Technical documentation

Check us on

WG.US-Rev.2.8 (09.2020)

WING W100-200

WING E100-200

WING C100-200

EN

WING W100-200

WING E100-200

WING C100-200

1. Table of content

1. INTRODUCTION ...................................................................................................................... 3

1.1. PRECAUTIONS, REQUIREMENTS, RECOMMENDATIONS ........................................ 3

1.2. TRANSPORT ................................................................................................................. 3

1.3. INITIAL STEPS TAKEN BEFORE THE INSTALLATION ................................................. 3

2. STRUCTURE, INTENDED USE, PRINCIPLE OF OPERATION ............................................ 3

2.1. INTENDED USE ............................................................................................................ 3

2.2. PRINCIPLE OF OPERATION......................................................................................... 3

2.3. STRUCTURE (WING 100-200) ...................................................................................... 4

2.4. OVERALL DIMENSIONS (WING E, W, C 100-200) ........................................................ 4

3. MOUNTING .......................................................................................................................... 4

3.1. ASSEMBLY/ DISASSEMBLY OF JUNCTION BOX COVER .......................................... 5

3.2. INSTALLATION OF DEVICE ......................................................................................... 5

3.2.1. HORIZONTAL INSTALLATION BY MEANS OF HOLDERS. ................................... 6

3.2.2. VERTICAL ASSEMBLY USING INSTALATION HOLDERS. .................................... 7

3.3. ASSEMBLY AND INSTALLATION GUIDELINES ........................................................... 7

4. ELEMENTS OF CONTTROLS. ........................................................................................... 11

5. START-UP, OPERATION, MAINTENANCE ........................................................................ 11

5.1. START-UP/PUTTING INTO OPERATION ................................................................... 11

5.2. OPERATION AND MAINTENANCE .............................................................................. 11

6. SERVICING ........................................................................................................................ 12

6.1. PROCEDURE IN CASE OF MALFUNCTION ............................................................... 12

6.2. COMPLAINT PROCEDURE ......................................................................................... 12

7. INDUSTRIAL SAFETY INSTRUCTION ............................................................................... 12

8. TECHNICAL SPECIFICATION ............................................................................................. 13

8.1. WATER AIR CURTAIN – WING W100-200 .................................................................. 13

8.2. ELECTRIC AIR CURTAIN – WING E100-200 ............................................................... 14

8.3. WING C100-200 – COLD AIR CURTAIN ...................................................................... 14

9. ELECTRICAL DIAGRAMS .................................................................................................. 15

9.1. Electrical diagram of WING W100-200-EC – 1~240V ...................................................... 15

3

1. INTRODUCTION

1.1. PRECAUTIONS, REQUIREMENTS, RECOMMENDATIONS

Detailed analysis of this documentation, as well as assembly and use of equipment, according to the descriptions contained th erein, and following all safety requirements, is the basis for the

correct and safe operation of the device. Any other use that contradicts this instruction may cause accidents with serious consequences. Unauthorized personnel should have limited access

to the device, while the personnel should be properly trained. The term operational personnel ref ers to people, who, as the result of completed training, own experience and knowledge of

important standards, documentation and provisions, concerning safety and working conditions, have been authorized to carry out necessary work and are able to recognize potential hazards

and avoid them. This technical documentation must be delivered together with the device. The documentation contains information concerning all possible configurations of air curtains.

Examples of air curtain assembly and installation, as well as activation, use, repair and maintenance. Provided that the device is operated according to the intended use, this documentation

contains a sufficient number of ins tructions, required by the qualified personnel. The documentation should be placed n ear the device and be readily available to the service team. The

manufacturer reserves the right to introduce changes to the instruction, as well as changes to the device that affect its operation, without prior notice. VTS shall bear no responsibility for ongoing maintenance, inspections, programming of equipment and damage, caused by standstills of equipment related to the waitin g for warranty services, all and any damage related to the

Client’s property, other than the device in question, as well as malfunctions that result from incorrect installation or improper use of the device.

WING air curtains are intended for indoor installation only.

DO NOT COVER

WARNING: To avoid overheating - do not cover the device!

1.2. TRANSPORT

Prior to the installing and taking the device out of the cardboard box, it is required to check whether the cardboard box has not been damaged in any way and/or the adhesive tape (in stalled

at the company) has not been broken off or cut. It is recommended to check whether the device’s casing has not been damaged in transport. Should any of the above situation occur, please

contact us through telephone or e-mail: Tel. +1 470-809-6811, email: america@vtsgroup.com, fax: +1 470-809-6815.

The device should be transported by two people. Use appropriate tools, when transporting the device, so as to avoid the damaging of goods and potential hazard to health.

1.3. INITIAL STEPS TAKEN BEFORE THE INSTALLATION

Record the serial number of the device on the warranty card, prior to the commencement of the installation process. It is required to properly fill-in the warranty card, once the installation is

complete. Prior to the commencing of any installation or maintenance work, it is required to disconnect power supply and protect it against unintentional activation.

Installation and start-up should be performed by qualified personnel, according to the guidelines provided in this manual. The order of

installation steps are as follows:

• Mount the device in its intended operation place

• Perform the hydraulic connection, check connections for tightness and vent the system

• Perform the electrical connection

• Make sure the device is correctly connected (according to the diagram)

• In the case of an electrical curtain, vacuum the heaters to avoid the unpleasant smell of burning dust

• Turn the power on and start the device.

2. STRUCTURE, INTENDED USE, PRINCIPLE OF OPERATION

2.1. INTENDED USE

For the convenience of users as well as different types of installations in commercial and industrial facilities we have designed an air curtain in three different options and three sizes:

● a WING W100 240/1/60 curtain 42in wide with a water heater (13.6-58MBH, 1089 CFM)

● a WING E100 (models: WING E100 240/1/60, WING E100 240/3/60, WING E100 480/3/60) curtain 42in wide with electric heaters (6.8/13.6/20.5 MBH, 1089 CFM)

● a WING C100 240/1/60 curtain 42in wide (1107 CFM)

● a WING W150 240/1/60 curtain 62in wide with a water heater (34.1- 109 MBH, 1825 CFM)

● a WING E150 (models: WING E10 240/3/60, WING E150 480/3/60) curtain 62in wide with electric heaters (13.6/27.3/40.9 MBH, 1854 CFM)

● a WING C150 240/1/60 curtain 62in wide (1884 CFM)

● a WING W200 240/1/60 curtain 82in wide with a water heater (58- 160 CFM, 2590 CFM)

● a WING E200 (models: WING E200 240/3/60, WING E200 480/3/60) curtain 82in wide with electric heaters (20.5/30.7/51 MBH, 2649 CFM)

● a WING C200 240/1/60 curtain 82in wide (2708 CFM)

The above sizes of curtains are available with three options of voltage supply: 1x240VAC, 3x240VAC, 3x480VAC

! Voltage supply 1x240VAC is available only for the curtains WING E100 240/1/60, all WING W and all WING C

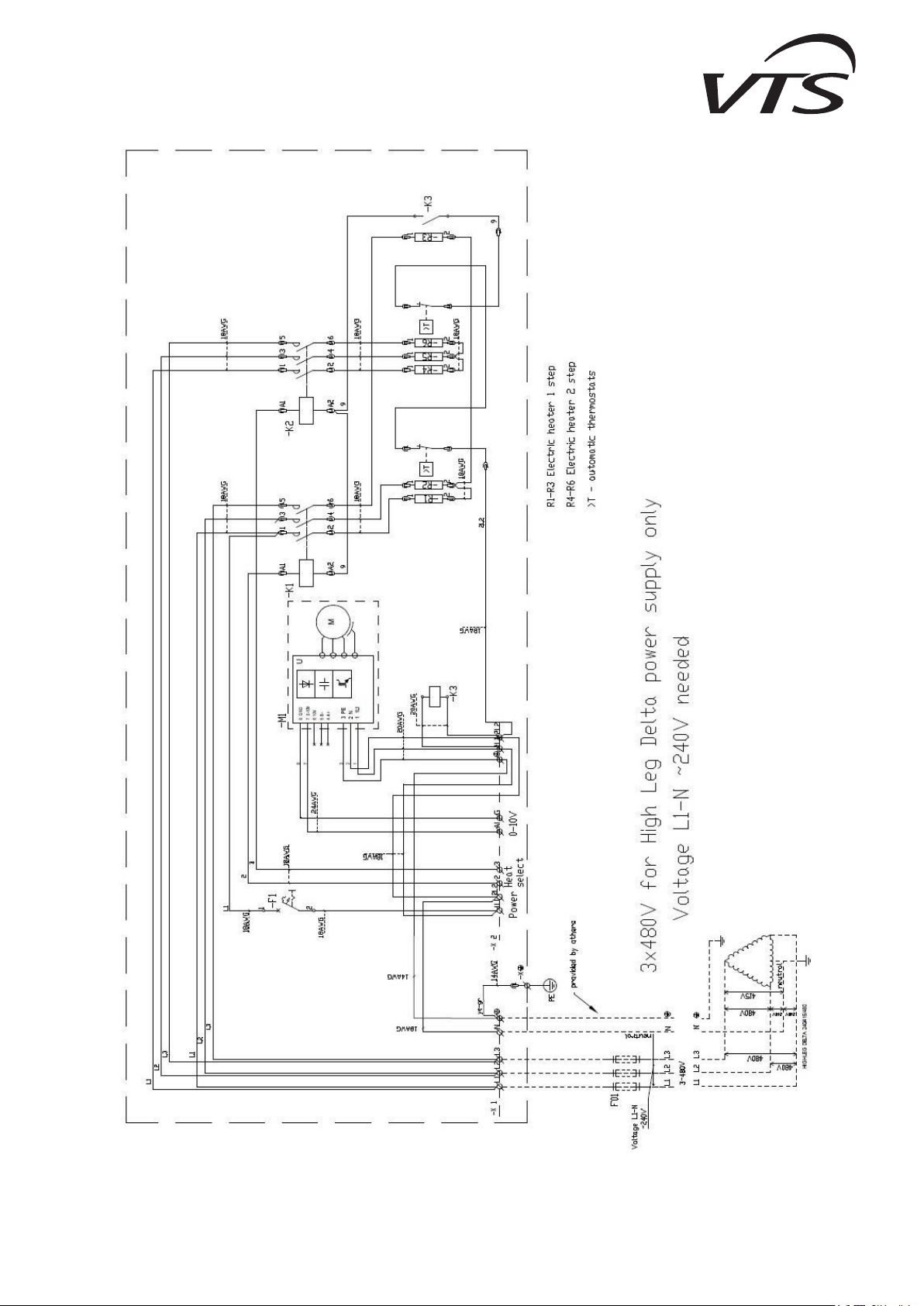

! Caution

The following models of WING air curtains must be supplied using High-Leg Delta supplying

circuit:

• WING E100 480/3/60 Air Curtain

• WING E150 480/3/60 Air Curtain

• WING E200 480/3/60 Air Curtain

For these models, the L1-N voltage will must be 240 VAC.

The use of the WING air curtain enables the leaving of the room door open, regardless of weather conditions, thus providing a protective barrier. The curtain also enables a simultaneous keeping of

the required heating comfort inside the room/facility. T he modern design of the WING air curtain is a result of its wide range of application. The places in which it is possible to install the device include:

malls, office buildings, supermarkets, cinema complexes, as well as shops, store-rooms, manufacturing facilities or warehouse rooms. Please notice that the use of an air curtain not only provides a

protective barrier, but also it is an additional heat source in the room. APPLICATION: warehouse rooms, warehouses, sports facilities, supermarkets, religious buildings, hotels, clinics, pharmacies,

hospitals, office buildings, manufacturing facilities. PRIMARY ADVANTAGES: protection of climatic conditions in the room, reduction of heating/cooling costs, universal size, ability to work both in

vertical and horizontal position; simple, quick and intuitive assembly.

2.2. PRINCIPLE OF OPERATION

WING W100-200 - heating medium, for example hot heating water, returns

heat through a heat exchanger with a wide heat-exchange surface, thus

providing high heating output (13.6-160 MBH). A transverse fan (518-2590

CFM) sucks in the air in the room, and pumps it through the heat exchanger,

back into the room. The jet of warm air is directed downstream at high

velocity, thus providing an air barrier.

WING E100-200 - electric heaters (6.8-51.2 MBH) heat up, as a result of the

flowing of electric current, and return the heat to the air; the air is blown off

through the fan, which sucks in the air in the room. A jet of warm air is directed

downstream at high velocity, thus providing an air barrier.

EN

WING W100-200

WING E100-200

WING C100-200

4

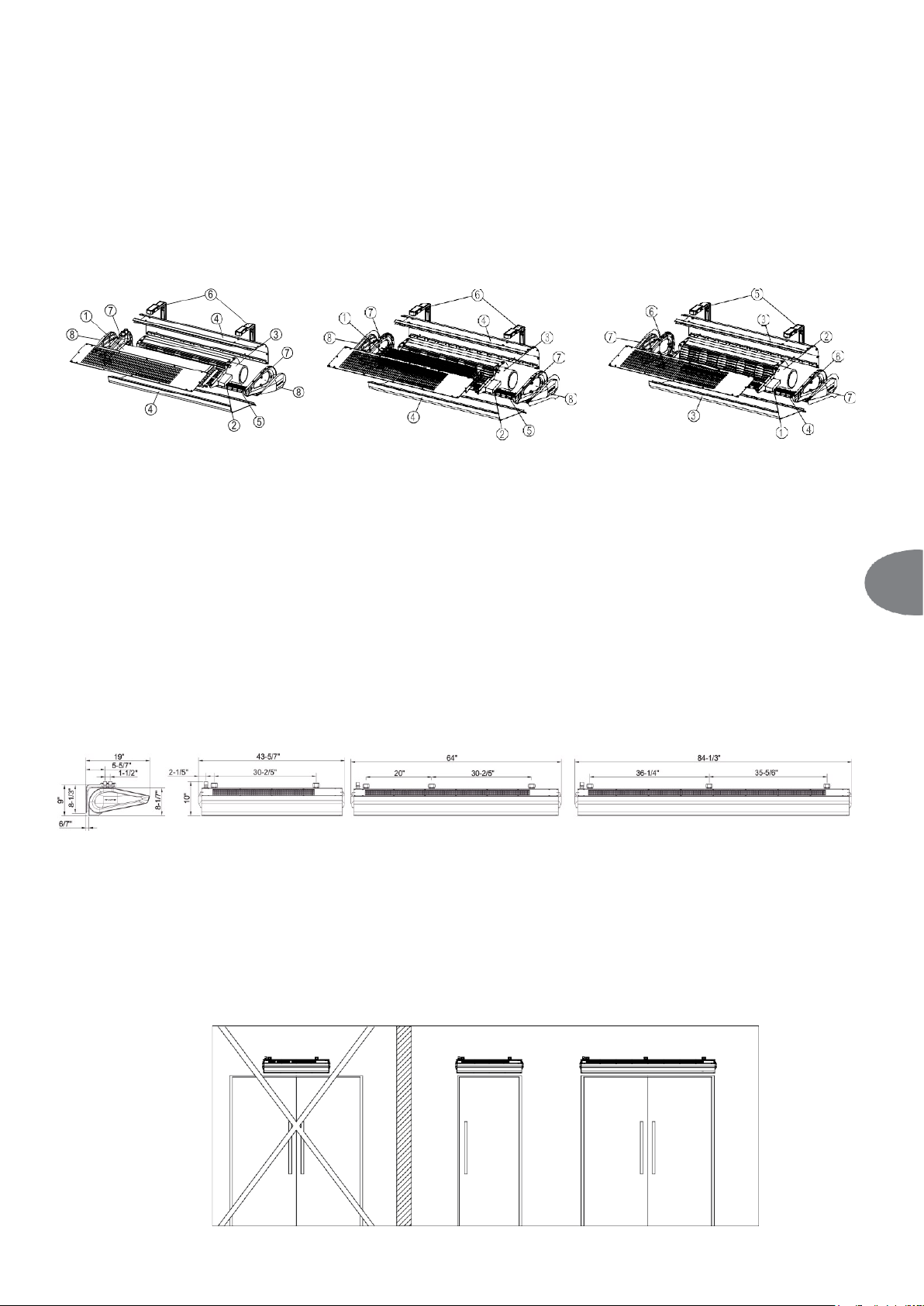

2.3. STRUCTURE (WING 100-200)

WING W100-200 – WATER AIR CURTAIN

1. Heat exchanger

2. Control system

3. Transverse fan

4. Casing

5. Outlet grille

6. Assembly jigs

7. Side cover

8. Side cap

WING E100-200 – ELECTRIC AIR CURTAIN

1. Electric heaters

2. Control system

3. Transverse fan

4. Casing

5. Outlet grille

6. Assembly jigs

7. Side cover

8. Side cap

WING C100-200 – COLD AIR CURTAIN

1. Control system

2. Transverse fan

3. Casing

4. Outlet grille

5. Assembly jigs

6. Side cover

7. Side cap

1. HEAT EXCHANGER – WATER HEATER: Maximum parameters of the heating agent for the heat exchanger are: 200°F, 232 psi. The aluminum and copper construction consists of copper

pipes of the coil and aluminum lamellae. The connection manifold (¾” male thread) is situated in the upper part of the housing. An optimally selected water exchanger was adapted to work in

three positions: horizontally and vertically, with stub pipes facing upwards and downwards. Appropriate lead of hydraulic connections makes it possible for the curtain to be assembled directly by

the wall as close to the door frame as possible. The air curtain with a water heater generates power from 13.6 to 160 MBH.

ELECTRIC HEATER: each electrical curtain consists of 6 electrical heaters of 670W to 2,950W, depending on the size of the curtain. The heaters are connected into two sections of 2 and 4 kW for

a 42in curtain, 4 and 8 kW for a 62in curtain, and 6 and 9kW for an 82in curtain. The heating section is connected to form a 1x230V or 3x230V, 3x480V power supply star depend on the chosen

device. Thanks to such technical solutions and the application of a wall-mounted controller, the heater of each curtain can work in two heating programs, e.g. for a WING E100 curtain - option

1): heating program 1 - 2kW, heating program 2 - 4kW, option 2): program 1 - 4kW, program 2 - 6kW, and analogously for the remaining curtain sizes. Change of program is displayed on the

diagram and consists in a cable switch in controller HMI. The heating program is independent from the fan speed setting.

Electric heater are protected with 4 thermostats, 2 for each section: one with automatic reset and second with manual reset. The thermostat button for manual reset is available to push from

the top of the curtain via the top cover grid on the motor side.

2. CONTROL SYSTEM: it is equipped with an outlet on the connection clamp block X1 for WING W100-200 and on the X2 block for WING E100-200 for connecting an on-wall controller as well as

a valve actuator for WING W100-200. WING air curtains can be additionally equipped with a wall-mounted DX controller. The DX controller has a three-position heating switch. In the case of a

water curtain, to guarantee the proper functioning of the water valve, the heating switch must be set to position II (central) - otherwise the valve will not open.

The system of WING E100-200 is equipped with a safety device in the form of a fuse in the 115 V AC circuit.

3. HORIZONTAL FAN: the maximum temperature of operation is 200°F; the rated voltage is 240 V/60Hz. The motor protection level is IP44. The horizontal fan applied in the device with an advanced

profile of blades and impeller geometry made of plastic makes it possible to obtain air capacities up to 2648 CFM. The control of the electric motor as well as thermal protections of the winding has

been coupled with the control system which resulted in increasing safety of operation. Due to optimum power of the motor the WING curtain is energy saving and durable.

5. INSTALLATION BRACKETS: WING is characterized by simple, quick and aesthetic assembly that can be performed on a wall in both horizontal and vertical position. There are from 2

to 3 installation handles attached (as an option) to the curtain (depending on the option (length). Connections of electric wires and water channels have been especially designed not to

interfere with the general aesthetic values of the device. The name WING includes devices that are 42, 62 and 82in long that, if necessary, can be additionally joined both horizontally

and vertically to achieve different air supply options: from the left to the right and the opposite. The reach of the air stream is up to 13 ft.

2.4. OVERALL DIMENSIONS (WING E, W, C 100-200)

3. MOUNTING

IMPORTANT!

● The place of assembly should be carefully selected, taking into account the occurring of potential loads or vibrations.

● Prior to all installation or maintenance work, disconnect power supply and secure it against unintentional reactivation.

● It is recommended to use filters in the hydraulic system. It is recommended to clean/rinse the system, draining a few liters of water, prior to the connecting of hydraulic conduits (the supply

conduits, in particular).

IMPORTANT!

The air is blown out of the curtain at high velocity, along the surface of the opening, thus creating a protective barrier. Air curtains should cover the entire width of the door opening, in order to

obtain the maximum performance of the curtain.

IT IS RECOMMENDED TO TAKE INTO ACCOUNT THE FOLLOWING PARAMETERS, WHEN ASSEMBLING THE CURTAIN:

The width of the door frame should be less or equal to the width of the supplied air stream.

INCORRECT

CORRECT

EN

5

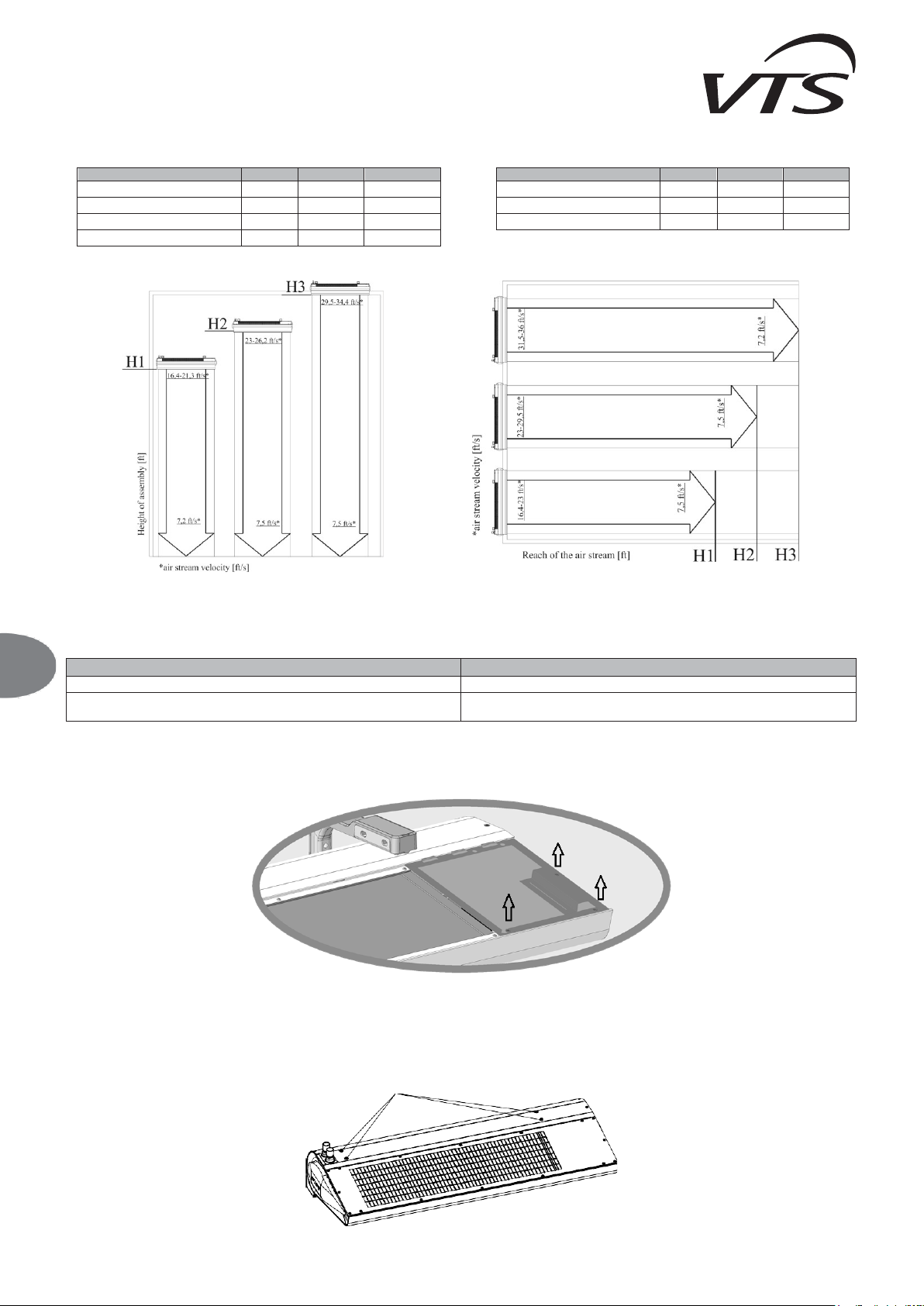

The range of the air jet - installation height

- Horizontal installation - Vertical installation

CAUTION! Air curtains with electric heat (models E100, E150 and E200) are not intended for vertical installation.

IMPORTANT! The heating output should be adjusted to the temperature inside the room, as well as the strength and direction of the wind outside. The primary criterion for the regulation of the

heating power is the temperature inside the room, near the door. Should a room thermostat be used, WING activates the heating mode, depending on the temperature settings.

IMPORTANT! Please consider additional factors that affect device operation.

Factors that have a negative effect on curtain operation

Factors that have a positive effect on curtain operation

doors or windows that are constantly open in the room, thus creating a draft

presence of awning, roofs etc. on the outer side of the door

constant and open access to staircases, available through the room, the chimney draft

effect

use of revolving doors

3.1. ASSEMBLY/ DISASSEMBLY OF JUNCTION BOX COVER

To access the terminal block remove the screws from the junction box cover and tilt it.

3.2. INSTALLATION OF DEVICE

For directly installation use the threaded sleeves (5/16”) in the top of the device.

5/16”

IMPORTANT! The minimum distance between the unit and the ceiling should be 4 in.

fan speed

III

II

I

height of installation [ft]

H3

H2

H1

WING W100, W150, W200

12

9-1/2

7-1/2

WING E100, E150, E200

12

9-1/2

7-1/2

WING C100, C150, C200

13

9-1/2

7-1/2

fan speed

III

II

I

width of the door [ft]

H3

H2

H1

WING W100, W150, W200

12

9-1/2

7-1/2

WING C100, C150, C200

13

9-1/2

7-1/2

EN

WING W100-200

WING E100-200

WING C100-200

6

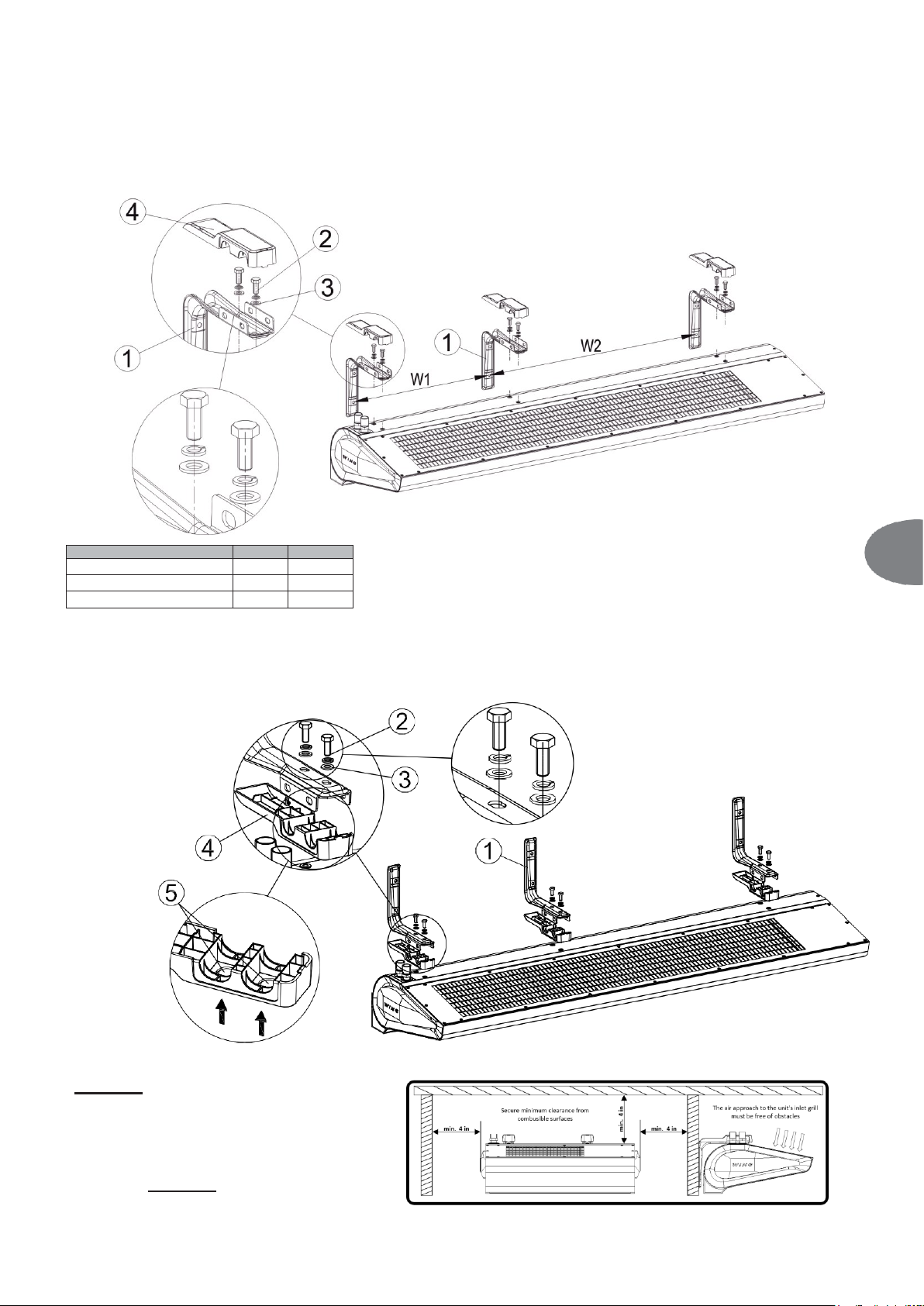

3.2.1. HORIZONTAL INSTALLATION BY MEANS OF BRACKETS.

It is possible to install the WING do the wall horizontally in two options:

OPTION I: installation brackets with their arms faced upwards. In this option you should first screw the installation brackets to the wall (1) with intervals W1 for a 42in curtain (there are 2 installation

handles) and W1, W2 for 62in and 82in curtain (there are 3 installation handles) so that the handles' arms are levelled. Then lift the curtain and assembly with using screws (2) 1/4-UNC x 3/4 and plain

washers (3). Tighten the screws (2) and close the handle's covers (4).

W1 [in]

W2 [in]

WING W, E, C100

30 - WING W, E, C150

20

30

WING W, E, C200

36

35

OPTION II: Installation brackets with their arms faced downwards.

Installation consists in screwing brackets to the curtain (1). To mount the brackets to the curtain, with the housing upside down, punch holes (5) from the outside in the shields (4) using a hammer and a

screw. Click the shields on the brackets (1). Mount the brackets on the curtain using 1/4-UNC x 3/4 screws (2) and washers (3). This installation option allows for mounting brackets to the curtain first,

and then screwing the entire housing to the wall.

Caution!

For any of above listed installation

method, the minimum distance between

the unit and the ceiling/side walls -

minimum 4 inches.

EN

7

3.2.2. VERTICAL INSTALLATION USING INSTALLATION BRACKETS.

It is possible to install WING to a wall vertically on both sides of the gate (with the motor on the bottom or on the top).

For this option it is not important if you screw the handles down to the unit first and then screw the whole down to the wall or first attach the handles to the wall and then screw the curtain down to the

handles.

To install the curtain vertically, use 1/4-UNC x 2 3/4 (outside the scope of VTS delivery) screws. Screw 2 or 3 brackets using the screws, passing through flat washers (3), to the threaded sleeves mounted

in the upper part of the housing.

IMPORTANT: For vertical installation, keep minimum distance of 4 inches between the floor and the lower end of the curtain. This is to secure free access to the water coil air vent.

E

IMPORTANT! The device is intended for the operation in dry rooms, exclusively. Thus, pay particular attention to the condensation of wat er vapor on engine elements, since it is not fitted

for operating in humid environment.

IMPORTANT! The WING air curtains are not intended for the installation:

● Outdoor.

● In humid rooms;

● In rooms categorized as explosive environments.

● In rooms with very high levels of dustiness;

● In rooms with aggressive atmosphere (due to the presence of copper and aluminum structural elements in the heat exchanger and electric heaters).

IMPORTANT! The WING EH air curtains are not intended for the installation on suspended ceilings.

3.3. INSTALLATION GUIDELINES

CONNECTION OF THE HEATING MEDIUM

When connecting the air curtain to the heating water pipeline, secure the coil headers from excessive torque using set of two keys. The weight of installed pipelines should not impose a load on

the heater’s headers.

IMPORTANT! Pay particular attention to the leak-tightness of connections, when filing the hydraulic system. Make sure that the water flowing from a leaky connection does not leak to the

electric engine (at the vertical installation)

IMPORTANT! It is recommended to use filters in the hydraulic system. It is recommended to clean/rinse the system, draining a few liters of water, prior to the connecting of hydraulic conduits

(the supply conduits, in particular).

EXAMPLE OF HYDRAULIC SYSTEM

1. WING 100-200

2. VALVE WITH ACTUATOR

3. VENT VALVE

4. SHUT-OFF VALVE

5. FILTER

6. CIRCULATING PUMP

7. BOILER

1

VENTING OF DEVICE/DRAINING OF HEATING MEDIUM

To perform horizontal and vertical installation, the exchanger on the right-hand side of the door vents automatically. In the case of horizontal installation with the stub pipes facing downwards, to

vent the exchanger, remove the side cover. Unscrew the screws (1) around the cover and remove the cover. A valve with a hose is situated below the cover.

RETURN

SUPPLY

SUPPLY

RETURN

min.

4 in

EN

WING W100-200

WING E100-200

WING C100-200

8

VENTING OF DEVICE/DRAINING OF HEATING MEDIUM

Venting of the curtain water coil followed by loosening the union connection on the outlet connection. In case of the vertical installation with the coils connection on the bottom side, the access

to the vent valve is by removing the side cover. To do it one should remove the screws (1) around the cover and lift the cover. There is a valve (2) with a hose.

VENT/DRAIN MARKING

2 3

3

2

1

IMPORTANT! While venting the exchanger you should pay special attention to securing the device against accidental penetration of water into electrical elements.

IMPORTANT! Remember to vent the heater, if it has been activated after a prior draining of the heating medium.

IMPORTANT! Pay particular attention to the leak-tightness of connections, when filing the hydraulic system. Make sure that the water flowing from a leaky connection does not leak to the

electric engine (at the vertical instaallation).

CONNECTING OF POWER SUPPLY

IMPORTANT! The system must be equipped with protective equipment that guarantees the disconnecting of the device on all poles of the power source.

Connection to the electric system must be performed by a duly authorized and qualified person. Wire grommets are located on the back side of the curtain, a per drawing below.

• Central gland [1]

o Power supply input

• Left gland [2]

o Heating stage control signals input - only Wing air curtains with electric heat (E type)

• Right gland [3]

o Fan revolutions control signal input

CAUTION

For all connections (Power supply input, Heating stage control input, Fan revolutions

control signal input):

Minimum cables rating: UL/CSA 600 Volts.

CABLES CROSSING BETWEEN THE GLANDS AND TERMINAL BLOCK

To ensure proper separation between high and low voltage cables, follow below wiring instruction:

Power supply cable (high voltage)

• Cross the cables through the central gland (No. 1 on the drawing above).

• Cross the cable through the central mounting point and tight the strain relief.

• Gently pull the cable from outside to make it straight between the gland and mounting point. Then tighten the

gland.

• Connect the wires to the relevant high-voltage terminals.

Heating stages control H1 & H2 (High voltage)

• Cross the cables through the gland no. 2 on the drawing above.

• Cross the cable through its mounting point (see diagram on the right) and tight the strain relief.

• Gently pull the cable from outside to make it straight between the gland and mounting point. Then tight the

gland.

• Connect the wires to the relevant high-voltage terminals.

Low voltage cable (0-10 volts fan revolutions control (low voltage)

• Cross the cable between the small gland no 3 on the drawing above.

• Mount the cable to the top mounting arm of the motor using cable tie (supplied with the curtain kit) – auxiliary

mounting point no 1.

• Cross the cable through its mounting point (see diagram on the right) tighten the strain relief.

• Cross the cable through auxiliary mounting points no 2 and 3.

• Connect the wires to the relevant low-voltage terminals.

• Gently pull the cable from outside to make it straight between the gland and mounting point. Then tighten the

gland.

*Heating stages high-voltage control signals concern only Wing air curtains with electric heat.

Cables marked as below:

Power supply cable

Electric heating stages control signal cable

0-10 volts fan revolutions control cable

EN

WORKING POSITION

A

horizontal (downward air feed)

drain

automatic venting

B

vertical (air feed from left to right)

drain

automatic venting

C

vertical (air feed from right to left

venting

drain

Heating stages cable

mounting point

Power supply cable

mounting point

0-10 volts cable

auxiliary mounting

point 2

0-10 volts cable

auxiliary mounting

point 1

Power supply cable

gland

Heating stages

cable gland

0-10 volts

cable gland

0-10 volts cable

auxiliary mounting

point 3

Recommended safety devices and wires

Device

WING E100-200

E100 E150 E200

Supply voltage 1~240V

MCB

35A

MCA

33.5A

FLA

27.1A

Power wire cross-section

3 x 10 AWG

Cable Nominal Voltage UL/CSA 600 V

Supply voltage 3~240V

MCB

25A

45A

55A

MCA

20.5A

38.8A

49.8A

FLA

16.7A

32A

40.6A

Power wire cross-section

5 x 12 AWG

5 x 10 AWG

5 x 8 AWG

Cable Nominal Voltage UL/CSA 600 V

Supply voltage 3~480V

MCB

15A

25A

30A

MCA

11A

20.2A

26.7A

FLA

9.1A

17.2A

22.1A

Power wire cross-section

5 x 14 AWG

5 x 12 AWG

5 x 12 AWG

Cable Nominal Voltage UL/CSA 600 V

IMPORTANT! The specification of cables and protections refers to unbounded arrangement of. One should always abide by the local laws and recommendations concerning device connection.

WING is equipped with a terminal strip adjusted to an appropriate thickness of wires.

Air curtain model

Terminals view

Terminals description and function

WING E100 240/1/60 EC

L1 – Power supply phase

L2 – Power supply phase

– Ground

1L1 – N/C

L2 – N/C

2 – first heating stage controlled by applying

240VAC

3 – second heating stage controlled by applying 240VAC

Ai – 0-10VDC analog input for fan speed regulation

G – Reference ground for 0-10VDC speed regulation

– connected internally

1L1 – connected internally

L2 – connected internally

WING E100 240/3/60 EC

L1 – Power supply phase

L2 – Power supply phase

L3 – Power supply phase

– Ground

1L1 – N/C

L2 – N/C

2 – first heating stage controlled by applying

240VAC

3 – second heating stage controlled by applying 240VAC

Ai – 0-10VDC analog input for fan speed regulation

G – Reference ground for 0-10VDC speed regulation

– connected internally

L1 – connected internally

L2 – connected internally

WING E100 480/3/60/HLD EC

L1 – Power supply phase

L2 – Power supply phase

L3 – Power supply phase

– Ground

1L1 – N/C

L2 – N/C

2 – first heating stage controlled by applying

240VAC

3 – second heating stage controlled by applying 240VAC

Ai – 0-10VDC analog input for fan speed regulation

G – Reference ground for 0-10VDC speed regulation

– connected internally

1L1 – connected internally

2L2 – connected internally

WING E150 240/3/60 EC

WING E200 240/3/60 EC

L1 – Power supply phase

L2 – Power supply phase

L3 – Power supply phase

– Ground

1L1 – N/C

L2 – N/C

2 – first heating stage controlled by applying

240VAC

3 – second heating stage controlled by applying 240VAC

Ai – 0-10VDC analog input for fan speed regulation

G – Reference ground for 0-10VDC speed regulation

– connected internally

1L1 – connected internally

L2 – connected internally

WING E150 480/3/60/HLD EC

WING E200 480/3/60/HLD EC

L1 – Power supply phase

L2 – Power supply phase

L3 – Power supply phase

– Ground

1L1 – N/C

L2 – N/C

2 – first heating stage controlled by applying

240VAC

3 – second heating stage controlled by applying 240VAC

Ai – 0-10VDC analog input for fan speed regulation

G – Reference ground for 0-10VDC speed regulation

– connected internally

1L1 – connected internally

2L2 – connected internally

WING W100 240/1/60 EC

WING W150 240/1/60 EC

WING W200 240/1/60 EC

L1 – Power supply phase

L2 – Power supply phase

– Ground

1L1 – N/C

L2 – N/C

2 – input signal form HMI to control on/off valve

9 – valve with actuator Control

10 – valve with actuator control

Ai – 0-10VDC analog input for fan speed regulation

G – Reference ground for 0-10VDC speed regulation

– connected internally

1L1 – connected internally

L2 – connected internally

WING C100 240/1/60 EC

WING C150 240/1/60 EC

WING C200 240/1/60 EC

L1 – Power supply phase

L2 – Power supply phase

– Ground

L1 – N/C

L2 – N/C

Ai – 0-10VDC analog input for fan speed regulation

G – Reference ground for 0-10VDC speed regulation

– connected internally

1L1 – connected internally

L2 – connected internally

Device

WING W100-200 and WING C100-200

W/C100

W/C150

W/C200

Fan supply voltage 1~240V

MOP

15

15

15

MCA

1.9A

2.8A

4.4A

FLA

1.5A

2.2A

3.5A

Power wire cross-section

3 x 14 AWG

Cable Nominal Voltage UL/CSA 600 V

WING W100-200

WING E100-200

WING C100-200

10

Air curtains control

• The motor is controlled by applying voltages in the range 0-10VDC to terminals Ai and G

• The motor will not start when a voltage of 0-1VDC is applied to terminals Ai and G

• The motor speed is controlled by changing the voltage supply to the terminals Ai and G in the range 1-10VDC. The value of the given voltage in a linear manner influences the motor speed in the

range from 10-100% of its full efficiency.

• The electric heating coils should only be turned ON when the motor is running at least 45% of its full capacity. Starting electric heating coils when the motor is switched OFF can be dangerous and

can lead to damage to the device.

• Electric heating coils are divided into two independent sections controlled by applying 240VAC to terminals 2 and 3 on the terminals of electric curtains

EN

IMPORTANT!

• It is recommended to connect wires to the terminal strip with previously clamped appropriate clip ends.

• Make sure that the space around the place where the air is sucked in by the curtains, as well as around the exhaust grid, is free of any structural elements of the building, which might hamper the

flow of air (e.g. suspended ceilings, covering development, ventilating ducts etc.).

HMI-WING EC

4. ELEMENTS OF CONTROLS.

Electrical connections can be carried out only by qualified electricians, according to the binding regulations of:

● industrial safety;

● installation instructions.

● technical documentation for each individual element of automatics.

IMPORTANT! Before starting the controls installation, please read the operation and installation instruction for each of them. Instructions are included in the box for each control.

MODEL

DIAGRAM

TECHNICAL DATA

COMMENTS

HMI WING UL

HMI-WING UL

•

Device operation: touch buttons

•

Power supply: 120-240 V AC

•

Temperature measurement: 14 °F ... 210 °F ; NTC10K

•

Outputs:

- 1 analog output 0-10V (8 bit, Imax = 20 mA)

- 2 relays outputs (250 VAC, AC1 500 VA dla 230 VAC)

•

Communication: Modbus RTU

•

used for control all types of WING EC curtains

•

touch control panel

•

the main on / off switch (ON / OFF)

•

three-stage adjustable fan speed of the EC motor

•

built-in thermostat with possibility weekly programing

•

continuous mode

•

function of heating and ventilation

•

door sensor operation

•

3-levels of heating power

•

RS 485 with ModbusRTU

•

Suggested cross sections of electrical cables::

- L, N : 2x18 AWG

- H1, H2 : 2x18 AWG

- AO, GND : 2x18 AWG

- RS 485 : 2xAWG18

TWO-WAY VALVE WITH

ACTUATOR

TWO-WAY VALVE

● Terminal diameter: 3/4”

● Mode of operation: two-way ON/OFF

● Maximum differential pressure: 13psi

● Pressure class: PN 16

● Kvs flow ratio: 2.65 CFM

● Maximum temperature of heating medium: 200°F

● Parameters of working environment: from 32 to 140°F

VALVE ACTUATOR

● Power consumption: 7 VA

● Supply voltage: 230VAC +/-10%

● Closing/opening time: 4-5/9-11 s

● Position without power: closed

● Level of protection: IP54

● Parameters of working environment: from 89 to 200°F

● It is recommended to install a two-way valve on the return pipeline.

● The drawings with the elements of automatics contain only visualizations of

sample products.

● It is recommended to connect the supply, using a conductor of the min. size

0.08x0.03 in2.

● The drawings with the elements of automatics contain only visualizations of

sample products.

IMPORTANT! If required, the conductors that belong to additional elements of control automatics (thermostat, door switch, wall-mounted controller) should be installed in separate cable

channels, out-of-parallel to the supply conductors.

5. START-UP, OPERATION, MAINTENANCE

5.1. START-UP/PUTTING INTO OPERATION

● Prior to the commencing of any installation or maintenance work, disconnect power supply and secure it against unintentional reactivation.

● It is recommended to use filters in the hydraulic system. It is recommended to clean/rinse the system, draining a few liters of water, prior to the connecting of hydraulic conduits (the supply conduits,

in particular).

● It is advised to use vent valves in the highest point of the system.

● It is recommended to install shut-off valves directly after the device, should the disassembly of the device be necessary.

● All protective equipment is to be installed before the pressure increases, according to maximum the permissible pressure rating of 232 psi.

● Hydraulic connection should be free of any stresses and loads.

● Check the correctness of hydraulic connections (leak-tightness of the vent, collecting pipes, correctness of fittings installation), prior to the initial start-up of the device.

● It is recommended to check the correctness of electrical connections (of automatics, power supply), prior to the initial start-up of the device. It is advised to use an additional, external residual-

current protection.

IMPORTANT! All connections should be carried out, according to this technical documentation and the documentation delivered with automation equipment.

5.2. OPERATION AND MAINTENANCE

● It is advised to carefully analyze all the operational and installation guidelines listed in chapter 3 and 4.

● The casing of the device does not require maintenance.

● The heat exchanger should be cleaned on a regular basis from dust and fat deposit. It is especially recommended to clean the exchanger before the heating season with the use of compressed air

from the air intake side (after removing the inlet grid). You should pay special attention to the exchanger's lamellae which are very delicate.

● Should the lamellas be deformed (bent), straighten them with a special tool.

● The fan's motor does not require any exploitation service, the only service activities that may be necessary concern cleaning the air intakes from dust and fat deposit.

● Disconnect phase voltage, if the device is shut down for longer periods of time.

● The heat exchanger does not have any anti-freezing protections.

● It is recommended to provide a periodical purging of the heat exchanger, preferably using compressed air.

● Should the temperature in the room drop below 32°F, with a simultaneous drop of the heating medium temperature, there is a risk that the heat exchanger might freeze (crack).

● The level of air pollutants should meet the criteria allowable concentrations of pollutants in indoor air, for non-industrial areas, the level of dust concentration up to 1.87x10-5 lbs/ft3.

● It is forbidden to use device for the duration of the construction works except for the start-up of the system.

● The equipment must be operated in rooms used throughout the year, and in which there is no condensation (large fluctuations in temperature, especially below the dew point of the moisture

content). The device should not be exposed to direct UV rays.

● The device should be operated at the supply water temperature up to 200 °F with working fan.

EN

WING W100-200

WING E100-200

WING C100-200

12

6. SERVICING

6.1. PROCEDURE IN CASE OF MALFUNCTION

EN

It is forbidden to place, dispose of and store worn-out electric and electronic equipment, together with other waste. Dangerous compound contained in electronic

and electric equipment have a very adverse impact on plants, micro-organisms, and, most importantly, on humans, as they damage our central and peripheral

nervous system, as well as circulatory and internal system. Additionally, they cause serious allergic reactions. Worn-out equipment is to be delivered to a local

collection point for used electric equipment, which carries out a selective collection of waste.

REMEMBER!

The user of equipment intended for households, and which has been worn out, is obliged to transfer such equipment to a collecting unit that collects worn-out

electric and electronic equipment. The selective collecting and further processing of waste from households contributes to the protection of environment,

reduces the penetration of hazardous substances into the atmosphere and surface waters.

6.2. COMPLAINT PROCEDURE

In order to report a problem with the device or elements of automation, please fill in and send the appropriate form (p.74), using one of the three available ways:

1. E-mail:

america@vtsgroup.com

2. Fax: +1 470-809-6815

3. Website: https://vtsgroup.com/us/service-vts

Our service department will contact you immediately.

In the case of damage in transport, send a complaint notification, including the delivery documentation (bill of lading, inventory issue) and photographs showing the defects.

Should you have any questions, please contact us, using this telephone number: +1 470-809-6811

IMPORTANT! The complaint procedure shall be initiated when the Service Department has received a correctly filled complaint notification, a copy of the purchase invoice and the Warranty

Card, filled by the company that carried out the installation.

7. INDUSTRIAL SAFETY INSTRUCTION

Special instructions concerning safety

IMPORTANT!

● Prior to the commencing of any work related to the device, it is required to disconnect the system, secure it properly and wait, until the fan stops revolving.

● Use stable working platforms and hoists.

● Depending on the temperature of the heating medium, pipes, elements of casing and surfaces of the heat exchanger can be very hot, even after the fan has stopped revolving.

● Sharp edges may be present! Wear gloves, protective shoes and clothing, when transporting the device.

● Strictly observe safety guidelines and industrial safety regulations.

● Loads can be placed only in the previously selected areas on the transporting unit. Protect the edges of the device, when lifting it, using a set of machines. Remember to distribute weight evenly.

● The equipment must be protected against moisture and dirt, and kept in rooms protected against the impact of weather conditions.

● Utilization of waste: make sure that operating and auxiliary materials, including packaging material and spare parts, are disposed of in a safe, environment friendly manner, according to the binding,

local statutory regulations.

WING W100-200/EHN

Symptoms

What to check

Description

Leakage in the WING

W100-200 heat

exchanger

● Fitting of the heat exchanger terminals, using two keys acting in two opposite

directions (apply the keys on each terminal), which protects against the possibility

of internal breaking of the collecting pipes.

● Relation between the leaking and a potential mechanical damage to the

exchanger.

● Leaking of vent valve elements or drain plug.

● Parameters of the heating medium (pressure and temperature) should not

exceed the permissible values.

● Correctness of the draining of the exchanger.

● type of agent (it cannot be any aggressive substance Al or Cu active),

● Circumstances in which leaking occurred (e.g. during the trial/initial start-up of

the system; after having drained the heating medium, followed by the filling of

the system) and the external ambient temperature at the moment of the defect

taking place (freezing hazard to the exchanger).

● Potentially aggressive atmosphere (air) in the place of work (e.g. high

concentration of ammonia in the sewage-treatment plant).

● Pay particular attention to the possibility of the freezing of the heat

exchanger in the winter. 99% of leaks occur during start-up/pressure

checks. The rectifying of the defect consists in the pulling back of the

vent/drain valve.

The fan of the device

works too loudly WING

W100-200, EHN

● Installation of the device, according to the guidelines in the Operation and

Maintenance Documentation (among others, the distance from the ceiling).

● Minimum distance: 4 in from the ceiling

● Correctness of the horizontal alignment of the device.

● Correctness of electrical connections and qualifications of

● Parameters of the supply current (among others: voltage, frequency).

● Incorrect covering of the curtain in the suspended ceiling.

● Noise in lower speeds (damaged winding).

● Noise present only in the higher speeds – blocking of the air outlet.

● Type of other equipment working in the facility (e.g. exhaust fans) – increasing

noise may be a result of several pieces of equipment working simultaneously.

● Louder operation of WING devices may be a result of inappropriate place

of installation: e.g. choking the fan or the acoustic specifics of a room.

The fan in the device

is not operational

WING W100-200

● Correctness and quality of electrical connections and qualifications of the fitter.

● Parameters of the supply current (among others: voltage, frequency) on the

terminal block of the fan’s engine.

● Operational correctness of other pieces of equipment present in the facility.

● Correct fitting of the conduits on the engine side – information available from VTS

Service Department.

● Voltage on the PE conductor (if present, it may indicate a breakdown).

● The electrical connection of the device must be carried out, according to

the diagrams found in the Operation and Maintenance Documentation.

Damaged casing of the

device

WING W100-200

● Circumstances in which the defect occurred: remarks on the bill of lading,

inventory issue, condition of cardboard).

● Should the casing be defective, it is required to present photos of the

cardboard and device, as well as photos that confirm the compliance

between the serial number on the device and cardboard. If the damage

was done in transport, it is necessary to prepare a proper statement by the

driver/forwarder that delivered the goods.

Actuator does not open

the valve

● Correctness of electrical connections and qualifications of the fitter.

● Operational correctness of the thermostat (the characteristic “ticking” when

switching the device).

● Parameters of the supply current (among others: voltage).

● The most important step is to check whether the actuator has reacted to

the electrical impulse within 11 s. When actuator damage is claimed, a

complaint must be submitted for the damaged element, and the actuator

must be uninstalled from the valve to open the valve mechanically

(permanently).

EN

13

8. TECHNICAL SPECIFICATION

8.1. WATER AIR CURTAIN – WING W100-200

T

z –

temperature of water at the inlet to the device

Tp – temperature of water at the outlet from the device

T

p1

– temperature of air at the inlet to the device

T

p2

– temperature of air at the outlet from the device

P

g –

heating output of the device

Qw – water flow

Δp – pressure drop in the heat exchanger

EN

Parameters

WING W150

Tz/Tp [°F]

164/158

176/140

158/122

140/104

T

p1

[°F]

41

50

59

68

41

50

59

68

41

50

59

68

41

50

59

68

III/1824[CFM]/61dB(A)*

P

g

[MBH]

108

100

91

83

91

83

75

67

75

66

59

50

58

49

41

32

T

p2

[°F]

93

99

104

110

85

90

96

102

77

82

88

93

69

74

79

84

Qw [CFM]

0.82

0.76

0.70

0.64

0.70

0.64

0.59

0.53

0.59

0.53

0.47

0.41

0.41

0.35

0.29

0.23

Δp [psi]

0.304

0.261

0.232

0.188

0.232

0.203

0.174

0.130

0.174

0.145

0.116

0.087

0.116

0.087

0.058

0.043

II/1206[CFM]/48dB(A)*

P

g

[MBH]

90

83

76

70

76

70

63

56

63

56

49

42

48

41

34

26

T

p2

[°F]

98

104

109

114

89

95

100

105

81

86

91

96

71

76

81

85

Q

[CFM]

0.70

0.64

0.59

0.53

0.59

0.53

0.47

0.41

0.47

0.41

0.35

0.29

0.35

0.29

0.23

0.17

Δp [psi]

0.217

0.188

0.174

0.145

0.174

0.145

0.116

0.101

0.130

0.101

0.087

0.058

0.087

0.058

0.043

0.029

I/835[CFM]/43dB(A)*

P

g

[MBH]

73

68

62

57

62

57

51

46

51

45

40

34

39

33

27

16

T

[°F]

104

110

115

120

95

100

105

110

85

90

95

99

75

79

83

83 Q[CFM]

0.60

0.53

0.47

0.41

0.47

0.41

0.41

0.35

0.41

0.35

0.29

0.23

0.29

0.23

0.23

0.12

Δp [psi]

0.159

0.130

0.116

0.101

0.116

0.101

0.087

0.072

0.087

0.072

0.058

0.043

0.058

0.043

0.029

0.014

Parameters

WING W200

T/T[°F]

164/158

176/140

158/122

140/104

T

p1

[°F]

41

50

59

68

41

50

59

68

41

50

59

68

41

50

59

68

III/2589[CFM]/62dB(A)*

P

[MBH]

160

145

134

122

134

122

111

100

111

99

88

76

87

76

64

52 T[°F]

94

100

106

111

86

92

98

103

78

84

90

95

70

76

81

86

Qw [CFM]

1.17

1.12

1.00

0.94

1.00

0.94

0.82

0.76

0.82

0.76

0.64

0.59

0.64

0.59

0.47

0.41

Δp [psi]

0.812

0.710

0.609

0.522

0.623

0.536

0.449

0.377

0.464

0.377

0.304

0.246

0.319

0.246

0.188

0.130

II/1854[CFM]/48dB(A)*

P

[MBH]

139

129

118

108

119

108

98

88

98

88

78

68

77

67

57

46

T

p2

[°F]

97

103

109

114

89

95

100

106

81

86

92

97

72

78

83

88

Qw [CFM]

1.06

1.00

0.88

0.82

0.88

0.82

0.76

0.64

0.76

0.64

0.59

0.53

0.59

0.53

0.41

0.35

Δp [psi]

0.652

0.565

0.493

0.420

0.507

0.435

0.362

0.304

0.377

0.304

0.246

0.203

0.261

0.203

0.145

0.101

I/1206[CFM]/45dB(A)*

P

g

[MBH]

116

107

98

90

99

90

82

73

82

73

65

56

64

56

47

38

T

p2

[°F]

103

109

114

119

94

100

105

110

85

90

95

100

76

81

85

90

Qw [CFM]

0.88

0.82

0.76

0.70

0.76

0.70

0.64

0.59

0.64

0.59

0.47

0.41

0.47

0.41

0.35

0.29

Δp [psi]

0.464

0.406

0.348

0.304

0.362

0.319

0.261

0.217

0.275

0.232

0.174

0.145

0.188

0.145

0.101

0.072

Parameters

WING W100

Tz/Tp [°F]

194/158

176/140

158/122

140/104

T

p1

[°F]

41

50

59

68

41

50

59

68

41

50

59

68

41

50

59

68

III/1088[CFM]/59dB(A)*

P

[MBH]

60

55

50

46

50

45

40

35

39

34

29

23

27

17

14

12

T

p2

[°F]

89

95

101

107

81

87

92

98

73

78

83

88

63

64

71

78

Qw [CFM]

0.47

0.41

0.41

0.35

0.41

0.35

0.29

0.29

0.29

0.29

0.24

0.18

0.24

0.12

0.12

0.12

Δp [psi]

0.073

0.058 0.058 0.044 0.058 0.044 0.029 0.029 0.029 0.029 0.015 0.015 0.015

0.015 0.006

0.00

4

II/794[CFM]/48dB(A)*

P

[MBH]

51

47

43

39

42

38

34

30

33

29

24

16

18

15

13

11 T[°F]

94

100

105

110

85

90

96

101

76

81

85

85

60

66

73

80

Qw [CFM]

0.41

0.35

0.35

0.29

0.35

0.29

0.24

0.53

0.24

0.24

0.18

0.12

0.12

0.12

0.12

0.06

Δp [psi]

0.058

0.044

0.044

0.029

0.044

0.029

0.029

0.015

0.029

0.015

0.015

0.015

0.015

0.015

0.006

0.004

I/518[CFM]/44dB(A)*

P

[MBH]

40

37

33

30

33

30

27

23

26

22

15

13

15

13

11

9

T

p2

[°F]

101

106

111

116

91

96

100

104

79

83

83

89

64

70

76

83

Qw [CFM]

0.29

0.29

0.24

0.24

0.24

0.24

0.24

0.18

0.18

0.18

0.12

0.12

0.12

0.12

0.12

0.06

Δp [psi]

0.029

0.029

0.029

0.015

0.029

0.015

0.015

0.015

0.015

0.015

0.015

0.000

0.015

0.006

0.004

0.003

WING W100-200

WING E100-200

WING C100-200

14

8.2. ELECTRIC AIR CURTAIN – WING E100-200

T

p1

– temperature of air at the inlet to the device

T

p2

– temperature of air at the outlet from the device

P

g

– heating output of the device

Parameters

WING E100

WING E150

WING E200

T

[°F]

41

50

59

68

41

50

59

68

41

50

59

68

III/1088[CFM]/59dB(A)*

III/1854[CFM]/61dB(A)*

III/2648[CFM]/62dB(A)*

P

g

[kW]

2/4/6

2/4/6

2/4/6

2/4/6

4/8/12

4/8/12

4/8/12

4/8/12

6/9/15

6/9/15

6/9/15

6/9/15

T

[°F]

46/51/59

55/60/68

64/69/77

73/78/86

48/53/59

57/62/68

66/71/77

75/80/86

48/50/57

57/59/66

66/68/75

75/77/84

II/824[CFM]/48dB(A)*

II/1206[CFM]/48dB(A)*

II/1883[CFM]/48dB(A)*

P

g

[kW]

2/4/6

2/4/6

2/4/6

2/4/6

4/8/12

4/8/12

4/8/12

4/8/12

6/9/15

6/9/15

6/9/15

6/9/15

T

p2

[°F]

48/53/60

57/62/69

66/71/78

75/80/87

50/57/66

59/66/75

68/75/84

77/84/93

50/53/60

59/62/69

68/71/78

77/80/87

I/541[CFM]/44dB(A)*

I/853[CFM]/43dB(A)*

I/1265[CFM]/45dB(A)*

P

g

[kW]

2/4/6

2/4/6

2/4/6

2/4/6

4/8/12

4/8/12

4/8/12

4/8/12

6/9/15

6/9/15

6/9/15

6/9/15

T

p2

[°F]

51/60/69

60/69/78

69/78/87

78/87/96

55/66/78

64/75/87

73/84/96

82/93/105

53/59/69

62/68/78

71/77/87

80/86/96

8.3. WING C100-200 – COLD AIR CURTAIN

Parameters

WING C100

WING C150

WING C200

Fan speed

III

II I III

II I III

II I Qp [CFM]

1147

882

618

1883

1324

882

2707

2001

1377

noise level [dB(A)]*

62

49

45

63

49

43

63

49

45

* The noise level has been measured within a 10 ft distance from the device; reference conditions: semi-open space – wall-mounted device.

Parameters

WING W100-200

WING E100-200

WING C100-200

unit of

measure

W100

W150

W200

E100

E150

E200

C100

C150

C200

Maximum width of a single door for one

device

in

39

59

79

39

59

79

39

59

79

Maximum height of door

ft

12

13

Heating output range

MBH

13 –

58

34 – 109

58 –

160

7/20 or 14/20

13/41

or

27/4

1

20/51 or

30/51

-

Maximum flow rate

CFM

1089

1824

2589

1088

1854

2648

1147

1883

2707

Maximum temperature of heating

medium

°F

200 - -

Maximum working pressure

psi

232 - -

Water volume

in³

97

158

219

-

-

Diameter of stub pipe connectors

"

3/4 - -

Supply voltage

V/ph/Hz

~240/1/(50/6

0)

~240/1/(50/60)

or

~240/3/(50/60)

or

~480/3/(50/60)

~240/3/(50/60) or

~480/3/(50/60)

~240/1/(50/6

0)

Power of the electric heater

kW - 2 and 4

4 and 8

6 and 9

-

Rated current of the electric heater

A

-

9 or

5/10/15 or

3/5/8

10/20/30 or

5/10/15

15/22/37 or

8/11/19

- -

-

EC Engine power

HP

0,27

0,4

0,64

0,27

0,4

0,64

0,27

0,4

0,64

EC engine rated current

A

1.5

2.2

3.5

1.5

2.2

3.5

1.5

2.2

3.5

Weight

lbs 47 64 83 49 67 86 42 56 72

IP

-

20

EN

15

9. ELECTRICAL DIAGRAMS

9.1. Electrical diagram of WING W100-200-EC – 1~240V

WING W100-200

WING E100-200

WING C100-200

16

9.2. Electrical diagram of WING C100-200-EC – 1~240V

17

9.3. Electrical diagram of WING E100-EC 1~240V

WING W100-200

WING E100-200

WING C100-200

18

9.4. Electrical diagram of WING E100-EC -3~240V

19

9.5. Electrical diagram of WING E100-EC- 3~480V

WING W100-200

WING E100-200

WING C100-200

20

9.6. Electrical diagram of WING E150-200-EC- 3~240V

21

9.7. Electrical diagram of WING E150-200-EC- 3~480V

WING W100-200

WING E100-200

WING C100-200

22

Complaint Form

VTS America Inc.

3535 Gravel Springs Rd

Ext #203, Buford, GA

30519

PH: 470-809-6811, FAX:

470-809-6815

The company submitting the notification:

The company that installed the equipment:

Date of notification:

Type of device:

Factory number*:

Date of purchase:

Date of installation:

Place of installation:

Detailed description of defect:

Contact person:

Name and surname:

Telephone:

E-mail:

* This field must be filled, if the complaint notification refers to the following equipment: VOLCANO VR1, VR2, VR3 and VRMini unit, and WING air curtains.

23

Warranty card

1. Stamp of the company to carry out installation

VTS America Inc.

3535 Gravel Springs Rd Ext #203, Buford, GA 30519

PH: 470-809-6811, FAX: 470-809-6815

2. Factory number of device

3. Place of installation

4. Date of installation

5. Address, street

6. Apartment number

7. City

8. Postal code

Based on these Warranty Terms and Conditions, the company from the VTS Group (hereinafter: VTS) specified in the warranty card hereby guarantees to the owner

(hereinafter: Customer) that the Volcano VR, WING W100 - 200, WING E100 – 200, WING C100 - 200 devices (hereinafter: devices) sold by VTS will work without

malfunctions.

another place, after they are sent for repair.

Service Technicians and the costs of transporting spare parts. The current list of VTS Licensed Service Centres, hereinafter service centres, is available on

www.vtsgroup.com and in VTS business offices.

item.

consent of VTS.

the device, the Operation & Maintenance Manual or by individuals without proper qualifications.

Maintenance Manual or by individuals without proper qualifications.

or whose technical inspections or maintenance activities were conduc ted by individuals without proper qualifications.

Customer other than the devices.

another country than the country of purchase, VTS is under no obligation to provide service under the warranty.

sending the electronic application specified above.

delivered to the place of repair specified by VTS. The device serial number must be consistent with the number on the original packaging and in the Warranty Card.

line with the technical service price list available on www.vtsgroup.com

necessary, to remove and re-install the devices,

the complaint,

making sure that the service performance site meets the requirements defined in legal regulations.

of the warranty service, the Customer has the right to complain to VTS. Provisions of § 4 hereof shall apply to such a complaint as appropriate.

Terms and Conditions shall prevail. In such an event, any contradictory provisions of the Proposal and the Purchase Order shall not apply.

and Conditions shall prevail.

Loading...

Loading...