VQ Models Volksplane VQA133US, Volksplane VQA134BLUE, Volksplane VQA134RED Instruction Manual

Radio control model

R/C Flugmodell

INSTRUCTION MANUAL

MONTAGEANLEITUNG

Designed for brushless electric motors

Entwickelt für Brushless Elektro Motoren

VOLKSPLANE

U.S VERSION: VQA133US SWISS VERSION: VQA134BLUE

SWISS VERSION: VQA134RED

SPECIFICATIONS

Wingspan 62.9in.

Length 46 in.

Electric Motor (See next page)

Radio 5 Channel / 4 Servos

TECHNISCHE DATEN

Spannweite 1600mm

Lange 1170mm

Elektroantrieb (siehe nächste Seite)

Fernsteuerung 5 Kanal / 4 Servos

WARNING! This radio controlled model is NOT a toy. If modified or flown carelessly it could go out of controll and

cause serious human injury or property damage. Before flying your airplane, ensure the air field is spacious enough.

Always fly it outdoors in safe areas and seek professional advice if you are unexperienced.

ACHTUNG! Dieses ferngesteuerte Modell ist KEIN Spielzeug! Es ist für fortgeschrittene Modellflugpiloten bestimmt,

die ausreichende Erfahrung im Umgang mit derartigen Modellen besitzen Bei unsachgemäßer Verwendung kann

hoher Personen- und/oder Sachschaden entstehen. Fragen Sie in einem Modellbauverein in Ihrer Nähe um

professionelle Unterstützung, wenn Sie Hilfe im Bau und Betrieb benötigen. Der Zusammenbau dieses Modells ist

durch die vielen Abbildungen selbsterklärend und ist für fortgeschrittene, erfahrene Modellbauer bestimmt.

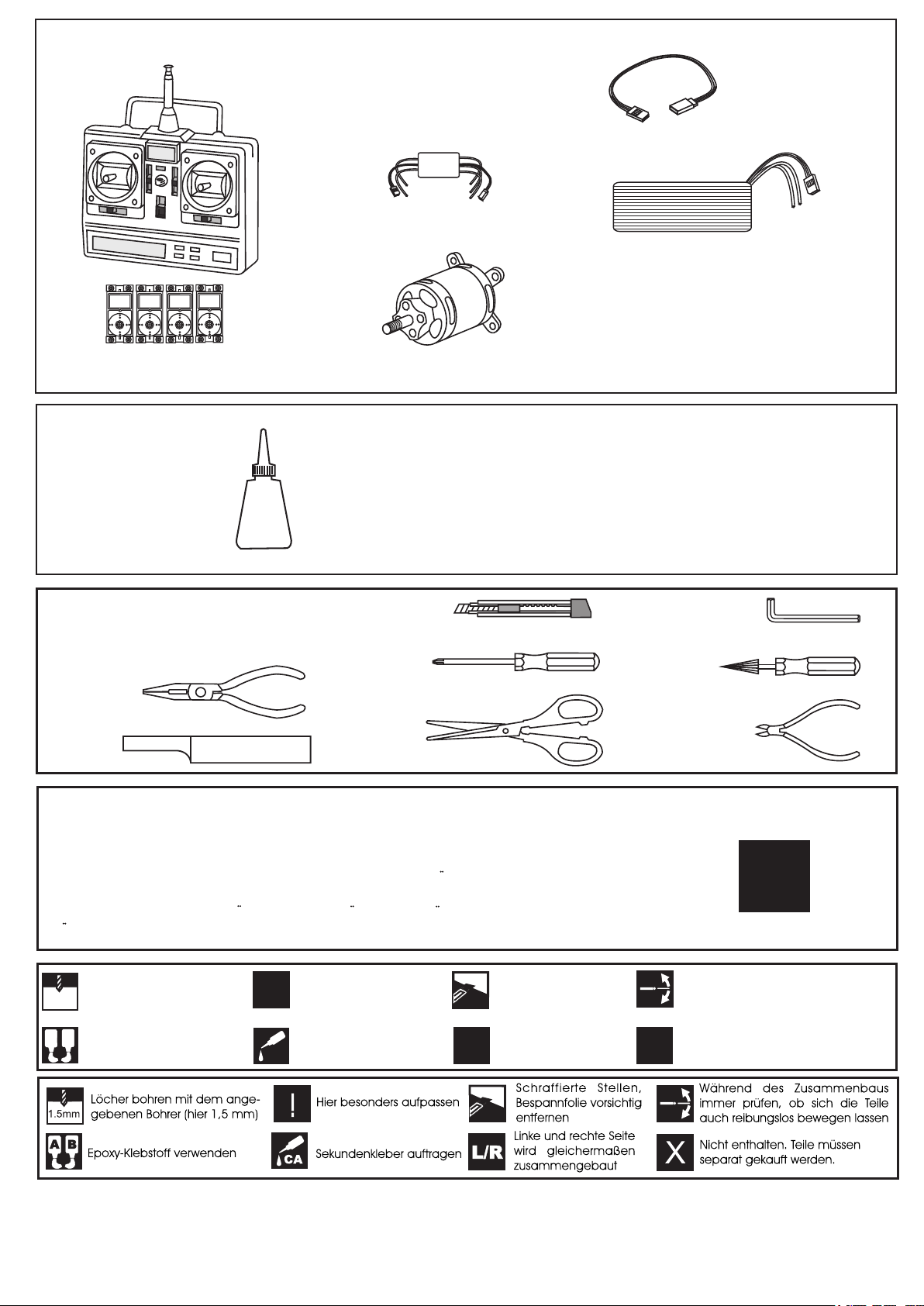

REQUIRED FOR OPERATION (Purchase separately)

Motor Control

Extension for aileron

servo.

Li-Po Battery, 3700mAh.

Minimum 5 channel radio

650-800W Brushless Motor

for airplane with 4 servos

Cyanoacrylate Glue

Sekundenkleber

CA

Tool Required/ Empfohlenes Werkzeug

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

The pre-covered film on ARF kit may wrinkle due to variations of temperature.

Store model in a cool and dry place for awile.

Then, staring with low heat, you may carefully use a hair dryer to smooth out wrinkels.

Die Bespannung des Modells kann durch Temeratureinflusse erschlaffen oder Falten

werfen z.b bei zu starker Sonnenenstrahlung oder Hitze.

Stellen Sie das Modell zunachst an einen kuhlen Platz fur eine bestimmte Zeit. Danach

konnen Sie versuchen die restlichen Falten vorstichtig mit einem Haartrockner zu behandeln.

Drill holes using the stated

1.5mm

size of drill

(in this case 1.5 mm Ø)

A

B

Use epoxy glue

Take particular care here

!

Apply cyano glue

CA

Hatched-in areas:

remove covering

film carefully

Assemble left and right

L/R

sides the same way.

X

CONVERSION TABLE

1.0mm = 3/64”

1.5mm = 1/16”

2.0mm = 5/64”

2.5mm = 3/32”

3.0mm = 1/8”

4.0mm = 5/32”

5.0mm = 13/64”

6.0mm = 15/64”

10mm = 13/32”

12mm = 15/32”

15mm = 19/32”

20mm = 51/64”

25mm = 1”

30mm = 1-3/16”

45mm = 1-51/64”

!

Check during assembly that these

parts move freely, without binding

Not included.

These parts must be

purchased separately

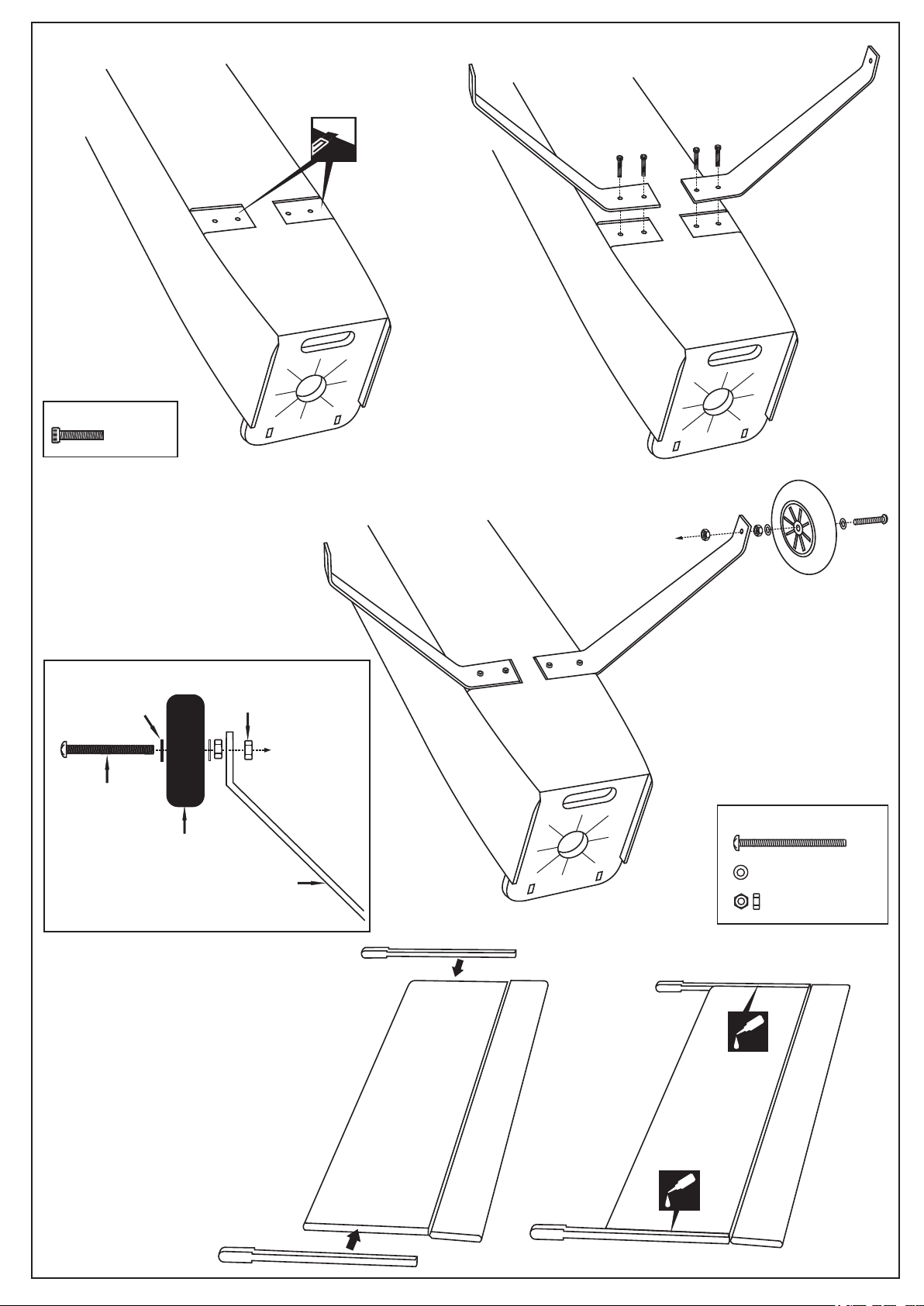

1

FUSELAGE - BOTTOM VIEW

Cut away only

the covering

1A

3x15mm screw

* WARNING: When removing any covering from the airframe, please ensure that you secure the

cut edge with CA or similar cement. This will ensure the covering remain tight.

4mm washer

...4

4mm bolt

1B

1C

4x45mm screw

75mm wheel

Aluminum landing gear

4X45mm

...2

4mm ...................4

4mm.................4

CA

CA

2

NOTE: cut inside the pencil lines.

Cut away only

the covering

both sides.

2B

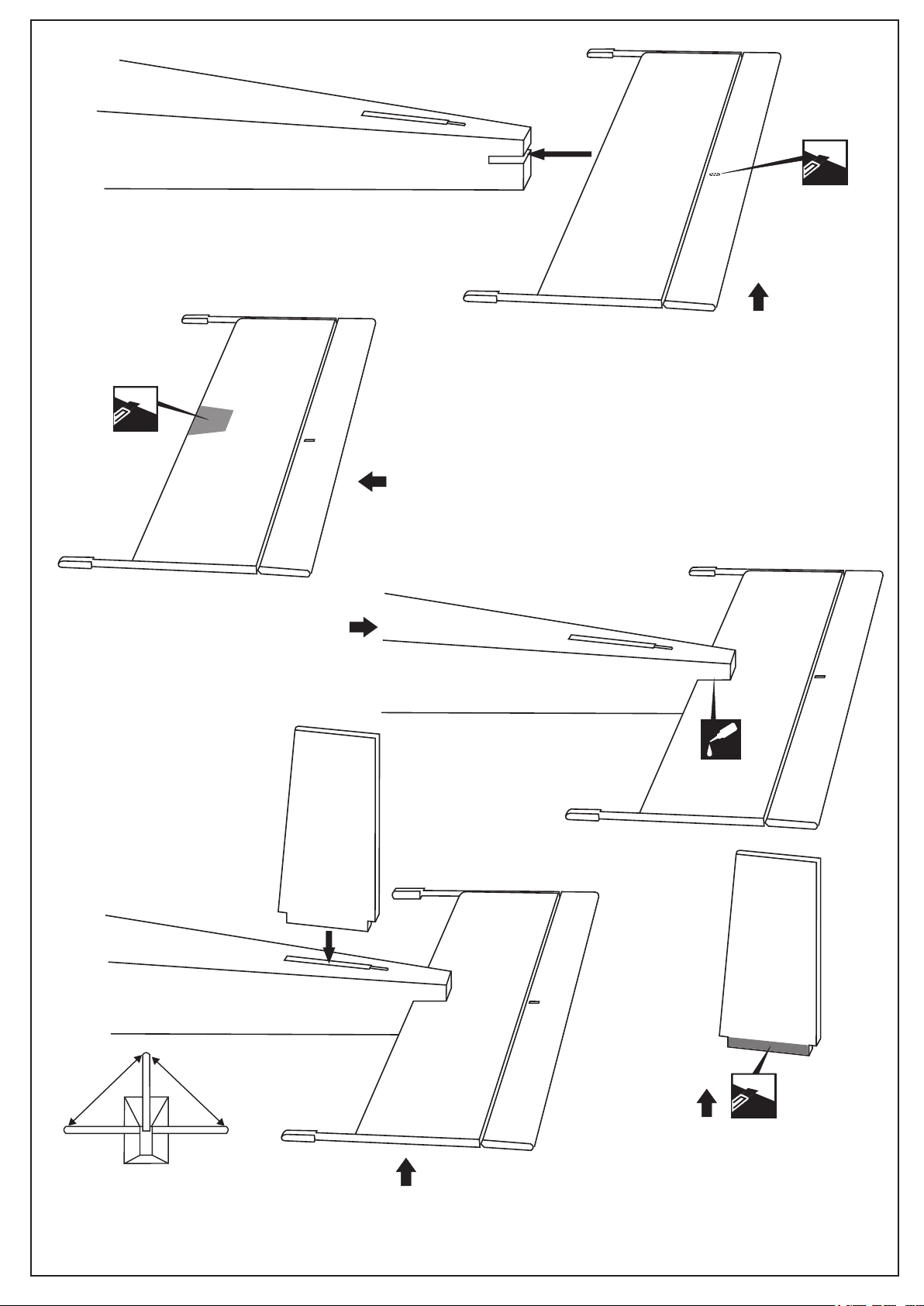

Trial fit the horizontal stabilizer in place on the

fuselage. Check the alignment of the horizontal

stabilizer by measuring from a fixed point along

the center line of the fuselage to the leading edge

on each side of the horizontal stabilizer. The

distance must be equal on both sides.

Using the pencil trace around the top and bottom

of the stabilizer where it meets the fuselage.

NOTE: Do not glue the horizontal stabilizer into

Remove the horizontal stabilizer from the fuse lage. Remove the covering material from the gluing

surfaces on both the top and bottom of the horizontal

stabilizer.

the fuselage at this time.

Cut away only

the covering

2A

Again, slide the horizontal stabilizer into the

fuselage. Check the alignment of the horizontal

stabilizer. Secure the horizontal stabilizer in place

using the thin CA glue.

Securely glue together. If coming off during

flight, you lose control of your air plane.

2D

2C

CA

2E

B

Trial fit the horizontal stabilizer in place on the fuselage.

Check the alignment with the horizontal stabilizer The distance must

be equal on both sides (B=B’).

Using the pencil trace around the top and bottom of the stabilizer where it

meets the fuselage.

B’

Cut away only

Remove the vertical stabilizer from the fuselage.

Remove the covering material from the gluing

surfaces on both the left and right of the vertical

stabilizer.

* WARNING: When removing any covering from

the airframe, please ensure that you secure the

cut edge with CA or similar cement. This will

ensure the covering remain tight.

the covering

both sides

3

Again, push the vertical stabilizer into the

fuselage. Check the alignment with the horizontal

stabilizer. Secure the vertical stabilizer in place

using the thin CA glue.

3A

CA

Securely glue together. If coming off during

flight, you lose control of your air plane.

Thin CA

CA

3D

After snapping, secure the

control horn flat with thin

CA glue.

3B

Cut away only

the covering

3C

Plastic control horn

.....................1

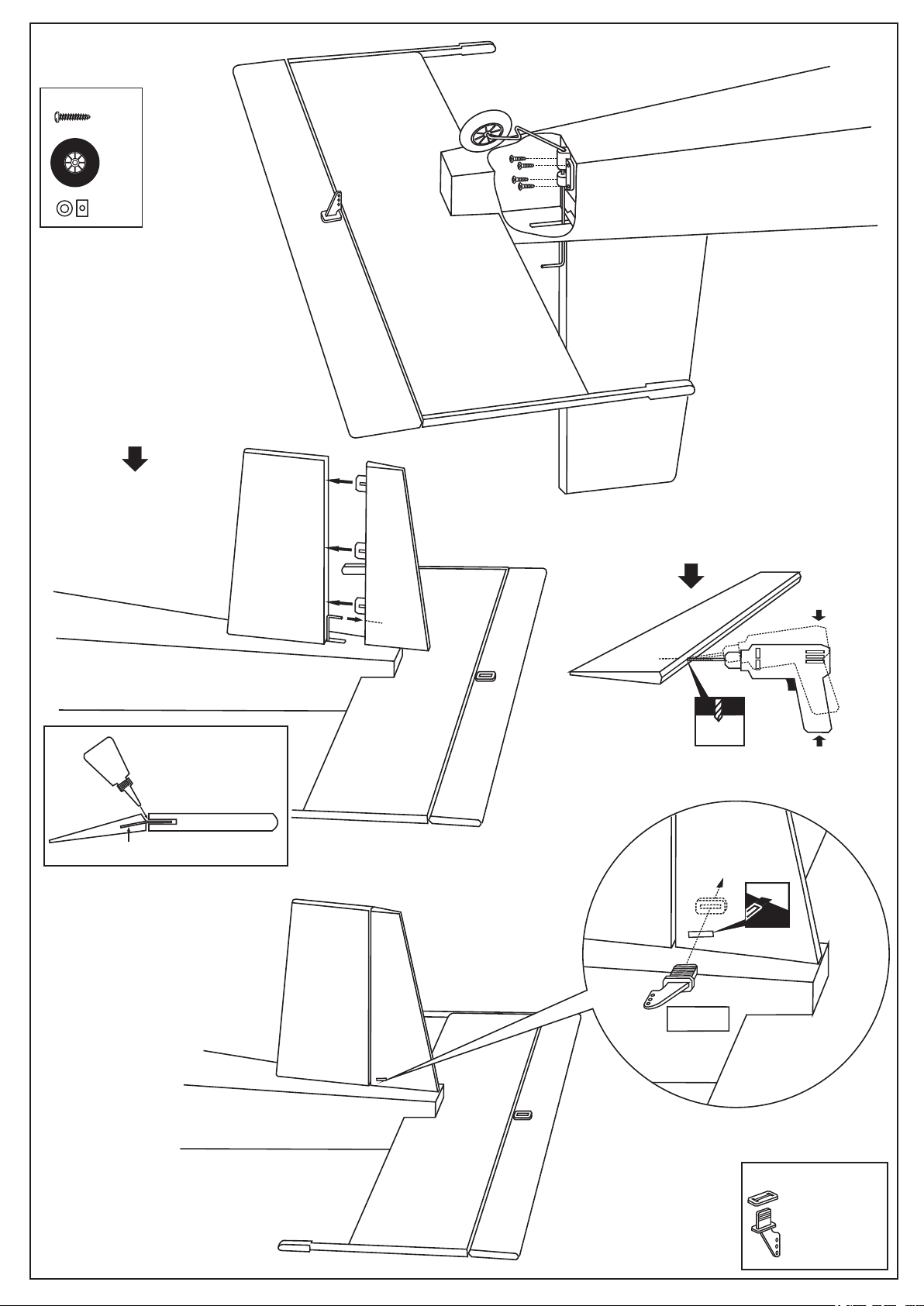

4

3x10mm

Without using glue yet, push the rudder

and its hinges into the hinge slots in the

trailing edge of the vertical stabilizer.

When satisfied with the alignment, mark

the mounting hole position, where the

rudder torque rod meets the rudder with

a pencil.

....4

....1

....2

4B

4A

Remove the rudder and drill a 2mm diameter hole in

torque rod mounting slot, making sure that you drill

the hole perpendicular to the leading edge of the

rudder.

CA

Apply thin CA to both

side of the hinge

Hinge

STABILIZER

4D

4C

5/64”

2mm

Cut away only

the covering

WRONG

RIGHT

Plastic control horn

.....................1

5

950mm steel wire

Steel clevis

5A

......2

......2

FUSELAGE - BOTTOM VIEW

5B

FUSELAGE - TOP VIEW

6

Using a aluminum motor mounting as a template,

mark the fire-wall where the four holes are to be

drilled .

6A

4mm

Remove the motor and drill a 4mm hole

through the fire-wall at each of the four marks

marked .

6B

6C

3x15mm

...4

...4

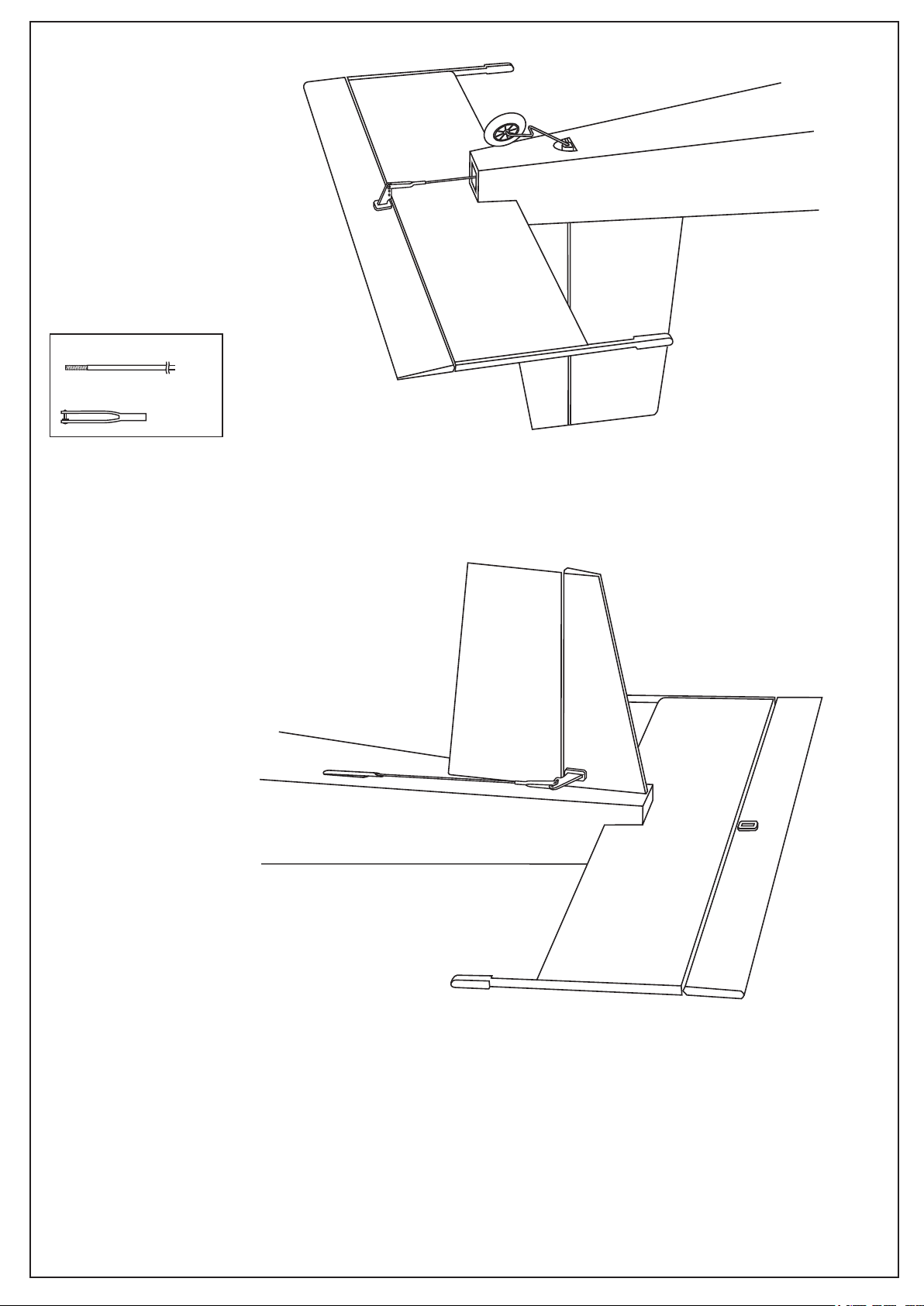

7

7A

7B

7C

Adhesive tape

1mm

1mm

1mm

2x8mm

7D

2x8mm

......6

2x8mm

7E

1mm

2x8mm

......4

8

2mm connector

...2

CA

Rudder servo

Elevator servo

Fuselage - Top view

8B

8A

Note: The holes for the connector installation

are pre-drilled at factory

3mm connector

...4

CA

8C

Cut away only

the covering

9

CA

CA

L/R

Do the same way with other wing half

BOTTOM - VIEW

9A

Control horn

..........2

2x30mm

...4

2mm

2mm connector

175mm steel wire

Steel clevis

X

........2

......2

......2

Aileron

extension cord

9B

Aileron pushrod

X

L/R

Do the same way with other wing half

BOTTOM - VIEW

10

10A

10B

10C

Note: The hole on the surface of the top of the

wing is pre-drilledat factory.

3x15mm screw

.........2

Secure the wing in place

using 3x15mm screw.

TOP

Aluminum

tube inside

2.mm drill bit

A

2mm

3x15mm screw

B

11

3x12mm

3x12mm

.........4

3x12mm

Note: The holes on the top of the

12

wing are pre-drilled at factory.

Note: The length of the wing brace can adjust by turn the

metal hook.

The recommended C.G (Center of Gravity) location for the Volksplane is 89 ~ 91mm

Adjust the location of the battery pack as required to achieve this C.G location.

If necessary , add weight to either the tail or nose until the correct balance is achieve.

78 ~ 83mm

Wing brace

CG

WARNING ! Securely install the receiver and power pack, ensuring they will not come loose or rattle during flight.

Never fly before checking the Cg’s required position.

Control Surface

25/64”(10mm)

25/64”(10mm)

AILERON STROKE

25/64”(10mm)

25/64”(10mm)

ELEVATOR STROKE

1”(25mm)

1”(25mm)

RUDDER STROKE

Loading...

Loading...