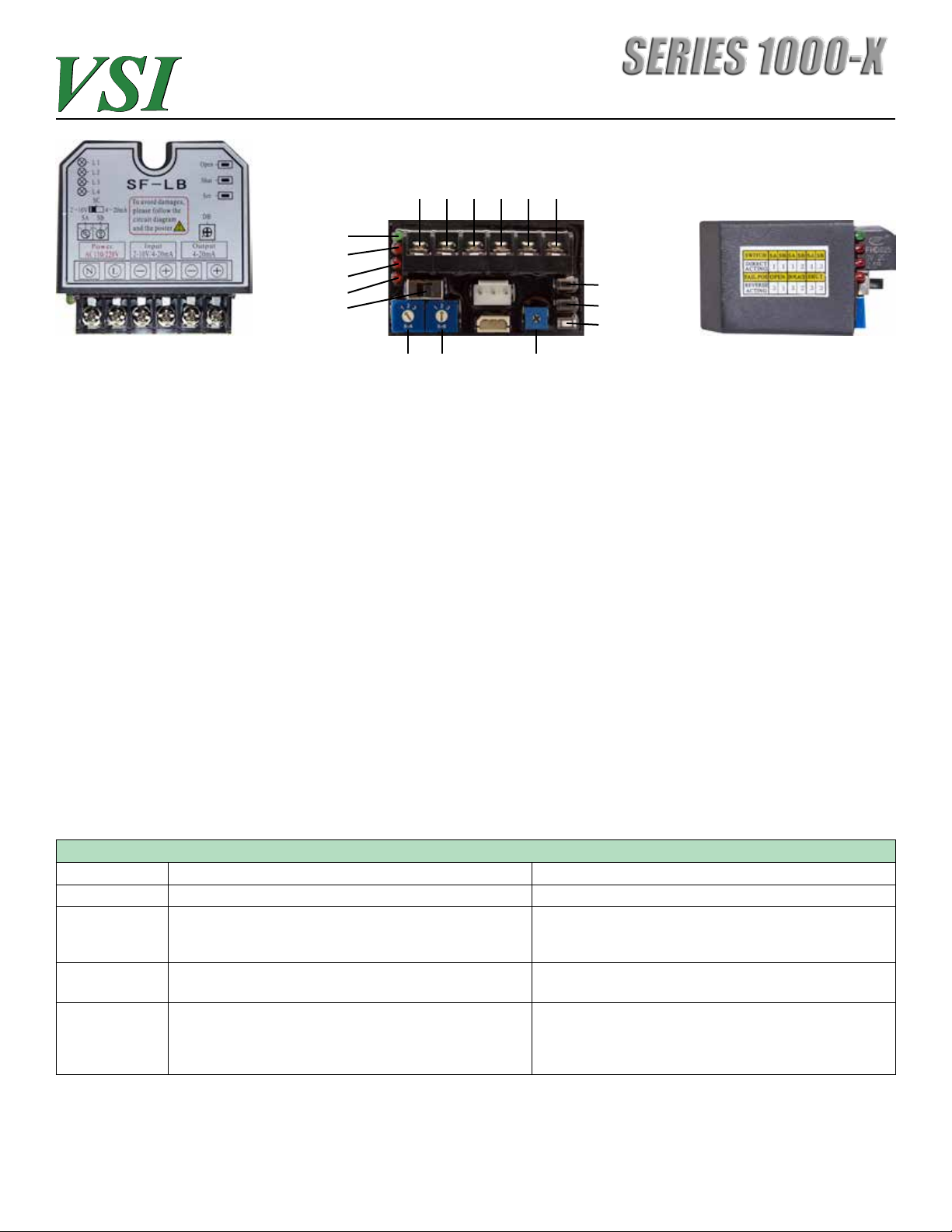

VSI 1000-X Series, SF-LB Quick Setup Manual

SF-LB QUICK SETUP GUIDE

FEED

POWER CTRL

LED 1

LED 2

LED 3

LED 4

SC

FIGURE A FIGURE B FIGURE C

SA SB DB

BACK

++ + -- -

OPEN

SHUT

SET

The SF-LB control pack, if shipped together with a Series 1000-X actuator, is factory calibrated and

set for 90° rotation and no adjustment should be needed. However, if you are replacing the SF-LB

or the factory settings do not conform to your actuator/valve application, some adjustment may be

necessary.

INITIAL SETUP

If the SF-LB is not installed – install in the actuator by plugging in the two cables into the unit. Connect the appropriate power to terminals 1&2. Connect the control signal to terminals 3&4 and note

that the polarity must be positive and negative.

If feedback is being used connect the wiring to terminals 5&6. The SF-LB provides position feedback

of 4-20mA.

At this point the Green LED “L1” should be illuminated. If red LED “L2” is illuminated then the control

signal is faulty or SC is not set correctly for your control signal. Ensure that SC is set for your application control signal (2-10V or 4-20mA). See the chart below for failure mode conditions on the SF-LB

control pack. Your actuator should be ready to operate.

SF-LB CONTROL PACK LED’S

LED CAUSE DESCRIPTION REMEDY

LED-1 (GREEN) POWER IS PRESENT ON INPUT TERMINALS ALL IS NORMAL - NONE NEEDED

LED-2 (RED) CONTROL SIGNAL IS WRONG OR NOT PRESENT CHECK SC SWITCH TO ENSURE PROPER CONTROL

SIGNAL IS SELECTED - CHECK TO ENSURE SIGNAL IS

PRESENT

LED-3 (RED) POTENTIOMETER IS NOT CALIBRATED WITH ACTUATOR

OUTPUT

LED-4 (RED) OVERTORQUE CONDITION PRESENT - VALVE BINDING,

OR MANUAL OVERRIDE HAS BEEN USED AND

ACTUATOR IS OUT OF SYNC WITH CONTROLLER

NOTE: THE ACTUATOR WILL NOT OPERATE WHEN MANUAL OVERRIDE PUSH BUTTON IS DEPRESSED

RE-CALIBRATE POTENTIOMETER PROCEDURE IN IOM

(CALL FOR ASSISTANCE)

CHECK TO MAKE SURE VALVE IS NOT BINDING. RESET

CONTROL PACK BY ROTATING S-A FROM 1 TO 2 AND

BACK TO 1, or REMOVE POWER TO THE ACTUATOR AND

REPLACE

SF-LB QUICK SETUP GUIDE

FIGURE D

MANUAL OVERRIDE PUSH BUTTON

The Series 1000-X units are equipped with a manual override power button which disconnects

the power to the actuator motor so that the unit can be rotated using the provided hand crank or

the optional hand wheel. Although SF-LB LED’s are operating, the motor power is disconnected

internally. If manual operation of unit is performed, the unit will need to be re-set by switching SA

from 1 to 2 and back to 1 again.

SWITCH SETTINGS

SA is used for setting the “direct acting” (2V=closed and 10V=open) or “reverse acting “(2V=open and

10V=closed) rotation of the actuator. SA is also used for placing the actuator in “set mode”. Set mode

is used to stroke the actuator using the “open” and “shut” buttons and used for setting the stoke limit

position of the actuator. SB is used for setting the positioning of the actuator in the case of a control

signal loss. Figure C shows the side of the controller with the options using SA and SB. Actuators

are shipped with the SF-LB control packs set to “direct acting” and fail “in place”. SC is used for

selecting the control signal (2-10V or 4-20mA). DB is used for setting the sensitivity on the “dead

band” – rotate clockwise for less sensitive, rotate CCW for more sensitive. Units are set to mid-range

sensitivity from factory.

SETTING THE POSITION LIMITS

NOTE: ACTUATOR IS EQUIPPED WITH MECHANICAL STOPS. THESE ARE FOR SAFETY ONLY AND

SHOULD NOT BE USED TO SET THE POSITION LIMITS ON THE ACTUATOR.

Position limits are factory set to 90° rotation. If desired, the position limits can be re-configured to

rotate less than 90°. To re-set the position limits of the unit, SA should be placed in “set mode”

by switching to “2”. At this point, the open and shut buttons can be used to stroke the actuator to

the desired position. To set the closed limit, make sure the control signal is applied with the proper

setting. For example – 2V is need for closed. Rotate the valve to the closed position. While holding

the white “set button” also press the “shut” (middle) button and hold until the LED flashes – then

release both buttons. This sets the closed limit. To set the open limit, rotate the actuator to the

open position using the “open” (top) push button. Place 10V control signal on input. While holding

the white “set button”, press and hold the “open” button until the LED flashes – then release both

buttons. This sets the open limit. Finally, switch SA back to 1 or 3 depending on the operation of the

unit (1 is direct acting and 3 is reverse acting).

For the complete IOM on the Series 1000-X actuators, please visit www.valvesolutions.com or if

technical support is needed during setup or troubleshooting, please call 770-740-0800.

Loading...

Loading...