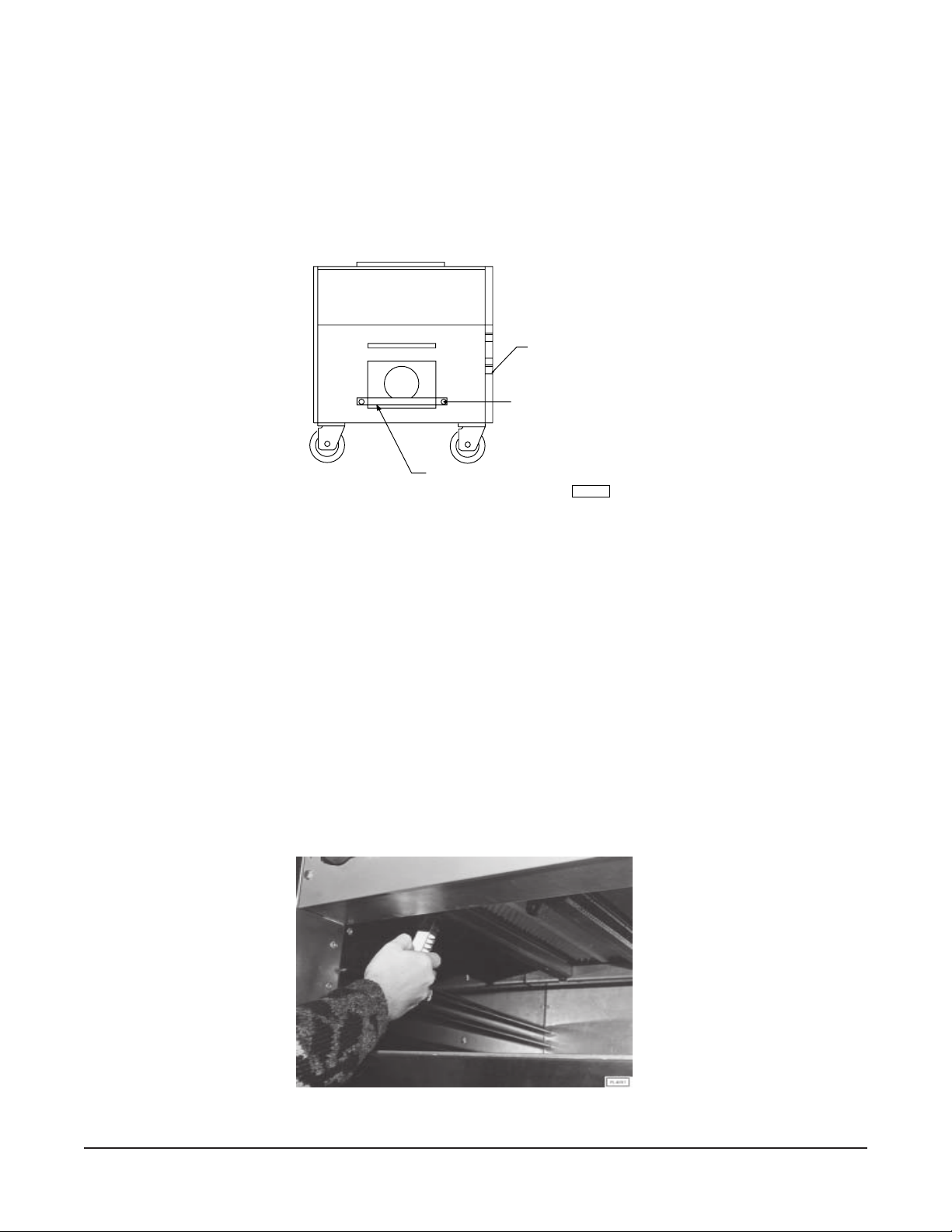

Installation of Broiler/Griddle Bricks

The Restaurant Range broiler/griddle utilizes ceramic fire bricks for heat radiation of the burners. Install

the broiler bricks before connecting the gas supply line.

1. Remove the six 5

1

/4" x 21/4" (133 x 57 mm) and (6) 51/4" x 51/16" (133 x 128 mm) bricks from the

shipping box.

2. Install the six 51/4" x 21/4" (133 x 57 mm) bricks to the left- and right-hand sides of the burner. To

install the bricks, insert them one at a time through the opening in the front of the broiler. Angle the

brick sideways so that it will slip between the burner edges. Set the bricks flat in place resting on

these edges. Push each brick installed as far to the rear of the burner as possible so that the last

brick will install easily (Fig. 3).

3. Install the six 5

1

/4" x 51/16" (133 x 128 mm) bricks to the center burners as described in Step 2.

Fig. 3

— 6 —

Page 7

Installation of Standard Griddle Top Bricks

The griddle is shipped mounted on the range when it is received by the customer. However, the

thermostat bulb, capillary and griddle bricks must be installed before operating the griddle.

The bricks are shipped in a rectangular box with the range.

1. Locate the bricks and gently unpack them (bricks are fragile and brake easily). There will be (4)

bricks per griddle baffle section, (2) 10" x 4" (254 x 102 mm) and (2) 7" x 4" (178 x 102 mm) bricks.

NOTE: If a brick has been broken into two pieces, it can still be used. Just place the pieces into

position as shown in Fig. 4. However, if a brick is broken into more than two pieces, it will need to

be replaced. Contact your local Vulcan servicer.

Fig. 4

2. Lift up and secure the griddle plate assembly.

3. Install (2) 10" x 4" (254 x 102 mm) bricks to the front of each baffle section, with the mitered edge

facing up. Install (2) 7" x 4" (178 x 102 mm) bricks to the rear of each baffle section (Fig. 4).

— 7 —

Page 8

Installation of Thermostat Bulb and Capillary

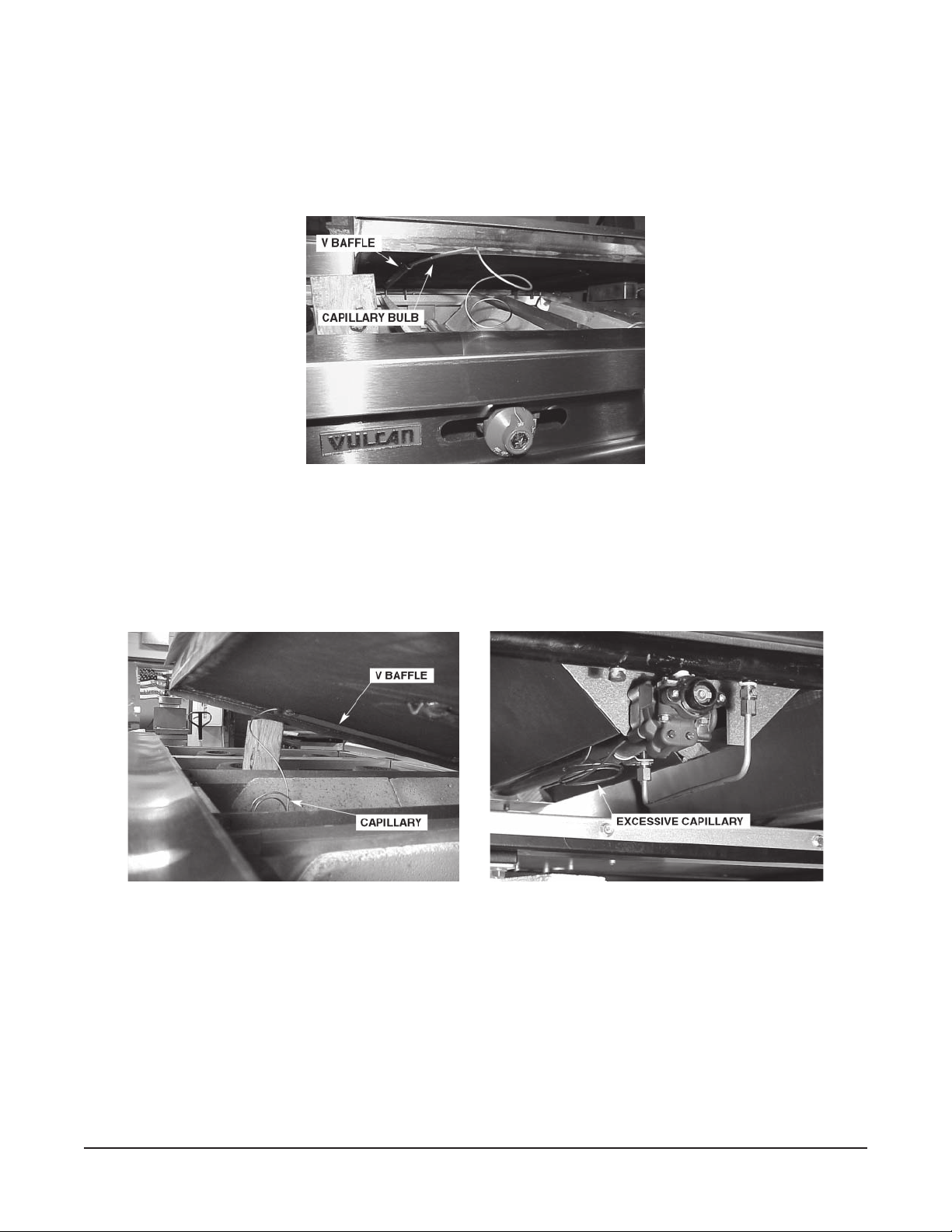

The thermostat bulb and capillary are located underneath the griddle plate.

1. Uncoil a few turns (only enough to reach into the V-baffle) of the bulb and capillary assembly

for each griddle thermostat (Fig. 5).

Fig. 5

2. Carefully feed the bulb into the V-baffle in each section of the griddle. There will be (1)

capillary bulb for each griddle thermostat. Make sure that the bulb is fully inserted into the

V-baffle so there is no exposure of the capillary to the burner flame (Fig. 6).

Fig. 6 Fig. 7

3. After all bricks and capillary bulbs are installed, carefully align and lower griddle assembly down

so that it is resting evenly on the unit. Check to insure that all excess capillary is resting below the

brick baffle area (Fig. 7).

Clean and Season the griddle top before placing the unit into operation.

— 8 —

Page 9

Installation of Hot Top Bricks

The Restaurant Range hot top sections utilize composite/mortar fire bricks for heat distribution of the

burners. Install these bricks before connecting the gas supply line or installing the back riser.

1. The composite/mortar bricks are shipped in a rectangular cardboard box. Locate box and carefully

remove two 10" x 4" (254 x 102 mm), and two 7" x 4" (178 x 102 mm) bricks. There should be one

box of bricks per hot top section ordered.

NOTE: If a brick has been broken into two pieces, it can still be used. Just place the pieces into

position as shown in Fig. 4. However, if a brick is broken into more than two pieces, it will need to

be replaced. Contact your local Vulcan servicer.

2. Rest the hot top plate in a secure area.

3. Install two 10" x 4" (254 x 102 mm) composite/mortar bricks, placing the miter edge, one to each

side of the front burner baffle area (see Fig. 4).

4. Install two 7" x 4" (178 x 102 mm) bricks, one to each side of rear burner baffle area ( Fig. 4).

5. If burner has been strapped down, remove the wire strapping device, using wire cutters.

6. Check to ensure that all bricks and the burner are secure. Carefully replace the hot top section on

top of the range.

Backsplash

The standard Restaurant Range is equipped with a 23" (584 mm) high backsplash and shelf.

1. Remove the backsplash components from the crating materials.

2. Check the backsplash component parts against the list on page 10 to ensure that all the required

parts for the backsplash installation have been obtained. (See Fig’s. 8 & 9.) If any parts are missing,

contact your dealer or closest parts depot immediately.

3. Assemble the required components as shown in Fig’s. 8 and 9.

4. Lift the assembly up, sliding the channels into the space provided at the rear of the range (this may

require two people).

Fig. 8 Fig. 9

— 9 —

Page 10

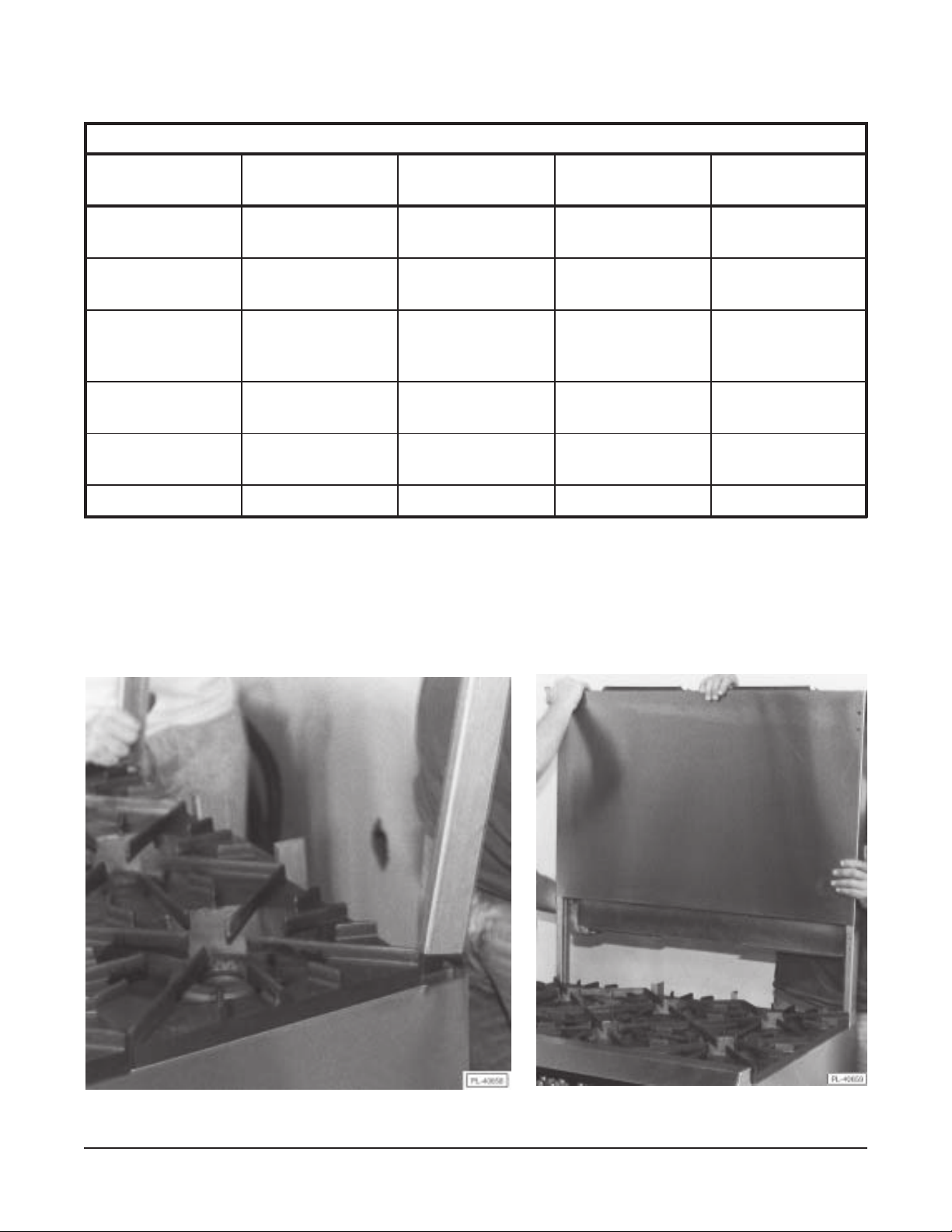

Backsplash Component Parts

MODELS

*48L, 481L, & *148L 60L & *160L

24L/VG24 36L/VG36 *VG48 VG60/*160 260L/VG260

Std. 23" (584 mm) High Std. 23" (584 mm) High Std. 23" (584 mm) High Std. 23" (584 mm) High Std. 23" (584 mm) High

Backsplash (1) Backsplash (1) Backsplash (1) Backsplash (1) Backsplash (1)

Backsplash Channel Backsplash Channel Backsplash Channel Riser Channel Backsplash Channel

(2) (2) (2) (1) (2)

Heat Shield (1) Heat Shield (1) Heat Shield (48L) (1) Heat Shield (1) Heat Shield (1)

Heat Shield (481L) (1)

#10 Sht.Metal Screw #10 Sht. Metal Screw #10 Sht. Metal Screw #10 Sht. Metal Screw #10 Sht. Metal Screw

(16) (16) (16) (20) (4)

1

/4-20 x 25/16" (59 mm) Lg.1/4-20 x 25/16" (59 mm) Lg.1/4-20 x 25/16" (59 mm) Lg.1/4-20 x 25/16" (59 mm) Lg.1/4-20 x 25/16" (59 mm) Lg.

Machine Screw (4) Machine Screw (4) Machine Screw (4) Machine Screw (4) Machine Screw (6)

Shelf Assembly (1) Shelf Assembly (1) Shelf Assembly (1) Shelf Assembly (1) Shelf Assembly (1)

* Indicates discontinued model.

5. It may be necessary to pull the heat shield bottom out slightly in order to clear the oven flue box area.

Be sure the backsplash is resting evenly and the channel holes are lining up with the holes provided

in the right- and left-hand body side (Fig’s. 10 & 11).

Fig. 10 Fig. 11

— 10 —

Page 11

6. Install eight #10 sheet metal screws (4 to each channel leg) (Fig. 12).

Fig. 12

7. From the front, install four 1/4-20 x 25/16" (59 mm) long machine screws and secure bolts with

locknuts. Do not tighten the screws all the way down. Leave about

1

/4" (6 mm) of play in each screw

(Fig. 13).

8. Lift the shelf up and slide the shelf into position over the screw heads (Fig. 14).

9. Tighten the four screws to secure the shelf.

Fig. 13 Fig. 14

— 11 —

Page 12

LEVELING

Check the leveling of the range. Place a carpenter’s level inside the oven cavity across the oven rack(s).

Level front-to-back and side-to-side.

To adjust the leveling, tilt the range to one side and, using channel locks, unscrew the adjustable leg

insert as required. Repeat this procedure as necessary for each leg.

Casters for this range are of the non-adjustable type. Therefore, the floor must be level. If floor surface

is not level, the range will experience cooking problems.

GAS CONNECTIONS

CAUTION: All gas supply connections and any pipe joint compound used must be resistant

to the action of propane gases.

Each range is factory-equipped for the type gas specified on the rating plate. The installation gas

connection is a

3

/4" (19 mm) 14 FPT ANSI schedule #40 standard pipe.

Connect gas supply. Make sure the pipes are clean and free of obstructions.

Codes require that a gas shutoff valve be installed in the gas line ahead of the range.

Standard ranges are equipped with fixed burner orifices which coincide with installation elevation.

Install the gas pressure regulator.

Before installing, ensure that regulator supplied agrees with rating plate gas supply.

As of 7/11/90, the gas pressure regulator is NOT factory installed. The regulator for this gas type is

sealed within a plastic bag attached to the oven rack inside the oven cavity. This regulator must be field

installed by a qualified installer.

Natural gas regulators are preset for 3.7" W.C. (Water Column) (.92 kPa); propane gas regulators for

10.0" W.C. (2.5 kPa)

3

1. Locate

/4" (19 mm) gas connection pipe extending from rear of range.

2. Cover pipe threads with leak sealant.

3. Screw regulator hand-tight onto pipe with regulator arrow pointing towards range body back (Fig. 15).

4. Using pipe wrench, tighten regulator securely in an upright position (Fig. 15).

The arrow on the regulator shows the direction of the gas flow (Fig. 15). The pressure regulator must

be mounted horizontally to ensure proper preset outlet pressure. If the regulator is installed in any other

position, the outlet pressure must be reset for proper operation.

A leak limiter is supplied with every regulator to allow excess gas pressure to escape. Do not obstruct

leak limiter on gas pressure regulator, as obstruction may cause regulator to malfunction.

— 12 —

Page 13

Fig. 15

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

Before operation, verify thermocouple is securely seated in the safety valve. The thermocouple should

be tightened a 1/4 turn past finger tight. DO NOT OVERTIGHTEN. Overtightening may damage the

thermocouple or safety magnet.

TESTING THE GAS SUPPLY SYSTEM

When gas supply pressure exceeds

1

/2 psig (3.45 kPa), the range and its individual shutoff valve must

be disconnected from the gas supply piping system.

When gas supply pressure is 1/2 psig (3.45 kPa) or less, the range should be isolated from the gas supply

system by closing its individual manual shutoff valve until the range is ready for start-up.

FLUE CONNECTIONS

DO NOT obstruct the flow of flue gases from the flue located on the rear of the range. It is recommended

that the flue gases be ventilated to the outside of the building through a ventilation system installed by

qualified personnel.

From the termination of the flue to the filters of the hood venting system, a minimum clearance of 18"

(457 mm) must be maintained.

Information on the construction and installation of ventilating hoods may be obtained from the standard

for the "Removal of Vapors from Commercial Cooking Equipment”, NFPA No. 96 (latest edition),

available from The National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

— 13 —

Page 14

ELECTRICAL CONNECTIONS (CONVECTION OVEN MODELS [90 SERIES] ONLY)

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE

PROVIDED WITH A THREE-PRONG GROUNDING PLUG. IT IS IMPERATIVE THAT THIS PLUG

BE CONNECTED INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF THE

RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO

NOT REMOVE THE GROUNDING PRONG FROM THIS PLUG.

The range is designed for 120 volt power supply or an optional 240 volt single-phase 15 Amp power

supply.

All 120 volt ranges are supplied with a flexible electric supply cord and plug and must be plugged into

the proper receptacle before turning on gas. If the appliance is not equipped with a grounding plug and

electric supply is needed, ground the appliance by using the ground lug provided. All 240 volt electric

systems are manufactured for hard wire installation connections. (Refer to the wiring diagram inserted

into this manual.) An electrical diagram is attached to the back near the motor mounting area.

Do not connect the range to electrical supply until after gas connections have been made.

— 14 —

Page 15

OPERATION

WARNING: THE RANGE AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE RANGE.

CONTROLS

THERMOSTAT DIAL - STANDARD OVEN — Allows operator to regulate oven temperature from low to

500°F (260°C).

THERMOSTAT DIAL - CONVECTION OVEN — Snap-acting type control which allows operator to regulate

oven temperature from 150°F to 500°F (65.5°C to 260°C).

OPEN TOP BURNER KNOB STANDARD AND CONVECTION OVENS — Regulates gas flow to top burners. To increase heat, turn

knob counterclockwise; to decrease, turn knob clockwise.

POWER SWITCH - CONVECTION OVEN — ON-OFF switch controls power supply to convection oven

control.

HEATING LIGHT - CONVECTION OVEN — When lit, indicates that the oven thermostat is calling for

heat to the oven.

GRIDDLE BURNER KNOB STANDARD AND CONVECTION OVENS — Regulates gas flow to the griddle or hot top burner. To

increase heat, turn knob counterclockwise; to decrease,

turn knob clockwise.

BEFORE FIRST USE

Griddle Seasoning

CAUTION: This griddle plate is steel, but the surface is relatively soft and can be scored

or dented by the careless use of a spatula or scraper. Be careful not to dent, scratch, or

gouge the plate surface. Do not try to knock off loose food that may be on the spatula by

tapping the corner edge of the spatula on the griddle surface.

A new griddle surface must be seasoned to do a good cooking job. The metal surface of the griddle is

porous. Food tends to get trapped in these pores and stick; therefore, it is important to “season” or “fill

up” these pores with cooking oil before cooking. Seasoning gives the surface a slick, hard finish from

which the food will release easily.

To season, heat griddle top section at a low burner setting. Pour one ounce of cooking oil per square

foot of surface over the griddle top section. With an insulated cloth, spread the oil over the entire griddle

surface to create a thin film. Wipe off any excess oil with an insulated cloth.

Repeat this procedure 2 to 3 times until the griddle has a slick surface.

— 15 —

Page 16

LIGHTING AND SHUTTING DOWN PILOTS

All adjustment procedures associated with pilot lighting must be performed by an authorized Vulcan-Hart

installation or service person.

HOT TOP AND GRIDDLE TOP BURNERS

1. Turn main gas supply ON.

2. Wait 30 seconds and, using a taper, light the hot top or griddle top pilot (Fig. 16).

Shown with old style burner knobs New style burner knobs effective 1/98

Fig. 16

3. If pilot fails to light, turn main gas supply OFF. Wait 5 minutes and repeat the above procedures.

4. Turn one hot top or griddle top burner valve ON to remove air from the gas line. Turn burner valve

OFF when gas begins to flow.

Nightly Shutdown

Turn burner valve OFF; pilot will remain lit.

Complete Shutdown

1. Turn burner valve OFF; pilot will remain lit.

2. Turn main gas supply OFF.

— 16 —

Page 17

OPEN TOP BURNERS

1. Turn main gas supply ON.

2. Wait 30 seconds and, using a taper, light the open top pilot (Fig. 17).

Fig. 17

3. If pilot fails to light, turn main gas supply OFF. Wait 5 minutes and repeat the above procedures.

4. Turn one open top burner valve ON to remove air from the gas line. Turn burner OFF when gas

begins to flow.

Nightly Shutdown

Turn burner valve OFF; pilot will remain lit.

Complete Shutdown

1. Turn burner valve OFF; pilot will remain lit.

2. Turn main gas supply OFF.

BROILER/GRIDDLE

1. Turn main gas supply ON.

2 Wait 30 seconds and, using a taper, light broiler/griddle pilot (see Fig. 16).

3. If pilot fails to light, turn main gas supply OFF. Wait 5 minutes and repeat Steps 1 and 2.

4. Turn burner valve ON to purge air from the lines. Turn burner valve OFF when gas begins to flow.

Nightly Shutdown

Turn burner valve OFF; pilot will remain lit.

Complete Shutdown

1. Turn burner valve OFF; pilot will remain lit.

2. Turn main gas supply OFF.

— 17 —

Page 18

STANDARD OVEN

Light open top/griddle pilots before lighting oven pilot.

1. Open kick panel and lift up the pilot lighting hole cover (Fig. 18).

Fig. 18 Fig. 19

2. Light pilot by depressing the reset button located behind the kick panel (Fig. 19). Continue to hold

reset button in for 1 minute. If pilot fails to light, turn main gas supply OFF and wait 5 minutes before

repeating Step 2.

3. After pilot is lit, turn the thermostat to the desired setting.

Nightly Shutdown

Turn oven thermostat OFF.

Complete Shutdown

1. Turn oven thermostat OFF.

2. Turn main gas supply OFF.

STANDARD OVEN WITH SPARK IGNITION (FIG. 20)

1. Move toggle switch to ON position. Oven On Light

will illuminate. The oven pilot will automatically light.

2. Once the oven pilot is established, the oven READY

light will illuminate.

3. Set oven thermostat to desired temperature.

Nightly Shutdown

Push toggle switch to OFF position.

THERMOSTAT

TOGGLE

SWITCH

Complete Shutdown

1. Push toggle switch to OFF position.

2. Turn main gas supply OFF.

— 18 —

OVEN "ON"

LIGHT

OVEN "READY"

LIGHT

Fig. 20

PL-53531

Page 19

CONVECTION (SNORKEL®) OVEN (90 SERIES ONLY)

Light open top/griddle pilots before lighting oven pilot.

1. Open the kick panel and lift up the pilot lighting hole cover (see Fig. 18).

2. Turn red gas valve ON (located behind the kick panel), purging the gas line of all air (Fig. 21). Turn

gas valve and power switch OFF. Close oven door.

Fig. 21 Fig. 22

3. Light oven pilot by depressing the reset button (Fig. 22) and, using a taper, ignite the pilot. Hold reset

button in for 30 seconds or until pilot remains lit. Turn gas valve ON.

4. If pilot fails to light, turn main gas supply OFF. Wait 5 minutes and repeat Steps 2 and 3.

5. After pilot is lit, push the power switch ON and turn the thermostat to the desired setting.

Nightly Shutdown

Turn the power switch OFF and the thermostat to 0 degrees.

Complete Shutdown

1. Push power switch OFF.

2. Turn red gas valve OFF (behind kick panel).

3. Turn main gas supply OFF.

4. Disconnect electrical supply cord.

— 19 —

Page 20

CONVECTION (SNORKEL®) OVEN WITH SPARK IGNITION (FIG. 23)

TOP SECTION

BURNER KNOB

OVEN "ON"

LIGHT

THERMOSTAT

KNOB

THERMOSTAT

LIGHT

ROCKER

SWITCH

OVEN READY

LIGHT

PL-53530

Fig. 23

1. Move rocker switch to ON position (oven ON light will illuminate). The oven pilot will automatically

light.

2. Once the oven pilot is established, the oven READY light will illuminate.

3. Set oven thermostat to desired temperature. (The thermostat light will illuminate. This indicates

that the thermostat is calling for heat.)

The convection oven thermostat must be ON and calling for heat for the oven pilot to light.

Nightly Shutdown

Push rocker switch and turn all knobs to the OFF position.

Complete Shutdown

1. Push rocker switch and turn all knobs to the OFF position.

2. Turn main gas supply OFF.

— 20 —

Page 21

RACK ARRANGEMENT - STANDARD OVEN

The standard oven has two rack positions and is supplied with one oven rack. Additional racks may be

obtained through a Vulcan-Hart parts depot.

For best results when baking cakes and pastries, it is recommended that only a single rack position be

utilized. However, proper rack usage and positioning is really determined by the individual cooking

needs of the operator. If you are cooking a large roast, the entire oven cavity may be utilized. Remove

the oven rack completely from the range and place the roasting pan directly on the oven bottom.

RACK ARRANGEMENT - CONVECTION OVEN (90 SERIES ONLY)

The convection (Snorkel

®

) oven is supplied with three oven racks (maximum capacity). The oven cavity

provides a 5-position rack support for maximum cooking flexibility. The arrangements described below

are the most commonly recommended. The rack positions are numerically sequenced starting at the

bottom.

Arrangement #1

Three racks in Positions 1, 3, and 5 for oven broiling, baking cookies, or reconstitution of frozen meals.

This is also the recommended position arrangement for general baking in sheet pans with products not

over 2

1

/2" (64 mm) high.

Arrangement #2

Two racks in Positions 2 and 4 for general baking in sheet pans, muffin pans, pie or cake tins and

pudding pans 3

for casseroles or meat dishes in #200 series food service pans 12" x 20" x 2

1

/2" (89 mm) high with products not over 4" (102 mm) high. This arrangement may also be used

1

/2" (305 x 508 x 64 mm).

Arrangement #3

Two racks in Positions 1 and 4 for baking breads or cakes in loaf or tube pans and high meringue pies.

This arrangement may also be used for casseroles, meat dishes or roasting in pans up to 4

1

/2" (114 mm)

deep with products up to 5" (127 mm) high.

When mix loading of food products is a regular kitchen practice, some operators have developed other

rack position arrangements to suit their particular needs.

— 21 —

Page 22

INSERTING AND REMOVING STANDARD AND CONVECTION OVEN RACKS

The oven rack has a stop to keep the rack from being pulled all the way out when unloading product.

To install rack, place rack along side of top of side liner runners and slide rack completely to the rear

of the oven compartment until rack drops into place (Fig’s. 24 & 25).

Fig. 24 Fig. 25

To remove rack, reverse the procedure above by raising rear of oven rack stop above runner and pulling

rack forward (Fig. 26).

Fig. 26

— 22 —

Page 23

PREHEATING

Standard Oven

Turn thermostat control to the desired cooking temperature and preheat oven for 25 minutes. To save

on gas consumption, do not operate oven at maximum heat when it is not necessary. Turn thermostat

down to 250°F (121°C) or OFF when oven is not in use or during idle cooking periods.

Convection Oven (90 Series Only)

With power switch in the ON position, turn oven thermostat knob to the proper cooking temperature and

allow oven to preheat for 15 minutes. To save on gas and electrical consumption, turn thermostat to

one-half the cooking temperature or completely OFF during idle cooking periods.

Hot Top Burners

Turn burner ON to highest heat to heat hot top section quickly. Hot top will be ready to cook on in about

10 minutes. After top section has reached operation temperature, turn some of the burners down. You

will save as much as 80% of gas consumption and notice very little difference in cooking performance

as long as you have allowed the entire hot top section to preheat properly.

Open Top Burners

Open top burners ignite quickly and do not require any preheating time. When food comes to a rolling

boil, cut back to slower boil to conserve energy, yet continue boiling. Turn burners ON only when in use.

Broiler/Griddle

Turn the three manual gas valve knobs to full ON. After preheating for 5 minutes, turn valves down until

desired flame or heating level is achieved. Position the removable broiler grid into one of the two slide

positions, depending on which will achieve the proper product results.

LOADING AND UNLOADING STANDARD AND CONVECTION OVENS

WARNING: WHEN USING CONVECTION OVENS, DO NOT STAND DIRECTLY IN FRONT OF

THE OVEN WHILE OPENING THE OVEN DOOR. ALTHOUGH OPENING THE OVEN DOOR

WILL AUTOMATICALLY SHUT THE FAN OFF, SOME HEAT ESCAPES. STEP AWAY TO AVOID

HOT AIR.

Open the door and load as quickly as practical to conserve heat. Take care to avoid spilling liquids while

loading. Close the door and refer to recipe for cooking time.

Provide adequate space for product unloading. Rapid unloading will conserve heat and reduce

preheating for the next load.

— 23 —

Page 24

COOKING CHART

Recommended temperatures and times are intended as a guide only. Adjustments must be made to

compensate for elevation, variations in recipes, ingredients, preparation and personal preference on

product appearance.

Meat roasting is most satisfactory at temperatures of 225°F to 325°F (107°C to 162.7°C) for beef, lamb,

poultry and ham, and 325°F (162.7°C) for fresh pork as recommended by USDA and American Meat

Institute.

A pan, approximately 12" x 20" x 1" (305 x 508 x 25 mm), full of water may be placed in the oven bottom

to supply humidity; this will reduce shrinkage. Water should be added if necessary during roasting.

Roasting pans should be no deeper than necessary to hold drippings, usually 2" to 2

1

/2" (51 to 64 mm).

Cooking time and shrinkage may vary with roasting temperature, cut, grade of meat and degree of

doneness. Smaller cuts will generally show greater time savings than larger cuts at a given temperature.

ROASTING TEMPERATURES AND TIMES

PRODUCT TEMPERATURE APPROXIMATE TIME

Standing Rib Roast 250°F/121°C 3-4 Hrs. - Rare

Oven Ready - 15 lbs. (6.8 kg) 4-41/2 Hrs. - Med.

Rolled Rib Roast - 20-22 lbs. (9.1-10 kg) 275°F/135°C 4 Hrs. - Med.

Veal Roast - 15 lbs. (6.8 kg) 300°F/148.9°C 3 Hrs. - Med. Well

Turkey - 15-20 lbs. (6.8-9.1 kg) 300°F/148.9°C 3 Hrs.

Meat Loaf - 8-10 lbs. (3.6-4.5 kg) 350°F/176.7°C 45 to 60 Min.

RECOMMENDED TEMPERATURES, TIMES AND LOADS FOR BAKING

APPROXIMATE

TIME

PRODUCT TEMPERATURE (MIN.)

Cakes (Standard Oven)

31/2 lbs. (1.6 kg) Sheet Cakes - 18 x 26 x 1" (457 x 660 x 25 mm) 350°F/176.7°C 45 Min.

31/2 lbs.(1.6 kg) Sheet Cakes - 12 x 18 x 2" (305 x 457 x 51 mm) 350°F/176.7°C 1 Hr. and 15 Min.

— 24 —

Page 25

APPROXIMATE TIME

PRODUCT TEMPERATURE (MIN.)

Angel or Sponge Cakes

Sheet pans 18 x 26 x 1" (457 x 660 x 25 mm)

Scaled 5-6 lbs. (2.3-2.7 kg) per pan 300 to 325°F/148.9 to 162.8°C 15 to 20

Loaf or Tube Pans 315 to 340°F/157.2 to 171°C 20 to 30

Cup Cakes 350 to 400°F/176.7 to 204.4°C 6 to 12

Frozen Fruit Pies 350 to 375°F/176.7 to 190.5°C 30 to 45

Pumpkin or Custard Pies 300 to 350°F/148.9 to 176.7°C 30 to 45

Cobblers

12 x 18 x 2" or 12 x 20 x 21/2" pans

(305 x 457 x 51 mm or 305 x 508 x 64 mm) 350 to 400°F/176.7 to 204.4°C 30 to 45

Meringue Pies 350 to 425°F/176.7 to 218.3°C 6 to 10

Fruit Turnovers

Sheet pans 350 to 375°F/176.7 to 190.5°C 15 to 25

NOTE: Cobblers, fruit, custard and pumpkin pies should be placed on sheet pans for baking.

Cookies

Rolled or Pressed 350 to 400°F /176.7 to 204.4°C 6 to 12

Drop 350 to 400°F/176.7 to 204.4°C 6 to 15

Brownies 350°F/176.7°C 12 to 20

Yeast Breads

NOTE: Yeast breads should be fully proofed for best results.

Rolls - 1 oz. (.28 grams) 350 to 400°F/176.7 to 204.4°C 5 to 10

11/2 to 21/2 oz. (42.5 to 70.8 grams) 350 to 400°F/176.7 to 204.4°C 8 to 15

Loaf Bread - 1 lb. (0.5 kg) 325 to 375°F/162.8 to 190.5°C 20 to 40

Sweet Rolls and Pastries 325 to 375°F/162.8 to 190.5°C 5 to 15

Biscuits - Rolled 1/2" (13 mm) thick 350 to 400°F/176.7 to 204.4°C 5 to 15

Muffins 325 to 375°F/162.8 to 190.5°C 6 to 18

Corn Bread

18 x 26 x 1" (457 x 660 x 25 mm) pan,

5-7 lbs. (2.3-3 kg) per pan 335 to 400°F/168.3 to 204.4°C 10 to 20

18 x 26 x 2" (457 x 660 x 51 mm) pan,

8-20 lbs. (3.6-9.1 kg) per pan 335 to 400°F/168.3 to 204.4°C 15 to 25

Corn Muffins 335 to 385°F/168.3 to 196°C 10 to 20

— 25 —

Page 26

OVEN BROILING OR FRYING

APPROXIMATE TIME

PRODUCT TEMPERATURE (MIN.)

Hamburger Patties

8 per lb. (0.5 kg) - Med. well done 400 to 450°F/204.4 to 232.2°C 5 to 6

6 per lb. (0.5 kg) 400 to 450°F/204.4 to 232.2°C 7 to 10

4 per lb. (0.5 kg) 375 to 385°F/190.5 to 196°C 8 to 12

Fish Sticks & Portions

Frozen bread. - 1 oz. (28.3 grams) 350 to 400°F/176.7 to 204.4°C 6 to 10

21/2 to 3 oz. (70.8 to 85 grams) 350 to 375°F/176.7 to 190.5°C 8 to 15

Chicken Pieces

Broiled or Oven Fried

2 to 21/2 lbs. (0.9 to 1.1 kg) 375 to 425°F/190.5 to 218.3°C 8 to 15

21/2 to 3 lbs. (1.1 to 1.4 kg) 350 to 400°F/176.7 to 204.4°C 15 to 25

Lobsters

1 to 11/2 lbs. (0.5 to 0.6 kg) 400 to 450°F/204.4 to 232.2°C 12 to 16

Lobster Tails

Frozen, 1/2 to 1 lb. (0.2 to 0.5 kg) 350 to 400°F/176.7 to 204.4°C 16 to 20

REHEATING PREPARED FOODS

Frozen French Fries 400 to 450°F/204.4 to 232.2°C 6 to 8

Frozen TV Dinners 350 to 400°F/176.7 to 204.4°C 10 to 12

Frozen Entrees - 1" (25 mm) thick 300 to 350°F/148.9 to 176.7°C 10 to 20

Frozen Meals

8 oz. (0.2 kg) foil package 350 to 400°F/176.7 to 204.4°C 20 to 30

CASSEROLES

Food Service Pans

2" to 3" (51 to 76 mm) deep 325 to 375°F/162.8 to 190.5°C 15 to 25

3" to 4" (76 to 102 mm) deep 325 to 375°F/162.8 to 190.5°C 20 to 35

Ramekins or Foil Pans

Up to 11/2" (38 mm) Deep 350 to 400°F/176.7 to 204.4°C 5 to 6

Frozen 350 to 400°F/176.7 to 204.4°C 10 to 15

— 26 —

Page 27

MISCELLANEOUS PRODUCTS

APPROXIMATE TIME

PRODUCT TEMPERATURE (MIN.)

Baked Potatoes

120 count per 50 lbs (22.7 kg) 400 to 450°F/204.4 to 232.2°C 25 to 35

100 count per 50 lbs. (22.7 kg) 400 to 450°F/204.4 to 232.2°C 35 to 45

80 count per 50 lbs. (22.7 kg) 400 to 450°F/204.4 to 232.2°C 40 to 60

Pizzas

Frozen or with prebaked

crust 425 to 475°F/218.3 to 246°C 5 to 10

Grilled Cheese Sandwiches 400 to 425°F/204.4 to 218.3°C 8 to 10

SPECIAL BAKING PROCEDURES

YEAST BREADS

Cooking starts immediately in the convection oven. Yeast breads do not usually rise as much in

the convection oven as in a conventional oven. Therefore, it is necessary to allow 2

1

/2 to 3 times

longer for the dough to reach its proofing capacities.

PIES

When baking pies in your convection oven, 3 or 4 pies should be put on an 18 x 26" (457 x 660 mm)

sheet or bun pan. This procedure helps the bottom crust to bake, makes handling easier and

reduces the possibility of boil-over, spoiling the appearance of the pies on the lower racks.

— 27 —

Page 28

CLEANING

Do not use Dawn

®

dish detergent to clean the exterior or interior components of the range.

Do not use scouring powder. It is extremely difficult to remove completely. It can build up accumulations

that will damage the oven.

Vulcan painted surfaces may be cleaned using a soft cloth and mild detergent solution.

RANGES

Daily

Remove nickel-plated racks and clean in a sink.

While still warm, wipe top with a soft cloth or other grease absorbing material to remove spillovers,

grease, etc., before they burn in. A crust on top of the hot top range looks unsightly and slows down

cooking speed because it reduces the flow of heat to the utensil.

Clean oven and oven door daily, especially if fruit pies or tomato sauces were baked, meats roasted,

and if there have been spillovers.

After processing some foods at low temperatures, odors may linger in the oven. These odors may be

cleared by setting the thermostat at 500°F (260°C) and allowing the oven to operate unloaded for 30

to 45 minutes.

Empty the broiler grease pan/trough daily or as often as necessary. CAUTION: Remove the grease

pan/trough slowly and be careful of liquid wave action. It is recommended that the grease pan/

trough be emptied whenever it is

3

/4 filled. The drip shield, grids and grease pan/trough should be

washed with a mild grease-dissolving solution. Some chefs scrape the grid with a three-cornered metal

scraper. Scrub the broiler chamber and body front frequently and you will have less smoking.

Clean cast iron open top grates with a mild soap and water solution. Rinse thoroughly and dry with a

clean, water-absorbent towel. Immediately after drying (with grates still removed from the range top),

season grates lightly with liquid vegetable or Pam spray-type cooking oil.

After seasoning, replace grates onto the range. Turn all open top sections ON LOW and allow them to

burn for at least 15 minutes before using pots or pans on the range top.

Season the open top grates after each cleaning. Failure to season grates will cause grates to rust.

Weekly

Boil burners in a solution of washing soda. Rinse and dry parts thoroughly. Flash rusting may occur.

This is a normal condition and will not affect the performance or the product prepared.

When reinstalling the burner back onto the range, be sure the burner heads are properly connected.

Do not light the pilot or turn burner valve ON with the burner head removed.

— 28 —

Page 29

CONVECTION OVENS (90 SERIES) ONLY

The Snorkel tube opening must be kept clear from blockage. If usage of aluminum foil is a common

practice during the operation of this oven, be sure to periodically check the Snorkel tube for foil particles.

Clean this tube with standard oven cleaner at least once a week. Be sure to thoroughly clean all

cleansing solution off the tube before using oven again. It is also recommended that the oven be run

at 400°F (204°C) for 20 minutes to burn off any cleaning solution that was not thoroughly rinsed from

the tube.

Oven Door Gasket (90 Series Connection Ovens Only)

To clean the oven door gasket, use a soft cloth or sponge and a mild cleanser. DO NOT USE STRONG

OVEN CLEANERS SUCH AS EASY OFF

®

OR MR. MUSCLE®. Cleaners of this nature will destroy the

gasket material.

GRIDDLE PLATE

Cleaning the griddle section will produce evenly cooked, perfectly browned griddle products and will

keep the cooking surface free from carbonized grease. Carbonized grease on the surface hinders the

transfer of heat to the food. This results in loss of cooking efficiency and spotty browning which gives

foods an unappetizing appearance. To keep the griddle clean and operating at peak efficiency, follow

these simple instructions:

After Each Use

Carefully clean griddle with wire brush or flexible spatula.

Daily

Thoroughly clean backsplash, sides and front. Remove grease pan, empty and wash out in the same

manner as any ordinary cooking utensil.

Clean griddle surface thoroughly. If necessary, use a griddle stone, wire brush or steel wool over the

surface. Rub with the grain of the metal while still warm. A detergent may be used on the plate surface

to help clean it, but the cleaner must be thoroughly removed. After removal of detergent, the surface

of the plate must be reseasoned with a thin film of oil to prevent rusting and food sticking.

If the griddle is to be shut down for an extended period, put a heavy coat of grease over the griddle plate.

— 29 —

Page 30

MAINTENANCE

WARNING: THE RANGE AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE RANGE.

LUBRICATION

All Vulcan convection oven motors are permanently lubricated and require no additional maintenance.

OVEN DOOR GASKET REPLACEMENT - CONVECTION OVEN (90 SERIES) ONLY

To remove the old gasket, gently pry the arrow-like gasket pins from the oven front frame using a

standard screwdriver.

Install new gasket by aligning and inserting the arrow-like pins into the holes provided in the front frame

(Fig’s. 27 & 28).

Fig. 27 Fig. 28

VENT

When cool, the vent should be checked every six months for obstructions.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this model, contact the Vulcan-Hart Service Agency

in your area (refer to our website, www.vulcanhart.com for a complete listing of Authorized Service and

Parts depots).

When calling for service, the following information must be available: model number, serial number,

manufacture date (MD) and voltage.

— 30 —

Page 31

TROUBLESHOOTING GUIDE

STANDARD AND CONVECTION OVEN RESTAURANT RANGE

OVEN

PROBLEM CAUSES

1. Too much bottom heat a) Insufficient ventilation

b) Improper fluing

1a. Too low temperature c) Improper thermostat bypass setting

1b. Side burning d) Thermostat out of calibration

1c. Too much top heat e) Fluctuating gas pressure

2. Uneven bake side to side a) Not level side to side

b) Oven burner, bottom or baffles improperly installed

c) Warped pans

3. Uneven bake front to rear a) Overactive flue

b) Not level front to back; check casters and legs

c) Door not closing properly

4. Dried out products a) Too low temperature (overcooking)

5. Pilot outage a) Pilot flame too low

TOP BURNER OPERATION

1. Improper burner combustion a) Improper ventilation

Excessive valve handle temperatures b) Poor door fit

Sticking top burner valves c) Oven door left open

2. Poor ignition a) Insufficient input

b) Too long baking time

c) Thermostat calibration

b) Restriction in pilot orifice

c) Problem with shutoff valve

d) Possible fluing problems

e) Low pressure

f) Improper gas line sizing

g) Burner box cover not properly installed

h) Oven cavity requires resealing

d) Improper use of excessively large pans or pots

b) Poor air-gas adjustment

c) Restriction in pilot orifice

d) Restriction in main burner ignition port

— 31 —

Loading...

Loading...